C4000 Master Manual

Version 1.0.0

ii

Conditions of Use

Read this manual completely before working on or

making adjustments to the Compac equipment.

Compac Industries Limited accepts no liability for

personal injury or property damage resulting from

working on or adjusting this unit incorrectly or

without authorisation.

Along with any warnings, instructions, and

procedures in this manual, you should also observe

any other common sense procedures that are

generally applicable to equipment of this type.

Failure to comply with any warnings, instructions,

procedures, or any other common sense procedures

may result in injury, equipment damage, property

damage, or poor performance of the Compac

equipment

The major hazard involved with installing and

operating the unit is electrical shock. This hazard

can be avoided if you adhere to the procedures in

this manual and exercise all due care.

Compac Industries Limited accepts no liability for

direct, indirect, incidental, special, or consequential

damages resulting from failure to follow any

warnings, instructions, and procedures in this

manual, or any other common sense procedures

generally applicable to equipment of this type. The

foregoing limitation extends to damages to person or

property caused by the unit or damages resulting

from the inability to use the unit including loss of

profits, loss of products, loss of power supply, the

cost of arranging an alternative power supply, and

loss of time, whether incurred by the user or their

employees, the installer, the commissioner, a

service technician, or any third party.

Compac Industries Limited reserves the right to

change the specifications of its products or the

information in this manual without necessarily

notifying its users.

Variations in installation and operating conditions

may affect the unit's performance. Compac

Industries Limited has no control over each

installation's unique operating environment. Hence,

Compac Industries Limited makes no

representations or warranties concerning the

performance of the unit under the actual operating

conditions prevailing at the installation. A technical

expert of your choosing should validate all operating

parameters for each application.

Compac Industries Limited has made every effort

to explain all servicing procedures, warnings, and

safety precautions as clearly and completely as

possible. However, due to the range of operating

environments, it is not possible to anticipate every

issue that may arise. This manual is intended to

provide general guidance. For specific guidance

and technical support, contact your authorised

Compac supplier, using the contact details in the

Product Identification section

Information in this manual shall not be deemed a

warranty, representation, or guarantee. For

warranty provisions applicable to this unit, please

refer to the warranty provided by the supplier.

Unless otherwise noted, references to brand

names, product names, or trademarks constitute

the intellectual property of the owner thereof.

Subject to your right to use the unit, Compac does

not convey any right, title, or interest in its

intellectual property, including and without

limitation, its patents, copyrights, and know-how.

Every effort has been made to ensure the accuracy

of this document. However, it may contain technical

inaccuracies or typographical errors. Compac

Industries Limited assumes no responsibility for

and disclaims all liability of such inaccuracies,

errors or omissions in this publication.

iii

Contents

Product Identification C4000 Processor ......................................................................................................................... v

Document Control Information ........................................................................................................................................ 6

Symbols and Units of Measure ........................................................................................................................................ 7

Safety - C4000 Controller .................................................................................................................................................. 8

Mechanical Safety .................................................................................................................................................... 8

Electrical Safety ....................................................................................................................................................... 8

Safety Precautions ................................................................................................................................................... 8

Electrical Commissioning ................................................................................................................................................ 9

Cable Requirements ................................................................................................................................................ 9

Connecting Mains Power and Communication ...................................................................................................... 10

Electrical Commissioning C4000 ........................................................................................................................... 11

Main Features .................................................................................................................................................................. 12

C4000 Components ............................................................................................................................................... 12

Configurations ........................................................................................................................................................ 13

Set-up Modes ................................................................................................................................................................... 16

Configuration Code ................................................................................................................................................ 16

'b' Settings .............................................................................................................................................................. 18

C4000 Set-up ......................................................................................................................................................... 21

Calibration ('K') Factor............................................................................................................................................ 23

No Flow Cut-Off Timer ........................................................................................................................................... 25

Display (Litres) Resolution ..................................................................................................................................... 26

Solenoid Delay ....................................................................................................................................................... 27

Pre-Set Cut-Off ...................................................................................................................................................... 28

Further Settings Available on the 'K' Factor Switch ................................................................................................ 28

Parameter Switch ................................................................................................................................................... 33

Printer Set-up ......................................................................................................................................................... 40

Displaying and Printing Totals ................................................................................................................................ 41

Basic Systems (Comcard Compin & CWIDKey) .................................................................................................... 43

Electrical Wiring C4000................................................................................................................................................... 45

Compac Wireless Transceiver ............................................................................................................................... 49

Displays: Litres only, Retail, Multi-price & Preset ................................................................................................... 52

End of Sale Indications ................................................................................................................................................... 58

Software Upgrade Procedure ................................................................................................................................ ......... 59

Solid State Relays (Triacs) ............................................................................................................................................. 61

Triacs C4000 Single, Dual & Quad ........................................................................................................................ 62

Triacs C4000 MPD6 & MPP6 side A ...................................................................................................................... 63

Triacs C4000 LPG Single/Dual, CNG & Bulk Meter ............................................................................................... 64

High Current Triac Option ...................................................................................................................................... 65

Indicator LEDs ................................................................................................ ................................................................. 66

Fault Finding .................................................................................................................................................................... 68

Error Codes ............................................................................................................................................................ 70

Error Messages ...................................................................................................................................................... 71

iv

Appendix A ...................................................................................................................................................................... 72

C4000 with RS232 Wiring ...................................................................................................................................... 72

RS485 Wiring ......................................................................................................................................................... 73

C4000 with RS485 Wiring ...................................................................................................................................... 75

Gilbarco Interface Wiring........................................................................................................................................ 76

Glossary of Terms ........................................................................................................................................................... 77

v

Product Identification C4000 Processor

Manual Title

C4000 Processor Master Manual

Models Covered

All C4000 Series

Application

Power Supply

220 - 240 VAC; 50 Hz; 2 Amp +/- 10%

Related Manuals

Title

Publication Date

C4000 Futra Manual

October 2008

ComFutra Installation &

Service Manual

September 2010

C4000 LPG Manual

Validity

Compac Industries Limited reserves the right to revise or change product

specifications at any time. This publication describes the state of the

C4000 processor at the time of publication and may not reflect the product

at all times in the past or in the future.

Manufacturer Contact

Details

The Compac C4000 processor is designed and manufactured by:

Compac Industries Limited

52 Walls Road, Penrose, Auckland 1061, New Zealand

P.O. Box 12-417, Penrose, Auckland 1641, New Zealand

Phone: + 64 9 579 2094

Fax: + 64 9 579 0635

www.compac.co.nz

Copyright ©2010 Compac Industries Limited, All Rights Reserved

Document Control Information

Compac Industries Ltd.

Page 6

www.compac.co.nz

Document Control Information

Document Information and Revision History

Document Details:

C4000 Master Manual

File Name and Location:

G:\Masters\Manuals\Authorised Manuals\C4000

Current Revision Author(s):

R Lacey

Authorised By:

A Kingstone

Release Date: 06/09/2010

Version

Date

Author(s)

Revision Notes

1.0.0

06/09/2010

R Lacey

Added RS485 info

Distribution

Name

Indicator

Location

Symbols and Units of Measure

Compac Industries Ltd.

Page 7

www.compac.co.nz

Symbols and Units of Measure

Symbols

Symbols are used in this manual to highlight information that is critical

to the safety of people and equipment, and for the safe and correct

operation of the Compac equipment

An extreme hazard that may result in death or injury if

proper precautions are not taken.

A reminder of safety practices or unsafe practices that

could result in personal injury or damage to associated equipment.

A reminder of safety practices or unsafe practices that

could result in damage to associated equipment and/or voids the

warranty.

Important information essential to the installation and

operation of the Compac equipment

Units of Measure

The following units of measure are used in this manual:

Unit

Measure

Pressure

Bar (bar)

Temperature

Degrees Celsius (°C)

Volume

Litres (L)

Cubic Metres (m³)

Mass

Kilograms (kg)

Length

Metres (m)

Millimetres (mm)

Microns, Micrometres (m)

Inches (")

Torque

Newton Metres (Nm)

Voltage

Volts (V)

Current

Amps (A)

Frequency

Frequency (Hz)

Mechanical Safety

Safety - C4000 Controller

Compac Industries Ltd.

Page 8

www.compac.co.nz

Safety - C4000 Controller

You must adhere to the following safety precautions at all times when

working on the Compac C4000 processor. Failure to observe these safety

precautions could result in damage to the Compac C4000 processor, injury,

or death.

Make sure that you read and understand all safety precautions before

operating the Compac Compac C4000 processor.

Mechanical Safety

Observe the following mechanical precautions:

Make sure that the service area is thoroughly clean when

servicing. Dust and dirt entering the components reduce the life span of the

components and can affect operation.

Electrical Safety

Observe the following electrical precautions:

Always turn off the power to the Compac C4000 processor

before opening the flame proof box. Never touch wiring or components

inside the high voltage area with the power on.

Always turn off the power to the Compac C4000 processor at

the mains switch before removing or replacing software or memory ICs.

Always take basic anti-static precautions when working on the

electronics, i.e., wearing a wristband with an earth strap.

Safety Precautions

The C4000 head, and its associated circuits and wiring, is a

certified piece of electrical equipment approved for use in a hazardous area

(Class 1 Zone 1, Group IIA T3). Only parts identical to those covered by the

certification may be used where the integrity of the intrinsic safety may be

affected. All circuit boards are to be repaired only by Compac Industries

Ltd.

Static Electricity Precautions

Electronic components used are sensitive to static. Please take anti-static

precautions.

All circuit boards must be carried and transported in static-shielded bags.

An anti-static wrist strap should be worn and connected correctly when

working on any electronic equipment. If an anti-static wrist strap is

unavailable, or in an emergency, hold onto an earthed part of the

pump/dispenser frame whilst working on the equipment. This is not a

recommended alternative to wearing an anti-static wrist strap.

Compac Industries Limited reserves the right to refuse to

accept any returned circuit boards if proper anti-static precautions have not

been taken.

Electrical Commissioning

Cable Requirements

Compac Industries Ltd.

Page 9

www.compac.co.nz

Electrical Commissioning

Cable Requirements

Cable requirements are as follows:

Cable Type

Requirements

Power

3 Core Steel Wire Armour Cable 2.5mm2,

220 - 240 Volts. 50 Hz, +/-10%

Core 1: 230 Volt Supply (Active).

Core 2: Neutral.

Core 3: Earth.

Dispenser:

25w Idle, 200W with all solenoids active.

Pumps with one motor (40 and 80 lpm Single hose)

Motor start current = 30 amps, run current = 6 amps

Pumps with two motors -40 and 80 lpm Dual pumps and 160 lpm

Single hose pumps

Motor start current = 30 amps, run current = 6 amps

(software prevents both motors starting simultaneously)

Comms

2 Core Steel Wire Armour Cable 1.5 mm2. Maximum cable length 100 m.

12 V current loop.

Make sure that there is at least a two metre cable tail on

both the incoming underground 230 V and comms cables to reach the

C4000 flameproof box.

Connecting Mains Power and Communication

Electrical Commissioning

Compac Industries Ltd.

Page 10

www.compac.co.nz

Connecting Mains Power and Communication

In sites where the electrical supply is unstable, it is

recommended that a power conditioner or UPS is installed.

To connect the dispenser:

1. Wire the power and comms to the C4000 Termination Board, as shown

in the diagram below.

2. Connect the earth lead of the supply cable to the earth stud in the

flameproof junction box.

All cables must be terminated with approved flameproof

glands. The thread is 20 mm.

COMMS

Neutral

Phase

Earth

+ve

-ve

SW 3

SW 4 SW 2 SW 1

L

O

A

D

2

L

O

A

D

1

N

E

U

T

R

A

L

N

E

U

T

R

A

L

N

E

U

T

R

A

L

P

H

A

S

E

P

H

A

S

E

P

H

A

S

E

F3

1A

F1

0.5A

V

C

C

R

E

D

B

L

K

D

T

R

D

C

D

C

T

S

G

N

D

T

X

D

P

D

T

R

P

G

N

D

N

N

N

N

N

N

P

H

T

1

0

T

7

T9T8T6T

5

T3T

2

T

4T1

TE S T

Refer Electrical Wiring C4000 (see page 45) for all other connections.

Electrical Commissioning

Electrical Commissioning C4000

Compac Industries Ltd.

Page 11

www.compac.co.nz

Electrical Commissioning C4000

This procedure outlines how to perform an electrical operational test

before carrying out full mechanical commissioning and making sure that

the dispenser is functioning correctly. Check for any damage that may

have occurred in transit. Check all terminals, plugs, and chips to make

sure that they are securely in place.

Damage to electronics occurs most commonly from

vibration and jarring.

Before beginning this test, check that fuel has not been applied to the

dispenser. The factory set-up information should be programmed into

the dispenser but all K-factor and Parameter switch settings should be

checked and confirmed before commissioning tests are carried out.

Check that pump number is set. See Setting the Dispenser/Pump

Number (see page 37)

Check the pump price is set. See Setting the Price per Litre (see page

34)

To perform an electrical operational test:

1. Make sure that the inlet shut-off valves are closed (these are the

valves in the inlet lines at the base of the dispenser, but they are not

part of the dispenser).

2. Turn on the power supply to the dispenser.

3. With the dispenser in a ready state, check that the C4000

Microprocessor Power LED (D1) is turned on

If the dispenser is receiving information, Comms RXD

LED (D6) will poll. If the dispenser responds to polls for its

respective pump number/s, Comms TXD LED (D7) will also poll.

Diagnostic LED (D18) slowly flashing. (If the dispenser is

connected to an operational Controller, it flashes slowly but

erratically. If the dispenser is not connected to a Controller, it

flashes slowly and consistently.)

Watchdog LED (D5) is turned off

4. Lift the nozzle

The display will show 888888 and the solenoids energise,

starting the pump motor. Check that Diodes D8, D10 and D11 turn

on, indicating a signal is being sent to the triacs to open the solenoid

valves.

The diagnostic LED (D18) flashes quickly when the start button is

pushed or the nozzle removed from the holster to initiate a fill. When

the button is released or nozzle returned to the holster it will return

to the normal state and flash slowly.

5. Verify solenoid operation by listening for a click, or by using a

screwdriver tip or some other metallic tool to check for a magnetic

field present on the solenoid coils.

The solenoids will switch off after four minutes. This is a default

time-out setting in the software for situations when there is no fuel

flow registered.

Topic Number: 2321

C4000 Components

Main Features

Compac Industries Ltd.

Page 12

www.compac.co.nz

Main Features

The Compac C4000 is a microprocessor-based circuit board designed for

use in liquid and gaseous fuel metering systems. It is suitable for

commercial, retail, and bulk-metering applications and can be used for tank

gauging, card reader access, and many other control functions.

Connectors:

J1: Comms Test J7: Displays J13: CWIT/Secure

J2: To I.S. Power J8: Temperature Comp. PINPad

J3: Encoder 1 J9: PINPads J14: Printers

J4: Encoder 2 J10: Totes J15: Cardreader 1

J5: Encoder 3 J11: ParSw & Buzzer J16: Cardreader 2

J6: Encoder 4 J12: Nozzle Switches J17: Backlighting

Figure 1. Layout of C4000 Microprocessor Board

C4000 Components

The main components associated with the C4000 head are:

Encoder

Displays

Litres

Dollars, litres and price

Litres, rate of flow and

preset

Preset

Last Sale, kilograms,

litres and price (CNG

only)

Temperature

compensation

Card-reader

PIN/Odometer Pad

Printer

Modem

Mechanical Totaliser

(Tote)

Nozzle Switch

Main Features

Configurations

Compac Industries Ltd.

Page 13

www.compac.co.nz

Configurations

The C4000 'head' can be used with the equipment listed below in the following standard configurations:

Single Commercial Fuel Dispenser

Standard Options:

Extras:

Litres only display,

two - one per side

Motor circuit, one only

One Encoder

One Nozzle Switch

C4000 Head

Also see 'FUTRA'

configuration.

Card-reader

High/Low Flow Operation

PIN-Pad

Single Suction Dual Commercial (Duo)

Standard Options:

Extras:

Litres only display, four - two

per side

Two motor circuit.

Two Encoders

Two Nozzle Switches

C4000 Head

Preset

Dual Commercial (Dual or Double)

Standard Options:

Extras:

Litres only display, four - two

per side

Two Motor circuits

Two Encoders

Two Nozzle Switches

C4000 Head

Preset

Single Retail

Standard Options:

Extras:

Dollars, litres and price

display, two - one per side

Presets, two - one per side

One Encoder

One Nozzle Switch

One Motor Output

C4000 Head

* Also see 'FUTRA' configuration

Card-reader

PIN-Pad

Receipt Printer

Configurations

Main Features

Compac Industries Ltd.

Page 14

www.compac.co.nz

Single Suction Dual Retail (Duo)

Standard Options:

Extras:

Dollars, litres and price

display, two - one per side

Presets, two - one per side

Two Encoders

Two Nozzle Switches

Two Motor Outputs

C4000 Head

Dual Retail (Dual or Double)

Standard Options:

Extras:

Dollars, litres and price

display, four - two per

side

Presets, four - two per

side

Two Encoders

Two Nozzle Switches

Two Motor Outputs

C4000 Head

Multi Product (4 hose) Retail

Standard Options:

Extras:

Dollars, litres and price

display, two - one per side

Presets, two - one per

side

Four Encoders

Four Nozzle Switches

Two Motor Outputs

One C4000 Head

Multi-price Displays, four

– one per product per

side

Card-reader

PIN Pad

Receipt Printer

Multi Product (4 hose) Retail, Type 'A'

Standard Options:

Extras:

Dollars, litres and price

display, four - one per

product per side

Presets, four - one per

product per side

Four Encoders

Four Nozzle Switches

Two Motor Outputs

One C4000 Head

Main Features

Configurations

Compac Industries Ltd.

Page 15

www.compac.co.nz

Multi Product (6 hose) Retail

Standard Options:

Extras:

Dollars, litres and price

display, two - one per side

Presets, two - one per

side

Six Encoders

Six Nozzle Switches

Three Motor Outputs -

shared by C4000 Heads

Two C4000 Heads

Multi-price Displays, six -

one per product per side

Card-reader

PIN Pad

Receipt Printer

Multi Product (6 hose) Retail, Type 'A'

Standard Options:

Extras:

Dollars, litres and price

display, six - three per

side

Presets, six - three per

side

Six Encoders

Six Nozzle Switches

Three Motor Outputs -

shared by C4000 Heads

Two C4000 Heads

Futra (Uses 'Futra' Software)

(This type is a stand-alone system that cannot be set up to communicate to any type of controller.)

Standard Options:

Extras:

Litres Only Display

Motor Circuit (One only)

One Encoder

One Nozzle Switch

C4000 Head

PIN-Pad

Card Reader

Retail Displays

Preset

Modem

High/Low Flow Operation

Tank Gauging, for one tank only

Receipt Printer

Configuration Code

Set-up Modes

Compac Industries Ltd.

Page 16

www.compac.co.nz

Set-up Modes

To enable the C4000 to operate as desired two things must be set:

1. Configuration (K Factor) Switch Settings

Refer C4000 Set-Up K Factor Switch Settings (see page 21)

This switch accesses different options that must be set appropriately for the

particular type of dispenser.

2. Parameter Switch Settings

Refer Parameter Switch (see page 33)

This switch is used to conduct the Display Segment Test, set price (product

density - if a bulkmeter or LPG), and set pump number. Also, when the

C4000 is configured for 'Comcard', 'Compin', or 'CWIDKey' the parameter

switch is used for card/pin/key validation and for setting the card/key

system number

Configuration Code

The C4000 pump/dispenser software, the configuration code (used to set

the pump/dispenser to single, dual or multi mode) has been extended to 5

digits. When configuring the pumps/dispensers, the litre display will display

each digit.

For FUTRA software configuration options, see the FUTRA

service supplement.

Multi-hosed Pump/Dispenser with LPG

An MPD with LPG is configured by setting digits 5=3 and 4=5.

With COM125 magnetic or Bennett meters, to set LPG compensation and

motor spirit without correction, set digit 1=4.

For COM125 optical meters when motor spirit correction is required as well,

set digit 1=6.

Refer Setting the Configuration Code (see page 16)

Setting the Configuration Code

Refer to Figure 3. While setting the configuration code, the price display

shows 'C' and the volume display shows 'XXXXX'.

Set-up Modes

Configuration Code

Compac Industries Ltd.

Page 17

www.compac.co.nz

Figure 3 Configuration Code Options

'b' Settings

Set-up Modes

Compac Industries Ltd.

Page 18

www.compac.co.nz

'b' Settings

While setting the „b‟ settings, the price display shows 'b' and the volume

display shows 'bXXXX'.

Figure 2 'b'Settings

Auto Authorise (Digit 4)

0: If digit 4 is set to zero, then the pump/dispenser software defaults

to conventional operation, (i.e. the nozzle switch controls the pump start

after initial authorisation).

1: If digit 4 is set to one, then the dispenser/pump software will run in

the AUTO AUTHORISE mode of operation (used for wharf & aviation or

any other sites where the hose reel is remote from the pump unit):

The pump/dispenser will start automatically after it has been initialised

by the card-reader or remotely by a Compac controller.

The dispenser/pump will switch off after four minutes if flow does not

commence.

The pump/dispenser will switch off XXX * seconds after flow rate stops.

Can be adjusted to clients' requirements, between 1 and 256 seconds

The nozzle switch becomes a shut-off switch (i.e., the nozzle switch

can be replaced with a stop pushbutton or normally closed toggle

switch).

In AUTO AUTHORISE mode the nozzle input must be

shorted out.

Transaction Data (Digit 3)

0: If digit 3 is set to zero, the system will function as a conventional

dispenser/pump and the sale data goes through to Point of Sale as soon as

the preset is reached. This is the default setting.

1: If digit 3 is set to one, the system will function as a convention

dispenser/pump but the sale data will go through to the Point of Sale only

after the nozzle has been hung up.

Set-up Modes

'b' Settings

Compac Industries Ltd.

Page 19

www.compac.co.nz

2: With digit 3 set to two, the head is set up for Comcard Basic,

Compin Basic, or CWIDKey Basic, which are self-contained systems

operating independently of any controller.

To operate, a card-reader/CWIDKey reader must be plugged into the 'head'

and the correct access code and card/key number validations must be set

by the Parameter switch.

For the Bulk Meter Register, digit 3 must be set to zero or

one. Comcard, Compin, and CWIDKey Basic systems are not available in

this mode.

Price per Litre (Digit 2)

0: If digit 2 is set to zero, the price per litre is displayed as dollars per

litre ($0.000)

1: If digit 2 is set to one, the price per litre is displayed as cents per

litre (000.0 cents).

For CNG Only: If digit 2 is set to one then the display that normally shows

the dollar value of the transaction, will display the CNG pressure during the

fill. At the end of the fill the display will revert to displaying the value.

Controller Option (Digit 1)

The function of this digit (1) depends on whether the head has been set up

as one of the Basic Systems (Comcard, Compin, or CWIDKey) or a

conventional pump/dispenser, using digit 3.

Basic Systems: (digit 3 set to two)

With all Compac pumps/dispensers, the 'head' will display the dollars and

litres grand totals when the nozzle switch is pressed quickly five or more

times.

On a commercial pump/dispenser with litres-only display, only

the total litres can be read.

If the 'head' is set-up as a Comcard, Compin, or CWIDKey Basic system

then, after displaying the grand totals as above, the head will also printout

the totals for each card/pin/key, irrespective of the digit 1 setting.

By setting digit 1 to one, the 'Scrolling Totes' option is selected. Refer

Displaying and Printing Totals (see page 41). In this mode of operation,

after printing the totals as above, the 'head' will flash card totals on the

pump's main display. All non zero card totals are displayed consecutively,

for 10 seconds each.

The totals can only be zeroed by replacing the memory chip.

Conventional Pump/Dispenser (digit 3 set to zero or one)

If digit 1 is zero, the pump/dispenser can be operated in 'stand-alone' mode

irrespective of the pump/dispenser number loaded.

If digit 1 set to one, the pump/dispenser will not work in 'stand-alone' mode,

(i.e., it requires initialisation from a controller).

The pump/dispenser ceases to work in 'stand-alone' mode if

digit 1 is set to zero and it is connected to a controller. Generally on retail

forecourts, this switch should be left off. Hence, if the forecourt controller

breaks down, the dispensers/pumps can be set to work in the 'stand-alone'

'b' Settings

Set-up Modes

Compac Industries Ltd.

Page 20

www.compac.co.nz

mode simply by turning them OFF for 1 minute minimum, then back ON.

However, for unattended situations (e.g. truck stops), the pumps must not

be left able to work in the 'stand-alone' mode in case of a controller failure.

Therefore, digit 1 should always be set to one for unattended operation.

For the Bulk Meter Register configuration, when digit 1 is zero, the unit will

work in the 'stand-alone' mode. When digit 1 is one, the unit must be

connected to a Compac Central Controller.

Set-up Modes

C4000 Set-up

Compac Industries Ltd.

Page 21

www.compac.co.nz

C4000 Set-up

The 'K' Factor switch is located on the C4000 PCB as shown in Figure 1.

The 'K' Factor switch is used to access and change various set-up options

of the C4000 head. The following charts detail the operation of setting up

the C4000 head:

Any change of set-up made by the 'K' Factor switch takes effect as soon as

the C4000 resets. The power supply does not have to be interrupted.

Set up of the C4000 must be done in the following sequence:

„K‟ Factor Switch Settings - starting with configuration setting and moving

back through the options to the K Factor setting:

K Factor Switch Settings

Setting

Price Display

Litres Display

Reference

Configuration Code

„C‟

„XXXXX‟

Refer Configurations C4000 (see page 13)

Display Resolution

„Sr‟

„Sr X.XX‟

Refer Display (Litres) Resolution (see page 26)

Temperature

„E‟

„E XXX.X‟

Refer Temperature Calibration (see page 31) LPG

and Bulk-metering only

ACV Flow rate

„FLO‟

„r XXXX‟

Refer ACV Valve Flow Rate (see page 31)

Density Calibration

„LP6‟

„00000‟

Refer Calibrating Specific Density (see page

30)LPG only.

No-flow cut-off

„n‟

„n XXX‟

Refer No Flow Cut-Off Timer C4000 (see page 25)

Solenoid delay

„Sd‟

„d XXX‟

Refer Solenoid Delay (see page 27)

Preset Cut-Off

„PCut‟

„PC X.XX‟

Refer Pre-Set Cut-Off (see page 28)

‘b’ settings

„b‟

„b XXXX‟

Refer 'b' Settings (see page 18)

‘K’ Factor

„F‟, „Fb‟, „F1‟,

„F2‟, or „F3‟

„X.XXXX‟

Refer Setting the 'K'Factor (see page 24)

H-Cut

„HCut‟

„HXXXX‟

Refer H-Cut (see page 31) Bulk-metering only

L-Cut

„LCut‟

„LXXXX‟

Refer L-Cut (see page 31) Bulk-metering only

F-Cut

„FCut‟

„FXXXX‟

Refer F-Cut (see page 32) Bulk-metering only

Density Factor

„dSF‟

„X.XXXX‟

Refer Product Density Factor (see page 29) CNG

only

The K Factor setting should be done last of all (i.e. until

parameter switch settings are made, the pump/dispenser may not be

operational, and so a calibration fill may not be possible).

C4000 Set-up

Set-up Modes

Compac Industries Ltd.

Page 22

www.compac.co.nz

'K'Factor Switch

Using the ‘K’ Factor Switch

Using the ‘K’ Factor Switch to Change a Setting

Step

ACTION

RESULT

1

Ensure that the nozzles are

hung up

Dispenser in idle state

2

Press and release the „K‟

Factor switch, in quick

succession, until the

desired setting is displayed.

The price display and volume

display indicates the desired

setting. See following

paragraphs.

3

Press and hold the „K‟ factor

switch.

A digit, of the displayed setting,

will begin to increment.

4

When the digit is correct,

release the „K‟ Factor

switch.

5

Repeat steps 3 and 4 for

each digit of the setting

The C4000 will

reset itself if the „K‟ factor

switch is left for more than 10

seconds.

Continue for multiple hose units, if appropriate.

6

Press and release the „K‟

factor switch 8 or more

times in quick succession

The setting for side “B” (or

hose 2, 3, or 4) is displayed.

7

Repeat steps 3 to 5 above.

The C4000 will reset at any stage during the 'K' Factor

operation if the switch is not pressed for ten (10) seconds. If the C4000

resets out of any field before the numbers have been set correctly, then that

field must be entered again to ensure the details are correct.

The K-Factor switch must be sealed with a lead or paper seal

after commissioning.

Set-up Modes

Calibration ('K') Factor

Compac Industries Ltd.

Page 23

www.compac.co.nz

Calibration ('K') Factor

The 'K' Factor is a ratio of litres dispensed per revolution of the meter.

Below is the method of calibration, including how to calculate the new 'K'

Factor and how to enter it in the C4000 memory.

(See also Encoder (see page 55) for more information on the

encoder/pulser)

Calibration

To calibrate the dispenser/pump, dispense fuel into a certified measuring

container, and compare the display value with the amount dispensed.

Example:

Display shows 10.00

True volume 20.00

To calculate the correct 'K' Factor from the information above; firstly record

the existing 'K' Factor.

2 Factor K'' Existing

10.00

20.00

Factor K'' Existing

Amount Dispensed

Factor K'' Factor K''

AmountDisplayed

ExistingNew

Change the existing "K" factor to this value

Calibration ('K') Factor

Set-up Modes

Compac Industries Ltd.

Page 24

www.compac.co.nz

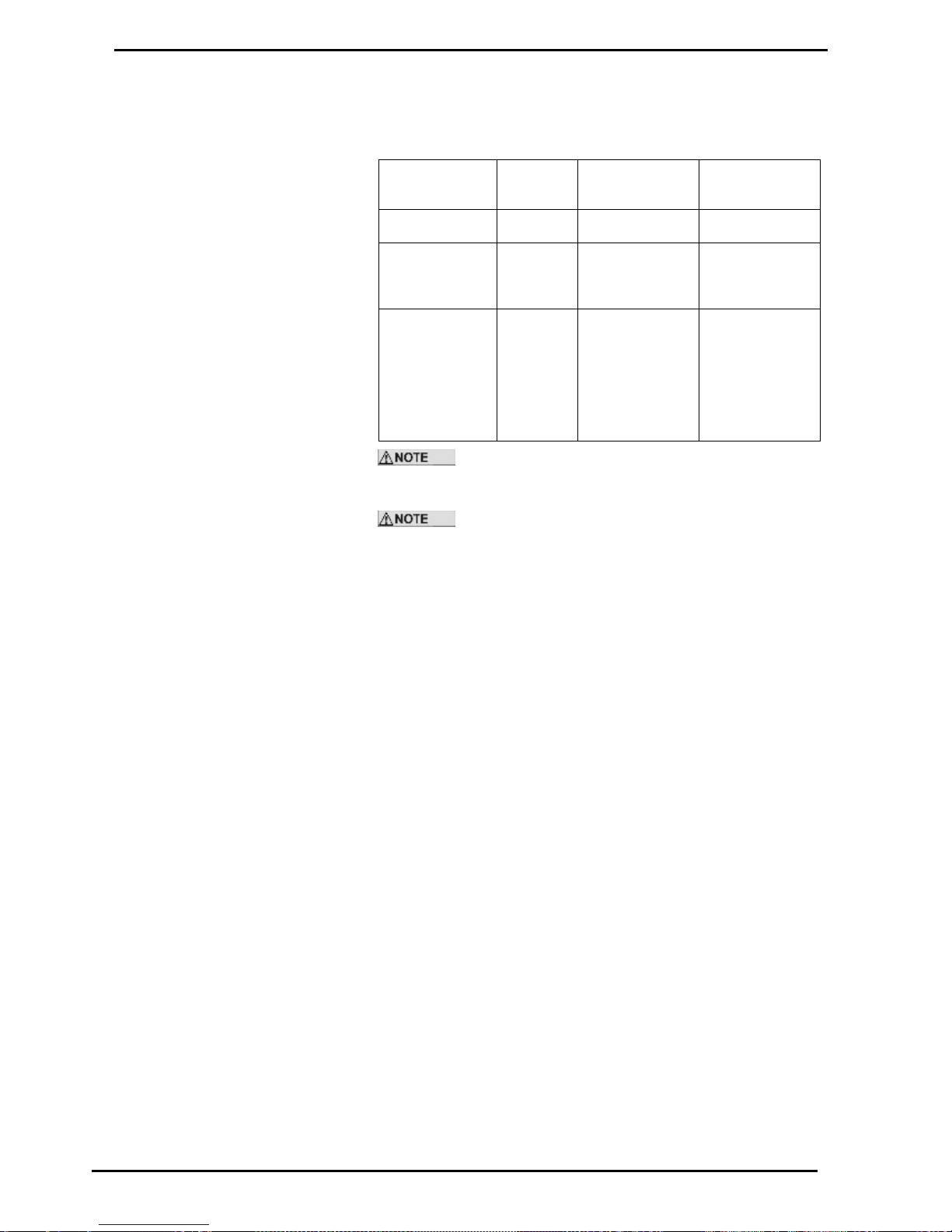

Setting the Calibration 'K'Factor

Refer to C4000 Set-Up K Factor Switch Settings (see page 21) The

displays will indicate as below

Type

Price Display

indication

Volume Display

Indication

Single Hose

„F‟

„X.XXXX‟

Dual Hose

Side “A”

Side “B”

„F‟

„Fb‟

„X.XXXX‟

Quad or Multiproduct

Hose 1

Hose 2

Hose 3

Hose 4

„F1‟

„F2‟

„F3‟

„F4‟

„X.XXXX‟

Once the dispenser/pump resets with the correct 'K' factor

entered, the display will show the new volume unless the 'head' is in

"Compensation Mode", in which case the display volume will not change.

Be careful when calibrating dual or multi-hose pumps &

dispensers to ensure that the correct 'K' factor is being changed.

Loading...

Loading...