Page 1

INSTALLATION AND OPERATION MANUAL

FVT/FVR40D2I1C4E

4-CHANNEL 10-BIT DIGITALLY ENCODED VIDEO

+ 2 BI-DIRECTIONAL DATA + AIPHONE™ INTERCOM

+ 4 CONTACT CLOSURE

+ 100MB ETHERNET

+ REDUNDANT POINT-TO-POINT DUAL SFP OPTICAL PORTS

The FVT/FVR40D2I1C4E series utilize 10-bit digital video encoding and decoding

for high-quality video transmission that meets the requirements of EIA RS-250C

for short-haul video transmission. These environmentally hardened units provide

transmission of four independent video channels and two bi-directional data

channels. They also provide transmission of one Aiphone™ intercom channel and

four contact closure channels with tamper supervision in addition to one 10/100Mb

Ethernet channel.

The ComNet™ FVT/FVR40D2I1C4E has dual optical (SFP) ports to provide a redundant

point-to-point fail safe topology in the event of loss of one fiber or one optical module.

Operational status can be monitored by using the web management interface

through the addition of the ComNet network managed chassis and network

management interface module.

Bi-color (red/green) LED indicators are provided for confirming operating status in

addition to alarm contacts for fault monitoring. See Figure 15 on Page 9 for LED

explanations.

Packaged in the exclusive ComNet ComFit housing, these units may be either wall

or rack-mounted (using ComNet C2 network-managed rack), or may be DIN-rail

mounted by the addition of ComNet model DINBKT1 adaptor plate. See Figure A on

Page 10 for mounting instructions.

INS_FVT/FVR40D2I1C4E_REVA 06/22/12 PAGE 1

Page 2

INSTALLATION AND OPERATION MANUAL FVT/FVR40D2I1C4E

VIDEOIN

1234

GND

+Vin

GND

+Vin

PWR1 PWR2

CONTACTAIPHONE

DATA 2DATA 1

NETWORK

MANAGEMENT

4CHVIDEO TX +

2CHBI-DIRDATA+

4CHCONTACT +

1CHETHERNET

FVT40D2I1C4E

VIDEO 1

VIDEO 2

VIDEO 3

VIDEO4

POWER

10/100LINK

SFP1

SFP2

SFP2

SFP1

10/100

12 12 12 12

ON

S4

DATA1

IN

ETHERNET

S3

S2

S1

OUT

DATA2

IN

OUT

ALARM

LE-D

LE-F

CONTACT

C

S

VIDEOIN

1234

GND

+Vin

GND

+Vin

PWR1 PWR2

CONTACTAIPHONE

DATA 2DATA 1

NETWORK

MANAGEMENT

VIDEOIN

1234

GND

+Vin

GND

+Vin

PWR1 PWR2

CONTACTAIPHONE

DATA 2DATA 1

NETWORK

MANAGEMENT

VIDEOOUT

1234

GND

+Vin

GND

+Vin

PWR1 PWR2

CONTACTAIPHONE

DATA 2DATA 1

NETWORK

MANAGEMENT

4CHVIDEORX+

2CHBI-DIRDATA+

4CHCONTACT +

1CHETHERNET

FVR40D2I1C4E

VIDEO 1

VIDEO 2

VIDEO 3

VIDEO4

POWER

10/100LINK

SFP1

SFP2

SFP2

SFP1

10/100

12 12 12 12

ON

S4

DATA1

IN

ETHERNET

S3

S2

S1

OUT

DATA2

IN

OUT

ALARM

LE-D

LE-F

CONTACT

C

S

VIDEOOUT

1234

GND

+Vin

GND

+Vin

PWR1 PWR2

CONTACTAIPHONE

DATA 2DATA 1

NETWORK

MANAGEMENT

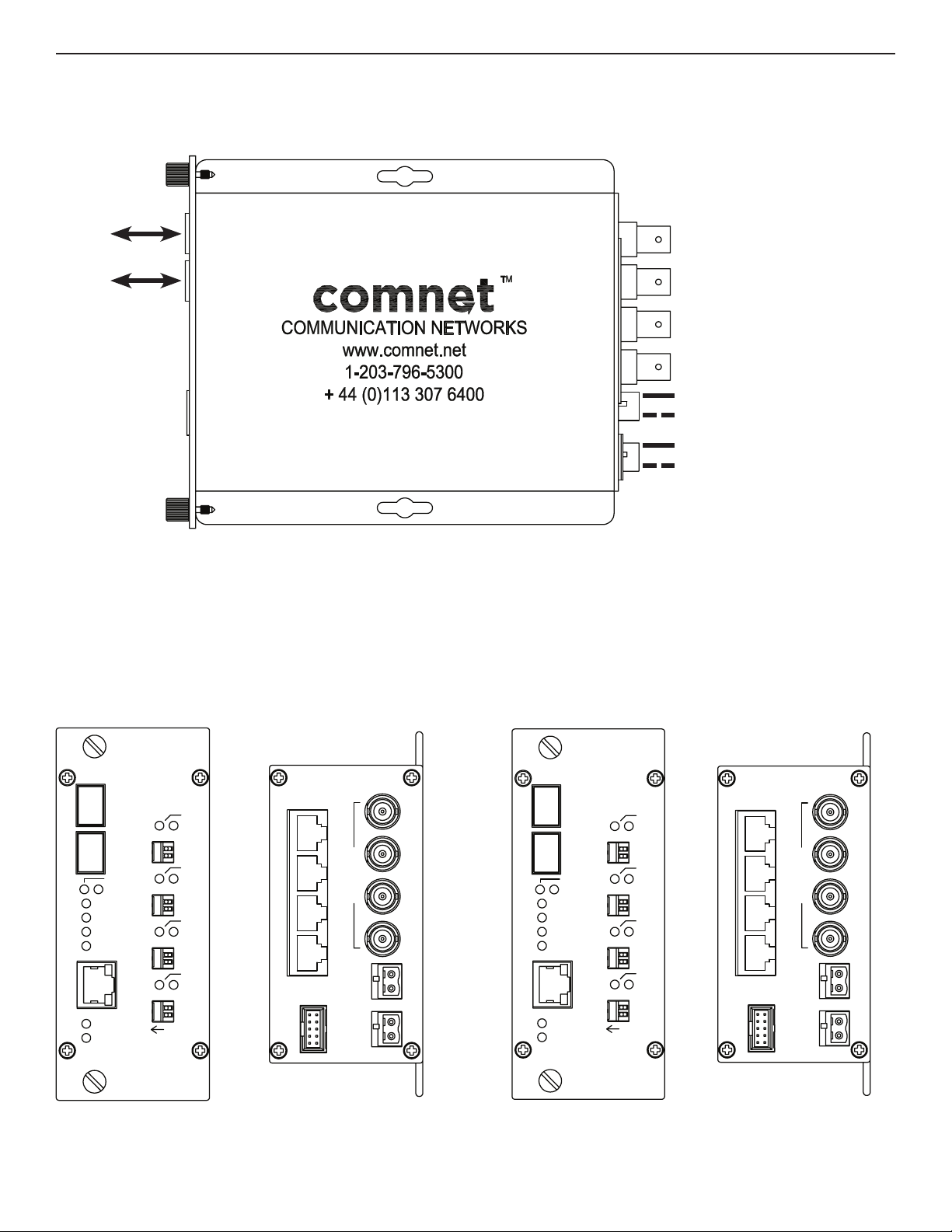

FIGURE 1 – FVT/FVR40D2I1C4E TRANSMITTER AND RECEIVER

Optical fiber determined by Selection of Small Form-factor Pluggable (SFP) modules*.

(–) BLACK

(+) BLACK W/ WHITE STRIPE

(–) BLACK

(+) BLACK W/ WHITE STRIPE

* One SFP required for point-to-point operation. Two SFPs required for redundant operation.

Consult factory for compatible SFP Modules.

FIGURE 2 – FVT40D2I1C4E TRANSMITTER

REAR PANEL REAR PANELFRONT PANEL FRONT PANEL

TECH SUPPORT: 1.888.678.9427

Power Supply:

Dual 8-24VDC @ 4W

Rack Mount: C2 Network-Managed

NOTE: Remove PWR1 Electrical

Connector for Rack Mount Units

FIGURE 3 – FVR40D2I1C4E RECEIVER

INS_FVT/FVR40D2I1C4E_REVA 06/22/12 PAGE 2

Page 3

CONTACTAIPHONE

DATA 2DATA 1

12 12 12 12

DATA1

IN

S3

S2

S1

OUT

IN

ALARM

LE-D

LE-F

CONTACT

C

S

INSTALLATION AND OPERATION MANUAL FVT/FVR40D2I1C4E

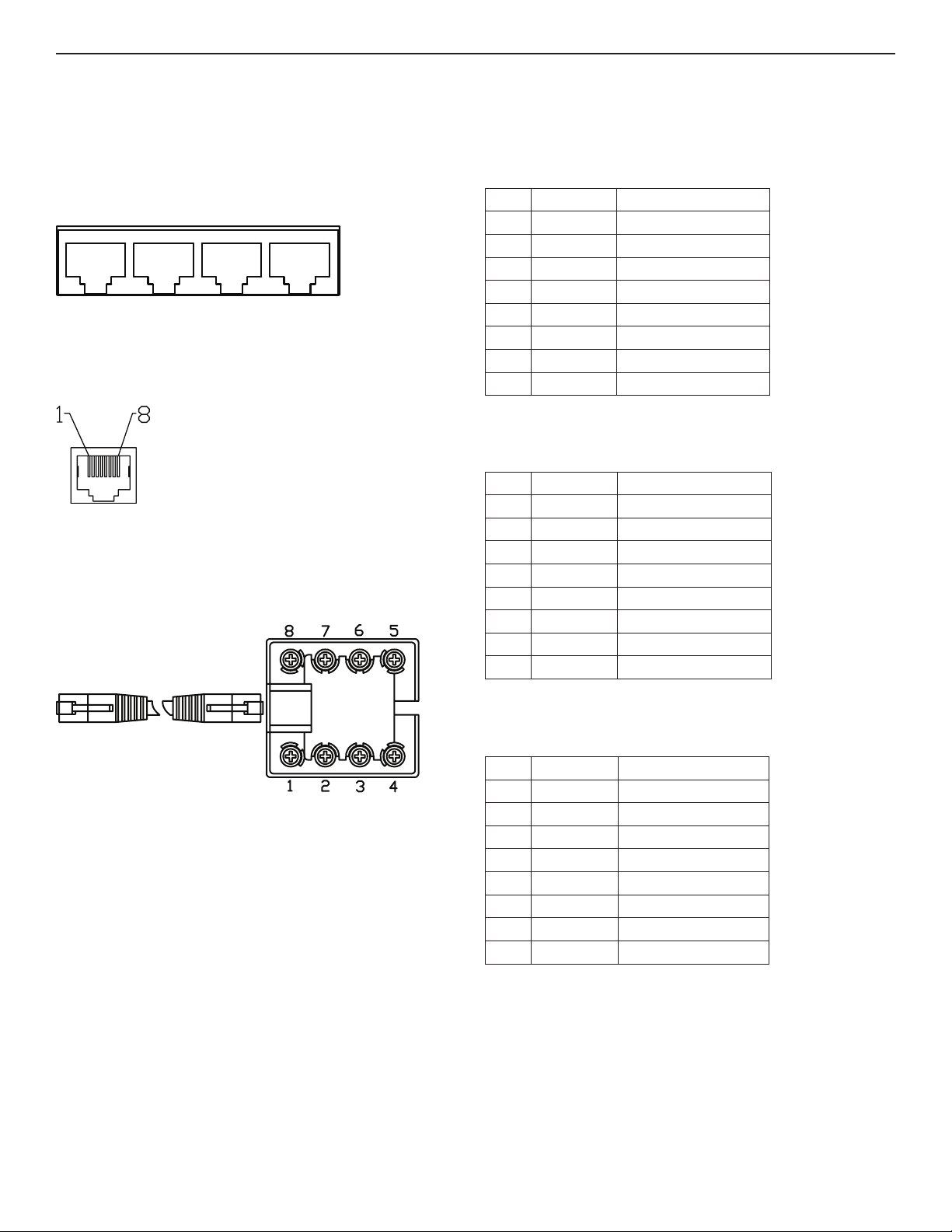

FIGURE 4 – RJ45 BREAK-OUT – FVT40D2I1C4E TRANSMITTER

4 pc. Factory Supplied

RJ-45 PORTS

Located on Rear Panel

D (DATA PORTS)

PIN # Wire Color Data Connections

CADD

VIEW INSIDE RJ-45 PORT

C (CONTACT PORT)

PIN # Wire Color TX Connections

RJ-45 BREAK-OUT KIT

Screw Number Corresponds to RJ-45 Port Pin Number

1 Blue DATA OUT –

2 Orange DATA OUT +

3 Black DATA IN +

4 Red RELAY OUT

5 Green RELAY OUT

6 Yellow DATA IN –

7 Brown GND

8 White +5V (BIAS)

1 Blue IN 1+

2 Orange IN 1–

3 Black IN 2+

4 Red IN 3+

5 Green IN 3 –

6 Yellow IN 2–

7 Brown IN 4+

8 White IN 4–

TECH SUPPORT: 1.888.678.9427

A (AIPHONE™ PORT)

PIN # Wire Color Aiphone Connections

1 Blue LE-D ‘-’ TERMINAL

2 Orange LE-D ‘1’ TERMINAL

3 Black LE-D ‘E’ TERMINAL

4 Red RELAY OUTPUT COM

5 Green RELAY OUTPUT N.C.

6 Yellow RELAY OUTPUT N.O.

7 Brown GND

8 White GND

INS_FVT/FVR40D2I1C4E_REVA 06/22/12 PAGE 3

Page 4

CONTACTAIPHONE

DATA 2DATA 1

12 12 12 12

DATA1

IN

S3

S2

S1

OUT

IN

ALARM

LE-D

LE-F

CONTACT

C

S

INSTALLATION AND OPERATION MANUAL FVT/FVR40D2I1C4E

FIGURE 5 – RJ45 BREAK-OUT – FVR40D2I1C4E RECEIVER

4 pc. Factory Supplied

RJ-45 PORTS

Located on Rear Panel

CADD

VIEW INSIDE RJ-45 PORT

RJ-45 BREAK-OUT KIT

Screw Number Corresponds to RJ-45 Port Pin Number

D (DATA PORTS)

PIN # Wire Color Data Connections

1 Blue DATA OUT –

2 Orange DATA OUT +

3 Black DATA IN +

4 Red RELAY OUT

5 Green RELAY OUT

6 Yellow DATA IN –

7 Brown GND

8 White +5V (BIAS)

C (CONTACT PORT)

PIN # Wire Color RX Connections

1 Blue OUT1 +

2 Orange OUT1 –

3 Black OUT2 +

4 Red OUT3 +

5 Green OUT3 –

6 Yellow OUT2 –

7 Brown OUT4 +

8 White OUT4 –

TECH SUPPORT: 1.888.678.9427

A (AIPHONE™ PORT)

PIN # Wire Color Aiphone Connections

1 Blue LEF ‘E’ TERMINAL

2 Orange LEF ‘1’ TERMINAL

3 Black LEF ‘–’ TERMINAL

4 Red NC

5 Green CONTACT INPUT +

6 Yellow NC

7 Brown GND

8 White GND

NC = No Connection

INS_FVT/FVR40D2I1C4E_REVA 06/22/12 PAGE 4

Page 5

INSTALLATION AND OPERATION MANUAL FVT/FVR40D2I1C4E

12 12 12 12

DATA1

IN

S3

S2

S1

OUT

ALARM

LE-D

LE-F

CONTACT

C

S

12 12 12 12

ON

S4

DATA1

IN

S3

S2

S1

OUT

DATA2

IN

OUT

ALARM

LE-D

LE-F

CONTACT

C

S

FIGURE 6 – DATA SWITCH POSITIONS

The mode for each data channel is configured using a set of two switches labeled DATA1 (S3) and DATA2 (S4), located on the front panel of the unit.

DATA1 (S3) DATA2 (S4)

Resulting Mode1 2 1 2

ON ON ON ON RS232

ON OFF

OFF ON OFF ON RS485 2-Wire, Sensornet

OFF OFF OFF OFF RS485 4-Wire

FIGURE 7 – RJ-45 PIN OUT

OFF RS422, Bi-Phase or Manchester

ON

PIN # RS232 RS422 RS485 2-Wire RS485 4-Wire

1 NC RS422 OUTPUT – NC RS485 OUTPUT –

2 RS232 – OUTPUT RS422 OUTPUT + NC RS485 OUTPUT +

3 NC RS422 INPUT + RS485 INPUT + RS485 INPUT +

4 RELAY OUT RELAY OUT RELAY OUT RELAY OUT

5 RELAY OUT RELAY OUT RELAY OUT RELAY OUT

6 RS232 – INPUT RS422 INPUT – RS485 INPUT – RS485 INPUT –

7 GND GND GND GND

8 +5V (BIAS) +5V (BIAS) +5V (BIAS) +5V (BIAS)

NC = No Connection

PIN # Wire Color Data Connections

1 Blue DATA OUT –

2 Orange DATA OUT +

3 Black DATA IN +

4 Red RELAY OUT

5 Green RELAY OUT

6 Yellow DATA IN –

7 Brown GND

8 White +5V (BIAS)

TECH SUPPORT: 1.888.678.9427

INS_FVT/FVR40D2I1C4E_REVA 06/22/12 PAGE 5

Page 6

INSTALLATION AND OPERATION MANUAL FVT/FVR40D2I1C4E

FIGURE 8 – DATA CONNECTIONS

See Page 5 for Switch Settings

Customer

Equipment

FVT40D2I1C4E

FVR40D2I1C4E

Customer

Equipment

RS232

RS422

Bi-phase or

Manchester

2-Wire

RS485,

Sensornet

Data Transmit

Data Receive

Signal Ground

Data Out (+)

Data Out (-)

Data In (+)

Data In (-)

Data In (+)

Data In (-)

Data (A)

Data (B)

DIN(-)

DOUT(+)

GND

DIN(+)

DIN(-)

DOUT(+)

DOUT(-)

DOUT(+)

DOUT(-)

DIN(+)

DIN(-)

DOUT(+)

DIN(-)

GND

DOUT(+)

DOUT(-)

DIN(+)

DIN(-)

DIN(+)

DIN(-)

DIN(+)

DIN(-)

Data Receive

Data Transmit

Signal Ground

Data In (+)

Data In (-)

Data Out (+)

Data Out (-)

Data Out (+)

Data Out (-)

Data (A)

Data (B)

4-Wire

RS485

Data Out (A)

Data Out (B)

Data In (A)

Data In (B)

DIN(+)

DIN(-)

DOUT(+)

DOUT(-)

FIGURE 9 – POSSIBLE ETHERNET CONFIGURATION

Ethernet IEEE 802.3 Network Element determined by user.

CAT5e/6 with

RJ45 Connections

Ethernet IEEE 802.3

Network Element

FVT40D2I1C4E FVR40D2I1C4E

Optical Fiber

SC or LC

Connectors

SINGLE FIBER

SFP MODULE

DOUT(+)

DOUT(-)

DIN(+)

DIN(-)

Data In (A)

Data In (B)

Data Out (A)

Data Out (B)

CAT5e/6 with

RJ45 Connections

Ethernet IEEE 802.3

Network Element

TECH SUPPORT: 1.888.678.9427

INS_FVT/FVR40D2I1C4E_REVA 06/22/12 PAGE 6

Page 7

INSTALLATION AND OPERATION MANUAL FVT/FVR40D2I1C4E

VIDEOIN

1234

GND

+Vin

GND

+Vin

PWR1 PWR2

CONTACTAIPHONE

DATA 2DATA 1

NETWORK

MANAGEMENT

4CHVIDEO TX +

2CHBI-DIRDATA+

4CHCONTACT +

1CHETHERNET

FVT40D2I1C4E

VIDEO 1

VIDEO 2

VIDEO 3

VIDEO4

POWER

10/100LINK

SFP1

SFP2

SFP2

SFP1

10/100

12 12 12 12

ON

S4

DATA1

IN

ETHERNET

S3

S2

S1

OUT

DATA2

IN

OUT

ALARM

LE-D

LE-F

CONTACT

C

S

VIDEOOUT

1234

GND

+Vin

GND

+Vin

PWR1 PWR2

CONTACTAIPHONE

DATA 2DATA 1

NETWORK

MANAGEMENT

4CHVIDEORX+

2CHBI-DIRDATA+

4CHCONTACT +

1CHETHERNET

FVR40D2I1C4E

VIDEO 1

VIDEO 2

VIDEO 3

VIDEO4

POWER

10/100LINK

SFP1

SFP2

SFP2

SFP1

10/100

12 12 12 12

ON

S4

DATA1

IN

ETHERNET

S3

S2

S1

OUT

DATA2

IN

OUT

ALARM

LE-D

LE-F

CONTACT

C

S

FIGURE 10 – SFP CONNECTIONS

Number of fibers and type of fiber connectors will be determined by selected SFP modules and if point-to-point or redundant modes are required.

FIGURE 11 – AIPHONE™ INTERCOM CONNECTIONS

The units are designed to operate with the Aiphone™ LE-D and LEF intercom system.

FVT40D2I1C4E

PIN # Wire Color Aiphone Connections

1 Blue LE-D ‘-’ TERMINAL

2 Orange LE-D ‘1’ TERMINAL

3 Black LE-D ‘E’ TERMINAL

4 Red RELAY OUTPUT COM

5 Green RELAY OUTPUT N.C.

LE-D FVR40D2I1C4E

TECH SUPPORT: 1.888.678.9427

FVT40D2I1C4E

3 –3E

2 121

1 E

5 54 76

6 Yellow RELAY OUTPUT N.O.

7 Brown GND

8 White GND

Form ‘C’ Relay

Output

Door/Barrier

Contact Input

FVR40D2I1C4E

PIN # Wire Color Aiphone Connections

1 Blue LEF ‘E’ TERMINAL

2 Orange LEF ‘1’ TERMINAL

3 Black LEF ‘–’ TERMINAL

4 Red NC

5 Green CONTACT INPUT +

6 Yellow NC

7 Brown GND

8 White GND

LEF

1–

INS_FVT/FVR40D2I1C4E_REVA 06/22/12 PAGE 7

Page 8

INSTALLATION AND OPERATION MANUAL FVT/FVR40D2I1C4E

12 12 12 12

S1

CONTACT

C

S

ON

S4

DATA1

IN

S3

S2

S1

OUT

DATA2

IN

OUT

ALARM

LE-D

LE-F

C

S

FIGURE 12 – CONTACT SWITCH POSITIONS

The mode for contact closure operation is configured using a set of two switches labeled CONTACT (S1) located on the front panel of the unit. There are four

supervised contacts in the forward (video) direction.

CONTACT (S1)

Resulting Mode1 2

ON ON Full Supervision – When a 1K resistor is connected in series with

the contact closure input, and a 1K resistor is connected in parallel

across the contact closure input. Both open circuits and short

circuits can be detected as well as normal opens and closes.

OFF Series Supervision – When a 1K resister is connected in series with

the contact closure input. In this mode, shorts across the contact

inputs can be detected but open circuits cannot be detected.

across the contact closure input. In this mode, open circuits can be

detected but short circuits cannot be detected.

no Supervision.

NOTE: These switch settings refer to the trans-

mitter (FVT40D2I1C4E). On the receiver

(FVR40D2I1C4E), S1 SWITCH 1 inverts the

contact outputs. S1 SWITCH 2 is not used.

ON

OFF ON Parallel Supervision – When a 1K resistor is connected in parallel

OFF OFF No Supervision – The contacts will behave as normal contacts with

FIGURE 13 – CONTACT CLOSURE SUPERVISED INPUT CIRCUIT

INTERNAL

1K Series*

5V

1K

1K

Parallel*

1K

* Optional external resistors

(provided) are required for

supervision. Place close to

the switch for optimal results.

TECH SUPPORT: 1.888.678.9427

INS_FVT/FVR40D2I1C4E_REVA 06/22/12 PAGE 8

Page 9

INSTALLATION AND OPERATION MANUAL FVT/FVR40D2I1C4E

12 12 12 12

S2

S1

ALARM

LE-D

LE-F

CONTACT

C

S

ON

S4

DATA1

IN

S3

S2

S1

OUT

DATA2

IN

OUT

ALARM

LE-D

LE-F

C

S

POWER

10/100LINK

10/100

ON

S4

ETHERNET

S3

DATA2

IN

OUT

FIGURE 14 – ALARM SWITCH POSITIONS

The mode for alarm operation is configured using a set of two switches labeled ALARM (S2) located on the front panel of the unit. There are two alarm outputs on each unit. One on each RJ45 data connector. See Figures 4 & 5 on Pages 3 & 4.

ALARM (S2)

Resulting Mode1 2

Alarm 1 – SFP 1 Failure

Alarm 2 – SFP 2 Failure

Alarm 1 – SFP 1 or SFP 2 Failure

Alarm 2 – Video Loss

Alarm 1 – SFP 1 Failure or Video Loss

Alarm 2 – SFP 2 Failure or Video Loss

Alarm 1 – SFP 1 or SFP 2 Failure or Video Loss

Alarm 2 – SFP 1 or SFP 2 Failure or Video Loss

NOTE: The ALARM will also open when Fiber Link

on either SFP port is lost or if Power is lost

on either unit.

ON ON

ON OFF

OFF ON

OFF OFF

FIGURE 15 – LED INDICATORS

10/100 LINK – No Ethernet signal Ethernet signal linked –

CONTACT (C)

CONTACT (S) –

TECH SUPPORT: 1.888.678.9427

OFF RED GREEN FLASHING

SFP SFP not installed No optical link Link is good and is in use

VIDEO – No video signal

One or more contacts are

open

LE-D – Quiet / No Audio Audio Present Call button active

LE-F – Quiet / No Audio Audio Present –

DATA IN Tri-state Low state High state Data activity

DATA OUT Tri-state Low state High state Data activity

POWER Unit powered down – Unit powered up –

Fiber link failed

Supervised contact alarm

or fiber link failed

An active video

signal is present

All four contacts

are closed

No supervised contacts in

alarm state

Link is good but is not in

use

–

–

–

GREEN Solid: Link (no activity)

YELLOW Solid: Highest data rate (100Mbs)

Blinking: Activity

Off: No link

INS_FVT/FVR40D2I1C4E_REVA 06/22/12 PAGE 9

Page 10

MECHANICAL INSTALLATION INSTRUCTIONS

INSTALLATION CONSIDERATIONS

This fiber-optic link is supplied as a Standalone/Rack module. Units

should be installed in dry locations protected from extremes of

temperature and humidity.

C2 NETWORK MANAGED RACKS

CAUTION: Although the units are hot-swappable and may be installed

without turning power off to the rack, ComNet recommends that the

power supply be turned off and that the rack power supply is disconnected

from any power source. Note: Remove electrical connector before

installing in card cage rack.

1. Make sure that the card is oriented right side up, and slide it into the

card guides in the rack until the edge connector at the back of the card

seats in the corresponding slot in the rack’s connector panel. Seating

may require thumb pressure on the top and bottom of the card’s front

panel.

CAUTION: Take care not to press on any of the LEDs.

2. Tighten the two thumb screws on the card until the front panel of the

card is seated against the front of the rack.

WARNING: Unit is to be used with a Listed Class 2 power supply.

FIGURE A

Dimensions are for a standard ComNet™ two slot module

.156 [3.96 mm]

.313 [7.95 mm]

IMPORTANT SAFEGUARDS:

A) Elevated Operating Ambient - If installed in a closed or multi-unit rack

assembly, the operating ambient temperature of the rack environment may

be greater than room ambient. Therefore, consideration should be given to

installing the equipment in an environment compatible with the maximum

ambient temperature (Tma) specified by the manufacturer.

B) Reduced Air Flow - Installation of the equipment in a rack should be such

that the amount of air flow required for safe operation of the equipment is not

compromised.

3 CORPORATE DRIVE | DANBURY, CT 06810 | USA

T: 203.796.5300 | F: 203.796.5303 | TECH SUPPORT: 1.888.678.9427 | INFO@COMNET.NET

8 TURNBERRY PARK ROAD | GILDERSOME | MORLEY | LEEDS, UK LS27 7LE

T: +44 (0)113 307 6400 | F: +44 (0)113 253 7462 | INFO-EUROPE@COMNET.NET

© 2013 Communications Ne tworks Cor poration. All Rights Reser ved. “ComNet ” and the “ComNet Logo” are regis tered trademarks of Communic ation Networ ks, LLC.

INS_FVT/FVR40D2I1C4E_REVA 06/22/12 PAGE 10

Loading...

Loading...