Comnet FVT4014SHR, FVR1010SHR, FVR4014SHR, FVT1010SHR, FVR8018SHR Installation And Operation Manual

Page 1

INSTALLATION AND OPERATION MANUAL

FVT/FVR8018(M)(S)1SHR

8-CHANNEL 10-BIT DIGITALLY ENCODED VIDEO

+ 8-CHANNEL BI-DIRECTIONAL DATA

+ SELF-HEALING RING TOPOLOGIES

The FVT/FVR8018SHR are part of ComNet’s SHR product family. The FVT8018SHR

transmits eight channels of video and eight channels of bi-directional data over its

Install fiber and power up

!

receiving modem prior to

power up of FVT8018SHR

two fiber optic interfaces. The FVR8018SHR receives eight channels of video and

eight channels of bi-directional data over its two fiber optic interfaces. The

FVT/FVR8018SHR are fully compatible with the other products in ComNet’s SHR product

family (e.g. FVT/FVR1010SHR and FVT/FVR4014SHR).

The NTSC or PAL video signals are digitized with 10-bits of resolution providing

superior image quality. The link also transmits bi-directional data over the same fiber.

Each data channel can be configured for an electrical interface of RS232, RS422 or

RS485 (2 Wire or 4 Wire).

Utilizing wave division multiplexing (WDM) technology, only one optical fiber is required

between units. It’s possible to implement a fully self-healing ring, linear add-drop, and even

point-to-point topologies. A maximum of eight (8) video signals can be placed onto the ring

through any combination of transmitter units, and an unlimited number of receiver units

can be used to view any or all of these eight video signals.

Bi-Color (Red/Green) LED indicators are provided for rapidly ascertaining equipment

operating status including the location of fiber breaks. See Figure 10 on Page 7 for an

explanation of LED indicators. An alarm relay output on the FVR8018SHR indicates when a

fault has occurred anywhere in the system.

These units are interchangeable between stand-alone or card-cage mount configurations.

See Figure A on Page 11 for mounting instructions.

See Figures 1 – 13 for complete installation information.

INS_FVT/FVR8018SHR_REVA

11/14/11

PAGE 1

Page 2

INSTALLATION AND OPERATION MANUAL FVT/FVR8018SHR

FIGURE 1 – FVT/FVR8018SHR TRANSMITTER AND RECEIVER

MULTIMODE OR SINGLE MODE

OPTICAL FIBER (Depending on Model)

BLACK

BLACK WITH WHITE STRIPE

Power Supply:

Surface Mount: 8–15 VDC @ 3W

Rack Mount: From Rack

FIGURE 2 – FVT8018SHR TRANSMITTER

REAR PANEL REAR PANELFRONT PANEL FRONT PANEL

FIGURE 3 – FVR8018SHR RECEIVER

NOTE: Remove Electrical Connector for Rack Mount Units

TECH SUPPORT: 1.888.678.9427

INS_FVT/FVR8018SHR_REVA

11/14/11

PAGE 2

Page 3

INSTALLATION AND OPERATION MANUAL FVT/FVR8018SHR

FIGURE 4 – DATA CONNECTIONS

See Figure 6 for Switch Positions

RS232

RS422

Bi-phase or

Manchester

2-Wire

RS485

Customer

Equipment

Data Transmit

Data Receive

Signal Ground

Data Out (+)

Data Out (–)

Data In (+)

Data In (–)

Data Out (+)

Data Out (–)

Data (A)

Data (B)

FVT8018SHR

DIN(–)

DOUT(–)

GND

DIN(+)

DIN(–)

DOUT(+)

DOUT(–)

DIN(+)

DIN(–)

DIN(+)

DIN(–)

FVR8018SHR

DOUT(–)

DIN(–)

GND

DOUT(+)

DOUT(–)

DIN(+)

DIN(–)

DOUT(+)

DOUT(–)

DIN(+)

DIN(–)

Customer

Equipment

Data Receive

Data Transmit

Signal Ground

Data In (+)

Data In (–)

Data Out (+)

Data Out (–)

Data In (+)

Data In (–)

Data (A)

Data (B)

Data Out (A)

4-Wire

RS485

Data Out (B)

Data In (A)

Data In (B)

TECH SUPPORT: 1.888.678.9427

DIN(+)

DIN(–)

DOUT(+)

DOUT(–)

DOUT(+)

DOUT(–)

DIN(+)

DIN(–)

Data In (A)

Data In (B)

Data Out (A)

Data Out (B)

INS_FVT/FVR8018SHR_REVA

11/14/11

PAGE 3

Page 4

INSTALLATION AND OPERATION MANUAL FVT/FVR8018SHR

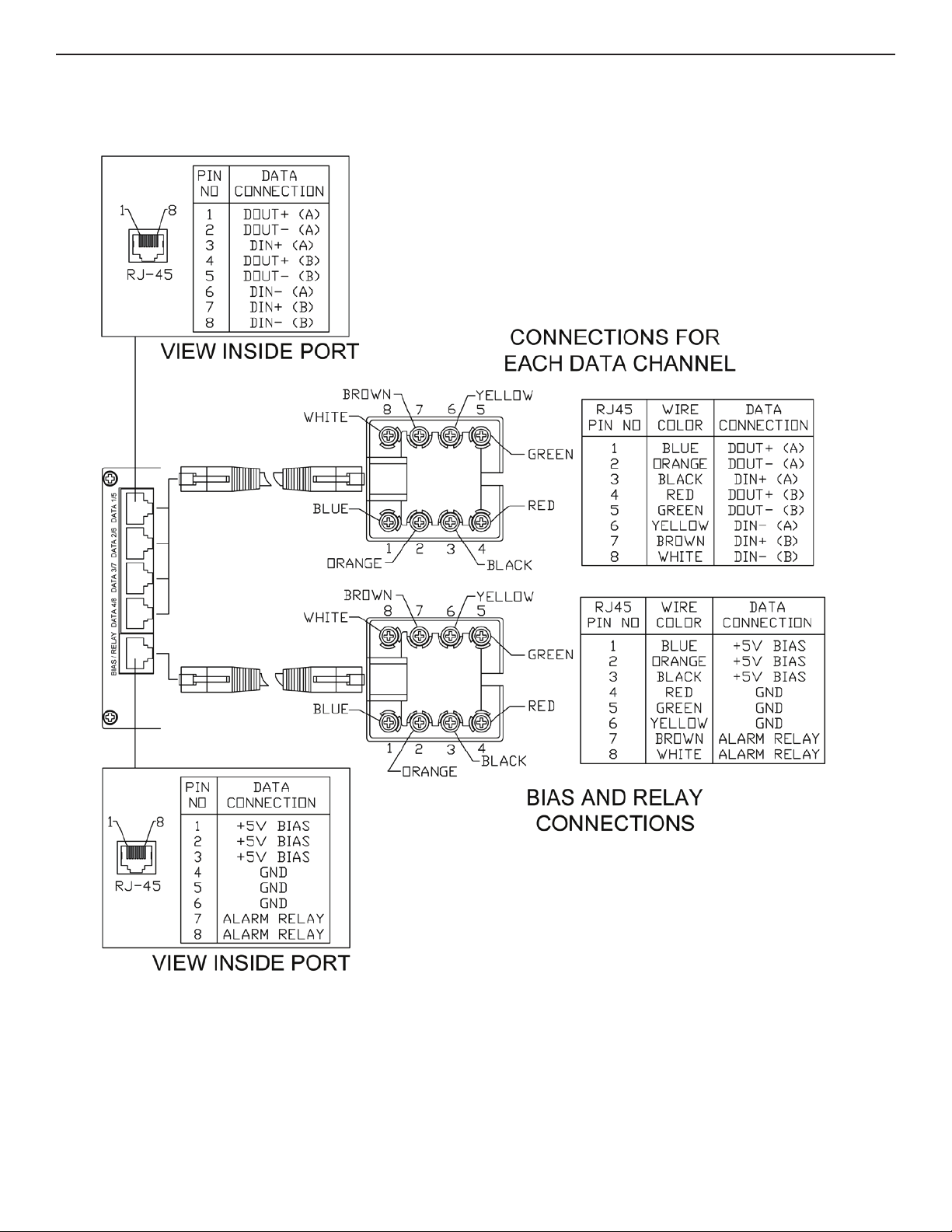

FIGURE 5 – RJ45 BREAK-OUT

5 pc. Factory Supplied

TECH SUPPORT: 1.888.678.9427

INS_FVT/FVR8018SHR_REVA

11/14/11

PAGE 4

Page 5

INSTALLATION AND OPERATION MANUAL FVT/FVR8018SHR

FIGURE 6 – DATA SWITCH POSITIONS

The mode for each data channel is configured using a pair of switches on the front panel of the unit.

Switch

FIGURE 7 – SWITCH SETTINGS

A Ports - Data Channels 1-4

B Ports - Data Channels 5-8

RS232

1 NC

2 Out A (-)

3 Ground A

4 NC

5 OUT B (-)

6 IN A (-)

7 GROUND B

8 IN B (-)

RS485 (2W)

& SENSORNET

1 NC

2 NC

3 IN A (+)

4 NC

5 NC

6 IN A (-)

7 IN B (+)

8 IN B (-)

RS422, RS485 (4W),

Manchester

& Bi-Phase

1 OUT A (+)

2 OUT A (-)

3 IN A (+)

4 OUT B (+)

5 OUT B (-)

6 IN A (-)

7 IN B (+)

8 IN B (-)

NC = No Connection

TECH SUPPORT: 1.888.678.9427

INS_FVT/FVR8018SHR_REVA

11/14/11

PAGE 5

Page 6

INSTALLATION AND OPERATION MANUAL FVT/FVR8018SHR

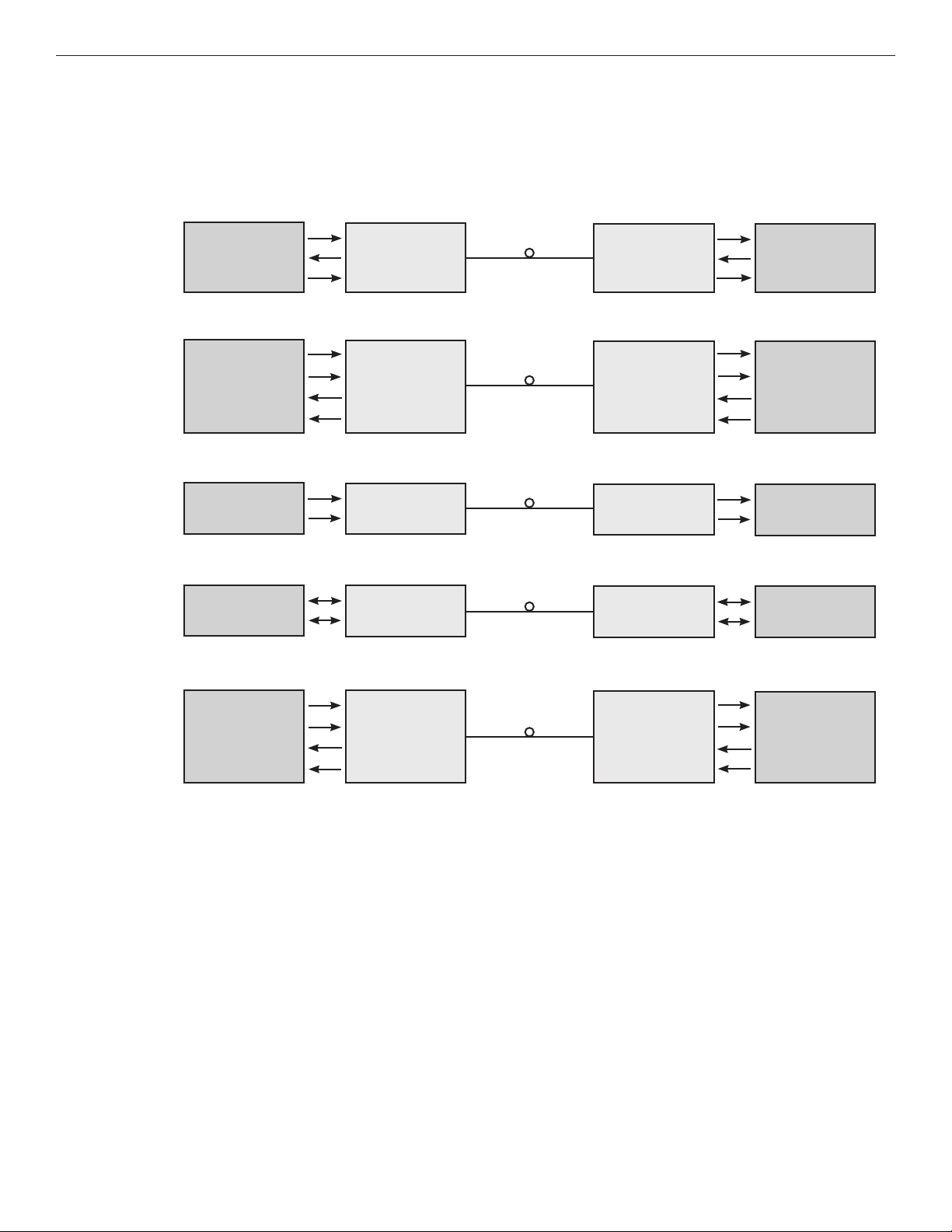

FIGURE 8 – FIBER CONNECTIONS

Many ring configurations are possible, including the addition of other Video/Data units in the ComNet SHR Product Line. Note that

Optic A is always connected to Optic B on the next unit.

Self Healing Ring:

FVT4014SHR FVR1010SHRFVT4014SHR FVR4014SHR FVR8018SHR

Linear:

OPTICAL

FIBERS

OPTICAL

FIBERS

OPTIC A

OPTIC B

OPTIC A

OPTIC B

OPTIC A

OPTIC B

OPTIC A

OPTIC B

OPTIC A

OPTIC B

FVT1010SHR FVT1010SHRFVT1010SHR FVT1010SHR FVR4014SHR

OPTIC A

OPTIC B

OPTIC A

OPTIC B

OPTIC A

OPTIC B

OPTIC A

OPTIC B

OPTIC A

OPTIC B

TECH SUPPORT: 1.888.678.9427

INS_FVT/FVR8018SHR_REVA

11/14/11

PAGE 6

Page 7

INSTALLATION AND OPERATION MANUAL FVT/FVR8018SHR

FIGURE 9 – SHR SWITCH POSITIONS

DCH1/SHR Switch

1 2

Resulting Configuration

NA* ON Disable Remote Fault Locator (RFL) feature

NA* OFF Enable Remote Fault Locator (RFL) feature

* Switch 1 on the FVT/FVR8018SHR unit is not used currently and is reserved

for a future release.

FIGURE 10 – LED INDICATORS

OPTIC A/B VIDEO DATA POWER

GREEN

RED

GREEN/RED

BLINK

OFF

Communication link has been established

over optical fiber

Communication link has not been

established.

Communication has been established

over optical fiber. However a fiber break

has been detected in the system.

Unit powered down Unit powered down No data signal is present. Unit powered down

An active video signal is present on

the BNC connector.

No video signal is present.

– – –

SHR Switch 2 can disable the Remote Fault Locator (RFL) feature of the OPTIC

A and OPTIC B LEDs as described in Figure 10. For self-healing ring topologies,

this switch would normally be turned OFF at every unit in the system so that

the RFL is enabled. However, for linear topologies this switch would be turned

ON at the two end points and turned OFF at the rest of the units. Disabling the

RFL at these two locations prevents them reporting their disconnected optic

ports as a fault to the rest of the units in the system. Fiber breaks throughout

the rest of the system will still be reported normally, even at the two endpoints. It is also possible to completely disable the RFL by setting this switch to

the ON position at every unit in the system. In this case, the OPTIC A and OPTIC

B LEDs will only report the status of the optical link between this unit and the

next; the LEDs would either be solid green or solid red.

An active data signal is present on the

pins of the data connector.

Unit powered up

– –

Remote Fault Locator (RFL) using the OPTIC LEDs

The Bi-color OPTIC A and OPTIC B LEDs on the front panel convey the status of the optical link between one unit and the next unit around the ring, as well as

the status of the ring as a whole. They can be used to identify the location of a remote fiber fault based on their color and pattern:

• Solid Green Optical link has been established between this optical port and the adjacent unit over fiber.

Furthermore, every other unit in the system is also reporting that link has been established.

There are no faults in the system.

• Solid Red Optical link over this port has been lost.

This could be due to a broken fiber, a bad connection, or loss of power at the adjacent unit.

• Blinking

Green/Red Optical link has been established between this optical port and the adjacent SHR unit.

However, a fault condition has been detected somewhere in the system. The OPTIC LED will be green for a period of time, and

then flash red some number of times. The number of red flashes indicates the location of the fault by “hops” around the ring. If

the LED flashes red three times, then the location of the fault is three hops away (i.e. three SHR units away). For larger systems

with faults greater than 9 hops away, the LED will use a combination of long and short red flashes. Each long flash indicates 10

hops. Each short flash indicates 1 hop. For example, a fault 47 hops away would be encoded as 4 long red flashes, followed

immediately by 7 short red flashes. The pattern repeats indefinitely until the fault is resolved.

INS_FVT/FVR8018SHR_REVA

TECH SUPPORT: 1.888.678.9427

11/14/11

PAGE 7

Page 8

INSTALLATION AND OPERATION MANUAL FVT/FVR8018SHR

FIGURE 11 – EXAMPLE SYSTEM IN LINEAR TOPOLOGY

The figure below shows a system with FVT/FVR1010SHR units connected in a linear topology. The system demonstrates a video distribution application.

A

A single video input is transmitted by a FVT1010SHR over fiber optic cable to three daisy-chained FVR1010SHR units. The last unit in the chain is

connected to an audible alarm to indicate faults.

Three receivers are used in this example, but there is no limit to the number of receivers used in a system. This example could also be expanded to

distribute four or eight channels of video using FVT/FVR4014SHR or FVT/FVR8018SHR units, respectively.

A

FVT1010SHR

Unit 1

VIDEO IN

B BB B

V

The table below shows the SHR configuration switches for each unit in the system. Once the system is configured, all of the POWER, OPTIC and VIDEO

B

A A A

FVR1010SHR

Unit 2

VIDEO OUT

V

FVR1010SHR

Unit 3

VIDEO OUT

V

FVR1010SHR

Unit 4

VIDEO OUT

V

LEDs will be solid green except for the OPTIC A LED on Unit 1 and the OPTIC B LED on Unit 4, which would both be solid red. No faults will be reported

because RFL has been disabled at Units 1 and Unit 4. The alarm relay will be closed.

Unit

SHR Switch

1 2 3 4

Notes

1 ON ON ON ON Transmit video on Channel 1. Do not report fiber faults to other units.

2 ON ON ON OFF Receive video from Channel 1.

3 ON ON ON OFF Receive video from Channel 1

4 ON ON ON ON Receive video from Channel 1. Do not report fiber faults to other units.

Let’s consider how the system would respond to a broken fiber between Units 2 and 3:

C

ALARM

A

FVT1010SHR

Unit 1

VIDEO IN

B BB B

V

The video would no longer be displayed at Units 3 and 4 because this is system has a linear topology (i.e. there is no redundant fiber path).

D

A A A

FVR1010SHR

Unit 2

VIDEO OUT

FIBER

BREAK

V

FVR1010SHR

Unit 3

NO VIDEO NO VIDEO

V

FVR1010SHR

Unit 4

V

The alarm relay will open and cause the audible alarm at Unit 4 to sound. In addition, the other units in the system would indicate the location of the

fault using their OPTIC LEDs as described in the table below.

Unit OPTIC A LED OPTIC B LED

1 Solid Red Green, then Blink Red 1 time

2 Solid Green Solid Red

3 Solid Red Solid Green

4 Green, then Blink Red 1 time Solid Red

INS_FVT/FVR8018SHR_REVA

TECH SUPPORT: 1.888.678.9427

ALARM

11/14/11

PAGE 8

Page 9

INSTALLATION AND OPERATION MANUAL FVT/FVR8018SHR

FIGURE 12 – EXAMPLE SYSTEM IN SELF-HEALING RING

The figure below shows a system of four FVT1010SHR units, a FVT4014SHR unit and a FVR8018SHR unit connected as a self-healing ring. Eight channels of

A

video enter the system at the five transmitter units and are sent to the video receiver and are displayed on a bank of monitors.

A

V

VIDEO IN

FVT1010SHR

Unit 1

B BB

A

B

V

VIDEO IN

FVT1010SHR

Unit 2

FVT4014SHR

Unit 5

4

A

VIDEO IN

1 – 4

V

VIDEO IN

A A

FVT1010SHR

Unit 3

FVR8018SHR

B

Unit 6

8

B

A

VIDEO OUT 1 – 8

(e.g., Bank of Monitors)

V

VIDEO IN

FVT1010SHR

Unit 4

VV

The table below shows the SHR configuration switches for each unit in the system. Once the system is configured, all of the POWER, OPTIC and VIDEO

B

LEDs will be solid green. No faults will be reported.

Unit

SHR Switch

1 2 3 4

Notes

1 ON ON ON OFF Transmit video on Channel 1.

2 OFF ON ON OFF Transmit video on Channel 2.

3 ON OFF ON OFF Transmit video on Channel 3.

4 OFF OFF ON OFF Transmit video on Channel 4.

Unit

5 OFF OFF Transmit video on Channels 5 – 8

6 NA* OFF Receive video from Channels 1 – 8

Switch 1 on the FVR8018SHR unit is not used currently and is reserved for a

future release.

SHR Switch

1 2

Notes

TECH SUPPORT: 1.888.678.9427

INS_FVT/FVR8018SHR_REVA

11/14/11

PAGE 9

Page 10

INSTALLATION AND OPERATION MANUAL FVT/FVR8018SHR

FIGURE 13 – EXAMPLE SYSTEM IN SELF-HEALING RING (CONT’D)

Let’s consider how the system would respond to a broken fiber between Units 2 and 3:

C

A

V

VIDEO IN

FVT1010SHR

Unit 1

B BB

A

B

V

VIDEO IN

FVT1010SHR

Unit 2

FVT4014SHR

Unit 5

4

A

VIDEO IN

1 – 4

FIBER

BREAK

V

VIDEO IN

A A

FVT1010SHR

Unit 3

FVR8018SHR

B

Unit 6

8

B

A

VIDEO OUT 1 – 8

(e.g., Bank of Monitors)

V

VIDEO IN

FVT1010SHR

Unit 4

VV

Because the system is connected as a self-healing ring, all eight channels of video will still be displayed even after the fiber break. All of the units in the

D

system will indicate the location of the fault using their OPTIC LEDs as described in the table below.

Unit Optic A LED Optic B LED

1 Green, then blink Red 4 times Green, then blink Red 1 time

2 Green, then blink Red 5 times Solid Red

3 Solid Red Green, then blink Red 5 times

4 Green, then Blink Red 1 time Green, then blink Red 4 times

5 Green, then blink Red 3 times Green, then blink Red 2 times

6 Green, then blink Red 2 times Green, then blink Red 3 times

TECH SUPPORT: 1.888.678.9427

INS_FVT/FVR8018SHR_REVA

11/14/11

PAGE 10

Page 11

MECHANICAL INSTALLATION INSTRUCTIONS

INSTALLATION CONSIDERATIONS

This fiber-optic link is supplied as a Standalone/Rack module. Units should

be installed in dry locations protected from extremes of temperature and

humidity.

C1-US, C1-EU, C1-AU OR C1-CH CARD CAGE RACKS

CAUTION: Although the units are hot-swappable and may be installed

without turning power off to the rack, ComNet recommends that the

power supply be turned off and that the rack power supply is disconnected

from any power source. Note: Remove electrical connector before

installing in card cage rack.

1. Make sure that the card is oriented right side up, and slide it into the

card guides in the rack until the edge connector at the back of the card

seats in the corresponding slot in the rack’s connector panel. Seating

may require thumb pressure on the top and bottom of the card’s front

panel.

CAUTION: Take care not to press on any of the LEDs.

2. Tighten the two thumb screws on the card until the front panel of the

card is seated against the front of the rack.

WARNING: Unit is to be used with a Listed Class 2 or LPS power supply rated 8-15

VDC @ 3W.

FIGURE A

Dimensions are for a standard ComNet™ three slot module

.156 [3.96 mm]

.313 [7.95 mm]

IMPORTANT SAFEGUARDS:

A) Elevated Operating Ambient - If installed in a closed or multi-unit rack

assembly, the operating ambient temperature of the rack environment may

be greater than room ambient. Therefore, consideration should be given to

installing the equipment in an environment compatible with the maximum

ambient temperature (Tma) specified by the manufacturer.

B) Reduced Air Flow - Installation of the equipment in a rack should be such

that the amount of air flow required for safe operation of the equipment is not

compromised.

3 CORPORATE DRIVE | DANBURY, CT 06810 | USA

T: 203.796.5300 | F: 203.796.5303 | TECH SUPPORT: 1.888.678.9427 | INFO@COMNET.NET

8 TURNBERRY PARK ROAD | GILDERSOME | MORLEY | LEEDS, UK LS27 7LE

T: +44 (0)113 307 6400 | F: +44 (0)113 253 7462 | INFO-EUROPE@COMNET.NET

© 2011 Communicat ions Network s Corporation. All Rights Reserved. “ComNet” and the “ComNet L ogo” are registered tr ademarks of Communication Networks, LLC.

INS_FVT/FVR8018SHR_REVA

11/14/11

PAGE 11

Loading...

Loading...