Page 1

W SERIES

W

Premium Quality All-Weather/All-Purpose

Installation Loudspeakers

ET

II

Weather Environmental Technology

Operation and Installation Manual

Page 2

COMMUNITY PROFESSIONAL LOUDSPEAKERS

A TRADITION OF EXCELLENCE AND INNOVATION

Since the founding of our company in 1968, Community has been a constant developer and

innovator of loudspeaker technology. Many of our engineering achievements were

undertaken to solve problems, where no prior solutions existed. Others resulted from simply

seeing a better way to do things. Over the years our technologies have been imitated, and our

methods have become common practice throughout the professional sound industry.

However, developments like carbon fiber diaphragm compression drivers still stand alone,

and well ahead of the competition. Just a few of Community’s unique accomplishments

include the following:

First successful fiberglass mid, high frequency, and large-format bass horns.

First compression loaded mid-range horn for touring systems - the LMF.

First suspension-less diaphragm HF driver - the VHF100.

First mid-range, full-decade (200 Hz - 2 kHz) high-power compression driver - the M4.

First carbon fiber diaphragm compression drivers - M4, EM280, EM282.

First Ferrofluid-cooled professional woofers - the VBS Series.

First product series with all drivers Ferrofluid-cooled.

First air-cooled loudspeakers for touring systems - AirForce.

First three-way cinema loudspeaker systems - Paramount Executive Studio Theatre, Warner

Bros. screening theatre and dubbing rooms.

First electro-acoustic system to equal the sound level of pneumatic warning sirens.

First to provide loudspeaker coverage over an entire country – Denmark Emergency System.

First comprehensive, calibrated data acquisition of sound reinforcement products.

First integral signal-aligned three-way sound reinforcement systems - RS Series.

First pro audio company with an Internet Web site.

First all horn-loaded, high-fidelity, weather-resistant loudspeakers - R2 Series.

In line with our history of excellence and innovation, each Community product is manufactured in

accordance with a complicated and exacting chain of procedures that ensure absolute quality. With

our unique designs, our sophisticated techniques, and our proprietary materials and transducers, we

are committed to bringing only the finest quality audio products to the many thousands of professional

sound engineers, performers, and end users who rely on them daily.

Community’s philosophy is to build products that are uncompromised in sound quality, reliability,

durability and flexibility, all at a fair price. We provide comprehensive technical support and we stand

behind every product we manufacture. We pledge to do our best to insure that you are satisfied with

your Community purchase!

Community Professional Loudspeakers

333 East Fifth Street

Chester, PA 19013-4511 USA

Phone: (610) 876-3400 Fax: (610) 874-0190

www.communitypro.com

© 2015 All Rights Reserved

Community WET II - Operation and Installation Manual - Page 2

Page 3

REFERENCE TO EC STATEMENT OF CONFORMITY

This document confirms that the range of products of Community Professional Loudspeakers bearing

the CE label meet all of the requirements in the EMC directive 89/336/EEC laid down by the Member

States Council for adjustment of legal requirements. Furthermore, the products comply with the rules

and regulations referring to the electromagnetic compatibility of devices from 30-August-1995.

The Community Professional Loudspeaker products bearing the CE label comply with the following

harmonized or national standards:

DIN EN 55013:08-1991

DIN EN 55020:05-1995

DIN EN 55082-1:03-1993

The authorized declaration and compatibility certification resides with the manufacturer and can be

viewed upon request. The responsible manufacturer is the company:

Community Light & Sound

333 East Fifth Street

Chester, PA 19013-4511

USA

TEL: 1-610 876-3400

FAX: 1-610 874-0190

Chester, PA USA March 2015

Community WET II - Operation and Installation Manual - Page 3

Page 4

Community WET II Operation and Installation Manual

Table of Contents

CHAPTER PAGE

INTRODUCTION ........................................................................................................................................................................................... 6

W SERIES WET II Loudspeaker Systems from Community ............................................................................................... 6

Important Safety Information ..................................................................................................................................................... 8

C-Tips ................................................................................................................................................................................................... 8

Precautions & Safety Considerations ...................................................................................................................................... 8

Introduction to Weather-Resistant Loudspeakers ............................................................................................................. 9

Unpacking and Inspection ............................................................................................................................................................ 9

Important Note – Mounting/Rigging Provisions ................................................................................................................. 10

WET II FEATURES AND TECHNOLOGY ................................................................................................................................................. 10

GETTING ACQUAINTED ............................................................................................................................................................................. 11

Physical Features ........................................................................................................................................................................... 11

GENERAL DESCRIPTION ........................................................................................................................................................................... 13

HIGH-PASS FILTERS .................................................................................................................................................................................. 13

CONNECTING THE AMPLIFIER TO THE LOUDSPEAKER ..................................................................................................................14

Impedance and Combining Loudspeakers .............................................................................................................................14

Unequal Impedances .....................................................................................................................................................................14

Know Your Amplifier...................................................................................................................................................................... 15

70V AND 100V OPERATION ..................................................................................................................................................................... 16

Using Power Taps ........................................................................................................................................................................... 16

Wiring Diagrams for 70V/100V Operation ............................................................................................................................. 17

70.7V and 100V Systems .............................................................................................................................................................. 18

SELECTING AMPLIFIERS ........................................................................................................................................................................... 19

Amplifiers for 70V/100V Operation ......................................................................................................................................... 19

AUTOFORMERS ......................................................................................................................................................................................... 20

WET II APPLICATIONS .............................................................................................................................................................................. 20

INSTALLATION CONSIDERATIONS ........................................................................................................................................................ 21

Installing with Yokes ..................................................................................................................................................................... 21

RIGGING AND MOUNTING WET II ENCLOSURES .............................................................................................................................. 22

Safety First! ..................................................................................................................................................................................... 22

Rigging Guidelines ......................................................................................................................................................................... 22

WET II MOUNTING YOKES AND MOUNTING KITS ........................................................................................................................... 25

W2-218, W2-228 and W2-2W8 Yoke Assembly ................................................................................................................. 25

SSY25KIT Mounting Kit for W2-112 and W2-312 ............................................................................................................................ 28

MAINTAINING WEATHER RESISTANCE ............................................................................................................................................... 31

SERVICING WET II LOUDSPEAKERS ...................................................................................................................................................... 31

Replacement Parts .............................................................................................................

TROUBLESHOOTING GUIDE ................................................................................................................................................................... 32

TECHNICAL SPECIFICATIONS ................................................................................................................................................................. 33

Compact WET II Models ............................................................................................................................................................... 33

Large Full-Range WET II Models .............................................................................................................................................. 34

WET II Subwoofer Models .......................................................................................................................................................... 35

SUMMING THINGS UP ............................................................................................................................................................................. 36

WARRANTY INFORMATION AND SERVICE ........................................................................................................................................ 36

........................................................... 31

Community WET II - Operation and Installation Manual - Page 4

Page 5

TABLE OF FIGURES PAGE

FIGURE 1 - PHYSICAL FEATURES OF A TYPICAL LARGE WET II ENCLOSURE 12

FIGURE 2 - WIRING DIAGRAMS FOR W2-218T 17

FIGURE 3 - WIRING DIAGRAMS FOR W2-228T, W2-2W8T AND W2-312-HT 17

FIGURE 4 - W2-218 YOKE DIMENSIONS 25

FIGURE 5 - W2-218 YOKE ASSEMBLY 25

FIGURE 6 - W2-228 AND W2-2W8 YOKE DIMENSIONS 26

FIGURE 7 - W2-228 AND W2-2W8 YOKE ASSEMBLY 27

FIGURE 8 - SSY25KIT DIMENSIONS 28

FIGURE 9 - SSY25KIT ASSEMBLY 29

FIND THE LATEST ONLINE

Every effort has been made to ensure that the information contained in this manual was complete and accurate at

the time of printing. However, due to ongoing technical advances, changes or modifications may have occurred

that are not covered in this publication.

information published by Communtiy is always available at http://www.communitypro.com. The publication date

can be found on the rear cover or last page.

The latest version of this manual and the most recent product

Community WET II - Operation and Installation Manual - Page 5

Page 6

COMMUNITY W SERIES WET II

OPERATION AND INSTALLATION MANUAL

INTRODUCTION

Thank you for selecting Community’s W SERIES WET II premium all-weather/all-purpose installation

loudspeakers. WET is an acronym standing for Weather Environmental Technology, which describes one of

the main design goals of this product line.

WET II products are built using unique weather-resistant materials that can survive sustained exposure to

harsh climatic conditions. In addition to weather-resistance, these materials also possess favorable

acoustical properties. The result is a line of loudspeaker products that not only performs consistently in

tough, problematic environments, but also provides superlative acoustic performance, typically associated

only with high fidelity “indoor” loudspeakers.

WET II Loudspeaker Systems from Community

The upgraded WET II from Community combines all of WET’s original weather-defying characteristics with

improved styling and technology. WET II is entirely constructed of corrosion-resistant materials like

fiberglass, stainless steel, polyimide and carbon fiber, using sophisticated technologies to ensure they will

withstand exposure to harsh environmental conditions. Some of our unique materials include:

Carbon Fiber. Used for LF and MF cones, carbon fiber exhibits a superior strength-to-mass ratio (high

Young’s Modulus [E]), over that of traditional cone material, thus improving transient response and

efficiency while simultaneously lowering distortion.

Polyimide. Used for HF diaphragms due to its excellent flexural strength and low resonance; quite unlike

brittle metallic diaphragms.

Fiberglass. All enclosures and horns are constructed of hand-laid fiberglass. Fiberglass is inherently

weather-resistant while exhibiting the strength, stiffness, and non-resonant characteristics needed to

insure an acoustically inert loudspeaker enclosure.

Stainless Steel. All hardware and fasteners, wherever possible, are made of stainless steel, highly resistant

to corrosion and oxidation.

Weather-Stop™ Grille. Each enclosure is fitted with Community’s proprietary Weather-Stop protective

grille. The grille consists of an outer layer of perforated steel finished with Community’s proprietary duallayer powder coating process, a center later of reticulated foam, and an inner layer of fine mesh screen

made from a rustproof UV-resistant synthetic material. This grille assembly prevents water intrusion, while

providing a high degree of acoustic transparency.

Ferrofluid. Most LF, MF & HF drivers use Ferrofluid in their voice coil gaps. Ferrofluid provides improved

heat transfer resulting in higher power handling, reduced distortion from fluidic dampening of mechanical

resonance, and it seals the air gaps against corrosion and oxidation.

Input Cables. WET II uses type SJOW neoprene jacketed cables rated for outdoor use.

Community WET II - Operation and Installation Manual - Page 6

Page 7

These materials provide the absolute best in sound quality, appearance, and longevity.

WET II products offer a wide range of power levels, frequency response capability, and directional pattern

control. The WET II product line consists of a basic complement of six sizes of loudspeaker enclosures with

multiple dispersion patterns available in three of the size formats. The models in this range include:

The W2-218 compact two-way, 8-inch full-range system

The W2-228 quasi three-way, 8-inch full-range system

The W2-2W8 compact two-way, dual 8-inch, fill loudspeaker with ultra-wide 120° HF pattern

control

The W2-215 two-way, 15” full-range system

The W2-312 three-way, 12” full-range system

The W2-322L three-way, dual 12” full-range system

The W2-315 three-way, 15” full-range system

The W2-112 single 12” subwoofer system

The W2-122 dual 12” subwoofer system

The W2-125 dual 15” subwoofer system

WET II features greater precision and tighter tolerance fit. Frequency dividing networks have been finetuned for improved acoustical linearity. Plus, a newly developed low-loss, low-distortion 200 Watt high

fidelity autoformer has been developed and is optionally available for 70V/100V applications in the W2-218,

W2-228 and W2-2W8.

While handling outdoor applications with ease, the elegant styling of WET II makes them suitable for many

indoor applications as well. All WET II systems are available in standard black or white fiberglass finishes,

with an enclosure-matching black or white stainless steel grille finished with Community’s proprietary duallayer powder coating process. White WET II enclosures include matching white grilles, white bezels, white

gland nuts, and white cable, making them perfect for cruise ships, clubs or residential applications. Custom

color exteriors are also possible at a nominal fee.

A black or white powder-coated stainless steel mounting bracket is included with smaller WET II models

W2-218, W2-228 and W2-2W8, while optional mounting accessories are available for the larger full-range

and subwoofer systems. WET II is protected by a five-year product warranty plus a fifteen-year enclosure

warranty. WET II loudspeakers are flexible, easy to install and most importantly, they provide unparalleled

sound quality. They are designed to withstand sustained use under severe climatic conditions, functioning

year after year in even the harshest environments.

This manual is intended to help you install and use WET II loudspeakers safely and effectively. It provides

useful information to help you obtain the best performance, sound quality, and reliability from your WET II

systems. We’ve provided a series of Quick-Start diagrams to enable you to install and operate the products

immediately if required; however, we recommend that you read this manual in its entirety, to help insure

that your WET II installation meets the highest possible standards. While every attempt has been made to

ensure this information is correct and up-to-date, Community continuously incorporates worthwhile

improvements to each product which may include changes and/or modifications not contained in this

manual.

Community WET II - Operation and Installation Manual - Page 7

Page 8

Important Safety Information

Always follow these basic safety precautions when installing and using WET II loudspeakers and

accessories:

Read these instructions.

Keep these instructions.

Heed all warnings.

Follow all instructions particularly those pertaining to rigging, mounting, hanging, or suspending the

products, and all information pertaining to electrical connections.

Only use accessories that are specified and approved by the manufacturer.

The terms CAUTION, WARNING, and DANGER are used throughout this manual to alert the reader to

important safety considerations. If you have any questions or do not understand the meaning of these

terms, do not proceed with installation. Contact your local dealer, distributor, or call Community directly for

assistance. These terms are defined below:

CAUTION: describes an operating condition or user action that may expose the equipment or user to

potential damage or danger.

WARNING: describes an operating condition or user action that will likely cause damage to the

equipment or injury to the user or to others in the vicinity.

DANGER: describes an operating condition or user action that will immediately damage the equipment

and/or be extremely dangerous or life threatening to the user or to others in the vicinity.

C-Tips

Occasionally, in this manual, you’ll come across some useful tips that are intended to help you

better plan and execute your installations. We call these C-TIPS (short for COMMUNITY-TIPS).

These tips originate from Community staff members as well as from installers and end users. We

welcome any C-TIPS that you may want to share with us, and we’ll acknowledge you as the source if

we print them in future user’s manuals.

Precautions & Safety Considerations

English - The loudspeakers described in this manual are designed and intended to be ‘flown’ or suspended

for maximum acoustical performance using a variety of rigging hardware, means, and methods. It is

essential that all installation work involving the suspension of these loudspeaker products be performed by

competent, knowledgeable persons who understand safe rigging practices. Severe injury and/or loss of life

may occur if these products are improperly installed. Please read the section on rigging for additional

information.

Français - Les haut-parleurs décrits dans ce manuel sont conçus et sont projetés pour être ‘volé’ ou

suspendu pour l'exécution acoustique maximum utilisant une assortiment d'équiper matériel, les moyens, et

les méthodes. C'est essentiel que tout travail d'installation ait impliqué la suspension de ces produits

d'haut-parleur est exécutée par les personnes compétentes et entraînées qui comprennent équiper les

pratiques sûres. La perte sévère de et/ou de blessure de vie peut arriver si ces produits sont incorrectement

installés. S'il vous plaît lire la section d'équiper pour l'information supplémentaire.

Deutsch - Die Lautsprecher, die in diesem Handbuch beschrieben werden, sind entworfen und sind zu sein

‘geflogen' vorgehabt oder sind für maximale hörbare Leistung verschiedene Manipulierenhardware, Mittel,

und Methoden suspendiert benutzend. Es ist wesentlich, dass alle Installationarbeit, die die Aufhängung

von diesen Lautsprechernprodukten verwickelt, von fähigen, ausgebildeten Personen durchgeführt werde,

die sichere Manipulierenpraxis verstehen. Schwere Verletzung bzw. Verlust des Lebens können stattfinden,

wenn diese Produkte unrichtig installiert sind. Bitte lesen Sie den Abschnitt über Manipulieren für

zusätzliche Informationen.

Community WET II - Operation and Installation Manual - Page 8

Page 9

Italiano - Gli altoparlanti descritti in questo manuale sono disegnati e sono intesi essere ‘volato' o sospeso

per la prestazione massima acustica usando una varietà di attrezzare di hardware, i mezzi, ed i metodi. È

essenziale che tutta il lavoro di installazione coinvolgendo la sospensione di questi prodotti di altoparlante è

eseguita da dalle persone competenti, addestrate che capisce le pratiche di attrezzare di cassaforte. La

lesione severe e/o la perdita di vita possono accadere se questi prodotti sono erratamente installati. Per

favore di leggere la sezione di attrezzare per le ulteriori informazioni.

Español - Los altavoces descritos en este manual se diseñan y son pensados ser ‘volado' o suspendido para

el desempeño acústico máximo que utiliza una variedad de aparejar hardware, de medios, y de los métodos.

Es esencial que todo trabajo de la instalación que implique la suspensión de estos productos del altavoz sea

realizado por personas competentes y entrenada que entienden aparejar seguro las prácticas. La herida y/o

la pérdida severas de la vida pueden ocurrir si estos productos se instalan impropiamente. Lea por favor la

sección a aparejar para la información adicional.

Introduction to Weather-Resistant Loudspeakers

Weather-resistant is a relative term that implies a loudspeaker’s ability to resist the effects of weather in

outdoor environments. Loudspeakers have been designed to be weather-resistant with varying degrees of

success. Typical weather-related damage problems encountered in such designs, in general order of

significance, concern the enclosure, drivers, hardware, and internal components such as crossovers.

WET II loudspeakers have been designed to be highly weather-resistant. WET II enclosures are fabricated

entirely of hand-laminated fiberglass, making it virtually impervious to weather-related effects. The drivers

and their diaphragms are made of highly weather-resistant materials, as in the case of the mid and high

frequency drivers, or are treated to repel moisture, as in the case of the low frequency drivers. All external

hardware on the loudspeaker is stainless steel. The three-layer Weather-Stop™ grille is acoustically

transparent but highly resistant to moisture intrusion. The crossover is located within a sealed chamber

that forms the enclosure for the low frequency drivers. A weather-tight gland nut provides a seal for the

input cable. The input cable is a type SJOW with neoprene insulation which is resistant to weather and UV

effects.

Unpacking and Inspection

WET II loudspeakers are inherently rugged and are carefully packed in well designed cartons. However, it’s

wise to thoroughly inspect each unit after it has been removed from the packaging, as damage could occur

during shipping.

Please note that once the shipment has left your dealer or the Community factory, the responsibility for

damage is always borne by the freight company. If damage has occurred during shipping, you must file a

claim directly with the freight company. It’s very important to contact the freight company as soon as

possible after receiving your shipment, as most freight companies have a short time limit within which they

will investigate claims. Make sure to save the carton and the packing material, as most claims will be denied

if these materials are not retained. Your Community dealer and the factory will try to help in any way they

can, but it is the responsibility of the party receiving the shipment to file the damage claim.

It’s always a good idea to retain the carton and packing materials indefinitely, if possible, in the event that

the unit may need to be returned to your dealer or distributor for repair in the future.

Each shipping carton contains the following items:

Loudspeaker System (Qty 1)

Operation and Installation Manual (Qty 1)

Warranty Card (Qty 1)

Mounting Yoke for W2-218, W2-228 and W2-2W8 models only (Qty 1)

Community WET II - Operation and Installation Manual - Page 9

Page 10

Important Note – Mounting/Rigging Provisions

The mounting/rigging points found on the sides and back of the enclosure must either be used for mounting

hardware or “plugged” with the bolts and washers provided. The rubber washer provides the water seal and

must be used. The reason for this is that if all these holes are not plugged up, they created leaks in the

enclosure that will compromise its weather-resistance. Open holes will also be detrimental to low

frequency performance with reduced output and/or distortion.

DANGER: All rigging fittings must be fitted with either optional mounting hardware or they must remain

sealed with the Stainless Steel hex-head bolts that come installed in the enclosure, in order to maintain

weather resistance. Additionally, if the rigging fittings are not sealed, air leaks could occur in the

enclosure that will compromise the low frequency performance with added distortion and reduced output.

WARNING: WET II rigging fittings are rated at a Working Load Limit of 150 lbs (68 kg) per point. No

single rigging fitting should ever be subjected to a load that is greater than 150 lbs. Failure to heed this

warning could result in injury or death!

WET II FEATURES AND TECHNOLOGY

In addition to extreme weather-resistance, WET II loudspeakers offer numerous features and advances in

technology that provide unprecedented sonic quality and installation flexibility. Some of these include:

Finely tuned internal crossover networks for reduced off-axis lobing, consistent coverage

throughout the crossover region, and greater acoustic linearity.

Uniform-voicing filters minimize sonic variations among the different models.

Geometrically correct large-format hand-laid fiberglass mid and high frequency horns. A wide

selection of dispersion patterns is available.

Aesthetically pleasing, uniquely shaped curved fiberglass enclosures. The enclosure

composition and the enclosure geometry work together to reduce internal reflections and

standing waves, resulting in superior sound quality. Externally, the lack of flat surfaces

minimizes water buildup.

Envirotech coating seals crossovers against moisture.

Stainless steel mounting points.

Powder-coated stainless steel yoke brackets included with the four smaller models (W2-218,

W2-228 and W2-2W8); available as an optional accessory kit for the W2-312 and W2-112.

Optional internal 70V/100V autoformer available for the W2-218, W2-228, W2-2W8 and W2-312

for constant voltage distributed systems.

All models are available in black or white finish at no additional charge. Custom colors are

available at a nominal fee.

Community WET II - Operation and Installation Manual - Page 10

Page 11

GETTING ACQUAINTED

y

y

y

Physical Features

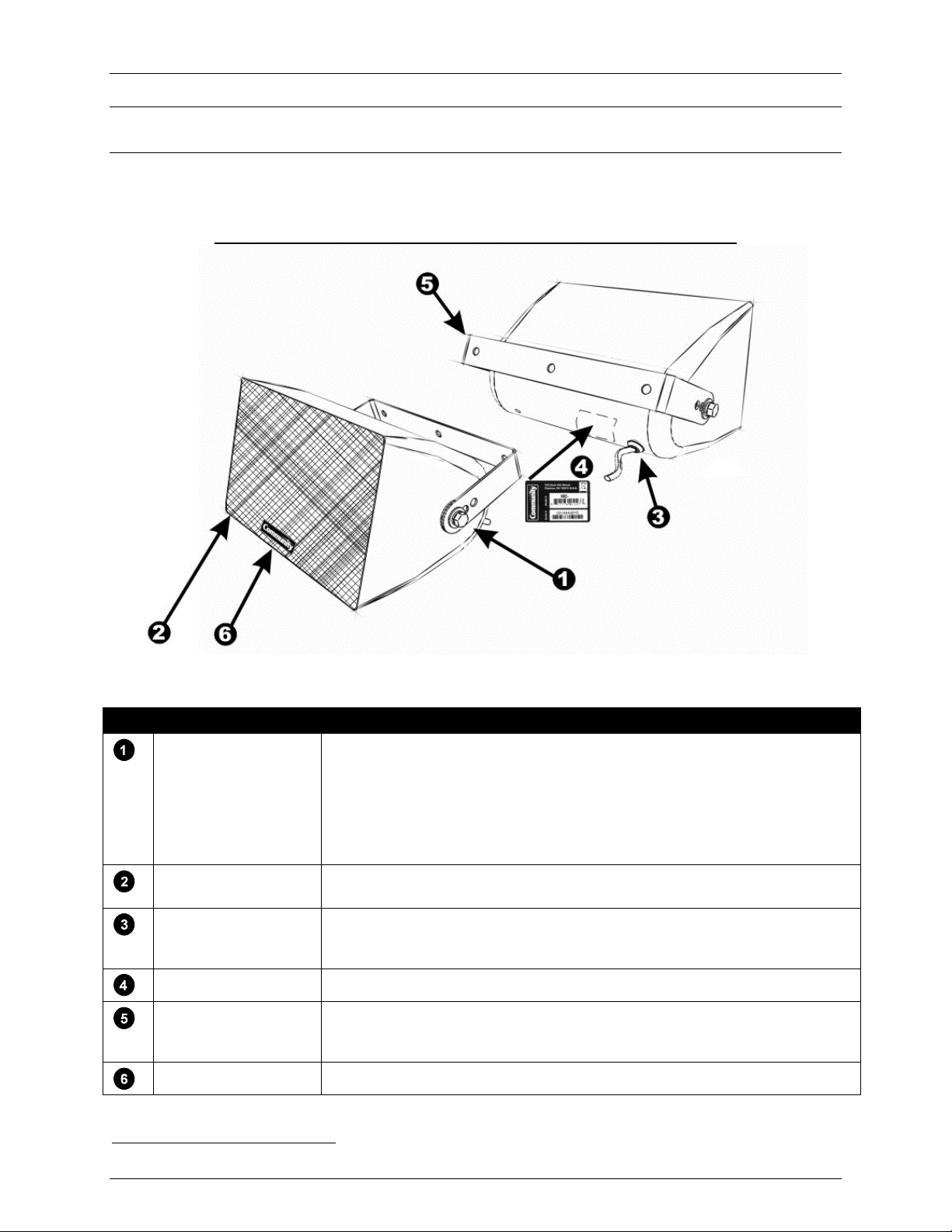

Note: These drawings show the physical features of a W2-218 and a W2-312 enclosure. Other WET II

enclosures may differ in size, shape, and number of mounting points.

Figure 1 – Physical Features of a Typical Compact WET II Enclosure

NO. FEATURE DESCRIPTION

MOUNTING/RIGGING

POINTS

GRILLE Powder-coated perforated steel backed b

INPUT CABLE For signal connections to the loudspeaker. About 12 feet of 16-2 SJOW (or 18-

WET II LABEL Model number, coverage pattern and serial number.

MOUNTING YOKE The

NAMEPLATE Communit

1

½”-13 captive zinc plated inserts with ½”-13 x 2” stainless steel bolts and

lock, flat and rubber washers. Used for attaching the yoke mounting brackets

or customer-supplied mounting system.

W2-218, W2-228 and W2-2W8 include two ½”-13 rigging points.

W2-112 and W2-312 include four ½”-13 rigging points.

W2-215, W2-322L, W2-315, W2-122 and W2-125 include six ½”-13 rigging

points.

resistant layer of fine-mesh screen. Supplied, mounted to front of enclosure.

gauge, 5-conductor, UV-resistant for 70V/100V models) retained by a

factory-sealed gland nut.

oke shown is supplied with W2-218, W2-228 and W2-2W8. An optional

mounting kit (model SSY25KIT) is sold separately for W2-312 and W2-112 that

utilizes two metal plates in addition to a yoke for added safety.

logo.

reticulated foam and a UV-

1

150 lbs (68 kg) Working Load Limit / 15:1 Safety Factor

Community WET II - Operation and Installation Manual - Page 11

Page 12

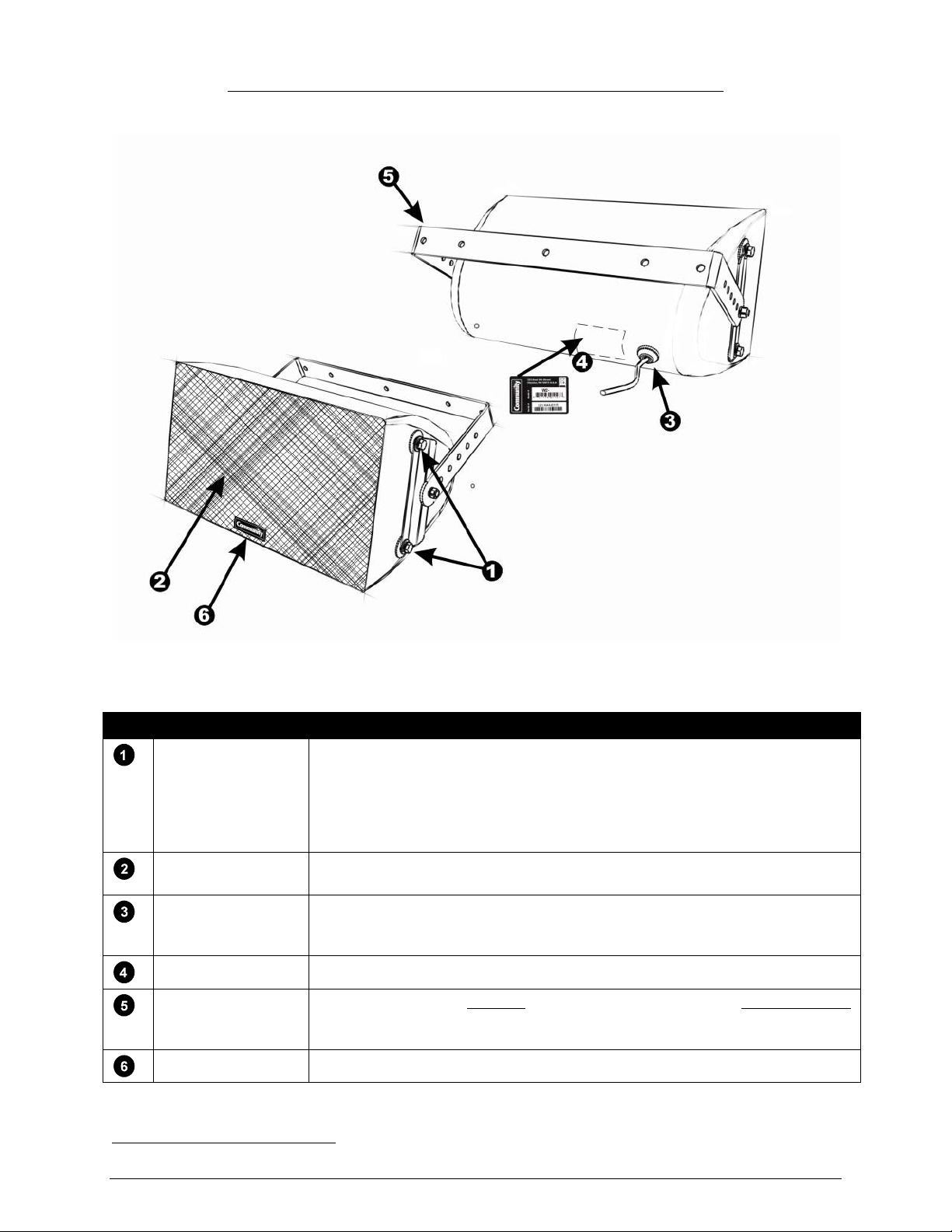

Figure 1 - Physical Features of a Typical Large WET II Enclosure

y

p

y

NO. FEATURE DESCRIPTION

MOUNTING/RIGGING

POINTS

2

½”-13 captive zinc plated inserts with ½”-13 x 2” stainless steel bolts and lock,

flat and rubber washers. Used for attaching the yoke mounting brackets or

customer-supplied mounting system.

W2-218, W2-228 and W2-2W8 include two ½”-13 rigging points.

W2-112 and W2-312 include four ½”-13 rigging points.

W2-215, W2-322L, W2-315, W2-122 and W2-125 include six ½”-13 rigging points.

GRILLE Powder-coated perforated steel backed b

INPUT CABLE For signal connections to the loudspeaker. About 12 feet of 16-2 SJOW (or 18-

layer of fine-mesh screen. Supplied, mounted to front of enclosure.

gauge, 5-conductor, UV-resistant for 70V/100V models) retained by a factorysealed gland nut.

WET II LABEL Model number, coverage pattern and serial number.

MOUNTING YOKE

The yoke shown is an o

for W2-312 and W2-112 that utilizes two metal plates in addition to a yoke

bracket for added safety.

NAMEPLATE Communit

logo.

reticulated foam and a UV-resistant

tional mounting kit (model SSY25KIT) sold separately

2

150 lbs (68 kg) Working Load Limit / 15:1 Safety Factor

Community WET II - Operation and Installation Manual - Page 12

Page 13

GENERAL DESCRIPTION

WET II loudspeakers are designed for top-of-the-line installation work. Their premium components are

housed in rugged, uniquely shaped curved enclosures that are acoustically inert. WET II systems are

characterized by high power and low distortion, with exceptional musicality and speech intelligibility.

The WET II line comprises six form-factors, three of which may be ordered with a choice of horn patterns.

The four smaller models may be ordered with an internal 70V/100V autoformer for constant voltage

applications, and all models are available in either a black or white finish. Custom colors are also available;

prices will be quoted upon request. Three models of WET II subwoofers round out the line, providing

extended bass response for foreground music applications.

HIGH-PASS FILTERS

We strongly recommend the use of an external, active high-pass filter to protect the cone drivers from

excessive low frequency excursion. Additionally, a high-pass filter will avoid wasting amplifier by

attempting to reproduce frequencies below the loudspeaker’s intended operating range. The recommended

filter settings are as follows:

Model High-Pass Filter

W2-218 70 Hz, 24db/octave

W2-228 60 Hz, 24db/octave

W2-2W8 60 Hz, 24db/octave

W2-215 50 Hz, 24db/octave

W2-312 55 Hz, 24db/octave

W2-322L 40 Hz, 24db/octave

W2-315 60 Hz, 24db/octave

W2-112 50 Hz, 24db/octave

W2-122 45 Hz, 24db/octave

W2-125 30 Hz, 24db/octave

Many modern DSP loudspeaker controllers or loudspeaker management devices can provide the required

high-pass filter mentioned above, as well as general equalization to correct for room response problems,

digital delay to correct for timing differences among multiple loudspeakers, as well as other DSP ‘tools’ that

can help solve acoustic anomalies. Such devices can also be used as protective peak limiters to protect the

system from damage, as further described below.

Community WET II - Operation and Installation Manual - Page 13

Page 14

CONNECTING THE AMPLIFIER TO THE LOUDSPEAKER

All WET II loudspeakers come with an attached input cable that is coated with an EPDM rubber jacket, twelve

feet in length and colored to match the finish of the enclosure. The cable enters the enclosure through a

waterproof gland nut. The other end of the cable is un-terminated.

A typical installation method is to bring the cable into a waterproof Junction Box equipped with a waterproof

gland nut. Connections within the J-Box may be made with barrel-type crimp connectors, wire nuts, solder

and heat-shrink, or terminal strips. We recommend using barrel-type crimp connectors that are crimped

with a forged crimp tool (such as Klein 1005) or a ratcheting tool (such as Klein T1720), as this method, when

properly executed, results in a gas-tight connection that is quick and easy to accomplish.

DANGER: When wiring the amplifier(s) to the loudspeaker(s), always power-down the amplifier(s) and

disconnect its AC Mains plug(s). Many modern, high-power amplifiers can deliver enough voltage and

current to cause a harmful or lethal electric shock. Shocks from very low frequencies, such as kick drums,

can cause the human heart to stop beating at relatively low voltage levels.

WARNING: After wiring the amplifier(s) to the loudspeaker(s), first power-up all devices that are upstream

of the amplifier, such as mixers, equalizers, compressor/limiters, etc., before powering-up the amplifier.

This is to avoid passing any clicks or pops that may originate in the upstream devices to the loudspeakers.

The amplifier should initially be powered-up with its gain controls turned all the way down. After making

sure that a continuous signal is present, such as a CD playing, slowly raise the level of the gain controls to

establish that the wiring has been installed correctly. Only then should the loudspeaker be operated at

normal output levels.

Impedance and Combining Loudspeakers

Loudspeakers of identical type may be wired together on the same amplifier. This forms a parallel circuit.

When two loudspeakers are wired in parallel, the nominal impedance of the circuit will divide in half. For

example, if two 8 ohm loudspeakers are wired in parallel, the result will be a 4 ohm load and the power from

the amplifier will be divided equally between both. If four 8 ohm (or two 4 ohm) loudspeakers are wired in

parallel, the result will be a 2 ohm load and again, the power will be divided equally among the

loudspeakers.

If an uneven number of loudspeakers are wired in parallel, you can use the following formula to calculate

the resultant impedance, where Z is the impedance in ohms: 1/Z + 1/Z +1/Z = 1/Zt = Z.

Here is an example: 1/8 + 1/8 + 1/8 = 1/.375 = 2.666 ohms.

Unequal Impedances

It’s important to note that when wiring loudspeakers of unequal impedances in a parallel circuit, the power

will not be divided equally among each loudspeaker.

For example, if an 8 ohm and a 4 ohm loudspeaker are wired in parallel the resultant load will be 2.6 ohms.

The 4 ohm loudspeaker will draw twice as much power from the amplifier than the 8 ohm loudspeaker. In

this example, if the amplifier is capable of producing 1800 watts into the 2.6 ohm load of the paralleled

loudspeakers, the 4 ohm loudspeaker will receive 1183 watts while the 8 ohm loudspeaker receives 591

watts.

Community WET II - Operation and Installation Manual - Page 14

Page 15

Know Your Amplifier

Not all amplifiers can safely drive loads below 4 ohms. Very low impedance loads may cause the amplifier

to overheat which may lead to device failure. Even if the amplifier is quite stable driving a low impedance

load, the cable loss will be greater, the damping factor is reduced, and if the amplifier were to fail, a larger

portion of the sound system would be taken off-line.

C-TIP: Keeping the loads at 4 ohms or higher will lengthen the life of your amplifier(s), while improving

the reliability and overall sound quality of your sound system.

Below is a table that gives a quick look at the effect of wire size on line loss. These numbers assume that

the amplifier is producing a constant 48 Volts at its output terminals, which is equivalent to 288 watts into

8Ω or 576 watts into 4Ω:

Size Length Load Z Loss in dB

#10 AWG

#10 AWG

#10 AWG

#10 AWG

#12 AWG

#12 AWG

#12 AWG

#12 AWG 200’ 4 Ω -2.39 dB

#14 AWG 100’ 8 Ω -1.03 dB

#14 AWG

#14 AWG

#14 AWG

100’ 8 Ω -0.42 dB

200’ 8 Ω -0.83 dB

100’ 4 Ω -0.83 dB

200’ 4 Ω -1.58 dB

100’ 8 Ω -0.66 dB

200’ 8 Ω -1.28 dB

100’ 4 Ω -1.28 dB

200’ 8 Ω -1.95 dB

100’ 4 Ω -1.95 dB

200’ 4 Ω -3.55 dB

Community WET II - Operation and Installation Manual - Page 15

Page 16

70V AND 100V OPERATION

Using Power Taps

A WET II loudspeaker equipped with an optional autoformer has four selectable power taps. These are set at

12.5W, 25W, 50W and 100W on the W2-218, and at 25W, 50W, 100W and 200W on the W2-228, the W2-2W8,

and the W2-312 for 70V systems (note: for 100V systems the taps equal twice the numeric value stated

above; i.e. a 25W tap becomes a 50W tap, and so on). Note that the autoformer has a maximum output

capability of 200W regardless of the primary voltage.

By choosing one of the four taps, you can govern how much amplifier power is available for each

loudspeaker. For example, if the 50W tap is selected, that particular loudspeaker will draw 50 watts of

power when a 70V amplifier is run at its maximum level. A second loudspeaker might be connected to the

same amplifier, but tapped at 100W (100 watts). In such case, the second loudspeaker will draw 100 watts

from the same amplifier, making it 3dB louder than the first loudspeaker. A third loudspeaker might be

tapped at 200 watts, which would make it 3dB louder than the second loudspeaker, and 6dB louder than the

first.

By using the various taps, one can balance the relative sound levels in a system. A loudspeaker that is closer

to audience members will need to be tapped at a lower wattage than one that is farther away, in order to

produce similar output levels (of course the amplifier must be capable of delivering output power that is at

least equal to the sum of the taps).

As a guideline, every time you double the distance from a sound source, the level typically will drop by 6 dB,

which is equivalent to one-fourth of the power. Although this is an acoustical law, and is true in a free space

environment such as outdoors, the effect of room acoustics can radically change the actual results. Even

outdoors, it is normally not possible to validate this acoustical law using a sound level meter, due to the

ground plane effect.

Community WET II - Operation and Installation Manual - Page 16

Page 17

Wiring Diagrams for 70V/100V Operation

Figure 2 - Wiring Diagrams for W2-218T

Figure 3 - Wiring Diagrams for W2-228T, W2-2W8T and W2-312-HT

Community WET II - Operation and Installation Manual - Page 17

Page 18

70.7V and 100V Systems

Several voltage standards have been put in place regarding so called ‘constant voltage systems.’ In the

United States, 25V, 70.7V and 100V are common. Occasionally 140V systems can be found, usually in very

large venues such as racetracks, where the need to overcome cable resistance by scaling the voltage

upwards becomes extremely important, due to the very long cable lengths from the amplifiers to the

loudspeakers. In Europe and Asia, most constant voltage systems use the 100V standard.

A WET II loudspeaker equipped with an optional autoformer supports both the 70.7V and 100V standards.

The same physical conductors are used for both voltage standards, but the power level of each tap is

different, depending on whether the voltage is 70.7V or 100V.

A 100V system will produce twice the power at a given tap, as that of a system that is operated at 70.7 volts.

This can be verified by the simple Ohm’s Law calculation E

load impedance, and W is the power expressed in Watts. Assuming a load impedance of 50 ohms, we can

see that 70.7 x 70.7 / 50 = 99.97 and that 100 x 100 / 50 = 200. Therefore, when scaling up from 70.7V to

100V the power will double; when scaling down, the power will halve.

CAUTION: Be sure to carefully observe polarity when wiring your loudspeakers. If one loudspeaker is

wired with the opposite polarity from another loudspeaker, acoustic cancellation will occur. The result

will be less power output than if only one loudspeaker were used by itself.

2

/Z = W, where E is the voltage applied, Z is the

Community WET II - Operation and Installation Manual - Page 18

Page 19

SELECTING AMPLIFIERS

Amplifiers are a vital part of the sound system’s performance and should be carefully selected for

appropriate power output. A table is provided below to help you size your amplifier’s power output

capability to the various models in the WET II product line.

Typically, it’s good practice to select an amplifier that can provide substantially more power than the

continuous rating of the loudspeaker. This is so that enough reserve power will be available for transient

peaks. More loudspeakers are damaged by under-powering them than by over-powering.

If you know in advance that a particular loudspeaker, or zone of loudspeakers will never be used at, or near

their maximum rated power, then it’s acceptable to select a power amplifier that is equal to, or slightly

larger than the loudspeaker’s power handling specification. We do not recommend operating WET II

loudspeakers with an amplifier that does not at least meet the rated power handling of each model.

Model Rated Power Handling Recommended Amplifier Power

W2-218 125W RMS / 300W Program 250 - 375 WRMS at 8 Ω

W2-228 250W RMS / 600W Program 500 - 750 WRMS at 4 Ω

W2-2W8 250W RMS / 600W Program 500 - 750 WRMS at 8 Ω

W2-215 200W RMS / 500W Program 400 - 600 WRMS at 8 Ω

W2-312 200W RMS / 500W Program 400 - 600 WRMS at 4 Ω

LF: 400W RMS / 1000W Program

W2-322L

W2-315 200W RMS / 500W Program 400 – 600 WRMS at 4 Ω

W2-112 200W RMS / 500W Program 400 – 600 WRMS at 8 Ω

W2-122 400W RMS / 1000W Program 800 – 1200 WRMS at 4 Ω

W2-125 400W RMS / 1000W Program 800 – 1200 WRMS at 4 Ω

Note: “WRMS” = “Watts RMS” = “Watts Root Mean Squared”

MF/HF: 160W RMS / 400 W

Program

Bi-amped

LF: 800 - 1200 WRMS at 4 Ω

MF/HF: 320 to 640 WRMS at 8 Ω

Amplifiers for 70V/100V Operation

In past times, nearly all 70V/100V amplifiers were of modest power level and employed step-up

transformers to increase their output voltage to a fixed value of 70V (or 100V) at their maximum operating

level. The purpose of stepping up the output voltage is largely to decrease the wire size needed for a given

system, particularly when long wire runs are unavoidable. A basic rule of Ohm’s Law is that the higher the

voltage and the higher the load impedance, the less effect the cable resistance has on the absorption of

power within the cable. A 70V/100V system achieves both of these desirable design goals.

A second important reason for constant voltage systems is that the use of a step-down transformer at each

loudspeaker (or in the case of WET II products… a step-down autoformer) permits the installer to choose

among several power taps at each individual loudspeaker location. This lets the installer adjust each

loudspeaker’s level in relation to the other loudspeakers, even though multiple loudspeakers are driven by

the same amplifier on the same circuit. Without a transformer (or an autoformer), level adjustment could

only be accomplished by adding resistance to one or more loudspeakers. Resistors would in fact reduce the

operating level, but would also consume valuable power from the amplifier, as well as produce unnecessary

heat as a byproduct.

Community WET II - Operation and Installation Manual - Page 19

Page 20

AUTOFORMERS

Autoformers, or autotransformers as they’re often called, perform similarly to transformers but with certain

distinct advantages. First, they exhibit inherently lower distortion and lower insertion loss than an

equivalent rated transformer. Second, they are less prone to magnetic core saturation than a transformer,

providing better linearity under peak operating conditions. Lastly, they can be manufactured to a greater

level of precision than that of a transformer at a similar or lower cost. For these reasons, WET II

loudspeakers have been designed to use autoformers rather than transformers, when equipped for

70.7V/100V constant voltage applications.

WET II APPLICATIONS

WET II loudspeakers can be used in many different ways to fulfill numerous application requirements. The

most obvious are related to outdoor environments and/or harsh climatic conditions. Some of these include:

Cruise Ships

Stadia

Outdoor Clubs & Resorts

Themed Entertainment Attractions

Water Parks

Swimming Pools

Skating Rinks

Public Parks

Outdoor Home Entertainment

Perhaps less obvious are the many applications that WET II products can fulfill in normal ‘indoor’

environmental conditions. Some typical applications are listed below:

Sound Reinforcement in Houses of Worship

Theatrical Sound

Concert Halls & Performing Arts Centers

Night Club and DJ Sound Systems

Bars and Restaurants

Gymnasium and Field House Sound

Arena Sound

Auditoria and Corporate Training Facilities

Health Clubs

Retail Environments

Aquatic Centers

WET II loudspeakers produce the same superb sound quality both indoors and out! Their attractive and

uniquely shaped enclosures often lend an interesting visual aspect to architectural design themes.

Community WET II - Operation and Installation Manual - Page 20

Page 21

INSTALLATION CONSIDERATIONS

Installing WET II loudspeakers is simple and straightforward. In most cases they will simply be affixed to a

wall or ceiling surface by means of the stainless steel yoke-style mounting bracket that accompanies the

four smaller models, and is available as an optional accessory to the larger models. Always pay close

attention to the type of fasteners used, the nature of the mounting surface(s), and the suitability of the

mounting method.

CAUTION! If there is any doubt as to the structural integrity of the mounting surface(s) and/or the nature

and use of the fasteners or other mounting materials, means, or method(s), consult a licensed

professional engineer who can provide accurate information that will assure a safe and reliable

installation. The potential for injury and/or death resulting from improper installation practices and/or

inadequate materials is very high. Please read the section on Safe Rigging Practices for additional

information, found elsewhere in this manual.

C-TIP: When installing WET II loudspeakers, particularly the larger models, it is helpful to wear a pair of

heavy-duty industrial grade rubber gloves. The glass surface material and the unique curved shape of the

enclosures can otherwise be difficult to handle.

Installing with Yokes

When attaching a yoke bracket to a WET II loudspeaker, always make sure to use the rubber washers

(supplied). They are intended to be placed between the yoke and the loudspeaker enclosure. They provide a

seal to inhibit the penetration of water into the enclosure, as well as increase the friction between the

enclosure and the yoke assembly. The bolts should be fitted with a lock washer and a flat washer

(supplied), and tightened to a torque of approximately 8 to 12 foot lbs. Be cautious, as overtightening can

cause deformation or damage to the fiberglass enclosure. Use a torque wrench!

IMPORTANT! Make sure that all rigging and mounting fittings have bolts, lock washers, flat washers and

rubber washers installed before completing the installation. No rigging or mounting fitting should be left

open to the elements.

Community WET II - Operation and Installation Manual - Page 21

Page 22

RIGGING AND MOUNTING WET II ENCLOSURES

One of the most important tasks the installer faces is the rigging and mounting of the loudspeaker system.

WET II loudspeakers have been designed with rigging and mounting in mind; thus, there are numerous ways

to safely and easily install these loudspeakers in optimal locations in a venue.

Safety First!

There is no way to overemphasize the importance of safety. But we’ll try. The kinetic energy of an 80 lb.

loudspeaker enclosure dropping from 30 feet and contacting a concrete floor is enormous. The loudspeaker

will be traveling at a speed of about 35 MPH at the time of impact. Imagine if you were seated under it. You

might have a better chance of surviving a dynamite blast.

If you do not have knowledge of safe rigging practices and experience in applying them, contact a qualified

rigging contractor to design and carry out the installation! Rigging that is improperly installed is like a time

bomb; sooner or later it will fail, with the potential to cause serious injury, paralysis, dismemberment, or

loss of life. Even if no one is directly in the line-of-fall of a failed suspension system, the panic that might

ensue could in itself cause multiple deaths. Do not take chances!

Rigging Guidelines

The following guidelines on rigging are not intended as a comprehensive rigging manual, nor are they meant

to replace the knowledge of safe rigging practices that might be obtained from receiving professional

training on the subject. These guidelines are intended only to provide basic safety information, and to call

your attention to some commonly made mistakes. Books, seminars, and hands-on courses are available

that teach safe rigging techniques; we highly recommend that you seek them out if you do not already

possess the requisite knowledge and experience to perform rigging work safely.

DISCLAIMER: Community warrants that its loudspeaker systems and its optional mounting and rigging

hardware have been carefully designed and tested. Community loudspeakers may be safely mounted and

rigged when each loudspeaker model is installed with Community-manufactured optional mounting and

rigging brackets specifically designed for use with that particular model of loudspeaker. This warranty

applies only for use under normal environmental conditions,3 and when all loudspeakers, component parts,

brackets and hardware are assembled and installed in strict accordance with Community’s installation

guidelines contained herein. Beyond this, Community assumes no further or extended responsibility or

liability, in any way or by any means whatsoever. It is the responsibility of the installer to insure that safe

installation practices are followed, and that such practices are in accordance with any and all local, state,

federal, or other, codes, conditions, and regulations that may apply to, or govern the practice of, rigging,

mounting, and construction work in the relevant geographic territory. Any modifications made to any parts

or materials manufactured or supplied by Community shall immediately void all pledges of warranty or

surety, related in any way to the safe use of those parts and materials.

1. Load Rated Components

All components of the rigging system such as wire rope, shackles, chain, eyebolts, etc., must be load rated.

This means that they are marked or rated with a Safe Working Load (SWL) or Working Load Limit (WLL). All

such items should be designed and manufactured by reputable companies that regularly supply the

theatrical and industrial rigging industries, such as The Crosby Group, or equivalent. It is strongly

recommended that you source your rigging items from an industrial supplier or specialty rigging house,

never from a hardware store. Items found in local hardware stores are often poor copies of the original

designs and may not be safe, as well as typically being more costly than items purchased from an industrial

supplier. By planning ahead, you will not be in the uncomfortable position of having to delay the work if you

can’t locate a shackle or eyebolt at the last minute.

3

Normal Environmental Conditions are defined as the following: -15 to 55º C, no excessive or unusual air-born contaminants or

pollutants present, no chemicals or contaminants coming in direct contact with the product, no excessive vibration or wind loads.

Community WET II - Operation and Installation Manual - Page 22

Page 23

2. Safety Factor

No component in a rigging system should be stressed to its maximum load rating. A suitable Safety Factor

or Design Factor must be determined and applied, so that every component in the rigging system has

reserve load capacity. The manufacturer’s stated SWL or WLL is the quotient of the component’s ultimate

strength, or breaking point, divided by the manufacturer’s stated safety factor. If the safety factor is not

stated on the component or in the manufacturer’s technical specification sheet, the component should not

be used, as its ultimate strength is unknown.

In addition to the manufacturer’s rated Safety Factor, the prudent installer will determine and apply an

additional Safety Factor to insure that the suspension system is installed in a manner that cannot fail under

the prevailing conditions.

Safety factors may be regulated by local, state, federal or international agencies and therefore may vary

based on your geographic location. Safety factors typically assume normal environmental conditions;

additional consideration must be given when unusual conditions are encountered, such as in corrosive

marine environments (e.g. loudspeakers mounted on a cruise ship or in a venue located near sea water), or

in conditions involving high-vibration, high wind-loads, or other unusual conditions. A common safety factor

is a 6:1 ratio; however many theatrical rigging companies voluntarily work at a 7:1 ratio or higher. A 10:1 ratio

is required in most countries that are members of the European Union. At 10:1, this means that a component

rated at 10,000 lbs of ultimate strength should never be subjected to a load greater than 1,000 lbs. The derated value of 1,000 lbs should take into account the additional force of dynamic loading, such as when a

motorized hoist starts and stops. Such dynamic loading can easily exceed 200% of the static load and is

dependent on the hoist design, how close to capacity it is loaded, the length of the cable or chain, and the

elasticity of the supporting structure.

Seismic Considerations

Seismic events (earthquakes) can cause great dynamic loading of a rigging system. In the case of strong

quakes, which occur regularly in some regions, a rigged system may merely sway back and forth with no

damage, or it may be subjected to many times its static load rating, particularly in the case of unequal

loading of a multi-part suspension system due to uneven roof or beam movement. It’s also possible that

one loudspeaker rig may contact another rig or a lighting truss, during the quake. The results cannot be

predicted because seismic events occur with differing forms of wave motion at varying axes to the

suspended system. An earthquake might produce long, rolling waves in one axis then later, an aftershock on

the same day could produce short, violent waves in another axis.

Aging of Components

Over time, rigging components will degrade causing them to lose some, or even much, of their load capacity.

Factors include strain, oxidation, exposure to corrosive or acidic atmospheric conditions, exposure to water

and chemicals, exposure to UV light, and metal fatigue. In consideration of long-term durability, a high

safety factor should always be chosen, particularly when future conditions cannot be clearly foreseen

(which is almost always the case).

3. Safety Cable

Safety cables must be sized appropriately for the loads they will carry, and should be attached to a different

point or points on the wall, ceiling, truss, frame, bumper, or other, than that of the primary suspension

system, as well as to a different point or points on the objects that are suspended.

Community WET II - Operation and Installation Manual - Page 23

Page 24

4. Threaded Fasteners

Threaded fasteners are often used in rigging and mounting systems. As with eyebolts, many of Community’s

optional mounting brackets, yokes, and rigging plates utilize threaded fasteners. The fasteners that come

with each Community rigging kit are load rated to a sufficient strength to be safe when used within their

specified parameters. If replacement bolts are needed, or if additional bolts are required for mounting a

bracket to a beam, wall, or ceiling etc., such bolts should be purchased from a reputable manufacturer with a

minimum Grade 5 rating. On hex-head bolts this can be readily identified by looking at the head. A Grade 5

bolt will be marked with three lines; a Grade 8 bolt, which is even stronger, with six lines. Allen drive

fasteners are often made of high-strength steel (Grade 5 or better) if they are purchased from an industrial

suppler. As with any other rigging component, check the rating on the box or the manufacturer’s

specification sheet to be sure.

5. Support Points & General Practices

A vital part of planning the mounting or suspension system is to first determine the strength of the

building’s support points. Nothing should be assumed, even for the lightest loads. A ten pound loudspeaker

falling from ten feet can maim or kill just as readily as a heavy loudspeaker array falling from thirty feet.

The services of a registered structural or professional engineer should be employed to determine if the

materials and design of the supporting structure are adequate to support the intended load, and how to best

install mounting brackets or derive suspension points.

Fasteners

As a general rule, lag bolts driven into wooden beams should be avoided whenever possible, as they can pull

out as the wood ages or swells due to changes in temperature and humidity. Safe riggers will instead utilize

machine bolts of Grade 5 ratings or higher, rated beam clamps, brackets fabricated and welded by certified

welders, wire rope wrapped around beams with cushioning materials, and so on.

Certain wooden beams, or trusses, made of many laminations (often called Glue Lams) are intolerant of

holes. These beams are commonly used in modern construction, particularly in tilt-up concrete industrial

buildings. Drilling a hole through such beams can set up internal fractures, resulting in total failure of the

beam. Alternatives to drilling include fabricating steel brackets to surround the beam, or wrapping the beam

with a steel sling and fabric cushions, to derive a hang point.

Concrete expansion bolts, such as Hilti Kwik-bolts or equivalent, can provide an excellent means of

attaching moderate loads to concrete surfaces. However, as they rely on an expanding wedge to obtain

their strength, they must always be used in strict accordance with the manufacturer’s instructions. Such

instructions specify the diameter and depth of the hole, the composition of the concrete, permissible

spacing of the anchors, and the torque of the bolts. As a general rule, they should only be used for sheer

loads, not tension loads.

6. Liability

When you install a loudspeaker that is mounted or suspended over people’s heads, it is your responsibility

and yours alone to insure that the installation is performed in a safe manner. Never take the word of

someone who tells you, “That beam is safe to drill into,” or “This point can handle the load,” or “I’ll take

responsibility if anything happens.” To paraphrase Harry Donovan from his excellent book on safe rigging

practices entitled

when you use such statements by others as your defense?’

Never do anything you aren’t 100% sure is safe. If a manufactured product looks poorly designed and built, it

probably is poorly designed and built. If you aren’t absolutely sure where the wire rope came from or how

strong it is, don’t touch it. If the bolt looks too flimsy to hold the load, it probably is too flimsy. Always use

your best judgment, just as you do when driving at high speeds in traffic. The life you save may be your own,

or that of your friend or colleague.

Entertainment Rigging, ‘How is it going to sound to the jury at your manslaughter trial

Community WET II - Operation and Installation Manual - Page 24

Page 25

WET II MOUNTING YOKES AND MOUNTING KITS

W2-218, W2-228 and W2-2W8 Yoke Assembly

The compact W2-218, W2-228 and W2-2W8 loudspeakers include a yoke mounting bracket, constructed of

304 stainless steel finished in black or white with Community’s proprietary dual-layer powder coating

process. The yoke bracket is fitted with a series of mounting holes that allow the installer to vary the

distance from the enclosure to the mounting surface in order to suit the requirements of the installation. It

is engineered to provide a high margin of safety when supporting the appropriate loudspeaker.

All hardware required to attach the mounting yoke to the loudspeaker enclosure is included. No additional

hardware is provided to attach the yoke bracket to the mounting surface. Such hardware must be supplied

by the installer and should be sized and rated for the weight load of the enclosure, keeping in mind that

additional torque load may occur when focusing the loudspeaker within the yoke assembly. The installer is

solely responsible for determining if the mounting surface is capable of safely supporting the weight load of

the loudspeaker and bracket, and for selecting appropriate hardware to install it.

DANGER: All rigging fittings must be fitted with either optional mounting hardware or they must remain

sealed with the fasteners that come installed in the enclosure. These fasteners attach to internal steel

rigging brackets, thereby providing structural integrity. Without these fasteners, the structural integrity of

the enclosure would rely solely on the enclosure material and bonded joints, which over time could

deteriorate. Therefore, all rigging fittings must have fasteners in place so that the enclosure may be

safely ‘flown’ or suspended overhead.

Additionally, if the rigging fittings are not sealed, air leaks will occur in the enclosure that will

compromise the low frequency performance with distortion and reduced output.

WARNING: WET II loudspeaker rigging fittings are rated at a Working Load Limit of 150 lbs (68 kg) with

a 15:1 safety margin. No single rigging fitting should ever be subjected to a load that is greater than 150

lbs. Failure to heed this warning could result in injury or death!

Figure 4 - W2-218 Yoke Dimensions

Community WET II - Operation and Installation Manual - Page 25

Page 26

Figure 5 - W2-218 Yoke Assembly

Figure 6 - W2-228 and W2-2W8 Yoke Dimensions

Community WET II - Operation and Installation Manual - Page 26

Page 27

Figure 7 - W2-228 and W2-2W8 Yoke Assembly

Community WET II - Operation and Installation Manual - Page 27

Page 28

SSY25KIT Mounting Kit for W2-112 and W2-312

An optional mounting bracket kit (model SSY25KIT) is available for the W2-112 and W2-312 loudspeakers. It

is sold separately. The SSY25KIT is designed to mount a W2-112 or W2-312 loudspeaker in either a vertical or

horizontal orientation, providing precise acoustic focusing. The SSY25KIT consists of a yoke mounting

bracket and two adapter plates, constructed of powder-coated stainless steel.

The yoke bracket is fitted with a series of mounting holes that allow the installer to vary the distance from

the enclosure to the mounting surface in order to suit the requirements of the installation. It is engineered

to provide a high margin of safety when supporting a W2-112 or W2-312 loudspeaker.

All hardware required to attach the SSY25KIT to the loudspeaker enclosure is included in the kit. No

additional hardware is provided to attach the yoke bracket to the mounting surface. Such hardware must be

supplied by the installer and should be sized and rated for the weight load of the enclosure, keeping in mind

that additional torque load may occur when focusing the loudspeaker within the yoke assembly. The

installer is solely responsible for determining if the mounting surface is capable of safely supporting the

weight load of the loudspeaker and bracket, and for selecting appropriate hardware to install it.

DANGER: All rigging fittings must be fitted with either optional mounting hardware or they must remain

sealed with the fasteners that come installed in the enclosure. These fasteners attach to internal steel

rigging brackets, thereby providing structural integrity. Without these fasteners, the structural integrity of

the enclosure would rely solely on the enclosure material and bonded joints, which over time could

deteriorate. Therefore, all rigging fittings must have fasteners in place so that the enclosure may be

safely ‘flown’ or suspended overhead.

Additionally, if the rigging fittings are not sealed, air leaks will occur in the enclosure that will

compromise the low frequency performance with distortion and reduced output.

WARNING: WET II loudspeaker rigging fittings are rated at a Working Load Limit of 150 lbs (68 kg) with

a 15:1 safety margin. No single rigging fitting should ever be subjected to a load that is greater than 150

lbs. Failure to heed this warning could result in injury or death!

Figure 8 - SSY25KIT Dimensions

SSY25KIT Yoke Bracket

Community WET II - Operation and Installation Manual - Page 28

Page 29

SSY25KIT Adapter Plate

Figure 9 - SSY25KIT Assembly

Community WET II - Operation and Installation Manual - Page 29

Page 30

SSY25KIT Assembly Instructions

1. First, remove the two ½” hex head bolts located towards the front of the enclosure on both of the two end

panels (four total).

2. Next, attach one adapter plate to each end panel of the enclosure using the two ½-13 hex head bolts

fitted with lock washers and flat washers. Make sure to install a large rubber washer between the adapter

plate and the enclosure. Tighten these bolts to 15 foot-lbs using a torque wrench. Do not over tighten!

3. Now, attach the yoke to the mounting surface. No hardware is provided for this purpose. Such hardware

must be supplied by the installer, and should be rated for the weight load of the enclosure. The installer is

solely responsible for determining if the hardware used to mount the yoke is adequately sized and rated,

and if the structure it is attached to is capable of safely supporting the weight load of the enclosure and

bracket.

4. After attaching the yoke to the mounting surface, next attach the yoke to the two adapter plates on the

loudspeaker enclosure using the two ½”-13 x 1.25” hex head bolts provided. Fit each hex head bolt with a flat

washer and lock washer. Tighten the fasteners until snug. After focusing the loudspeaker in the desired

position, the bolts should be tightened to a torque of 12 to 15 foot-lbs, using a torque wrench. Do not over

tighten!

Note that a series of holes are provided in the yoke bracket, allowing the enclosure to be positioned at

varying distances from the mounting surface. The closer the yoke is to the rear of the enclosure, the neater

the installation will look; the farther away the rear of the enclosure is from the yoke, the greater the

available range of motion will be.

CAUTION: Installation of loudspeakers should only be performed by trained and qualified personnel. It is

strongly recommended that a licensed and certified professional structural engineer approve the

mounting design.

Community WET II - Operation and Installation Manual - Page 30

Page 31

MAINTAINING WEATHER RESISTANCE

There are several things that must be observed when installing a WET II loudspeaker in order to maintain its

weather-resistant integrity for outdoor use.

1. Always orient the loudspeaker so the mouth of the horn is, at a minimum, pointing at least 15

degrees downward. Failure to do this could result in water collecting inside the enclosure under

extreme weather conditions.

2. When handling a WET II, be careful not to scratch or scrape the finish on the grille or enclosure.

3. All mounting holes must be sealed off with the stainless steel bolts, washers, and rubber washers

supplied. If, for any reason, these bolts must be removed, seal off the hole with silicone caulking or

some other suitable weather-tight sealant.

4. The rubber washers supplied with the mounting bolts must always seat against the enclosure.

5. The gland-nut securing the loudspeaker cable to the enclosure is sealed at the factory. Do not

attempt to remove this nut or the weather-tight seal will be broken. If it is desired to replace the

gland-nut with a jack, the jack must be a weatherproof design. It must be suitably sealed to the

enclosure with silicone caulk or some other suitable weather-tight sealant.

6. The grille assembly is designed to prevent normal and wind-driven rain from directly entering the

mouth of the loudspeaker. The grille is not designed to withstand such things as being directly

sprayed from a hose; therefore this should be avoided.

7. If you use any hardware in place of the stainless steel screws, bolts, nuts and washers supplied, it

should also be made of stainless steel.

CAUTION: If the above instructions are not observed, the weather-resistant integrity of a WET II enclosure

can be compromised. This can result in damage to or failure of the hardware or internal components.

SERVICING WET II LOUDSPEAKERS

Servicing a WET II loudspeaker is straightforward and easy. All drivers and crossover assemblies are

serviceable by removing the screws that attach the protective grille to the front of the enclosure. There are

no other user-serviceable parts.

Replacement Parts

Replacement parts may be ordered through your local authorized dealer or directly from Community. Outside

the United States, please contact your authorized Community distributor.

Community WET II - Operation and Installation Manual - Page 31

Page 32

TROUBLESHOOTING GUIDE

Should you have a problem with your WET II loudspeaker(s), find the symptom and follow the associated

“What To Do” instructions below. Be aware that a particular symptom may have several possible causes.

SYMPTOM PROBABLE CAUSE WHAT TO DO

High distortion, low

output, or no output

from any or all

drivers.

Distortion from the

loudspeaker at higher

volume levels.

Distortion from the

loudspeaker at

moderate to high

Faulty connection to the

loudspeaker.

Possible solder joint

failure on crossover

card.

Too little amplifier

power.

Using an ohmmeter, check the continuity of the wiring to the

loudspeaker. If the wiring is OK, remove the input panel and

check all solder joints on the crossover and the wiring to the

drivers. Visually inspect solder joints as cold joints may only

malfunction under high current. Repair as needed.

If the power rating of the amplifier is too low, it will clip at

higher volume levels. Reduce the volume level or use a more

powerful amplifier.

Driver is malfunctioning. Using a sine wave oscillator or wide range program at

moderate levels, listen to each driver to isolate the problem.

Replace as needed.

volume levels.

Low or no output

from the low

frequency driver.

Low or no output

from the mid and

high frequency

Low frequency driver,

crossover, or amplifier is

malfunctioning.

Mid frequency driver,

crossover, or amplifier is

malfunctioning.

Test and replace as needed.

Test and replace as needed.

drivers.

Low or no output

from the highfrequency driver.

High frequency driver,

crossover, or amplifier is

malfunctioning.

Test and replace as needed.

Low volume level. System gain is too low. Check to make sure that the audio signal to the amplifier is

high enough to drive it properly. Check all volume/level

controls and gain switches in the system including the

amplifier input attenuator.

Low volume level. Signal or speaker wire

connection is shorted.

Make sure the signal and input wire connections inside all

system connectors are not shorted or open. Even one small

wire strand shorting the +/– signal terminals together

anywhere in the system can cause this problem.

No sound. Amplifier is not on or

loudspeaker is

Check that amplifier is turned on and that loudspeaker is

properly connected to the amplifier.

disconnected.