Page 1

VERIS Series

VERsatile Installation Systems

Exquisite Performance… Exceptional Value

Operation Manual

Page 2

EC STATEMENT OF CONFORMITY

This document confirms that the range of products of Community Professional Loudspeakers bearing

the CE label meet all of the requirements in the EMC directive 89/336/EEC laid down by the Member

States Council for adjustment of legal requirements. Furthermore, the products comply with the rules

and regulations referring to the electromagnetic compatibility of devices from 30-August-1995.

The Community Professional Loudspeaker products bearing the CE label comply with the following

harmonized or national standards:

DIN EN 55013:08-1991

DIN EN 55020:05-1995

DIN EN 55082-1:03-1993

The authorized declaration and compatibility certification resides with the manufacturer and can be

viewed upon request. The responsible manufacturer is the company:

Community Light & Sound

333 East 5

Chester, PA 19013

USA

TEL: 1-610 876-3400

FAX: 1-610 874-0190

Chester, PA USA February 2007

th

Street

Community VERIS Series - Operation and Installation Manual - Page 2

Page 3

TABLE OF CONTENTS

Table of Figures .......................................................................................................... 4

C-Tips ....................................................................................................................... 4

Important Safety Information ....................................................................................... 5

Precautions & Safety Considerations .............................................................................. 6

Introduction ............................................................................................................... 7

VERIS Technology ....................................................................................................... 7

Unpacking and Inspection ............................................................................................ 8

VERIS Specifications .................................................................................................... 9

Getting Acquainted ..................................................................................................... 11

PHYSICAL FEATURES OF VERIS FULL-RANGE MODELS .................................................................... 11

PHYSICAL FEATURES OF VERIS SUBWOOFERS .............................................................................. 12

General Description .................................................................................................... 13

DYNA-TECHTM Driver Protection System ......................................................................... 13

Cool-Coil™ Technology ............................................................................................... 14

High-Pass Filters ........................................................................................................ 15

Connecting the Amplifier to the Loudspeaker.................................................................. 16

PIN DESIGNATIONS ............................................................................................................. 16

USING POWER TAPS ............................................................................................................ 17

70.7V AND 100V SYSTEMS ................................................................................................... 18

WIRING NEUTRIK TYPE CONNECTORS ........................................................................................ 18

KNOW YOUR AMPLIFIER ........................................................................................................ 19

CHOOSING LOUDSPEAKER WIRE .............................................................................................. 19

CONDUCTORS AND INSULATION .............................................................................................. 20

THE EFFECT OF WIRE GAUGE ON DAMPING FACTOR ...................................................................... 21

SELECTING AMPLIFIERS ........................................................................................................ 21

VERIS Applications ..................................................................................................... 22

Positioning Subwoofers ............................................................................................... 23

POLARITY ......................................................................................................................... 24

Choosing the Right Loudspeakers and Electronics ........................................................... 26

COMMISSIONING THE SYSTEM ................................................................................................ 26

FOR MORE INFORMATION AND APPLICATIONS ASSISTANCE .............................................................. 27

Rigging / Suspension and Safety .................................................................................. 27

IMPORTANT NOTES ON RIGGING LOUDSPEAKERS .......................................................................... 27

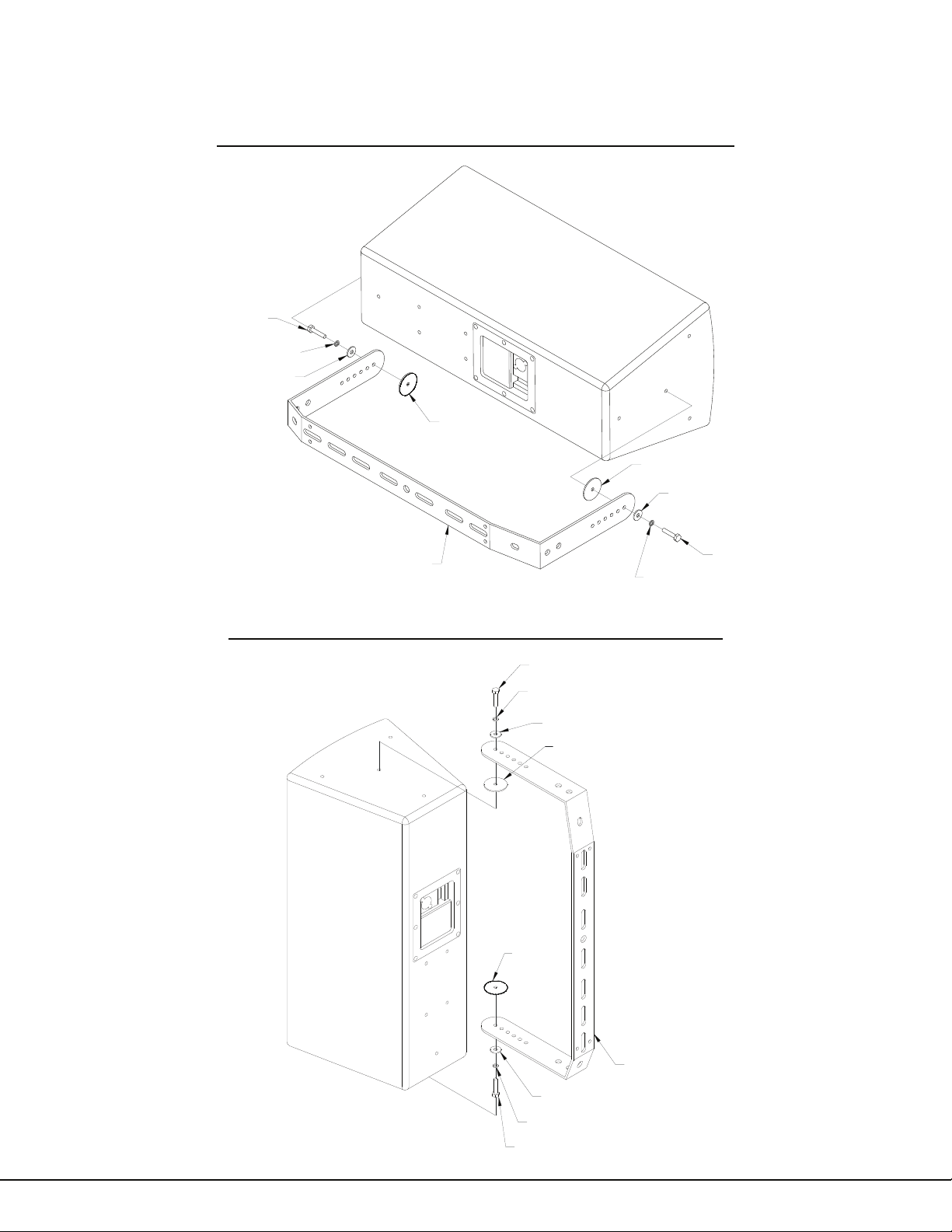

VERIS Mounting Brackets and Accessories ..................................................................... 28

Troubleshooting Guide ................................................................................................ 30

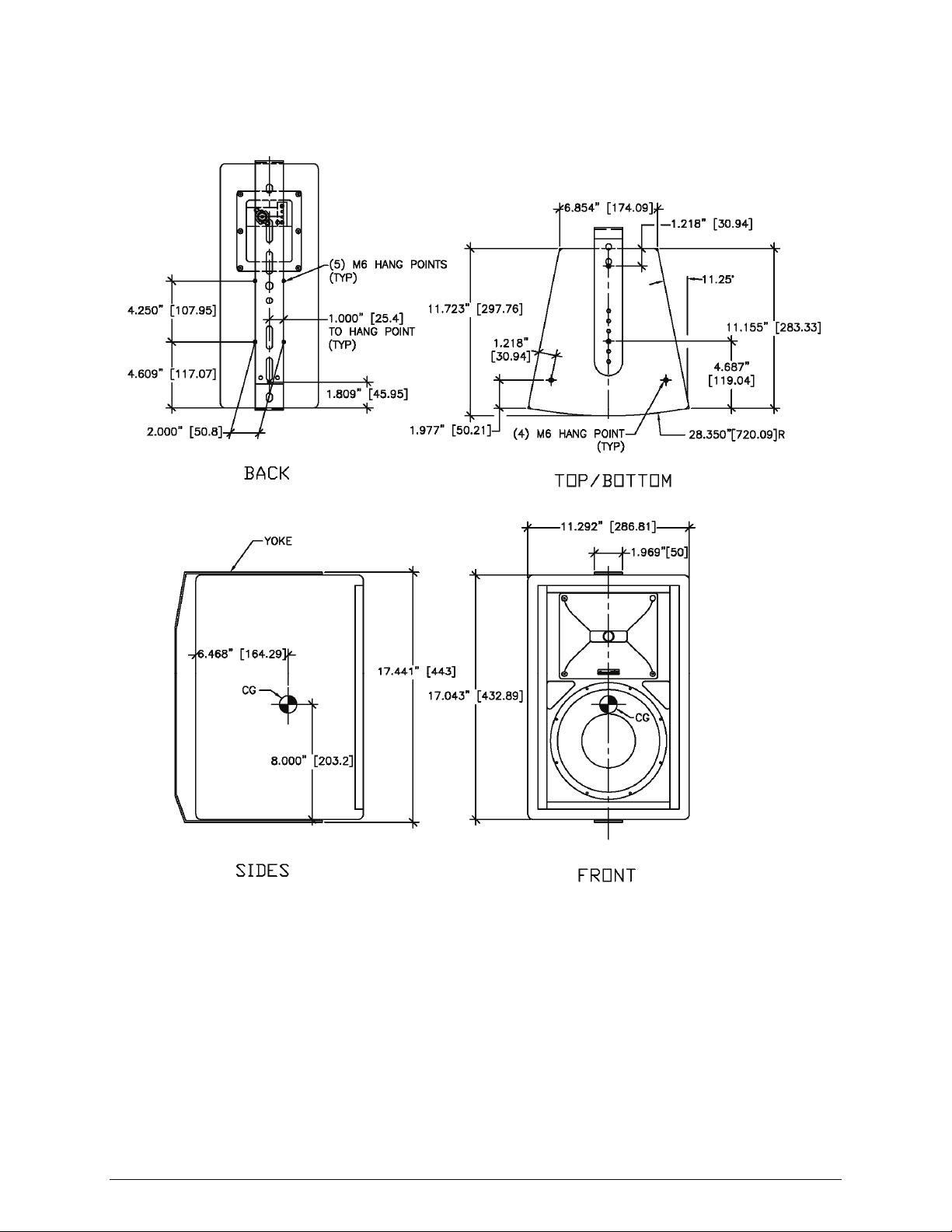

Technical Drawings .................................................................................................... 31

VERIS 6 ........................................................................................................................... 31

VERIS 8 ........................................................................................................................... 32

VERIS 26 ......................................................................................................................... 33

VERIS 28 ......................................................................................................................... 34

VERIS 12 ......................................................................................................................... 35

VERIS 15 ......................................................................................................................... 36

VERIS 32 ......................................................................................................................... 37

VERIS 35 ......................................................................................................................... 38

Community VERIS Series - Operation and Installation Manual - Page 3

Page 4

V

ERIS 210S ..................................................................................................................... 39

VERIS 212S ..................................................................................................................... 40

Servicing VERIS Loudspeakers ..................................................................................... 41

Warranty Information and Service ................................................................................ 41

TRANSFERABLE WARRANTY "(LIMITED)” VALID IN THE USA ONLY ...................................................... 41

OBTAINING WARRANTY SERVICE ............................................................................................. 41

WARRANTY INFORMATION AND SERVICE FOR COUNTRIES OTHER THAN THE USA .................................... 42

Summing Things Up ................................................................................................... 42

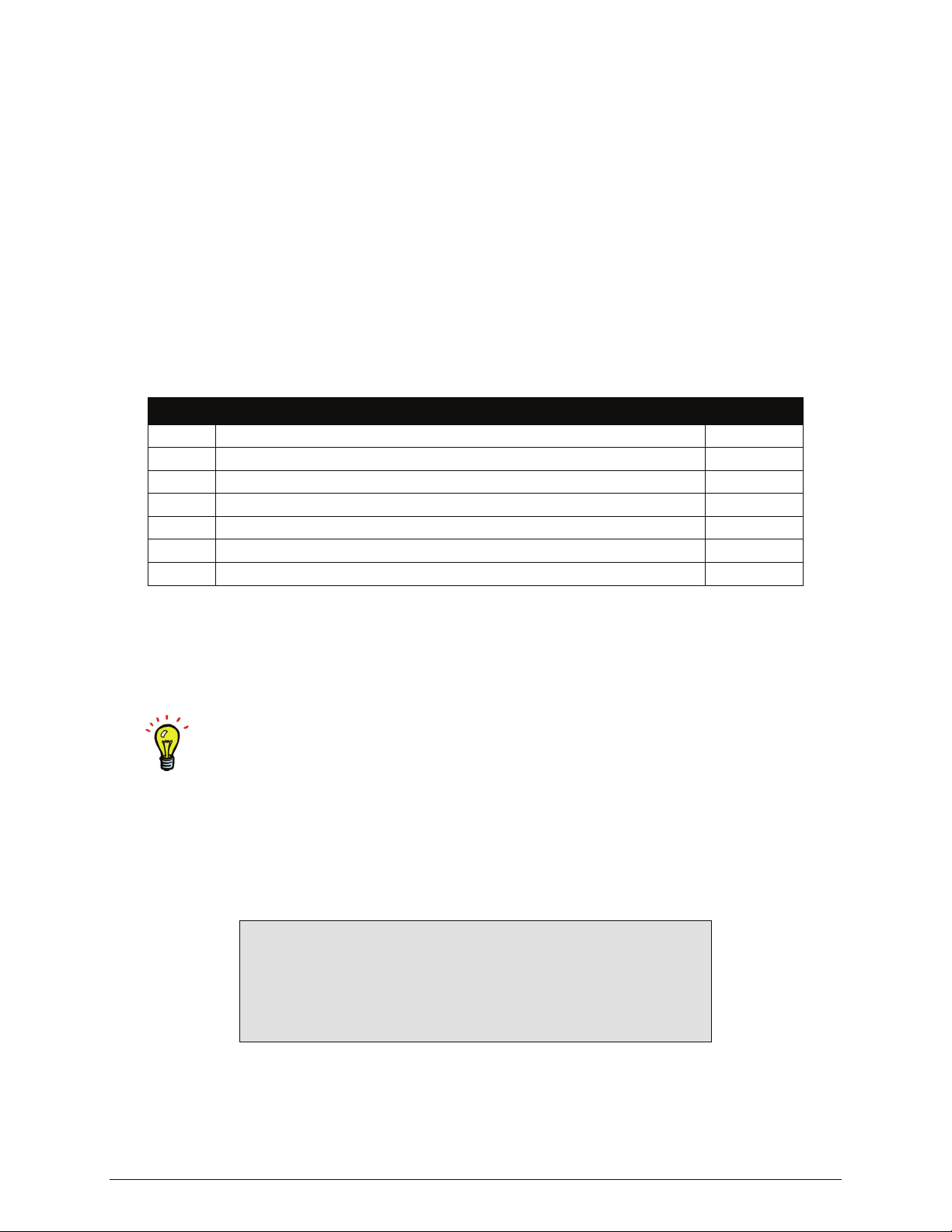

TABLE OF FIGURES

Following is a list of figures found in this manual:

Figure Title Page

1 Physical Features of a Typical VERIS Full-Range Model 10

2 Physical Features of a Typical VERIS Subwoofer 11

3 Community’s Cool-Coil™ Heat Evacuation System 14

4 VERIS Input Panel 15

5 VERIS Input Panel (Optional Autoformer Version) 16

6 NL4-Type Connector 17

7 Effect of Boundary Surfaces on Power Output 22

C-TIPS

Occasionally, in this manual, you’ll come across some useful tips that are intended to help

you get the most from your use of VERIS loudspeakers in portable applications and fixed

installations. We call these C-TIPS (short for COMMUNITY-TIPS or COOL-TIPS…we’ll let

you decide!). These tips originate from Community staff members as well as from installers

and end users. We welcome any C-TIPS that you may want to share with us, and we’ll

acknowledge you as the source if we print them in future user’s manuals.

Notice: Every effort has been made to insure that

the information contained in this manual was complete

and accurate at the time of printing. However, due to

ongoing technical advances, changes or modifications

may have occurred that are not covered in this manual.

Community VERIS Series - Operation and Installation Manual - Page 4

Page 5

IMPORTANT SAFETY INFORMATION

Always follow these basic safety precautions when using or installing VERIS loudspeakers

and accessories:

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions, particularly those pertaining to rigging, mounting,

hanging and electrical connections.

5. Only use accessories that are specified and approved by the manufacturer.

The terms CAUTION, WARNING, and DANGER are used throughout this manual to alert

the reader to important safety considerations. If you have any questions or do not

understand the meaning of these terms, do not proceed with installation. Contact your

local dealer, distributor, or call Community directly for assistance. These terms are defined

below:

CAUTION: describes an operating condition or user action that may expose the equipment

or user to potential damage or danger.

WARNING: describes an operating condition or user action that will likely cause damage to

the equipment or injury to the user or to others in the vicinity.

DANGER: describes an operating condition or user action that will immediately damage the

equipment and/or be extremely dangerous or life threatening to the user or to others in the

vicinity.

Installation of loudspeakers should only be performed by trained and qualified personnel. It is strongly

recommended that a licensed and certified professional structural engineer approve the mounting design.

Community VERIS Series - Operation and Installation Manual - Page 5

Page 6

PRECAUTIONS & SAFETY CONSIDERATIONS

English

The loudspeakers described in this manual are designed and intended to be ‘flown’ or

suspended for maximum acoustical performance using a variety of rigging hardware,

means, and methods. It is essential that all installation work involving the suspension of

these loudspeaker products be performed by competent, knowledgeable persons who

understand safe rigging practices. Severe injury and/or loss of life may occur if these

products are improperly installed. Please read the section on rigging for additional

information.

Français

Les haut-parleurs décrits dans ce manuel sont conçus et sont projetés pour être ‘volé’ ou

suspendu pour l'exécution acoustique maximum utilisant une assortiment d'équiper

matériel, les moyens, et les méthodes. C'est essentiel que tout travail d'installation ait

impliqué la suspension de ces produits d'haut-parleur est exécutée par les personnes

compétentes et entraînées qui comprennent équiper les pratiques sûres. La perte sévère

de et/ou de blessure de vie peut arriver si ces produits sont incorrectement installés. S'il

vous plaît lire la section d'équiper pour l'information supplémentaire.

Deutsch

Die Lautsprecher, die in diesem Handbuch beschrieben werden, sind entworfen und sind zu

sein ‘geflogen' vorgehabt oder sind für maximale hörbare Leistung verschiedene

Manipulierenhardware, Mittel, und Methoden suspendiert benutzend. Es ist wesentlich,

dass alle Installationarbeit, die die Aufhängung von diesen Lautsprechernprodukten

verwickelt, von fähigen, ausgebildeten Personen durchgeführt werde, die sichere

Manipulierenpraxis verstehen. Schwere Verletzung bzw. Verlust des Lebens können

stattfinden, wenn diese Produkte unrichtig installiert sind. Bitte lesen Sie den Abschnitt

über Manipulieren für zusätzliche Informationen.

Italiano

Gli altoparlanti descritti in questo manuale sono disegnati e sono intesi essere ‘volato' o

sospeso per la prestazione massima acustica usando una varietà di attrezzare di hardware,

i mezzi, ed i metodi. È essenziale che tutta il lavoro di installazione coinvolgendo la

sospensione di questi prodotti di altoparlante è eseguita da dalle persone competenti,

addestrate che capisce le pratiche di attrezzare di cassaforte. La lesione severe e/o la

perdita di vita possono accadere se questi prodotti sono erratamente installati. Per favore

di leggere la sezione di attrezzare per le ulteriori informazioni.

Español

Los altavoces descritos en este manual se diseñan y son pensados ser ‘volado' o suspendido

para el desempeño acústico máximo que utiliza una variedad de aparejar hardware, de

medios, y de los métodos. Es esencial que todo trabajo de la instalación que implique la

suspensión de estos productos del altavoz sea realizado por personas competentes y

entrenada que entienden aparejar seguro las prácticas. La herida y/o la pérdida severas de

la vida pueden ocurrir si estos productos se instalan impropiamente. Lea por favor la

sección a aparejar para la información adicional.

Installation of loudspeakers should only be performed by trained and qualified personnel. It is strongly

recommended that a licensed and certified professional structural engineer approve the mounting design.

Community VERIS Series - Operation and Installation Manual - Page 6

Page 7

VERIS SERIES

OPERATION MANUAL

INTRODUCTION

Thank you for selecting Community’s VERIS Series. VERIS is a stunning collection of

affordable loudspeakers designed for permanent installation in venues such as nightclubs,

cafes, discotheques, houses of worship, auditoriums, lecture halls, restaurants, theatres,

and most anywhere else that people gather to enjoy music and hear the spoken word.

VERIS excels in applications requiring controlled coverage patterns, high-impact power

response, and intelligible sonic output.

VERIS loudspeakers are flexible, easy to install and use, and most importantly they provide

excellent sound quality.

This Operation Manual is intended to help you install VERIS loudspeakers effectively and

safely. It provides useful information to assist in obtaining the best performance, sound

quality, and reliability from your VERIS products.

We’ve provided several easy-to-understand diagrams to enable you to quickly grasp the

main features of VERIS loudspeakers; however, we recommend that you take the time to

read the entire manual to insure that your VERIS-powered installations meet the highest

possible quality and safety standards.

VERIS TECHNOLOGY

VERIS loudspeakers offer numerous advances in technology that provide superb sound and

long-term reliability. Some of these include:

• Sophisticated internal crossover networks for reduced off-axis lobing and consistent

coverage throughout the crossover region.

• Carbon Ring Cone Technology. Used on all full-range low-frequency drivers, this

technology reduces distortion, improves transient response, and provides as much

as 30% greater cone area than that of conventional cone drivers (patent pending).

• Ferrofluid-cooled high-frequency and mid-frequency drivers for improved heat

transfer and dramatically reduced distortion, through viscous damping of driver

resonant modes.

• Powerful 1-inch-throat high-frequency compression drivers offer extended high-end

response, smooth output, and lower distortion than larger format drivers.

• Non-metallic high-frequency diaphragms provide a further reduction in distortion

by eliminating the mechanical resonance normally associated with brittle metallic

materials.

• Community’s patented Cool-Coil

driver power compression and ensures long-term reliability (used in subwoofers).

• DYNA-TECH

under abusive conditions.

• Rugged 11-ply, 18mm cross-laminated Birch enclosures, coated with a two-part

catalyzed polyester paint for durability.

• Protective steel grilles covered with durable powder-coat finish.

TM

active protection circuitry reduces the likelihood of driver damage

TM

heat evacuation technology minimizes cone

Community VERIS Series - Operation and Installation Manual - Page 7

Page 8

• Load-rated threaded rigging fittings on tops, bottoms, and rear of enclosures for

safe & easy rigging.

• NL4-compatible locking connector with terminal strip in parallel for easy

connectivity.

• Factory designed rigging hardware and mounting brackets available from stock.

• Smaller models may be ordered with an optional low distortion, low insertion-loss

autoformer for 70V and 100V applications.

• All models available in black or white finish at no additional cost.

UNPACKING AND INSPECTION

VERIS loudspeakers are inherently rugged and are carefully packed in sturdy cartons.

However, it’s wise to thoroughly inspect each unit after it has been removed from the

packaging, as damage could occur during shipping.

Please note that once the shipment has left your dealer or the Community factory, the

responsibility for damage is always borne by the freight company. If damage has occurred

during shipping, you must file a claim directly with the freight company. It’s very important

to contact the freight company as soon as possible after receiving your shipment, as most

freight companies have a short time limit within which they will investigate claims. Make

sure to save the carton and the packing material, as most claims will be denied if these

materials are not retained. Your Community dealer and the factory will try to help in any

way they can, but it is the responsibility of the party receiving the shipment to file the

damage claim.

It’s always a good idea to retain the carton and packing materials indefinitely, if possible, in

the event that the unit may need to be returned to your dealer or distributor for repair in

the future.

Each shipping carton contains the following items:

• Loudspeaker System (Qty 1)

• Operation Manual (Qty 1)

• Warranty Card (Qty 1)

DANGER: VERIS rigging fittings are rated at a Working Load Limit (WLL) of 100 lbs

(45.4kg) with a 10:1 safety margin. No single rigging fitting should ever be subjected to a

load that is greater than this stated limit. Failure to heed this warning could result in injury

or death!

IMPORTANT: The flat-head Allen-drive rigging screws that come installed in each

enclosure must either be replaced with rigging brackets and threaded fasteners, or they

must be kept in place to seal the enclosure from air leaks. If the rigging fittings do not

remain sealed, air leaks will occur in the enclosure that will compromise the low-frequency

performance with distortion and reduced output.

Community VERIS Series - Operation and Installation Manual - Page 8

Page 9

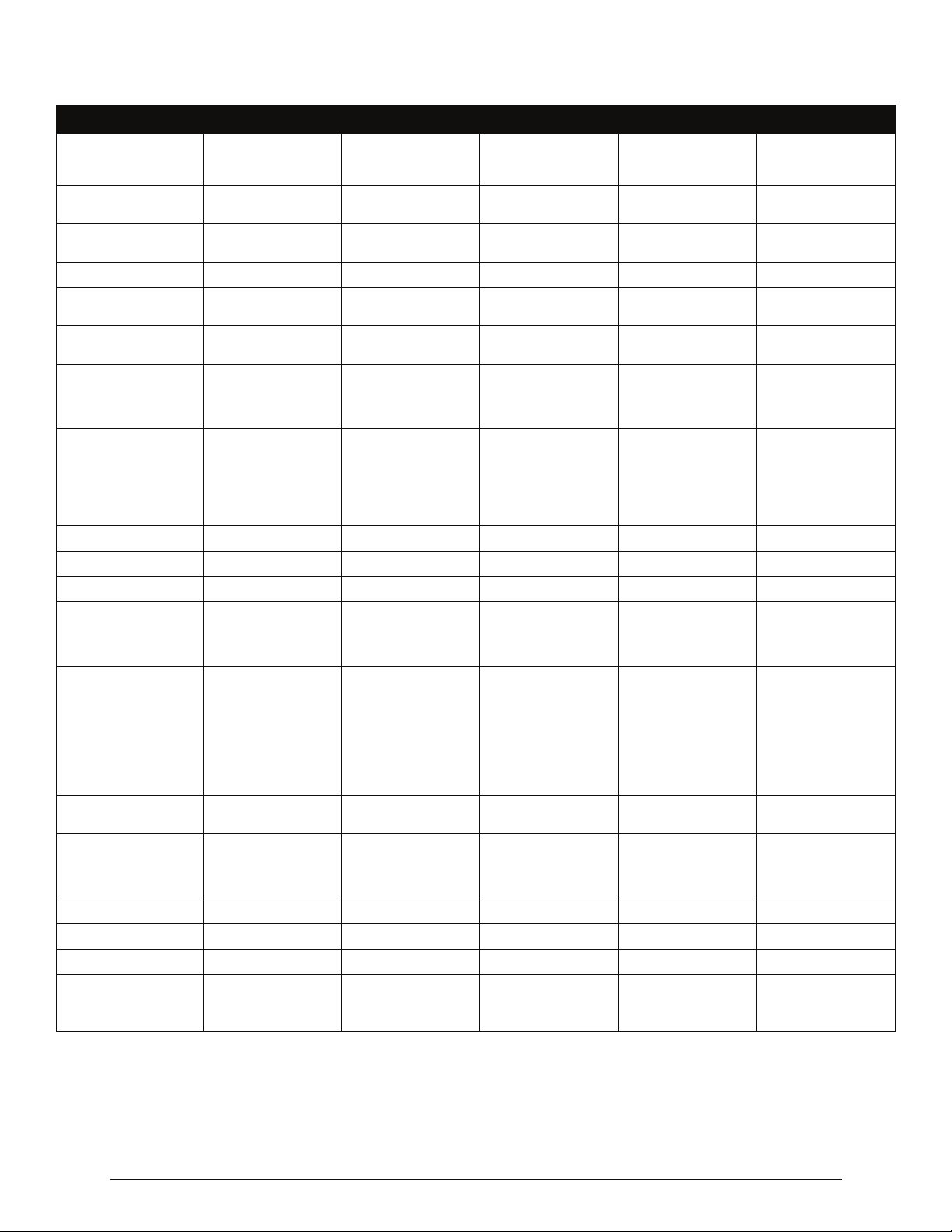

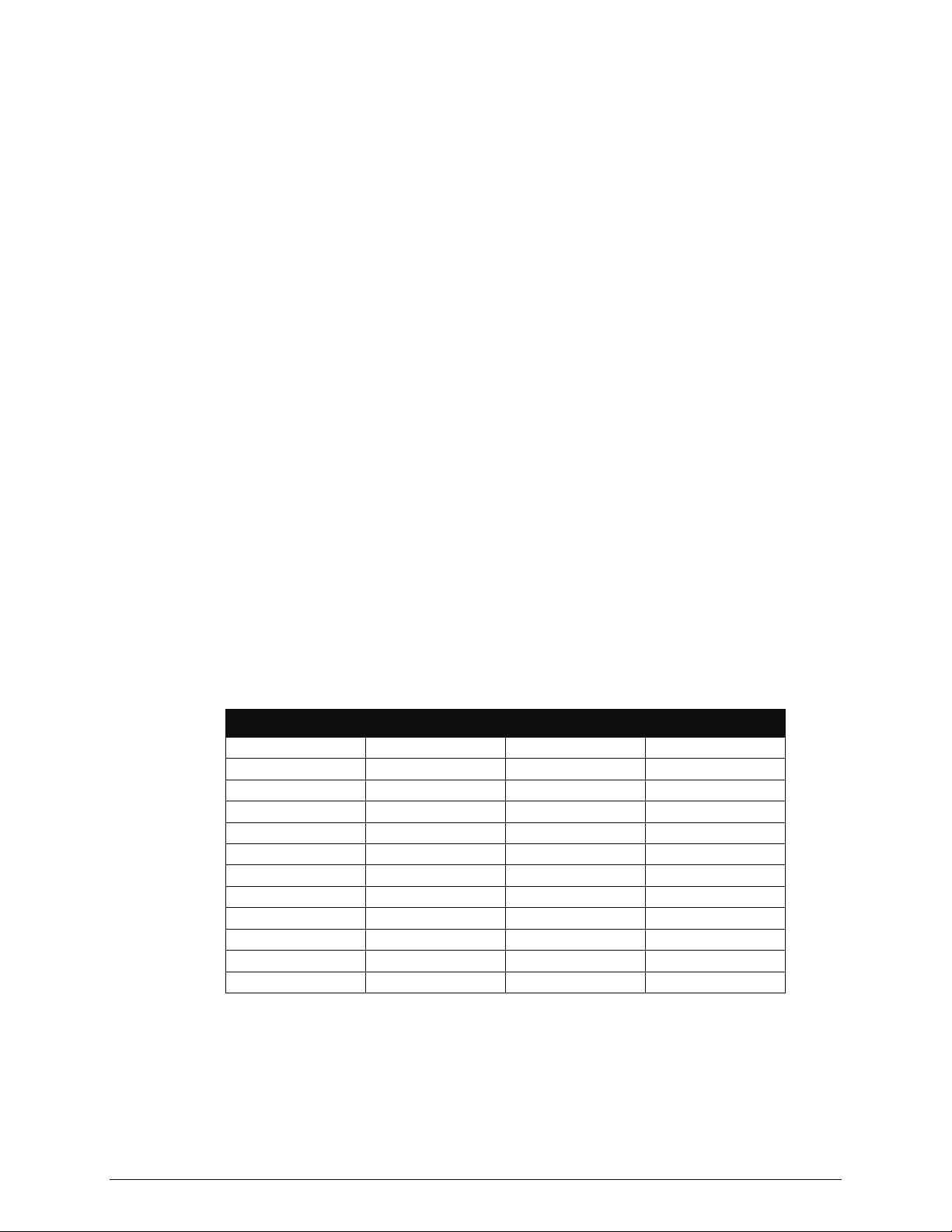

VERIS SPECIFICATIONS

T

T

T

No No

Model VERIS 6 * VERIS 8 * VERIS 26 * VERIS 28 * VERIS 12

Loudspeaker Type Two-way, full-range,

trapezoidal, vented

bass

Driver Complement LF: 1 x 6"

HF: 1 x ¾"

Nominal Dispersion

90° x 70° 90° x 70°

Two-way, full-range,

trapezoidal, vented

bass

LF: 1 x 8"

HF: 1 x ¾"

(H x V)

Operating Range 100 Hz – 18 kHz 90 Hz – 18 kHz

Frequency Response 125 Hz – 10 kHz

±3dB

Input Ratings 100W RMS (28.3V)

250W PGM

Sensitivity 1W/1m

90 dB 91 dB 92 dB

100 Hz – 10 kHz

±4.5dB

150W RMS (34.6V)

375W PGM

(free space SPL)

125 Hz – 10 kHz

1/3 octave bands

Maximum SPL

• Continuous

• Peak

110 dB cont.

117 dB peak

113 dB cont.

120 dB peak

Nominal Impedance 8 Ohms 8 Ohms

Crossover Frequency 2 kHz 2 kHz 2 kHz

Horn Rotatable No No No

Input Connection NL4-compatible

locking connector

with terminal strip in

parallel

Rigging Provisions (9) M6 threaded

rigging fittings

(4) M6 threaded

fittings for V-HSS and

OmniMount™ 30 bolt

pattern

Construction 18mm, 11-ply

cross-laminated birch

Finish Catalyzed polyester

two-part paint,

available in black

or white

NL4-compatible

locking connector

with terminal strip in

parallel

(9) M6 threaded

rigging fittings

(4) M6 threaded

fittings for V-HSS and

OmniMount™ 30 bolt

pattern

18mm, 11-ply

cross-laminated birch

Catalyzed polyester

two-part paint,

available in black

or white

Height 15.5 in / 395 mm 17.0 in / 433 mm

Width 9.8 in / 249 mm 11.3 in / 287 mm

Depth 10.1 in / 258 mm 11.7 in / 298 mm

Net Weight

16.5 lbs / 7.5 kg

19 lbs / 8.6 kg with

Autoformer

21.5 lbs / 9.8 kg

24.5 lbs / 11.1 kg

with Autoformer

* VERIS models 6/8/26/28 include a yoke-style mounting bracket at no additional charge. These four models may be

ordered with an optional 200W autoformer to accommodate 70V/100V system designs.

Due to ongoing development, specifications are subject to change without notice.

wo-way, full-range,

trapezoidal, vented

bass

LF: 2 x 6"

HF: 1 x ¾"

90° x 70°

wo-way, full-range,

trapezoidal, vented

bass

LF: 2 x 8"

HF: 1 x ¾"

wo-way, full-range,

trapezoidal, vented

bass

LF: 1 x 12"

HF: 1 x 1"

90° x 70° VERIS 1264: 60° x 40°

VERIS 1296: 90° x 60°

70 Hz - 18 kHz

Hz - 10 kHz ±3dB 90 Hz - 10 kHz ±4dB 90 Hz - 13 kHz ±3dB

90

200W RMS

(28.3V)

500W PGM

70 Hz - 18 kHz 60 Hz – 18 kHz

300W RMS (34.6V)

750W PGM

93 dB

200W RMS

500W PGM

VERIS 1264: 99 dB

VERIS 1296: 97 dB

115 dB cont.

122 dB peak

118 dB cont.

125 dB peak

VERIS

1264:

122 dB cont.

129 dB peak

VERIS 1296:

120 dB cont.

127 dB peak

4 Ohms

NL4-compatible

locking connector

with terminal strip in

parallel

(9) M6 threaded

rigging fittings

(4) M6 threaded

fittings for V-HSS and

OmniMount™ 30 bolt

pattern

4 Ohms 8 Ohms

2 kHz

NL4-compatible

locking connector

with terminal strip in

parallel

(9) M6 threaded

rigging fittings

(4) M6 threaded

fittings for V-HSS

(4) M8 threaded

fittings for

1.5 kHz

NL4-compatible

locking connector

with terminal strip in

parallel

(13) M10 threaded

rigging fittings

(4) M8 threaded

fittings for

OmniMount™ 60 bolt

pattern

OmniMount™ 60 bolt

pattern

18mm, 11-ply

cross-laminated birch

Catalyzed polyester

two-part paint,

available in black

or white

22.5 in / 572 mm

9.8 in / 249 mm

10.1 in / 258 mm

22.5 lbs / 10.2 kg

26.5 lbs / 12.0 kg

with Autoformer

18mm, 11-ply

cross-laminated birch

Catalyzed polyester

two-part paint,

available in black

or white

18mm, 11-ply

cross-laminated birch

Catalyzed polyester

two-part paint,

available in black

or white

25.5 in / 649 mm 23.9 in / 607 mm

11.3 in / 287 mm 15.4 in / 390 mm

11.7 in / 298 mm 14.3 in / 362 mm

31 lbs / 14.1 kg

35 lbs / 15.9 kg with

36.5 lbs / 16.6 kg

Autoformer

(40V)

Community VERIS Series - Operation and Installation Manual - Page 9

Page 10

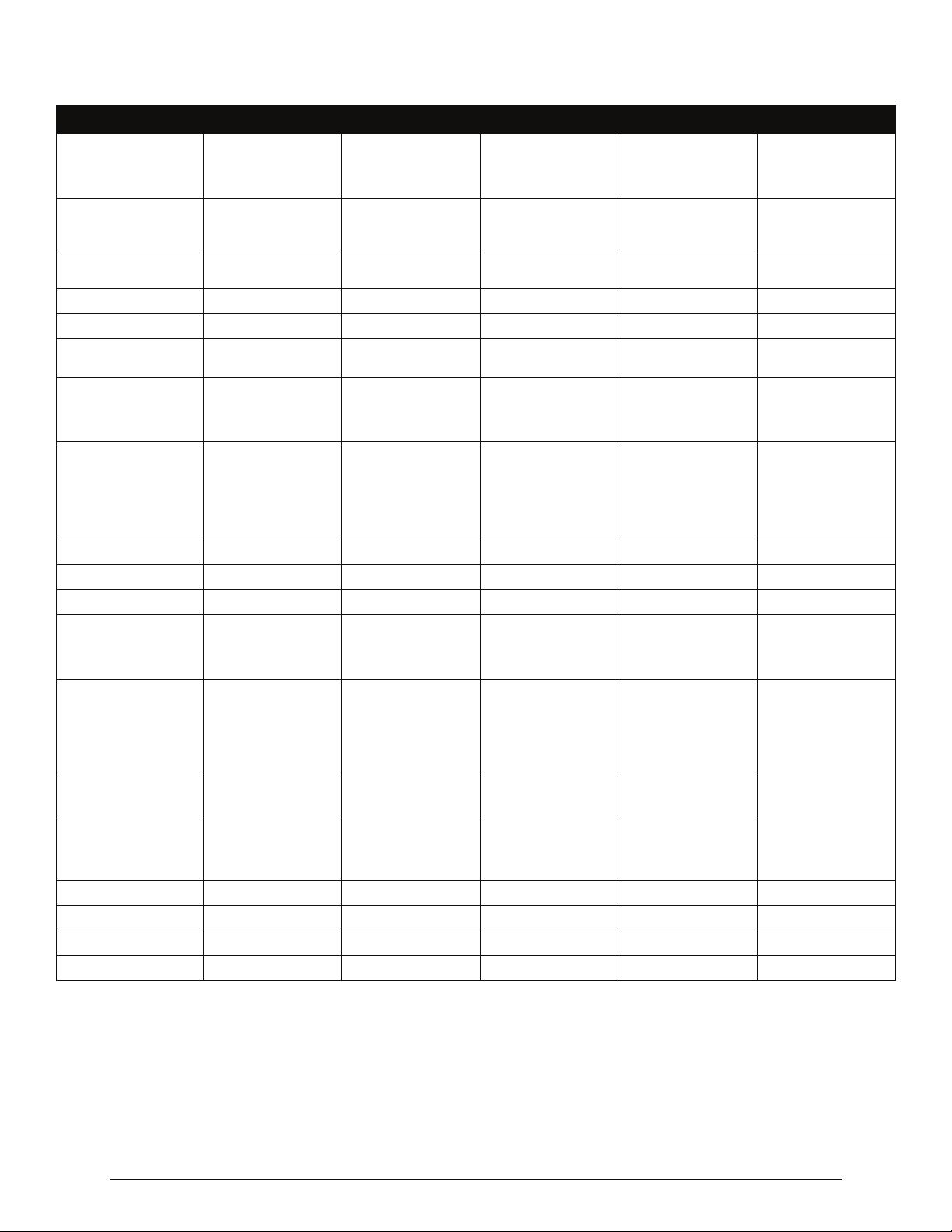

VERIS SPECIFICATIONS

T

L

Model VERIS 15 VERIS 32 VERIS 35 VERIS 210S VERIS 212S

Loudspeaker Type Two-way, full-range,

trapezoidal, vented

bass

Driver Complement LF: 1 x 15"

HF: 1 x 1"

Three-way, fullrange, trapezoidal,

vented bass

LF: 1 x 12"

MF: 1 x 6.5"

HF: 1 x 1"

Nominal Dispersion

(H x V)

VERIS 1564: 60° x 40°

1596: 90° x 60°

VERIS

VERIS

3264: 60°

x 40°

VERIS 3294: 90° x 40°

Operating Range 60 Hz - 18 kHz 60 Hz - 18 kHz

Frequency Response 80 Hz - 13 kHz ±3dB 80 Hz - 13 kHz ±4dB 70 Hz - 13 kHz ±4dB 50 Hz – 150 Hz ±3dB 50 Hz - 125Hz ±1.5 dB

Max Input Ratings 200W RMS (40V)

500W PGM

Sensitivity 1W/1m

(free space SPL)

125 Hz – 10 kHz

1/3 octave bands

Maximum SPL

• Continuous

• Peak

VERIS 1564:

100 dB

SPL

VERIS 1596:

99 dB SPL

VERIS 1564:

123 dB cont.

130 dB peak

VERIS 1596:

122 dB cont.

129 dB peak

200W RMS (40V)

500W PGM

3264:

VERIS

100 dB SPL

3294:

VERIS

98 dB SPL

3264:

VERIS

123 dB cont.

130 dB peak

VERIS 3294:

121 dB cont.

128 dB peak

Nominal Impedance 8 Ohms 8 Ohms

Crossover Frequency 1.5 kHz 800 Hz / 3 kHz

Horn Rotatable No Yes Yes

Input Connection NL4-compatible

locking connector

with terminal strip in

parallel

Rigging Provisions (13) M10 threaded

rigging fittings

(4) M8 threaded

fittings for

OmniMount™ 60 bolt

pattern

Construction 18mm, 11-ply

cross-laminated birch

Finish Catalyzed polyester

two-part paint,

available in black or

white

NL4-compatible

locking connector

with terminal strip in

parallel

(13) M10 threaded

rigging fittings

(4) M8 threaded

fittings for

OmniMount™ 60 bolt

pattern

18mm, 11-ply

cross-laminated birch

Catalyzed polyester

two-part paint,

available in black or

white

Height 27.2 in / 690 mm 29.3 in / 744 mm

Width 18.4 in / 467 mm 17.4 in / 441 mm

Depth 15.9 in / 404 mm 15.4 in / 390 mm

Weight 47 lbs / 21.3 kg 52.5 lbs / 23.8 kg

Due to ongoing development, specifications are subject to change without notice.

hree-way, fullrange, trapezoidal,

vented bass

LF: 1 x 15"

MF: 1 x 6.5"

HF: 1 x 1"

VERIS

3564: 60°

VERIS 3594: 90° x 40°

55 Hz – 18 kHz

200W RMS

(40V)

500W PGM

3564:

VERIS

101 dB SPL

3594:

VERIS

99 dB SPL

3564:

VERIS

124 dB cont.

131 dB peak

VERIS 3594:

122 dB cont.

129 dB peak

8 Ohms

800 Hz / 3 kHz

NL4-compatible

locking connector

with terminal strip in

parallel

(13) M10 threaded

rigging fittings

(4) M8 threaded

fittings for

OmniMount™ 60 bolt

pattern

18mm, 11-ply

cross-laminated birch

Catalyzed polyester

two-part paint,

available in black or

white

32.4 in / 823 mm

18.4 in / 467 mm

15.9 in / 404 mm

58 lbs / 26.3 kg

Dual driver

subwoofer,

rectangular, vented

bass

LF: 2 x 10" LF: 2 x 12"

360°

x 40°

x 180°

40 Hz - 500 Hz 37 Hz - 500 Hz

300W RMS (34.6V)

750W PGM

dB SPL

96

(63 Hz – 160 Hz)

dB cont.

121

128 dB peak

4 Ohms 4 Ohms

N/A

N/A

NL4-compatible

locking connector

with terminal strip in

parallel

(8) M10 threaded

rigging fittings

18mm, 11-ply

cross-laminated birch

Catalyzed polyester

two-part paint,

available in black

or white

11.9 in / 303 mm 13.9 in / 354 mm

32.7 in / 830 mm 35.9 in / 912 mm

15.9 in / 404 mm 17.9 in / 455 mm

55.5 lbs / 25.2 kg 67.5 lbs / 30.6 kg

Dual driver

subwoofer,

rectangular, vented

bass

360° x 180°

300W RMS

(34.6V)

750W PGM

98 dB SP

(63 Hz – 160 Hz)

123 dB cont.

130 dB peak

N/A

N/A

NL4-compatible

locking connector

with terminal strip in

parallel

(8) M10 threaded

rigging fittings

18mm, 11-ply

cross-laminated birch

Catalyzed polyester

two-part paint,

available in black

or white

Community VERIS Series - Operation and Installation Manual - Page 10

Page 11

GETTING ACQUAINTED

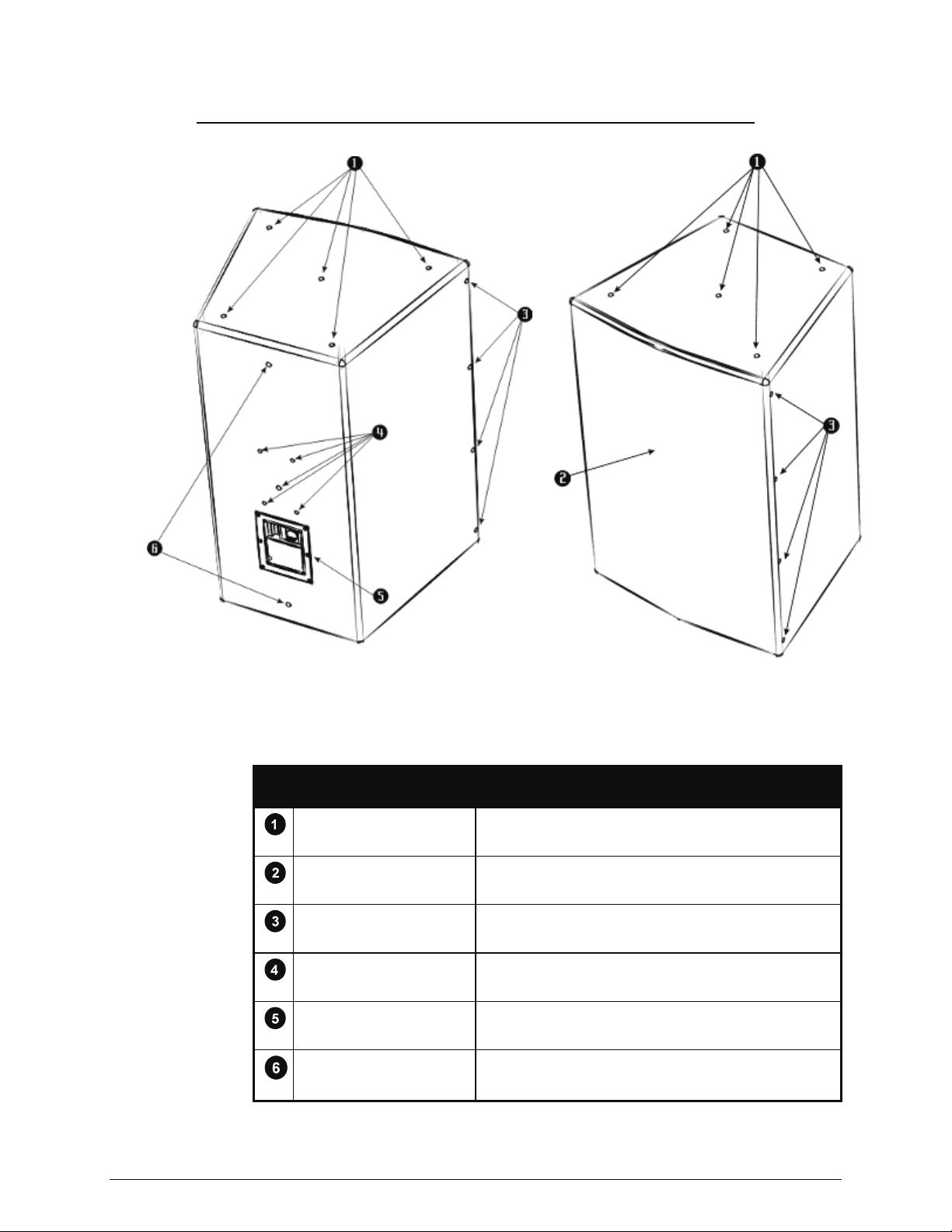

Figure 1: Physical Features of a Typical VERIS Full-Range Model

PHYSICAL FEATURES OF VERIS FULL-RANGE MODELS

FEATURE DESCRIPTION

TOP & BOTTOM RIGGING

POINTS

PROTECTIVE GRILLE

GRILLE RETENTION

SCREWS

THREADED FITTINGS

FOR OMNIMOUNT™

INPUT PANEL

REAR PULL-BACK POINTS

Community VERIS Series - Operation and Installation Manual - Page 11

M6 or M10 threaded fittings, depending on model.

Powder-coated steel grille protects drivers from foreign

objects.

#6 x 5/8” sheet metal screws. Remove grille to

service drivers.

Fits OmniMount™ 30 or OmniMount 60™ series,

depending on model.

For amplifier connection to the loudspeaker. NL4 and

terminal strip are wired in parallel.

Used for angling enclosure downward; not intended

for primary rigging.

Page 12

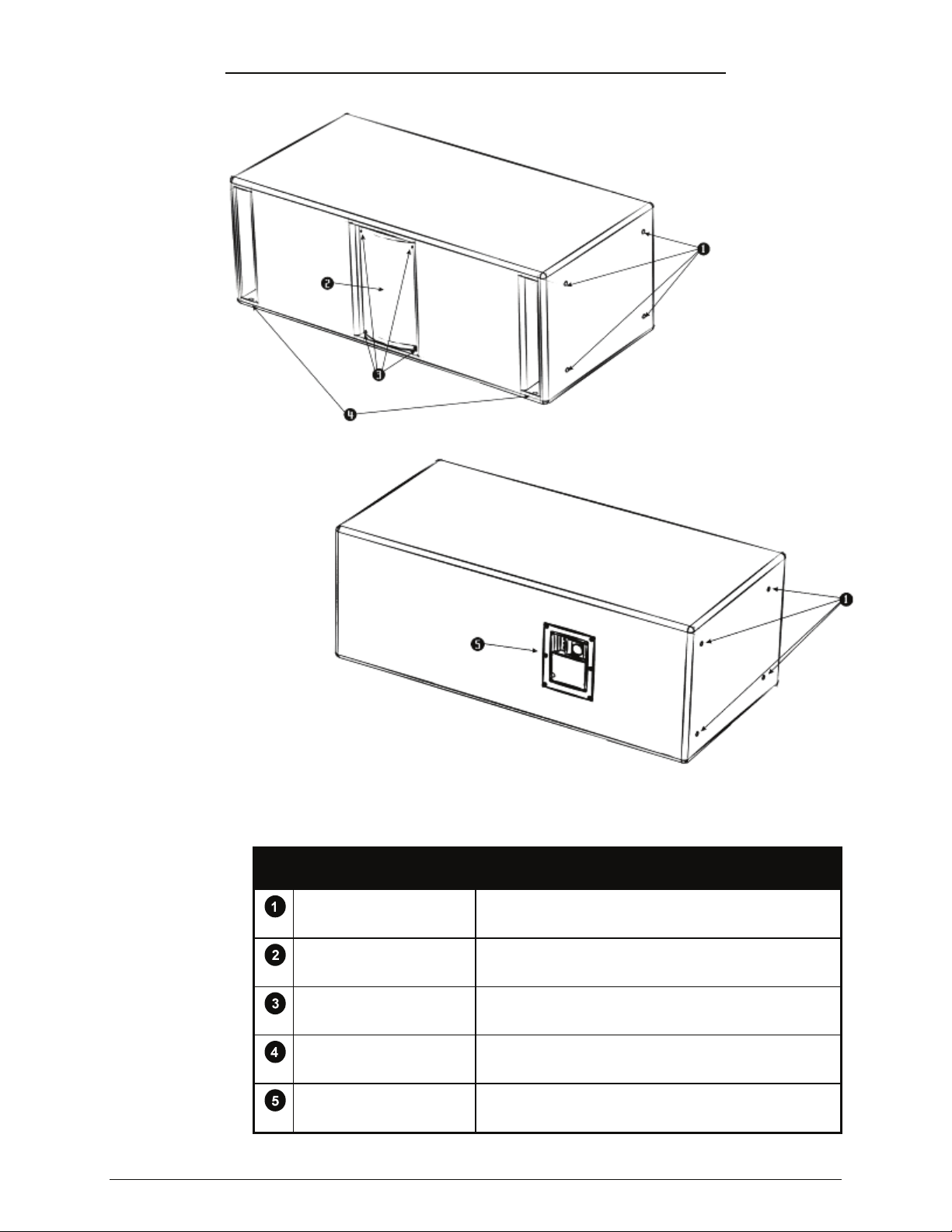

Figure 2: Physical Features of a Typical VERIS Subwoofer

PHYSICAL FEATURES OF VERIS SUBWOOFERS

FEATURE DESCRIPTION

RIGGING POINTS M10 threaded fittings. Four (4) on each side panel.

PROTECTIVE GRILLE

GRILLE RETENTION

SCREWS

FEET

INPUT PANEL

Community VERIS Series - Operation and Installation Manual - Page 12

Powder-coated steel grille protects drivers from foreign

objects.

#6 x 5/8” sheet metal screws. Remove grille to

service drivers.

Four synthetic rubber feet protect surfaces from

marring.

For amplifier connection to the loudspeaker. NL4 and

terminal strip are wired in parallel.

Page 13

GENERAL DESCRIPTION

VERIS Series loudspeakers are designed for demanding day-to-day use in a wide range of

fixed installations. Their high quality driver components are housed in rugged, acoustically

inert enclosures equipped with rigging fittings. VERIS systems are characterized by a highpower, low distortion linear response that provides exceptional musicality and speech

intelligibility.

The VERIS line consists of 10 models:

· VERIS6 - a 6” / ¾” two-way in a trapezoidal enclosure.

· VERIS8 - an 8” / ¾” two-way in a trapezoidal enclosure.

· VERIS26 - a dual 6” / ¾” two-way in a trapezoidal enclosure.

· VERIS28 – a dual 8” / ¾” two-way in a trapezoidal enclosure.

· VERIS12 – a 12” / 1” two-way in a trapezoidal enclosure with a choice of 60 x 40 or

90 x 60 horn patterns.

· VERIS15 – a 15” / 1” two-way in a trapezoidal enclosure with a choice of 60º x 40º

or 90º x 60º horn patterns.

· VERIS32 – a 12” / 6.5” / 1” three-way in a trapezoidal enclosure with a choice of

60º x 40º or 90º x 40º horn patterns. Horn is rotatable.

· VERIS35 - a 15” / 6.5” / 1” three-way in a trapezoidal enclosure with a choice of

60º x 40º or 90º x 40º horn patterns. Horn is rotatable.

· VERIS210S - a dual 10” subwoofer in a rectangular enclosure.

· VERIS212S - a dual 12” subwoofer in a rectangular enclosure.

Note: the specification table on pages 9 and 10 depicts dimensions, weights, and detailed

specifications of the ten VERIS models described above.

VERIS loudspeakers may be used in multiples, forming clusters and arrays. Systems may

be designed around horizontal splayed arrays, vertical splayed arrays, as well as exploded

clusters and distributed configurations. Rigging kits are available from the factory as

standard items.

DYNA-TECHTM DRIVER PROTECTION SYSTEM

All VERIS Series loudspeakers employ Community’s advanced technology DYNA-TECH

driver protection system. Functioning as a multi-stage limiter, DYNA-TECH circuitry

provides precise and repeatable protection by reducing excessive power to the drivers

under abusive conditions.

The first stage of limiting is designed to protect against short-term excess power applied to

the high-frequency driver(s) in the system. This circuit utilizes an HPCCR (High Positive

Current Coefficient Resistor) in series with the driver(s). The HPCCR increases resistance

as the current flowing through it increases. As its resistance rises above nominal, the

heating of the element provides RMS conversion. The result is an RMS limiter with a ratio

that varies according to the demands of the program material.

The second stage of limiting protects against excessive power levels to all drivers in the

system. This stage is based on an electro-mechanical relay driven through a voltage

sensing circuit. The relay engages at a pre-determined voltage, corresponding to a power

level that would otherwise cause driver damage. When engaged, the relay introduces a

bank of high-wattage resistors in series with the drivers. These resistors cause a voltage

drop to the drivers, thereby reducing the power applied to them. A red LED on the rear

panel indicates that this protection circuit has been engaged.

When the relay protection circuit is activated, there will be a noticeable drop in the system’s

level (approximately 3 to 4 dB). The red LED, as well as the drop in level, serves as a

warning to the operator that the loudspeaker is being overdriven. When this stage of

protection is engaged, the level of the console and/or the amplifier’s output to the

system should be reduced.

Community VERIS Series - Operation and Installation Manual - Page 13

Page 14

IMPORTANT: If the operator continues to run the system at excessive levels, or worse, if

the operator raises the drive level to compensate for the drop in output caused by the

protection circuitry, eventually an additional stage of protection will engage that shuts down

the system entirely (note that this additional stage of protection will never engage until

after the second stage has been triggered). If the system shuts down entirely, the operator

can immediately restore sound by simply reducing the drive level to the system.

Advantages of Community’s DYNA-TECH Circuitry

There are numerous advantages to this type of multi-stage protection circuitry. The trip

point is pre-set to engage at exactly the same time on all speakers that are powered from

the same amplifier. The initial stages of DYNA-TECH protection circuitry do not rely on, and

are not affected by heat build-up. Some manufacturers use circuit breakers that require

heat build-up before they trip; this limits their ability to protect a cold speaker. The trip

points of such breakers are also affected by ambient temperature, their own internal

heating curves, and small variations in speaker impedance or crossover component

tolerances, all of which can cause unpredictable behavior.

Because the first and second stages of Community’s DYNA-TECH circuits are not thermally

sensitive, they react nearly instantaneously to protect against an excessive increase in

level. Moreover, the protection disengages almost immediately when the drive level to the

system is reduced; it is not necessary to wait for a circuit breaker to cool down. This

means that your loudspeaker can operate at its full dynamic range and still react quickly to

protect against excessive musical peaks, avoiding damage to the system. It also means

that your loudspeaker is protected from the moment the power amplifier is plugged in and

turned on, regardless of the ambient temperature.

As mentioned above, the protection circuitry provides a third level of protection for the

entire loudspeaker to guard it from severe misuse. If the system is operated in the secondstage mode of protection for a long period of time, or if the input level is increased to try to

overcome the volume drop from the second-stage protection circuitry, a solid-state circuit

breaker will trip and remove all signal from the loudspeaker until the input level is reduced.

Because this circuit breaker is heat sensitive, it provides a final level of protection that

takes heat into account as well as power. However, unlike most implementations of circuit

breakers that take time to cool down before resetting, DYNA-TECH circuits respond

instantly to a reduction in level, restoring the system to its full dynamic range without

needing to wait for the circuit breaker to reset itself.

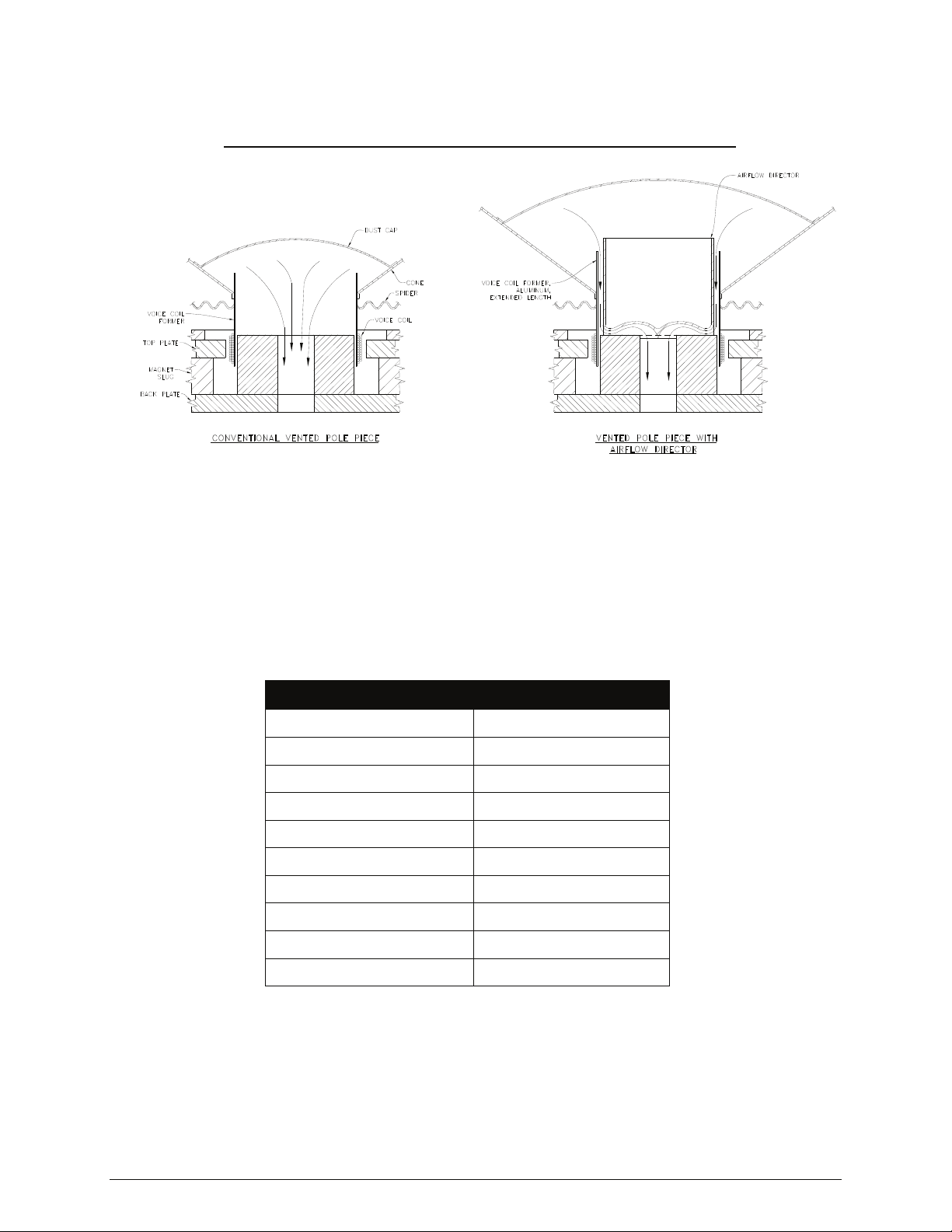

COOL-COIL™ TECHNOLOGY

The cone drivers used in the VERIS subwoofers utilize Community’s patented Cool-Coil™

heat evacuation technology. A proprietary process, Cool-Coil employs an airflow director to

remove heat from the voice coil, thereby increasing both the performance and reliability of

the cone drivers. In particular, the effect of Power Compression is significantly improved by

Cool-Coil technology. Power Compression occurs when drivers respond non-linearly to

applied power, producing less and less output as their voice coils heat up and their

impedance rises.

High voice coil temperatures have other undesirable effects on performance. Most materials

used in drivers, particularly adhesives and insulation, suffer some diminished properties

under extremes of heat. Thermal expansion can result in warpage and misalignment of

components. A voice coil in which the diameter has increased due to thermal expansion

will often no longer be round, and certainly has a greater possibility of rubbing against the

magnetic structure.

Any amount of cooling that can be applied to a woofer will be beneficial. One very

commonly used cooling method is venting of the pole piece of the magnet structure.

The motion of the cone assembly will pump air in and out of the cavity under the dust cap.

This air passing through the pole vent helps to cool the magnet structure. Community has

improved on this common cooling method by introducing an airflow director (US patent

6,390,231) into the air path. Figure 3 shows a conventional woofer motor with a vented

pole piece, and also a similar motor with the addition of an airflow director. The voice coil

former in the airflow motor is aluminum, and is taller than normal. This extended

aluminum former becomes a cooling fin for the voice coil, and the airflow director causes

the air to pass in close proximity to the former. By directing the air to flow over the hot

aluminum former, more heat is removed from the voice coil than simply allowing the

Community VERIS Series - Operation and Installation Manual - Page 14

Page 15

pumped air to take its natural path in and out of the cavity. This results in woofers that can

handle higher power with greater reliability than those of conventional design.

Figure 3: Community’s Cool-Coil™ Heat Evacuation System

HIGH-PASS FILTERS

We strongly encourage the use of an external, active high-pass filter to protect the cone

drivers from excessive low-frequency excursion. A high-pass filter will eliminate the

potential of low-frequency modulation from wind noise, turntable rumble, stage vibration,

and other causes that result in a poorly defined and ‘muddy’ bass response. Additionally, a

high-pass filter will avoid wasting amplifier power by keeping the amplifier from attempting

to reproduce frequencies below the loudspeaker’s intended operating range. The table

below shows the recommended filter settings:

Model High-Pass Filter

VERIS6 Full-Range: 100 Hz, 24db/octave

VERIS8 Full-Range: 90 Hz, 24db/octave

VERIS26 Full-Range: 80 Hz, 24db/octave

VERIS28 Full-Range: 70 Hz, 24dB/octave

VERIS12 Full-Range: 60 Hz, 24db/octave

VERIS15 Full-Range: 60 Hz, 24db/octave

VERIS32 Full-Range: 60 Hz, 24db/octave

VERIS35 Full-Range: 60 Hz, 24db/octave

VERIS210S Subwoofer: 40 Hz, 24db/octave

VERIS212S Subwoofer: 40 Hz, 24db/octave

Community VERIS Series - Operation and Installation Manual - Page 15

Page 16

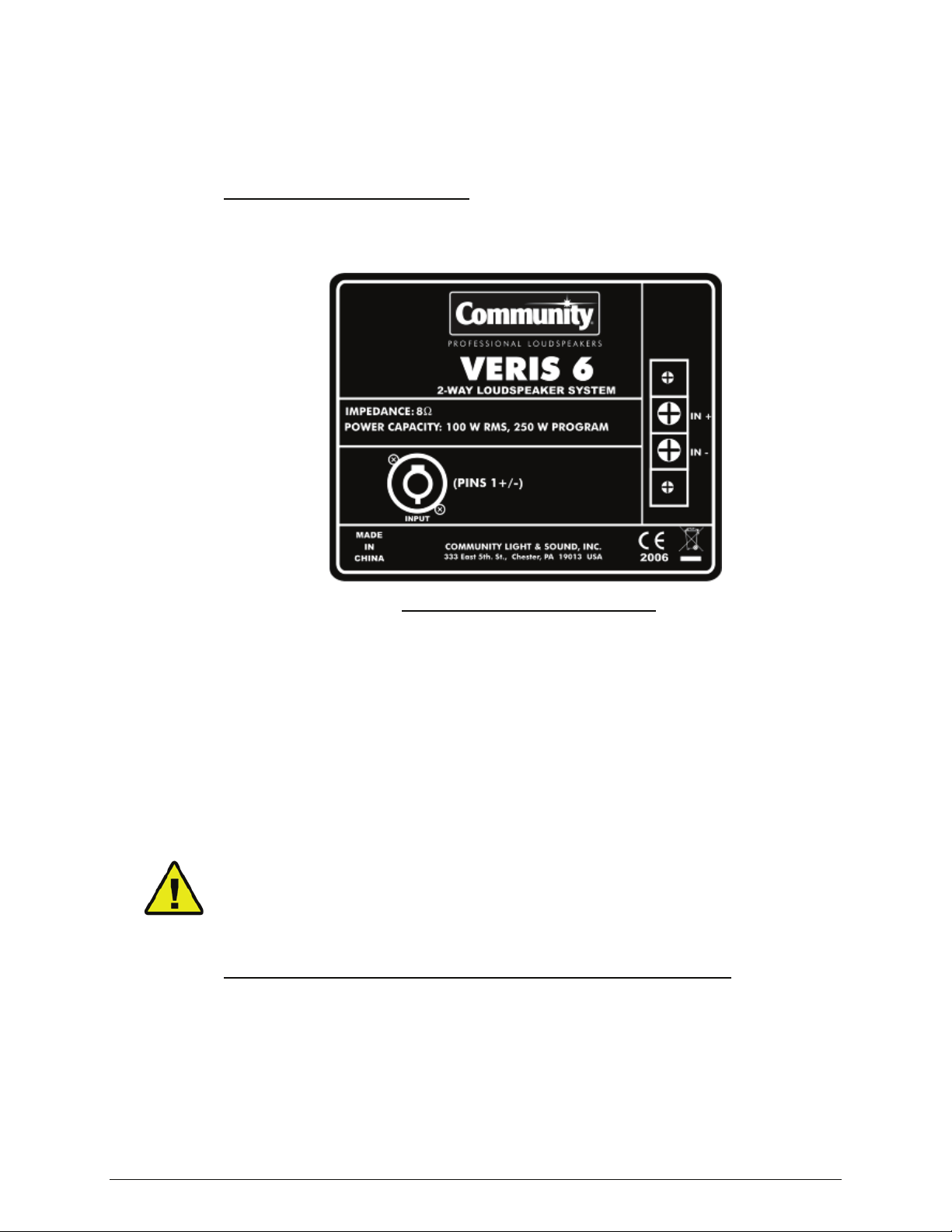

CONNECTING THE AMPLIFIER TO THE LOUDSPEAKER

All VERIS Series loudspeakers come with two methods of connecting the amplifier to the

loudspeaker. One is an industry standard NL4 type locking connector, and the other is a

terminal strip. These two connectors are wired in parallel with each other, on all models.

Figure 4: VERIS Input Panel

The following figure is an example of a typical input panel used on VERIS loudspeakers.

A similar panel is used on all standard, low impedance VERIS models. The loudspeaker is

intended to be connected directly to the amplifier.

Typical Standard Input Panel

PIN DESIGNATIONS

For all models the pin designation is as follows:

• NL4 Pin 1+ or the terminal screw labeled (+) connect to the positive (red)

output of the amplifier.

• NL4 Pin 1- or the terminal screw labeled (-) connect to the negative (black)

output of the amplifier.

Note that the NL-4 and the terminal strip are wired in parallel, and that Pins 2+ and 2- on

the NL4 connector are not utilized.

CAUTION: Be sure to carefully observe polarity when wiring your loudspeakers. If one

loudspeaker is wired with the opposite polarity from another loudspeaker, acoustic

cancellation will occur. The result will be less acoustic power output than if only one

loudspeaker were used by itself.

Figure 5: VERIS Input Panel, Optional Autoformer Version

The following figure is an example of the input panel used on VERIS loudspeakers equipped

with an optional autoformer. Such models are intended to be used in a 70V or 100V

“constant voltage distribution system.”

Community VERIS Series - Operation and Installation Manual - Page 16

Page 17

Typical Input Panel for Autoformer Equipped Models

PIN DESIGNATIONS

The pin designation is as follows:

• ‘C’ or ‘common’ connects to the ‘C’ or Ground connection on the amplifier

(typically a black binding post).

• One of the taps connects to the positive output of the amplifier (typically a red

binding post).

USING POWER TAPS

A VERIS loudspeaker equipped with an optional autoformer has four taps. These are set at

25W, 50W, 100W and 200W on the two larger models, and 12.5W, 25W, 50W and 100W on

the two smaller models.

By choosing one of the four taps, you can govern how much amplifier power is available for

each loudspeaker. For example, if the 50W tap is selected, that particular loudspeaker will

draw 50 watts of power when a 70V amplifier is run at its maximum level. A second

loudspeaker might be connected to the same amplifier, but tapped at 100W (100 watts). In

such case, the second loudspeaker will draw 100 watts from the same amplifier, making it 3

dB louder than the first loudspeaker. A third loudspeaker might be tapped at 200 watts,

which would make it 3 dB louder than the second loudspeaker, and 6 dB louder than the

first.

By using the various taps, one can balance the relative sound levels in a system. A

loudspeaker that is closer to audience members will need to be tapped at a lower wattage

than one that is farther away, in order to produce similar levels.

Typically, every time you double the distance from a sound source, the level drops by 6 dB,

which is equivalent to one-fourth of the power. Although this is an acoustical law, and is

true in a free space environment such as outdoors, be aware that the effect of room

acoustics can radically change the actual results. Even outdoors, it is normally not possible

to validate this acoustical law using a sound level meter, due to the ground plane effect.

That said, the use of pink or white noise to excite the system, and a sound level meter to

take nearfield measurements, will help you precisely balance the relative level of each

loudspeaker in a sound system. Just make sure to take your readings at an identical

distance from each of the loudspeakers in the system, otherwise the results will be skewed.

Community VERIS Series - Operation and Installation Manual - Page 17

Page 18

70.7V and 100V SYSTEMS

Several voltage standards have been put in place regarding so called ‘constant voltage

systems.’ In the United States, 25V, 70.7V and 100V are common. Occasionally 140V

systems can be found, usually in very large venues such as racetracks, where the need to

overcome cable resistance by scaling the voltage up is extremely important. In Europe and

Asia, most constant voltage systems use the 100V standard.

A VERIS loudspeaker equipped with the optional autoformer will support both the 70.7V and

100V standards. The same screw terminals are used for both voltage standards, but the

power level of the tap is different, depending on whether the voltage is 70.7V or 100V.

Note that on the rear input panel, the power levels above the horizontal line refer to a

70.7V system, while the power levels below the line refer to a 100V system.

A 100V system will produce twice the power at a given tap, as that of a system run at 70.7

volts. This can be verified by the simple Ohm’s Law calculation E

2

/Z = W, where E is the

voltage applied, Z is the load impedance, and W is the power expressed in Watts.

Assuming a load impedance of 50 ohms, we can see that 70.7 x 70.7 / 50 = 99.97 and that

100 x 100 / 50 = 200. Therefore, when scaling up from 70.7V to 100V the power will

double; when scaling down, the power will halve.

CAUTION: Be sure to carefully observe polarity when wiring your loudspeakers. If one

loudspeaker is wired with the opposite polarity from another loudspeaker, acoustic

cancellation will occur. The result will be less power output than if only one loudspeaker

were used by itself.

C-TIP: When using the barrier strip for wiring, we recommend that you first terminate the

wire with a plated copper crimp-on type spade lug, using moderate to heavy pressure on

the crimp tool. When the spade lug is tightened firmly on the barrier strip, it will form a

gas-tight connection resistant to corrosion. Be careful not to over-tighten the barrier strip

screws, as they can sheer off under too much torque. This is the recommended method of

wiring for fixed installations, especially those that may be exposed to inclement

environmental conditions.

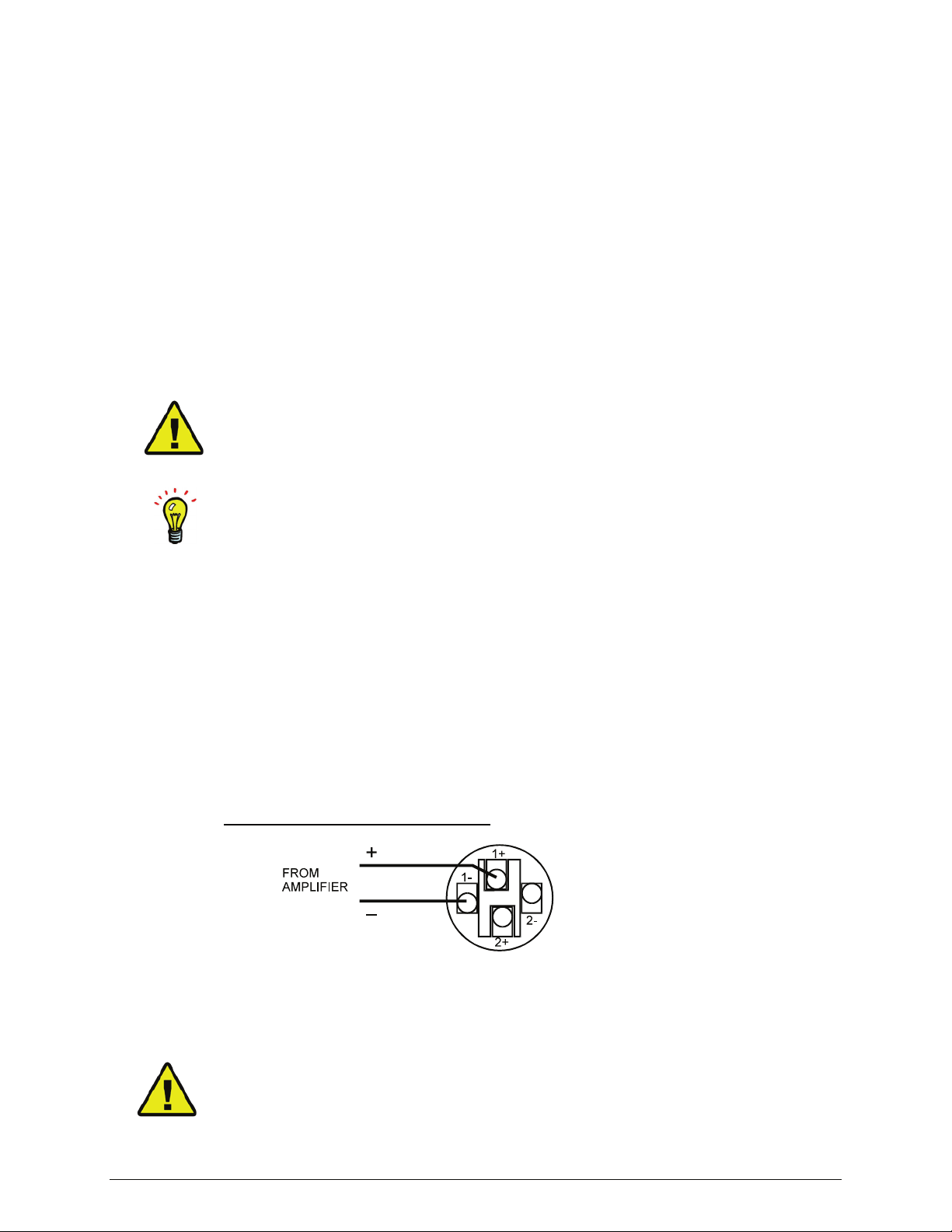

WIRING NEUTRIK TYPE CONNECTORS

The following diagram shows how connections are made to a Neutrik SpeakonTM style

loudspeaker connector. Terminations may be soldered, or made by means of their built-in

screw and pressure clamp. If using the pressure clamp, it’s important to tighten it fully,

then to wait about ten minutes (longer is better), then to tighten it again. This is because

copper wire flows under pressure. After initially tightening the screw clamp, some minutes

later the screw will no longer be as tight due to the effect of the compression on the

copper. Typically, only one cycle of “tighten – wait – re-tighten” is required for a secure

connection.

Figure 6: NL4-Type Connector

NEUTRIK SPEAKON™

CONNECTOR – NL4FC

Note: Pins 2+ and 2- are not used in the VERIS loudspeaker series.

DANGER: When wiring the amplifier(s) to the loudspeaker(s), always power-down the

amplifier(s) and disconnect their AC Mains plug(s). Many modern, high power amplifiers

can deliver enough voltage and current to cause a harmful or lethal electric shock. Shocks

from very low frequencies, such as kick drums, can cause the human heart to stop beating

at relatively low power levels.

Community VERIS Series - Operation and Installation Manual - Page 18

Page 19

WARNING: After wiring the amplifier(s) to the loudspeaker(s), first power up all devices

that are upstream of the amplifier, such as mixers, equalizers, compressor/limiters, etc.,

before powering-up the amplifier. This is to avoid passing any clicks or pops that may

originate in the upstream devices to the loudspeakers. The amplifier should initially be

powered-up with its gain controls turned all the way down. After making sure that a

continuous signal is present, such as a CD playing, slowly raise the level of the gain

controls to establish that the wiring has been installed correctly. Only then should the

loudspeaker be operated at normal output levels.

KNOW YOUR AMPLIFIER

Not all amplifiers can safely drive low-impedance loads, though usually 4 ohms and higher

is not a problem. Very low impedance loads may cause the amplifier to clip prematurely,

overheat, shutdown, or fail altogether due to internal device damage.

Even when an amplifier is quite stable driving a low impedance load, cable loss will be

greater than with moderate impedance loads, damping factor will be reduced, and if the

amplifier were to fail, a larger portion of the sound system is likely to be taken off-line due

to the fact that a low impedance load implies a larger number of loudspeakers being

powered from a common amplifier.

C-TIP: Keeping the loads at 4 ohms or higher will lengthen the life of your amplifier(s) and

improve the reliability and overall sound quality of the system.

CHOOSING LOUDSPEAKER WIRE

Wire and cable is used to transfer power between the amplifier and the loudspeaker. Wire

and cable can be purchased with copper and aluminum conductors; for loudspeakers only

copper conductors should be utilized.

The construction, conductor type, and insulation material of wire and cable vary widely.

Wire can be purchased with solid core construction, stranded core construction, and densely

stranded construction. Cables are typically available only as stranded or densely stranded.

Speakers may be driven through individual conductors bundled together and pulled through

conduit, or through a cable made up of a number of conductors covered with an overall

jacket, which then may or may not necessarily be installed in a conduit. Wire and cable

manufacturers offer multi-conductor cables with 30 or more high current conductors

covered with a variety of jacket types. Jackets may be made of PVC, rubber, neoprene,

and other materials, depending on the intended conditions of use.

Generally speaking, the wires and cables that power loudspeakers do not need to be

twisted into pairs, though there is some benefit to doing so. A twisted pair of conductors

has the effect of cancelling electro-magnetic radiation, thereby reducing mutual induction

among circuits that share the same physical space (such as a cable tray or conduit), along

with canceling the crosstalk that might otherwise result.

Twisted pairs are commonly used for balanced line signal and microphone cables, in which

the nominal voltages are very low and the input impedance of the load is typically quite

high (>10K ohms). Under such conditions, the use of a twisted pair is essential to reduce

crosstalk among adjacent cables. The twisting insures that the differential amplifier in a

balanced line receiver will see identical phase and amplitude of any extraneous Electro

Magnetic Interference (EMI) induced in the cable on both polarities, thereby allowing the

EMI to be differentially cancelled.

In contrast, however, loudspeakers have input impedances that are quite low and operate

on much higher voltages. The potential of inducing an audible signal from adjacent wiring

is close to zero. The installer may, however, choose to use twisted pair loudspeaker cable

for other reasons. Certain amplifiers may exhibit instability when driving long lengths of

wire installed in conduit. A twisted pair will insure that the reactance of the loudspeaker

cable is identical on both the plus and minus wires, thereby presenting a more stable load

to the amplifier.

Note that when specifying multiple twisted pairs of speaker cables intended to share the

same conduit, the conduit will need to be sized much larger than with loose or bundled

conductors.

Community VERIS Series - Operation and Installation Manual - Page 19

Page 20

CONDUCTORS AND INSULATION

Solid conductor wire is slightly less expensive than stranded wire, but much more difficult

to pull through conduit. Also, it does not terminate to most speaker connectors as easily as

stranded wire. Therefore, we recommend using stranded THHN type wire for installations

that involve conduit.

Densely stranded cables, typically used for portable cordage, will coil up easily and lay flat

on the stage, making them a good choice for applications requiring portability such as floor

monitors. Typical examples are 14/2 and 14/4 SJO. Such cable is normally stocked in

many hardware stores.

Wire and cable insulation is always rated for a working voltage and a maximum

temperature. In power distribution systems, wire and cables can get very hot, making the

temperature rating extremely important. When used with loudspeakers, the temperature of

the wire or cable will hardly ever rise more than 10º C above ambient, and voltages will

never exceed 300V (which is the minimum rating of most industrial wire and cable).

Special cables are manufactured for installation in air plenums, while others are made for

direct burial. Use of such products can save a lot of time and expense compared to

installing conduit. However, local, state, or federal building codes may require that

loudspeaker cables are installed in conduits or in cable trays. Therefore, it’s a good idea to

check applicable regulations carefully, before beginning any installation.

In the United States, conductors are sized according to a numbering system know as the

American Wire Gauge, or AWG. Larger numbers, such as #22 or #24 indicate smaller

diameter wire, while smaller numbers such as #10 and #12 indicate larger diameter wire.

In other parts of the world, the metric system is widely used to define conductor diameter.

Metric equivalents can be converted to US AWG sizes, with only a small loss of precision.

The larger the diameter of the conductor, the lower the resistance will be for a given length.

Resistance is normally stated per foot, or per hundred feet of wire. For example, #10

stranded copper THHN has a resistance of .204 ohms per hundred feet, though this can

vary slightly among manufacturers.

The resistance of the wire, the impedance of the load, and the output voltage of the

amplifier will determine how much loss occurs in the wire. These parameters also govern

the damping factor of the amplifier/speaker combination (more on this later).

Below is a table that gives a quick look at the effect of wire size on line loss. These

numbers assume that the amplifier is producing a constant 48 Volts at its output terminals,

which is equivalent to 288 watts into an 8Ω load or 576 watts into a 4Ω load:

Size Length Load Z Loss in dB

#10 AWG 100’ 8Ω -0.42 dB

#10 AWG 200’ 8Ω -0.83 dB

#10 AWG 100’ 4Ω -0.83 dB

#10 AWG 200’ 4Ω -1.58 dB

#12 AWG 100’ 8Ω -0.66 dB

#12 AWG 200’ 8Ω -1.28 dB

#12 AWG 100’ 4Ω -1.28 dB

#12 AWG 200’ 4Ω -2.39 dB

#14 AWG 100’ 8Ω -1.03 dB

#14 AWG 200’ 8Ω -1.95 dB

#14 AWG 100’ 4Ω -1.95 dB

#14 AWG 200’ 4Ω -3.55 dB

The worst-case scenario shown above is the 200’ run of #14 AWG into a 4 ohm load. This

will result in a staggering loss of -3.55 dB, or more than half of the amplifier’s total power

output. Use of wire that’s one size smaller, #16 AWG, would cause a power loss of -5.11

dB. This approaches a 75% loss of total available power! As you can readily see, it’s very

important to use the largest gauge wire that you possibly can, particularly when long lines

are unavoidable. Note: NL4-compatible connectors easily accept #12 AWG.

Community VERIS Series - Operation and Installation Manual - Page 20

Page 21

C-TIP: When choosing cable for a situation that requires only two conductors, consider

using 14/4 (that is, #14 AWG with 4 conductors) and wiring each pair of conductors in

parallel, at both ends of the cable. This will provide the equivalent conductance of #11

AWG, but in a cable that’s more easily obtainable and smaller in diameter.

THE EFFECT OF WIRE GAUGE ON DAMPING FACTOR

As significant as power loss can be, the effect of wire resistance on the damping factor of

the loudspeaker/amplifier network is even greater for a given resistance value.

Amplifier designers intend for the output impedance of their amplifiers to be as low as

possible, in order to achieve a high damping factor. However, the laws of physics dictate

that a very low output impedance will cause the resistance of the speaker cable to have a

significant effect on the amplifier/speaker network. Unfortunately there’s no way to get

around it.

Example: With five feet of #10 AWG feeding a 4 ohm load, a given amplifier exhibits a

respectable 100:1 damping factor. With fifty feet of #10 AWG feeding the same 4 ohm

load, the damping factor decreases to 10:1, which is likely to be audible as a loss of ‘punch’

and tightness in the low frequencies.

Unless the power amplifiers are located directly alongside the loudspeakers (a good design

technique to consider when possible), it will be difficult to maintain a high damping factor

without using impractically large conductors. Therefore, keeping cable lengths as short as

possible, is the most practical and cost-effective way to maintain a respectable damping

factor without incurring undue difficulties.

C-TIP: Although it’s beyond the scope of this manual to test and rate the many specialty

loudspeaker cables sold in audio shops, studies conducted by skilled engineers have

conclusively shown that the majority of such cables offer no real performance advantages

(and in some cases, notable disadvantages) over that of readily available industrial grade

wire.

SELECTING AMPLIFIERS

Amplifiers are a vital part of any sound system’s performance capability. As such, they

should be carefully selected for appropriate power output, as well as for other attributes

(more on this later). A table is provided below to help you size your amplifiers’ power

output capability to the various models in the VERIS line.

Model Recommended Power

VERIS6 Full-range 200 to 300 WRMS at 8Ω

VERIS8 Full-range 310 to 450 WRMS at 8Ω

VERIS26 Full-range 420 to 600 WRMS at 4Ω

VERIS28 Full-range 630 to 900 WRMS at 4Ω

VERIS12 Full-range 420 to 600 WRMS at 8Ω

VERIS15 Full-range 420 to 600 WRMS at 8Ω

VERIS32 Full-range 420 to 600 WRMS at 8Ω

VERIS35 Full-range 420 to 600 WRMS at 8Ω

VERIS210S Subwoofer 630 to 900 WRMS at 4Ω

VERIS212S Subwoofer 600 to 900 WRMS at 4Ω

Note: “WRMS” = “Watts RMS” = “Watts Root Mean Squared”

Community VERIS Series - Operation and Installation Manual - Page 21

Page 22

VERIS APPLICATIONS

In choosing the right VERIS product for your application, the initial factors to consider are

the size of the venue, the style of music and speech to be reproduced, and the location(s)

of the loudspeaker(s).

In smaller venues with less demanding musical styles, one can usually achieve excellent

results with the VERIS12 and the VERIS15 models. A good rule of thumb is to use a pair of

these models for venues that host up to approximately 200 persons.

By adding a second pair of either the VERIS12 or VERIS15, venues that host as many as

300 to 400 persons can be effectively covered. Each pair of enclosures may be configured

side-by-side or one over another, to produce additional forward radiated power.

In rooms that are particularly wide but shallow in depth, a second pair may be required

simply to obtain the necessary horizontal coverage, even if overall power is not an issue.

The VERIS15, with its 15” cone driver, will provide additional low-frequency content than

that of the VERIS12, which has a 12” cone driver, resulting in a richer, fuller response.

However, if either model is to be used with the VERIS210S or VERIS212S subwoofers, the

difference in the response between the VERIS12 and the VERIS15 will be minimal.

VERIS32 and VERIS35 models are true three-way designs, employing horn loaded midrange drivers in addition to their horn loaded high-frequency drivers. This design yields

better directional control than a two-way system. The added directionality is an asset in

reverberant rooms where it’s important to keep the sound energy off of the walls, floor and

ceiling, and/or when there’s a need to cover long distances, either indoors or out.

The larger VERIS35 with its 15” cone driver will provide deeper low-frequency response

than that of the VERIS32 which employs a 12” cone driver, but here again the difference in

response will be minimal if either model is used with a VERIS subwoofer.

The small VERIS6 and VERIS8 loudspeakers are ideal for small rooms (25 – 75 persons), as

well as for distributed systems in large rooms. They can also be used as ‘delay speakers,’

augmenting a larger system to balance out the levels from the front of the room to the rear

of the room. The practice of driving small speakers through a delay line is used in many

theatrical systems, concert hall systems, and houses of worship. It gives the installer a

powerful tool when it comes time to equalize and balance the system.

In large rooms, and especially those in which the acoustical conditions are not ideal, we

strongly recommend the use of under-balcony delay speakers, over-balcony delay

speakers, front fill speakers, etc. In areas of the room that are too far away from the

primary loudspeaker(s) to enjoy clear intelligibility, the addition of local, delay speakers can

do wonders in solving problems.

The VERIS26 and VERIS28 models provide twice the woofer cone area of their smaller

cousins. The second woofer cone provides more overall power with greater bass response.

These models are a good choice for distributed music systems, such as in health clubs,

bars, restaurants and the like.

The VERIS line includes two subwoofers; the 210S employs dual 10” drivers, while the

212S features dual 12” drivers. Either model will add greatly increased power and

extended low-frequency response to the VERIS full-range loudspeaker(s) that it’s used

with.

The smaller of the two, the 210S, is characterized by a tight, punchy sound, while the

larger 212S adds a deeper low end, but still with a very rapid transient response. When

using multiple subwoofers, such as two or three on each side of a stage, it’s best to keep

the enclosures stacked or positioned tightly together for maximum mutual coupling.

If an external electronic crossover is employed, the use of a subwoofer will free up the lowfrequency power demand on the full-range loudspeaker(s), thereby increasing output

capability in the upper bass range. An electronic crossover will also reduce intermodulation

distortion in the amplifiers, resulting in much improved sonic performance.

Note: The guidelines referred to above are “rules of thumb only.” Performance

will vary based on room acoustics, room geometry (particularly ceiling height),

the location of the loudspeaker(s), the size and type of the amplifiers, and the

stylistic demands of the music and speech that are to be reproduced.

Community VERIS Series - Operation and Installation Manual - Page 22

Page 23

POSITIONING SUBWOOFERS

Subwoofers are far less directional than the mid-range and high-frequency loudspeakers

they are designed to augment. This is because low-frequency wavelengths are significantly

longer than mid-range and high-frequency wavelengths. A 30 Hz wave is approximately 35

feet in length and a 100 Hz wave is approximately 11.3 feet in length. These extremely

long wavelengths cause behavior that’s quite different from their shorter mid and highfrequency counterparts.

First, long wavelengths do not ‘see’ small or moderate size obstructions as obstacles; they

simply diffract around such barriers as if they’re not there.

Second, the substantial length of low-frequency waves can make it difficult to distinguish

their source direction. This is why a single subwoofer can often be used successfully to

augment a stereo pair of mid-high loudspeakers, without unduly harming the stereo

separation and image.

Third, low-frequency waves tend to add together quite graciously, even if their sources are

separated by considerable distances, as long as they are in phase with each other. An

example of this in operation is the typical accentuation or build-up of low-frequency content

that is often experienced in the middle of theatres and concert halls, generated by

subwoofers placed far apart on the opposite sides of the stage.

Overall, the characteristics mentioned above imply that the location of a subwoofer is not

particularly critical, and to a certain extent that is true. However, there are several factors

to consider before you finalize your intended location

(1) A subwoofer will benefit greatly in terms of power output when it’s placed adjacent to

boundary surfaces. If located at the junction of three walls, such as on the floor or

ceiling in a corner (called Eighth Space), a given subwoofer will produce a full 9dB more

output than if that same subwoofer is located in Free Space (such as when suspended

between the middle of a floor and ceiling). If located at the junction of two walls

(Quarter Space), the subwoofer will produce 6dB more output than if suspended in Free

Space. Located on a single wall, such as the floor or ceiling, the increase is 3dB. Free

Power! What could be better? See Figure 8 for additional clarification:

Figure 8: Effect of Boundary Surfaces on Power Output

1

. Some of these are:

1

A thorough understanding of how low-frequency waves transmit in acoustical environments is very helpful when designing,

installing, and optimizing sound systems. We recommend reading, “Fundamentals of Sound” and “Psychoacoustics” by F. Alton

Everest in the “Handbook for Sound Engineers” published by Howard Sams & Co.

Community VERIS Series - Operation and Installation Manual - Page 23

Page 24

When choosing subwoofer location(s), be careful, however, not to sacrifice sonic quality

for sheer power. If the available wall or corner location results in the subwoofer being

located behind, or too close, to one or more open microphones, early feedback is likely

to occur. If the wall or corner location is too far away from the full-range

loudspeaker(s), such a location may result in the subwoofer being drastically out of

time sync with one or more of the full-range speakers.

Sometimes the sound quality of a wall or corner placement is not desirable, simply due

to the room’s acoustical properties. Keep in mind that when wall and corner locations

are appropriate for use, they’ll provide a tremendous increase in power output, but

they may not always be the best choice for sound quality.

(2) Keeping the subwoofer(s) as close as possible to the mid and high loudspeaker(s) will

decrease phase irregularities and time smear. If the subwoofer(s) is placed too far

away from the mid/high loudspeaker(s), the listener will experience a disjointed

character to the program material, causing the musicality of the system to suffer.

(3) Although the subwoofer is not highly directional, still its acoustical output follows the

inverse square law. That is, every time the distance from the subwoofer to the listener

is doubled, the output level will decrease by 6dB. When covering a large space with

multiple subwoofers, it may be of benefit to space them some distance apart from one

another to even out the levels throughout the space. Typically, this would only be done

if the mid/high loudspeakers are also spaced apart from one another, such as in a

distributed system in a sports venue. Although this will help maintain an even level

throughout the listening space, there may be some areas that lie between two or more

subwoofers that experience a certain amount of power subtraction caused by

destructive interference. Destructive interference occurs when waveforms meet and

are partially or wholly out of phase with each other, due to unequal path lengths.

Conversely, if multiple subwoofers are located directly adjacent to one another, their

power output will add together almost seamlessly. This is known as constructive

acoustic addition. However, this may produce an undesirable hot-spot of low-frequency

energy that might possibly be too close to a seating area.

It’s always a good idea to experiment with trial locations, before finalizing your

installation plan. Even a very experienced sound system designer cannot predict the

precise effect that one location may have over that of another, if he/she is not

intimately familiar with the room acoustics. When planning loudspeaker locations, it’s

wise to discuss the matter with someone who may have prior experience operating

sound systems in that particular room, such as the resident mixing engineer, if the

building has previously had a sound system installed in it.

POLARITY

Unless the full-range loudspeaker(s) is stacked directly on top of the subwoofer(s) with its

cone drivers aligned with the subwoofer cone drivers, it’s likely that the phase relationship

of the two systems may not be optimal. This can be tested by reversing the polarity of one

system relative to the other, as described below.

First, however, it’s important to understand that the correct polarity of the full-range

system relative to the subwoofer is a function of their physical placement in relation to one

another. This is known as the Phase Relationship of the two systems, though Absolute

Polarity plays a role as well, which will be discussed later.

Depending on the placement of the subwoofer in relation to the full-range loudspeaker(s),

as well as the selected crossover point, the optimal response of the system might be

obtained by reversing the polarity of the full-range loudspeaker(s). The easiest way to

determine the proper polarity is to excite the system with a test signal (such as pink noise)

and to view the resultant response on an audio spectrum analyzer. If such equipment is

not available, it is also possible to determine the best polarity relationship by careful

listening.

One orientation of polarity, either normal or reversed, should result in a discernable dip

through the crossover region, due to acoustic cancellation. The opposite polarity should

result in either a flat response or a peak through the crossover region, due to acoustic

addition.

Note: When experimenting to determine the proper polarity, you can reverse the full-range

loudspeaker(s) or the subwoofer, but never both at the same time (reversing both at the

same time will not alter the phase relationship of the two systems). If there is one

Community VERIS Series - Operation and Installation Manual - Page 24

Page 25

subwoofer and several full-range enclosures in the same system, it will, of course, be easier

to reverse the subwoofer’s polarity to test the response. Ultimately, as we’ll see below, it’s

best to keep the subwoofer in a polarity-positive state.

If there is no discernable difference or only a very minimal difference in the measured or

audible response when the polarity is reversed, it indicates one of two things:

(1) The full-range system that the subwoofer is being used with does not reproduce

enough low-frequency output to cause either cancellation or addition with the

subwoofer. This would be true if the full-range system is a very small loudspeaker, like

those that are used for front-fill and underbalcony fill.

(2) The placement of the subwoofer in relation to the full-range loudspeaker is not

optimum. Little or no response variation will occur if the physical relationship results in

an approximate ¼ wavelength of offset at the center of the crossover frequency.

The solution to (1) is for both systems to remain in positive polarity. No harm will occur if

the full-range system simply does not reproduce enough low-frequency energy to either

add or cancel with the subwoofer’s output.

The solution to (2) is to either change the physical relationship of the two systems, or to

delay one of the two systems (whichever one is positioned closer to the listeners) with a

digital delay. A high-quality, high resolution measurement system that can read and depict

phase response or impulse response would be very useful in this situation. However,

without such a system, you can determine an effective delay time by trial and error.

Simply increment the delay time in small steps (1 ms), until the action of reversing the

polarity produces maximum cancellation in one orientation and maximum addition in the

opposite. By using a digital delay, you will have preserved the phase and impulse response

of the system and you can now filter out any objectionable mid-bass overlap with an

equalizer.

If a delay is not available, it is recommended that either the subwoofer or the full-range

loudspeaker be relocated closer together, so that reversing the polarity of either the

subwoofer or the full-range loudspeaker (but not both at once) will result in a distinct dip at

crossover as discussed above.

If this cannot be done due to physical restrictions, the subwoofer and the full-range

loudspeaker should be moved further apart, again until there is a distinct dip at the

crossover frequency in one position of polarity. It may take some trial and error to

determine the optimal physical relationships.

C-TIP: It’s a good idea to experiment with different loudspeaker locations by conducting

listening tests before you finalize the locations (especially important in permanent

installations). Make sure to use live microphones and live instruments (if applicable), as

well as track playback. Choosing the physical location of the loudspeakers in the room is

always the most important part of any successful system installation.

Note that in some acoustical environments, the system may sound better when the phase

relationship is non-optimum resulting in a dip at crossover, compared to optimum phase

where the crossover region is accentuated by the overlap of the subwoofer and the fullrange speaker(s). However, this is not the best way to achieve the sound that you’re

seeking. The proper course of action is to equalize (EQ) the peak at crossover with a

parametric equalizer until the response is flat, or until you’ve achieved the tonal response

you desire (we’ll explain why below).

Alternatively, you might insert a high-pass filter in the full-range system (typically at 80 –

100 Hz with a 12dB/octave slope), so that the overlap with the subwoofer is reduced in

magnitude.

A third technique is to increase the slope of the crossover to 24 dB per octave or 48 dB per

octave, if the crossover has such capability, thereby reducing the bandwidth of the

spectrum in which the two sources overlap.

There’s an important reason for taking one or more of the measures discussed above. If

that nice-sounding response dip at crossover is in fact due to phase cancellation, it means

that the drivers and amplifiers will be working harder than they should to produce less