Page 1

CONSTRUCTION HINTS FOR THE EB27A

These construction hints for the EB27A are only to supplement the Engineering Bulletin

and are not meant to be used as a construction manual.

HEATSINK PREPARATION

A heatsink of sufficient size to dissipate over 300 watts of power should be used. The

heatsink should be marked, drilled, and tapped before construction begins on the PC

board. Using the bare PC board as a pattern, lay the PC board on the heatsink in the

desired position and mark the four mounting holes and the mounting hole for D1. Drill

and tap the four mounting holes and the hole for D1 for 4-40 screws. Then bolt the bare

PC board flush on the heatsink and place the RF transistors through the PC board so

they rest on the heat sink. Mark the mounting holes for the RF transistors. Remove the

PC board from the heatsink and drill and tap the mounting holes for the RF transistors

(4-40 screws). The heatsink can also be fitted with connectors, cover, etc. at this time if

so desired.

1

Page 2

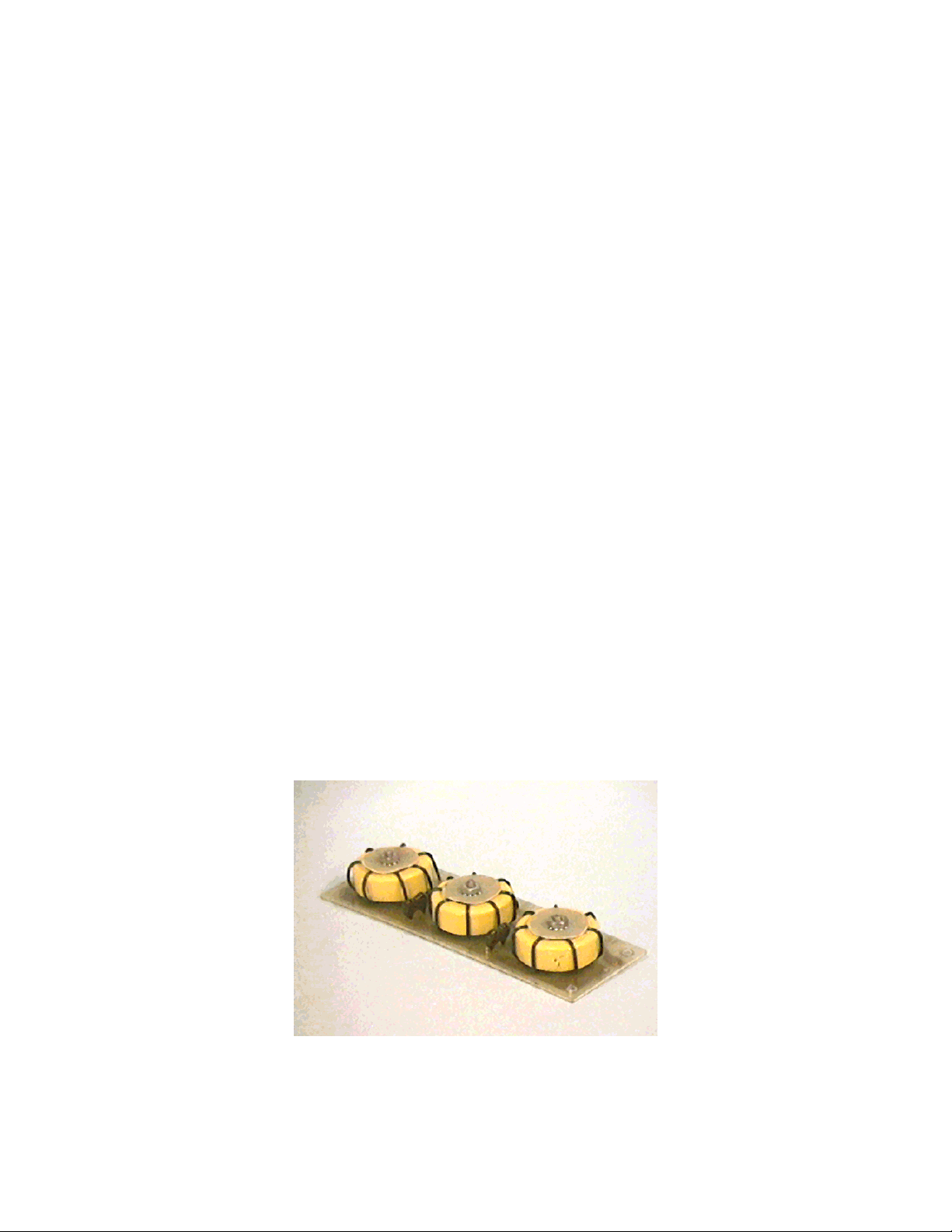

BROADBAND TRANSFORMERS

Just a quick word about the broadband transformers. The low impedance winding of the

input (T1) and output (T3) transformers consist of one winding. Two metal tubes form

the low impedance winding. The tubes are electrically shorted on one end by a piece of

copper-clad laminate (PC board) with holes for the tubes. The tube ends are soldered to

the copper foil. A similar piece of laminate is soldered to the opposite ends of the tubes

and the copper foil is divided into two sections, thus isolating the ends where the primary

connections are made. The high impedance winding is formed by threading Teflon

insulated wire through the tubes for the required number of turns. The transformers are

loaded with ferrite material to provide sufficient low frequency response.

PC BOARD ASSEMBLY

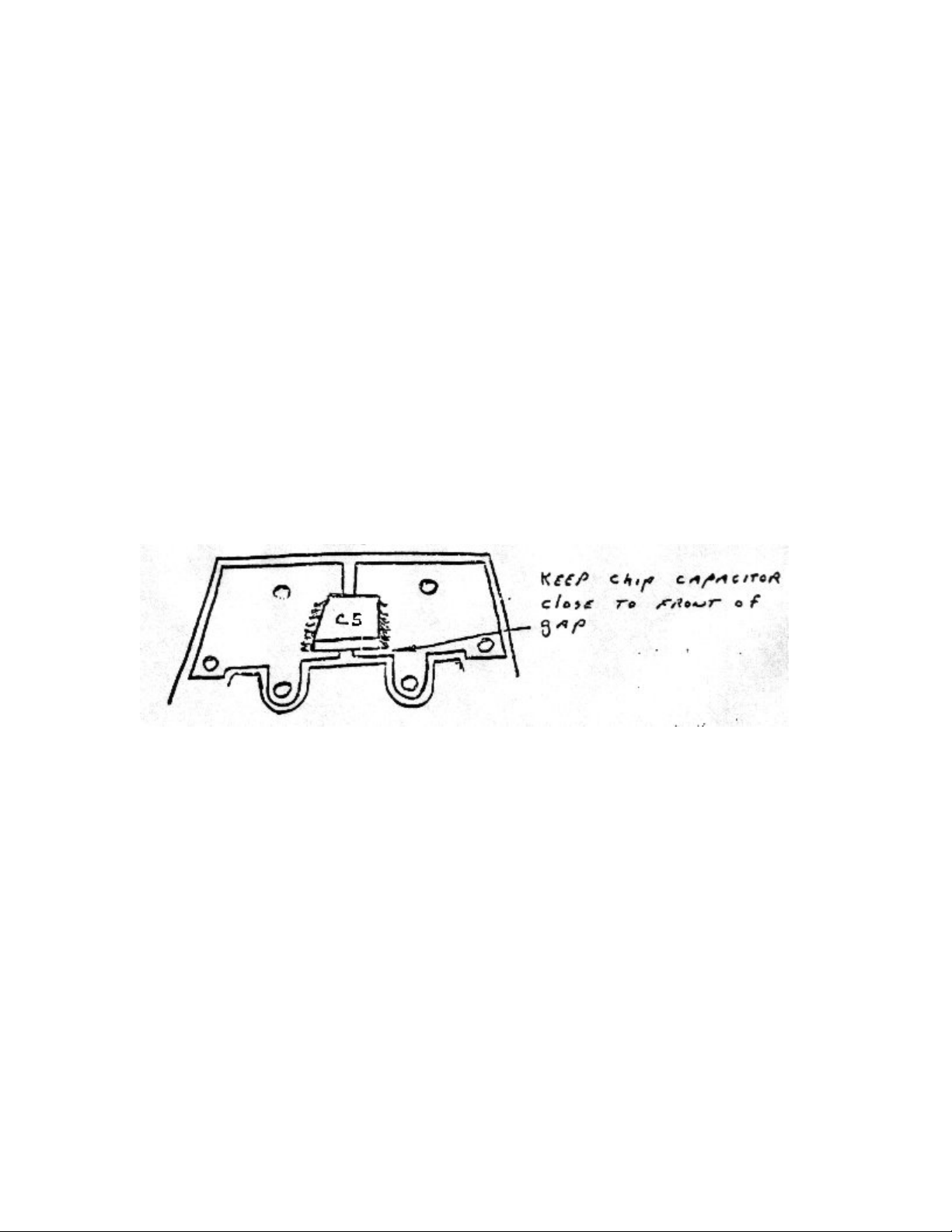

Flow some solder (a very light coat) on the PC board where the input end of T3

will be mounted and install the chip capacitor, C5. See Figure 1.

Figure 1

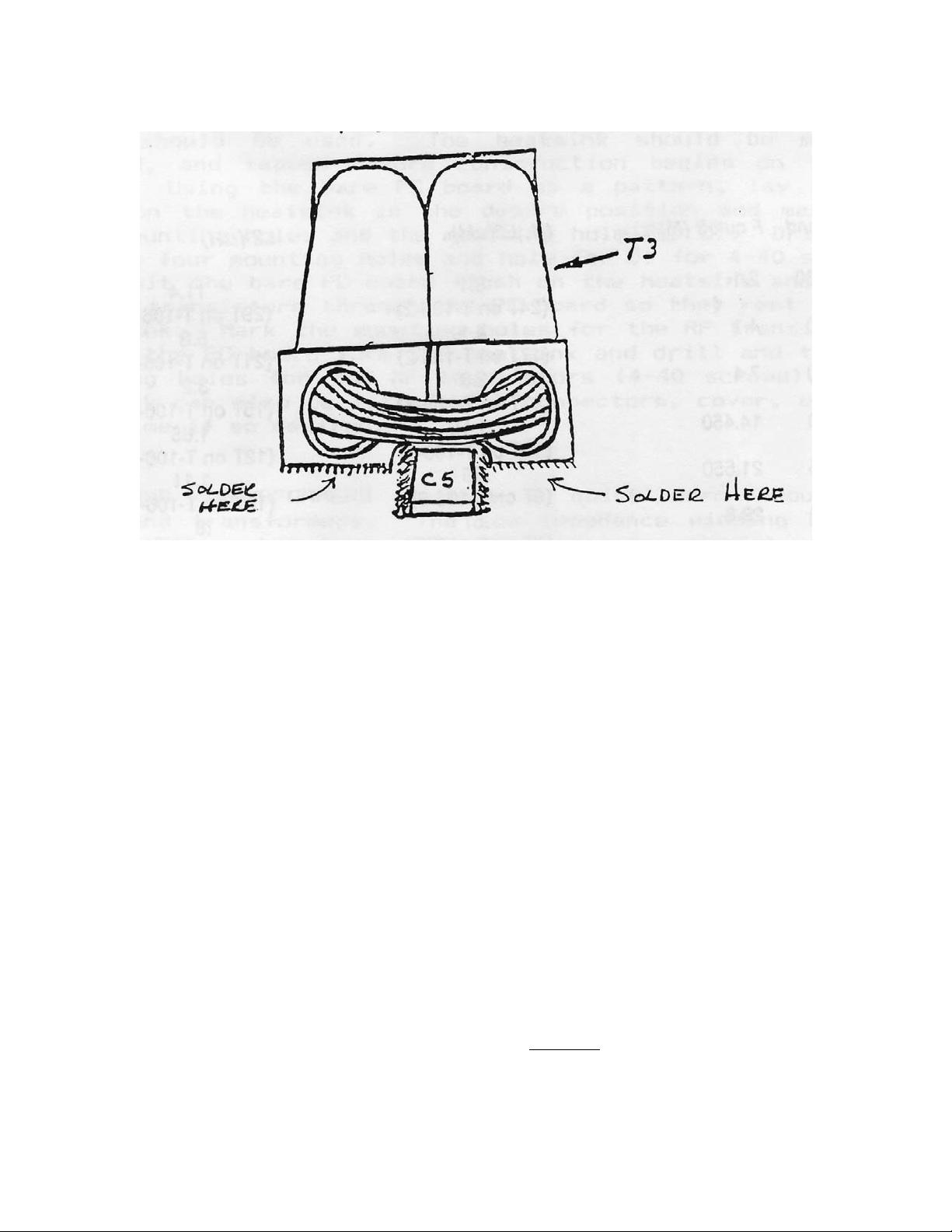

Strip the leads of the output transformer (T3) to ¼ inch of insulated wire from the

transformer end.

Place the leads of T3 into the proper holes on the output side (the transformer

must be installed with the wide gap on the input end placed down on the PC board).

Place a piece of Mylar, Teflon, or similar piece of insulating material under the

transformer, T3 to prevent it from shorting to the ground plane. Position the transformer,

T3 close to the chip capacitor, C5 on the input end of the PC board. Solder the splitends (two places) to the PC board with a fillet of solder (make sure the transformer is

held flat against the PC board). See Figure 2.

2

Page 3

Figure 2

Solder the wire leads from the output of T3 to the PC board. Clip the excess

leads close to the PC board.

The input transformer T1 is mounted next. Strip the wire leads back to

approximately 3/16 inch of insulated wire from the transformer end. If swage pins are

used (optional) mount them in the two holes on the PC board and solder on the bottom.

Insert the insulated wires in their holes and position the split-end of the transformer up

against the swage pins and solder. The transformer must be insulated from the PC

board using a piece of Mylar, Teflon, or some similar insulating material. In lieu of

swage pins, short pieces of #20 bus wire or something similar can be inserted into the

two holes on the PC board and soldered. Then bend the ends of the wires over to the

split-ends of the transformer and solder. Clip all Excess leads.

Install the regulator (MC1723). Match the TAB orientation of the regulator with

the notch on the PC board and push the device down to within 3/8 inch of the PC board.

Solder the regulator in place. (Be very careful …!!!, the PC lands in this area are

extremely close and solder bridges are easy to make.) Clip the excess leads.

Install the potentiometer (push it firmly down in place on the circuit board and

solder it in place). Note: The pot must be installed BEFORE

because of an interference fit between the pot (certain manufacturer) and the 1K resistor.

Clip the excess leads.

resistor R7 is installed

3

Page 4

Install all of the ½ watt carbon resistors in their proper locations (refer to the

placement layout in the Application Note and solder in place. Clip the leads closely to

the PC board.

The PC board includes provisions for an attenuator to attenuate the RF input

signal to the amplifier. If an attenuator is not needed, place a wire jumper in the position

shown in Figure A of the component placement diagram (above the trimmer resistor,

R11).

The 2N5990 and 2N5991 transistors are now obsolete. These transistors had an

unusual pin configuration for which a direct physical replacement is not available. Helge

Granberg from Motorola suggested using the 2N6488 transistor as a substitute.

However to fit the PC board configuration, the transistor must be mounted upside down

as shown in the Figure 3 below.

Figure 3

Position the pass transistor Q3 upside down over the screw hole. Bend the leads to fit

the hold pattern (Note: the metal side of the transistor facing up away from the PC

board). Using the 1/8 inch metal spacer, install the 4-40 x 3/8 inch screw from the

bottom up through the spacer and transistor and install a #4 KEP nut and tighten

snuggly. Solder the transistor leads from the bottom and clip the excess leads.

The transistor D1 mounts on the bottom of the PC board. Position the transistor

D1 over the screw hole. Trim the leads back to fit the lands on the PC board. (Note: the

metal side of the transistor must be away from the PC board, (i.e., toward the heatsink).

The collector lead can be trimmed off or soldered to ground with the emitter. Solder all

leads snugly against the board.

Install the ferrite chokes (2). Make sure the lead wires do not short out any of the

turns going through the chokes. Push the chokes down flat against the PC board and

solder. See Figure 4. Clip the excess leads close to the PC board.

4

Page 5

Figure 4

Install the current measurement loops on the output end of the PC board. These

are the two “U” shaped #18 wires with three (3) ferrite beads on each leg. If large beads

are used, use #16 wire for the loops. Solder the loops in place and clip the excess leads

close to the PC board.

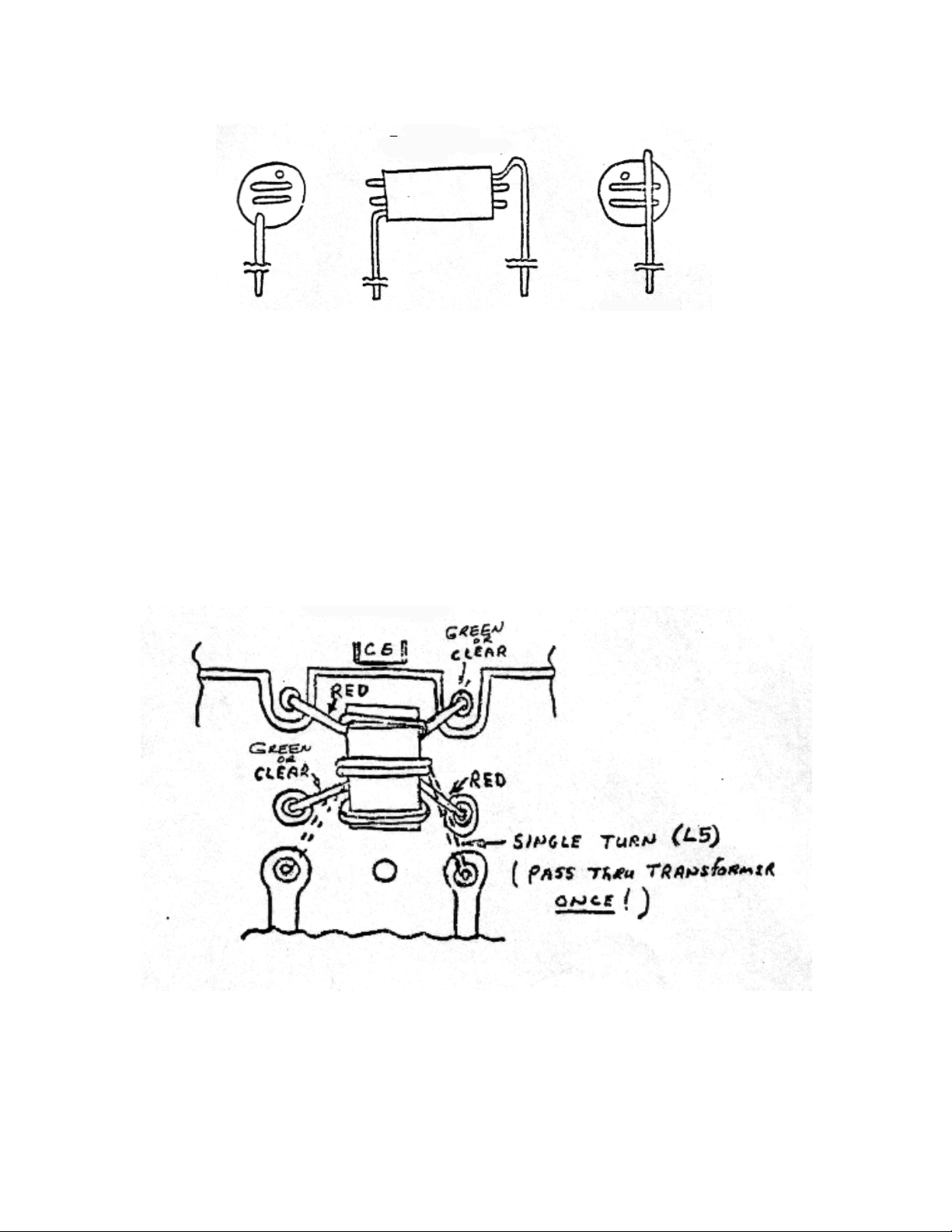

Install T2 (remove the extra short piece of wire supplied and save it). CAUTION:

The phase of these remaining leads is critical! They must cross in an “X” fashion, e.g., if

the red wire is closest to the output transformer T3 on one side, its other end must be

installed diagonally in the hole closest to the input transformer T1 (and vice versa for the

other wire). See Figure 5.

Figure 5

Note: there are six remaining holes and the heavy five turn leads are installed in the four

(4) holes closest to the output transformer T3 (make sure the insulation is scraped from

the leads before installation!). Solder and clip the excess leads close to the PC board.

5

Page 6

Cut the extra short piece of wire (L5) to 1 ¾ inch and scrape the insulation 3/8

inch back from each end. Install this wire through T2 and into the remaining holes in the

PC board (pass the wire through T2 only once!). Solder and clip the excess leads close

to the PC board.

Install the 47 ohm 5 watt resistor. Solder and clip the excess leads close to the

PC board.

Install the 470uF (470uF or 500uF) 6.3 volt capacitor (observe the polarity).

Solder and clip the excess leads close to the PC board.

Install the 10uF 100 volt capacitor (observe the polarity). Solder and clip the

excess leads close to the PC board.

Turn the PC board over and install the chip caps in the locations shown in the

Application Note. Install one capacitor at a time (open the envelopes carefully! – some

of the capacitors are very small). CAUTION: When soldering chip capacitors, flow a

small portion of solder on the PC board circuit and hold the capacitor in place. Put some

solder on the iron and tack one end in place. Do not let the iron touch the capacitor end,

but rather let a fillet build up between the board, the iron, and chip cap. The chip

capacitor ends will not take excessive heat.

This completes the PC board construction except for the RF transistors. Clean

the PC board if so desired, and inspect closely for solder bridges between the PC board

foil lands.

At this point, an intermediate electrical check can be performed to ensure that the

bias supply is functioning properly. Too large a bias voltage will destroy the RF

transistors..!! The bias supply check is performed before the RF transistors are mounted

on the PC board. Temporarily solder a 15 to 47 ohm 1//4 watt resistor between one of

the RF transistor base pads and the ground plane on the PC board. The resistor will

provide a small load for the bias voltage regulator. Apply 28 volts to the amplifier and

monitor the bias voltage across the resistor with a digital voltmeter. The voltage should

vary approximately 0.5 to 1.0 volts when the variable pot is varied through it range. If

the bias supply is working properly, set the pot to the minimum bias voltage (around 0.5

volts). When the bias is set later, the typical operating bias voltage will be around 0.68

volts. Remove the 15 to 47 ohm ¼ watt load resistor. This completes the bias voltage

regulator check.

Install the PC board on the heat sink with screws and 1/8 inch spacers or #6 nuts

used as spacers (not supplied). Apply thermal compound to the bottom of transistor D1.

The outmost 1/16” to 1/8” end of each RF transistor lead can be bent up at a 90

degree angle (this procedure is optional but will aid in removal of the RF transistor

should it ever become necessary).

Install the RF transistors with the clipped collector lead toward the output

transformer. CAUTION: Be sure to use thermal compound under the transistors (not

supplied). Fasten the transistors to the heatsink with 4-40 screws. Solder the

transistors in place.

6

Page 7

This completes the assembly of the amplifier PC board. The unit may now be

tested.

TESTING

1. Connect a power supply of suitable current output to the amplifier. A regulated

power supply capable of delivering 28 volts DC at 25 amps is recommended for

this amplifier operation.

2. Connect the RF output of the amplifier through a power meter to a suitable 50

ohm dummy load of a rating capable of handling the power output (use a quality

50 ohm coax cable).

3. The potentiometer should be turned fully clockwise when the bias voltage was

set to minimum volts at the end of the bias voltage regulator test.

4. With a DC current meter connected in the power lead and without any RF applied

to the amplifier input, turn on the DC power supply and adjust the bias

potentiometer to the recommended idling current noted in the Application Note.

The minimum recommended collector idling current is 100mA per device or

200mA total.

5. Slowly bring up the input RF power until the RF output power equals the

maximum power recommended in the Application Note.

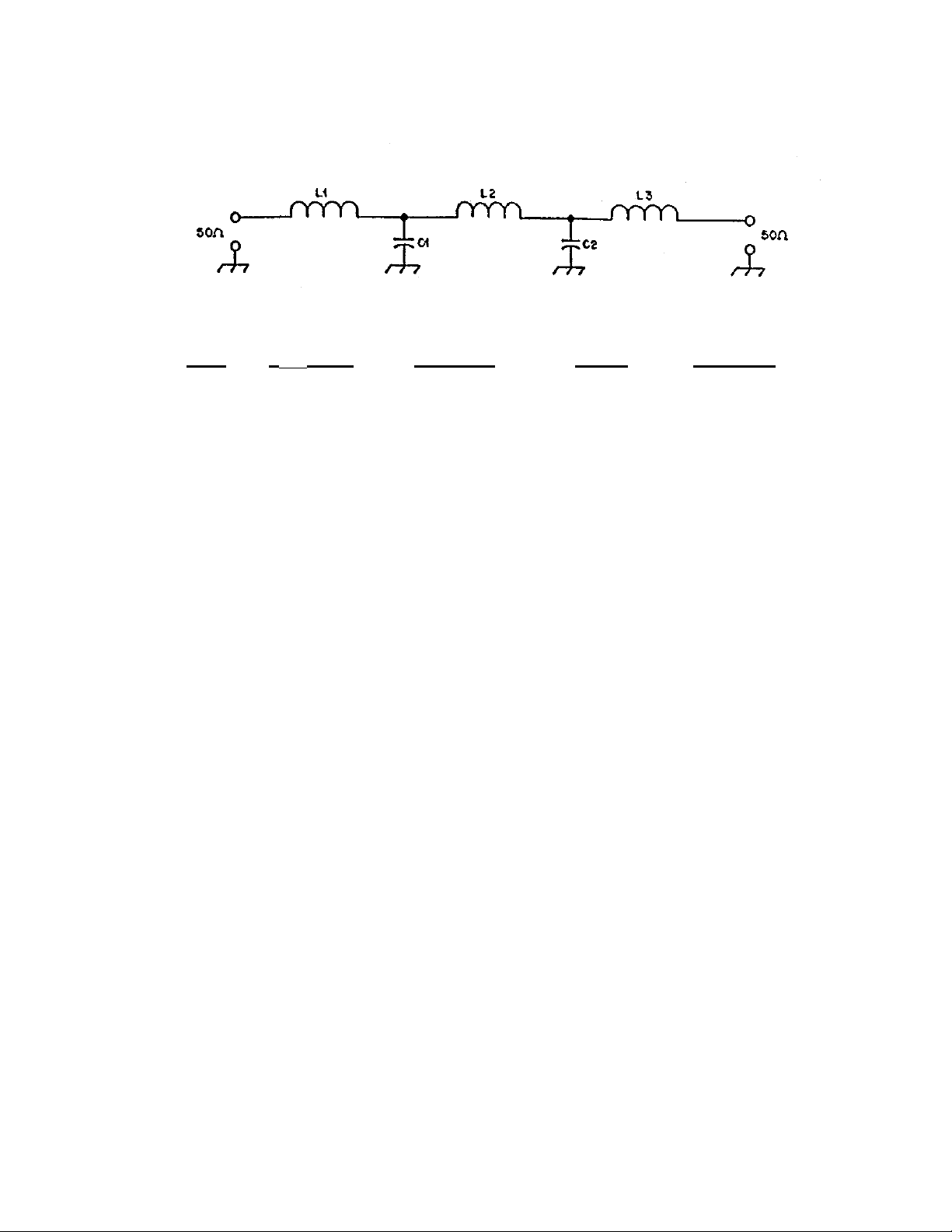

6. The output of the amplifier will contain harmonics of the input signal. Low pass

filters must be used on the output of the amplifier to reduce the harmonics to

meet FCC regulations for spectral purity. The filters shown in Figure 6 will

provide more than sufficient harmonic attenuation with less than 1 dB insertion

loss at the operating frequency.

7

Page 8

Band

160 2.1 8.1

80 4.1 4.1

40 7.4 2.3

20 14.450 1.18

15 21.550 0.79

10 29.8 0.57

F

(MHz) L1, L3 (uH) L2 (uH) C1, C2 (pF)

cutoff

11.4

(23T on T-106-2)

(16T on T-106-2)

(12T on T-106-2)

(9T on T-106-6)

(7T on T-106-6)

(6T on T-106-6)

Figure 6

(28T on T-106-2)

5.8

(20T on T-106-2)

3.2

(14T on T-106-2)

1.65

(11T on T-106-6)

1.11

(8T on T-106-6)

0.8

(7T on T-106-6)

1653

847

470

240

161

117

8

Loading...

Loading...