Table of Contents

•Tools and Material Requirements…………………………………..2

•M2M-W02 Unit Overview……..…………………………………. 3

•M2M-W02 LED Overview …… ………………………….………4

•M2M-W02 Installation Overview…………………………….…..5

•Step by Step installation …………………………………………... 6

-Aligning and Mounting the unit………………….………..6

-Pulling Wires…………………………….………….….…..7

-Connecting Wires……………………………….…..……..7

-Clean up and weather protect………………………...….9

-Calibration………………………………………..….……..9

-Verification…………...………………….…………..……10

1

M2M-W02 (Wireless Monitor Controller)

INSTALLATION GUIDE

This is a Step by Step guide to help you correctly install the M2M-

W02 controller. Please note that not all sites are the same, and

that this guide only deals with a couple of site possibilities.

Tools and Material Requirements:

•Flat head screwdriver

•Small Phillips head screwdriver

(preferably magnetic)

•Open end connectors (minimum

of 8 per site)

•Female connectors (minimum of 4

per site)

•Drill with approximately 13/16

hole bit, or multi hole bit.

•Silicone tube w/ gun

•3 to 4 self tapping metal screws

•Nipple w/ nut to pull wires through

•Wire cutter, stripper, and crimper

2

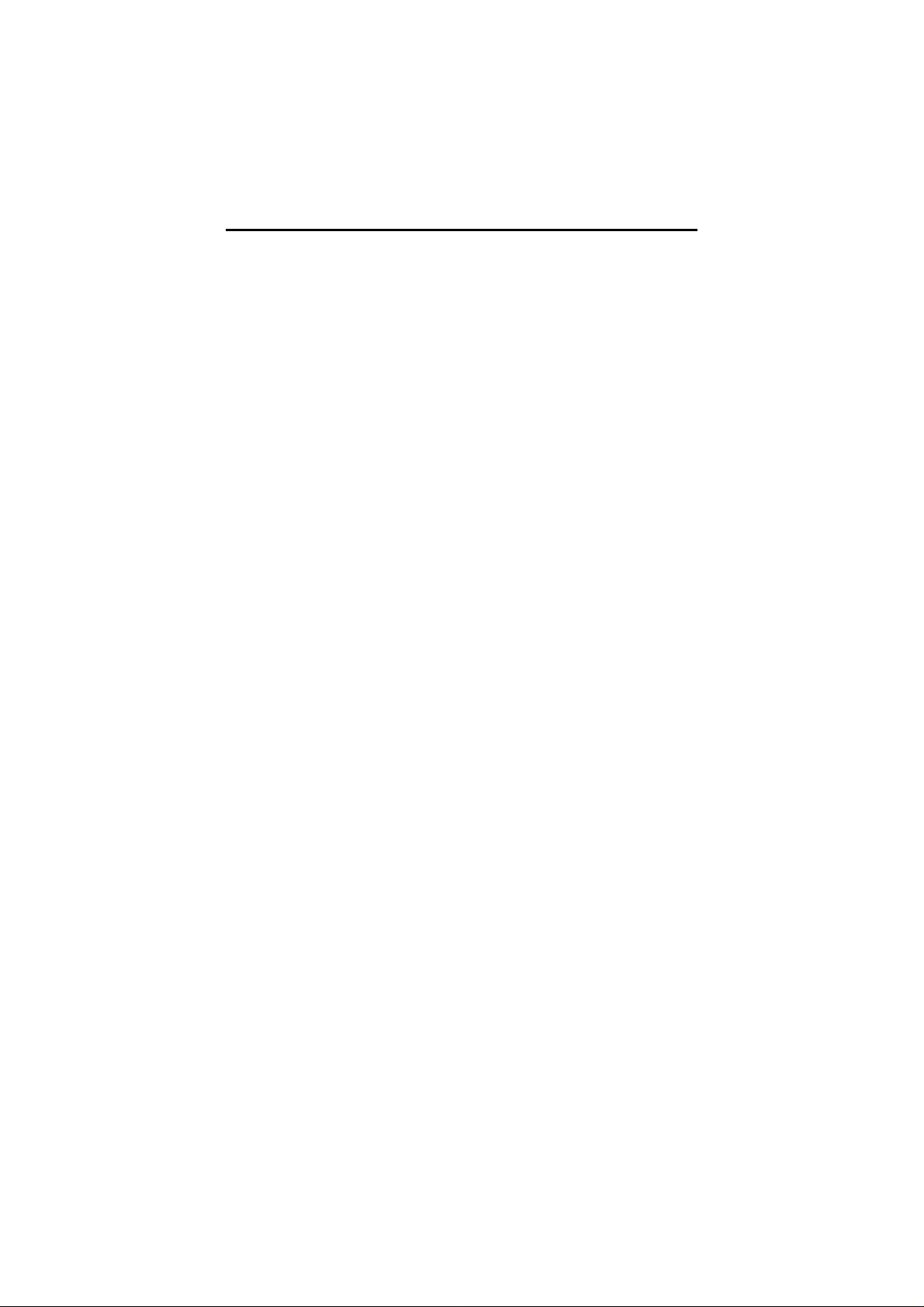

Battery

LED’s

Neutral

M2M-W02 Unit Overview

Cellular Module

SIM card

Current Sensors

Relays

Relay

Outputs

Power

Relay Inputs

Battery: So the controller will stay online in case utility power is lost

Current Sensors: Measures the amp reading during each on/off cycle

Cellular Module: Communicates with the cellular network to send and receive data

SIM card: Is the unique cellular address specific to the controller (same as a phone number)

Relays: The main control for turning the lights on and off

Relay Outputs: Wires going to the lights, once relays are activated voltage will flow throw these

wires to the lights.

Relay Inputs: Coming off the breakers to the relays, source voltage to the lights

Power: Connects to the Utility power from the breaker to power the controller

Neutral: Return path for the voltage, connects with the neutral from the breaker box

LED’s: Indicators to let you know what the controller is currently doing at any given time.

3

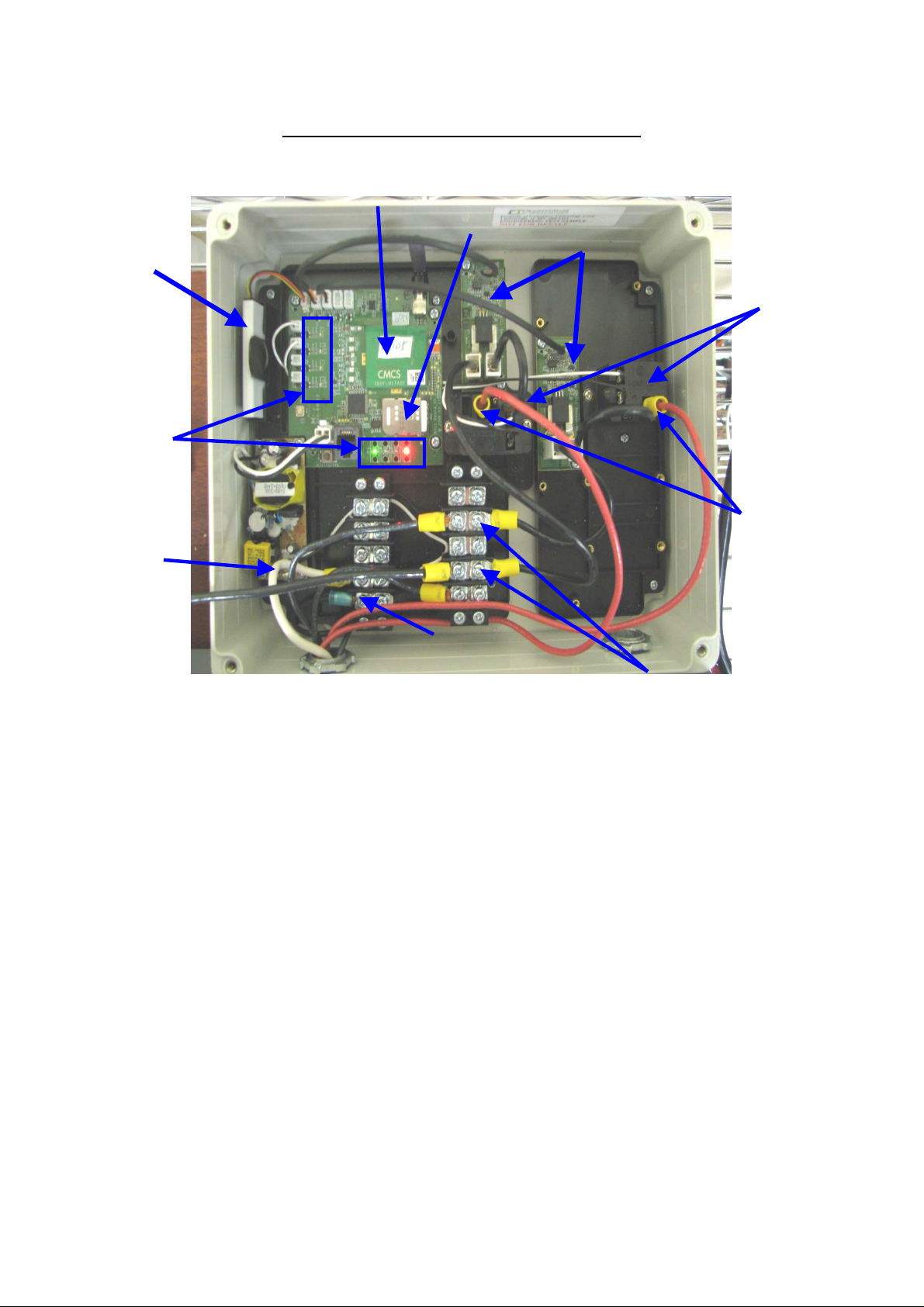

Relay

“on”

signal

LED’s Overview

Cellular

Connection

Receiving signal

Utility

Power

System Heartbeat

• Utility Power: (Red LED) Solid when the controller is connected to utility power

• System Heartbeat: (Green flashing LED) Flashes whenever the system is powered and

operating properly

• Receiving Signal: (Yellow LED) Shows when the controller is currently receiving a message

• Cellular Connection: (Green LED) Flashes if the controller is trying to connect or Solid when

connected to a cellular connection

• Relay “on” signal: (Red LED’s) Solid if the corresponding relays are on

During the calibration process there are a couple of combinations to the LED’s that also mean

something:

• When you receive system information messages you will notice that the Yellow LED will first

turn on showing it is receiving a message, but then both the middle LED’s will then flash

together for about 1 minute while it processes the message.

• Also, after you press the calibrate button the middle two LED’s should flash rapidly together

for about 20 minutes while the lights are warming up. And that is also when the Relay “on”

LED’s should also light up

4

Installation Overview

1. Activate the SIM card in the M2M-W02 monitor.

2. Turn all breakers off.

3. Determine where to mount the M2M-W02 monitor based on the site. Select a location where the M2M-W02 can

be mounted firmly in place, not interfere with access to (or the operation of) other equipment and where you will

have easy access to the required utility power.

4. Mark where to make a hole through the M2M-W02 enclosure for mounting.

5. BEFORE DRILLING any holes in the M2M-W02 enclosure remove the base plates inside the M2M-W02 monitor

with a magnetic Phillips head screwdriver (7 small screws).

6. Once the M2M-W02 enclosure is empty, drill the hole you marked in Step 4 through the enclosure and the

breaker box and drill 3 or 4 self-tapping screws into the M2M-W02 enclosure for mounting.

7. Securely mount the M2M-W02 enclosure to the breaker box and replace the base plates.

8. Pull wires through the True Tracker: Controller AC; Neutral; Relay Inputs (from circuit bre aker to relay) and

Relay Outputs (from relay to lights).

9. Refer to the wiring diagram that matches the site configuration and connect each wire inside the M2M-W02

enclosure as shown in the wiring diagram.

10. Seal the outside edges of the enclosure with silicone to protect from the environment.

11. Wrap the wires into the breaker box with electric tape or a tie wrap so they are neat and easy to work with in the

future.

12. Turn circuit breakers back on (Look for red and green LEDs to illuminate inside of the M2M-W02 monitor)

13. After the red LED inside of the M2M-W02 monitor is illuminated, plug in the Battery

14. After the green LED stops flashing and is solid green the M2M-W02 monitor has connected to the cellular

network.

15. Call Commtiva Technology Corp. to have information sent to the M2M-W02 monitor to enable it for operation.

You will need to provide site and location information such as number of panels, number of lights on each panel

and the SIM card number associated with the M2M-W02 Monitor.

16. Once the M2M-W02 monitor receives the required information the Yellow LED will light up.

17. Shortly after the Yellow LED illuminates the 2 middle LEDs (1 will be Yellow and 1 will be green) will flash

simultaneously for about 1 minute.

18. Once the 2 middle LEDs (1 will be Yellow and 1 will be green) stop flashing press the Brown calibrate button on

the main controller board. This will turn the billboard lights on for 20 minutes. During this time the 2 middle LEDs

(1 will be Yellow and 1 will be green) will flash rapidly and the relay “ON” LEDs will light up.

– SEE LED’s Overview on previous page

19. Verify that the M2M-W02 monitor is operational by confirming that the billboard lights are ON, or use an amp

clamp or current meter to see if the output wires are drawing any current. If the lights are on they should be

drawing current. You can figure about 4 amps per bulb on a 120V setup or 2 amps on a 240V setup.

20. After you have verified the M2M-W02 monitor is operational fasten the enclosure lid securely so no moisture can

get in.

5

STEP BY STEP GUIDE

As soon as you reach your work area the first thing

you should do is shut off each breaker to avoid

electrical shock (Illustration 6.1). You can also take

the top cover off of the M2M-W02 unit right away.

Keep in mind what is behind the door, as

there are only two places you can drill a

hole in back of the M2M-W02 enclosure

(see the red circles in Illustration 6.3). Try

to make it easy to reach each all of the

wires you need: Utility power, Neutral,

inputs and outputs off the relay(s).

In order to drill a hole you must take off

the base plates inside the enclosure, to

avoid damaging any parts while you drill

the hole.

Illustration 6.1 Illustration 6.2

Aligning and Mounting the Unit

Once the breakers are off a good place to start is to

find out where to mount the unit, in this example

(Illustration 6.2) it is mounted on the front of the

box. But in other cases it will also fit on the side or

the bottom of the box. Where it is mounted doesn’t

matter as long as it fits and can be mounted firmly.

If you are installing the unit on the front as shown,

be sure to leave room and extend the wires a bit

longer to allow the door to open and close with

ease.

6

Illustration 6.3

Be sure to mark where your going to drill

the hole before you take off the base plates.

(Illustration 6.3) There are 7 small screws

(blue circles in Illustration) that hold the

base plates on. It is best to use a magnetic

Philips screwdriver for these screws

because of their size.

The hole can be drilled in either the right or

left opening.

Be sure to also drill 3 or 4 self-tapping

screws into the box to mount it firmly. Once

it is mounted firmly you can then replace

the base plates that you took out earlier.

Pulling Wires

The example on the left is a 240v single face

board. So you will only need 6 wires to go from

the box and into the M2M-W02 Module. For

each additional relay in the box there will be 4

more additional wires to go to the M2M-W02

module on a 240v system (2 relay inputs and 2

outputs).

One of the wires you will need is utility power,

coming from the auxiliary breaker.

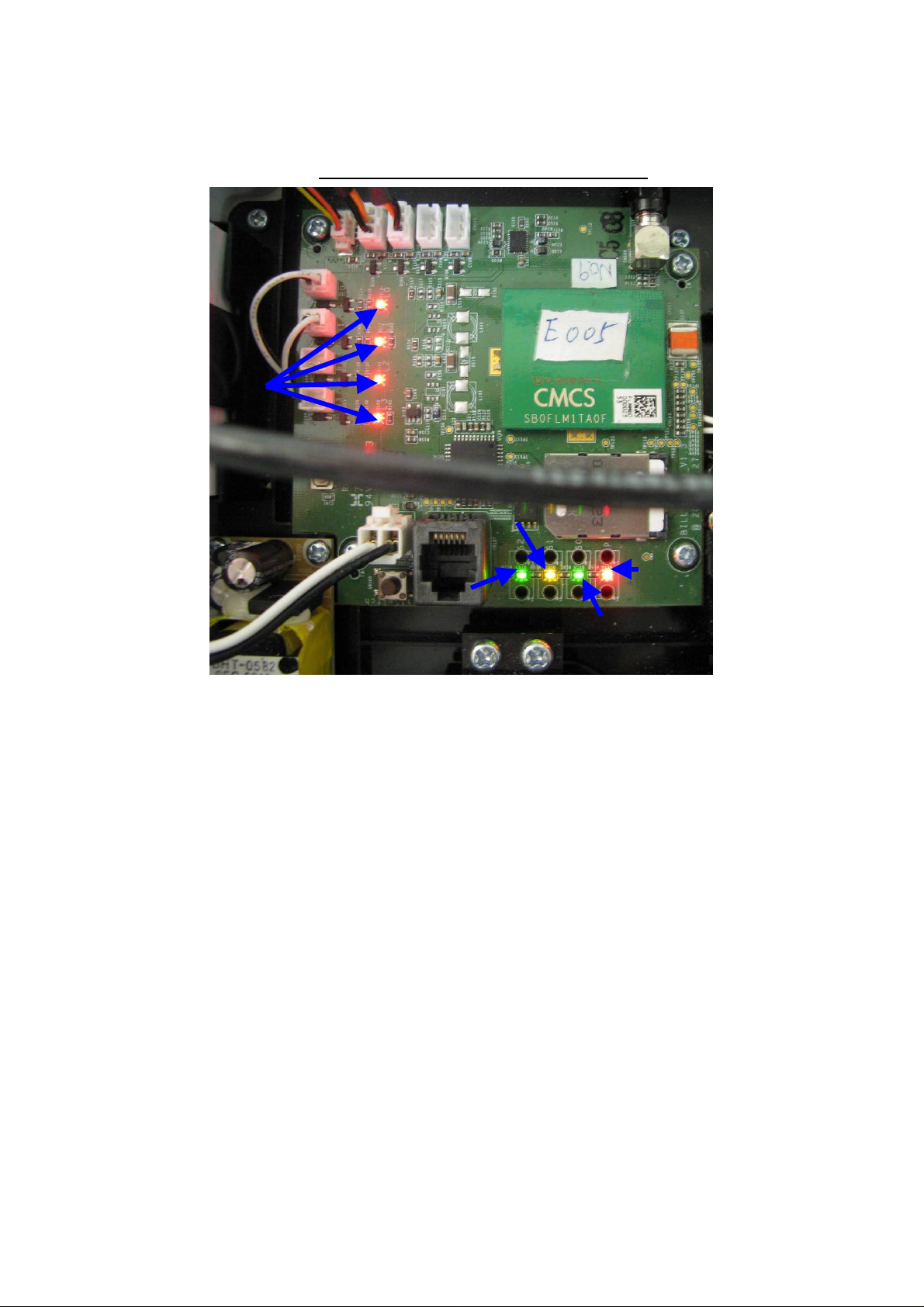

Connecting Wires

Now it is time to connect the wires to the

controller. (refer to Illustration 7.2) Begin by

pulling each wire through the hole you created

into the enclosure. The Utility power and

neutral will hook up next to each other on the

first connector block. Each will use an open end

connector. On the True Tracker, black is for the

power and white is for neutral.

The relay input wires will connect into the next

connector block using an open end connector.

For a detailed diagram on how you wire

different configurations please refer to the wiring

and configuration diagrams provided in the

Quick Install Guide that is in every M2M-W02

box.

The relay outputs will connect into the relays on

the module using a female connector.

Illustration 7.1

The relay inputs come off the breakers and

go to the relay inside the box (Illustration

7.1). Refer to the example on the right. You

will need one relay input for each relay in the

True Tracker. You will also need an output

wire for each relay that will deliver the

electricity to the lights when the relays are

on.

Another wire that you will need to go into the

unit is the neutral. Make sure that the exposed

copper is not corroded if you are using the

original wire.

Neutral (white)

Illustration 7.2

Utility power (black)

Relay outputs

Relay inputs

While making all of these connections inside the

True Tracker, try to keep each individual wire

neat and tucked away to prevent any

complications with future repairs.

7

North

15A

South

15A

East

15A

West

15A

120V 4Panel

Neutral

To lights

Auxiliar

y

15A

Neutral

R

3

Pan

el 4

S

3

R

2

Pan

el 3

R

0

S

2

Pan

el 2

R

If you have a 2 or more face board

however the order in which you

connect the wires does matter. In

this example (refer to Illustration

R0R1R2R3

S0

S1

S2

S3

8.1) you will see 4 relays inside the

M2M-W02 module. If you were to

have a 4 face board you would

connect the lowest panel number to

Relay 0 or “R0”. And the highest

S

0

panel number to relay 3 or “R3”

For Example if the panel numbers

were 2111, 2112, 2113, and 2114.

2111 relay outputs would connect

to R0 while 2112 would connect to

S1

1

R1, 2113 to R2, and 2114 to R3.

As for the relay input wires simply

follow from the relay to the

connection block to see which

Pane

wires match up.

l 1

Illustration 8.2 is a 2 face

board 240v. Again the

lower panel number would

go to the lower relay

numbers.

For example, if your panel

numbers where 2140 and

2141. Panel 2140 would

connect to R0 an R1 while

panel 2141 would connect

to R2 and R3.

Also keep in mind that

these relays are not

actually numbered and this

diagram is simply for

reference.

NORTH

30A

Nort

h

30A

SOUTH

30A

Sout

h

30A

Auxiliar

y

15A

240V 2Panel

R0R1R2R3

S0

S1

S2

S3

S0

R0

Neutral

S2

R3 R2 R1

Pane

8

l 2

Pane

l 1

Clean up and Weather Protect

Once the unit is wired make sure to seal around

the entire enclosure with silicone to prevent

moisture from getting inside. (refer to Illustration

9.1)

Be sure to remember to plug in the battery after

you turn the power on and you see the red light

on the controller board.

Illustration 9.1

Now would also be a good time to make

everything neat and easy to work on next time it

may need maintenance. This may also prevent

wires from stretching or breaking every time the

door is opened. You can also turn the power

back on at this time.

Illustration 9.4

Calibration

Once you have the power turned on you will

notice two lights right away, the red light, which

is utility power and the green light, which

indicates whether or not the module is

connected to a cellular network. If the green

light is flashing that means it is trying to connect

and once it is solid means it is connected.

Once it is fully connected to a cellular network

you can then get the information sent to the

module. (refer to LED overview for LED

information)

To get the information sent to the controller

please contact Commtiva via telephone

(815)344-0678. Commtiva will need to know

the panel numbers, how many lights are on

each panel the location of the board, and the

SIM card number. They will then program the

controller and set it up for operation. You will

know when the controller has received the

information when the yellow light on the board

turns on.

Illustration 9.2 Illustration 9.3

9

The 2 middle LED’s should then flash

simultaneously for about 1 minute. Once they

stop flashing together you can then press the

Brown calibrate button. (Blue circle in Illustration

9.4)

After you press the calibrate button on the

M2M-W02 board and you have verified that it is

working properly you can now put the cover

back on the unit make sure the lid is fastened

securely to ensure no moisture can get in.

Once the button is pressed you will notice red

LED’s turn on for each relay.

Pressing the calibrate button will turn on the

billboard lights for 20 minutes to allow them to

warm up. During this time the middle 2 LED’s

should flash rapidly. The module will then go

through a 10 minute sampling to take a current

reading and calibrate itself. You do not have to

wait for the module to complete this warm up

before you verify that it is working.

Verification

A quick and easy way to see if the module is

working is to see if the lights are turned on after

you press the calibrate button. Usually during

the daytime however it is hard to tell if they are

on.

The other easy alternative is to use an amp

clamp or current meter (refer to illustration 10.1)

to see if the output wires are drawing any

current. If the lights are on then they should be

drawing current. You can figure about 4 amps

per bulb on a 120V setup, or 2 amps on a 240V

setup.

Congratulations on installing the M2M-W02

successfully!

Illustration 10.2

10

Illustration 10.1

FEDERAL COMMUNICATIONS COMMISSION INTERFERENCE STATEMENT

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses

and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

– Reorient or relocate the receiving antenna.

– Increase the separation between the equipment and receiver.

– Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

– Consult the dealer or an experienced radio/TV technician for help.

CAUTION:

Any changes or modifications not expressly approved by the party

responsible for compliance could void the user's authority to operate the

equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject

to the following two conditions:

(1) This device may not cause harmful interference and

(2) This device must accept any interference received, including

interference that may cause undesired operation.

FCC RF Radiation Exposure Statement

This equipment complies with FCC RF radiation exposure limits set forth for an

uncontrolled environment. This equipment must be installed and operated in

accordance with provided instructions and must not be co-located or operating

in conjunction with any other antenna or transmitter. End-users and installers

must be provide with antenna installation instructions and transmitter operating

conditions for satisfying RF exposure compliance.

RF exposure warningThis equipment must be installed and operated

in accordance with provided instructions and the antenna(s) used for

this transmitter must be installed to provide a separation distance of

at least 20 cm from all persons and must not be co-located or

operating in conjunction with any other antenna or transmitter.

End-users and installers must be provide with antenna installation

instructions and transmitter operating conditions for satisfying RF

exposure compliance

Loading...

Loading...