Page 1

Software Reference Guide

Revision 11/07/2013

Page 2

Spotcheck Reference Guide

Page 3

COPYRIGHT © 2013 Bently Nevada, Inc & GE Energy (New Zealand) Ltd.

All rights reserved.

No part of this document may be reproduced, stored in a retrieval

system, or transmitted in any form or by any means, electronic,

mechanical, photocopy, recording or otherwise without the prior written

permission of Bently Nevada.

The information provided in this document is subject to change without

notice. Names and data used in examples are fictitious unless otherwise

noted. This document is distributed as is, without warranty of any kind,

either expressed or implied, respecting the contents of this document,

including but not limited to implied warranties for the document’s

quality, performance, merchantability, or fitness for any particular

purpose. Neither GE Energy (New Zealand) Ltd, nor its employees,

dealers, agents or distributors shall be liable to the user of this document

or any other person or entity with respect to any liability, loss or damage

caused or alleged to be caused directly or indirectly by this document.

Disclaimer

Information in this document is subject to change without notice. Names

and data used in examples are fictitious unless otherwise noted. This

document is distributed as is, without warranty of any kind, either

expressed or implied, respecting the contents of this document,

including but not limited to implied warranties for the document’s

quality, performance, merchantability, or fitness for any particular

purpose. Neither GE Energy (New Zealand) Ltd nor its employees,

dealers, or distributors shall be liable to the user of this document or any

other person or entity with respect to any liability, loss, or damage

caused or alleged to be caused directly or indirectly by this document.

Spotcheck Reference Guide

Page 4

Contents

SECTION 1: INTRODUCTION .......................................................................... 1

PRODUCT SUPPORT ...................................................................................................................1

ISO 10816-3:2009 Category and Definition .......................................................1

PRODUCT OVERVIEW .................................................................................................................2

STANDARD FEATURES ................................................................................................................3

UNITS OF MEASURE ...................................................................................................................4

STANDARD KIT ITEMS ................................................................................................................4

PRECAUTIONS..............................................................................................................................5

INSTRUMENT INPUT AND OUTPUT PORTS ..............................................................................6

FRONT PANEL..............................................................................................................................7

BATTERY PACK ............................................................................................................................8

Charge Battery Pack......................................................................................................8

Remove Battery Pack ....................................................................................................9

SECTION 2: INSTRUMENT BASICS ............................................................... 10

POWER ON/OFF ...................................................................................................................... 10

ACCELEROMETER SENSOR ..................................................................................................... 11

Sensor Guidelines ........................................................................................................ 12

VIBRATION OVERALL MEASUREMENTS ................................................................................ 13

DISPLACEMENT, VELOCITY, ACCELERATION ........................................................................ 14

TAKE VIBRATION OVERALL MEASUREMENT ........................................................................ 15

Tips for Taking Measurements .............................................................................. 16

ISO 10816-3 Vibration Alarms ............................................................................... 17

CHECK STATUS OF BEARING ................................................................................................. 19

Bearing Alarms.............................................................................................................. 20

TAKE TEMPERATURE MEASUREMENT ................................................................................... 22

Laser Safety .................................................................................................................... 25

SECTION 3: SUPPLEMENTAL READING ....................................................... 26

ISO 10816-3 MACHINE GROUPS OVERVIEW .................................................................. 26

ISO 10816-3 SUPPORT CLASSES OVERVIEW .................................................................. 27

ASSESS BEARING STATE ......................................................................................................... 28

APPENDIX: SPOTCHECK SPECIFICATIONS ................................................. 29

SERVICING AND MAINTENANCE ............................................................................................ 31

INDEX ............................................................................................................... 32

Spotcheck Reference Guide

Page 5

Section 1: Introduction

Section 1: Introduction

Please read this guide thoroughly before operating your new Spotcheck

device, and retain for future reference.

IMPORTANT! It is essential to follow all appropriate safety

precautions when working near rotating machinery!

LASER RADIATION

DO NOT STARE INTO BEAM

CLASS 2 LASER

Product Support

If you have questions that are not answered by this reference guide,

please contact help@commtest.com for assistance. Alternatively, visit

our website at http://www.commtest.com for additional resources and

telephone contact details.

ISO 10816-3:2009 Category and Definition

Mechanical vibration. Evaluation of machine vibration by measurements

on non-rotating parts. Part 3: Industrial machines with nominal power

above 15 kW and nominal speeds between 120 RPM and 15 000 RPM

when measured in situ.

Spotcheck Instrument Reference Guide 1

Page 6

Section 1: Introduction

Product Overview

The Spotcheck device is a microprocessor-controlled, handheld

machinery condition monitoring tool capable of measuring mechanical

vibrations using an attached accelerometer sensor and temperature via

an integrated infrared thermal sensor.

By comparing vibration velocity levels (inches per second RMS) against

the international ISO 10816-3:2009 standard, the device is also able to

display simple machinery health alarms.

When measuring bearing vibrations, alarms may indicate existing or

approaching bearing failures or seizures. These alarms are generated by

analyzing velocity (BV, in ips RMS) or acceleration (BG, in g RMS)

measurements at the higher frequencies typically associated with

bearing defects (above 1 kHz).

In addition to its vibration measurement abilities, the Spotcheck device

includes an integrated non-contact IR thermal sensor and laser pointer.

This sensor allows temperature measurements to be taken from

distances up to 2 meters (6.5 feet) away, locating potential mechanical

problems before expensive failures occur.

These measurement capabilities allow users of the Spotcheck device to

evaluate the condition of machinery in the field and determine whether

further mechanical investigation is required.

Spotcheck Instrument Reference Guide 2

Page 7

Section 1: Introduction

Standard Features

Standard features on the Spotcheck device include:

• Overall Vibration Measurement. The Spotcheck device

measures overall vibration values for rotating machinery in

velocity (ips RMS), acceleration (g peak) and displacement (mil

Temperature values are displayed in Celsius (°C) or Fahrenheit (°F) units.

An integrated laser pointer is used to indicate the measurement location

on the surface being tested. This feature is typically used to measure

bearing temperatures.

peak-to-peak).

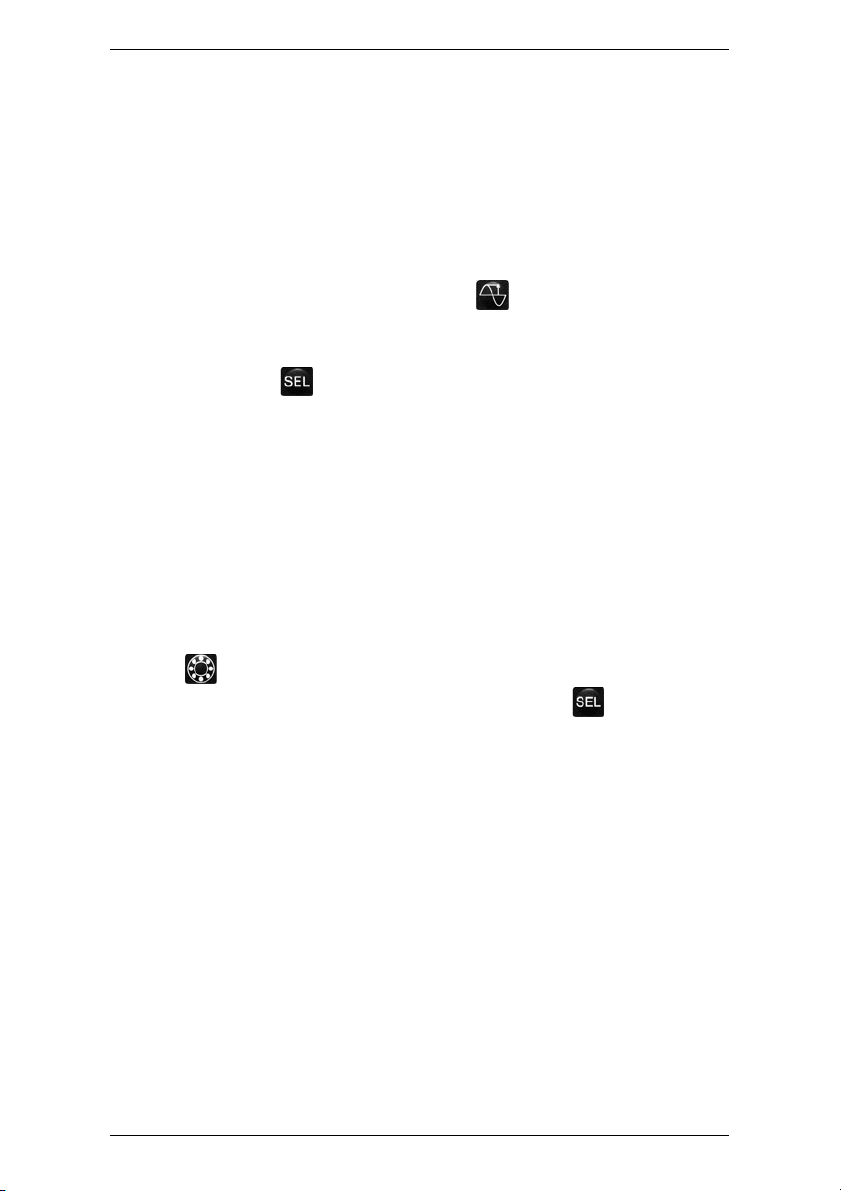

When measuring velocity, pressing the VIBRATION key will

'hold' the current measurement value onscreen and indicate an

alarm status according to the ISO 10816-3:2009 standard.

Pressing the SELECT key repeatedly will toggle between the

'machine groups' and 'support classes' that apply to this ISO

standard (machine groups and support classes are explained in

the 'Understanding ISO 10816-3 Vibration Alarms' section).

• Bearing Status Check. The Spotcheck device is able to measure

bearing vibration levels in velocity (ips RMS) and acceleration (g

RMS).

NOTE: Vibration acceleration and velocity levels for bearing

measurements include only frequencies between 1 kHz and 12

kHz.

When measuring bearing acceleration or velocity, pressing the

BEARING key will 'hold' the current measurement value

onscreen and indicate its alarm status. Pressing the SELECT

key repeatedly will toggle between bearing machine speeds,

allowing the selection of a bearing speed that most closely

approximates the speed of the bearing shaft.

• Temperature Measurement. The device's non-contact IR

temperature sensor measures surface temperatures between 20 °C and 120 °C (-4 °F to 248 °F) from distances of up to 2

meters or 6.5 feet.

Spotcheck Instrument Reference Guide 3

Page 8

Section 1: Introduction

Units of Measure

The Units of Measure are factory-configured to be either imperial or

metric, however you can change this according to your preference. The

table shows how the values are displayed in units.

Unit of Measure Metric Imperial

Acceleration g peak g peak

Velocity mm/s rms in/s rms

Displacement µm p-p mils p-p

Temperature °C °F

Standard Kit Items

The following kit items are included in your kit when you purchase a

Spotcheck device:

• Spotcheck portable device

• 3.6 V, 1700 mA rechargeable Lithium battery pack

• 100 mV/g accelerometer sensor with integrated 80 cm cable

(BNC connector)

• Magnetic accelerometer base

• Accelerometer stinger probe attachment

• Mains battery charger (AC 100-240 V, 50/60 Hz input; 4.2 V DC

600 mA output)

• In-car battery charger (DC 12-24 V input; 4.2 V DC 600 mA

output)

• Instrument Reference Guide

• Hard carry case

NOTE: Thoroughly inspect your kit's contents upon receipt. If any

kit items are missing, please contact Commtest customer support

or your sales agent for assistance.

Spotcheck Instrument Reference Guide 4

Page 9

Section 1: Introduction

Precautions

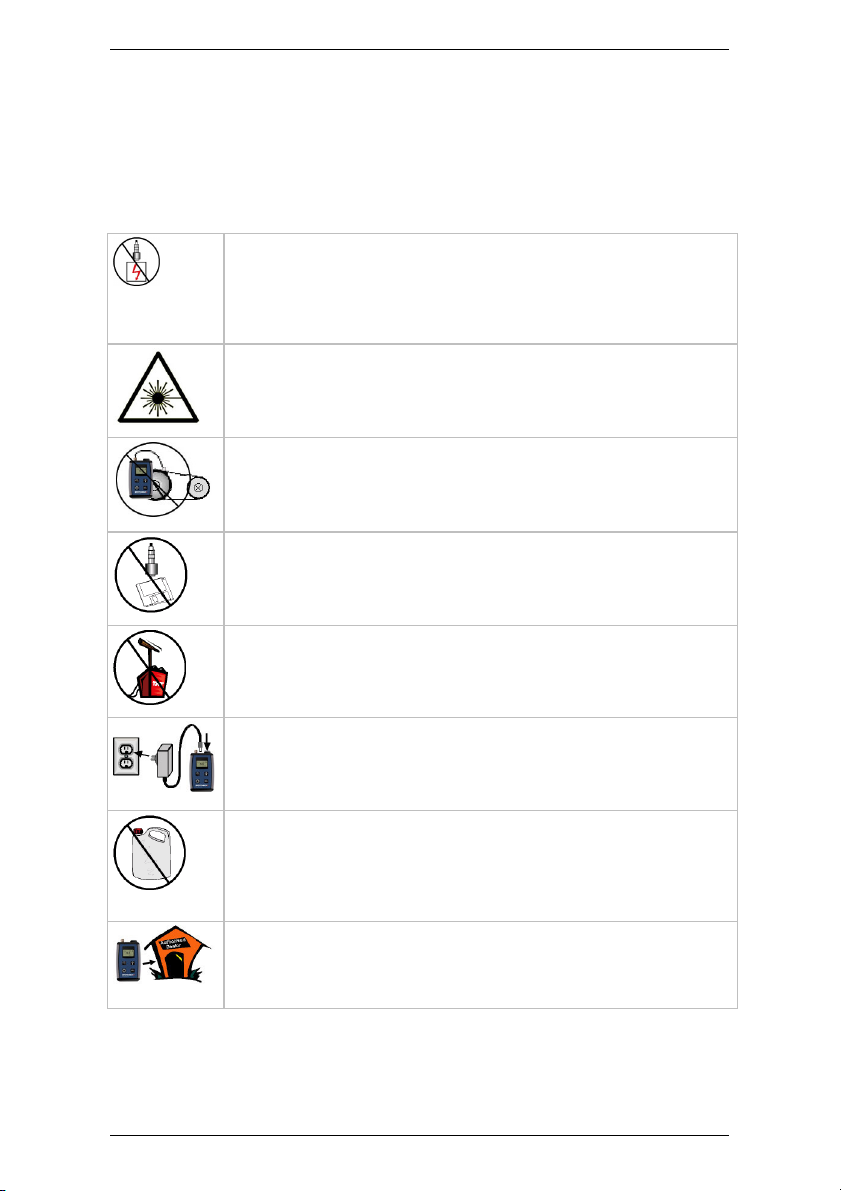

Please read and understand this section before operating your

Spotcheck device. Heed all warnings and recommendations to prevent

data inaccuracy, damage to the instrument, or injury.

Do not attach sensors to any object with a high potential

voltage i.e. a voltage that exceeds 50 V DC or 32 V AC or

the ‘safety extra low voltage’ (SELV) defined by your local

power authority.

Do not stare directly into the laser pointer, or point the laser

at others. Doing so may cause permanent eyesight

damage.

Ensure the accelerometer cable cannot become entangled

with any rotating or moving machinery.

Do not bring any objects sensitive to magnetic fields near

the magnetic mounting bases (e.g. credit cards, floppy

disks, mechanical watches).

Do not operate the instrument in an explosive environment.

Use only an approved power adapter 4.2 V, 600 mA output,

center positive.

Use a mild detergent diluted in warm water to clean the

device. Do not use abrasive or polishing substances,

hydrocarbons, petrochemicals or solvents, as they will

degrade the plastic casing.

If the instrument malfunctions, return it to an authorized

dealer. Do not attempt to repair the instrument yourself as

this will void your warranty.

Spotcheck Instrument Reference Guide 5

Page 10

Section 1: Introduction

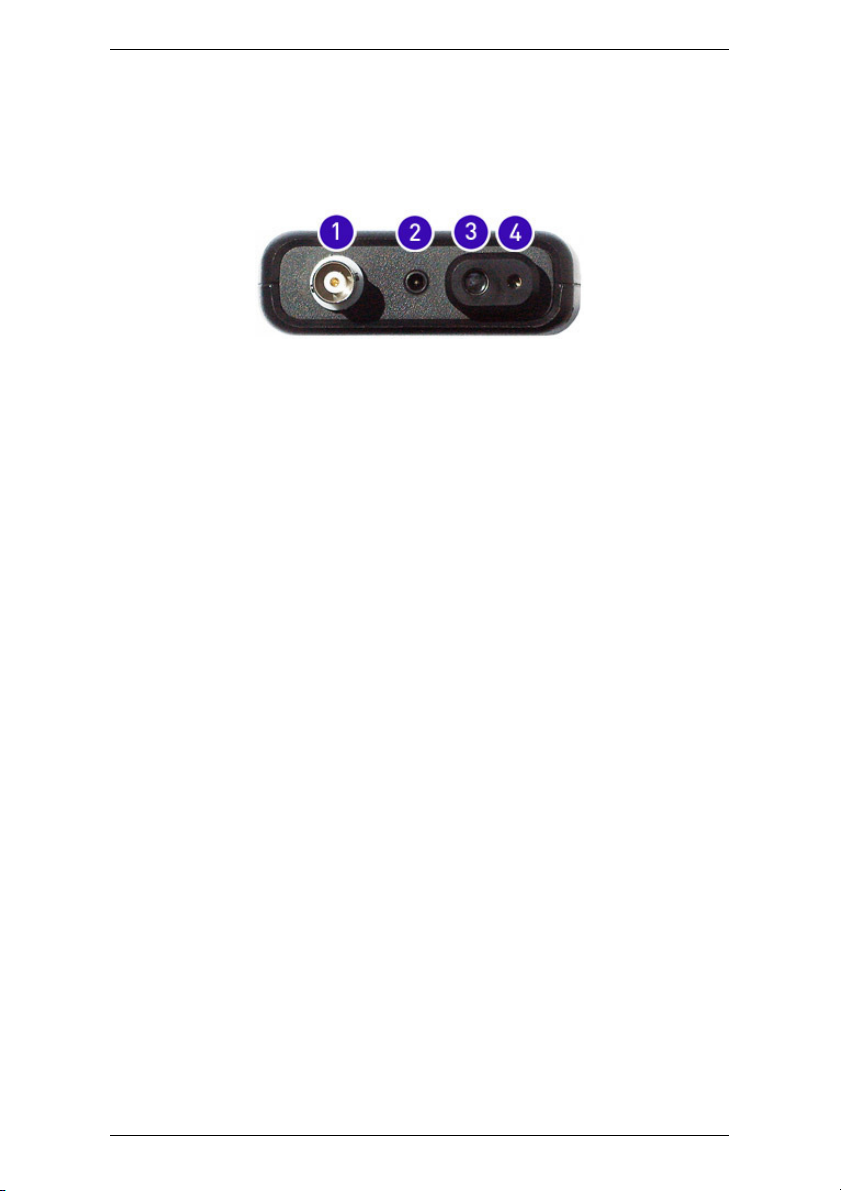

Instrument Input and Output Ports

The top panel of the instrument is equipped with the following Input and

Output ports:

Device Top Panel (I/O)

1. BNC sensor input

2. Charger power input socket (4.2 Volt, 600 mA input)

3. Non-contact infrared temperature sensor

4. Laser pointer

Spotcheck Instrument Reference Guide 6

Page 11

Section 1: Introduction

Front Panel

The table outlines the functions available on the front panel of the

Spotcheck device.

Instrument Front Panel

Function Description

Turns the instrument on and toggles selected values.

Activates the device's vibration measurement mode.

Holds or releases the current vibration reading on the LCD

screen. When taking Velocity measurements, pressing this

button will display an alarm value (see the

'Understanding ISO 10816-3 Vibration Alarms' section).

Activates the device's temperature sensor.

Enables/disables the laser pointer and holds/releases the

current temperature measurement on the LCD screen.

Activates the device's bearing measurement mode. When

taking a BG measurement, pressing this button will

display an alarm value (see the 'Understanding Bearing

Alarms' section).

Spotcheck Instrument Reference Guide 7

Page 12

Section 1: Introduction

Battery Pack

The Spotcheck device is powered by a removable, rechargeable LithiumIon 3 V, 1700 mA battery pack. Once fully charged, the battery pack will

allow the device to operate continuously for up to 48 hours.

The battery's current charge level is indicated by a battery icon in the

upper right-hand corner of the LCD screen.

Charge Battery Pack

Battery Level Indicator (Top Right)

To charge the battery pack:

1. Connect the AC power adapter included with the device to a

powered outlet (100-240 Volt, 50/60 Hz).

2. Connect the charger power output plug to the device's charger

input socket — The included DC in-car charger may be used to

charge the battery pack in a vehicle with a 12 V negative-chassis

power system.

3. Connect the in-car charger's DC output to the device's charger

power socket.

Bi-color LEDs on the battery chargers indicate the battery's charge state

when connected and powered: orange when the battery is charging and

green once the charge cycle has completed.

A full battery charge from empty will complete in approximately three

hours.

IMPORTANT! Use only the AC mains or DC in-car battery chargers

included in your Spotcheck device kit. Other chargers may damage

the device and/or battery pack and may void your warranty.

Charge the battery pack for two hours before or during your first use of

the device. Replacement battery packs are available from Commtest

Instruments.

Spotcheck Instrument Reference Guide 8

Page 13

Section 1: Introduction

Remove Battery Pack

To remove the battery pack:

1. Open the rear battery compartment by pressing the cover firmly

then sliding downward.

2. Set the battery cover aside and remove the battery from its

compartment.

3. Disconnect the power plug and socket (positive and negative are

indicated by color and the socket and plug can be connected in only

one direction).

Replacement batteries (part number SPOT0503) are available from

authorized Commtest Instruments distributors.

WARNING! Power should not be supplied to the device when

removing the battery. Unplug any connected charger before

proceeding.

WARNING! Damaged batteries should not be re-inserted into the

Spotcheck device.

WARNING! Dispose of damaged batteries responsibly and in

accordance with local regulations.

WARNING! Do not disassemble the battery pack or dispose of in

fire.

Spotcheck Instrument Reference Guide 9

Page 14

Section 2: Instrument Basics

Section 2: Instrument Basics

This section describes how to use the measurement and analysis

functions of your Spotcheck device. You will learn to:

• Power up the instrument and turn it off

• Attach the accelerometer sensor and stinger probe

• Take a vibration overall measurement

• Evaluate a vibration overall measurement alarm

• Take a bearing BG and BV vibration measurement

• Evaluate a bearing BG and BV alarm

• Take a temperature measurement

Power On/Off

To switch on your Spotcheck device, press and hold the SELECT key

for more than 1 second to power on the Spotcheck device.

To switch off you device, press and hold the SELECT key then press

either the BEARING key or the VIBRATION key to power off the

Spotcheck device.

NOTE: The Spotcheck device will power down automatically if no

keypad buttons are pressed for 3 minutes.

Spotcheck Instrument Reference Guide 10

Page 15

Section 2: Instrument Basics

Accelerometer Sensor

The accelerometer sensor is connected to the device via BNC, then

attached to the machinery being measured using the included magnetic

mount or a stud.

1. Attach the sensor cable plug to the BNC connector by inserting and

gently turning clockwise. Remove by turning in an anti-clockwise

direction then pulling away.

2. Screw the accelerometer in a clockwise direction onto the magnetic

3. If the measurement location is smaller than the magnetic base of

4. Remove the accelerometer sensor from the magnetic base by

5. Screw the stinger probe onto the end of the accelerometer in a

6. Press the tip of the stinger probe firmly against the surface being

WARNING! Do NOT remove the connector by pulling the sensor

cable. This may damage the cable. Always remove by gripping the

BNC connector then gently twisting in an anti-clockwise direction

for one quarter of a turn before pulling away.

base. Attach the base and sensor to the measurement point.

the accelerometer, use the included stinger probe.

unscrewing in an anti-clockwise direction.

clockwise direction.

measured.

Spotcheck Instrument Reference Guide 11

Stinger Probe

Page 16

Section 2: Instrument Basics

Sensor Guidelines

When attaching your accelerometer sensor using its magnetic base or a

stud, the following guidelines should be observed:

• Attach the accelerometer to a sturdy, rigidly mounted and non-

flexible structure, where vibration from the rotating part of the

machine will be accurately transmitted. Do not attach sensors

to sheet metal, guards, or any machine structure which is not

closely coupled to the source of vibration in the spinning rotor,

as the vibration of such a structure will be different to the

vibration source.

• The attachment structure must be at least 10 times heavier

than the accelerometer itself. Do not mount the accelerometer

on lightweight motors or similar parts as the weight of the

accelerometer will distort the vibration signal. Use the stinger

probe for small structures or small/inaccessible measurement

points.

• Attach the accelerometer as closely as possible to, and in line

with, the centerline of the bearings in order to avoid distorted

signals.

• The mounting surface should be flat and smooth where the

accelerometer makes contact. Attach the accelerometer using

the supplied magnetic accelerometer base or a threaded stud

on the machine surface. The accelerometer should not move

independently of the machine part it is attached to, nor should

the accelerometer cable.

• Ensure the accelerometer is oriented correctly as vibration can

differ greatly with respect to direction.

• If you are undertaking an ongoing study of a particular

measurement point, always attach the accelerometer at exactly

the same position used for previous measurements (mark the

position if necessary).

• Keep the accelerometer clear from other cables, ensuring it is

not twisted, kinked or tangled.

Spotcheck Instrument Reference Guide 12

Page 17

Section 2: Instrument Basics

Vibration Overall Measurements

The Spotcheck device measures broadband frequencies to generate a

machine's ‘overall’ summed vibration level. High overall vibration levels

are typically an indicator of unbalance, mechanical failure or wear.

If overall vibration measurements are taken at regular intervals (weekly,

for example) and noted, an historical trend of typical or ‘normal’ machine

vibration levels can be generated. This is called a ‘baseline’. When new

measurements are compared with this baseline value any significant

increases in the overall vibration level of the component can more easily

be identified.

As always, when determining the state of mechanical components you

must use common sense. In addition to measured vibration levels you

should visually inspect machinery for dirt, wear or movement; listen for

unusual mechanical noises and vibrations, and feel for temperature

changes.

NOTE: The Spotcheck device includes a temperature sensor that

can be used to identify temperature baseline values. These

temperature values can be used in conjunction with vibration

baselines to more effectively monitor machinery condition over

time. See the 'Take a Temperature Measurement' section for more

information.

Spotcheck Instrument Reference Guide 13

Page 18

Section 2: Instrument Basics

Displacement, Velocity, Acceleration

The Spotcheck device measures in displacement, velocity and

acceleration.

• Displacement is a measurement of the distance between two

points in mil (thousandth of an inch). In this case between the

resting position of the vibration sensor and its position of

maximum excursion during movement (caused by motion of the

machinery it is attached to).

• Velocity is a measurement of the rate of change of

displacement in inches per second, or the speed of the vibration

sensor in a particular direction. For example, if an object is

moving Northward, the velocity of the object in the North

direction is its speed, but its velocity in the East or West

direction is zero, and its velocity in the South direction is the

negative of its speed.

• Acceleration is a measurement of the rate of velocity change of

the vibration sensor around its rest location in g. That is, the rate

at which the sensor is gaining or losing speed in a particular

direction.

Spotcheck Instrument Reference Guide 14

Page 19

Section 2: Instrument Basics

Take Vibration Overall Measurement

The steps below assume that you have already successfully connected

and mounted the accelerometer sensor (or are holding the stinger probe

tip against the machinery surface).

1. Press and hold the SELECT key for 1 second to power on the

Spotcheck device — The velocity measurement type will be selected

('Vel' will be displayed in the LCD screen's top left-hand corner). A

vibration measurement numeric value will be shown in the center of

the screen.

NOTE: If the sensor has not been connected to the device, or if a

sensor fault is detected, the device will display a sensor query icon

on the LCD screen.

Sensor Alert Icon

2. Press the SELECT key repeatedly to toggle between the device's

available measurement types: 'Vel' (velocity in ips RMS), 'Disp'

(displacement in mil peak-to-peak) and 'Acc' (acceleration in g peak).

3. Press the VIBRATION key to hold the value being shown

onscreen, and again to return to the active measurement mode.

Spotcheck Instrument Reference Guide 15

Page 20

Section 2: Instrument Basics

Tips for Taking Measurements

Here are some tips for taking measurements:

• You should always take measurements using the machine

operating mode that is typical for that machine (using a typical

load and running speed). This will ensure that the loads on the

components, such as bearings, are the same as those that

define their wear. For multi-operating mode machines it is best

to take measurements when the loads on the bearings are at a

maximum and to take all future measurements in the same

mode.

• When taking the measurement, try not to lean on the machine

and do not put heavy objects (e.g. heavy tool boxes) on it since

this will change the vibratory behavior of the machine.

• If there are machines operating nearby that might affect the

vibration of the machine you are measuring, stop those

surrounding machines if possible.

• In addition to the measurements that you will be taking, if

possible, stop and listen to the sound of the machine; look for

loose bolts and oil leaks; take note of any machine parts that

are vibrating visibly; feel for hot bearings and manually ‘feel’ the

vibration (e.g. with a screwdriver) to look for symptoms that

might later aid vibration analysis. This should be done only if it is

safe to do so.

• If you have a stroboscope you may wish to use it to ‘freeze’

rotating shafts, belts, couplings etc. to observe their operating

shapes and relative speeds.

Spotcheck Instrument Reference Guide 16

Page 21

Section 2: Instrument Basics

ISO 10816-3 Vibration Alarms

If a velocity measurement is taken and the VIBRATION key is then

pressed, the measured value will be retained on the LCD screen (placed

on 'hold'). A vibration alarm level using the ISO 10816-3:2009 standard

will also be displayed on the LCD screen. Three alarm levels are possible

and may be shown:

• OK (indicated by a tick icon)

• Alert (indicated by a single bell icon)

• Danger (indicated by two bell icons)

The alarm level displayed is only applicable to the machine group

(determined by the machinery's size and power) and support class

(determined by the support structure the machinery has been mounted

to: rigid, or flexible) specified in the bottom left-hand corner of the

screen.

You must manually cycle through the four machine group and support

class options available. Press the SELECT key repeatedly until the

machine and support type combination most appropriate for the

machinery being measured is displayed.

The four available combinations are:

• ISO 1 & 3 - R

• ISO 1 & 3 - F

• ISO 2 & 4 - R

• ISO 2 & 4 - F

The first two numbers indicate the machine group applicable to the

alarm, and the last letter the support class.

Spotcheck Instrument Reference Guide 17

Page 22

Section 2: Instrument Basics

Machine Groups

The following machine groups are available:

• Group 1. These are large machines with rated power output

above 300 kW and shaft diameters greater than or equal to 315

mm. These machines are typically equipped with sleeve

bearings and operate at speeds between 120 RPM and 15 000

RPM.

• Group 2. These are medium sized machines with rated power

output between 15 kW and 300 kW and shaft diameters of

between 160 mm and 315 mm. These machines are typically

equipped with element bearings and operate at speeds greater

than 600 RPM.

• Group 3. Pumps with multi-vane impellers and separate drive

motors (centrifugal, mixed flow or axial flow) with rated power

above 15 kW.

• Group 4. Pumps with multi-vane impellers with integrated drive

motors (centrifugal, mixed flow or axial flow) with rated power

Support Class

above 15 kW.

The following support classes are available:

• R (Rigid). Appropriate for machinery mounted on rigid

mountings, such as steel or concrete.

• F (Flexible). Appropriate for machinery mounted on flexible

mountings, such as rubber or springs.

NOTE: A quick reference list of these values is printed on the

device's rear label. For more information on machine groups and

support classes, see the 'ISO 10816-3 Machine Groups Overview'

section and the 'ISO 10816-3 Support Classes Overview' section.

Using a combination of the vibration level, the machine group and the

support class, alarms are generated as follows:

Spotcheck Instrument Reference Guide 18

Page 23

Section 2: Instrument Basics

Check Status of Bearing

The steps below assume you have already successfully connected and

mounted the accelerometer sensor (or are holding the stinger probe tip

against the machinery surface).

1. Press and hold the SELECT key for 1 second to power on the

Spotcheck device.

2. Press the BEARING key. The BG measurement type will be

selected ('Bg' will be displayed in the LCD screen's top left-hand

corner). A vibration measurement numeric value will be shown in the

center of the screen.

3. Press the SELECT key to toggle between the device's two

4. Press the BEARING key to hold the value being shown onscreen,

NOTE: If the sensor has not been connected to the device, or if a

sensor fault is detected, the device will display a sensor query icon

on the LCD screen.

Sensor Alert Icon

available bearing measurement types: 'Bg' (acceleration in g RMS),

'Bv' (velocity in ips RMS).

and again to return to the active measurement mode.

Spotcheck Instrument Reference Guide 19

Page 24

Section 2: Instrument Basics

Bearing Alarms

If a bearing vibration measurement is taken and the BEARING key is

then pressed, the measured value will be retained on the LCD screen

(placed on 'hold'). A vibration alarm level will also be displayed on the

LCD screen. Three alarm levels are possible and may be shown:

• OK (indicated by a tick icon)

• Alert (indicated by a single bell icon)

• Danger (indicated by two bell icons)

Bearing alarm values displayed by the Spotcheck device are based on

'rule of thumb' tables and should therefore be used as simple indicators

of potential problems. They should not be used as the sole determinant

of a component's condition.

Acceleration Alarms (BG)

When taking a BG (bearing acceleration) reading, the alarm level

displayed by pressing the BEARING key is only applicable to the

bearing shaft speed specified in the bottom left-hand corner of the LCD

screen.

You must manually cycle through the five bearing shaft speed options

available. Press the SELECT key repeatedly until the shaft speed

most appropriate for the machinery being measured is displayed.

The five available shaft speeds are:

• RPM:<500. Suitable for shafts rotating at below 500 RPM.

• RPM:<1000. Suitable for shafts rotating at between 500 RPM

and 1000 RPM.

• RPM:<2000. Suitable for shafts rotating at between 1000 RPM

and 2000 RPM.

• RPM:<5000. Suitable for shafts rotating at between 2000 RPM

and 5000 RPM.

• RPM:<10000. Suitable for shafts rotating at between 5000 RPM

Spotcheck Instrument Reference Guide 20

and 10 000 RPM.

Page 25

Section 2: Instrument Basics

BG alarms are based on acceleration readings taken between 1 kHz and

12 kHz. These are the frequencies in which bearing failures are typically

most easily detected. The alarms are generated using the following

vibration level against shaft speed matrix:

Velocity Alarms (BV)

BV alarms are based on velocity readings in ips RMS taken between 1

kHz and 12 kHz. Like BG alarms, BV alarms are based on established

'rule of thumb' measurement levels that have traditionally given reliable

indications of a bearing's condition with up to 90% accuracy.

These alarms are generated using the following vibration levels:

• OK. Bearing velocity levels of less than 0.04 ips RMS suggesting

correctly greased bearings operating normally.

• Warning. Bearing velocity levels of between 0.04 ips RMS and

0.08 ips RMS indicating the existence of internal surface wear

that may not be detectable by the human eye, actual bearing

damage or poorly/ungreased bearings.

• Danger. Bearing velocity levels above 0.08 ips RMS suggesting

Spotcheck Instrument Reference Guide 21

that a bearing failure may occur imminently.

Page 26

Section 2: Instrument Basics

Take Temperature Measurement

Heat is a strong indicator of a failing component or unbalance. Bearing

heat is typically generated by friction between surfaces resulting from

damage or poor lubrication. As surface contact increases, temperatures

will rise until a bearing failure occurs.

By regularly monitoring and noting the temperature of a rotating

component it becomes possible to ‘trend’ its temperature over time and

identify when the component may require attention (as indicated by an

unusual increase in temperature).

If comparing the casing temperatures of several identical components

(such as bearings or drives) under identical loads it is also possible to

identify components that are notably warmer than their companions,

suggesting mechanical deterioration.

NOTE: If establishing a temperature trend it is important that the

same physical location is sampled each time a measurement is

taken, and that measurements are taken from the same distance.

WARNING! The Spotcheck device's laser pointer will energize

automatically when measuring temperatures. Direct the laser lens

away from yourself and others in the vicinity before proceeding

with the steps below. Ensure you are familiar with the laser safety

guidelines described in the 'Laser Safety' section.

Spotcheck Instrument Reference Guide 22

Page 27

Section 2: Instrument Basics

To take a temperature measurement:

1. Press and hold the SELECT key for 1 second to power on the

Spotcheck device.

2. Press the TEMPERATURE key. The temperature measurement

mode will be selected ('Temp' will be displayed in the screen's top

left-hand corner). A temperature measurement numeric value will

be shown in the center of the LCD screen. This is the temperature in

front of the device's IR temperature sensor. Ambient temperature

will be displayed in the bottom left-hand corner and the

measurement unit in the bottom right-hand corner.

NOTE: The default temperature unit is degrees Celsius. To change

to Fahrenheit, press the SELECT key.

3. Point the laser guide at the surface to be measured. The laser

provides a visual indication of the field of view of the infrared

thermometer sensor. Ensure the surface is within the device's 2

meter (6.5 foot) effective range. The LCD screen will display the

surface temperature of the target surface.

NOTE: The temperature range supported by the IR sensor is -20 °C

to 120 °C (-4 °F to 248 °F).

4. Press the TEMPERATURE key to hold the value being shown

onscreen, and again to return to the active measurement mode.

Pressing this key will also disable and re-energize the laser pointer.

Accurate temperature measurement using an IR sensor depends largely

on the size of the target and the distance between the target and the

thermal sensor. IR detectors have a circular, conical field of view: small

and narrow directly in front of the sensor and gradually spreading wider

as the distance between the sensor and the target increases.

For this reason it is important that you consider the distance between

the Spotcheck device and the equipment being measured. At a distance

of 250 mm or 10 inches the sensor's field of field is a small circle with a

diameter of approximately 31.25 mm (1.2 inches). This is suitable for

many smaller bearings. However, at a distance of 2000 mm or 79 inches

(the device's maximum range) the field of view is a much larger 250 mm

(9.8 inches) in diameter.

Spotcheck Instrument Reference Guide 23

Page 28

Section 2: Instrument Basics

NOTE: For maximum accuracy, the IR sensor should include only

the target surface in its field of view. For this reason

measurements of smaller objects should, if possible, be taken at

close range. Beyond 2 meters or 6.5 feet temperature readings of

even large targets may become unreliable.

Spotcheck Instrument Reference Guide 24

Page 29

Section 2: Instrument Basics

Laser Safety

When using the Spotcheck device's laser pointer, please observe the

following laser safety guidelines:

• Never point the laser beam at a person. The laser pointer is

designed to target inanimate objects.

• Laser pointers are not toys. Keep out of reach of minors and

children.

• Do not look into the laser beam or view directly with optical

instruments. Eye damage may result.

• Do not direct the laser pointer at reflective surfaces. Reflected

beams can act like direct beams.

Spotcheck Instrument Reference Guide 25

Page 30

Section 3: Supplemental Reading

Section 3: Supplemental Reading

This section discusses suitable machine groups and support classes for

the ISO 10816-3 standard and the significance of a machine's support

structure. Additionally, this section includes a primer on assessing roller

bearing states using vibration measurements.

ISO 10816-3 Machine Groups Overview

The ISO 10816-3 standard encompasses a broad range of industrial

plant machinery with nominal power above 15 kW and nominal speeds

of between 120 RPM and 15 000 RPM when measured in situ. Machinery

that this standard applies to includes:

• Steam turbines with nominal power of less than 50 MW

• Steam turbines with nominal power above 50 MW and speeds

of less than 1500 RPM or over 3600 RPM (excluding machines

included in ISO 10816-2)

• Rotating compressors

• Industrial gas turbines with nominal power of less than 3 MW

• Centrifugal, mix flow, or axial flow pumps

• Electric generators, excluding hydroelectric generators and

pump stations

• Electric motors of all types

• Blowers and fans

Spotcheck Instrument Reference Guide 26

Page 31

Section 3: Supplemental Reading

ISO 10816-3 Support Classes Overview

The ISO 10816-3 standard classifies machinery according to its

mounting style, whether flexible or rigid. This is done as mounting type

typically reflects the location of the machinery's rigid-structure

resonances relative to basic machine running speed.

For example, a machine supported by flexible rubber mounts or a spring

will typically have resonances at lower running speeds. Vibrations may

be stronger at lower speeds, reducing as the machinery reaches its

operating speed. This type of machine is regarded as flexible by the ISO

standard.

Machinery mounted on flexible supports will also typically vibrate more

during run-up and coast-down.

Modern machines often operate at high speeds and are equipped with

flexible bearing supports and foundations. These can be treated as

flexible even when not mounted on rubber or springs.

Although the ISO 10816-3 standard allows for slightly higher vibration

limits when a machine's support is considered flexible rather than rigid,

resonant conditions (even at operating speeds) are regarded as

abnormal.

Spotcheck Instrument Reference Guide 27

Page 32

Section 3: Supplemental Reading

Assess Bearing State

When the rolling elements inside a bearing move, broadband noise and

vibration is generated. Noise and vibration levels will increase if the

bearing is not correctly greased, is overloaded (due to, for example,

misalignment) or has a damaged surface.

As the vibrations generated by bearing wear and damage are

broadband (that is, they cover a wide range of frequencies), any

frequency could be regarded as suitable for measurement. However, if

the chosen frequency band also contains low frequencies (below 1 kHz)

the measurement will not consist only of bearing frequencies. The

bearing condition may thereby become harder to interpret.

If the chosen frequency band contains only bearing frequencies the

bearing condition assessment will be more accurate. For this reason the

Spotcheck device measures only frequencies above 1 kHz when in its

bearing measurement mode.

High bearing readings can also be found in gearboxes and other

machines where steel meets steel and no bearing faults exist. The

reason for this is that these components naturally produce frequencies

in the same range as bearing faults.

Bearings should not typically be replaced only on the basis of a bearing

value displayed by the Spotcheck device. A high bearing vibration value

is merely an indicator that further analysis is required. Further analysis

will determine whether the elevated levels at specific frequencies

correspond with mathematically calculated bearing frequencies. More

advanced tools such as the vb7 and vb8 data analyzers, when used in

conjunction with the Ascent software, are ideal for this application.

Bearing condition values are influenced by bearing lubrication. If a high

value is displayed, the bearing should in the first instance be re-greased.

After greasing the bearing condition value will typically decrease.

However, if there is mechanical damage the value will quickly rise again.

Spotcheck Instrument Reference Guide 28

Page 33

Section 3: Supplemental Reading

Appendix: Spotcheck Specifications

The table lists the technical specifications for your Spotcheck device.

Specifications Spotcheck Device Remarks

Sensors

Sensor input 1 channel BNC

Sensor Accelerometer 100 mV/g IEPE/ICP© type. Top exit.

Vibration Acceleration 0 to 20 g Peak, 10 Hz to 12 kHz

Velocity 0 to 200 mm/s RMS, 10 Hz to 1000 Hz

Displacement 0 to 2000 µm Pk-Pk, 10 Hz to 1000 Hz

BG 0 to 20 g RMS, 1000 Hz to 12 kHz

BV 0 to 200 mm/s RMS, 1000 Hz to 12 kHz

Measurement Features

Accuracy ± 5%

Alarms Automatic Velocity Alarm Check

Automatic Bearing Alarm Check

Temperature -20 °C to 120 °C (-4 °F to 248 °F) Accuracy ± 2 °C. Built in IR sensor

Display & Communication

Display Monochromatic LCD LED backlit

Resolution 128 x 64 pixels

Viewing area 30 mm x 16 mm (1.2” x 0.6”)

Integrated 80 cm cable.

ISO 10816-3

BG and BV (proprietary)

with laser pointer

Spotcheck Instrument Reference Guide 29

Page 34

Section 3: Supplemental Reading

116 mm x 78 mm x 24 mm (4.6" x 3" x 0.9")

230 g (0.5 lb)

Laser

Type Compact laser diode Red

Frequency 650 nm

Class 2 IEC60825-

Power 1 mW (max)

Battery &

Charger

Battery type Custom Lithium Ion pack 3.6 V, 1700 mAh Rechargeable, user-replaceable

Operating time >48 hours

Charger type Internal charging, automatic control External Power pack 12 V DC, 3 A

Charge rate 600 mA nominal

Charge time 3 hours For complete charge

Mechanical

Size

Weight

Environment

Operating temp -10 °C to 50 °C (14 °F to 122 °F) Non-condensing atmosphere only

Storage

temperature

-20 °C to 60 °C (-4 °F to 140 °F)

1:1993+A1:1997+A2:2001

compliant

output, included in kit

128 mm (5") including BNC

connector

Including battery, sensor and cable

Sealing IP64 Dust tight, splashed water

Certification CE

Spotcheck Instrument Reference Guide 30

Page 35

Section 3: Supplemental Reading

Servicing and Maintenance

Servicing is not required to keep the Spotcheck device in proper

operating condition. In the event of a malfunction, the device should be

returned to GE Measurement & Control, New Zealand for inspection and

repair.

Do NOT open or disassemble. No user-serviceable parts.

Spotcheck Instrument Reference Guide 31

Page 36

Index

A

Acceleration • 14

Alarms

Vibration • 28

Appendix

Specifications • 29

Assessing Bearing State • 28

B

Battery • 8, 9

Bearings • 19, 28

C

Charging the Battery Pack • 8

Check the Status of a Bearing •

19

D

Displacement • 14

Displacement, Velocity and

Acceleration • 14

F

Front Panel • 7

I

Instrument I/O • 6

ISO 10816-3 • 26, 27

ISO 10816-3 Machine Groups

Overview • 18, 26

ISO 10816-3 Support Classes

Overview • 27

L

Laser

Safety • 1, 5, 22, 25

Laser Safety • 22, 25

P

Power • 10

Powering On/Off • 10

Precautions • 5

Product Overview • 2

R

Removing the Battery Pack • 9

S

Section 1

Introduction • 1

Section 2

Instrument Basics • 10

Section 3

Supplemental Reading • 26

Sensor Guidelines • 12

Servicing and Maintenance • 31

Standard Features • 3

Standard Kit Items • 4

T

Take a Temperature

Measurement • 13, 22

Take a Vibration Overall

Measurement • 15

The Battery Pack • 8

Tips for Taking Measurements •

16

U

Understanding Bearing Alarms

• 7, 20

Understanding ISO 10816-3

Vibration Alarms • 3, 7, 17

Using the Accelerometer Sensor

• 11

Using Vibration Overall

Measurements • 13

Spotcheck Instrument Reference Guide 32

Page 37

V

Velocity • 14

Vibration Overalls • 15

Spotcheck Instrument Reference Guide 33

Loading...

Loading...