Page 1

TECP-90-801 Issue 4 October 2017

Quareo High Density Equipment Panel (HDEP)

User Manual

25111-A

Content Page

INTRODUCTION ............................................................................. 2

RELATED PUBLICATIONS ...................................................................... 3

1 PRODUCT DESCRIPTION .................................................................. 4

1.1 Physical Description ............................................................... 4

1.2 Panel Electronics ................................................................. 5

1.3 Status LEDs on Front Panel and Modules ................................................. 5

1.4 Specifications ................................................................... 6

2 UNPACKING AND INSPECTION .............................................................. 7

3 INSTALLATION......................................................................... 7

3.1 Overview ....................................................................... 8

3.2 Tools and Hardware Needed ......................................................... 8

3.3 Rack Installation ................................................................. 8

3.4 Installing the Vertical Cable Guides (VCGs) ...............................................10

3.5 Grounding the Panel ...............................................................13

3.6 Installing the Management Unit .......................................................13

3.7 Connecting the Ethernet Cable and AUX Power Cable ........................................14

3.8 Connecting the Control Cable .........................................................14

3.9 Connecting the Panel to the Quareo Network ..............................................15

4 INSTALLING MODULES AND IFC CABLES.......................................................15

5 TECHNICAL ASSISTANCE..................................................................16

300100102902 Rev D Page 1

This product is covered by one or more U.S.patents or their foreign equivalents. © 2017 CommScope.

For patents, see http://www.commscope.com/ProductPatent/ProductPatent.aspx All Rights Reserved.

Page 2

TECP-90-801 • Issue 4 • October 2017

INTRODUCTION

This manual describes the Quareo High Density Equipment Panel (HDEP) and documents all

procedures required in installing it. Included are the procedures required to mount the panel on

a rack, ground the panel, and install Vertical Cable Guides (VCGs).

Note: This manual does not contain instructions for installing modules in access trays.

Instructions unique to the various module types are provided through QR code access to

the CommScope Field Support Link. This online site contains videos, animations, and

other information for the module being installed. The QR code is a label on the top of the

panel; the Field Support Link is accessed using a visual recognition app on a smart phone.

Note: This manual does not contain instructions for the Web Interface used when the

panel is installed to configure it within the Quareo network. Instructions for this are

provided in TECP-90-805.

Revision History

ISSUE DATE REASON FOR CHANGE

1 5/2014 Original.

3 January 2017 Reformatted for CommScope.

4 October 2017 Updated to remove incorrect logo.

Trademark Information

CommScope (logo), CommScope, and Quareo are trademarks

Applicable Standards

UL 60950-1, 2nd Edition, 2007-03-27 (Information Technology Equipment - Safety - Part 1:

General Requirements)

CSA C22.2 No. 60950-1-07, 2nd Edition, 2007-03 (Information Technology Equipment Safety

- Part 1: General Requirements)

Admonishments

Important safety admonishments are used throughout this manual to warn of possible hazards to

persons or equipment. An admonishment identifies a possible hazard and then explains what

may happen if the hazard is not avoided. The admonishments — in the form of Dangers,

Warnings, and Cautions — must be followed at all times.

.

Danger: Danger

injury, death, or substantial property damage if the hazard is not avoided.

Warning: Warning

injury, death, or substantial property damage if the hazard is not avoided.

Page 2

© 2017 CommScope. All Rights Reserved.

is used to indicate the presence of a hazard that will cause severe personal

is used to indicate the presence of a hazard that can cause severe personal

Page 3

Caution: Caution is used to indicate the presence of a hazard that will or can cause minor

personal injury or property damage if the hazard is not avoided.

General Safety Precautions

Danger: To prevent electrical shock, never install panel in a wet location or during a lightning

storm. When installing or modifying telephone lines, disconnect lines at the network interface

before working with uninsulated lines or terminals.

TECP-90-801 • Issue 4 • October 2017

Caution: When

connecting the equipment to the power sources, check the equipment nameplate

rating to avoid overloading circuits which may cause damage to over-current protection devices

and supply wiring.

Caution: If

the panel is installed in a closed or multi-rack assembly, the operating temperature

of the rack environment may be greater than the ambient temperature. Be sure to install the

panel in an environment that is compatible with the maximum rated ambient temperature. See

Specifications.

Caution: Installation

of the equipment in a rack should be such that air flow to the equipment is

not compromised.

Caution: When

mounting equipment in the rack make sure mechanical loading is even to avoid

a hazardous condition, such as loading heavy equipment in the rack unevenly. The rack should

safely support the combined weight of all equipment it supports.

Caution: Reliable

earthing of rack-mounted equipment should be maintained. Particular

attention should be given to supply connections other than direct connections to the branch

circuit (e.g. use of power strips).

Caution: This

equipment is to be installed only in Restricted Access Areas (dedicated

equipment rooms, equipment closets, etc.) in accordance with Articles 110-16, 110-17, and 11018 of the National Electrical Code, ANSI/NFPA 70

RELATED PUBLICATIONS

Listed below are related manuals and their publication numbers. Copies of these publications can

be ordered by contacting the CommScope Technical Assistance (refer to Topic 5 on Page 16).

Title/Description Publication Number

Quareo High Density Equipment Panel Web Interface User Manual TECP-90-805

Quareo Management Unit Installation Manual TECP-90-806

© 2017 CommScope. All Rights Reserved.

Page 3

Page 4

TECP-90-801 • Issue 4 • October 2017

1 PRODUCT DESCRIPTION

1.1 Physical Description

The Quareo High Density Equipment Panel (HDEP) is a fiber optic connector panel with six

access trays, each providing a mounting location for one adapter pack or cabled module. A

single access tray provides 24 LC connections for a panel total capacity of 144 LC connections.

The panel has mounting brackets intended for a 19-inch (48. 26 cm) rack-mount. Extender

brackets

shipped with the ETSI extender brackets already installed. The panel may also be mounted in a

cabinet providing a 19-inch, 23-inch, or ETSI rack mount configuration.

This panel contains electronics that enable connection information to be acquired and supplied

to

physical layer management system. Refer to Topic 1.2 on Page 5.

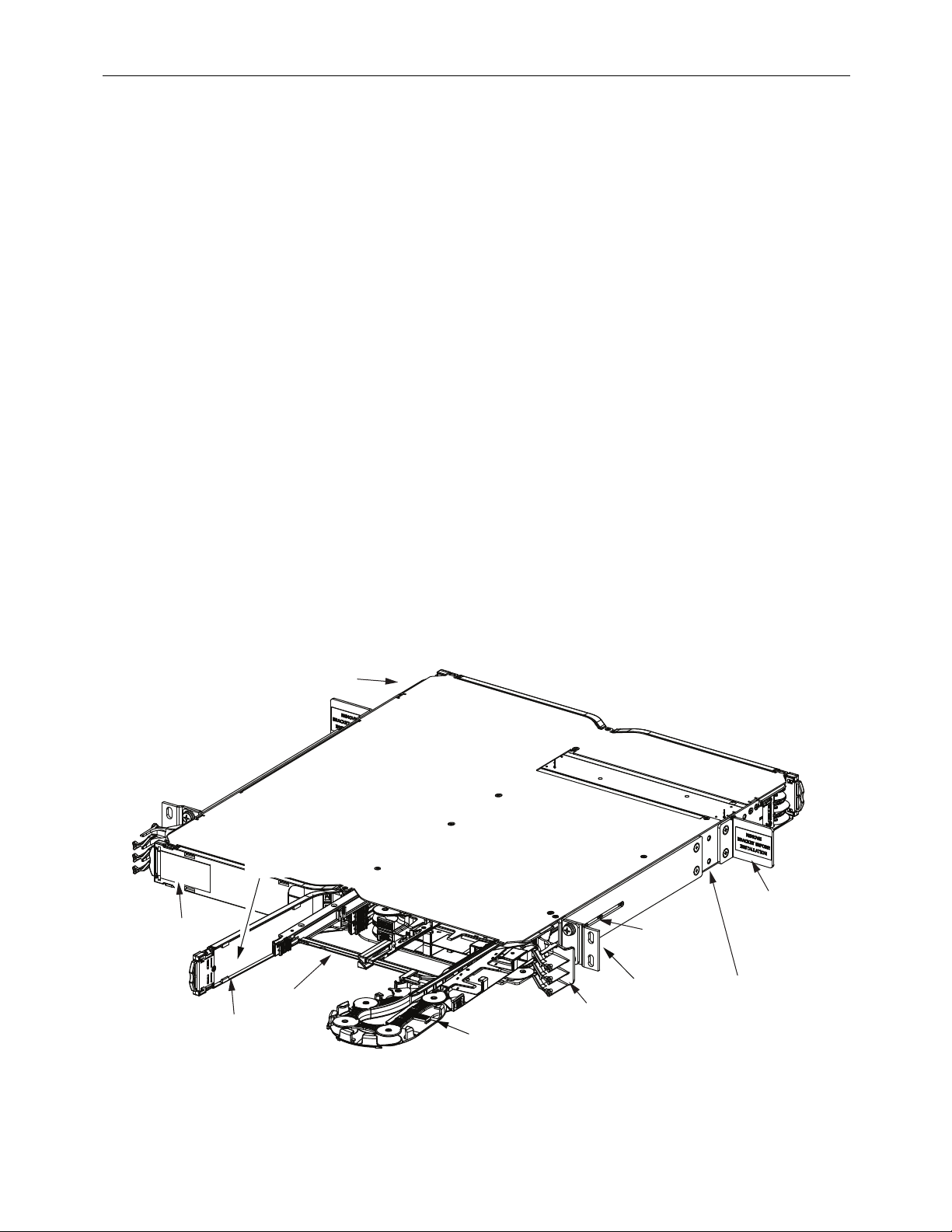

Figure 1 shows the main physical features of the 1RU panel, including the following:

configure the panel for an ETSI or 23-inch (58.42 cm) rack-mount. The panel is

the Infrastructure Configuration Manager (ICM), the central system software of the Quareo

QR CODE

ACCESS TRAY

• Access

• Access

• Designation

• QR

trays—hold adapter packs or cabled modules; open to front or rear of the panel.

tray doors—protect adapter pack or cabled module when access tray is closed.

cards—are used to record cable destinations.

code—is a label with a pattern recognizable by a visual recognition app on a smart

phone. The QR code causes the smart phone to link to the CommScope Field Support

Link, which contains user instructions specific to the 1RU panel.

GROUNDING

LOCATION

DESIGNATION CARDS

(LOCATED ON

BACKSIDE OF DOOR)

SHIPPING

BRACKET (2X)

REMOVED

BEFORE

INSTALLATION

RACK

OFFSET

SCREWDOWN

LOCATIONS

25316-C

DOOR (4X)

ACCESS

TRAY

CABLE

MANAGEMENT

LINKAGE

VERTICAL CABLE

GUIDE (4X)

(PROVIDED)

RACK

OFFSET

ADJUSTMENT

SLOT

MOUNTING

BRACKET

(WITH

EXTENSION)

Page 4

© 2017 CommScope. All Rights Reserved.

Figure 1. Quareo HDEP Physical Features

Page 5

TECP-90-801 • Issue 4 • October 2017

• Mounting brackets—are intended for a 19-inch (48. 26 cm) rack-mount. Extender

brackets configure the panel for an ETSI or 23-inch (58.42 cm) rack mount. The panel is

shipped with the ETSI extender brackets installed.

• Cable

or closed to ensure cables are not crimped or misaligned impeding tray movement.

• Rack

panel) provides offset options of 3, 4, 5, or 6.5 inches (7.62, 10.24, 12.7, or16.5 cm).

• Grounding

The Quareo HDEP is orderable with universal adapter packs designed to accept a variety of

connector

information, see Table 1. Adapter packs can be installed from the front or rear by snapping them

into position; no screws or tools are required. Cabled modules (ordered separately) are also

available

for this panel. For more information, see Table 1.

1.2 Panel Electronics

The Quareo HDEP has electronics that enable it to function by ICM in a Quareo physical

management system. A typical Quareo network includes both fiber and copper connector panels

and non-managed representations of the input and output devices (such as switches) to which

cables are connected.

Assuming all connections to the Quareo HDEP are made with managed modules and cables,

electronics provide an ICM user with the ability to know, on a real time basis, whether

these

each port of the Quareo HDEP is connected and to what it is connected (what other equipment

and port). On a network level, the user may plan future connections and disconnections of

equipment assisted by a dynamic schematic view of connectivity of the entire network.

management linkage—holds and repositions cables when access trays are opened

offset adjustment slot and rack offset screwdown locations—(on each side of

location—provides a mounting stud for a ground wire.

types. Available adapter pack types include LC-LC and MPO-MPO. For more

1.3 Status LEDs on Front Panel and Modules

The Quareo HDEP has six Light Emitting Diodes (LEDs) on the front middle of the panel

(Figure 2). These LEDs are identical in function. There is one LED for each access tray. The

LEDs have two states: unlit or lit (green).

FRONT MIDDLE OF PANEL

LEDs

Figure 2. Status LEDs

ONE

ACCESS

TRAY

25315-A

Page 5

© 2017 CommScope. All Rights Reserved.

Page 6

TECP-90-801 • Issue 4 • October 2017

The status LEDs on the front panel blink green at start-up. If a LED for a particular access tray

does not light at start-up, either there is no module installed in the access try or a module is

present but due to malfunction or mis-seating is unknown to the Quareo system. A blinking

green LED after start-up indicates an individual LED is lit for one of the connectors in the

module installed in that access tray. To identify which LED this is, open the access tray and

check the individual LEDs on the ports.

A LED lit for an individual port indicates that ICM has identified this port as requiring attention

for an active Work Order to be completed. The LED stays on until the entire Work Order is

successfully completed. There can be multiple steps in a Work Order such as Connect two ends

of cable, Disconnect two ends of cable, Insert one end of cable, Extract one end of cable, and so

on. LED blinking is different for Connect and Disconnect Work Orders. For a Connect Work

Order step, LEDs blink green on the two ports that need to be connected. For a Disconnect

Work Order step, LEDs blink yellow on the two ports that need to be disconnected.

A LED for an individual port or all LEDs for all ports on a particular module can also be lit for

identification purposes using the Quareo Panel Interface Web Browser.

1.4 Specifications

Table 1 lists specifications for the Quareo HDEP.

Table 1. Quareo High Density Equipment Panel

PARAMETER SPECIFICATION REMARKS

Electrical

Voltage 37-57 VDC, 48 VDC nominal

Input current 350mA (maximum (per IEEE 802.3af) at 48 VDC

Environmental

Operating conditions

Storage conditions

Mechanical

DimensionsDxWxH 13.35 in (33,9 cm) D x 19.01 in (48.29 cm)Wx1.7

Weight 4.1 lb. (1.86 kg.)

Components

Supported Adapter Packs* LC-LC 24 fibers (12 duplex ports)

+14F to +140F(10Cto+60C)

5% to 95% RH

40F to +158F(40C to +70C) 10% to 95% RH

in (4.32 cm) H

MPO-MPO 192 fibers (eight 24-fiber

No condensation

No condensation

ports)

Page 6

© 2017 CommScope. All Rights Reserved.

Page 7

TECP-90-801 • Issue 4 • October 2017

Table 1. Quareo High Density Equipment Panel

PARAMETER SPECIFICATION REMARKS

Supported Modules LC-MPO (straight configuration; left or right) 24 fibers (one 24-fiber rear

port)

LC-MPO (flipped configuration; left or right) 24 fibers (two 12-fiber rear

ports)

LC-MPO (10G HD; left or right) 24 fibers (two 12-fiber rear

ports)

LC cabled module Dual zip 24-fiber cable

2 UNPACKING AND INSPECTION

Unpack and inspect the various components as follows:

1. Inspect the exterior of the shipping container(s) for evidence of rough handling that may

have

damaged the components in the container.

2. Unpack each container while carefully checking the contents for damage and verify with

3. If damage is found or parts are missing, file a claim with the commercial carrier and notify

4. Refer to Topic 5 on Page 16 if you need to contact CommScope.

5. Save all shipping containers for use if the equipment requires shipment at a future date.

3 INSTALLATION

Warning: To prevent electrical shock, never install panel in a wet location or during a lightning

storm. When installing or modifying telephone lines, disconnect lines at the network interface

before working with uninsulated lines or terminals.

Caution: This

equipment rooms, equipment closets, etc.) in accordance with Articles 110-16, 110-17, and 11018 of the National Electrical Code, ANSI/NFPA 70.

Panel

Caution: If the panel is installed in a closed or multi-rack assembly, the operating temperature

of the rack environment may be greater than the ambient temperature. Be sure to install the

panel in an environment that is compatible with the maximum rated ambient temperature. See

Specifications.

the

packing slip.

CommScope

Customer Service. Save the damaged cartons for inspection by the carrier.

equipment is to be installed only in Restricted Access Areas (dedicated

© 2017 CommScope. All Rights Reserved.

Page 7

Page 8

TECP-90-801 • Issue 4 • October 2017

3.1 Overview

Installation involves the following:

• Mounting the panel on a rack;

• Grounding the panel;

• Connecting the network control cable;

• Connecting power;

• Connecting the panel to the Quareo network;

• Installing controlled modules and cables.

3.2 Tools and Hardware Needed

Tool and hardware requirements are listed in Table 2.

Table 2. Installation Tools and Hardware Needs

CONSIDERATION DESCRIPTION

Tools Needed #1 Phillips Screwdriver,

Rack Mounting 19” EIA/WECO/ETSI Rack Mounting. Use supplied #12-24 screws and #2

Grounding Secure panel to ground. Use #1 Phillips Screwdriver to tighten the 10-32

Incoming IFC Cable

Clamping

3.3 Rack Installation

The Quareo HDEP is shipped with extender brackets already attached for mounting the panel in

an ETSI equipment rack. The extender brackets may be removed for mounting the panel in a

19-inch (482.6mm) equipment rack. Mounting brackets for a 23-inch (58.42 cm) mounting are

supplied as ship along items.

Check the work order to determine the panel location in the rack or cabinet. Mounting hardware

shipped loose. Each panel is secured with either 12-24 screws, M6 hardware, or TrueNet

is

quick fit hardware depending on type of mounting used.

#2 Phillips Screwdriver,

3/16” Standard Screwdriver

Phillips Screwdriver to secure the panel to the rack or cabinet or use supplied

M6 screws, cage nuts and #2 Phillips Screwdriver to secure the panel to the

rack or cabinet or use TrueNet®Frame “quick fit” solution

screws through the ground lug (provided) into the panel ground PEM nuts.

Ground cables are NOT provided with the panel

Use supplied cable clamps and 3/16” standard screwdriver to secure the

incoming IFC cable

®

Use the following procedure to mount the panel (refer to Figure 3).

Page 8

© 2017 CommScope. All Rights Reserved.

Page 9

TECP-90-801 • Issue 4 • October 2017

Caution:

If panel is installed in a closed or multi-rack assembly, the operating temperature of the

rack environment may be greater than the ambient temperature. Be sure to install the panel in an

environment that is compatible with the maximum rated ambient temperature. See Specifications.

Caution: Installation of the equipment in a rack should be such that air flow to the equipment is

not compromised.

1. Obtain the following tools and equipment:

• Flat blade or Phillips screwdriver (type to match mounting screws)

• Locate mounting hardware required.

26574-A

LOCKWASHER

(4)

12-24 x 1/2 IN.

SCREW (4)

MOUNTING

BRACKET

RACK

FRONT

FLANGE

Figure 3. Mounting Panel

(Shown With 23-Inch Extender Brackets Installed)

2.

Determine what rack size is being used, and reconfigure the

mounting brackets if required

for the frame (or cabinet) in which the panel is being installed.

a. For an ETSI rack or cabinet, leave the panel as received from the factory with extender

brackets

attached.

b. For a19-inch rack or cabinet, remove the ETSI brackets and leave the inner mounting

brackets

in place.

c. For an 23-inch rack or cabinet, remove the ETSI brackets and in their place install the

23-inch

extender brackets (provided in ship along kit).

© 2017 CommScope. All Rights Reserved.

Page 9

Page 10

TECP-90-801 • Issue 4 • October 2017

3. Determine the rack offset position to be used. If other than the 3-inch position that the

panel is shipped in from the factory, remove the two screws holding the rack adjustment

bar, and slide it off the mounting posts and relocate onto the desired mounting posts.

Tighten down the screws in the new rack offset position.

Note: For

location of rack offset slot, see Figure 1 on Page 4.

4. Locate the equipment rack mounting space that is specified for the panel.

Note: Ethernet

Note: If

installing panel in a Q-Frame (Cross-Connect Solution), make ground connection

cabling distance to and from the panel should not exceed 328ft. (100m).

to panel before securing panel in the rack.

5. Place panel in the assigned mounting space and align the holes in the mounting brackets

the holes in the equipment rack. See Figure 3 on Page 9.

with

6. Secure panel to equipment rack using the appropriate hardware. Torque these screws to

approximately

Caution: When

27 pound-inches (3.1 Newton meters).

mounting equipment in the rack make sure mechanical loading is even to avoid

a hazardous condition, such as loading heavy equipment in the rack unevenly. The rack should

safely support the combined weight of all equipment it supports.

3.4 Installing the Vertical Cable Guides (VCGs)

Vertical Cable Guides (VCGs) are installed on the left and right sides of both the front and the

rear of the panel. Use the following procedure.

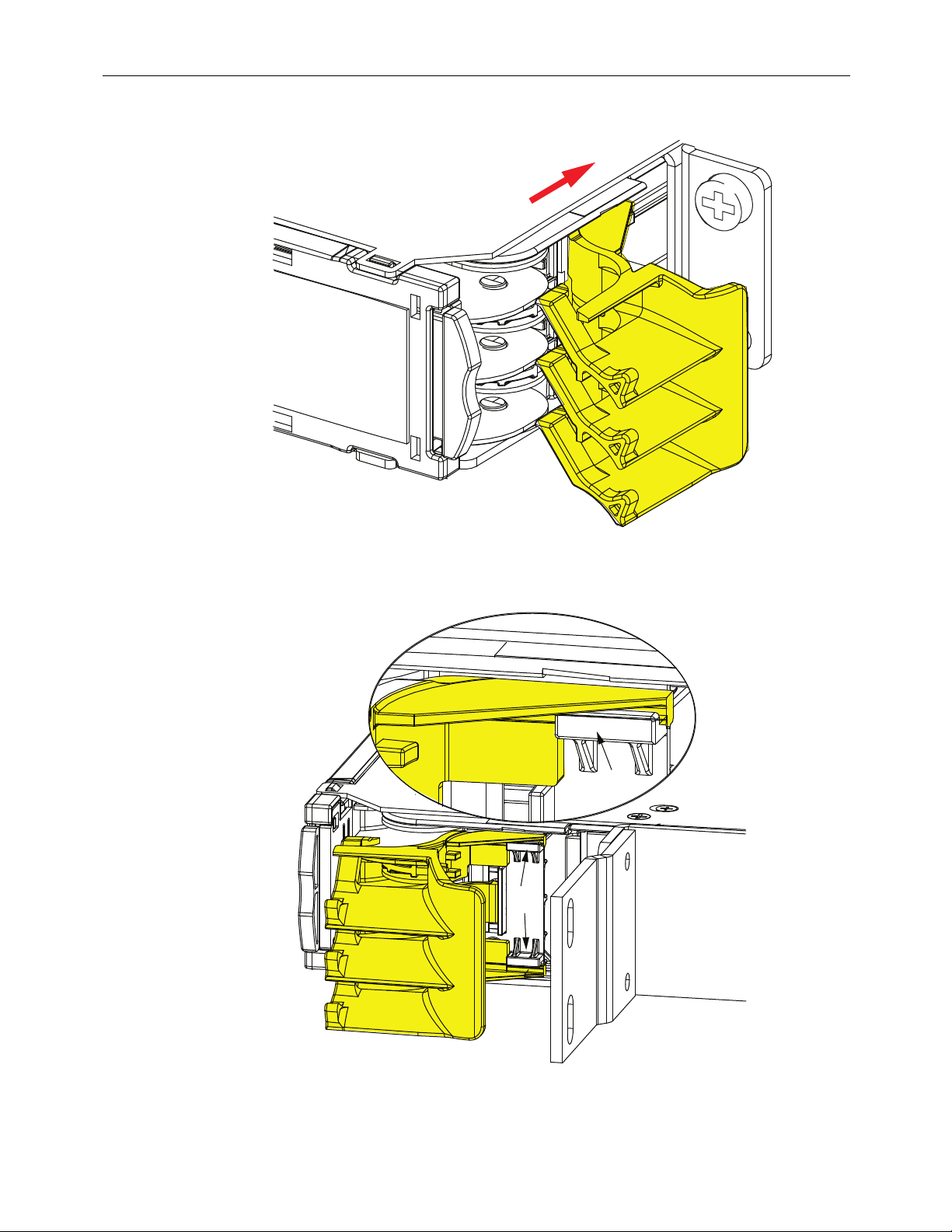

1. Orient the VCG with the panel as shown in Figure 4.

Note: The panel is shown here without extension brackets.

2. Insert the VCG into the panel using the orientation shown in Figure 5.

3. Press the VCG into position in the panel as shown in Figure 6.

Note: Make

sure the leading edge of the VCG is inserted under the guide rails as shown in

Figure 7.

Page 10

© 2017 CommScope. All Rights Reserved.

Page 11

FRONT VIEW

OF FRAME

TECP-90-801 • Issue 4 • October 2017

26575-A

VERTICAL

CABLE

GUIDE (VCG)

Figure 4. Orienting VCG With Panel (Shown Here Without Extension Bracket)

INSERTION POSITION

Figure 5. Inserting VCG in Panel

26576-A

Page 11

© 2017 CommScope. All Rights Reserved.

Page 12

TECP-90-801 • Issue 4 • October 2017

FINAL VCG POSITION

Figure 6. Pressing VCG Into Position

GUIDE

RAILS

GUIDE

RAILS

26577-A

FRAME

NOT

SHOWN

FOR

CLARITY

Page 12

© 2017 CommScope. All Rights Reserved.

25409-A

Figure 7. Make Sure to Insert VCGs Behind Guide Rails

Page 13

3.5 Grounding the Panel

A termination (for a 10-32 screw) is provided on the panel for a frame ground connection. The

connection must be made in accordance with local and national electrical codes.

1. Locate the ground location on the panel. See Figure 8.

2. Using AWG 14 (1.6mm) solid copper wire, secure a crimp lug to one end of the ground

wire

(installer provided). See Figure 8. Secure the crimp lug to panel with one 10-32

screw. Torque the screw to approximately 15 pound-inches (1.7 Newton meters).

TECP-90-801 • Issue 4 • October 2017

Caution:

Reliable earthing of rack-mounted equipment should be maintained. Particular attention

should be given to supply connections other than direct connections to the branch circuit (e.g. use

of power strips).

Note: To assure proper operation, the panel should be connected to a good earth ground.

There must be no switching or disconnecting devices in the grounding circuit conductor

between power source and point of connection to the grounding electrode conductor.

3. Connect the other end of the ground wire to the earth ground conductor. Ensure this

connection is made using methods and hardware that meets all applicable local and

national electrical codes.

Figure 8. HDEP Ground Location

© 2017 CommScope. All Rights Reserved.

Page 13

Page 14

TECP-90-801 • Issue 4 • October 2017

3.6 Installing the Management Unit

To install the Management Unit, refer to the separate instructions provided in TECP-90-805,

provided with the unit or via the QR code on the panel. The management unit contains the panel

controller and memory used to store system settings.

3.7 Connecting the Ethernet Cable and AUX Power Cable

Caution: When connecting the equipment to the power sources, check the equipment nameplate

rating to avoid overloading circuits which may cause damage to over-current protection devices

and supply wiring.

Each panel controller has two potential power sources. One is a Power over Ethernet (

PoE)

source, and the second is AUX power from an external source.

A RJ-45 connection to the panel is required to interface the Ethernet to the end user. Connect an

Ethernet cable to the RJ-45 port. If this connection originates at a PoE switch the panel is powered

over the Ethernet connection.

If only a PoE connection is made to the panel, the PoE connection powers the panel and the AUX

power

connection is not required. If both a PoE switch and an AUX power source connection is

made, the AUX power connection powers the controller. If a standard Ethernet (non PoE)

connection is made to the controller, the AUX power connection is required to power the

controller.

A PoE switch and an AUX power supply can simultaneously be connected. A PoE switch is

designed to shut power off when the presence of another power source (AUX power) is present.

If power is not provided through the AUX port, the controller assumes a PoE switch is the

voltage source. During the AUX power application to the controller, the transition from PoE to

AUX is seamless.

If AUX power is discontinued, there is an interruption of power and communications to the

controller

before power is supplied by the PoE switch. Refer to Management Unit Instructions

(TECP-90-806) for AUX power details.

3.8 Connecting the Control Cable

Connect the wiring to the Ethernet RJ45 jack on the PoE switch. Plug the other end of the

Ethernet cable into the controller at the front of the panel.

The Ethernet port supports a maximum cable length of 328 feet (100 meters) to a switch. Pins 1,

3, and 6 (See Figure 9) are used in 10BASE-T (10Mb/s) and 100BASE-TX (100Mb/s)

2,

networking. Set PoE switch to auto-negotiate, the controller Ethernet port supports 10/100Mb/s.

Page 14

© 2017 CommScope. All Rights Reserved.

Page 15

TECP-90-801 • Issue 4 • October 2017

PIN 1

PIN 8

RJ-JACK

Figure 9. RJ45 Connector Wiring

11899-A

When bringing Ethernet cable into the panel, make sure that cable is run vertically along the left

or right side of the bay. Route Ethernet Cable to the rear of the panel. Secure cable to panel

using tie points provided. Leave enough cable slack to make connection to the appropriate

location on the Controller.

Note: All

Ethernet or PoE cabling should be routed away from any sharp edges and

properly secured in place to prevent chafing and to provide strain relief. This may be

achieved by tie-wrapping the wires to the rack frame or by a similar means.

3.9 Connecting the Panel to the Quareo Network

After the Quareo HDEP has been physically installed on the rack, a software procedure must be

performed to access the panel controller and make the controller known on the Quareo network.

This procedure is done using a web browser to access the configuration web pages of the panel

controller. This can be done at the panel by connecting an ethernet cable from a computer to the

RJ-45 port of panel controller to gain network access to the controller. Once the IP address of

the panel is known, the user can input the address of the panel controller into the web browser to

access the configuration pages.

Instructions for performing the software procedure described above can be found in TECP-90-

which is available on the CommScope website.

805,

4 INSTALLING MODULES AND IFC CABLES

Note: Remove the dust cap, inspect, and clean MPO connector per ADCP-96-150

instructions before terminating. Remove the ferrule dust cap from one of the patch cord

connectors and then clean the connector as specified in the Optical Fiber Connector Wet

and Dry Cleaning Instructions (ADCP-90-159) or by locally approved procedures.

Modules available for use in the Quareo 1RU high density panel include the following:

• LC-LC adapter pack

• MPO-MPO adapter pack

• LC-MPO module

• LC cabled module

© 2017 CommScope. All Rights Reserved.

Page 15

Page 16

TECP-90-801 • Issue 4 • October 2017

In general, all modules are installed by opening the access tray, snapping the module into place

in the access tray, and routing the fiber cables through the access trays. Instructions unique to

the various module types are provided through QR code access to the CommScope Field

Support Link. This online site contains video, animations, and other information for the specific

module being installed.

The QR code is a label on the front of the panel; the Field Support Link is accessed using a

recognition app on a smart phone.

visual

5 TECHNICAL ASSISTANCE

http://www.commscope.com/SupportCenter

Page 16

Loading...

Loading...