Page 1

Commodore

Disk Drive

Technical Manual

Model

8250LP

SFD-1001

These

documents

are

for

repair service

information

only.

Part

numbers

are

for

reference

only.

Only

parts

on

current

dealer

parts

list

are available.

No

license

is given

for

any

use

by

possession

of

these

documents

and

may

not

be

reproduced

in

any

form

without

the

written

approval

of

Commodore

Electronics

Limited.

C::

commodore

COMPUTER

Page 2

CONTENTS

I.

GENERAL

rL

CAPACITY

m.

MEDIA

IV.

ENVIRONMENTAL

V.

RELIABILITY

VI.

POWER

VU.

DRIVE

VlII.

INTERFACE

IX.

SUGGESTED

GENERAL

CONTROL/DATA

TIMING

REQUIREMENTS

X. PHYSICAL OUTLINE

XI.

PARTS

LIST

(1)

Page 3

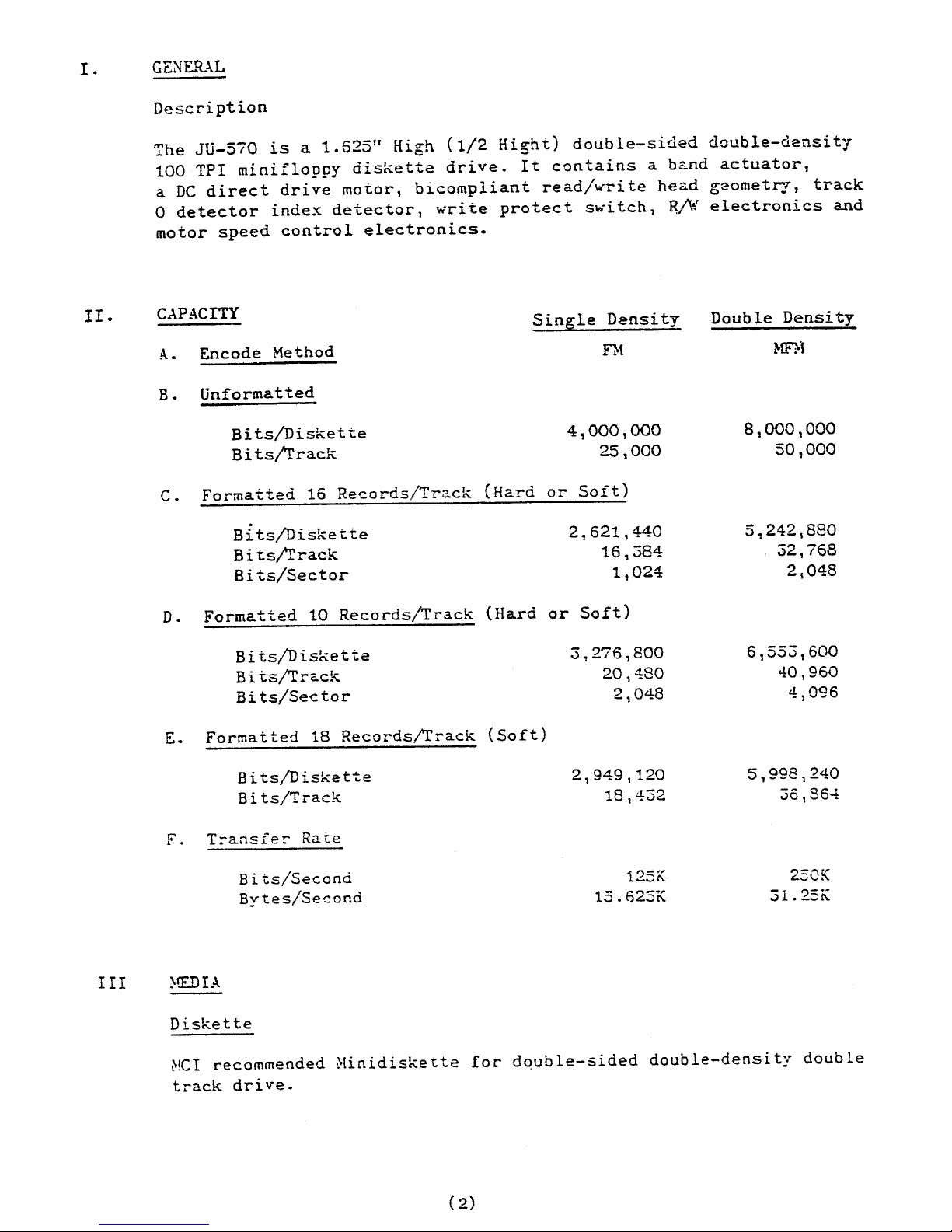

I.

GENERAL

II.

Description

The

JU-570

is

a

1.

625"

High

(1/2

Hight)

doub

le-sided

double-clensi

ty

100

TPI

minifloppy

diskette

drive.

It

contains

a

band

actuator,

a

DC

direct

drive

motor,

bicompliant

read/write

head

geometry,

track

o

detector

index

detector,

write

protect

switch,

~/W

electronics

and

motor

speed

control

electronics.

CAPACITY

Sin~le

Density

Double

Density

A.

Encode

Method

n{

~tF1>1

B.

Unformatted

Bits/Diskette

4,000,000

8,000,000

Bits/!rack

25

,000

50,000

C.

Formatted

16

Records/Track

(Hard

or

Soft)

Bits/Diskette

2,621,440

5,242,880

Bits/l'rack

16,384

32,768

Bits/Sector

1,024

2,048

D.

Formatted

10

Records/Track

(Hard

or

Soft)

Bits/Diskette

3,276,800

6,553,600

Bits/Track

20,480

40,960

Bits/Sector

2,048

4,096

E.

Formatted

18

Records/l'rack

(Soft)

Bits/Diskette

2,949,120

5,998,240

Bi

ts/Track

18,432

36,864

F.

Transfer

Rate

Bits/Second

125K

250K

Bytes/Second

15.f)25K

31.

25K

III

~!E.DIA

Diskette

Mcr

recommended

Minidiskette

for

double-sided

double-density

double

track

dri

'.-e.

(

2)

Page 4

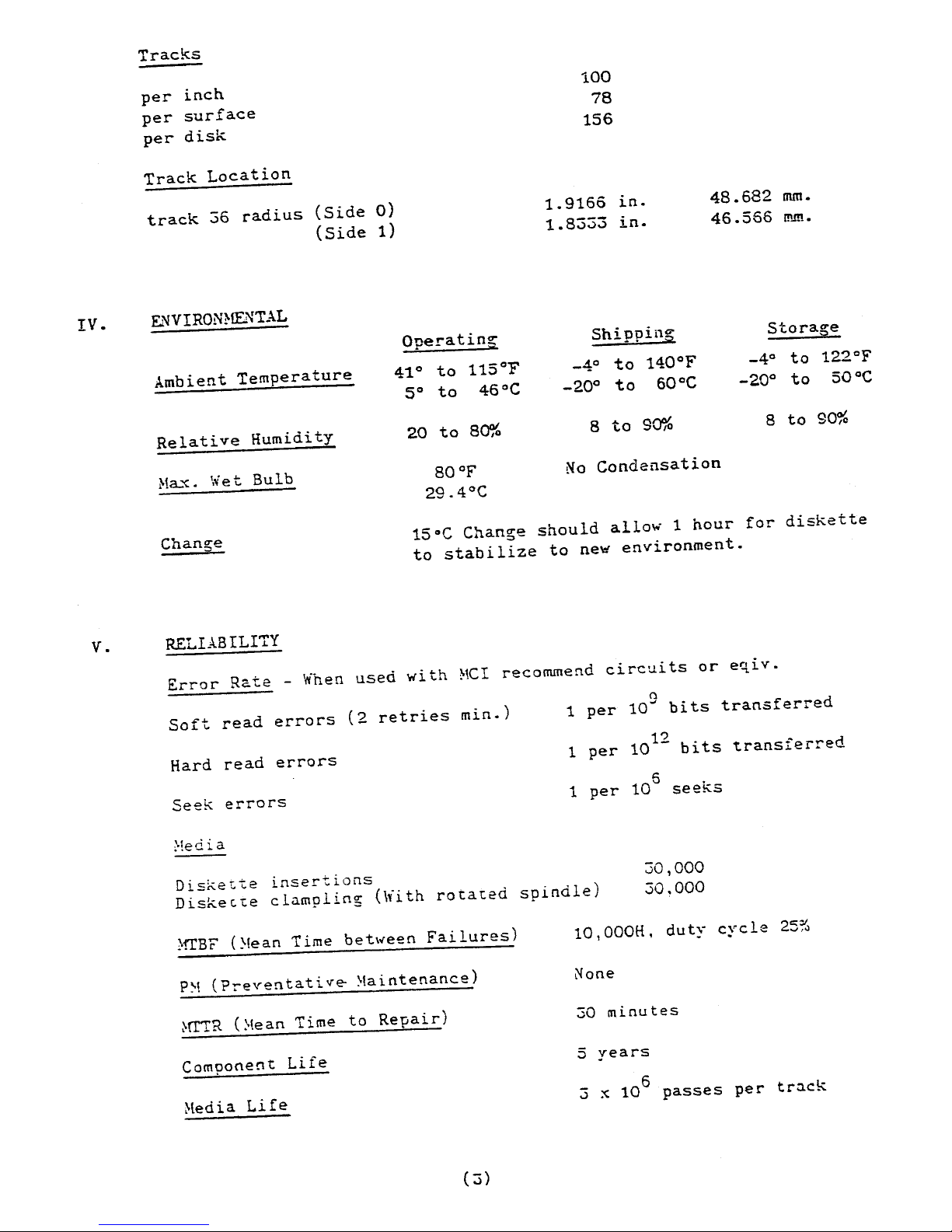

Tracks

per

inch

per

surface

per

disk

Track

Location

track

36

radius

(Side

0)

(Side

1)

IV.

Et'JVIRONHENTAL

Operatin~

Ambient

Temperature

41°

to

115°F

5°

to

46°C

Relative

Humidity

20

to

80%

Ha.'C.

\{et

Bulb

BO°F

29.4°C

100

78

156

1.9166

in.

1.8333

in.

Shippii1~

_4°

to

HO°F

-20°

to

60°C

8

to

90%

48.682

nun.

46.566

[!I.ln.

Stora~e

_4°

to

122

c

F

-20°

to

50°C

8

to

90%

No

Condensation

Change

15°C

Change

should

allow

1

hour

for

diskette

to

stabilize

to

ne~

environment.

v.

RELIABILITY

Error

Rate

-

\'ihen

used

wi

th

~'CI

recommend

circuits

or

eqi

v.

Soft

read

errors

(2

retries

min.)

n

1

per

10~

bits

transferred

Hard

read

errors

1

per

10

12

bits

t.ransferred

Seek

errors

1

per

10

5

seeks

:-!edia

Diskette

insertions

Diskette

clnmpling

(With

rotated

spindle)

30,000

30.000

~iTBF

(~Iean

T ime

bet\~een

Fai

lures)

10,OOOH.

duty

cycle

25%

p~

(Preventativ~

~aintenance)

None

~rrTR

(;o!ean

Time

to

Repair)

30

minutes

Component

Life

5

years

~!edia

Life

:;

x

10

6

passes

per

track

(3)

Page 5

VI.

PO\vER

VII.

DC

Voltages

+5.00

±

0.25

VDC

@

0.2A

typical

+12.00

±

0.60

VDC

@

1.2A

m~~.,

.75A

typical,

100

mV

p-p

ripple

BTU/Hr.

(1

watt

=

3.413

BTU/Hr.)

BTU

Typ.

Watts

Typ.

DRIVE

A.

~Iechanical

Seek

Settle

Time

Track

to

track

access

time

Drive

Motor

Start

Time

Rjlf

Head

Head

load

Radial

align./hysteresis

Azimuth

(-Iodulation

m~~.

Spindle

Speed

B.

~lour1ting

F:-on1:

Loading

42.7

12.5

18

ms

m~~.

Consisting

of

3

ms

track

to

track

seek

time

and

15

ms

settle

time

1

sec

m~"C.

17

±

:5

gr

70%

min.

33'

±

18'

20%

max.

300

RP~1

~

3%

Disket~e

Ver1:ical

(Side

1

left

or

right)

Yes

Disket~e

Horizontal

(Side

1

up)

Yes

Diskette

Horizontal

(Side

1 do",-n)

No

Top

Loading

:-;0

Page 6

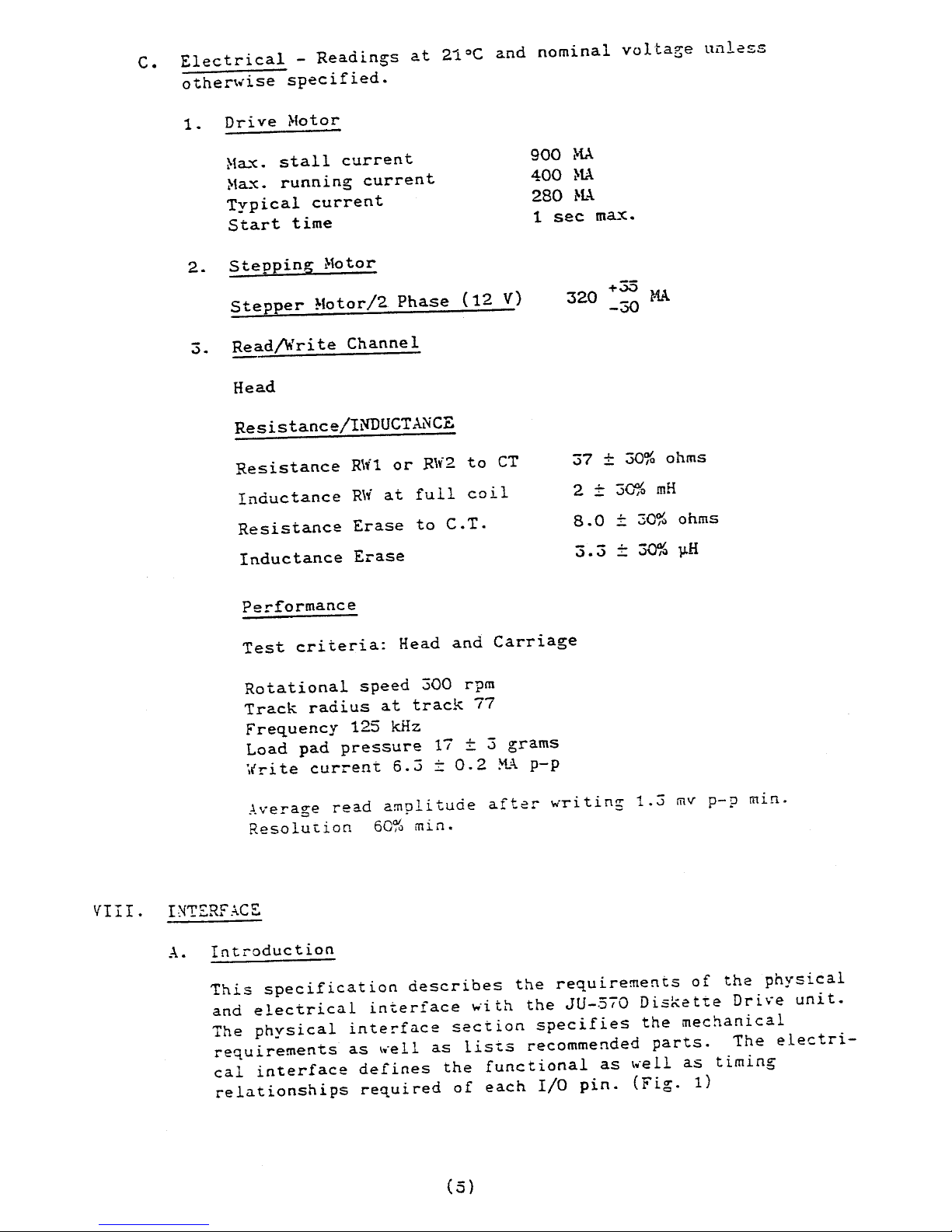

C.

Electrical

-

Readings

at

21°C

and

nominal

volta~e

unless

othen.ise

specified.

1.

Dri

ve

~Iotor

H3-'C.

stall

current

~t3-'C.

running

current

Typical

current

Start

time

2.

Stepping

:'1otor

Stepper

Motor/2

Phase

(12

V)

3.

Read/Write

Channel

Head

Resistance/1NDUCTANCE

Resistance

R\'i1

or

R\y-2

to

CT

Inductance

R\i

at

full

coil

Resistance

Erase

to

C.T.

Inductance

Erase

Performance

900

MA

400

HA

280

K.\.

1

sec

m3-'C.

1-35

320

-30

~1A

37

±

30%

ohms

2

±

3aYo

mH

8.0

_ 30%

ohms

3.3

_

30%

1J.H

Test

criteria:

Head

and

Carriage

Rotational

speed

300

rpm

Track

radius

at

track

77

Fre~uency

125

kHz

Load

pad

pressure

17

±

3

grams

',rri

te

current

6.3

::

0.2

M.A

p-p

Average

read

amplitude

after

writing

1.3

mv

p-p

min.

Resolu~ion

60%

min.

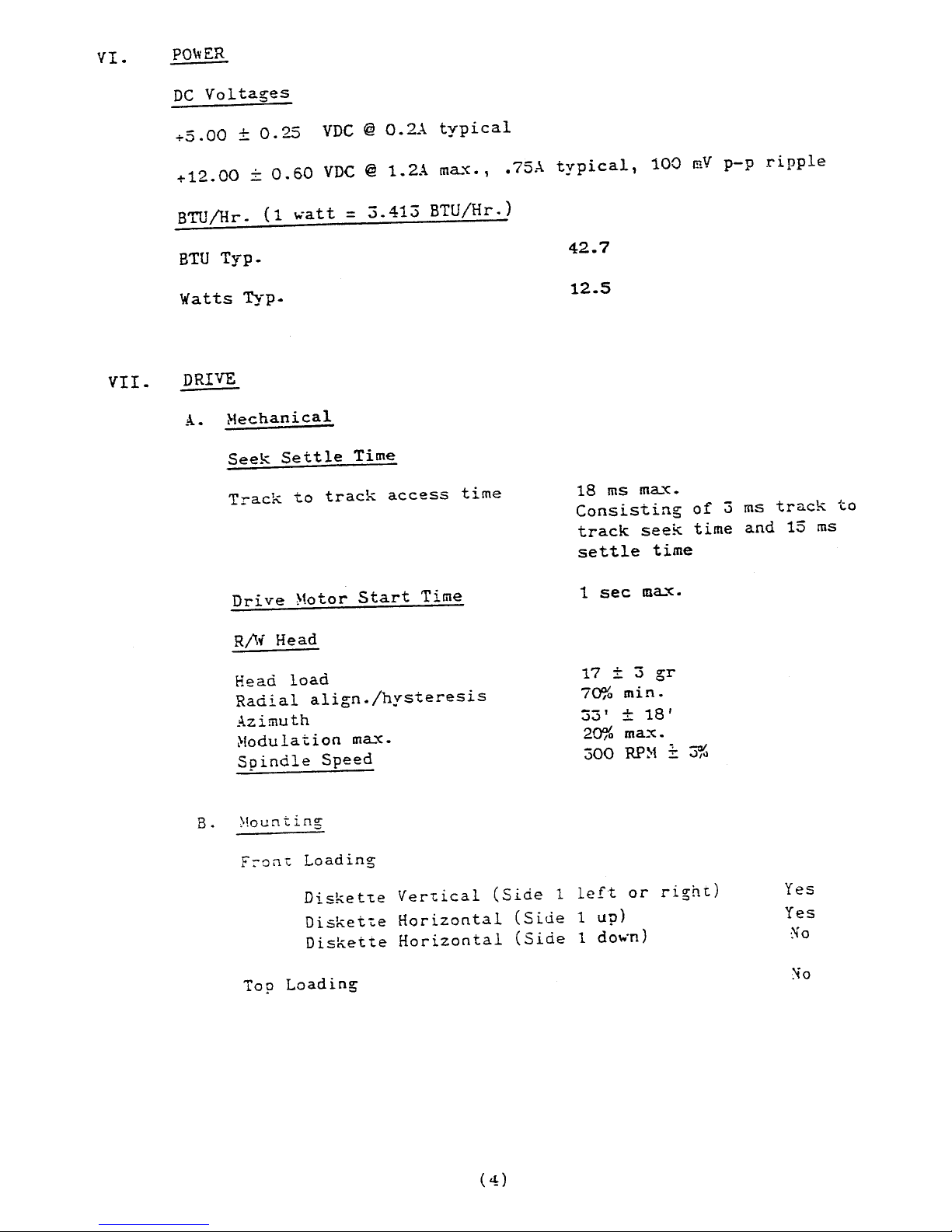

VIII.

I~T£RFACS

A.

Introduction

This

specification

describes

the

requirements

of

the

physical

and

electrical

interface

with

the

JU-570

Diskette

Drive

unit.

The

physical

interface

section

specifies

the

mechanical

requirements

as

well

as

lis~s

recommended

parts.

The

electri-

cal

interface

defines

the

functional

as

well

as

timing

relationships

required

of

each

I/O

pin.

(Fig.

1)

(5)

Page 7

GV

5V

(NC)

GV

12V

GV

Gi"iD

-HOTOR

ON

TRACK·

ZERO

PH·E

TR..,l"CK·

ZERO

PHC

TR..\CK·

ZERO

LED

K

(KEY)

(NC)

STEPPER

COM

0

STEPPER

CO/>!

1

Sl-ID

-4

S?-ID

-1

S:-ID

-2

Sl-ID

-3

ACTIVITY

LED·..\.

ACTIVITY

LED·K

WRITE·PROTECT.PHE

~~ITE·PROTECT·PHC

I~uLX·SECTOR·PHE

INDLX·SECTOR·PHC

(NC)

I

(NC)

ide

0

GND

tEY)

R/WZ

COMMON

R/Wl

E~ASE

d

e

1

NC

ER.ASe:

R/,N

1

COMMON

R/W2

GNO

P1

..

1

2

3

45

6

7

8

9

10

11

12

13

1415

16

17

18

19

20

21

22

23

24

PZ

1

3

5

7

9

1 1

2

4

6

8

10

12

.

(HEn

)

(ORA)

SPINDLE

~!OTOR

(BLK)

CONTROL

PCB

(\,HI)

(\"HI)

(GRN)

r------

--~

~

~

~

r'\

'I

(YEt)

'~'ONll05

l

: t.:1\ :

I

~

!

~--------

-

(RED)

(RED)

fl"I.

(ORG)

r-

----<

-----c

~,

..

-

I

(BUO

I

I

,.-

(BRN)

I

:

STEPPER

~iOTOR

(YEL)

..

I ..........

(GRY)

'-_!V

____

(WHI)

(BLK)

(G&'l

)

(ORG)

(

RED)

Pi

(C:--lT

C:--l)

R/W

I

•

•

____

..r.

tCi\

'C)I

,---....

PN1190

ER

CORE

I

~

.~

~------------------~

I

n

R/E

CORE

ER

CORE

J

J

WRT.P.

IND.

LED

LED

-Q-J

PN1184

Side

0

Sid

e 1

P2 (HE.;'O CN)

Fi~.

1

The

Electrical

Interface

Schematic

Page 8

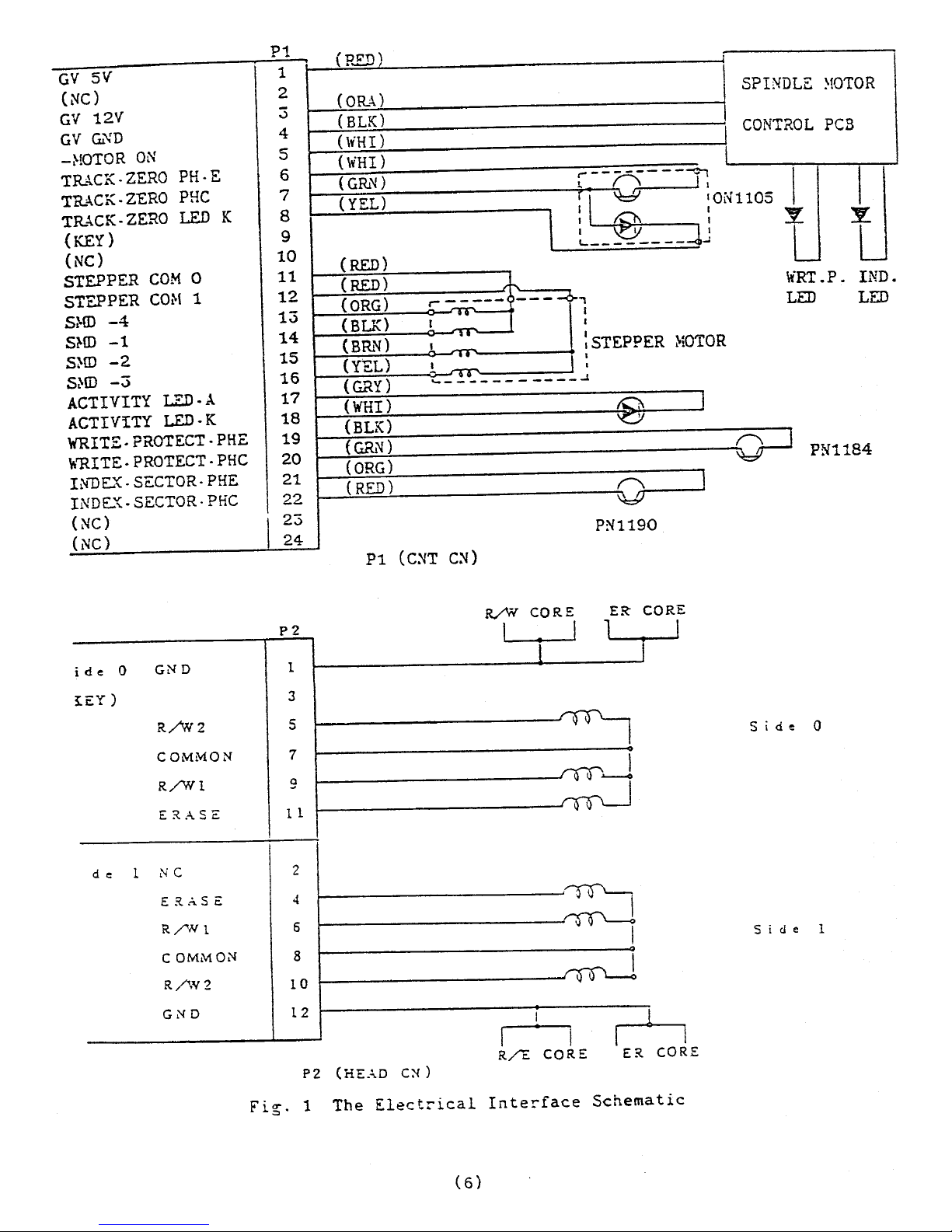

B-1.

RjI,{

Head

Interface

Connector

P2

provides

the

physical

interface

to

the

magnetic

head

as

shown

in

figure

2.

c:J

1

2

c:J

3 4

Q

c::J

5

6

c::J

7

B

c::J

9

10

c::J

11

12

3:

KEY

Fig.

2

P2

Connector

B-2.

Schematic

P2

5)

R./W2

C

RED)

l)GND

(YEL)

11)

ERAS

c:

(Grt.!i)

i

~

R/Vi

CT(WHT)

9 )

R./Wl

(ELK)

10)

R/W2

(RED)

12)

GND

(YE

L )

4)ER.:SE

(GRN)

8)

R~N

CT(WHT)

6 )

R/Wl

(

ELK)

(7)

Head

Core

~

7

~.---?--::t~

7

Side

0

Side

1

Page 9

B-3.

8-4.

Connector

Requirements

Housing

Contacts

PCB

Header

Honda

HKP-12F02

Honda

HK?-F303

Honda

FFC-12TLBW1B#3

The

w~ITE opera~lon

utilizes

both

read/write

coils

sequentially,

where

each

~ritten

bit

is

directed

to

alternate

read/write

coil,

creating

a

change

in

the

direction

of

current

flow

through

the

read/write

head.

The

required

current

is

6.3

±

.2

ma

peak

to

peak,

or

3.15

±

.2

ma

base

to

peak

on

all

tracks.

It

is

recom-

mended

that

the

write

current

transitions

are

within

0.5%

from

leading

edge

to

leading

edge.

Proper

write

damping

must

be

considered

during

design

for

write

transitions.

Note:

The

head

must

be

loaded

for

proper

write

operation.

4-2SA720

or

Eq.

4-MA162

or

Eq.

P2-9

·

~

i

>>---3

tZ2k

62k~

I

~ Sid~O

I

~

HEAD

P2-5

..,

)! •

I

>>---J

-WRITE

DATA

1

J-

'f

I

pt

~

2k

l~

I

-----:::~\'\.

150

22k

6?l.-

j""'-'

Side

1

2~~

332

~

~

332

,-.-!-_1_~_

....

I

__

---,L~,-··

..

pZ)10i.

?

HS.l.O

1:;

I

I

l~

•

7i

7.

AA

I?

I

WRITE

OA.Tf>..

J

_______

~~~.A-1_~----~

SV

Oi----

.... ,

--.....,V

l

1

P2-i

T~

0

?2-8

~

22k

CONSTANT

r

I

C~R~E~~

SOURCE

[0

;>

-

3.J.

_

0.1

rnA

iii

I

!

I

Lw

1

WRITE

GATE

6~1

~n-"I,I,--l

L..;L-J

6.30

I

I

E:X?

.....

NOED

WRITE

GA7E

O

II

I~:

-~I-----"

I

l~

I "

I

----------1-5~1

M

i

Zt

~+br----

...

,

-{:i~K---+--':::i

12VA

-S[OE1

SELECT

----------~I

\,I.\tr-----V·,~~--,

I'

470

l.Si<

I

12i

13

1 ; 0.01.::

m

i77

1TT"

Fig.

3 A

RECO~~fE

. .'mED

I~TEP..FACE

FOR

\~~ITE

OPE.RATIO."!

(8)

Page 10

B-5.

Side

0

Head

Side

1

Head

The

READ

operation

occurs

when

the

head

is

loaded

and

data

has

been

previously

recorded

on

the

track

of

interest.

Using

an

S/A

diskette

the

minimum

differential

amplitude

of

1.3

mY

peak-

to-peak

occurs

on

T~~

77

at

a

frequency

of

125

kHz.

A maximum

signal

amplitude

of

20

mY

occurs

on

TRK

00

at

a

frequency

of

625

kHz.

The

customer

is

cautioned

to

use

propzr

clamping

for

the

read

operation.

A

recommended

interface

is

shown

in

figure

4.

~

~n,

4-MA

162

:<

~

'tt'

'"

orEq

r

I

12VA

2-9.09k

1~

•

!1

p

~e

~.

--~~--'~~~-----<:<~----~

i

//

I

P2

-:.

0

,.-..----.-----

..

"

..

Diffe!"encial

Read

Que

:\mll.

I

p))>-I

______

l_.5_._:.:

...:.t

___

-<fo--l._S_k_:~r/-,..·-__:J>~

\

470

)1

Selected

5

ice

is

OV

P2-3

(or

ReAd

Qperacion

'----"7~>---------------...------\\'Y-.

-----,:;.:;..

-\70

Fig.

4 A

RECO~~~~DED

I~TE~~ACE

FOR

READ

OPE~\TION

XOTE:

Figure

3

and

4

interface

circuits

are

valid

only

when

used

in

connection

with

each

other.

(9)

Page 11

B-6.

The

ER~SE

COIL

requires

a

DC

curren~

of

40

ma

± 4 ma

energized

during

any

write

operation.

Both

erase

current

and

write

current

should

be

started

and

ended

simultaneously.

A

recommended

interface

for

the

erase

coil

is

sho~n

in

figure

5.

Delaied

Wri

te

Gate

90gn

1/8W

l~

+v

~

A,~

__

~

__

~

~;4n

1/8W

l~

+v

to

Fig 3 ______________

-.1

oE------.-.i

S

id~

0

I

I

I

I

P2-8

c::

Side

1

1£=40

::: 2

MA

ERASE

COIL

Fig.5

A

RECO~!}IE.'mED

INTERFACE FOR EAHSE

COIL

(10)

Page 12

C-1.

Stepping

Motor,

Drive

Motor,

Write

Protect,

Track.OO

and

ACTIVE

LED

Interface

Connector

Pl

provides

the

physical

interface

to

stepper,

drive

motor,

write

protect,

Track

OO,and

Inde:.:.

EO US

n"G

.

c;::

~.

~:-:-'

....

-"

'--

!'l

-.~

%4

I I I I

I

til

,(

1'-1

a a

L

__

\\_::Ji

fi

-

!

I I

=-

r

(?>Q.

I I_I

I I

-;+-,--

t.~4

II

i~~~

~~

I

I

_I

C-

I

I

I _

-...::..

,

,

r-------

....

-'""""-----.

........

--

.l'1--

. I

'i

~

L-

..

_____

I

~

!;

'~I~

Fig.6

Connector

Requiremen~s

Housing

Contacts

PCB

header

Honda

Honda

Honda

HKP-24F02

HKP-F403R

HKP-l0~12L

FFC-24TLB\\'lB

#9

(11

)

Page 13

C-2-

Step

Motor

Input

Requirement

The

motor

is

a

bifilar

wound,

four

phase

stepper

which

generates

a

1_80 step

with

single

phase

stepping.

BROWN

RED

YEL

LOW

__

S:=/.lM~D~-..>/-

__

~

,..,..,""t"V""""

•

~

~

/iii

U

Q

~

-c;

r.l

;;;

:::

0

To

Energize:

Both

red

center

taps

go

to

+12V

DC

and

go

to

+5V

DC

for

unselected

drive.

For

selected

drive

an

appropriate

two

phases

are

connected

to

ground.

PHASE T • .!,.BLE!T\W PHASE

DRIVE

TRK

POSITION

I

S~ID-3

I

S~ID-2

I

S~u)-4

I

S:''D-l

(YELLQ\y)

(BRQ\iN)

(

OR...!,.NGE)

(BL..l,.CK)

4 x n

+0

I

LQ\y·

I

HIGH

I

HIGH

I

LO\y·

4 x n

+1

I

Lo\v

I

LQ\y

I

HIGH

I

HIGH

4

x n

.;-2

I

HIGH

I

LO\v"

I

LQ\v

I

HIGH

4 x n

~

. .J

I

HIGH

I

HIGH

I

LOI(

I

LOli

(

12)

Page 14

C-3-

Stepper

Timing

Driven

in

Two

Phases

DR

rVE

STEP

-

STEP

SELECT

DIRECTION

S;'W-3

SMD-2

SMD-4

S"1O-1

4n+0

I

C--L

Stepper

Voltage

\\·he".

no

step

command

+1

+2

+3

to

inner

or

riO

selec:.ed

ste?per

is

s.,i

tched

to

+5V

to

avoid

+4

t

+3

I

1

----+

12Y

...

·----+5v

+2

I

to

outer

drive,

+12V

supplied

to

pO\'rer

consumption.

Page 15

D.

Hotor

On

This

input,

when

activated

to

a

logical

zero

level

(open

collector

with

1 K ohm

pull

up)

will

turn

on

the

drive

motor

allowing

reading

or

writing

on

the

drive.

A 1

sec

delay

after

activating

this

line

must

be

allowed

before

reading

or

writing.

In

general

when

the

drive

is

not

selected,

the

motor

should

be

off

to

extend

motor

and

diskette

life

and

decrease

pOlver

consumption.

System

timing

must

be

analyzed

to

determine

optimum

delay

bebieen

deselection

of

drive(s)

and

turning

off

motor(s).

Shown

below

is

one

of

examples

for

motor

control

PCB

~hich

should

resides

on

customer's

PCB.

12V

Pl-3

+MOTOR

ON

5V

1

0-«

l.5k

Pl-5

.

~~(---

---------1[:>

7406

Fig.

7

E.

Write

Protect

Switch

Interface

TO

DC

MOTOR

CONTR.OL

Connector

P1

provides

the

w~ITE

PROTECT

PHOTO

DETECTOR.

5V

I

1

f

'

47k

..,../l

150

P1-20

~~~~i------<~(----~~

I

o.l~F

Pl-19

r

"-0

--_«

7414

TTT

Fig.

8

I

r------

I

I

I

I

L

______

_

L

OX

DC

~!OTOR

COXTROL

BOAD

Page 16

This

interface

signal

is

provided

by

the

drive

to

give

the

user

an

indication

when

a

write

protected

diskette

is

installed.

This

signal

is

a

normally

opened

switch

contact

when

the

diskette

is

not

protected

and

closed

when

it

is

protected.

Writing

on

the

diskette

is

inhibited

on

the

drive

when

the

diskette

is

write

protected.

F.

TRACK

00

The

drive

need

the

11L~CK

00

signal

to

obstruct

BUMP

NOISE

in

recal

motion

USER

should

prepare

the

logic

circuits

that

make

stepper

stop

to

outer

direction

after

TRACK

00

signal

is

active

low.

step

n----')~

to

make

stepp.;:r

stop

force

out

+5V

P.1-7

---<((

,-------

SMD-2

,...----

SMD-4

150n

r----T-~~~~--------_<~-~

7414

IO.OIU

lTT

Pl-8

r-«

47'dl

~

150n

I I

m

177

}-----

0

[RECTON

(OUTER:

H

r )

Fig.

9

(15)

I

\V

Page 17

G.

ACTIVE

LED

Drive

have

the

interface

of

the

active

led

on

the

face

plat~.

Recomended

interface

is

shown

in

Fig.

10.

sv

Pl-17

or-------<~"~(---,I

V

Active

Led

,

_____

-<p

1£.-_1_8

__

---'1

(

Red)

----[>>-----Wy.. « -

330n

$;.'174

LS05

or

E'l

Fig.

10

(16)

Page 18

H.

Frame

Ground

The

drive

frame

must

be

grounded.

If

drive

is

incorporated

into

a

batte.:-y

powered

portable

system,

then

D.C.

ground

is

recomm:;n-

ded.

If

system's

input

power

is

line

voltage,

then

the

third

wire

SAFETY

GROUND

is

recommended.

A~W

PIN

61761-2

AC

or

DC

power

input

ground

and

mating

connector

A~W

PIN

60972-1.

I.

Power

Interface

Diskette

Storage

Drive

requires

DC

power

for

operation.

Th:;

t~,.o

required

voltages

are

as

follows:

(1)

+5.00

±

0.25

VDC @

0.2A

typical

(2)

+12.0

_

0.6

VDC @

1.2A

max.,

.75A

typical,

100

mv

max

allowable

p-p

ripple

Hotor

start

surge

(see

below)

The

12V

current

is

composed

of

tw·o

components;

diskett:;

drive

motor

current

and

read/write

steppe.:-

functions.

Also

the

diskette

drive

motor

is

energized

and

deenergized

by

the

"}Olotor On"

or

"Drive

Select"

interface

line.

Each

of

these

functions

has

the

following

contributions

to

the

+12V

current

requirements.

(1)

Read~vrite

function

and

stepper

motor

(driv-e

"standbyJl

cur.:-ent)

+5V

current

is

1.0A

typical

0.3A

max.

(B)

Diskette

drive

motor

start

+12V

current

is

1.0A

typical,

1.2A

max.

for

1

sec

max.

(C)

Diskette

drive

motor

running

+12V

current

is

.2SA

typical,

O.9A max.

(motor

stalled)

(

17)

Page 19

IX.

SUGGESTED GENERAL CONTROL/DATA

TUII0iG

REQUIRDiE.'ITS

P07.-ER

ON

lOOms

(Min)

~

____________________________________

~1~~1

________

_

MOTOR

ON

--------.1

L._~

___________________________

--,}~}

________

__

1<

I I

DRIVE

SELECT

-------.....,

L-

______________________________________

~~~}---------

VALID

TROO

M'D

-,

~

500as

(Max)

----~I

V~.PROT.OUT

I~'

----------------------------~»~----------

I

Ims

"

SIDE

SELECT---~--~------------~

(Min)

I

~

____________

~~~J----~

;---"--

l;.:s

(Min)

l I

DlRECTION---~-----~

I I I 1

ms

,(

I

))

I

l.c:s 2;.rs

(Min)

30;.rs

(M.in)

I I

~l----~,~(Min)

r

STEP---------------~

(Min)

2=

(Minj

2ms

~--~~------~'~

!

18ms

(:>1-in) I I

I

I 8;.rs

(Me

..

;;:)

WRITE

GATE---------------------------~

(Min)

(Min)

I

DELAIED

WRITE

GATE

EXPANDED

VvR

ITE

GATE

500ns(Min)

I I I

100;.r s

'-----------;/~

~

f'

~--..,.-;;..

!430us

,--

__

I 870,c:s

I

l..------'~\

I I

I

i I

wRITE

DATA

-----------------------~-

I""

ulJlJ

Ii :-----'---

~.~~:c(~:{/nn:

--,-;----iLJ=8-",(M.xJ~

(\;;':;:~

1-

VAL

ID

READ

DATA

------------------.:..-.

I

II~

~

I

I

j-

200us

(Min)

Z;ts(Max)

----

12

sec

(Max

jl---~

Fig.

11

(All

signals

are

sho~n

as

low

active)

Page 20

X.

PHYSICAL

OUTLINE

r

o _I

I I

"'·C::;-::N

I

167

~

, I

i

.~.I''=

,-

I ;

• ~ $

Fig.

12

m

~

~

I

! -:-

=

Page 21

XI.

PARTS

LIST

REF.

MANUFACTURE

DESCRIPTION

Q'TY

NO. PART

NUr-mER

1.

YJF3LOl141Bl

BASE

1

2.

YJFS\-W0150B2

FRONT

PANEL

1

3.

333046817670

HANDLE

1

4 .

YJFl-1D00170B4

DC

MOTOR

1

5.

YJF3101010A3

STEPPING

MOTOR

ASS'Y

1

6 .

YJ617612

FASTEN

TAB

1

7 .

YJUF56TRK-2S

DETECTOR

1

8 .

YJF2T00601B4

BFACKET

1

9 .

YJF2E00590B4

GUIDE

ROD

2

10.

333046331360

CLAMP

GUIDE

ROD

1

11.

YJF2E00580B4

CLAMP

GUIDE

ROD

( 2 )

1

12.

YJUFS6HCA-2

R/W

HEAD

ASS'Y

1

13.

YJF2H00681B3

SHIELD PLATE

1

16.

YJF2E00631B4

GUIDE SHAFT

ASS'Y

1

17.

YJF2E00560Bl

Cll.RTRIDGE GUIDE

1

18.

YJUF56WP-2S

DETECTOR

ASS'Y

1

19.

333036331610

LIFTER

1

20.

333046624810

LIFTER

SHAFT

1

2l.

333046625021

LIFTER

SPRING

1

22.

YJF3100160A4

COLLET

ASS'Y

1

23.

333046624770

LOCK

SPRING

1

24.

YJF3100461A3

CLl>.MP

CAM

ASS'Y

1

25.

333046817500

PAD

1

(20)

Page 22

(

21)

Loading...

Loading...