Commodore CM-141 Service Manual

-

CM-141

SERVICE MANUAL

......

PN

314004-02

~

commodore

COLOR VIDEO MONITOR

JULY 1984

Commodore Business Machines, Inc.

1200

Wilson Drive,

West

Chester, Pennsylvania

19380

U.S.A.

Commodore

makes no expressed

or

implied

war-

ranties

with

regard

to

the

information

contained

herein. The

information

is made available solely

on

an as is basis, and

the

entire risk

as

to

quality

and

accuracy

is

with

the

user.

Commodore

shall

not

be

liable

for

any

consequential

or

incidental

damages

in

connection

with

the

use

of

the

information

con-

tained

herein . The

listing

of

any

available replace-

ment

part

herein does

not

constitute

in

any

case

a

recommendation, warranty

or

guaranty

as

to

quality

or

suitability

of

such

replacement

part.

Reproduction or use

without

expressed permission,

of

editorial

or

pictorial

content,

in

any

matter

is

prohibited.

This manual

contains

copyrighted

and

proprietary

information.

No

part

of

this

publication

may

be reproduced,

stored

in a retrieval

system,

or

transmitted

in

any

form

or

by

any

means,

electronic,

mechanical,

photocopying,

recording or

otherwise,

without

the

prior

written

permis-

sion

of

Commodore

Electronics Limited.

Copyright © 1985

by

Commodore

Electronics

Limited.

All

rights

reserved.

...

CM-141

SERVICE MANUAL

CAUTION

Before

servicing

this

chassis,

it

is

important

that

service

technician

read

the

"Safety

Precaution"

and

Product

Safety

Notices"

in

this

service

manual.

PN

314004-02

CONTENTS

SPECIFICATIONS ...................................................................................................................... 2

SAFETY PRECAUTIONS . ......... .... .................... ........ ....... .................. ........ ........ ........ .......... ...... 3

MAJOR CIRCUIT DESCRIPTIONS ............................................................................................ 5

CIRCUIT DESCRIPTIONS ................ ................ ............ .................. ............................................ 6

BLOCK DIAGRAM

..

........ .......... ................ ...... .... ........ .............. ....... ....... .................................. 9

CHASSIS TOP VIEW ................................................................................................................. 10

COMPONENT AND TEST POINT LOCATION .........................................................................

11

INSTALLATION AND SERVICE ADJUSTMENTS ..................................................................... 12

REPLACEMENT PARTS LIST ................................................................................................... 16

TERMINAL VIEW OF SEMICONDUCTORS ..............................................................................

21

MECHANICAL DISASSEMBLIES .............................................................................................. 22

SCHEMATIC DIAGRAM ............................................................................................................ 23

PRINTED CIRCUIT BOARD ...................................................................................................... 24

~commodore

COLOR VIDEO MONITOR

JULY 1984

SPECIFICATIONS

1. SYSTEM ......................... NTSC

TV

SYSTEM (With luminance and chrominance

signal separate INPU

I).

2.

CPT

-Type

.............

.......

TV

Grade CRT, Slit type screen

• Size

& Deflection Angle ...............................................

13",

90° deflection angle

-

Neck

Diameter ....................................................................................... 29.1 mm

3.

INPUT

3-1. Video Input

Signal Type: Color video composite signal.

Input Level: 1.0 Vp-p (Negative synchronous signals)

3-2 Commodore Video Input

1)

Luminance Signal Input

Signal Type ....................................... Composite video signal

Input

Level.

............ ...... ........... . ................................. 1.0Vp-p

2)

Chromlnance Signal Input

Signal Type .................................... NTSC chrominance signal

Input

Level...

.... .

...

... ...

.......

..

...

........................ 1.0Vp-p

3-3 Audio

-Input

Signal

..

............................................

OAV RMS max.

3·4 Input Impedance

-Video

-Audio

4. Input

Terminal.

5.

Horizontal Scanning

Frequency.

.....

....... 75 ohm

...

10K ohm min.

RCA pin

jack

.

...........................

1575

KHz

6. Vertical

Scanning

Frequency. . ......

..................................................

60 Hz

7. Video Amplifier Type

8.

Horizontal Resolution (at center)

9.

Commendable

Display Area

10. Outside Controls

• Front Controls

• Rear Controls

-Side Controls

.........................

.

11.

Audio

Output

Power (Option) .

12.

Power

Input

...

...

.......

linear

..................

...............................

270

lines

. 235

x 190

(S

x S dot)

............................. Volume, Brightness

........ Tint. Color, Contrast. H-Posltlon, V-Hold

.....

. ........ Power ON/OFF

'

..

1.2 watts.

........................

(AC) 120V, 60 Hz

O.SA

- 2 -

..

-

-

-

....

-

-

--------------

.... -_______________

,

_______

•

___

,_.w,.

.........

________________

_

IMPORTANT SERVICE SAFETY PRECAUTION

Service

work

should be performed only after

you

are IhorooghIy

t.niliar

wittl

aI

0(

the loIIowing safety

checks

and

S8fviclf1g gUIdelines

WARNING

1. No modification

of

any circuit should

be

attempted for continued

safety,

2.

Disconnect

tne

AC plug from the

AC

outlet before repillcing parIS.

.1

Semiconductor heat sinks should

be

regarded

as

potential stlock

hazards when the

chaSSIS

is operating.

4 The chassis in this receiver is

hot

(connected to one side

0(

the

AC

~ne).

Use

an isolatIOn transformer between the line cord and power

recep~,

when servicing ttlis chassis.

;;ERVICING Of' HIGH

VOl

T AGE SYSTEM AND PICTURE

TUBE

When servicing the high voltage system, remove the static charge

by

connecting

a 10K ohm Resistor in series with an Insulated wire

(such as a test

probe)

between ttle chassis

and

the

anode

lead. (AC

!llle cOfd should

be

disconnected

from AC outlet,)

1.

Picture

tube

in this receiver employs integral Implosion protectIOn.

2.

Replace with

tube

of the

same

type

number

for continued safety.

3 Do not lift picture tube

by

the neck.

4 Handle the piclure tube only

when

weanng shatter-proof goggles

and

after discharging the

high

voltage completely.

X RADIATION

AND

HIGH VOLTAGE LIMITS

1. Be sure

your

service personnel are aware of the procedures

and

instructions

covenng

X-radiation The only potential sources of

X-

ray

In

current

sold

state

TV

receivers

is

the picture tube. However,

the picture

tube

does

not emit measurable X-ray radiations

if

the

high voltage

is

kept at factory·set levels

It

is

only

when

hlQh

voltage

IS

excessive that X -radiatIOn

is

capable

of penetraling the shell of the picture tube including the lead

In

glass matenal. The important precautIOn

IS

to keep the

hlQh

voltage

at factory-set

leVels,

q

It

is essential that servicemen have available at all times an

accurate high voltage meter. The calibration of this meter should

be

checked

periodically.

3.

High voltage should always

be

kept at rated value

no

higher.

Operalion

at higher voltages

may

cause a failure of the picture

tube

or

high

vo~age

Circuitry and, also,

under

certain conditIOnS,

may produce radiatIOn

In

excess of desirable levels When the high

voltage regulator

is

operating properly there

is

no possibility of

an X-radiation problem. Every time a color chassis

IS

serviced, the

brightness should

be

tested while monitonng the high voltage with

a meter to

be

certain that

the

high voltage does not exceed the

specified value and that it is regulating correctly.

-3-

X-RADIATION AHa

HIGH

VOlTAGE

LIMITS (Continued)

5.

Do not use a picture

tube

other than that

spedl8d

Of

make

unrecommended circuit modificattonS

in

the high voltage circuitry.

6.

When

trouble

~

and taking lest measurements

on

a receiver

With

an excessive high voltage, avoid being unnecessarily

close

to the receiver. Do not operate the receiver longer

thcw1

is

necessary

to locate the cause of excessive voltage.

BEFORE RETURNING THE RECEIVER (Fife &

Shoctc

Hullrd)

BefOfe returnlf1g the receiver to the user, perform the follooMng

safety checks.

1. Inspect

aN

lead dress to

make

certain that leads are not pinched

Of

that hardware

IS

nd

lodged between the chassis and other

rne1a1

parts in the

rec~ver.

2. Inspect all protective devices such as non-metallic control knobs.

IllSUlating fish papers,

cabinet backs, adjustment and compartment

covers

or

shields,

isolation resistor-capacity netwOfks. mechanical

insulators etc.

3. To

be

sure that

no

shock hazard exists, check for leakage cur-

rent in the following manner,

• Plug

the AC line

cord

directly into a 120 volt AC outlet.

(Do not use an isolatIOn transformer for

thiS

test)

• Using two clip leads,

connect

a 1,5K ohm. 10 watt resistor

paralleled by a

0

.15uF

capacitor

in

series with

an

exposed metal

cab4net parts

and a known

earth

ground,

such as water pipe

or

conduit

• Use a

VTVM

or

YOM

with 1000

ohm

per volt, or higher.

sensitivity to measure

the AC voltage

drop

across the resistor

(See Diagram).

• Move

tne

resistor connection to earth exposed metal part hav-

ing a return path to

the chassis (antenna. metal cabinet,

screw

heads. knobs and control

shafts,

escutcheon, etc.) and measure

the AC voltage

drop

across the resistOf.

All checks must

be

repeated with the AC line

cord

plug con-

nection reversed.

(If

necessary, a non-polarized

adapter

plug

must

be

used only for the purpose of comple\lng these checks.)

Any reading of 0.3 volt RMS (this corresponds to

0.2

milliamp.

AC.)

or

more is exces5lve and Indicates a potential stlock hazard

Which must

be

corrected before returning the receiver to the

owner.

---------------------------------------.--------------------------------------

IMPORTANT SERVICE SAFETY PRECAUTION (Continued)

TO

EXPOSED

METAL

PARTS

CONNECT

TO

KNOWN

EARTH

GROUND

- 4 -

SAFETY NOTICE

Many electrical

and

mechanical parts

in

television receivers have

special safety-related characteristics. These charactenstics are often

not evident from visual Inspection nor can the protectIOn afforded

by

them be necessarily increased by using replacement components

rated for higher voltage, wattage, etc. Replacement parts which have

these special safety charactenstlcs are Identified

In

this manual; electncal components having such features are identified by "@"and shaded areas

In

the Replacement Parts Lists and Schematic Diagrams.

For continued protection, replacement parts must be identical

to

those

used

In

the original CirculI. The use of a substitute replacement part

which does not have the same safety characteristics as the factory

recommended replacement parts shown

In

this service manual, may

creilte shock, fire, X radiation

or

other hazards.

..

til>

...

...

-

..

...

MAJOR CIRCUIT FEATURES

1.

Newly developed components.

Hybrid-IC type

STR

470A serves the stable B + output against

input and load variations.

In

application of this reliable component, the power

Circuit

has merits

as

listed:

a No adjustment for B

+ (DC115) output

IS

necessary.

b.

Simplification of the circuit.

c.

No voltage setting against the variation of main power voltage

is

necessary.

2.

MSI

(Medium Scale Intergrated Circuit)

This Monitor Consists of 3 MSls.

Each MSI

IS

prOVided with the function of the conventional circuits,

which enables

rt

to improve reliability and stability of picture quality

by reducing the number of parts and adjusting points.

3.

Low Loss Vertical Output CircuIt.

The power loss

In

the vertical output circuit

IS

reduced by changing

over from high voltage to low voltage

In

the front and back halves

of

the scanning period.

4.

High voltage Circuit

FBT (flyback transformer)

is

multl-smgle type, that

is,

high voltage

rectifier diodes are connected, between high voltage windmg, and

these are sealed.

This FBT decreases the variation of picture size and reduces the

dragging

of

the picture. The raised high voltage improves focuss-

Ing to make picture quality better.

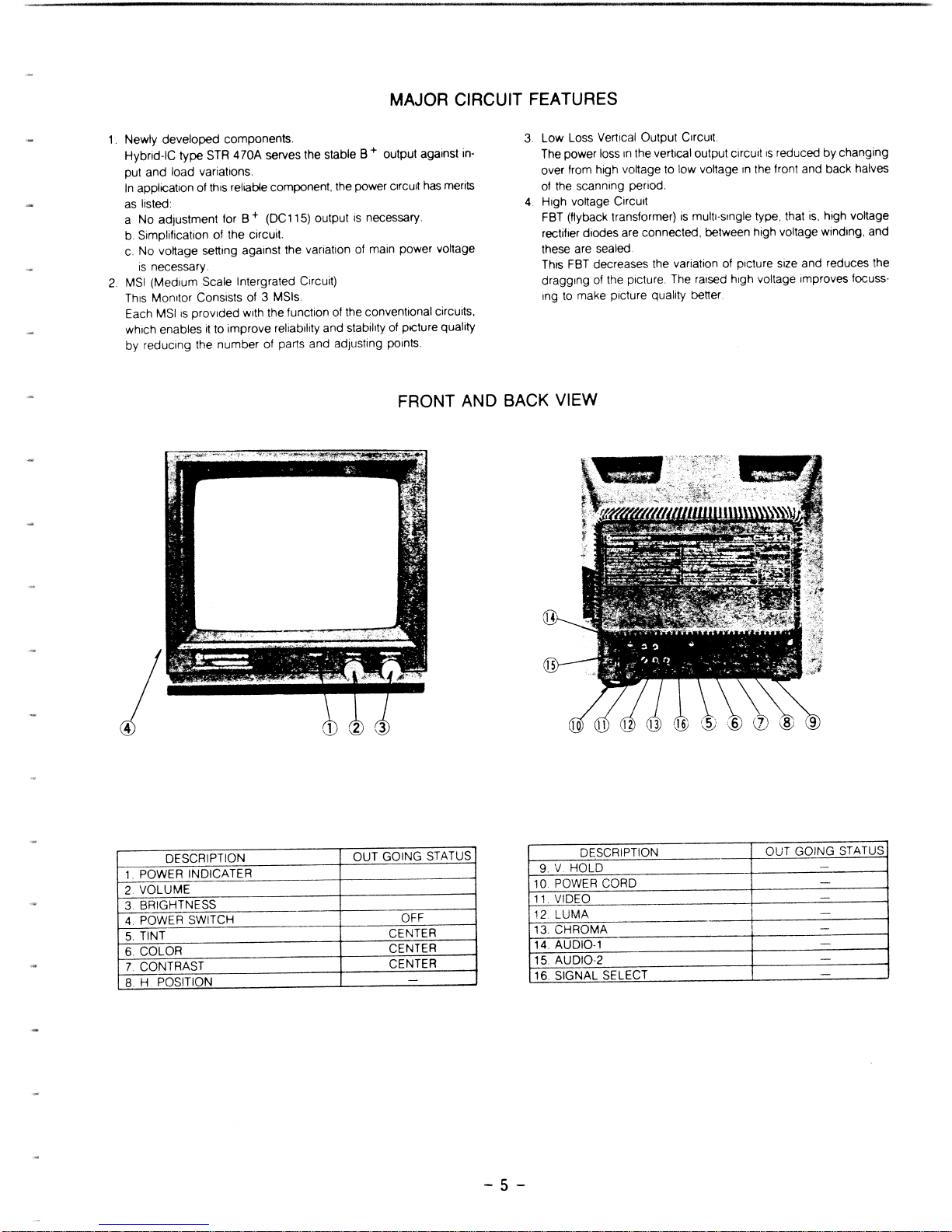

FRONT AND

BACK

VIEW

DESCRIPTION OUT GOING STATUS

DESCRIPTION

OUT GOING STATUS

1.

POWER INDICATER

9.

V HOLD

-

2.

VOLUME

10.

POWER

CORD

-

3

BRIGHTNESS

11.

VIDEO

4.

POWER SWITCH

OFF

12. LUMA

-

5.

TINT CENTER

13. CHROMA

-

6.

COLOR

CENTER

14.

AUDIO-1

-

7.

CONTRAST

CENTER

15. AUDIO-2

-

8.

H.

POSITION

-

16. SIGNAL SELECT

-

-5-

, ............ ------------------.... --------------------.......

----

....

--_

...

_ ........

----

......

----~--

............

--

CIRCUIT DESCRIPTIONS

1, POWER

SUPPLY

This Monitor

power

supply

IS

switching

mode

power

supply (SMPS)

that

is

consist of sWitching

IC

(IC901), SMPS TRANSFORMER

(TOO

1 )

pulse TRANSFORMER (T902) and assoCiated

component

The

BasIC

theory of the SMPS

IS

the circuit of Blocking Oscillation

and

by

tur'

ning ON, OFF of STRA470A. the secondary of the SMPS TRANS

is

applied

the pulse, Instant + 115V DC that pulse

is

rectlflred

IS

abtalns.

All other operating voltage and pulse are

drlved

from the

secondary

winding

of

the

high

voltage transformer (also

called FBT. T703)

2.

ST

Mn

UP

CIRCUIT

An

Initial start·up Circuit provides drive to the horlzontlal output stage

when

the set

IS

Initially turned on

ThiS

CIrcUIt

consists of

0703

and associated components

It

proveds

the Initial voltage necessary to activate IC701

and

pro·

vldes a drive pulse to the hOrizontal drive transistor

0701

Once

the FBT·drived voltages operational

0708

IS

forward· biased

and

0701

is

reverse-biared. prOViding + 45V DC

to

IC701 and 0701

SWitching voltage

supply

CirCUit

like

tr,IS

results

In

saving

power

consumption

3.

HORIZONTAL

DEFLECTION

SYNCHRONIZATION

AND

VERTICAL

Integrated Circuit IC701 perlorms the hOflzontal synchronIZation (also

called horizontal oscl'lator)

A hOrizontal rate output pulse

IS

coupled

from IC701 pin 15

to

hOrlzontai driver

0701.

The driver stage dflves the hOflzorltai out

put

0702.

HOrizontal synchronization slg'1al

IS

derived fronc composite v'deo

Signal which

coupled

to

IC701

pin

10.

Vertical synchronization signal

'5 derived from composite signal at

IC701 pin 8

and

coupled

to

pin 7 through R601

4.

HORIZONTAL

AFC

AND

OSCILLATION

LlMITIER

AFC Circuit

IS

conSists ot phase detection

CirCUit

of IC701 and

0704.

associated

component

Oscillation

limiT

CirCUit

.s

necessarv to

P'8-

vent from excessive high voltage.

ThiS

CirCUit

IS

located

In

IC70

1

and

controls the

OSCillator

to maintain the control signal

In

correct

frequency

and

phase w'th the hOfllonta' sync signal

5.

X-RAY

PROTECTION

CIRCUIT

Hle

X-ray protection

CIiCUltlS

consists

of

0703.

R731

(Hold. Down)

R729. R730

and

assoCiated

ccmponent

that connected to

pl'l

16

of IC701

A pulse

j'om

~BT

Pl~i

6 is rectified by

0705

Under nor-

mal operating condlt!OrlS. tne resui'a'lt voltage maintains

at

specified

value

If

a rna!f,mctlon causes excessive nigh

vOltage.

me

amplitude of pulse

from FBT Increases. cauSing a

corresponding

Increase

In

0703

which

results

In

vos!tage Increase at pin 16 of IC701. Voltage

In-

crease

at

IC701 pin 16 makes

Xray

protection cirCUit

conduct

and

hOrizontal oscliatlon operation

no

longer function.

The

C!fCUlt

wlil latch as

above

and

the IIlstrument

IS

necessary to

turn off for

at

least

30

seconds

to function again

6.

VERTICAL

OSCILLATION/DRIVE

CIRCUIT

Vertical oscillation and drive

CirCUit

are located

In

IC701 R603. R605.

R606

C604

and

R604

which

connected

at IC701 pin 6 are time

constant

CirCUit

that determine the verllcal

OSCillation

frequency

Vertical size control function

IS

performed

by

R604 causing the

negative

feed

back

to change.

7.

VERTICAL

OUTPUT

0601

and

0602

are SRPP (SHUNT

REGULATED

PUSH

PULL)

vertical output cllcuit.

45V-supply through

0604.

0605.

C6Q8 is the main voltage

supply line

R620. C613.

0603

IS

pump

up

circurt

whICh

supplies sufflCl9nt cur-

rent driVing the first half of vertical scan

8.

HORIZONTAL

DRIVE

CIRCUIT

To obtain horizontal drive Du'ses irOrr!

IC70t

Din

15

the honzon-

tal OsCli!3tor must be

wor"ng.

Horizontal

dnve

pulses

Irom

IC701 pin

15

are applied to hOrizon-

tal driver

0701.

8 + for

0701

\S

is

supplied from 45V line

through

0708.

OU'lng ''l'lial receiver turn·on before the

FElT

-DRIVED

SUPPL Y VOLTAGE ARE DEVELOPED.

0701

IS

s,,)plied

Initial

B + from the regul,'ted 115 volt I:ne through R736

9.

HORIZONTAL

OUTPUT

Horizontal

dnve

pulses from

0701

are coupled

through

T703

CO

the bare of hOrlzon[al output

0702.

0702

is

biased on when the

beam

IS

at

about

mid-screen.

The

charge

stored on C724.

C729

cause~current

to flow

through

the hOrizontal yoke Winding and

0702

to g'JI_!IId. When the

beam

reaches the fight

Side

of the screen.

0702

IS

turned off

and

the

current

In

the yoke

IS

dllected

Into C719. C720

At

the same time

current flows Into C719.

C720

from the regulated B + via the FBT

pnmary

Winding

Due

to

resonance. the current then reverses

ard

flows back through

the hOllzontai yoke Winding Into C724,

C729

This action aefects

the electron

beafT1

back to the 4- 115V regulated B + .

10.

PINCUSHION

CORRECTION

Pincushion

correction

CIICUlt

IS

T702

and

ItS

associated

components.

HOrizontal yoke current

IS

Increased or

decreased

In

response to

vertlca' parabola pulse The

CirCUit

of

0751

0752,

T751

and

assoclatea component.

IS

for

Improving

high voltage translcent

response

11.

POWER

SUPPLY

DETAIL

DESCRIPTIONS

- 6 -

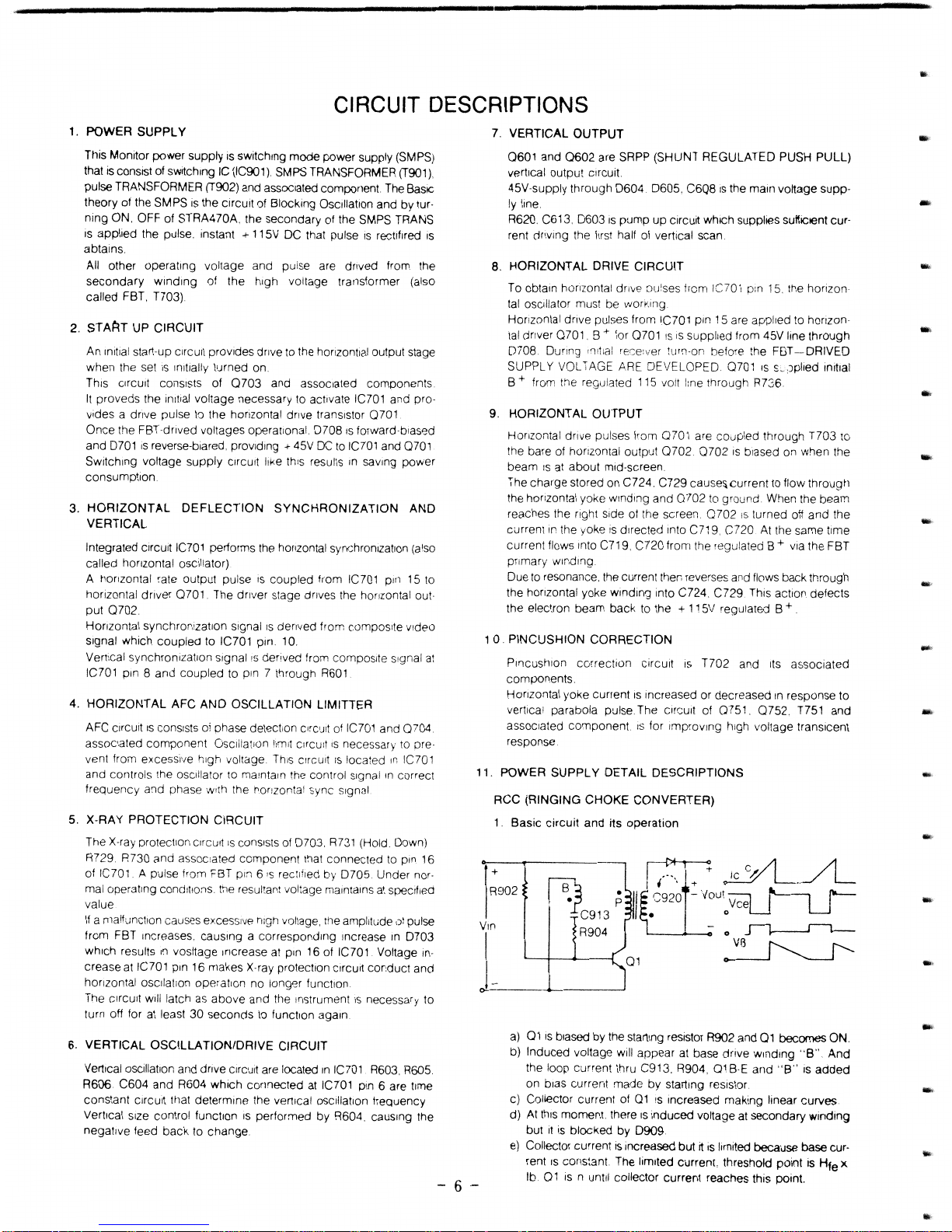

RCC

(RINGING

CHOKE

CONVERTER)

1.

Basic

circuit

and

its

operation

+

r:;-r~~

R902

fB.)

;

I~

~92;1'

V~O<:qJ~

C913

I.

0

R904

-0

~

01

~

-

~-------~--------~

a)

01

IS

biased by the starting resistor R902 and

01

becomes ON.

b)

Induced

voltage will appear

at

base drive

winding

"B"

And

the loop current thru C913. R904.

01BE

and

"B"

IS

added

on bias current

made

by

starting resistor.

c) Collector current of

01

is increased rnaking linear

curves

d)

At

thiS

moment. there

IS

Induced

voltage at secondary Winding

but

It

is

blocked

by

0909.

e) Collector current

is

Increased

but

rt

is

limited because base cur-

rent

IS

cons:ant. The limited current, threshold pOint

IS

Hie

x

lb.

01

is n until collector current reaches this point.

-

..

-

-

-

-

...

f)

During

Q1

is

ON, input vonage Yin

is

added on the primary

winding P But,

it

is

added on

Q1

C-E

suddenly.

g) At same time, inverted voltage appears at

"B"

which will bias

Q1

B·E reversely and

Q1

is OFF.

h) The energy charged in

P

is

discharged

by

the secondary

winding S thru D909.

i)

Q1

B-E

biased reversely.

j)

The energy

is

discharged thru D909 and when

Id

is

zero,

starting current

by

R902 makes

Q1

on again.

Repeating from

(a).

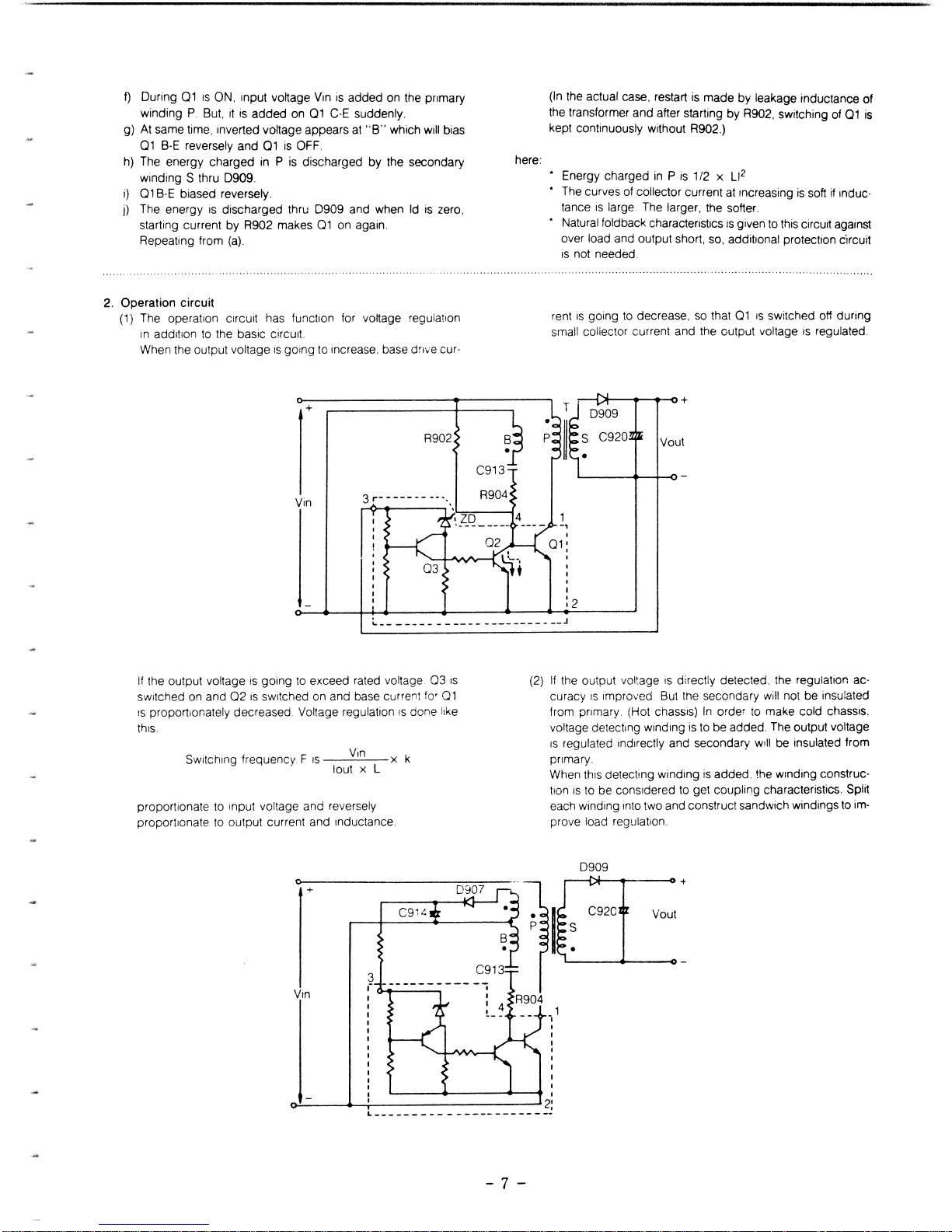

2. Operation circuit

(1) The operation Circuit has function for voltage regulation

in addition to the basic

cirCUIt.

When the output voltage

is

going to increase. base drive cur·

+

Yin

here:

(In the actual case, restart

is

made by leakage inductance of

the transformer and after starting by R902, switching of

Q1

is

kept continuously without R902.)

* Energy charged

in P is

1/2

X

Ll2

* The curves of collector current

at

Increasing

is

soft

if

induc·

tance

is

large. The larger, the softer.

Natural fold back characteristics

is

given to

this

circuit against

over load and output short, so, addibonal protection circuit

is

not needed.

rent

is

going

to

decrease,

so

that

Ql

IS

switched off during

small collector current and the output voltage

is

regulated.

.---Dl-

__

~

+

0909

S C920

Vout

•

________________________

J

If

the output voltage

is

going to exceed rated voltage. Q3

IS

switched on and Q2

is

switched on and base current for

Ql

IS

proportionately decreased Voltage regulation

IS

done like

this.

Yin

Switching frequency F

IS

X k

lout x L

proportionate to input voltage and reversely

proportionate to output current and inductance.

+

3

fo.-.

__

--.

(2)

If

the output voltage

is

directly detected. the regulation ac·

curacy

is

Improved. But the secondary will not be insulated

from primary. (Hot chassis)

In

order to make cold chassis.

voltage detecting winding

is

to be added. The output voltage

IS

regulated indirectly and secondary

w,1I

be insulated from

primary.

When this detecting winding

is

added. the Winding construc·

tlon

is

to be conSidered

to

get coupling characteristics. Split

each winding Into two and construct sandwich windings to im·

prove load regulation.

0909

.--1::.1--_---0

+

C920 Vout

s

•

I

~---~T-----------~2:

L

___________

- ---- - - - -

-_

...

- 7 -

Loading...

Loading...