Commodore 1930 Service Manual

Produced By:

Commodore International Spare Parts GmbH

Braunschweig, West Germany

SERVICE MANUAL

1930

VGA COLOR MONITOR

AUGUST, 1990 PN-314255-01

INTERNATIONAL EDITION

COMMODORE “INTERNATIONAL EDITION” SERVICE MANUALS CONTAIN

PART NUMBER INFORMATION WHICH MAY VARY ACCORDING TO COUN

TRY. SOME PARTS MAY NOT BE AVAILABLE IN ALL COUNTRIES.

Commodore Business Machines, Inc.

1200 Wilson Drive, West Chester, Pennsylvania 19380 U.S.A.

Commodore makes no express or implied warranties

with regard to the information contained herein. The

information is made available solely on an as is basis,

and the entire risk as to completeness, reliability, and

accuracy is with the user. Commodore shall not be

liable for any damages in connection with the use of

the information contained herein. The listing of any

available replacement part herein does not constitute

in any case a recommendation, warranty or guaranty

as to quality or suitability of such replacement part.

Reproduction or use without express permission, of

editorial or pictorial content, in any matter is prohibited.

This manual contains copyrighted and proprietary information. No part

of this publication may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means, electronic, mechanical, photo

copying, recording or otherwise, without the prior written permission

of Commodore Electronics Limited.

Copyright © 1990 by Commodore Electronics Limited.

All rights reserved. Printed in U.S.A.

1930 SERVICE MANUAL

IMPORTANT SAFETY NOTICE

Proper service and repair is im portant to the safe, reliable operation of all NAPCEC Equipment. The

service procedures recommended by NAPCEC and described in this service manual are effective

methods of performing service operations. Some of these service operations require the use of tools

specially designed for the purpose. The special tools should be used when and as recomm ended.

It is important to note that this manual contains various C AU TION S and NO TICES which should be

carefully read in order to minimize the risk of personal injury to service personnel. The possibility ex

ists th at improper service m ethods may damage the equipment. It also is im portant to understand

that these CA UTIO NS and NOTICES ARE NO T EX HA US TIVE. NAPCEC could not possibly know ,

evaluate and advise the service trade of all conceivable ways in w hich service might be done or of

the possible hazardous consequences of each w ay. Consequently, NAPCEC has not undertaken any

such broad evaluation. Accordingly, a servicer who uses a service procedure or tool which is not recom

mended by NAPCEC m ust first satisfy him self thoroughly that neither his safety nor the safe opera

tion of th e equipm ent will be jeopardized by the service method selected.

WARNING

Critical components having special safety characteristics are

identified with an S by the Ref. No. in the parts list and enclosed

within a broken line* along with the safety symbol on the

schem atics or exploded views.

Use of substitute replacement parts which do not have the same

specified safety characteristics may create shock, fire, or other

hazards.

Under no circum stances should the original design be modified

or altered w ithout written permission from the N.A.P. Consumer

Electronics Corp. NAPCEC assumes no liability, express or

implied, arising out of any unauthorized modification of design.

Servicer assumes all liability.

* Broken line:

___

.

___

.

___

.

___

.

© 1988 NAPCEC

1930 SERVICE MANUAL

TABLE OF CONTENTS

TITLE PAGE

SAFETY PR E CAU TIO N S.................................................................................

..

............................................

1

GE NER AL............................................................................................................................................................... 1

SP E CIF ICA T ION S .............................................................................................................................................. 2

CO N TR O LS ............................................................................................................................................................ 2

ME CH AN IC AL REPLACEMENT PARTS L IS T ....................................................................................... 3

CUSTOM ER A D J U S T M E N T S .................................................................................................................. . 3

AD JU STM ENT PROCEDU RES..................................................................................................................... 5

INTERCO NNECT W IRING DIAGRAM (EXPLODED V IE W )........................................................... 8

SCHEMA TIC NO T ES......................................................................................................................................... 9

CHA SSIS R E M O V A L ...................................................................................................................................... 9

W A VEF O R M S ................................................................................................. ..................................................... 10

SC HE MATIC DIAG RAM (MAIN & CRT SOCKET P A N E L S )

.....................................................

10

SCHEMA TIC DIAGRAM (POW ER SUPPLY).......................................................................................... 11

P.C. BOARD (M A IN PA N E L)..................................................................................................................... 12

P.C. BOARD (CRT SOCKET PA N E L ).................................................................................................... 13

P.C. BOARD (POWER SUPPLY PAN E L)............................................................................................... 14

REPLACEMENT PARTS L IS T .............................................................................. 15

SAFETY G U IDE LIN ES ...................................................................................................................................... 21

SCHEMA TIC D IA GR AM (1 93 0-B - CBM CASE COLOR M O N ITO R )

.......................................

2 3

SAFETY NOTICE

ANY PERSON ATTEMPTING TO SERVICE THIS CHASSIS MUST FAMILIARIZE HIMSELF

WITH THE CHASSIS AND BE AWARE OF THE NECESSARY SAFETY PRECAUTIONS TO

BE USED WHEN SERVICING ELECTRONIC EQUIPMENT CONTAINING HIGH VOLTAGES.

CAUTION

USE A SEPARATE ISOLATION TRANSFORMER FOR THIS UNIT WHEN SERVICING.

Reprinted w ith permission of N APCEC

1930 SERVICE MANUAL

SAFETY PRECAUTIONS

Picture Tube Replacement

The primary source of X-radiation in this monitor is the

picture tube. The picture tube utilized in this chassis is

specially constructed to limit X-radiation emissions. For

continued X-radiation protection, the replacement tube

must be the same type as the original, including suffix

letter, or N.A.P. Consumer Electronics corp. (NAPCEC)

approved type.

Safety goggles must be worn when the picture tube is

replaced.

Parts Replacement

Many electrical and mechanical parts in NAPCEC

monitors have special safety-related characteristics.

These characteristics are often not evident from visual

inspection nor can the protection afforded by them

necessarily be obtained by using replacement

components rated for higher voltage, wattage, etc. The

use of a substitute part which does not have the same

safety characteristics as the NAPCEC recommended

replacement parts shown in this service manual may

create shock, fire or other hazards.

GENERAL

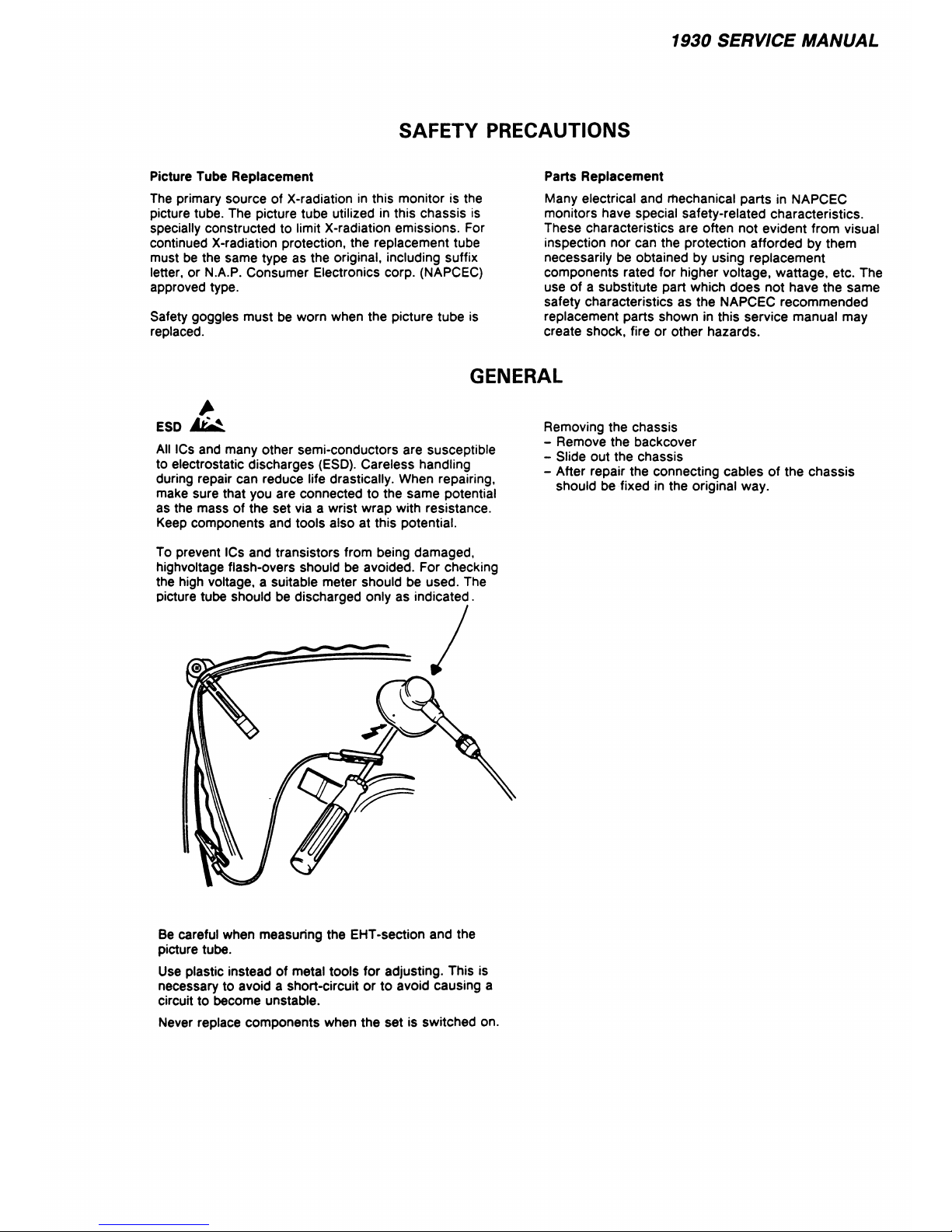

A

ESD

All ICs and many other semi-conductors are susceptible

to electrostatic discharges (ESD). Careless handling

during repair can reduce life drastically. When repairing,

make sure that you are connected to the same potential

as the mass of the set via a wrist wrap with resistance.

Keep components and tools also at this potential.

To prevent ICs and transistors from being damaged,

highvoltage flash-overs should be avoided. For checking

the high voltage, a suitable meter should be used. The

picture tube should be discharged only as indicated.

Removing the chassis

- Remove the backcover

- Slide out the chassis

- After repair the connecting cables of the chassis

should be fixed in the original way.

Be careful when measuring the EHT-section and the

picture tube.

Use plastic instead of metal tools for adjusting. This is

necessary to avoid a short-circuit or to avoid causing a

circuit to become unstable.

Never replace components when the set is switched on.

1930 SERVICE MANUAL

SPECIFICATIONS

(subject to modification)

AC voltage

- 120Vac + / - 10% - 60Hz

Power consumption at 120V

- 85 Watts

EHT

- 24 KV

Line frequency

- 31480 Hz

Frame frequency

- 60 Hz/70 Hz

Band width

- 18 MHz

Picture tu be (9C M08 2)

- M34 JPS 77 X 69

Picture tube (9C M 062)

- M34 JPM 70X69

RESOLUTION

Sync, polarity

HOR. VERT.

- pos/neg

Pos. Neg.

- 640 dots X 350 lines

Neg. Pos.

- 640 dots X 400 lines

Neg. Neg.

- 640 dots X 480 lines

INPUT SPECS

RGB linear - all colors

Sync TTL level - pos/neg

CONTROLS

Front : Power on/off SK1 (incl. LED indicator)

: Brightness (R558)

: Contrast (R322)

: Horizontal phase (centering) (R408)

: Vertical centering (R524)

Rear : Horizontal width (R541)

: Vertical height (R513 for 480 lines)

INPUT SIGNAL CONNECTOR

15 PIN ”D” SHELL CONNECTOR

1 - red

6 - red ground

11 - ground

2 - green

7 - green ground

12 - n.c.

3 - blue

8 - blue ground

13 - horizontal sync

4 - n.c.

9 - n.c. 14 - vertical sync

5 - self test

10 - ground 15 - n.c.

VGA STANDARD

Horizontal

Vertical H. Sync.

V. Sync. Resolution

frequency

frequency

polarity

polarity (horizontal lines)

31.5 kHz 70 kHz

Positive (+)

Negative (-) 350

31.5 kHz 70 kHz

Negative (-)

Positive (+)

400

31.5 kHz 60 kHz Negative H

Negative (-)

480

2

1930 SERVICE MANUAL

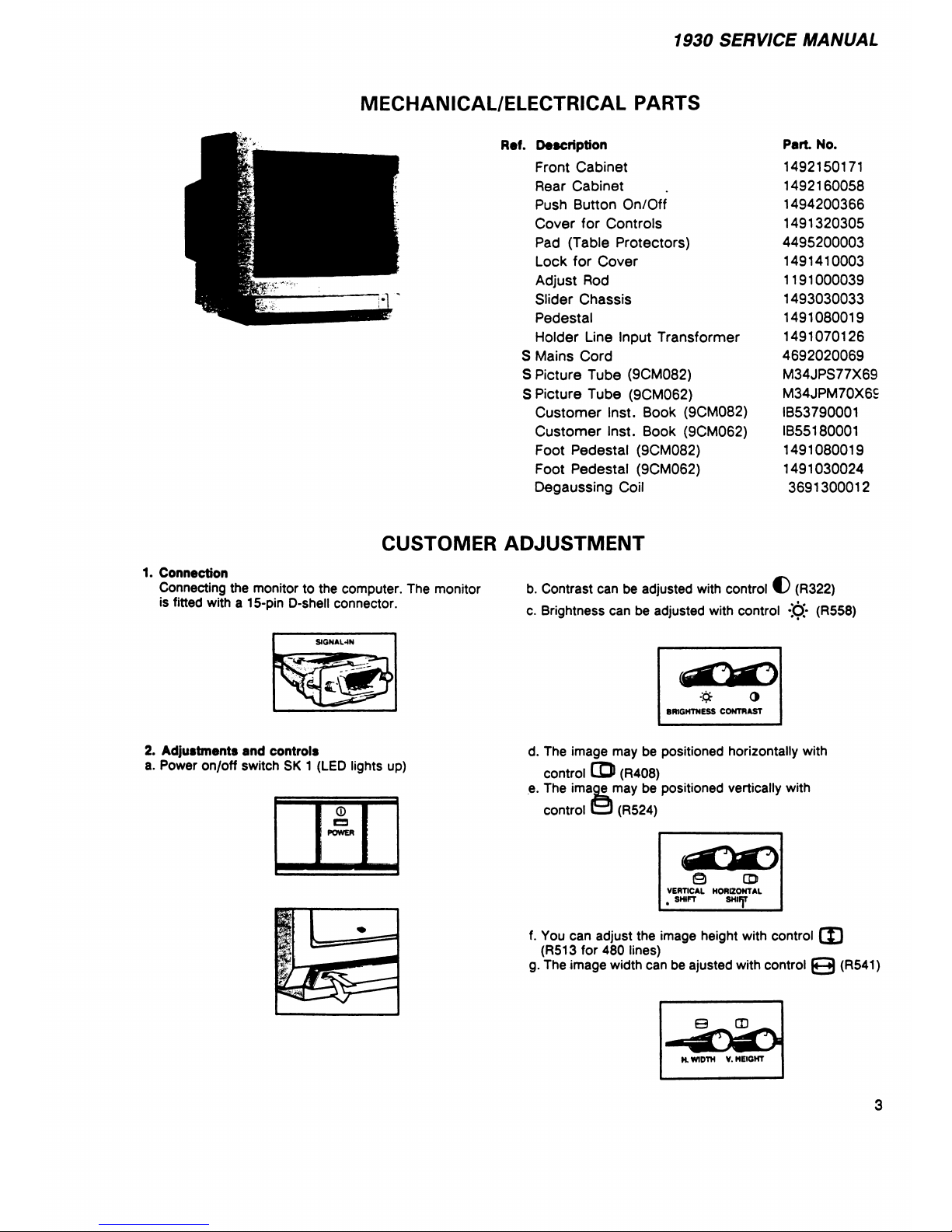

MECHANICAL/ELECTRICAL PARTS

Ref. Description

Pert No.

Front Cabinet

1492150171

Rear Cabinet 149216 0058

Push Button O n/O ff 149 4200366

Cover for Controls 149132 0305

Pad (Table Protectors)

44952000 03

Lock for Cove r 1491410003

Adjust Rod

1191000039

Slider Chassis

149303 0033

Pedestal

1491080019

Holder Line Input Transformer

149107 0126

S Mains Cord

4692 0200 69

S Picture Tube (9 CM 082)

M34JP S77X69

S Picture Tube (9C M062 )

M34JPM 70X 69

Custom er Inst. Book (9CM 082)

IB53790001

Custom er Inst. Book (9CM 062)

IB55180001

Foot Pedestal (9C M082)

1491080019

Foot Pedestal (9C M062)

1491030024

Degaussing Coil

36913000 12

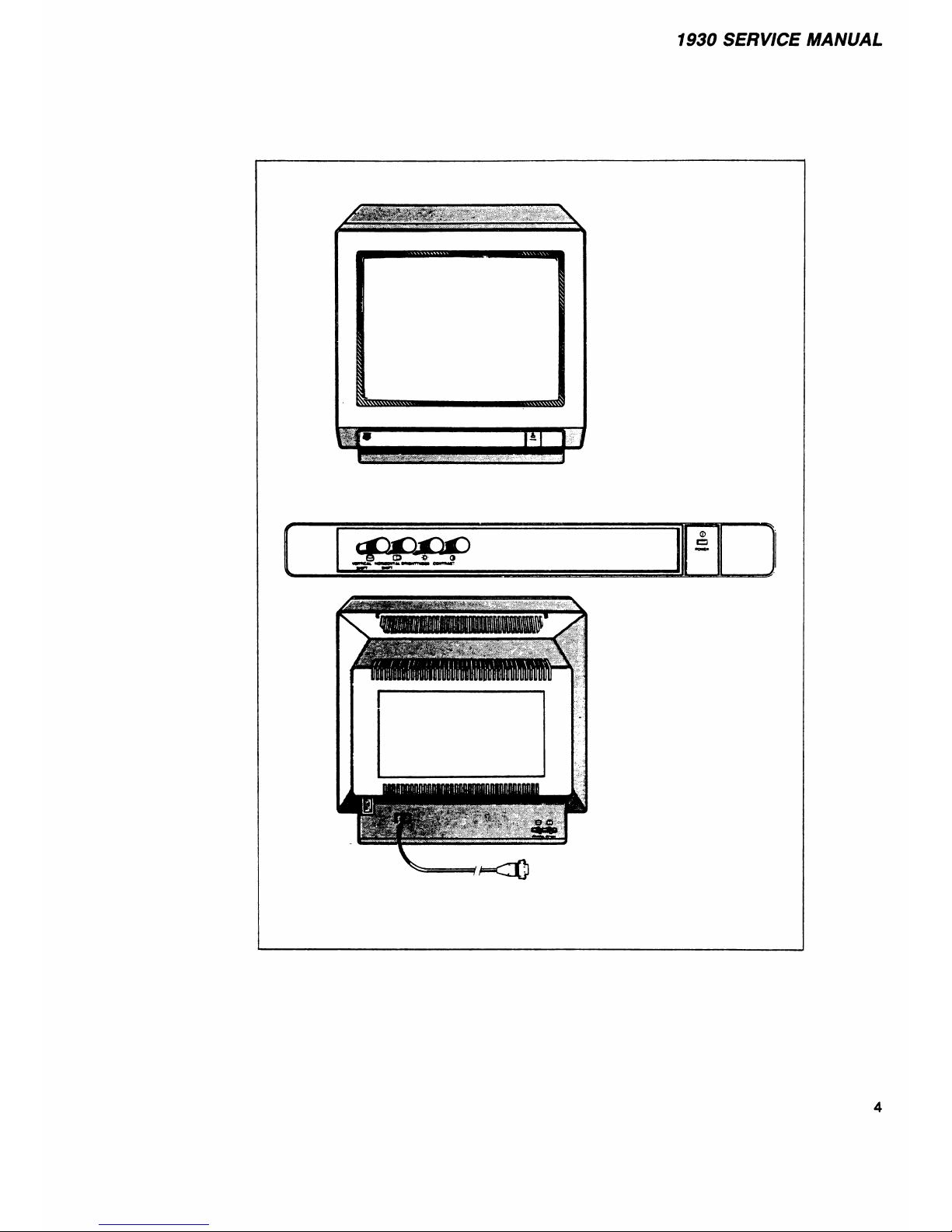

CUSTOMER ADJUSTMENT

1. Connection

Connecting the monitor to the computer. The monitor

is fitted with a 15-pin D-shell connector.

SIGNAL4N

2. Adjustments and controls

a. Power on/off switch SK 1 (LED lights up)

0

POWER

b. Contrast can be adjusted with control € (R322)

c. Brightness can be adjusted with control -j6/ (R558)

O

BRIGHTNESS CONTRAST

d. The image may be positioned horizontally with

control CD (R408)

e. The image may be positioned vertically with

control ( 3 (R524)

© CD

VERTICAL HORIZONTAL

, SHIFT SHIRT

f. You can adjust the image height with control CD

(R513 for 480 lines)

g. The image width can be ajusted with control

e

(R541)

b m

H. WIDTH V. HEIGHT

3

1930 SERVICE MANUAL

©

' © " 0 9

CD

4

1930 SERVICE MANUAL

SERVICE ADJUSTMENTS

Adjustment notes:

Caution

1. Use an isolation transformer when applying power to

the exposed chassis.

2. Line voltage maintained at 120V AC, 60Hz.

3. The unit should be allowed to warm up for at least 30

minutes prior to making any adjustments.

4. Voltages measured with respect to ground.

Adjustments

1. +120 Vdc supply voltage

- Contrast and brightness to minimum.

- Connect a voltmeter across C145 and turn on the

monitor.

- Adjust R114 for a reading of 120V on the meter.

2. Synchronization

Horizontal synchronization

- Inject a cross-hatch pattern and short R413/C415.

- Adjust R419 until the picture is straight.

- Remove the short-circuit

Vertical synchronization

- Turn off the vertical sync, by removing input signal.

- Adjust R504 for 47 Hz at pin 3 of IC501

3. Focus

Adjust the focus control for optimal focus.

4. Adjustment of picture geometry

- Inject a cross-hatch pattern and set brightness and

contrast to the mechanical mid-position.

East-West correction

- Adjust R539 so that the vertical lines at the left-hand and

the right-hand side are straight (480 lines).

Vertical linearity

- Adjust R516 so that a good linearity is obtained between

upper and lower side of the picture (480 lines).

Horizontal amplitude

- Set the horizontal width to 240 mm with R541 (480 lines).

Horizontal position

- The horizontal centering can be adjusted with R441.

- Adjust R411 so that R408 allows as much shifting to the

left as to the right (480 lines).

Vertical amplitude

- Adjust the vertical height to 180 mm with R513 (480

lines) (R507 for 400 lines and R509 for 350 lines).

- The vertical centering can be adjusted with R524.

Brightness presetting

- Set brightness to mechanical mid-position.

- Adjust R567 so that the voltage across C555 is -41V

#5. VG2 adjustment and cut-off points in picture tube

• Adjust brightness to mechanical mid-position and

adjust contrast to maximum.

- Adjust VG2 (SCREEN) to minimum.

- Adjust R726, R733 and R739 to mechanical

mid-position.

- Inject a white pattern signal and adjust VG2 (SCREEN)

until one color becomes visible.

- Set the pattern generator to purity with the color that

was first visible.

- Readjust VG2 to just visible light.

- Adjust the 2 remaining colors with their corresponding

purity color for the same light output using

potentiometers R726, R733 or R739.

- Now return to white pattern signal and adjust

potentiometers R726, R733 and R739 until an optimum

background color is formed.

- Using potentiometers R328, R332 and R335 (with

white pattern signal), adjust the background color so

that at minimum brightness and maximum brightness

the background color is the same.

5

Loading...

Loading...