Commodore 1541, 1540 Service Manual

SERVICE MANUAL

MODEL 1540/1541

DISK DRIVE

NOVEMBER, 1985 PN-314002-01

Commodore Business Machines, Inc.

1200 Wilson Drive, West Chester, Pennsylvania 19380

U.S.A

Commodore makes no expressed or

implied warranties with regard to

the information contained herein.

The information is made available

solely on as is basis, and the entire

risk as to quality and accuracy is

within the user. Commodore shall

not be liable for any consequential

or incidental damages in connection

with the use of the information

contained herein. The listing of any

available replacement part herein

does not constitute in any case a

recommendation, warranty or

guaranty as to quality or suitability

of such replacement part.

Reproduction or use without

expressed permission, of editorial or

pictorial content, in any matter is

prohibited.

This manual contains copyrighted and proprietary information. No

part of this publication may be reproduced, stored in a retrieval

system, or transmitted in any form by any means, electronic,

mechanical, photocopying, recording or otherwise, without the

prior written permission of Commodore Electronics Limited.

Copyright © 1985 by Commodore Electronics Limited.

All rights reserved.

• SPECIFICATIONS

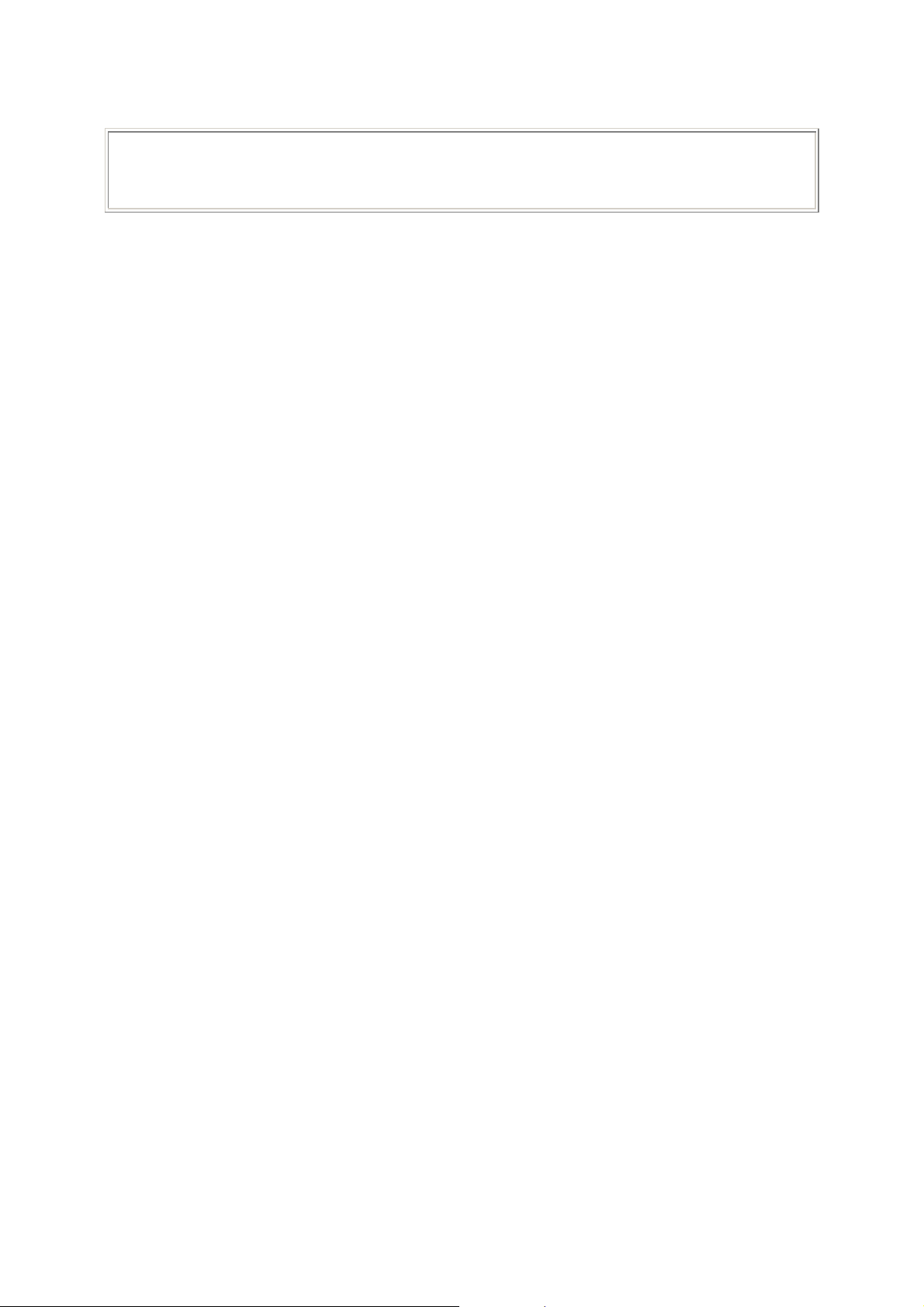

• BLOCK DIAGRAM

• CARE AND MAINTENANCE

• OVERVIEW

• FLASH CODE

• CIRCUIT THEORY

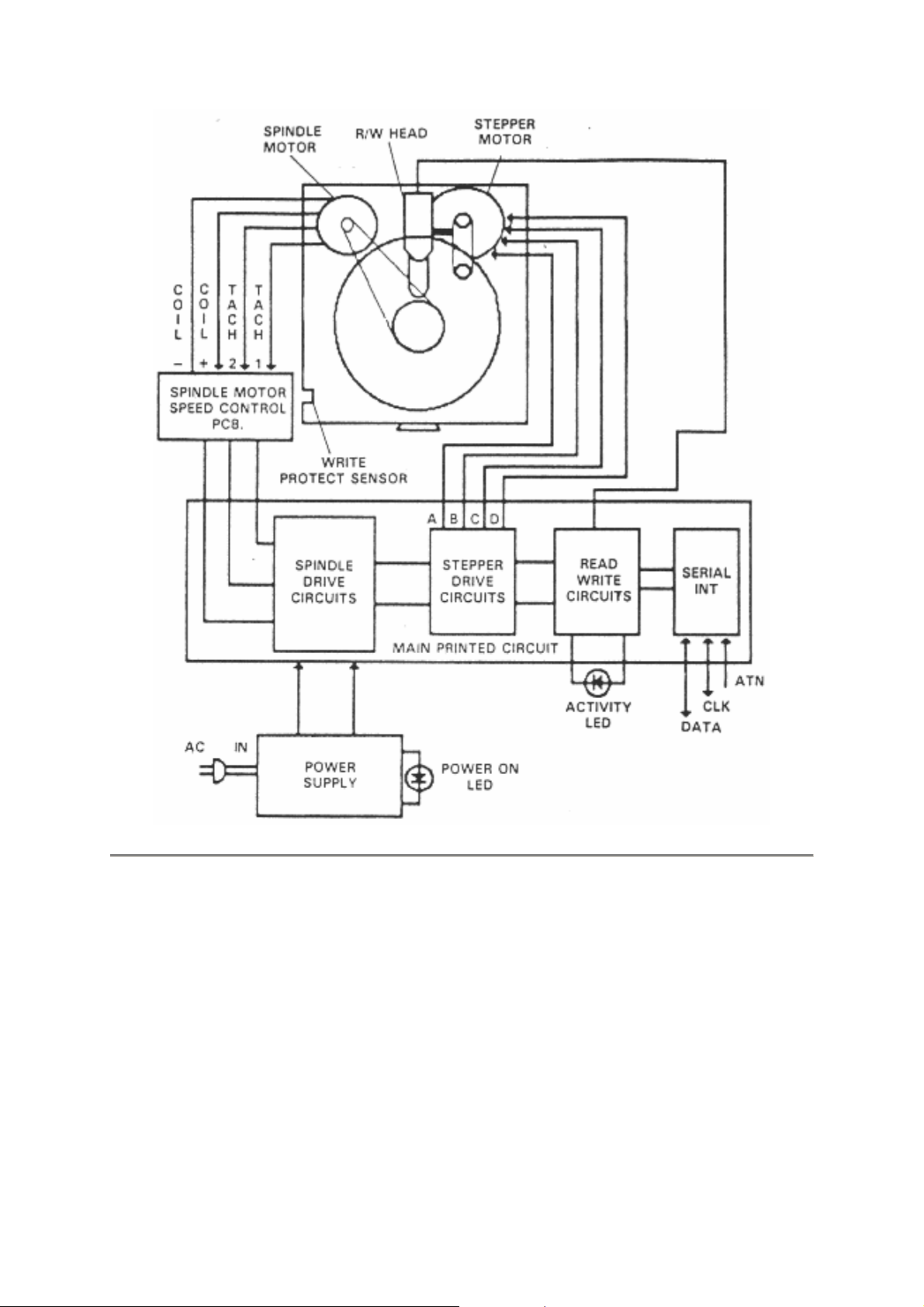

o POWER SUPPLY

o RESET LOGIC

o CLOCK CIRCUITS

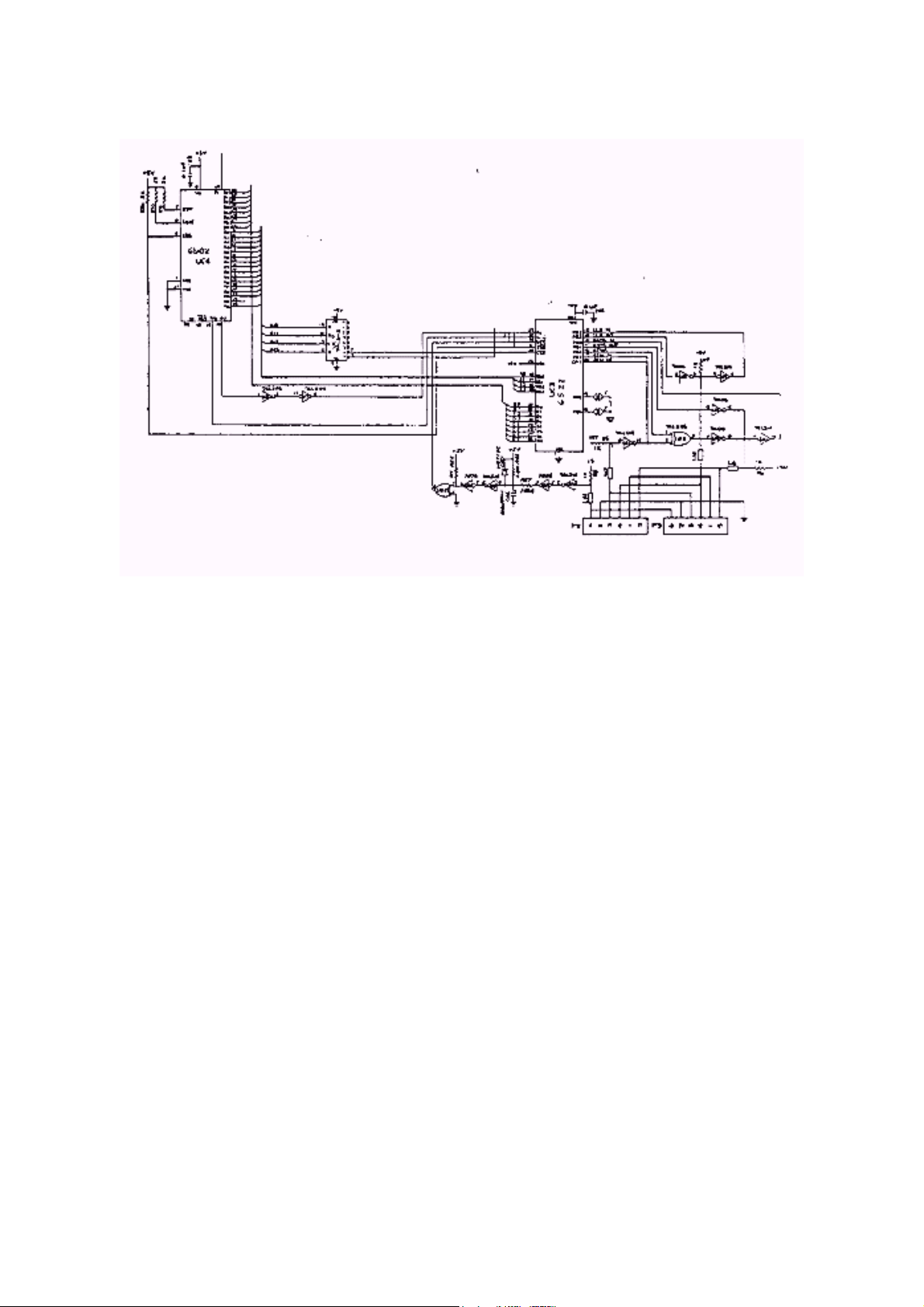

o MICROPROCESSOR CONTROL OF RAM AND ROM

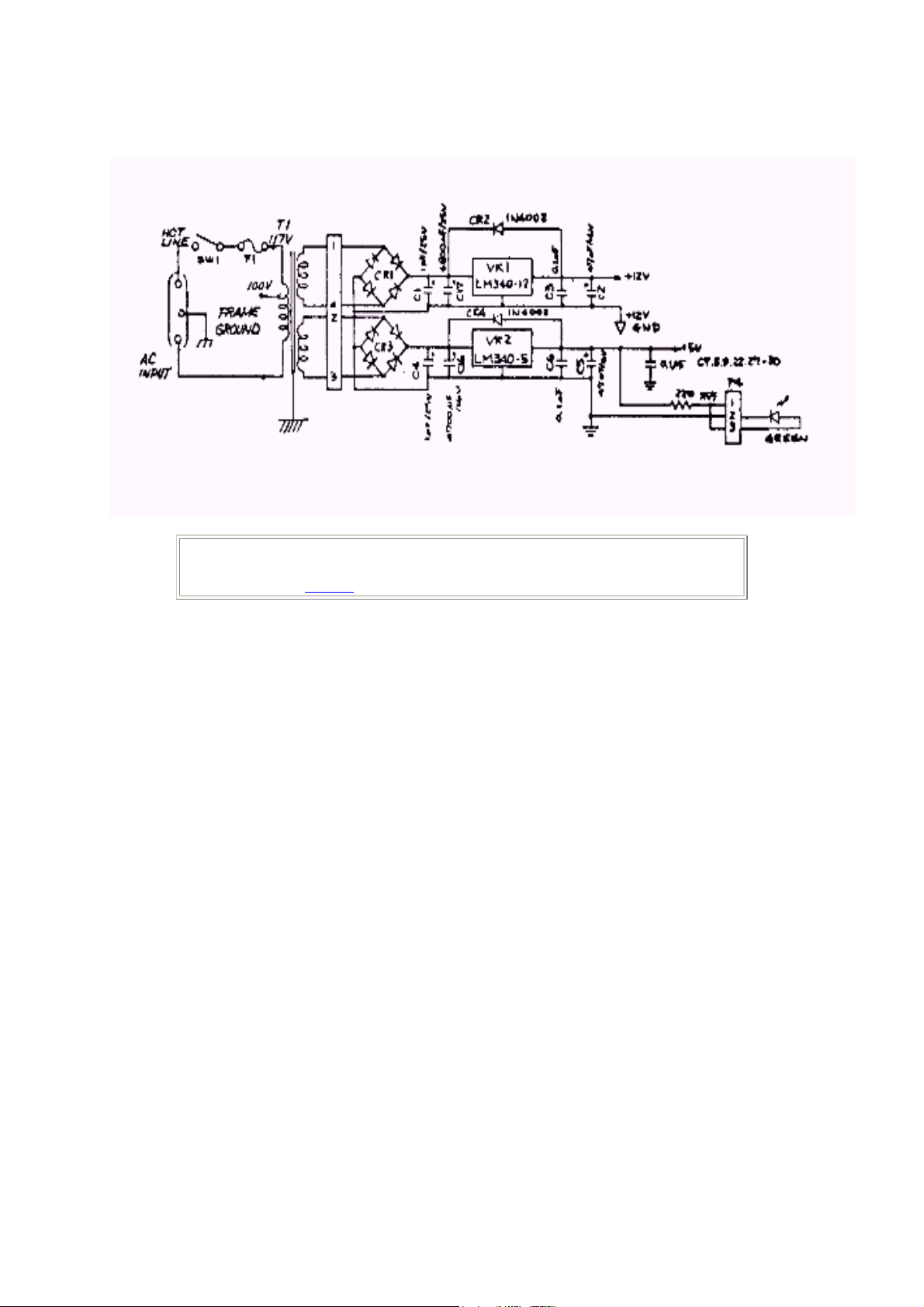

o SERIAL INTERFACE

o MICROPROCESSOR R/W AND MOTOR CONTROL LOGIC

o READ/WRITE CONTROL LOGIC

CONTENTS

o READ AMPLIFIER

o WRITE AMPLIFIER

o POWER UP/DOWN WRITE PROTECTION

o STEPPER MOTOR CONTROL CIRCUITS

o SPINDLE MOTOR CONTROL CIRCUITS

• TROUBLESHOOTING GUIDE

• RESISTANCE CHECKS

• CASEWORK/ACCESSORY PARTS LIST

• MODEL INDENTIFICATION

• DEVICE NUMBER CHANGE

• PC ASSEMBLY 1540001

o BOARD LAYOUT

o PARTS LIST

o PIN CONFIGURATIONS

o SCHEMATIC

• PC ASSEMBLY 1540048

o BOARD LAYOUT

o PARTS LIST

o UPGRADE NOTES

o SCHEMATIC

• PC ASSEMBLY 250442, 250446

o BOARD LAYOUT

o PARTS LIST

o IC PINOUTS AND INTERNAL DIAGRAMS

o SCHEMATIC

• POWER SUPPLY ASSEMBLY 154002

o PARTS LIST

o TRANSFORMER

o ASSEMBLY DRAWING

• ALPS DRIVE ASSEMBLY

o PARTS LIST

o WIRING DIAGRAM AND LAYOUT

o MOTOR CONTROL PCB SCHEMATIC

• NEWTRONICS DRIVE ASSEMBLY

o PARTS LIST

o WIRING DIAGRAM AND LAYOUT

o MOTOR CONTROL PCB SCHEMATIC

C1541 DISK DRIVE

PRODUCT SPECIFICATION

GENERAL DESCRIPTION

MAXIMUM STORAGE

MEDIA

INPUT/OUTPUT

CONTROLLER

MEMORY

DATA TRANSFER RATE

FILE TYPES

NUMBER OF FILES

COMPUTERS

MEDIA COMPATIBILITY

POWER REQUIREMENTS

The C1541 Disk Drive is an external 5-1/4 inch floppy diskette recorder,

offering high-speed and capacity for programs and data. It is an intelligent

device, containing its own microprocessor, RAM, ROM and operating systems

software for faster speed of throughput and memory efficiency in the computer

170K of data (formatted) - 35 tracks

5-1/4 Inch floppy disk. Single sided, single density, soft sectored (double

density can be used, but not needed)

Commodore serial interface

Second serial port for chaining a second drive or printer

MOS 6502 microprocessor - 1 MHz clock

2K RAM, 16K ROM

400 Bytes/sec

Program, sequential, relative, random-access and user

Up to 144 different files per diskette

C64, VIC 20, SX64, Educator 64, Plus/4, C16

2031, 4040, C1551, C1571

120 Volts AC, 60Hz - integral power supply with external 1 Amp fuse

POWER CONSUMPTION

30 Watts maximum

CARE AND MAINTENANCE

• DO NOT use MAGNETIZED tools when repairing or adjusting a disk drive.

• DO NOT place a disk drive near any device which generates "noise" e.g., - motors, radios televisions.

• DO NOT stack drives upon each other or in any way inhibit air flow around the unit. HEAT BUILD-UP

can cause disk failures.

• Periodically CLEAN the read/write head with 90% isopropyl alcohol and a cotton swab. CHECK load

pad for excess wear. Clean or replace as necessary.

• Take the following precautions when handling a diskette:

ALWAYS store a diskette in its jacket.

Use ONLY felt-tip pens when writing on the label of a diskette.

Do not bend or physically damage a diskette.

Do not place a diskette in the area of a magnetic field.

Do not attempt to clean a diskette.

Do not touch the exposed area of a diskette.

• DIAGNOSTIC and ADJUSTMENT procedures are outlined in detail on the diagnostic disk

(Commodore Part #31405101). A manual has been added to the diagnostic package. It contain

descriptions of testing procedures and adjustment methods.

OVERVIEW

The drive itself an independent memory device. THe drive is composed of a media clamp rotating mechanism, a

head positioning mechanism and an eject mechanism. All positioning operations, excluding insertion and

removal of diskettes, are controlled by the internal guide mechanism. Closing the front door causes the media

clamp mechanism to operate. Two operations are performed in the following order:

a)

The diskette is centered.

b)

The diskette is clamped and retained between the spindle and the hub.

The spindle and hub rotates at 300 r.p.m. through a closed/loop control circuit employing a D.C

motor/tachometer. It is important that the relationship between the head and the media is maintained correctly

during operation. For this purpose, a pressure pad is used to hold and press down the media (about 12g) from the

opposite side of the head. This head assembly is coupled by a metal band to a four base stepping motor which

performs the track positioning. One step of the stepping motor corresponds to a 1/2 track movement. The control

circuit on the logic board selects the direction and number of steps to the desired track.

The Read/Write head uses a glass-bonded, ferrite/ceramic head. Track-to-track erasing is

accomplished by the straddle erase method. The surface of the Read/Write head is mirrorground to minimize wear of the head and media. Also, the head is designed in such a way that

the maximum signal can be obtained from the media surface.

The spindle drive motor operates on 12 VDC and turns the spindle, through a belt drive, at

300 revolutions per minute. The speed of the drive motor is controlled by a feedback signal

from a tachometer, which is housed in the drive motor assembly. The feedback signal controls

a servo amp that supplies the 12 VDC drive current.

FLASH CODE

The 1541, upon power-up, goes through its own internal diagnostic. If an electronic problem is detected, it's

indicated by flash code. The led's will blink a number of times, pause, and then flash again until the problem is

corrected.

Number of flashes

2

3,4

5,6,7,8

Circuitry associated with these components can also cause the failure code. Therefore, it should be suspected as

the next possible defect.

Possible failure

Zero page

DOS ROM's

RAM

1541 CIRCUIT THEORY

All circuit diagrams have been taken from the short board schematic 1540049 unless

otherwise noted. The short board use a 6116 RAM which replaces the four 2114 I.C.s on

the long board. See page 11 for the Read/Write logic differences.

The Power Supply

The input AC voltage is controlled by switch 1 (SW1). Disk circuit protection is provided by fuse 1 (F1). If SW1

is closed, the AC voltage input is applied to the primary winding of transformer one (T1). T1 steps down th AC

input voltage into two smaller AC voltages. The top secondary AC output (approx. 16VRMS) is converted to DC

by the Full Wave Bridge Rectifier CR1. The DC output of CR1 is regulated at 12VDC by VR1. The bottom

secondary AC output of T1 (approx. 9VRMS) is converted to DC by the Full Wave Rectifier CR3. The DC

output of CR3 is regulated at +5VDC by VR2. High frequency filtering is provided by C1 and C3 for the

12VDC supply, and C4, C6 to C9, C22, C27 to C30 for the 5VDC supply. Low frequency filtering is provided

by C17 and C2 for the 12VDC supply, and C5 and C16 for the 5VDC supply.

1541 CIRCUIT THEORY

The Reset Circuit

The output of the exclusive 'or' gate UD3 pin 6 will be "low" until C46 has charged through R25. Once the

voltage across C46 reaches 2 volts, the output of UD3 pin 6 will go "high". This occurs when the disk is powered

on, or a reset pulse is generated by a device connected to the serial bus. The reset pulse on the serial bus interface

is input on, pin 6 of P2 or P3. This "low" to "high" going pulse on pin 6 of UD3 is input to the microprocessors

reset interrupt input. This causes a restart on reset routine to be executed giving control of the disk drive

operation to the Disk Operating System (DOS).

1541 CIRCUIT THEORY

Tracks

Clock Frequency

1

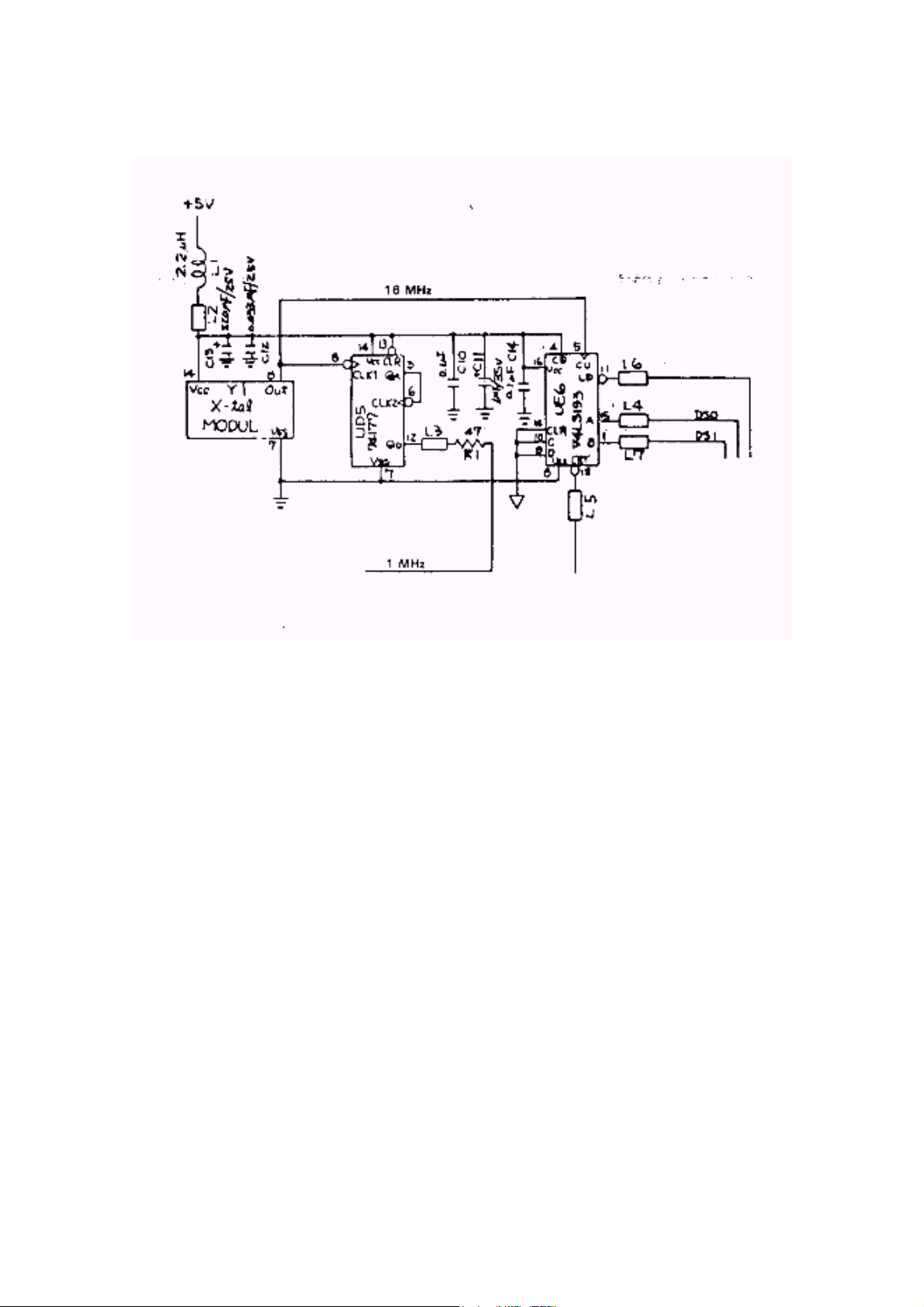

The Clock Circuits

Crystal Y1 outputs a 16Mhz clock signal. THis is input to UD5 on pin 8. UD5 is configured as a ÷ 16 frequency

divider. The output of UD5 pin 12 is a 1 MHz clock signal used as the system clock (Phase 0) for the

microprocessor. UE6 is a programmable counter ( ÷ 16, ÷ 15, ÷ 14, ÷ 13) that outputs a varying frequency clock

used to compensate for the difference in recording area/sector for sectors on inner tracks (Trks 1,2,3) as

compared to sectors on out most tracks (Trks 33,34,35). The area/sector for inner tracks is less than the

area/sector for out most tracks, so the recording clock frequency is increased when writing on inner tracks to

keep the flux density constant. This clock output is on pin 12 of UE6.

Divide By

1-17

1.2307 MHz 13

18-24 1.1428 MHz 14

15-30 1.0666 MHz 15

31-35

MHz 16

1541 CIRCUIT THEORY

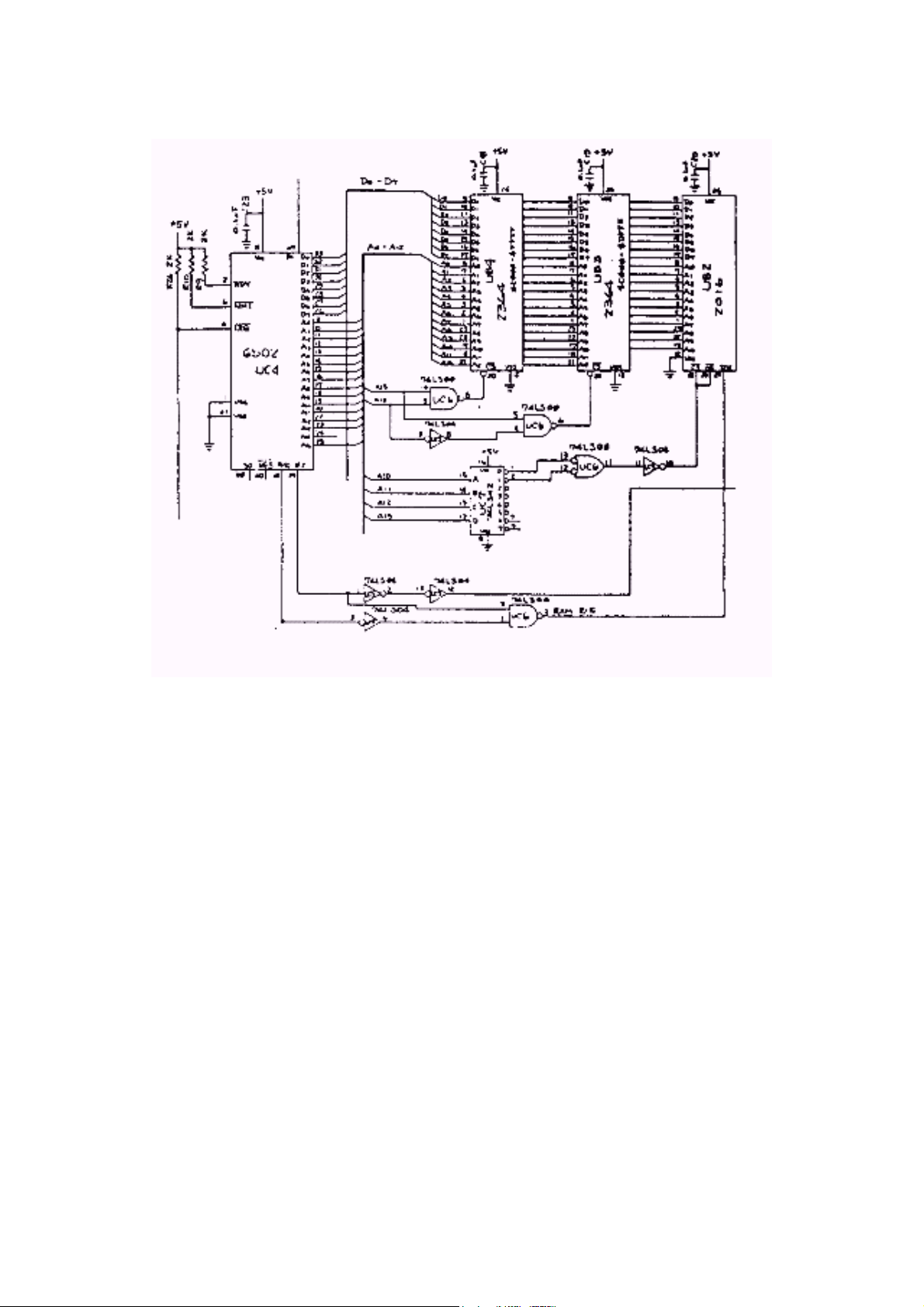

Microprocessor Control of RAM and ROM

UB3 and UB4 are 8192 x 8 bit ROMS that store the Disk Operating System (DOS). UB3 resides at memory

locations $C000-$DFFF. UB4 resides at memory locations $E000-$FFFF. UC5 and UC6 decodes the addresses

output from the microprocessor when selecting these ROMS.

UB2 is a 2048 x 8 bit RAM. UB2 resides at memory locations $0000-$07FF. This memory is

used for processor stack operations, general processor housekeeping, use program storage,

and 4 temporary buffer areas. UC5, UC6 and UC7 decode the addresses output from the

processor when selecting RAM.

1541 CIRCUIT THEORY

The Serial Interface

UC3 is a 6522 Versatile Interface Adapter (VIA). Two parallel ports, handshake control, programmable timers,

and interrupt control are standard features of the VIA. Port B signals (PB0-PB7) control the serial interface

driver ICs (UB1 and UA1). CLK and DATA signals are bidirectional signals connected to pins 4 and 5 of P2 and

P3. ANT (Attention) is an input on pin 3 of P2 and P3 that is sensed at PB7 and CA1 of UC3 after being inverted

by UA1. ATNA (Attention Acknowledge) is an output from PB4 of UC3 which is sensed on the data line pin 5

of P2 and P4 after being exclusively "ored" by UD3 and inverted by UB1. UC3 is selected by UC7 pin 7 going

"low" when the proper address is output from the processor. UC3 resides at memory locations $1C00-$1C0F.

Loading...

Loading...