Commodore 1526, 4023, MPS 802 Service Manual

SERVICE

MANUAL

1526 • MPS

802 • 4023

PRINTERS

APRIL

1985

PN-314003-03

(

:::

C;C

.n1n10dore

COMPUTERS

SERVICE

MANUAL

1526

•

MPS

802

•

4023

PRINTERS

APRIL

1985

PN-314003-03

Commodore Business Machines, Inc.

1200

Wilson

Drive,

West

Chester,

Pennsylvania

19380

U.S.A.

Commodore makes no expressed or implied

war-

ranties

with

regard

to

the

information

contained

herein. The

information

is made available solely on

an as is basis, and

the

entire risk as

to

quality

and

accuracy is

with

the

user. Commodore shall

not

be

liable

for

any consequential

or

incidental damages

in

connection

with

the

use

of

the

information

con-

tained herein. The listing

of

any

available replace-

ment

part

herein does

not

constitute

in any case

a

recommendation,

warranty

or

guaranty

as

to

quality

or

suitability

of

such replacement part.

Reproduction or use

without

expressed permission,

of

editorial

or

pictorial

content,

in

any

matter

is

prohibited.

This manual

contains

copyrighted

and proprietary

information.

No

part

of

this

publication

may

be reproduced, stored in a retrieval

system,

or

transmitted

in any

form

or

by

any

means, electronic, mechanical,

photocopying, recording or otherwise,

without

the

prior

written

permis-

sion

of

Commodore

Electronics Limited.

Copyright © 1985

by

Commodore

Electronics Limited.

All

rights reserved.

CONTENTS

Title

Page

SPECIFICATIONS

SET

UP

AND TESTING

RIBBON CARTRIDGE

....................................................................................

2

PAPER

INSTALLATION

.................................................................................

3

SELF

TEST

.................................................................................................

4

ACCESSORIES PARTS LIST

............

.............................................

.....................

...... 5

MAINTENANCE

................

.............

....................

........................

..............

.......

.......

5

FUNCTIONAL BLOCK DIAGRAM

.........................

.................................

.....

..........

.... 6

CIRCUIT THEORY

POWER

SUPPLY

..........................................................................................

7

RESET

LOGIC

..

..........................

......................................

............................

8

CLOCK CIRCUIT

........................

......................................

............................

9

MICROPROCESSOR LOGIC

...............................................

............................

10

PAPER

FEED

MOTOR

.......

..........

..............

.................................

.....

..............

11

CARRIAGE MOTOR

..........

.......

.................

............................

.....

...................

12

PRINT WIRE DRIVE

......................................................................................

13

PRINT WIRE COIL PROTECTION

.........................................................

...... .....

14

PAPER

CONTROL LOGIC

.............................................................................

.

CARRIAGE POSITION AND HOME SENSOR

...................................................

.

15

16

1526

• MPS

802

INTERFACE LOGIC

...........................

.................................

17

4023

INTERFACE LOGIC

..........................

....................................................

18

TROUBLESHOOTING GUIDES

................................................

.................................

19

PCB

PARTS

LiST...................................................................................................

22

ROM UPGRADES ....

....................................

.......

...................

..............

..... ....... ... ....

24

1526

• MPS

802

SCHEMATIC

.......

....................

...................

.........

.....

............

.......

24

DEVICE NUMBER CHANGE ...... ... ....

....................

..........................

.......

..............

.....

25

4023

SCHEMATIC

................................................................................................

25

MECHANICAL ADJUSTMENTS

HEAD SHIFT

LEVER

.............................................

........................................

26

PRINT HEAD

...............................................................................................

26

HOME SENSOR

..........

............

.............................................

...................

..... 27

WIRING DIAGRAM

....................

...................

..............

.................................

...

.......

28

MECHANICAL DISASSEMBLY

.................................................................................

29

ASSEMBLY NOTES

................................................................................................

36

CASE WORK/POWER SUPPLY

................................................................................

37

MECHANICAL ASSEMBLIES

..

.................................................................................

38

SPECIFICA TIONS

•

1526

• MPS

802

•

4023

•

PRINT

METHOD

• Bi-directional impact

dot

matrix

CHARACTER

MATRIX

• 8 X 8 Dot Matrix

CHARACTERS • Upper & lower case letters

with

true descenders. Numerals &

symbols. All

PET

graphic characters

GRAPHICS

• 8 Vertical dots - maximum

640

columns

CHARACTER CODES • CBM ASCII code

PRINT

SPEED •

60

CPS

MAXIMUM

COLUMNS

•

80

Columns

LINE FEED

SPACING

• 6 Lines/inch in character mode

• 9 Lines/inch in graphics mode

LINE FEED SPEED • 5 Lines/sec in character mode

•

7.5

Lines/sec

in

graphics mode

PAPER FEED

•

Pin

feed

PAPER

WIDTH

•

4.5

to

10"

Width (including tractor feed holes)

•

8.5"

Width (after tractor holes)

MULTIPLE COPIES • Original plus maximum

of

3 copies

POWER REQUIREMENTS •

120

Volts AC,

60

Hz,

1.5

Amp

•

1526/MPS

802

•

•

4023

•

INTERFACE

COMPUTERS

• SERIAL

• VIC20, C64,

SX64, C16,

PLUS

4

INTERFACE

COMPUTERS

•

IEEE

Protocol

•

4032,

8032,

8096,

SP9000,

B-MODEL

1

SET

UP

AND

TESTING

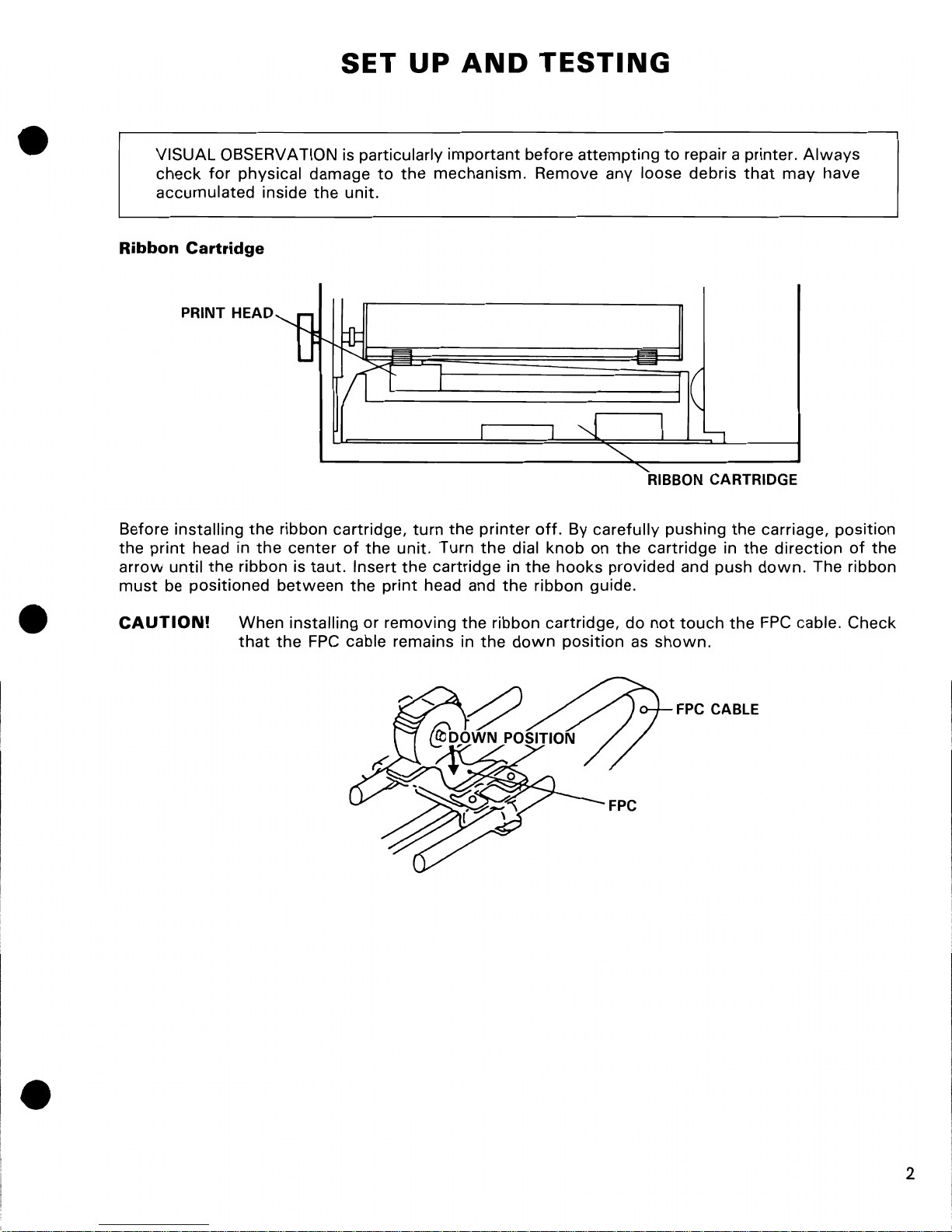

VISUAL OBSERVATION is particularly important before attempting

to

repair a printer.

Always

check

for

physical damage

to

the

mechanism. Remove any loose debris

that

may

have

accumulated inside

the

unit.

Ribbon

Cartridge

PRINT HEAD

RIBBON CARTRIDGE

Before installing

the

ribbon cartridge,

turn

the

printer

off.

By carefully pushing

the

carriage, position

the

print

head in

the

center

of

the

unit. Turn

the

dial knob on

the

cartridge in

the

direction

of

the

arrow

until

the

ribbon is

taut.

Insert

the

cartridge in

the

hooks provided and push

down.

The ribbon

must

be

positioned

between

the

print

head and

the

ribbon guide.

CAUTION!

When installing or removing

the

ribbon cartridge,

do

not

touch

the

FPC

cable. Check

that

the

FPC

cable remains in

the

down

position as

shown.

FPC

CABLE

2

SET

UP

AND

TESTING

(Continued)

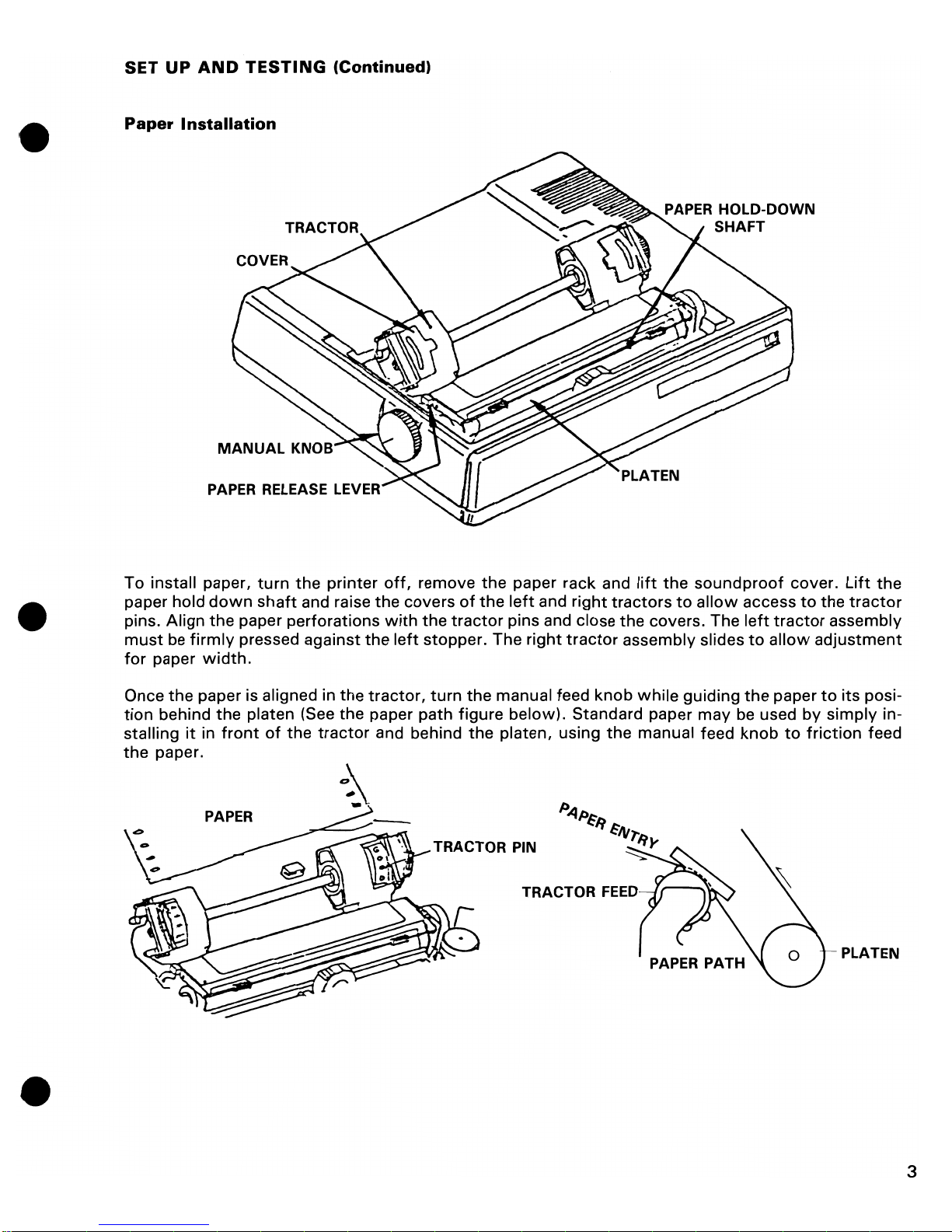

Paper Installation

PAPER RELEASE LEV

To install paper,

turn

the

printer

off,

remove

the

paper rack and

lift

the

soundproof

cover.

Lift

the

paper hold

down

shaft

and raise the covers

of

the

left

and

right

tractors

to

allow

access

to

the

tractor

pins. Align

the

paper perforations

with

the

tractor

pins and close the covers. The

left

tractor

assembly

must

be

firmly

pressed against

the

left

stopper. The right

tractor

assembly slides

to

allow

adjustment

for

paper

width.

Once

the

paper is aligned in

the

tractor,

turn

the

manual feed

knob

while

guiding

the

paper

to

its

posi-

tion

behind

the

platen (See

the

paper path figure below). Standard paper

may

be

used by

simply

in-

stalling

it

in

front

of

the

tractor

and behind

the

platen, using

the

manual feed knob

to

friction

feed

the

paper.

PAPER

TRACTOR PIN

TRACTOR

FEED

- PLATEN

3

SET

UP

AND

TESTING

(Continued)

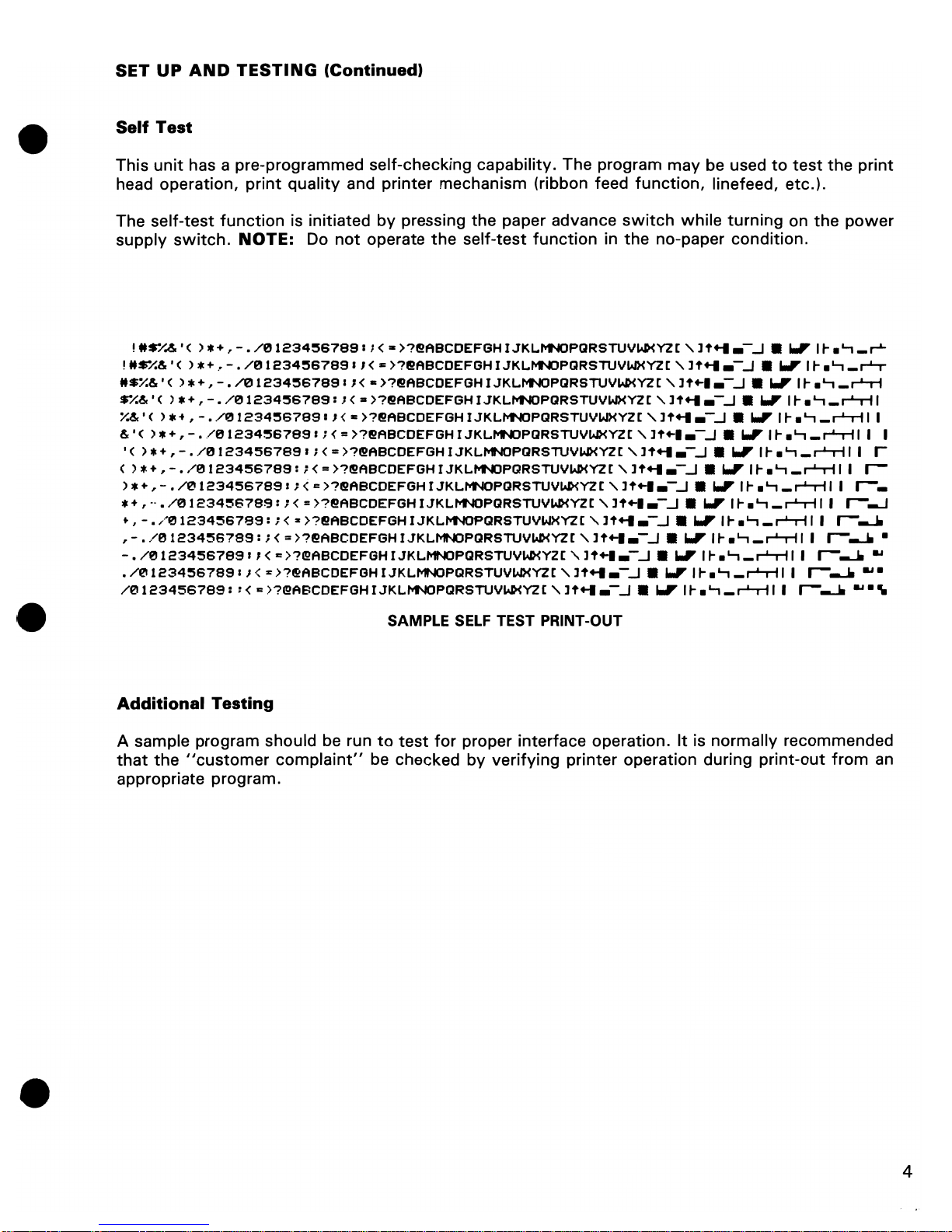

Self

Test

This

unit

has a pre-programmed self-checking capability. The program

may

be used

to

test

the

print

head operation,

print

quality

and

printer

mechanism (ribbon feed

function,

linefeed,

etc.).

The

self-test

function

is initiated

by

pressing

the

paper advance

switch

while

turning

on

the

power

supply

switch.

NOTE:

Do

not

operate

the

self-test

function

in

the

no-paper

condition.

!

H$"/.&

• ( ) * + , - •

/01234~6789

: ; <

:z

>?~ABCDEFGH

I

JKLI'r'NOPQRSTUVWXY2

[ " 11'+-11.-...1 •

.,

It-.

'-1

_

r'-

!

"$"/'&

• ( ) *

+.

- •

/01234~6789

I , <

..

>?@!ABCDEFGH I

JKLI'r'NOPQRSTUVWXY2

[ " 11'+-11.-...1 •

.,

It-.

'-1

_

~

"$%&

• ( ) * + , - •

/01234~6789

I ; <

..

)?~ABCDEFGH I JKL~PQRSTUVWXYl

[ "

11'+-1.-

...1 • .,

It- .'-1 _ r'-T-i

$"/.&

• (

).

+ ,

-.

/01234~6789:

,I

< =

>?~ABCDEFGH

I

JKLM'lOPQRSTUVWXYZ

[ "

If+-ll.

-...1 •

.,

It-.

'-1

_ r'-T-i I

X&·

( )

... , -.

/1211234:567891,

<

..

>?~ABCDEFGH

IJKL~PQRSTUVWXYzr"

11'+-11.-...1 •

.,

1t-.'-1

_r'-T-i

I I

eSc'

( ) * + , - • /EH

234567891

; < =

>?~ABCDEFGH

r

JKLMNJPQRSTUVWXYZ

[ " 11'+-1.-...1 •

.,

It-.

'-1

_ r'-T-i I I I

'(

) * + , - •

/0

123456789

I ; < =

)?@!ABCDEFGH r JKLMNOPQRSTUVWXYZ[

''If+-ll.

-...1 •

.,

It-.

'-1

_ r'-T-i I I r

( '* + , - •

/EH

23456789:

; < =

>?~ABCDEFGH

r

JKLMNJPGlRSTUVWXY2

[ " 11'+-11.-...1 •

.,

It-.

'-1

_ r'-T-i I I

r-

'* + , - •

/e'l123456789

I ; < c

>?~ABCDEFGH

r

JKLfw'NOPQRSTUVWXYl

[ " 1

l'

+-1

.-...1 • .,

It-.

'-1 _ r'-rll

I

r-_

* + ,

--

•

/121

1234~6789:

; < =

>?~ABCDEFGH

I

JKLfw'NOPQRSTUVWXYZ[

'-.11'+-1.-...1 •

.,

It-.

'-1 _ r'-rll

I

r--.J

t,

-.

/121123456789:

; < z

>'?~ABCDEFGH

I

JKLI'1'IOPQRSTUVWXYl

[

''If+-ll.-..J • .,

1t-.'-1

_r'-rll

I r---.J.

,

-.

/8123456789:

; < =

>?~ABCDEFGH

IJKLMNJPQRSTUVWXY2[

''\1

l'

+-1

.-...1 • .,

1t-.'-1

_r'-rll

I

r-

--.J.

•

-.

/121123456789

11 <

")?@!ABCDEFGH

rJKLMNOPQRSTUVWXYZ[

"]t+-I.-..J

•

.,

It-

.'-1_r'-rl1

I

r-

--.J.

...

•

/01234567891

) < :

>'?~ABCDEFGH

I

JKLMNOPGlRSTUVWXYl

[

''It+-ll

.-...1 • .,

1t-.'-1

_r'-rll

I r---.J.

...

.

/0123456789:

1<

'"

)?@!ABCDEFGHIJKLI'1'IOPGlRSTUVWXYl["

11'+-11.-...1 •

.,

1t-.'-1

_r'-rll

I

r-

--.J.

....

..

SAMPLE

SELF

TEST PRINT-OUT

Additional

Testing

A sample program should be run

to

test

for

proper

interface

operation.

It

is

normally

recommended

that

the

"customer

complaint"

be checked

by

verifying

printer

operation during

print-out

from

an

appropriate program.

4

Cleaning

ACCESSORIES

PARTS

LIST

C

314597-01

C314598-01

C

314598-02

C

314598-03

C

314599-01

C 1

51

5001 -01

C

903508-04

1526/802/4023

1526

MPS802

4023

1526/802/4023

1526/MPS802

1526/802/4023

MAINTENANCE

CAUTION

PAPER

RACK

USER'S

MANUAL

USER'S

MANUAL

USER'S

MANUAL

RIBBON

6PIN DIN CABLE

POWER CORD

Do

not

use chemicals

to

clean any

of

the

printer parts.

Using a clean,

dry

brush, remove

dust

and debris

from

the

ribbon guide, print head, platen area and

tractors

often.

Periodically remove

the

top

case and brush any accumulated

dust

or particles

from

the

unit.

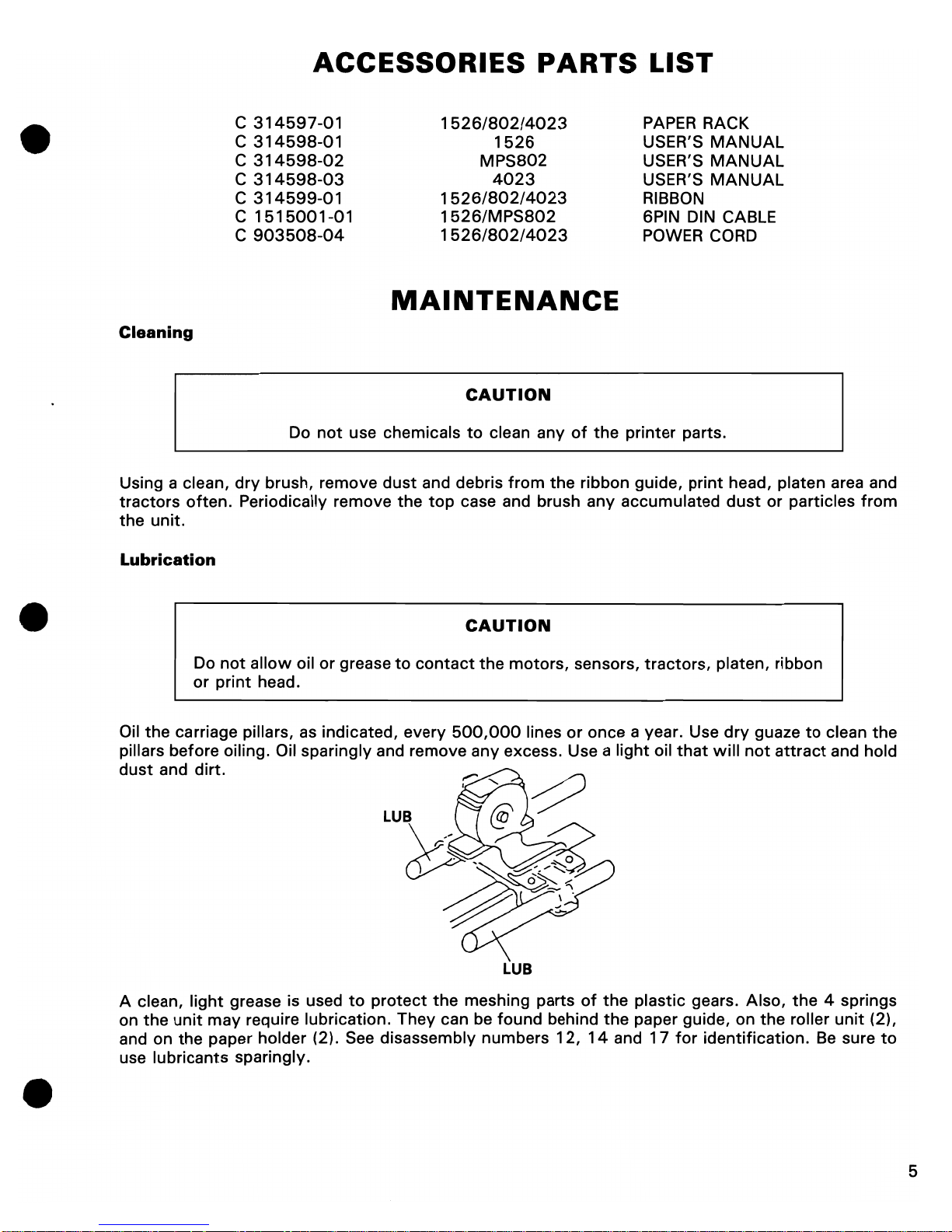

Lubrication

CAUTION

Do

not

allow

oil or grease

to

contact

the

motors,

sensors,

tractors,

platen, ribbon

or

print head.

Oil

the

carriage pillars,

as

indicated, every

500,000

lines

or

once a year. Use

dry

guaze

to

clean the

pillars before oiling. Oil sparingly and remove any excess. Use a light oil

that

will

not

attract

and hold

dust

and dirt.

LUB

A clean,

light

grease is used

to

protect

the

meshing parts

of

the

plastic gears. Also,

the

4 springs

on

the

unit

may

require lubrication. They can be found behind

the

paper guide, on

the

roller

unit

(2),

and on

the

paper holder (2). See disassembly numbers

12,

14

and 1 7

for

identification.

Be

sure

to

use lubricants sparingly.

5

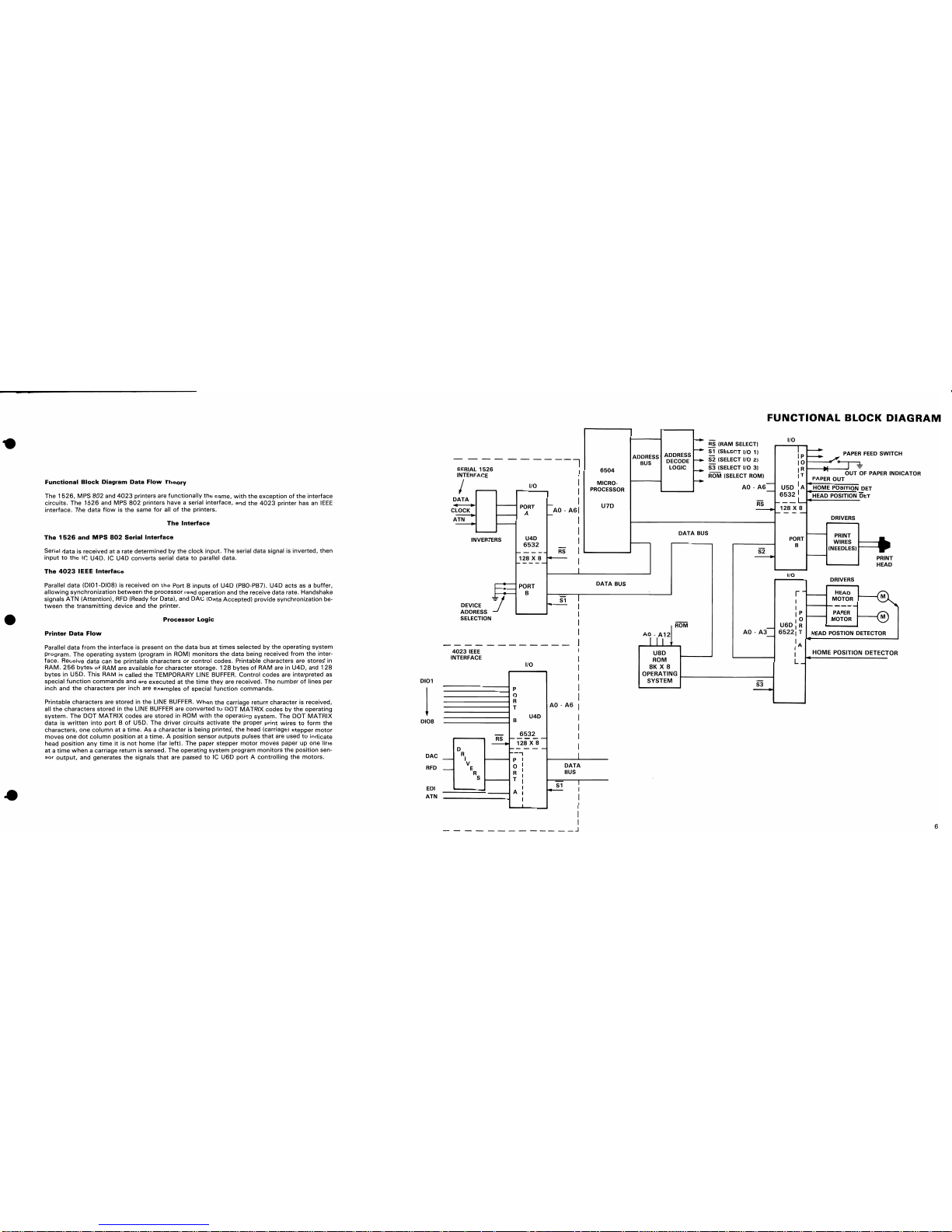

Functional

Block

Diagram

Data

Flow

Theory

The

1526,

MPS

802

and

4023

printers are

functionally

the

same,

with

the

exception

of

the

interface

circuits.

The

1526

and MPS

802

printers have a serial

interface,

and

the

4023

printer

has an

IEEE

interface.

The

data

flow

is

the

same

for

all

of

the

printers.

The

Interface

The

1526

and

MPS

802

Serial

Interface

Serial

data

is received at a rate determined

by

the

clock

input.

The serial

data

signal is

inverted,

then

input

to

the

IC

U4D.

IC

U4D

converts

serial data

to

parallel

data.

The

4023

IEEE

Interface

Parallel data (0101-DI08) is received on

the

Port B

inputs

of

U4D

(PBO-PB7).

U40

acts

as a buffer,

allowing

synchronization

between

the

processor

read

operation

and

the

receive data rate. Handshake

signals

ATN

(Attention),

RFD

(Ready

for

Oata), and DAC (Data

Accepted)

provide

synchronization

be-

tween

the

transmitting

device and

the

printer.

Processor

Logic

Printer

Data

Flow

Parallel

data

from

the

interface

is present

on

the

data bus

at

times

selected

by

the

operating

system

program.

The

operating

system

(program in ROM)

monitors

the

data

being received

from

the

inter-

face. Receive

data

can be printable

characters

or

control

codes. Printable

characters

are

stored

in

RAM.

256

bytes

of

RAM are available

for

character

storage.

128

bytes

of

RAM

are in

U40,

and

128

bytes

in

U5D.

This

RAM is called

the

TEMPORARY LINE BUFFER.

Control

codes are

interpreted

as

special

function

commands

and are

executed

at

the

time

they

are received. The

number

of

lines per

inch

and

the

characters per inch are

examples

of

special

function

commands.

Printable

characters

are stored in

the

LINE BUFFER.

When

the

carriage return

character

is received,

all

the

characters

stored in

the

LINE BUFFER are

converted

to

DOT

MATRIX

codes

by

the

operating

system.

The

OOT

MATRIX

codes are

stored

in ROM

with

the

operating

system.

The DOT

MATRIX

data

is

written

into

port B of

U50.

The

driver

circuits

activate

the

proper

print

wires

to

form

the

characters,

one

column

at a time.

As a character

is being

printed,

the

head (carriage)

stepper

motor

moves

one

dot

column

position

at a time. A position

sensor

outputs

pulses

that

are used

to

indicate

head

position

any

time

it

is

not

home (far

left).

The paper

stepper

motor

moves

paper

up

one line

at a time

when

a carriage return is sensed. The

operating

system

program

monitors

the

position

sen-

sor

output,

and generates

the

signals

that

are passed

to

IC

U60

port A controlling

the

motors.

0101

1

0108

DAC

RFD

EDI

ATN

SERIAL

1526

INTERFACE

I

----I

I

I

I

110

DATA

,~I

nr.K

~TN

t----I

PORT

A

INVERTERS

U4D

6532

DEVICE

ADDRESS

SELECTION

4023

IEEE

NTERFACE

----

128

X 8

1-----

r---~

PORT

1

-

B

I/O

--------------1

P

_______________

-1

0

----------------1 R

-----------------i T

---------------4

B

U4D

6532

RS

---

128

X 8

0

---

R

--,

I

P

I

V

0

1

E

R

R

I

S

T

I

I

I

A

f

I

- I

AD - A61

- I

RS

S1

AD -

A6

I

I

I

I

I

I

I

I

I

I

J

I

I

I

I

I

I

DATA

BUS

S1

I

I

I

I

I

__

J

6504

MICRO-

PROCESSOR

U7D

DATA

BUS

FUNCTIONAL

BLOCK

DIAGRAM

f---

RS

(RAM SelECT)

110

ADDRESS

BUS

ADDRESS

r--

-S1

(SELECT

110

1) I P

t::

DECODE

r--

S2 (SelECT

110

2) I 0

PAPER

FEED

SWITCH

LOGIC

r-- S3 (SelECT I/O 3)

II

~

t---.......--....I~UT

~F

PAPER

INDICATOR

ROM

(SELECT

ROM)

PAPER

OUT

r-- AD _

A6-

U5D

I

A~HUiOI~IME-;:;I':ru;ju:>llmllinul~IN

DET

'------I

-

6532

I :

HEAD

POSITION

DET

U8D

ROM

8K X 8

DATA

BUS

AD -

RS

---

--

OPERATING

t-------------I

SYSTEM

S3

___

L

128

X 8

1-----

PORT

B

I/O

r

-t----I

DRIVERS

PRINT

WIRES

(NEEDLES)

t---I

DRIVERS

HEAD

MOTOR

PRINT

HEAD

I

I

1----

....... ----

-

I P

1--_-1

1

0

PAPER

MOTOR

U6D

I R

65221T

HEAD

POSTION

DETECTOR

I A

.....

-----------'

I

I

L_

HOME POSITION DETECTOR

6

The

Power

Supply

CIRCUIT

THEORY

CR26

_::-::-::-:4

A:-'I/SO

V

or

1.S

AlSO

V

on

h.~t

sink

~-r:----r-:U)"""':::::

+5

V

N

I'"

",I

-.

uu

o"ai

L---~~~-+-~~-~---;uD

.

+.

RS

lO

k

C7

6800

SOV

+5V

GND

1--+_..::::::.+26

v

+26 V

GND

The

Power

Supply

generates

two

outputs,

+ 5VDC and +

26VDC.

Both

outputs

are regulated. The

5VDC

output

supplies

the

microprocessor and TTL circuits. The +

26VDC

output

supplies

the

print

wire

coils and

the

paper feed and carriage

motor

drive circuits.

+

5VDC

Supply

VR 1 is a series regulator. The series regulator keeps

the

output

voltage

constant

when

the

load varies.

Capacitive filtering eliminates

most

of

the

ripple voltage on

the

output.

CR26 is a full

wave

bridge

rectifier

which

converts

the

AC

voltage

generated

from

the

top

secondary

winding

of

the

power

transformer

to

DC voltage.

+

26VDC

Supply

A

shunt

type

regulator

circuit

generates

the

constant

26

VDC

output.

UNREG

DC

+26

VDC REGULATOR CIRCUIT

R7

023

,=-

.7V

27V

VOUT

=019

VBE

+ VCR23

26.3V = -.7V

+27V

+26

VOLT OUTPUT

~

C1

J

ILO

AD

The

output

voltage

is regulated

at

26.3VDC

because

the

base

to

emitter

voltage

of

019

opposes

the

voltage

developed across CR23.

Most

of

the

load

current

passes

through

the

power

transistor

023.

CR27 is a full

wave

bridge rectifier

which

converts

the

AC

voltage

output

from

the

bottom

secon-

dary

winding

of

the

power

transformer

to

DC voltage.

C7

filters

the

rectified DC

output

voltage.

7

CIRCUIT

THEORY

UIC

U20

UIC

6

UIC

RESET

1

_2

3

~4

5 _

.~

Jl""o--;:4~_---:..;R:.:E.:.S-t-+-iI-+-i

74LS14

+24

V

~

o

">::a£

N

"'>01

a:

>ri

7406

R21

~

I,

100

~r,1-'

B

I~>

t

....

c:

."

MN

APU

Q21

I +5 V

-..:- +5 V

-

GNO

Reset

Logic

Circuit

Theory

POWER ON

+5V

021

COLLECTOR

U1C5PIN

U1C6PIN

U1C4PIN

--------

APPROX.

350

ms

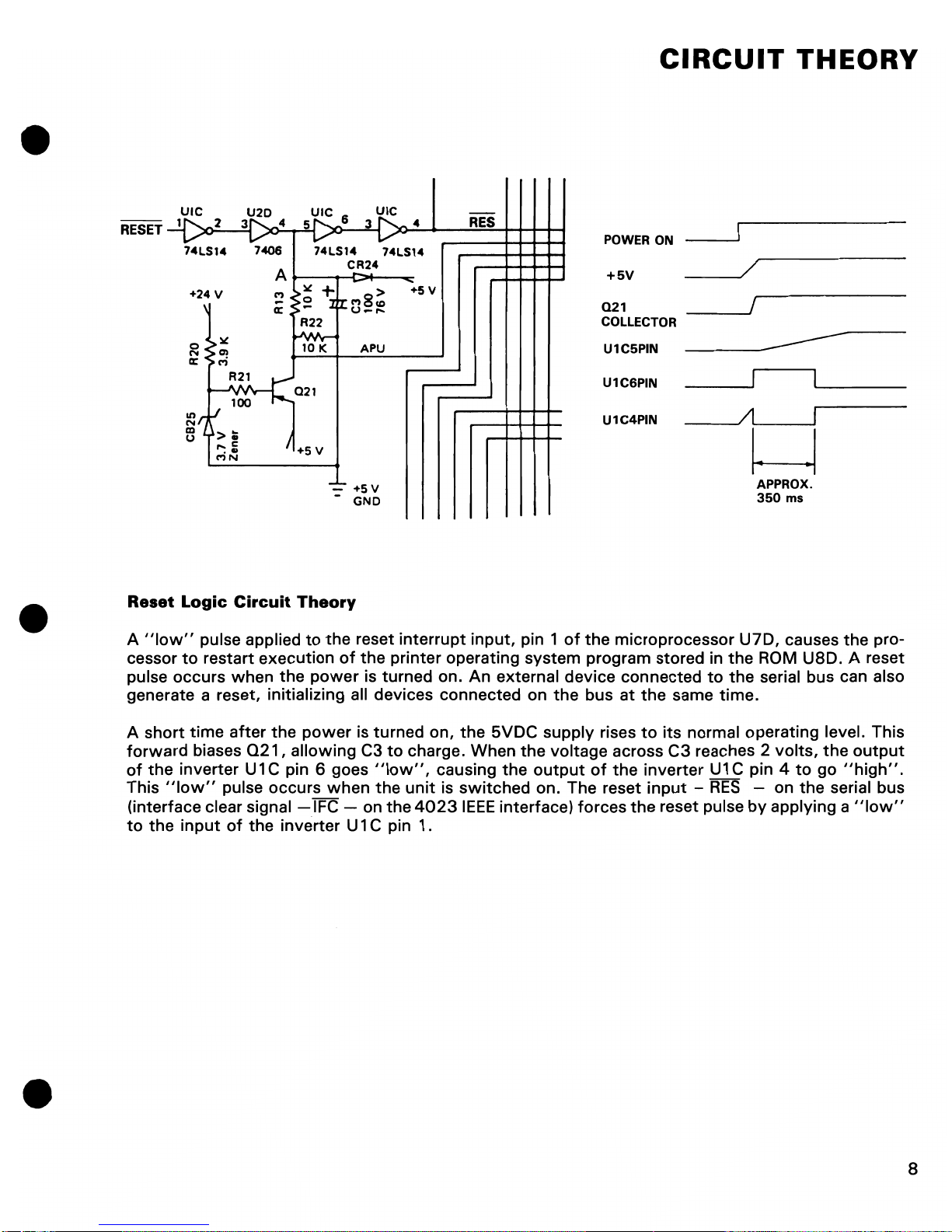

A

"low"

pulse applied

to

the

reset

interrupt

input,

pin 1

of

the

microprocessor

U7D,

causes

the

pro-

cessor

to

restart

execution

of

the

printer

operating

system

program stored in

the

ROM USD. A reset

pulse

occurs

when

the

power

is

turned

on.

An

external device connected

to

the

serial bus can also

generate a reset, initializing all devices connected on

the

bus

at

the

same

time.

A

short

time

after

the

power

is

turned

on,

the

5VDC

supply

rises

to

its

normal operating level. This

forward

biases

Q21,

allowing

C3

to

charge.

When

the

voltage across

C3

reaches 2

volts,

the

output

of

the

inverter U1C pin 6 goes

"low",

causing

the

output

of

the

inverter

U1C

pin 4

to

go

"high".

This

"low"

pulse

occurs

when

the

unit

is

switched

on. The reset

input -RES

- on

the

serial bus

(interface clear signal

-IFC

- on

the

4023

IEEE

interface)

forces

the

reset pulse

by

applying a

"Iow"

to

the

input

of

the

inverter U 1 C pin 1.

S

1526

AND

4023

CIRCUIT

THEORY

V1

..

MHz

l..r----?":

- , .

R56

--0-1--

L _

___

'~:

"

R55

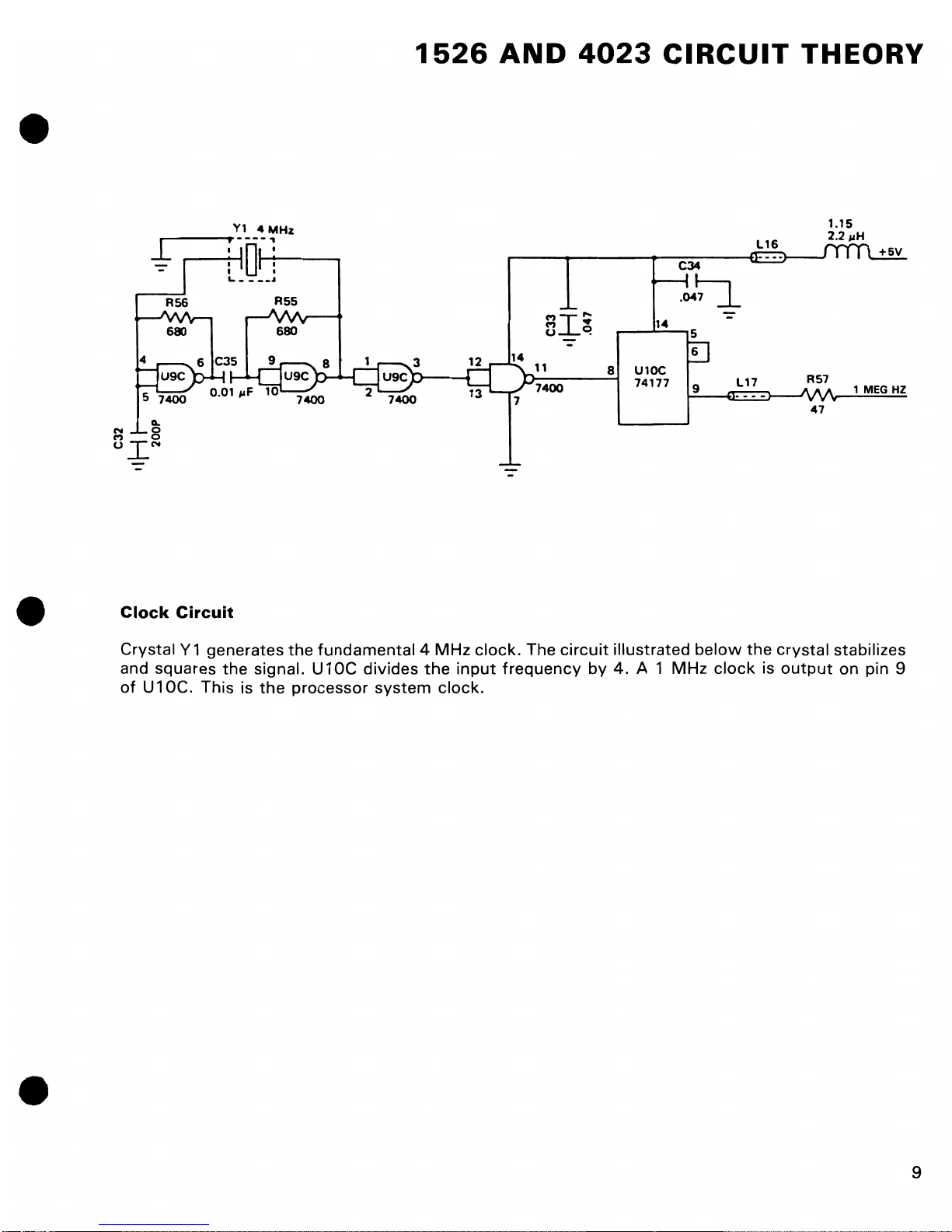

Clock Circuit

Crystal Y 1 generates

and squares

of

U 1

OC.

the

This is

signal. U 1

the

-~

7400

the

fundamental 4 MHz

OC

processor system clock.

7400

divides

the

input

11

D-

74

7

clock.

The

frequency by

"

.,

"I'"

o

C!

-

--......::..j

00

circuit

8 U10C

74177

illustrated

4.

A 1 MHz

C34

.04~

9

below

clock

117

the

R57

47

crystal stabilizes

is

output

1.15

2.2

"H

1 MEG

on pin 9

HZ

9

1526

+26V

AND

4023

CIRCUIT

THEORY

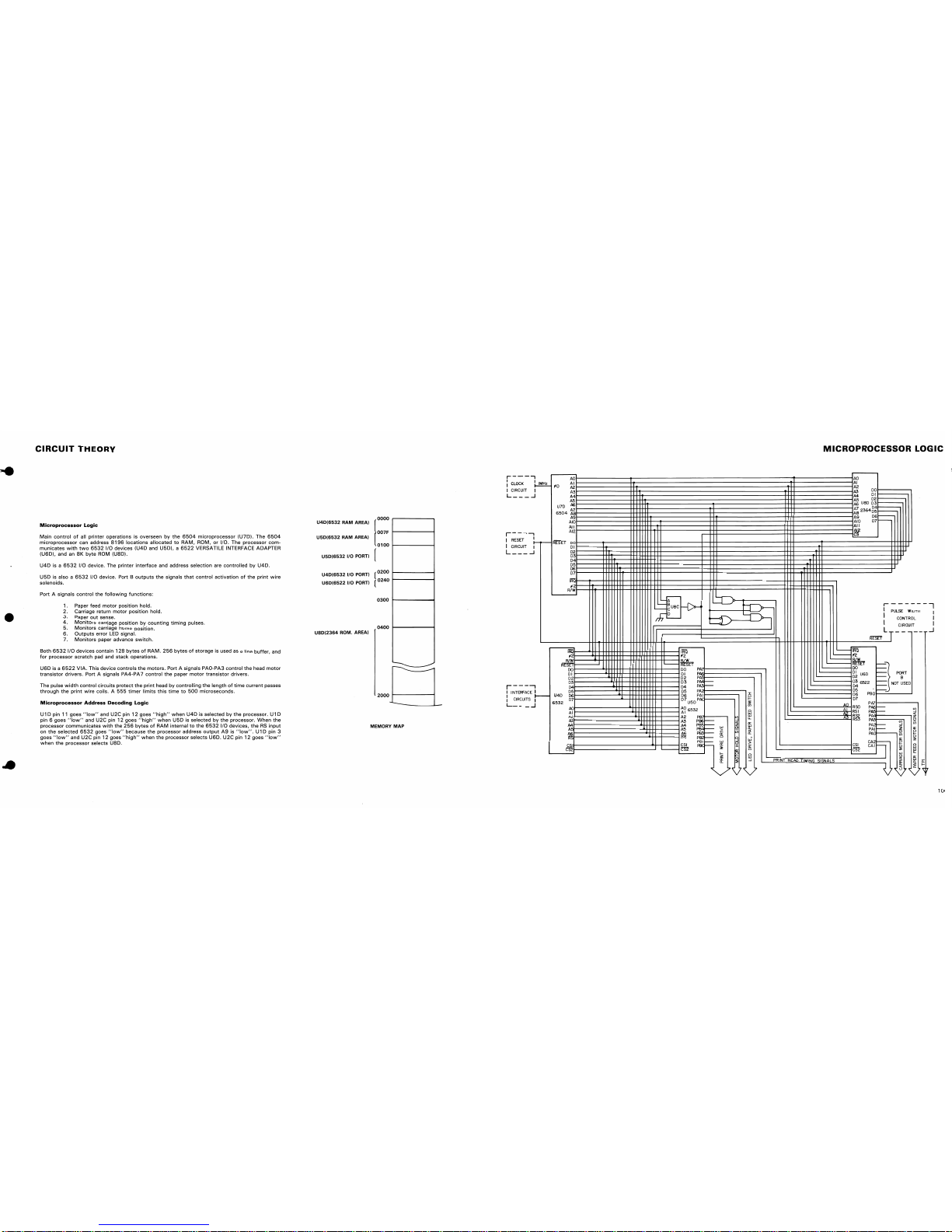

U5D

6532

6522

Paper

U6D

PAO

PA4

PAS

PA6

PA7

81PF

Holdl

61PMOI

7

(PM1)

81PM21

IllPM31

Feed

Motor

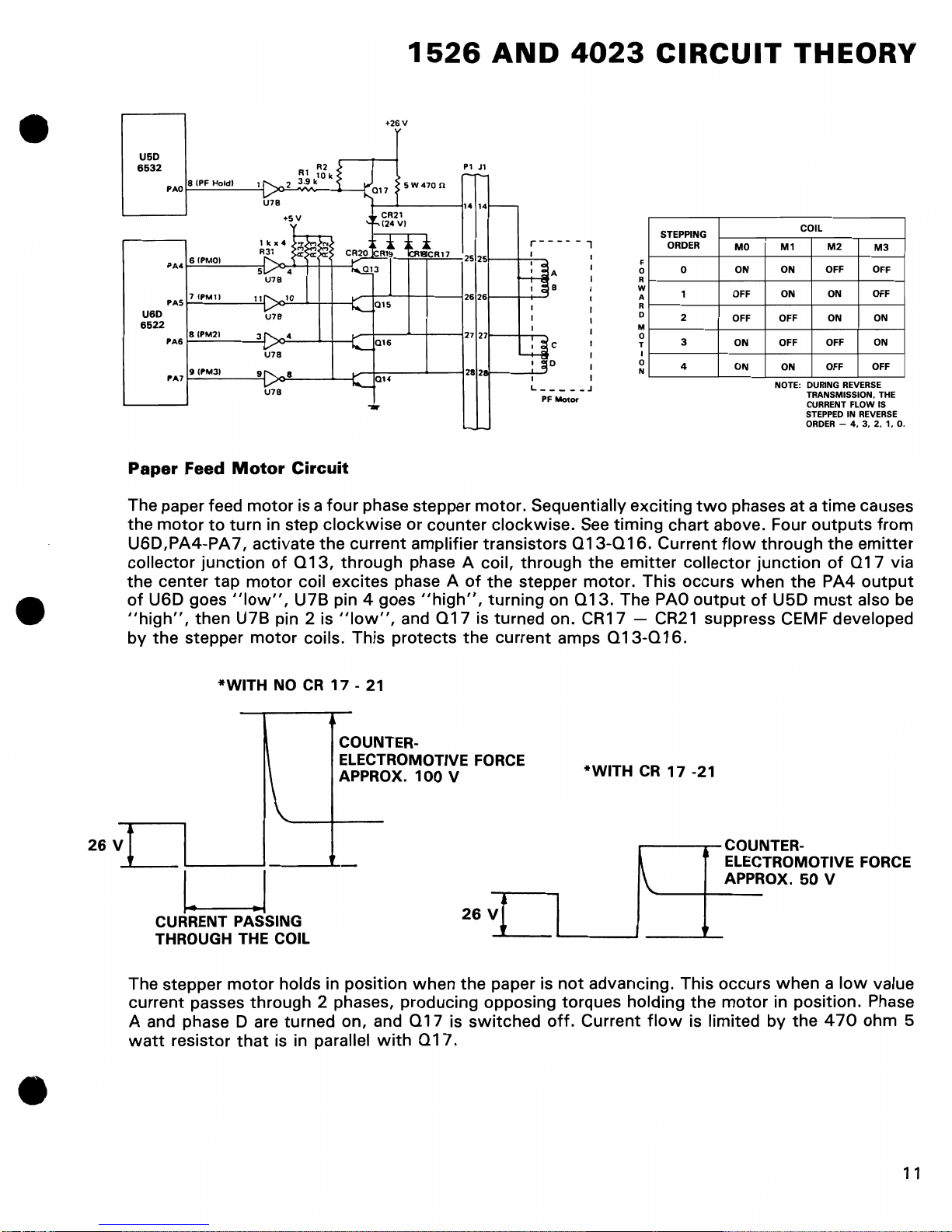

The paper feed

the

motor

to

turn

11

3

9

Circuit

motor

is a

four

phase stepper motor. Sequentially exciting

in step clockwise or counter clockwise. See timing chart above. Four

Pl

1.

2S

2626

27 27

282

2S

Jl

14

A

B

I

L

_____

PF

Motor

U6D,PA4-PA 7, activate the current amplifier transistors

collector

the

of

U6D goes

"high",

by

the stepper

junction

center tap

motor

"low",

then U7B pin 2 is

motor

of

013,

through phase A coil, through

coil excites phase A

U7B pin 4 goes

"low",

coils. This protects

"high",

and 0

of

the stepper motor. This occurs

turning on 0

17

is turned on. CR17 -

the

current amps

.J

013-016.

the

emitter

13.

The

013-016.

STEPPING

ORDER

F

0

R

W

A

R

0

M

0

T

I

0

N

Current

PAO

CR21

COIL

0

1

2

3

4

MO

M1

ON

ON

OFF

OFF

two

phases at a time causes

ON

OFF

ON

OFF

ON

ON

NOTE: DURING REVERSE

M2 M3

OFF

ON

ON

OFF

OFF

TRANSMISSION. THE

CURRENT FLOW IS

STEPPED

IN

ORDER -

4.

outputs

flow

collector

when

output

through

junction

of

U5D

the

the

of

PA4

must

017

suppress CEMF developed

OFF

OFF

ON

ON

OFF

REVERSE

3. 2. 1.

O.

from

emitter

via

output

also

be

*WITH

26

V

The stepper

current passes through

A and phase

watt

resistor

NO

CR

17 -21

COUNTERELECTROMOTIVE

APPROX.

motor

holds

in

position

2 phases, producing opposing torques holding

0 are turned on, and

that

is in parallel

with 0 17.

100

when

017

FORCE

V

*WITH

CR

17

-21

.---r-COUNTER-

__

--"~

L.

26

V=!~~~~""

the

paper is

is

switched

not

advancing. This occurs when a

off.

Current

flow

I ELECTROMOTIVE

_ _ APPROX.

the

motor

in position. Phase

is limited by the

50

V

low

470

FORCE

value

ohm 5

11

Loading...

Loading...