Page 1

USER GUIDE

& MANUAL

COMFORTCOMPANY.COM

BODILINK™ HEAD SUPPORT

UM-BODILINK-HEAD-SUPPORT REV0817

Page 2

Thank you for choosing COMFORT COMPANY

ABOUT US CONTENTS

®

At Comfort Company we are dedicated to creating and

manufacturing seating and postural support systems

designed for people with a wide range of rehabilitation

needs. Whether for pediatric, geriatric, or bariatric needs

we are committed to providing our customers with quality products designed for comfort, durability, and ease of

use. Our vision is to lead in the development, manufacturing, and delivery of the most innovative seating and

positioning products which provide the highest level of

comfort, functionality, and quality of life for the user.

CONTACT INFORMATION

1.800.564.9248

406.522.8563

customerservice@comfortcompany.com

www.comfortcompany.com

Customer Service

Bozeman, Montana

Manufacturing

New Berlin, Wisconsin

BEFORE USE

SAFETY GUIDELINES

Symbols 3

General Safety 3-4

Intended Use/User 4

Parts Detail 5

INSTALLATION & SET UP

Attachment To Back Supports 6-11

Acta-Back® Series, Acta-Embrace

Acta-Relief™ Head Support Bracket 7

Acta-Relief™ with Compass® 4 7

Acta-Relief™ with Compass® Power Mount 8

Using Radius & Posterior Mounting Plates 9

Mounting to Permobil® with Uni-Track 10

Mounting to Quantum® with TRU-Comfort

Adding a Link to the Hardware 12-13

Connecting Hardware and Support Pads 14

Adjustments 15-16

Finishing Installation 17

CLEANING AND MAINTENANCE

Cleaning 18

Inspection 19

Reuse 19

Storage 19

Disposal 19

WARRANTY AND REPLACEMENT

Lifetime Guarantee 19

Replacement Procedure 19

COMMENTS

®

(any hardware) 6

2

11

15

Back

Cover

The appropriate Comfort Company positioning product

is intended to improve every day user function and comfort while providing support and stability for a variety of

rehabilitation needs. However, prior to using any Comfort

Company support, it is important that each individual be

assessed by a qualied healthcare professional for but not

limited to, mobility, nutrition, current condition, goals, and

health history. In addition to this initial assessment, individuals should be regularly monitored by a health care professional for any changes in their condition.

This user guide and manual is for reference purposes only

and is not intended to substitute for advice given by a physician or other licensed healthcare professional. You should

not use this information for self-diagnosis or self-treatment

of a health problem or condition. Contact your healthcare

provider immediately if you suspect that your health problem or condition has changed or worsened.

Before using, make sure that you are properly trained to

operate the equipment for its application. Failure to do so

could lead to discomfort, injury or damages.

NOTE: “We,” “Us” and “Our” refers to Comfort Company. “You” refers to the product purchaser or user.

2

INTRODUCTION www.comfortcompany.com

Page 3

SAFETY GUIDELINES

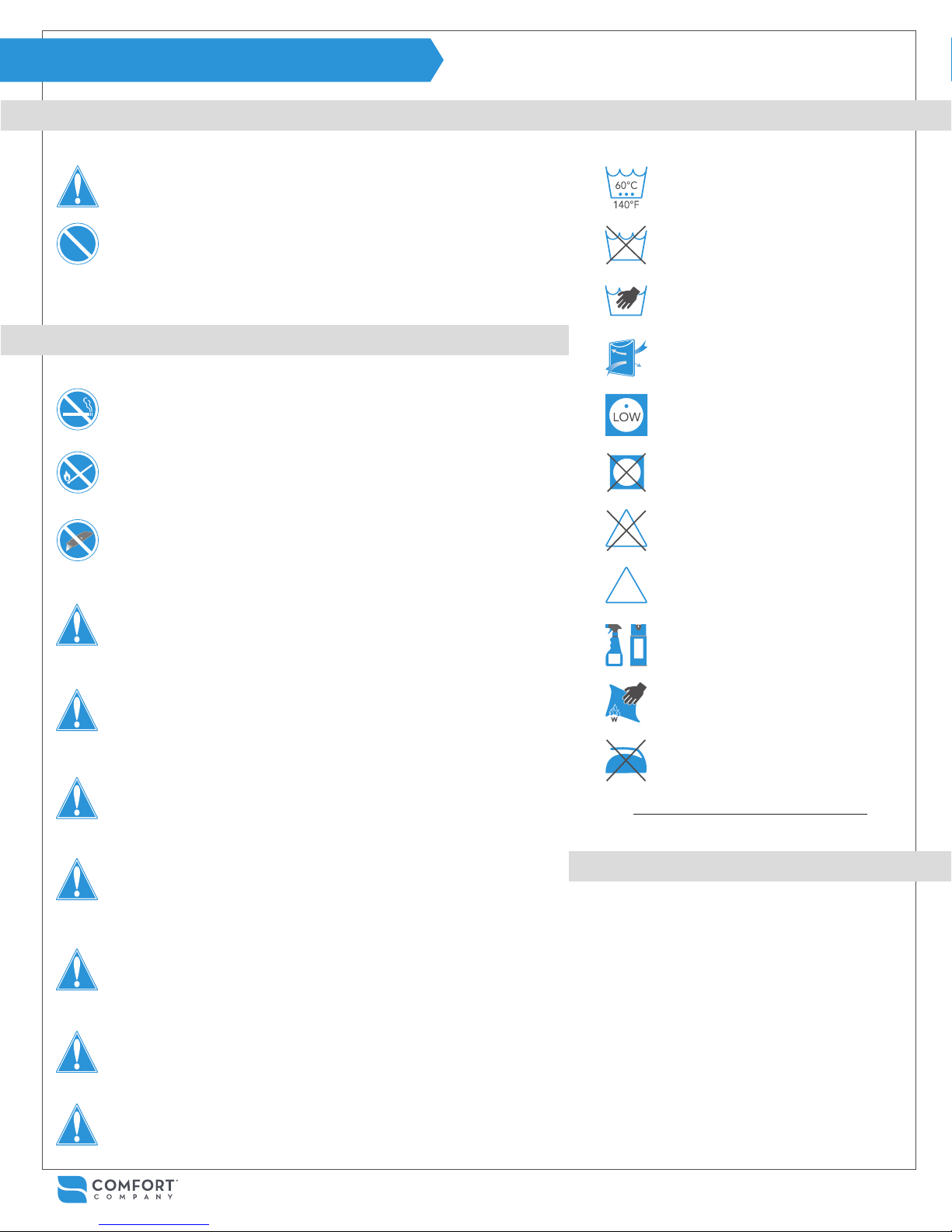

SAFETY SYMBOLS

Warning!

Prohibited!

GENERAL SAFETY

No Smoking

Do Not Expose to sources of excessive heat such as open ame or spark.

Do Not Cut

or Puncture

Without following the specied procedure, this indicates potentially

hazardous conditions that could lead to personal injury, inadequate

performance, product damage or malfunction.

Indicates actions that should NOT be performed at any time under any

circumstance. These actions could result in personal injury and/or damage

to the product or equipment being used.

Although this product meets ammability requirements, we do not

recommend smoking while using this product. Damage from smoke and

ame is not covered by the lifetime warranty. You must consider additional

safety precautions when choosing to smoke while using this product.

Avoid sharp objects. Do not modify the product. Doing so will void its

warranty and may lead to personal injury or alter the effectiveness of the

product by increasing the risk factors for skin breakdown and/or instability.

CARE SYMBOLS

Wash Cover Only Warm Cycle (Maximum Temperature)

Do Not Wash

Hand Wash

Air Dry Only

Hang to Dry

Tumble Dry Low

Do Not Tumble Dry, Steam Clean or

Autoclave

Do Not Bleach

You must READ and FOLLOW all instructions, notes and warnings included in this

manual. Understanding how to care for your product is the key to safe and proper

use. Share this information with all caretakers to help them meet your healthcare

needs and ensure your safety.

Comfort Company cannot be held responsible for damages or injury due to misuse

of the product or failure to follow instructions provided in this manual. Please contact

us if you require further assistance in understanding cautions, warnings or instructions

for using or maintaining your product.

Installing alternate parts to your wheelchair may change the intended structure and

function of the equipment. Be sure to assess the need for additional safety features

for your chair such as anti-tip bars or other available options in order to maintain

stability during use. Use this manual in conjunction with the user manual that came

with your chair to ensure safety guidelines are being met.

Check packaging and inspect all parts for damage before use. DO NOT USE if damaged and contact Comfort Company immediately for further instruction. Check regularly for loose components and tighten as necessary. Contact Comfort Company if

wear or damage is noted.

During the rst few hours of use, a healthcare professional should be available to

observe skin condition and assess the likelihood of skin breakdown.

During regular use, periodically check for skin discoloration and/or irritation. If discoloration should occur and not disappear after 30 minutes of non-use, discontinue use

and consult with your healthcare provider immediately.

Bleach Okay

Antibacterial or Disinfectant Spray

Wipe with Water Only

Do Not Iron

Detailed cleaning instructions on page 18

PLEASE NOTE

The information in this manual was gathered and recorded with

the latest specications available at the time of publication. Due

to our continued effort to reassess and improve our products,

information found in this manual such as drawings and notes may

vary slightly from the product that you purchased. We reserve the

right to make changes to products as they are deemed necessary. To check for the latest version of this manual please visit us

at www.comfortcompany.com.

DO NOT place anything in between the user and the product. Additional materials

may reduce the effectiveness of the product and increase risk factors for skin breakdown and instability.

Always use the cover and base with any inserts as a complete assembly. Never use a

cover other than one intended for your specic product and size.

The directions provided will help to maintain and extend the

life of your product and ensure it is covered by the Comfort

Company Lifetime Guarantee. Please see complete warranty

information on page 19.

SAFETY GUIDELINES

3

Page 4

SAFETY GUIDELINES

BODILINK™ HEAD SUPPORT SAFETY DETAILS

PROHIBITED! Never use the equipment to maneuver a

chair or anything that it is attached to. It is never to be

used as a handle, lift, guide or support for anything other

than what it was intended. (ex. support during transfers.)

PROHIBITED! Never use the equipment unless all components are fully functional. Any issues should be addressed

by contacting your dealer or customer service. Do not at-

tempt to make your own modications or repairs.

This product is designed for the intended user and use

only. Be aware that any modications could potentially

endanger the user, cause discomfort or damage.

This product passed crash testing. However, when

possible, do not use head support during transport.

Repeated or excessive force (braking or crash) could

potentially change adjustment or cause extra wear

shortening the life of the product. Use after a crash is

not recommended.

Caregivers: It is necessary to learn from a healthcare provider

how to properly adjust the equipment for the user’s specic

positioning needs and goals.

WARNING! Ensure that the product does not interfere with

any other chair components. Interference could jeopardize

effectiveness and user safety as well as cause damage.

WARNING! It is necessary to fully articulate power recline

features to ensure there is no possible equipment interference after installation. Do so slowly while watching closely.

ATTENTION! Make sure that the head support is securely

mounted to the back support system and it is adjusted

properly each time it is in use.

ATTENTION! Always check that the gear teeth in each joint

are aligned for full tooth engagement before nal tighten-

ing. Failing to do so could cause wear on the teeth leading

to parts slipping out of adjustment or hardware failure.

ATTENTION! Unless otherwise specied, fasteners

should be tightened to 10.5 Nm (93 lb-in).

CAUTION! Please consider that adding additional

links to the hardware may reduce the overall strength.

INTENDED USE - MATERIALS

COMFORT-TEK™ fabric cover is uid-resistant, easily cleaned at any time

and soft to the touch. Comfort-Tek™ fabric has stretch which helps alleviate

pressure and conforms to both support pad and user.

STRETCH-AIR™ fabric cover is 2-Ply designed to be breathable on the

surface for comfort while the bottom layer is uid-resistant for cleanliness.

The multi-directional stretch allows for optimal conforming to the user and

support pad shape.

GLIDEWEAR® fabric cover is intended for maximum hair and skin protection by reducing shear. Recommended most for those with abnormal tone

causing involuntary movements, difcult postures and frequent repositioning

All fabrics used in BodiLink™ Head Support covers are latex-free.

Comfort-Tek™ fabric is used on all head support pad covers along

the outer edge.

BodiLink™ Head Support pads come in 2 levels of rmness (soft and

extra soft). Both use a layer of Viscool® extra soft foam over a high

resiliency foam base layer. This combination allows for immersion and

conforming to the user for optimal surface contact, comfort and pressure redistribution.

INTENDED USER

BodiLink™ head support is intended for those with positioning and support needs as deemed necessary by a qualied healthcare professional.

BodiLink™ head support offers a wide variety of available positions to accommodate user rehabilitation needs and goals while allowing for function and

comfort. The sizes available and range of adjustability t pediatric to full grown users and should be matched by the healthcare provider to suit the user

needs. Adjustments or replacement components may be necessary as changes in condition occur or to accommodate developments such as growth.

4

SAFETY GUIDELINES - INSTALLATION & USE www.comfortcompany.com

Page 5

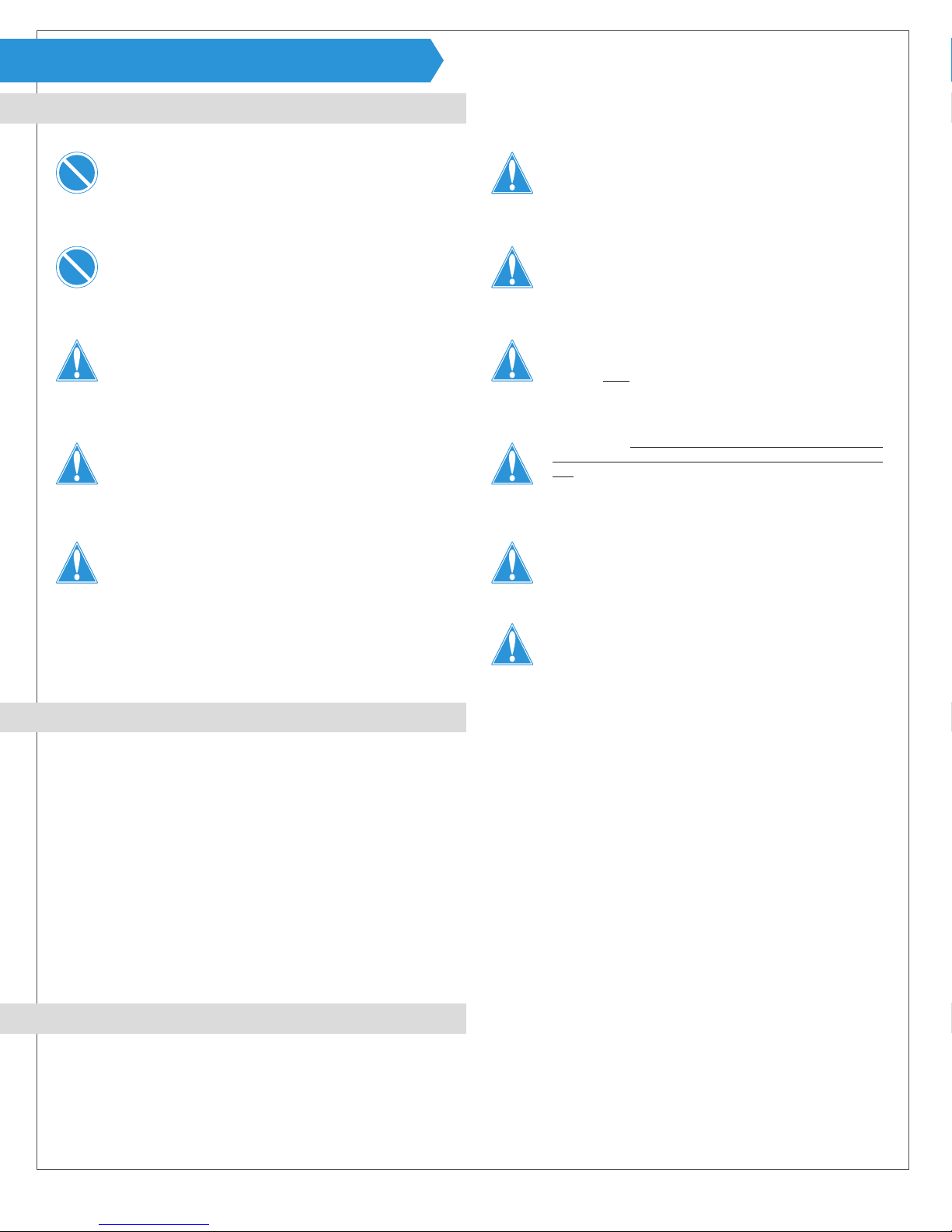

PARTS DETAIL

BODILINK™ HEAD SUPPORT

REMOVABLE HARDWARE

(BL-HSH-FX)

BODILINK™ HEAD SUPPORT PAD

6” W X 3.5” L (BL-HSP1-6W3L) (BL-HSP2-6W3L)

8” W X 4” L (BL-HSP1-8W4L) (BL-HSP2-8W4L)

10” W X 5” L with adjustable wings (BL-HSP1-10W5L) (BL-HSP2-10W5L)

14” W X 5” L with adjustable wings (BL-HSP1-14W5L) (BL-HSP2-14W5L)

18” W X 5” L with adjustable wings (BL-HSP1-18W5L) (BL-HSP2-18W5L)

BODILINK™ HEAD SUPPORT

REMOVABLE HARDWARE FOR

QUANTUM® (BL-HSH-FX-PW1)

*14WX5L size without cover shown

Soft Extra Soft

ADDITIONAL BODILINK™ HEAD SUPPORT HARDWARE

EXTRA SPACER PLATE

(BL-HSH-SPCR)

RADIUS MOUNTING PLATE

(BL-HSH-SPCR-RAD)

POSTERIOR MOUNTING PLATE

(BL-HSH-SPCR-POST1)

BODILINK™ HEAD SUPPORT

REMOVABLE HARDWARE FOR

PERMOBIL® (BL-HSH-FX-PW2)

ACTA-RELIEF™ HEAD SUPPORT BRACKET

For 14”W Back Supports (HSH-AR14W)

For 16”W Back Supports (HSH-AR16W)

For 18”W Back Supports (HSH-AR18W)

For 20”W Back Supports (HSH-AR20W)

QUANTUM MOUNTING PLATE

(BL-HSH-SPCR-POST2)

PERMOBIL MOUNTING PLATE

(BL-HSH-SPCR-TRCK1)

INSTALLATION & USE

5

Page 6

INSTALLATION (STANDARD)

For Acta-Back®, Acta-Back® Deep, Acta-Back® Contour,

Acta-Back® LTS, Acta-Embrace®, Acta-Embrace® LTS,

& Visco Back®. All tools needed are provided.

Note: Head support pad is not shown but in most

cases will come attached to hardware. See page

14 for instructions on attaching head support pad.

Instructions for adding a link on pages 12-13.

Start by turning knob A counterclockwise.

1

Remove hardware shaft C from mounting bracket B and set

2

aside.

Loosen bolts D with ⅛” allen wrench and remove along with

3

washers E and spacer plate F from mounting bracket B.

Remove back support cover (not pictured) allowing access

4

from both sides to head support holes on back support shell G.

Align mounting bracket B and spacer plate F with head sup-

5

port holes on the back support shell. When using Compass®

Power Mount Hardware, do not use spacer plate F so either

discard or retain for future use.

Attach B and F with bolts D and washers E from the front face

6

of the back support shell G and tighten to 65 lb-in.

Replace and secure back support cover.

7

Insert hardware shaft C into mounting bracket B and turn knob

8

A clockwise to secure. Note: Make sure at least ½” of shaft C

is completely through the bottom of B at all times (see page 7,

gure 2.5). See pages 15-17 for nal adjustments.

Figure 2.1

D

6

Figure 2.2

5

G

C

E

B

A

3

2

F

6

INSTALLATION & USE www.comfortcompany.com

1

Rear view of Acta-Back® support shell shown

Page 7

INSTALLATION (ACTA-RELIEF™)

For Acta-Relief™ & Acta-Relief™ LTS using Compass® 4

Mounting Hardware. All tools needed are provided.

If Acta-Relief™ Head Support Bracket is not already

attached, please follow the below prior to step 1.

G

Figure 2.3

J

K

L

Align 4 holes on back support shell G with head

support bracket H as shown in Figure 2.3 and

attach with fasteners and allen wrench provided.

Assembly order:

H - G - at washer J - safety washer K - screw L

Note: Please refer to Page 6, Figure 2.1 for steps 1 - 3.

Start by turning knob A counterclockwise.

1

Remove hardware shaft C from mounting

2

bracket B and set aside.

Loosen bolts D with ⅛” allen wrench provided

3

and remove along with washers E and spacer

plate F from mounting bracket B.

Align mounting bracket B and spacer plate F

4

(if desired) with desired head support holes on

head support bracket H. (Figure 2.4)

H

B,F

Figure 2.4

H

4

5

Attach B and F with bolts D and washers E

5

from the inner face of the head support bracket H and tighten to 65 lb-in.

Insert hardware shaft C into mounting bracket

6

B and turn knob A clockwise to secure. Note:

Make sure at least ½” of shaft C is completely through the bottom of B at all times (see

gure 2.5). See pages 15-17 for nal adjustments.

Note: Head support pad is not shown

but in most cases will come attached to

hardware. See page 14 for instructions on

attaching head support pad. Instructions

for adding a link on pages 12-13.

C

½”

min.

Figure 2.5

6

A

INSTALLATION & USE

7

Page 8

INSTALLATION (ACTA-RELIEF™ POWER)

For Acta-Relief™ & Acta-Relief™ LTS using Compass®

Power Mount Hardware. All tools needed are provided.

Note: Head support pad is not shown but in most

cases will come attached to hardware. See page

14 for instructions on attaching head support pad.

Instructions for adding a link on pages 12-13.

Start by turning knob A counterclockwise.

1

Remove hardware shaft C from mounting bracket B and set

2

aside.

Loosen bolts D with ⅛” allen wrench and remove along with

3

washers E and spacer plate F from mounting bracket B. Do

not use spacer plate F with Acta-Relief™ with Compass®

Power Mount so either discard or retain for future use.

Align mounting bracket B with desired head support holes

4

on power mount bracket G. Note: If needed, partially remove

back support cover (not pictured) allowing additional access

to head support holes on mounting bracket G from the front.

Attach B with bolts D, washers E, and additional thick wash-

5

ers H provided from the inner face of power mount bracket

G and tighten to 65 lb-in. Replace and secure back support

cover if it was removed.

Insert hardware shaft C into mounting bracket B and turn

6

knob A clockwise to secure. Note: Make sure at least ½” of

shaft C is completely through the bottom of B at all times (see

page 7, gure 2.5). See pages 15-17 for nal adjustments.

Figure 2.6

D

C

Figure 2.7

5

E

D

E

H

4

G

B

A

3

2

F

8

INSTALLATION & USE www.comfortcompany.com

1

Page 9

INSTALLATION (RADIUS & POSTERIOR MOUNTING)

For Radius Back® or other Posterior Mount Back Supports using Radius Mounting

Plate BL-HSH-SPCR-RAD or Posterior Mounting Plate BL-HSH-SPCR-POST1.

All tools needed are provided.

Note: Please refer to Page 8, Figure 2.6 for steps 1 - 3.

Steps 3 - 4 may be complete already depending on how BodiLink™ Head Support was ordered in conjunction with Radius Back®.

Start by turning knob A counterclockwise.

1

Remove hardware shaft C from mounting bracket B and set aside.

2

Loosen bolts D with ⅛” allen wrench provided and remove along with washers E and spacer plate F from

3

We can only guarantee that BodiLink® Head Support system

will properly mount to the Comfort Company products listed

in this manual. Modications made in attempt to interface with

any other products voids warranty.

mounting bracket B. Parts D, E and F will be replaced so either discard or retain for future use.

Align mounting bracket B and countersunk holes of alternate spacer plate J and attach with provided at

4

head screws K. Make sure the screw heads are ush with spacer plate J when nished.

Now attach J to back support with button head bolts L and safety washers M and tighten to 125 lb-in using

5

” allen wrench. L, M and allen wrench provided with alternate spacer plate.

Insert hardware shaft C into mounting bracket B and turn knob A clockwise to secure.

6

Note: Make sure at least ½” of shaft C is completely through the bottom of B at all times (see page 7,gure

2.5). See pages 15-17 for nal adjustments.

Figure 2.8

K

J

B

4

Radius Back® without cover shown

Figure 2.9

5

Note: Radius Back® requires creating holes in the back support

cover at the T-nut locations for attaching mounting hardware.

M

L

INSTALLATION & USE

9

Page 10

INSTALLATION (PERMOBIL MOUNTING)

For Permobil® Back Supports with Uni-Track System

using Permobil Mounting Plate BL-HSH-SPCR-TRCK1.

All tools needed are provided.

We can only guarantee that BodiLink® Head Support system will

properly mount to the Comfort Company products listed in this

manual. Modications made in attempt to interface with any other

products voids warranty.

Start by turning knob A counterclockwise.

1

Remove hardware shaft C from mounting bracket B and set

2

aside.

Loosen bolts D with ⅛” allen wrench provided and remove

3

along with washers E and spacer plate F from mounting bracket B. D, E and F will be replaced so either discard or retain for

future use.

Align mounting bracket B and countersunk holes of alternate

4

mounting plate H and attach with provided at head screws

J and tighten. Fasteners and allen wrench are provided with

alternate mounting plate.

Loosely attach button head bolts K and safety washers L to

5

double nuts M through alternate plate H.

Slide nuts M into Uni-Track System slots to desired position

6

and fully tighten bolts K with 4mm allen wrench to secure.

Insert hardware shaft C into mounting bracket B and turn knob

7

A clockwise to secure. Note: Make sure at least ½” of shaft C

is completely through the bottom of B at all times (see page 7,

gure 2.5). See pages 15-17 for nal adjustments.

Figure 2.10

D

C

Figure 2.11

H

B

J

4

M

E

Figure 2.12

B

6

3

2

A

5

F

10

INSTALLATION & USE www.comfortcompany.com

L

K

1

Page 11

INSTALLATION (QUANTUM MOUNTING)

For Quantum® Rehab TRU-Comfort2 Back Supports on

TRU-Balance3 Seating System using Quantum Mounting Plate

BL-HSH-SPCR-POST2.

Note: Please refer to Page 10, Figure 2.10 for steps 1 - 3.

Steps 3 - 4 may be complete already depending on how BodiLink® Head Support was ordered. If so, skip to step 5.

Start by turning knob A counterclockwise.

1

Remove hardware shaft C from mounting bracket B and set aside.

2

Loosen bolts D with ⅛” allen wrench provided and remove along with washers E and spacer plate F from mounting

3

bracket B. Parts D, E and F will be replaced so either discard or retain for future use.

Align mounting bracket B and countersunk holes of mounting plate J and attach with provided at head screws K

4

using phillips head screwdriver. Make sure the screw heads are ush with mounting plate J when nished.

Attach J to back support with socket head bolts L and tighten using 4mm allen wrench. L provided with alternate

5

mounting plate.

Insert hardware shaft C into mounting bracket B and turn knob A clockwise to secure.

6

Note: Make sure at least ½” of shaft C is completely through the bottom of B at all times (refer to page 7, gure

2.5). See pages 15-17 for nal adjustments.

Figure 2.13

K

J

B

Figure 2.14

4

5

J

L

INSTALLATION & USE

11

Page 12

INSTALLATION (ADDING A LINK)

BodiLink® Head Support Hardware Kit will include an extra link

and fasteners to use if needed to reach extreme positions.

Remove bolt N and safety washer O from curved link P and top of hardware shaft C.

1

Remove hardware shaft C from mounting bracket B by turning knob A counterclockwise.

2

Turn hardware shaft C 180° so the visible gear teeth are facing the opposite direction.

3

Insert hardware shaft C into mounting bracket B and turn knob A clockwise to secure.

4

CAUTION! Please consider that adding additional

links to the hardware may reduce the overall strength.

Note: Make sure at least ½” of shaft C is completely through the bottom of B at all times (refer to page 7, gure 2.5).

Figure 2.15 Figure 2.16

P

O

N

3

1

C

C

A

B

42

Note: Head support pad is not shown but in most

cases will come attached to hardware. See page

14 for instructions on attaching head support pad.

12

INSTALLATION & USE www.comfortcompany.com

Page 13

INSTALLATION (ADDING A LINK)

Comfort Company cannot be held responsible for damages or injury due to misuse of the product or failure to follow instructions provided in the manual. Please contact

us if you require further assistance in understanding cautions, warnings or instructions for using or maintaining your product. Customer Support 1.800.564.9248

5

Align extra link R with gear teeth on hardware shaft C in the orientation shown below and fasten with

safety washer S and bolt T.

6

Align the other end of extra link R with curved link P and fasten with safety washer O and bolt N.

7

See pages 15-17 for information on nal adjustments.

Proper gear tooth alignment and engagement is essential for a secure set up

Figure 2.17

R

6

S

T

P

O

N

6

C

5

5

Figure 2.18

Gear Teeth Alignment

INSTALLATION & USE

13

Page 14

INSTALLATION (SUPPORT PAD)

In most cases, head support pad will come preassembled

with mounting hardware. All tools needed are provided.

Align ball link A and ring B with ball receiver C.

1

Loosely engage bolts D and safety washers E with ball receiver C to complete the assembly.

2

Continue to pages 15-17 for nal adjustments.

3

Figure 2.19

8W x 4L support pad shown

C

B

A

1

E

2

D

14

INSTALLATION & USE www.comfortcompany.com

Page 15

SET UP & ADJUSTMENTS

BodiLink™ Head Support hardware has 6 points of adjustment for height, angle, rotation and depth. All BodiLink™ Head Support pads have a

preformed curvature for optimal posterior contact, but the 3 largest head support pads have 2 points of adjustment for additional lateral support.

1A- 45º

*

7

1B- 80º

1C- 360º

2- 240º

3- 240º

4- 240º

Figure 3.1

5- 360º

6- 4.5”

Adjustment Point Ranges

2

A

1

14W x 5L pad shown

7*- +90º/-10º each

*14W5L, 10W5L, 18W5L Support Pads Only

Figure 3.2 Figure 3.3

B

1

C

1

3

5

4

6

SET UP & ADJUSTMENTS

15

Page 16

SET UP & ADJUSTMENTS

Use the 4mm allen wrench provided for all adjustment bolts.

Loosen all adjustment point bolts 1-5 allowing

1

for full articulation of the head support to a

desired position.

Note: BodiLink™ head support pads are designed to

be used in any orientation including ipped 180º as

shown in figure 3.4 to better address the user’s needs.

Assess and alter height adjustment 6 using

2

knob A if needed. Remember to leave at least

½” of hardware shaft C showing through the

bottom of the mounting bracket B.

While holding the head support pad in place,

3

loosely tighten adjustment points1-5.

Once all hardware links are lightly set, go back

4

and tighten all bolts evenly.

ATTENTION: It is crucial that adjustment

point 1 is tightened evenly all around to

prevent unwanted movement and the

gear teeth on points 2-5 must be properly

aligned and engaged for a secure set up.

To access wing adjustment 7 channels on

5

10”/14”/18”W head support pads, partially unzip the locking zippers under the

cover aps. Ensure gear teeth are properly

aligned before nal tightening.

Figure 3.4

14W x 5L pad without cover shown

7

Figure 3.5

1

4

1

7

2

3

16

5

Figure 3.6

Gear Teeth Alignment

B

6

A

C

SET UP & ADJUSTMENTS www.comfortcompany.com

Page 17

FINISH

Only locking feature set screws require the smaller allen

wrenches provided.

Finish by positioning collar D on hardware shaft C at the top of mounting bracket B.

6

Locate set screw E in the collar and tighten with 2mm allen wrench until contact is made with the

7

hardware shaft. This allows for easy positioning of the hardware if it is removed and then replaced.

Note: Collar D is retained in a track in the shaft. If the collar needs to be removed, remove the set screw F

located in the track at the bottom of the shaft with the 1.5mm allen wrench provided.

14W x 5L pad without cover shown

Figure 3.7

E

7

C

D

6

B

F

SET UP & ADJUSTMENTS

17

Page 18

CLEANING

Frequent heat drying and bleaching naturally cause fabric break down.

Air drying and cleaning without bleach are recommended whenever possible to help extend the life of the cover.

SURFACE CLEANING COMFORT-TEK FABRIC ONLY*

Spray with common household or commercial antibacterial

cleansers or disinfectants.

Wipe with damp, water-only cloth after disinfecting and let dry before use.

COMPLETE CLEANING (ALL FABRICS)

Machine wash cover using any common laundry detergents. Let dry completely before use.

Machine Wash any temperature

Maximum 66°C/150°F

Tumble Dry Low Temperature Only

Do Not Steam Clean or Autoclave

Do Not Tumble Dry High Temperature

Do not wash or dry Stretch-Air™ and GlideWear® covers along with hook and loop fasteners or other materials that could snag the fabric.

Note: Doing so could pull at the fabrics causing changes in the appearance but not the effectiveness of the fabrics.

Unzip cover and remove from head support pad and hardware.

Hand Wash when possible

Air Dry when possible

Do Not Iron

DISINFECTING (ALL FABRICS)

Unzip cover and remove from head support pad and hardware. Wash cover with water and bleach followed by thorough rinse.

Follow directions on bleach container. Let dry completely before use.

Machine Wash Maximum 66°C/150°F

Soiled foams should be replaced. Remove cover, dab foam with water-only cloth and let dry completely before replacing cover.

DO NOT submerge foam in any liquid, including water.

DO NOT use contaminated foam with multiple users.

Foam should not be exposed to light for any extended period of time. Light will cause discoloration of the foam. This only effects the

appearance of the foam, not the functional features. There is no need to attempt to “clean” discoloration caused by light exposure.

18

CLEANING & MAINTENANCE www.comfortcompany.com

Bleach

FOAM

Dab with clean, damp, water-only cloth.

Air Dry Only.

Page 19

MAINTENANCE

WARRANTY

INSPECTION

Inspect all head support components monthly.

Check and tighten all fasteners and adjustment points.

Inspect all materials for wear such as stretching, fraying,

fractures, and bends. Some wear with regular use is expected. Signs of excessive wear to any component should be

addressed by contacting your dealer or customer service

for repair or replacement parts.

REUSE

You must re-t the support to the new user or after extended

periods of non-use by the same user. Follow the "Set up &

Adjustments" procedure on Pages 15-17 to do so.

Before transferring to a new user, the product must be completely cleaned and disinfected as outlined on page 18.

This product is covered by the Comfort Company Lifetime Guarantee.

If a manufacturing defect should occur, the product will be replaced at

no cost to the buyer. Register your product at www.comfortcompany.

com/registration to activate Lifetime Guarantee.

If manufacturing defects should occur, discontinue use immediately.

Wear from regular use is not considered a manufacturing defect. Replacement parts are available by contacting Customer Service or your

supplier, distributor, or retailer.

Any alterations made to the product or defects caused by irregular

use voids the warranty. We can only guarantee that BodiLink® Head

Support system will properly mount to the Comfort Company products

listed in this manual. Modications in attempt to interface with any

other products voids warranty.

STORAGE

Assembly or individual parts should not be stored in extreme

hot or cold temperatures. Only store in a clean and dry place

at room temperature.

Do not allow exposure to direct sunlight for prolonged periods

of time. This could age the product more rapidly and decrease

its effectiveness.

Do not store where there is risk of open ame or spark.

DISPOSAL

Please contact your local authorities for regulations on the

proper disposal of your product and its components.

DO NOT incinerate as a means of disposal.

WARRANTY REPLACEMENT PROCEDURE

Warranty claims should be led by the original purchaser. End-users

will need to contact the DME Supplier, Distributor or Retailer from

whom the product was purchased. In the event the original dealer is

not available, any authorized Comfort Company DME supplier, distributor or retailer will provide assistance.

DME suppliers, distributors or retailers with warranty issues will need

to contact Customer Service by phone or email and provide original

purchase order number, sales order number, or invoice number whenever possible. A Return Merchandise Authorization (RMA) will be issued by Customer Service so a warranty replacement order or quote

can be processed.

COMMENTS

If you would like to contact us with your comments or concerns, please

visit our website www.comfortcompany.com or refer to the "Contact

Information" section of this manual.

We invite you to leave testimonials of the product on our website on

the individual product pages.

CLEANING & MAINTENANCE

19

Page 20

© 2017 Comfort Company

Comfort Company®, Compass®, Acta-Back®, Acta-Embrace®, and Radius Back® are registered trademarks of Comfort Company.

BodiLink™, Acta-Relief™, Comfort-Tek™, and Stretch-Air™ are trademarks of Comfort Company.

GlideWear® is a registered trademark of Tamarack Habilitation Technologies, Inc.

Viscool® is a registered trademark of American Excelsior Company.

Permobil® is a registered trademark of Permobil AB.

Quantum® is a registered trademark of Pride Mobility Products Corporation.

CAL TB 117-2013

www.comfortcompany.com

BLOG

Stay connected to related news and updates through these resources.

www.comfortcompany.com/stay_connected

UM-BODILINK-HEAD-SUPPORT REV0817

Loading...

Loading...