COMEUP Industrial Winch User Manual

Industrial Winch

Thank you for purchasing a Winch. This manual covers operation and maintenance of

the winch. All information in this publication is based on the latest production information available at

the time of printing. We reserve the right to make changes without notice because of continued product

improvement.

The winch has been designed to give safe and dependable service if operated according to the

instructions. Please read and understand this manual before installation and operation of winch.

Careless winch operation can result in serious injury or property damage.

When requesting information or ordering replacement parts, always give the following information:

1. Winch Model and Voltage

2. Serial Number

3. Item. No. and Part Number

4. Part Description

WARNING

!

1. The winch is a very powerful machine. Treat with extreme care and observe all caution and warnings.

2. The winch is rated at the first layer of wire rope on the drum for intermittent-periodic duty.

3. The winch is not to be used to lift, support or otherwise transport personnel.

4. A minimum of five (5) wraps of rope around the drum is necessary to support the rated load.

5. Keep clear of winch, rope, hook, and fairlead while operating.

6. Wire rope can break without warning. Always keep a safe distance from the winch and rope

while under a load.

7. Failure to adequately align, support, or attach winch to a suitable mounting base could result in

a loss of efficiency of performance or damage the winch, wire rope and mounting channel.

1

I . Safety Requirement

General Rules

In some cases, the operator of a winch may be required to have

!

qualifications according to applicable laws and ordinances.

Check safety and environmental conditions prior to and

!

during use.

Only use correctly rated wire rope in construction, strength.

!

Inspect for damage and/or defects before use.

Don’t use an unsuitable hook and snatch block for rope.

!

!

The operator must remain with the winch during operation.

!

The winch duty rating is S3 (intermittent-periodic).

Do not use the winch as a lifting device or a hoist for vertical lifting and moving people

!

Ensure that the winch is connected to the correct power source such as hydraulic or12/24V DC.

!

Do not exceed maximum line pull ratings. Shock load must not exceed these ratings.

!

Keep hands clear of wire rope and roller fairlead opening.

!

Pull from an angle below 3° in the horizontal plane to straighten

!

up the vehicle or load.

Always use leather gloves when handling the wire rope.

!

When winching, always use a recovery damper. Place over

!

the wire rope in the middle third of its length.

A wire rope should be replaced if it shows signs of excessive

!

wear, broken strands, corrosion or any other defects.

If the winch fails to pull a load under normal conditions, stop

!

the operation within 30 seconds, or motor damage may occur.

Check that the clutch T-handle is in the “Engaged” position during and after use.

!

Remove the remote control from the winch when not in use.

!

Do not wrap the wire rope around the load and back onto itself. Always use a tree truck strap.

!

Keep hands and clothes away from the winch, wire rope, and roller fairlead.

!

Never unplug the remote control when winching a load.

!

To avoid insufficient power when winching a load, the vehicle should be running and in neutral.

!

!

If noise or vibration occurs when running, stop

the winch immediately and return it for repair.

The rope shall be wound in according to drum

!

rotation sticker or refer to owners manual.

2

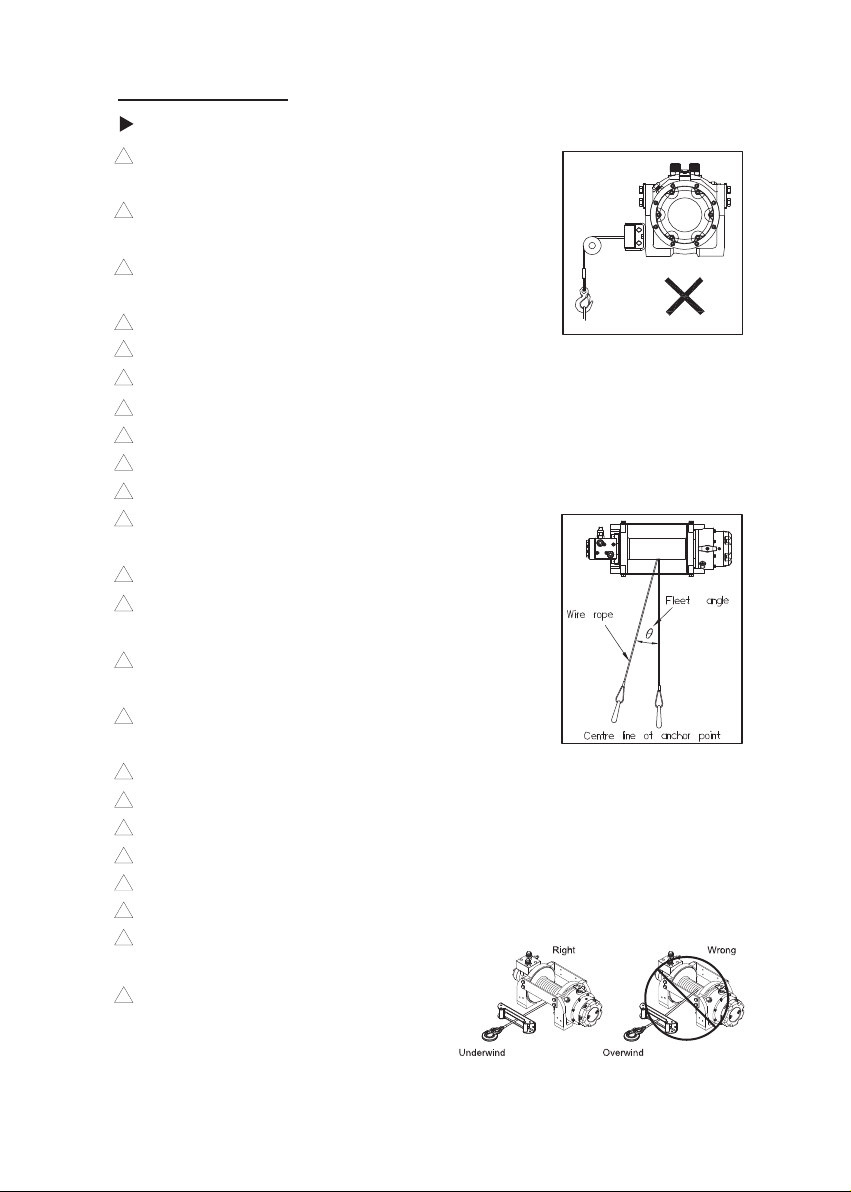

I I . Hydraulic System Installation

(Powered by PTO / power take off unit driven pump)

For HV winch

For Bison winch

Advantage: Professional winch system for “Working”

applications, cost effective, extremely

powerful, reliable, light weight and

variable line speed for high work rate.

3

Hydraulic Fluid

●

The hydraulic fluid should be a high grade, petroleum based fluid, with rust, oxidation and

wear resistance. Fluid cleanliness and operating viscosity are critical to winch reliability,

efficiency and service lift.

Hydraulic Pump

●

To maintain the maximum performance, the hydraulic pump must supply the maximum flow

of hydraulic fluid at the hydraulic pressure stated in specification.

●

With a max. oil supply mentioned on the instruction manual at top motor rpm and the pump

must be capable of delivering the operation pressure mentioned on the instruction manual too.

Hydraulic Control Valve

●

The control valve must have a four-way spring return to neutral feature, which provides for

open flow from the pressure ports of the winch to the reservoir in neutral position of the

control (motor spool).

Hydraulic Pressure Relief

●

The hydraulic system requires a pressure relief set at the operating pressured.

●

Failure to use the correct pressure and flow may result in damage to the winch, property or

personal injury.

Hydraulic Reservoir

●

The hydraulic reservoir has sufficient capacity to provide good heat dissipation in order to

prevent over-heating of the hydraulic fluid.

●

Must be fitted with an oil filler device comprising strainer and filter and a dip stick.The

capacity of the tank should be at least 60 liters.

Over-Center Valve / Counterbalance Valve

●

Give smoothly controlled winch out when under load and to provide full dynamic braking.

It must be installed to hold full load.

●

The Port A of over-center valve means the inlet port of oil from reservoir and the Port B

meaning the return port of oil to reservoir.

●

Over-center valve is a standard accessory for HV winch and counterbalance valve for Bison

winch.

Hydraulic Hoses

●

The following hydraulic hoses are recommended for maximum efficiency of the hydraulic

winch. The bigger nominal bore hose, the better winch performance.

●

All hose lengths are kept to a minimum because pressure and flow loss is increased as

hose length increases.

●

Pressure and return lines in excess of 3.5 meter (11.5”) should be compensated with an

increase in nominal bore size. Motor drain line pipe shall be rated at1/4” BSP N.B.

Inlet line ………….…... 1 1/4” – 1 1/2” nominal bore (N.B.) from reservoir to pump

Return line …………… 1” (N.B.) from control to reservoir

Pressure hoses …....... 1/2” (N.B.) from control valve to over-center valve

Motor drain line pipe… 1/4” BSP N.B.

4

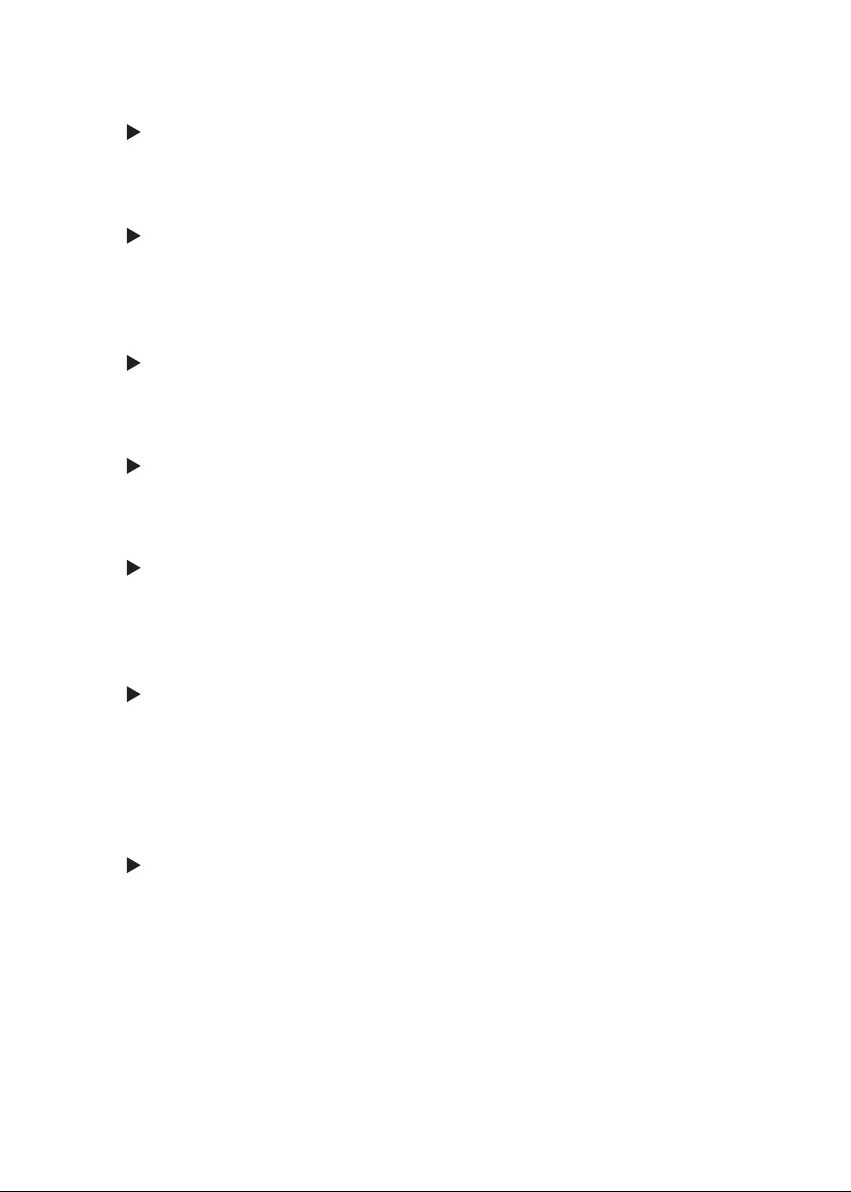

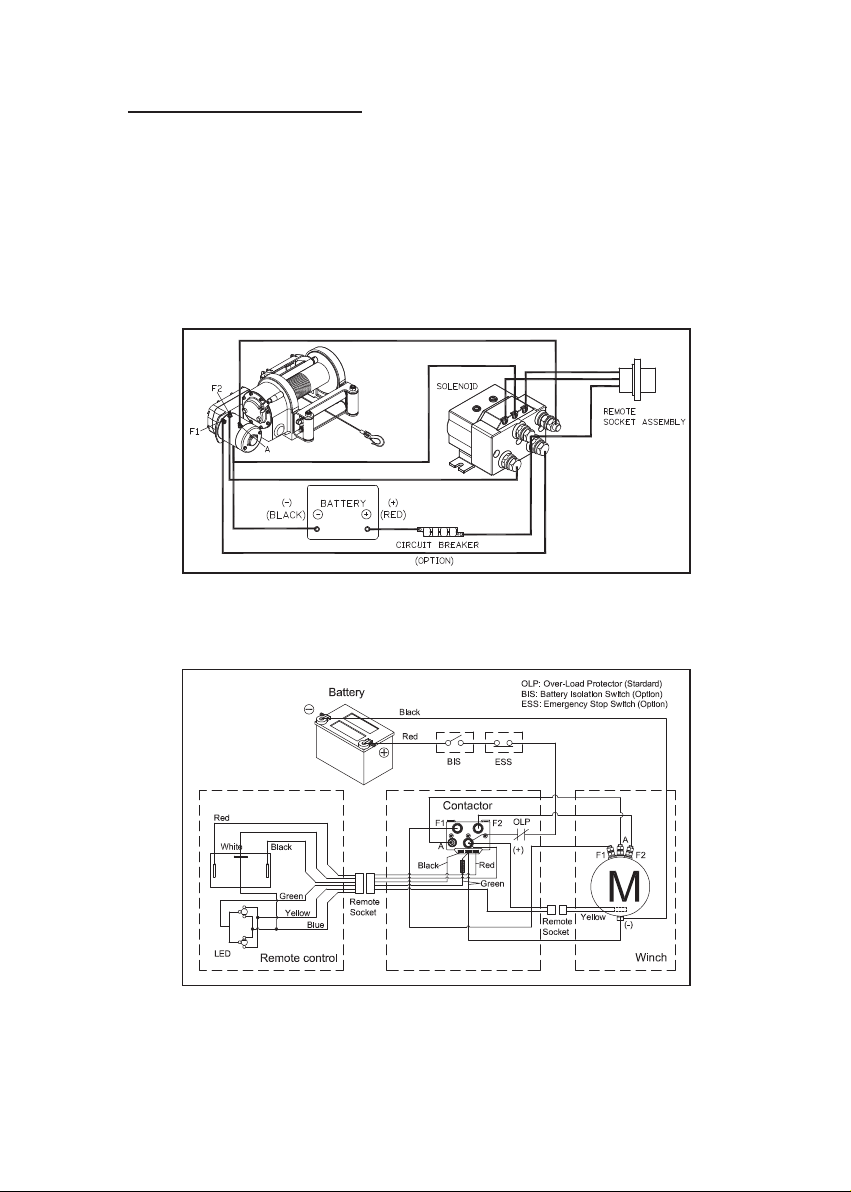

III . Electric System Installation

Attach the black lead firmly to the negative (–) battery terminal and red lead to the positive

(+) battery terminal. The voltage drop for the winch motor must not exceed 10% of the nominal

voltage of 12/24V DC. The recommended battery shall be 650 CCA minimum and battery lead

2

shall be 2 AWG ( America Wire Gauge for 38 mm

voltage drop will be happened.

For Wolf Winch

For Rhino Winch

in area ) at least, otherwise a considerable

5

Loading...

Loading...