COMEUP Electric Winch User Manual

Electric Winch

Limited One (1) Year Warranty Statement

Comeup Industries Inc. ( ) warrants to the original purchaser that the mechanical compnents

and electrical components of the Electric Winch will be free of defects in material and

workmanship for one (1) year. All mounting kits and other accessories carry one (1) year

limited warranty against defects in material workmanship.

This Warranty applies only to the original purchaser of the winch. To obtain any warranty service, the

Purchaser under this Limited Warranty is requested to report or his authorized distributors

of any claims. The Purchaser must provide a copy of the proof of purchase bearing the winch serial

number, date of purchase, owners name email, or Tel & Fax, address and registration number. Any

product determines to be defective will be repaired or replaced at sole discretion

without charge to Buyer upon Buyer’s compliance with these procedures. Seller or its Authorized

Distributors may make reasonable charges for parts and labour for repairs not covered by this Limited

Warranty.

takes the responsibility for all parts and components to be free from defects in materials and

workmanship, but the following are hereby excluded and disclaimed:

(1). All warranties of wire rope assemblies after initial use.

(2). All warranties of fitness for a particular purpose.

(3). All warranties of the product’s finish

(4). All warranties of merchantability

The Limited Warranty does not cover any failure that results from improper installation, operation or

the Purchaser’s modification in design. reserves the right to change Product design without

notice. In situations in which has changed a product design, shall have no

obligation to upgrade or otherwise modify previously manufactured products.

1

Electric Winch

Thank you for purchasing a Winch. This manual covers operation and maintenance of

the winch. All information in this publication is based on the latest production information available at

the time of printing.

General Safety Precautions

The winch has been designed to give safe and dependable service if operated according to the

instructions. Please read and understand this manual before installation and operation of the winch.

Follow these general safety precautions:

Confirm that the winch complies with the using conditions.

Keep the winch secure strongly and the rope is not wound to be deviated to the drum.

Don't use unsuitable pulleys or accessories concerned.

Don't use unsuitable rope in construction, strength or having any defects.

Pay attention to the grounding, it provides a path of least resistance for electric current to reduce

the risk of shock.

Check the winch for smooth operation without load before loading operation.

Make sure the wire rope to be wound evenly in the first layer on the drum, rewind it if a mixed

windings in existence.

If a wire rope is found an uneven winding or accumulated at one side of the drum, align it adequately.

WARNING

!

1. The winch is not to be used to lift, support or otherwise transport personnel.

2. A minimum of five (5) wraps of rope around the drum is necessary to support the load rated.

3. The owner and/or the operator shall have an understanding of these operating instructions and the

warning before operating the electrical winch. Failure to follow these warnings may result in loss of

load, damage to the winch, property damage, personal, or fatal injury.

4. The owner shall retain this manual for further reference to important warnings, installation, operating

and maintenance instructions.

2

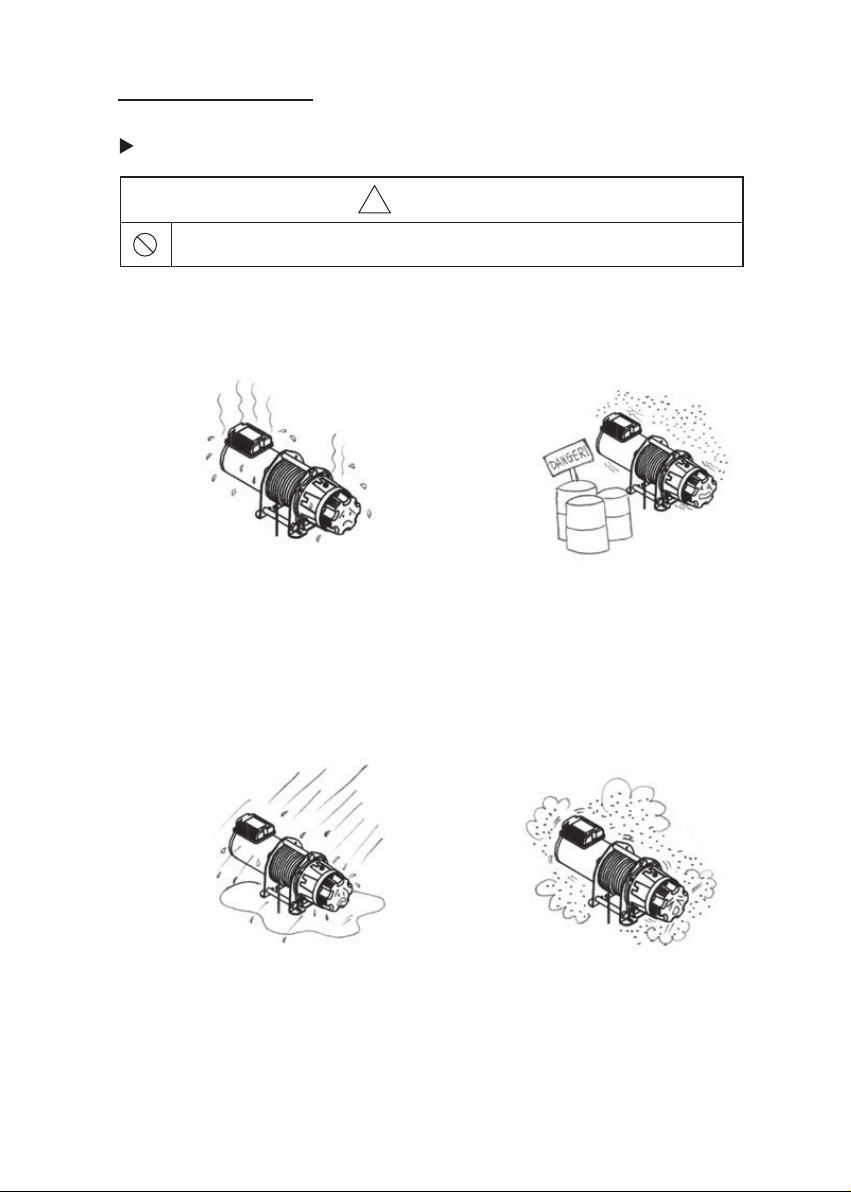

I . Installation Precaution

General Safety Precaution

The following environmental conditions may result in the possible causes of hoist trouble.

!

DANGER

● Low temperature below -10℃ ,high

temperature above 40℃ or humidity

above 90% conditions

※Cause malfunction of spare parts ※Cause explosion

● In heavy acid or salty conditions

● In rain or snow conditions

● In an organic chemistry or explosive

powder conditions

● In a heavy general powder

※Cause malfunction of spare parts

※Cause rust or short circuit

※Cause malfunction of performances

3

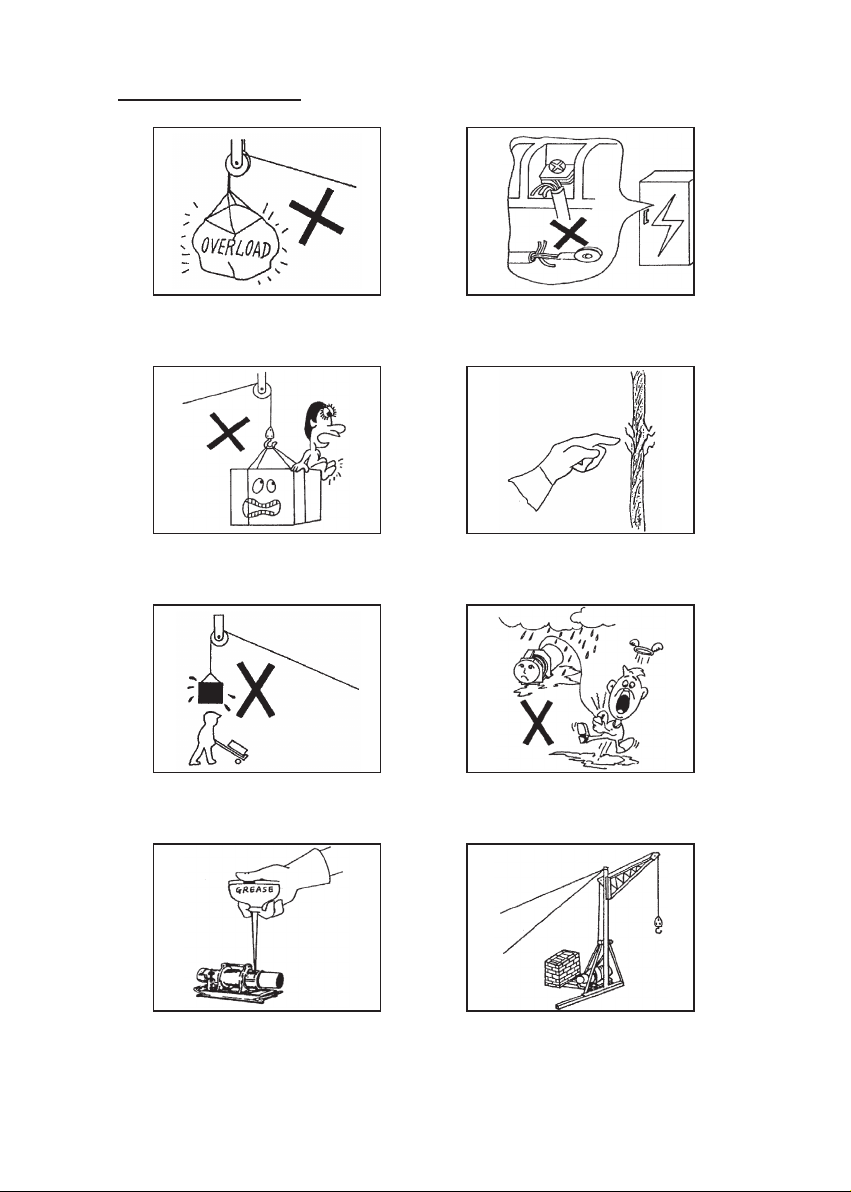

II. Handing Precautions

● It is forbidden to lift loads above

the rated capacity of the winch

● Ban on transporting persons ● Don’t ignore fault accessories

● Don’t stand under winching

operation

● Do connect the power lead on the

main power source directly and

fasten them

● Don’t operate hoist in rain or snow

● Do perform maintenance on

schedule

● Do anchor crane with ballasted

container and wire rope

4

III. Winching Principles

Percentage Duty Cycle

WARNING

!

Never hoist over the rated percentage duty cycle.

The life of the winch is depending on the conditions of the load and working frequency.

In the long time operation, make sure to use the machine within its continuous ratings.

Continuous ratings means the percentage duty cycle (%ED) is subject to the rated voltage,

rated frequency and a 63% of rated load.

Percentage duty cycle (%ED)= X 100 (%)

Tb: total sum of overall loadings operating hours.

Ts: total sum of stopping hours.

Tb + Ts = approximately 1 to 10 minutes.

For this reason, all electric winches are rated at a 25% percentage duty cycle (%ED).

Tb

Tb + Ts

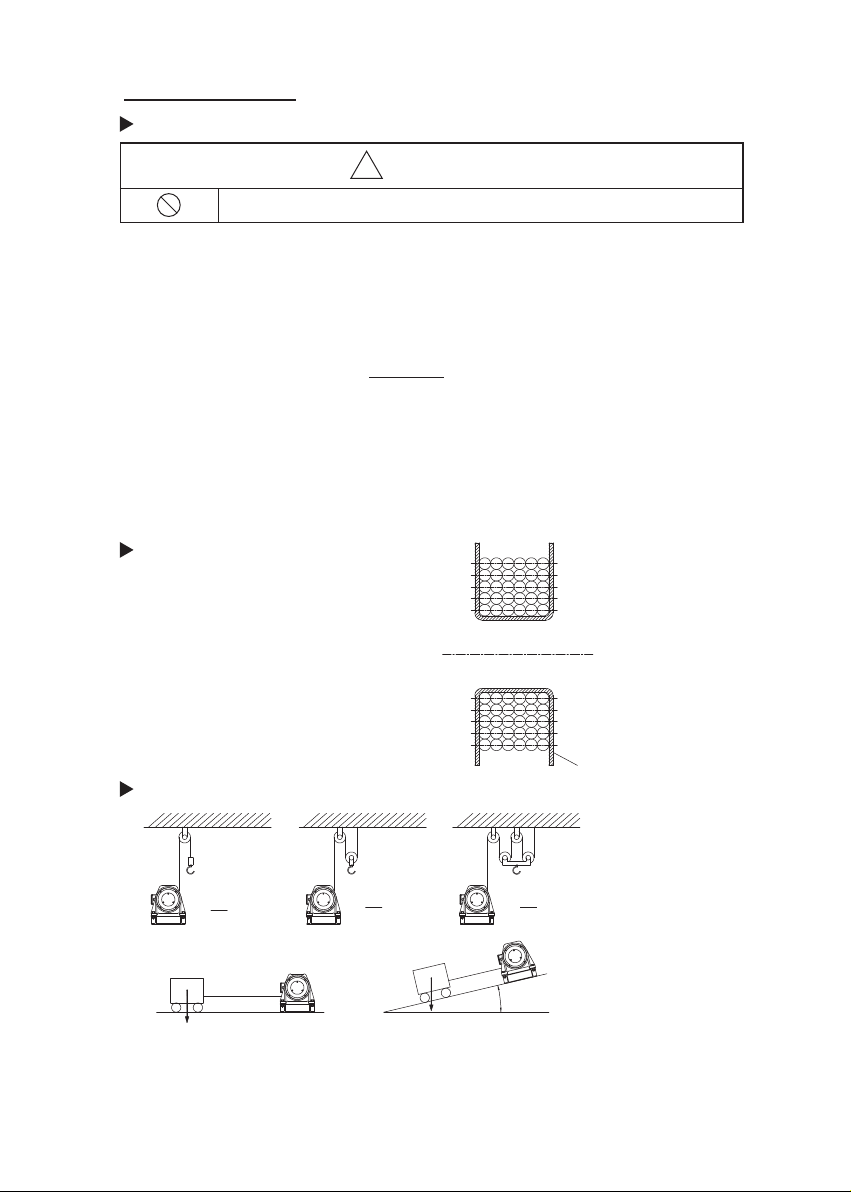

Load Rated

Load and speed vary according to how

much wire rope is on the drum. The first layer

Top layer (Max.speed Min.load)

Half layer (Med.speed Med.load)

First layer (Min.speed Max.load)

of rope on the drum delivers the slowest speed

and the maximum load. A full drum delivers the

maximum speed and the minimum load. For this

reason, all electric winches are rated at their

top layer of wire rope on the drum.

Flange of drum

Calculating Head Loads

W

P

W

P=

η

μ

W

P

.

μ

P=

W

W

P

W

P=

η

2

μ

P=

P

W

W

P=

η

4

P

sinθ +

θ

..

.

μ

W

cosθ

W

W

Use a tackle block for double fall operation to increase the rated load by approximately

85% but its speed will be deducted by half accordingly.

P: Rope tension

η: Sheave efficient

θ: Angle

W: Load

μ: Friction factor

5

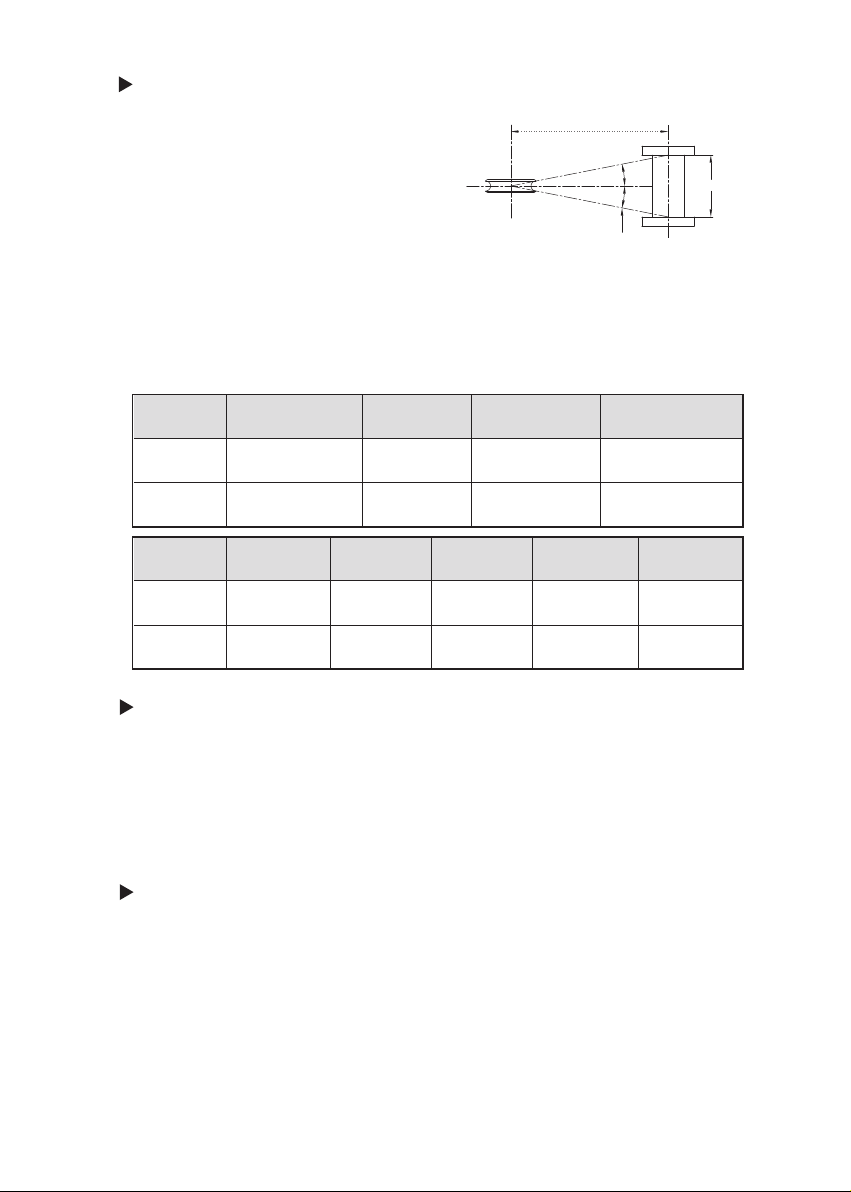

Calculating Fleet Angle

● The winch should be mounted as close to centre

and as perpendicular as possible to the direction

of the line pull. This will keep the wire rope fleet

angle centre on the drum as small as possible.

● If the proper fleet angle is not maintained, the wire

rope could wind onto one side of the drum.

Experience has shown that the best wire rope service is obtained if the maximum fleet angle

is not more than 1.5° for smooth drum and 2° for grooved drum.

For example, the correct distance varies according to drum length.

Model

Drum Length 110 mm 220mm 150 mm 240 mm

Correct

Distance

Model CWG-30375 CWG-30565 CWG-30750 CWG-31500 CWG-34000

Drum Length 230 mm 312 mm 312 mm 405 mm 680 mm

CP-200/250/300,

CWG-30075

2.09 m

at least

CP-500/500T CWG-10077

4.18 m

at least

2.85 m

at least

Correct Distance

Fleet Angle

θ

Drum Length

θ

CWG-10151/30151,

CP-750T/900T

4.56 m

at least

Correct

Distance

2.09 m

at least

5.92 m

at least

5.92 m

at least

7.7 m

at least

12.92 m

at least

D/d Ratio

It means ratio of pitch circle diameter of drum to the rope diameter.

In principle, a 12:1 D/d ratio is suggested for most pulling application and a 15:1 D/d ratio for

lifting and lowering applications. For example, a CP-200 comes with a 94 mm dia. drum and

a 6 mm x 30 m wire rope, therefore its D/d ratio is calculated as follow.

D/d ratio = ( 94 + 6 mm ) / 6 mm = 16.67 times

Rope Safety Factor

The working coefficient of the wire rope shall be determined from the ratio of the minimum

breaking force of the rope and the maximum possible lifting capacity.

In principle, a 3.5 times of rope safety factor is suitable for most pulling applications and a 5

times for lifting and lowering applications. For example, a CP-200 comes with a 6 mm x 30 m

wire rope with 2,010 kg minimum breaking force, therefore its rope safety factor is calculated

as follow.

Rope safety factor = 2,010 kg / 200 kg = 10 times

6

Loading...

Loading...