COMEUP Automotive Winch User Manual [en, de, es, fr, it]

1

Automotive WINCH

INSTRUCTION MANUAL

English……………………………...1

French……………………………..22

Spanish………………………….…43

German……………………………64

Italian……….……….…………….86

2

Automotive Winch

Thank you for purchasing a

Winch. This manual covers operation and maintenance

of the winch. All information in this publication is based on the latest production information available

at the time of printing. We reserve the right to make changes without notice because of continued

product improvement.

The winch has been designed to give safe and dependable service if operated according to the

instructions. Please read and understand this manual before installation and operation of the winch.

Careless winch operation can result in serious injury or property damage.

When requesting information or ordering replacement parts, always give the following information:

1. Winch model and voltage

2. Serial Number

3. Item. No. and Part Number

4. Part Description

1. The winch is a very powerful machine. Treat with extreme care and observe all caution and

warnings.

2. The winch is rated at the first layer of wire/synthetic rope on the drum for intermittent-periodic

duty.

3. The winch is not to be used to lift, support or otherwise transport personnel.

4. A minimum of five (5) wraps of steel wire rope and of ten (10) wraps of synthetic rope around

the drum is necessary to support the rated load.

5. Keep clear of winch, rope, hook, and fairlead while operating.

6. Wire/synthetic rope can break without warning. Always keep a safe distance from the winch

and rope while under a load

7. Failure to adequately align, support, or attach the winch to a suitable mounting base could

result in a loss of efficiency of performance or damage to the winch, wire/synthetic rope and

mounting channel.

WARNING

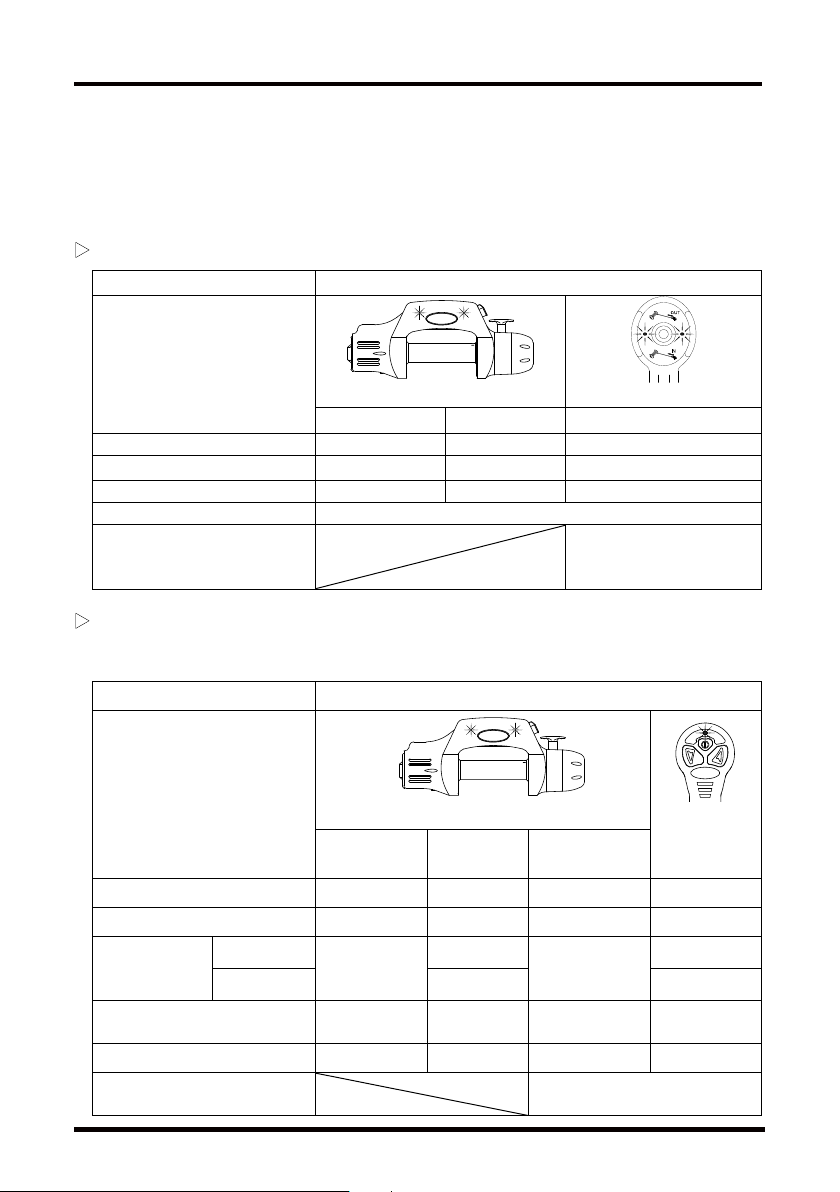

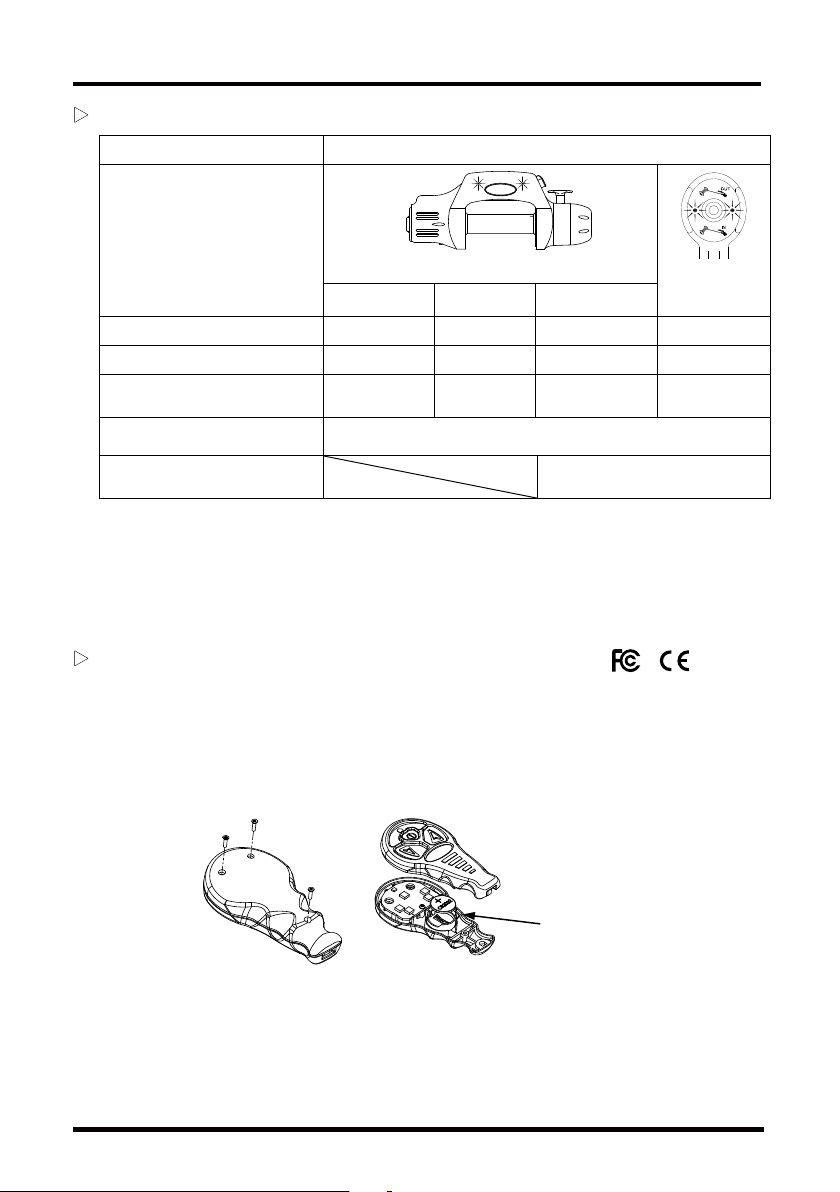

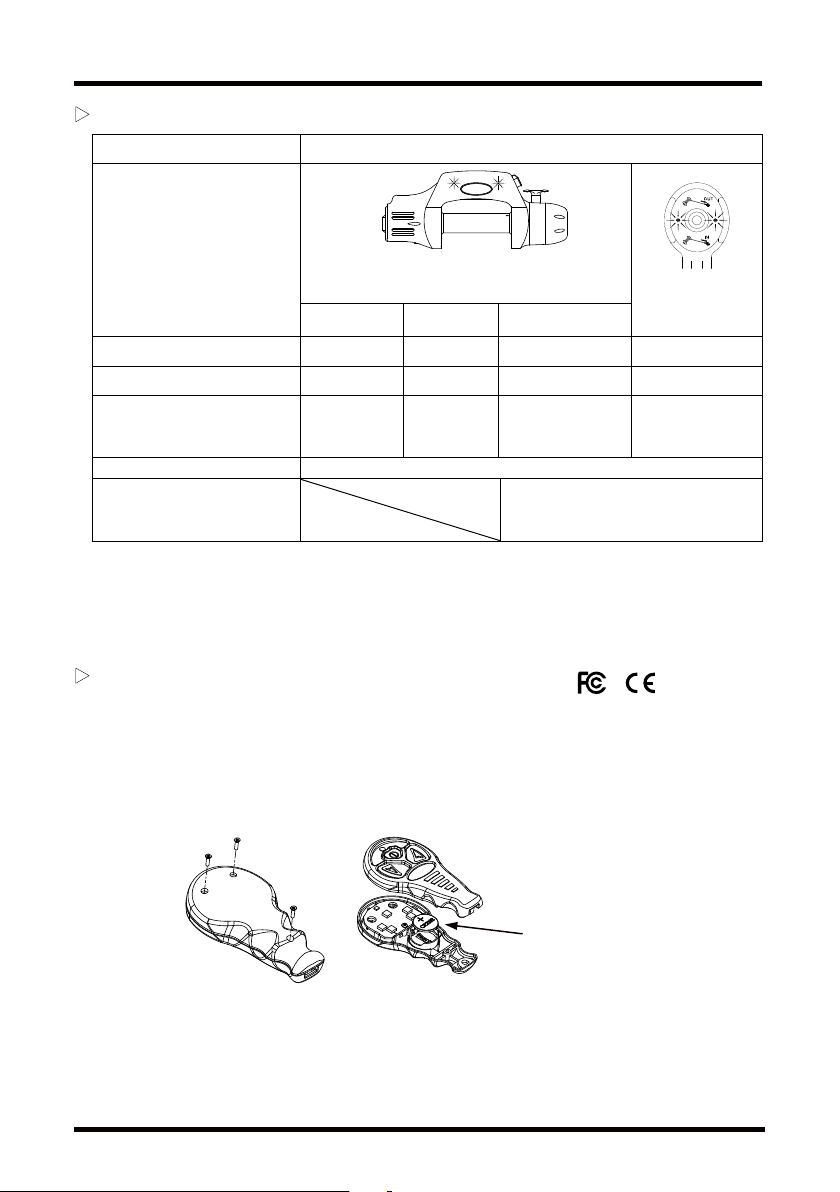

Control Indicator Guide

3

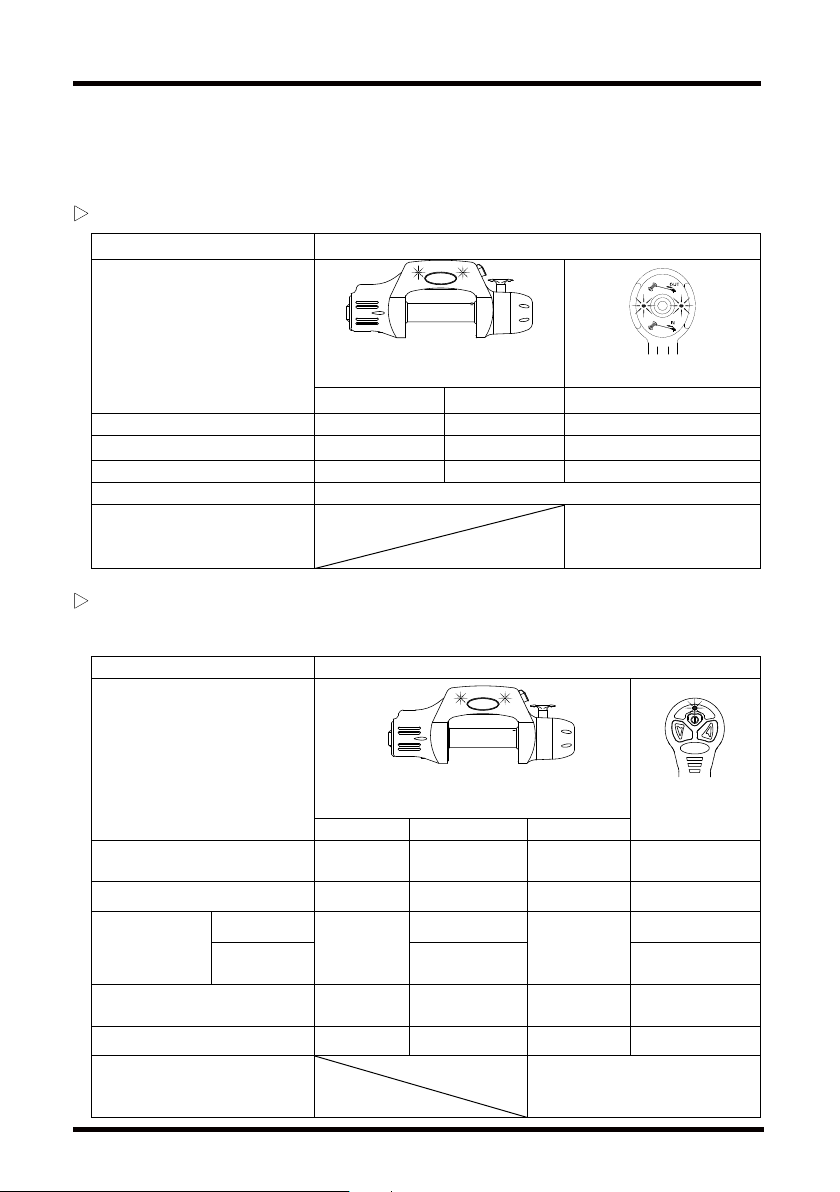

There are three control modules of the Comeup automotive winches. All are similar in setup, but have

differing responses in regards to their control type.

Determine which model you have and refer to the charts for you particular models signalling of its

condition through LED’s and buzzer

.

X Wired Remote Control Module

Available Winches Seal 9.5i/9.5si; DV-9i/9si

LEDs on the bridge control box

LEDs on the remote control

LED Locations

Left LED Right LED LEDs

Plug in Connector Green Green Green

Cable In/Out Operation Green Green Green

Motor Overheating Warning Red Red Red

Plug Out Connector LED turns off

Available Winches

Seal 9.5 / 9.5s/12.5/12.5s

DV-18/15/12/9/9s

DV-12 light/12s light

X

Wireless Control Module on the dual control modules

They can be controlled by the wireless control module or the wired remote control module, but only

one control way can activate the winch at the same time.

Available Winch Seal 9.5rsi

LEDs and buzzer on the bridge control box

LED & Buzzer

Left LED Right LED

Buzzer

LED on the

wireless

transmitter

Press Transmitter for 5 seconds Green X X Green

Cable In/Out Operation Green Blue X Red

Cable In/out Blue Red

Motor

Overheating

Warning

No Working

Red

X

2 short Beeps

every 5 seconds

Green

Low Voltage on Transmitter

Warning

X X X Blinking Green

Poor Signal Warning X Blinking Blue

X Blinking Red

Available Winches

Seal 9.5rs / 12.5rs

(Buzzer in the control box)

Control Indicator Guide

4

X Wired Remote Control Module on the dual control modules

Available Winch Seal 9.5rsi

LEDs and buzzer on the bridge control box

LED & Buzzer

Left LED Right LED

Buzzer

LEDs on the

remote control

Plug in Connector Green X X Green

Cable In/Out Operation Green X X Green

Motor Overheating Warning Red X

2 short Beeps

every 5 seconds

Red

Plug out Connector

LED turns off

Available Winches

Seal 9.5rs / 12.5rs

(Buzzer in the control box)

Remarks:

1. Green LED illuminates when the winch is operating under normal working conditions.

2. Red LED illuminates when the winch is operating when overheating of the motor. Stop operation

and allow winch to cool (Green LED)

3. The LEDs illuminate or the beeping buzzer alarms when the motor is overheating.

X

Wireless Receiver & Transmitter Operation

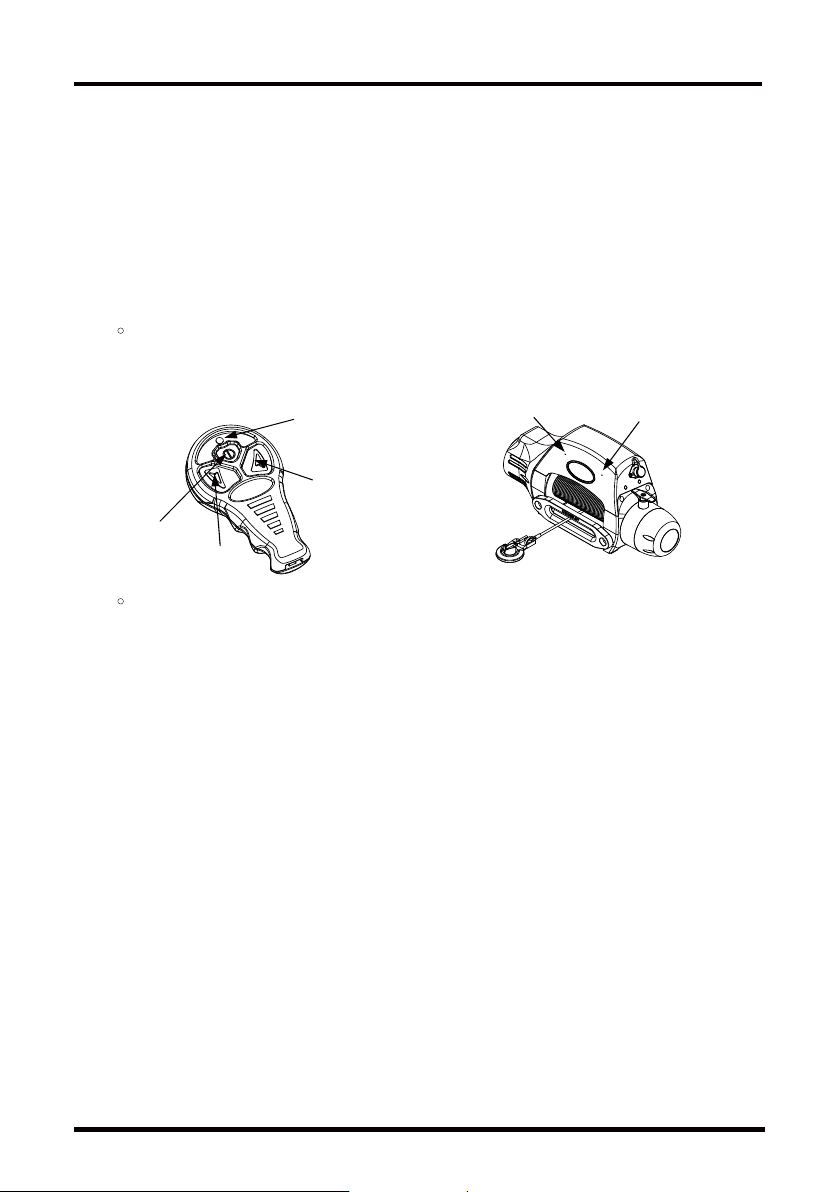

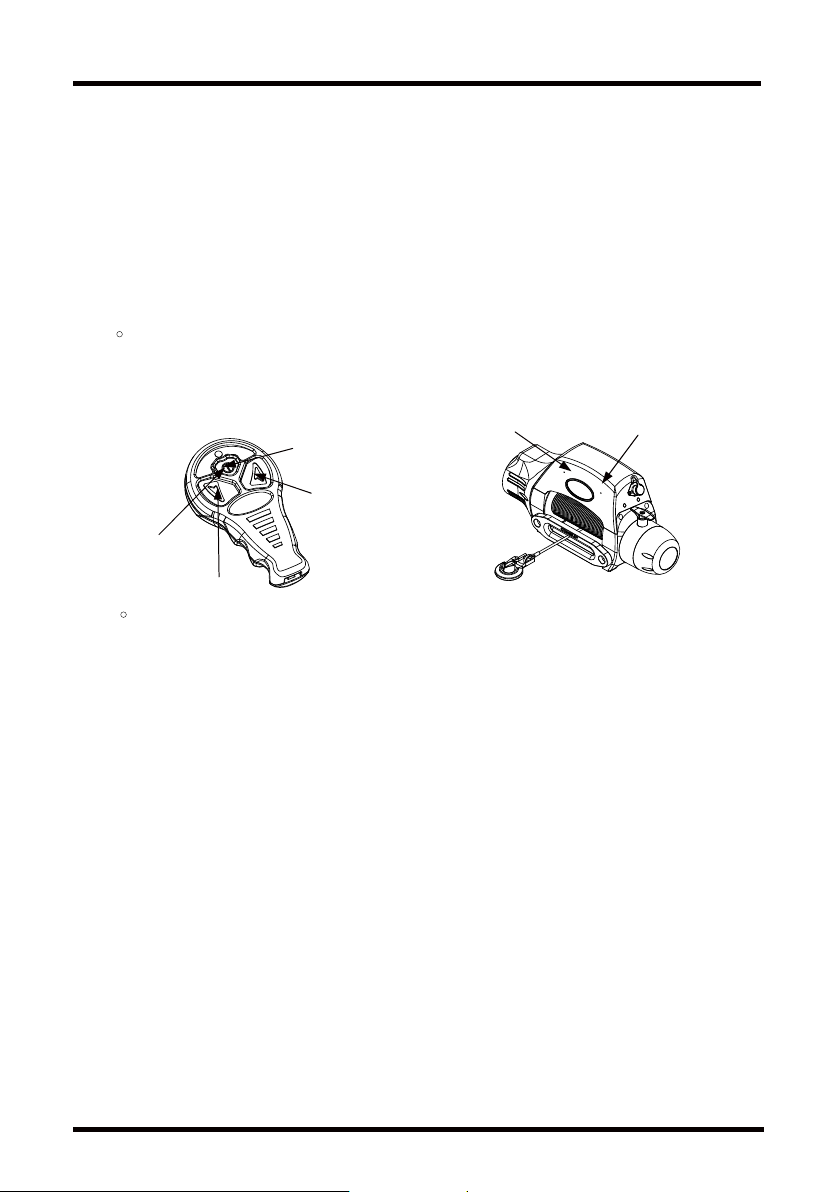

1. Replacing Battery

If the LED Indicator blinks Green, the battery is low and should be replaced.

a. Remove the three screws from the wireless transmitter.

b. Separate the top section and remove the old battery and dispose it.

c. Insert new lithium battery and join the top section with the bottom section.

d. Make sure to fasten the three screws.

2. First Installation/Re-programming the Receiver

The transmitter is programmed from the factory and under normal circumstances it won’t be

necessary to program it. Use the following procedures for any programming of the receiver.

a. Attach the red(+) and black(-) leads to battery set on the vehicle, then the buzzer beeps for 5

minutes and the Right LED on the bridge control box blinks Blue.

Lithium Battery: CR2032 (3V)

0678

Control Indicator Guide

5

b. Press and hold the Power Button for about 5 seconds, then the LED Indicator illuminates

Green permanently.

c. Press either Cable In Button or Cable Out Button for programming.

d. After the completion of programming, the buzzer sounds a long beep lasting for 5 seconds.

For Seal 9.5rsi winch, the Right LED turns off and the Left LED illuminates Green

permanently.

e. The process of the programming shall be completed within 5 minutes, if it fails to program,

turn off the power and restart the programming.

3. Start the Winch

․

For Seal 9.5rsi winch

Press and hold the Power Button for 5 seconds to start winch operation. The Left LED and

LED Indicator illuminate Green.

․

For Seal 9.5rs / 12.5rs winch

Press and hold the Power Button for 5 seconds to start winch operation. The LED Indicator

illuminates Green.

4. Shut down the Winch

a. Press and hold the Power Button for 5 seconds to stop winch function.

b. When operation of the winch is stopped for more than 5 minutes, the winch and the module

will turns off automatically. The Green LED Indicator also turns off.

5. Control Units

The wireless control module and remote control are compatible for activating the winch, but it

takes about a 10 second interval to exchange the wired remote control for the wireless control

module.

a. Blinking Red LED illuminate shows poor signal received.

b. The remote control can be used as a stand-alone, without the wired remote.

c.

If the motor is overheating, the Left LED of Seal 9.5rsi illuminates Red and the buzzer has 2

short beeps every 5 seconds until the temperature of the motor falls within the safety range.

d.

Only one remote can be programmed for each receiver.

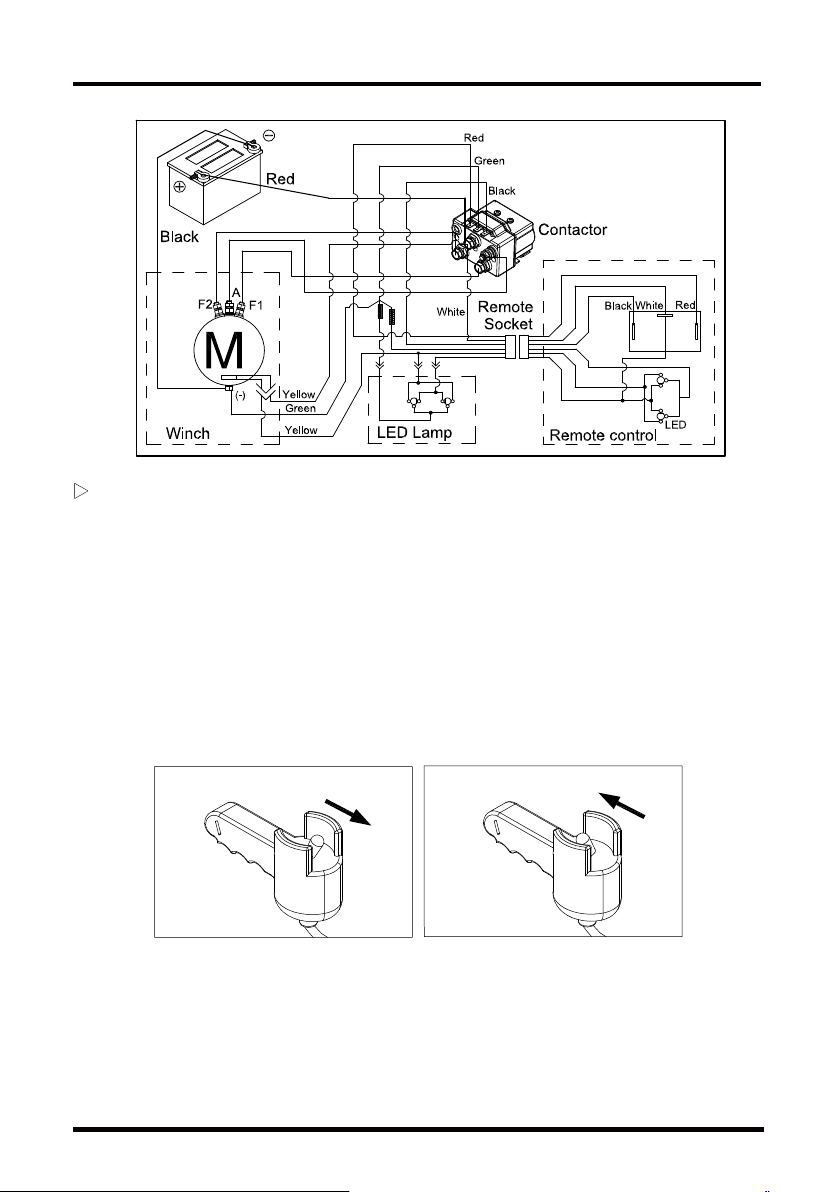

X Wiring Diagram

Attach the black lead firmly to the negative (–) battery terminal and red lead to the positive (+)

battery terminal. The voltage drop for the winch motor must not exceed 10% of the nominal voltage

of 12/24V DC.

LED Indicator

Cable Out

Cable In

Power Button

Left LED

Right LED

Seal 9.5rsi

Control Indicator Guide

6

X Battery Recommendations and lead size

A fully charged battery and good connections are essential for the proper operation of your winch.

The minimum requirement for battery is 650 cold cranking amp. The voltage drop for the winch

motor must not exceed 10% of the nominal voltage of 12/24V DC.

The battery lead shall be 2 gauge with 1.83 m in length at most, otherwise a considerable voltage

drop will be happened.

X Cable-in / Cable-out Operation

For Wired Remote Control

1. To “ Winch or Cable - Out”, trigger → out

2. To “ Winch or Cable - In”, trigger ← in

3. To stop winching, release the trigger

For Wireless Control Module:

1. Press and hold the Cable In Button of the Transmitter for rope winding in operation.

2. Press and hold the Cable Out Button of the Transmitter for rope winding out operation.

3. To stop winching, release the Cable In or Cable Out Buttons.

Cable-Out Cable-In

Mounting Guide

7

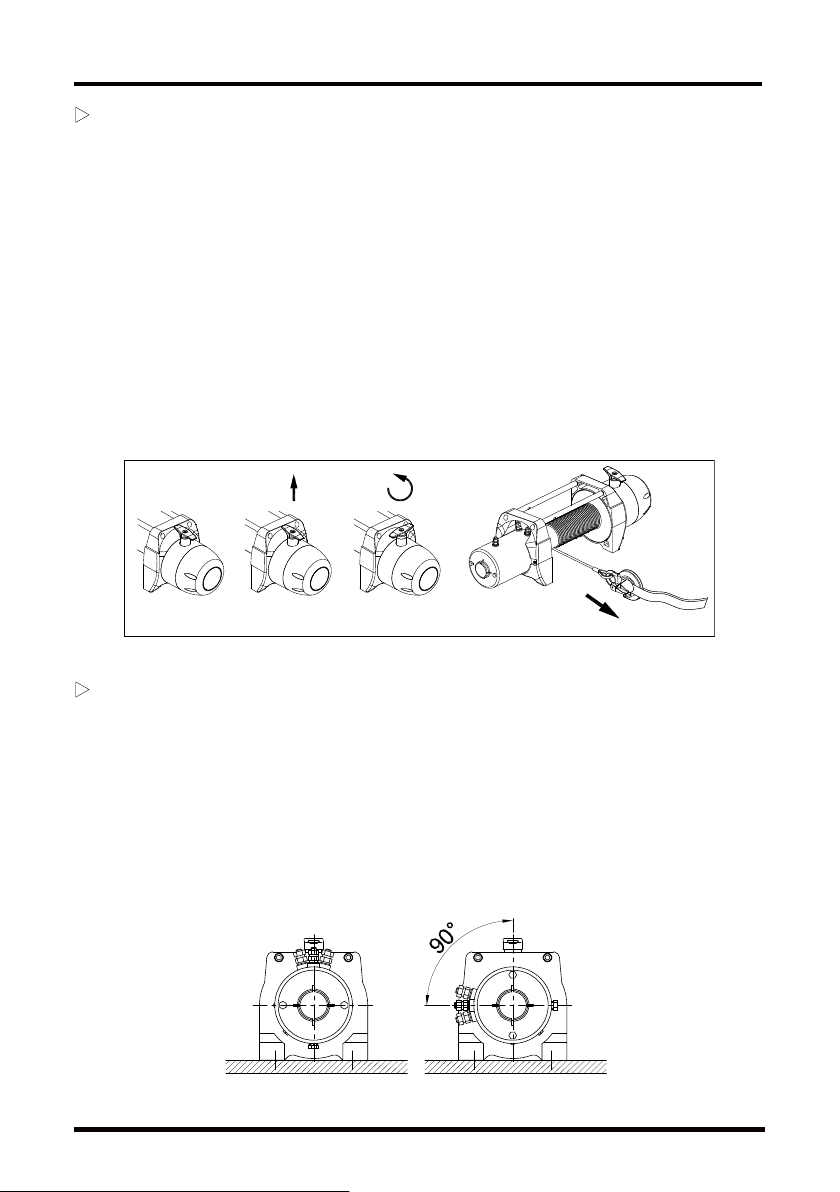

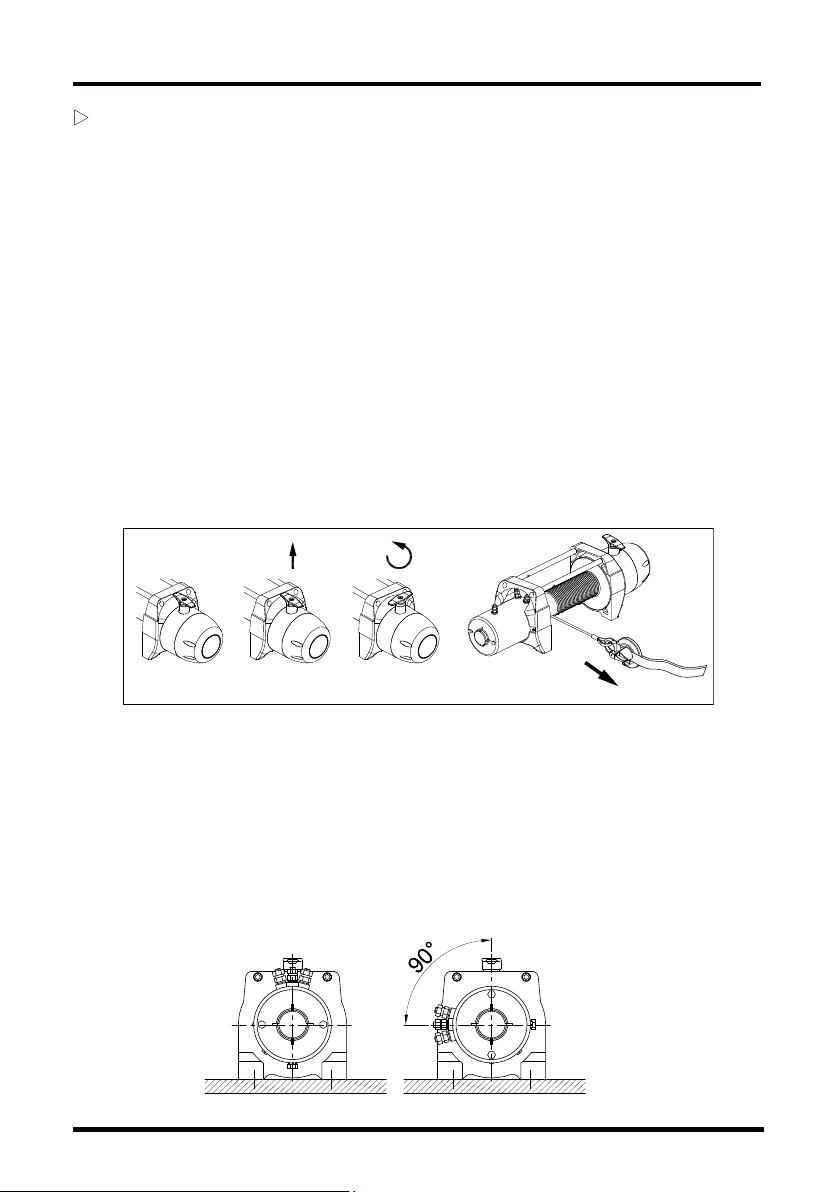

X Clutch Function

1. The clutch allows rapid pay-out of the wire/synthetic rope for hooking onto a load or anchor

points and is operated by a clutch T-handle.

2. The clutch T-handle must be in the “Engaged” position before winching.

3. To disengage, lift the clutch T-handle up and turn it at the proper angle mentioned in the

mounting configurations chart below in a counter-clockwise direction to the “Disengaged”

position. Wire/synthetic rope can now free spool off the drum.

4. To engage, lift the clutch T-handle up and turn it at the proper angle mentioned in the

mounting configurations chart below in a clockwise direction to the “Engaged” position.

5. If a clutch T-handle can’t be properly locked in the “Engaged” position, rotate the drum to help

the clutch device engage the gear train.

6. Wear gloves and use a hand saver strap when guiding the wire/synthetic rope off the drum.

7. Never disengage the clutch while wire/synthetic rope is under load.

X

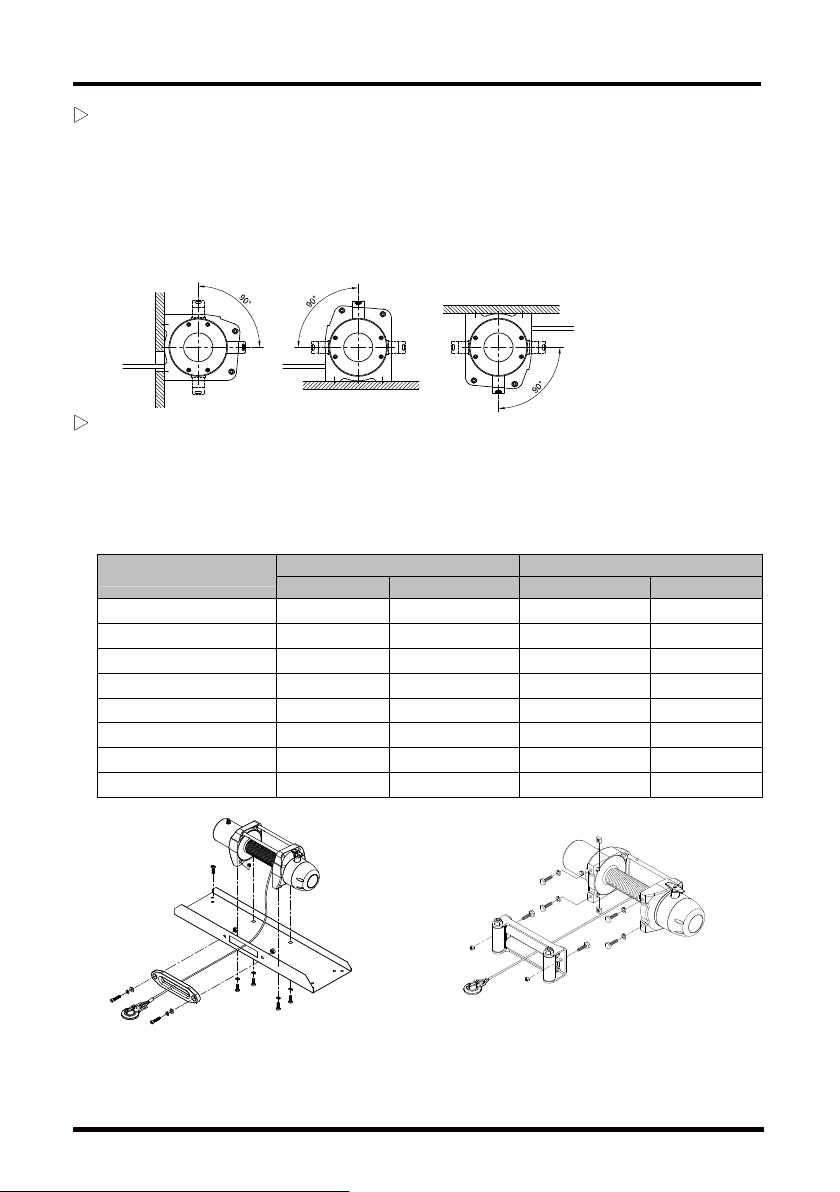

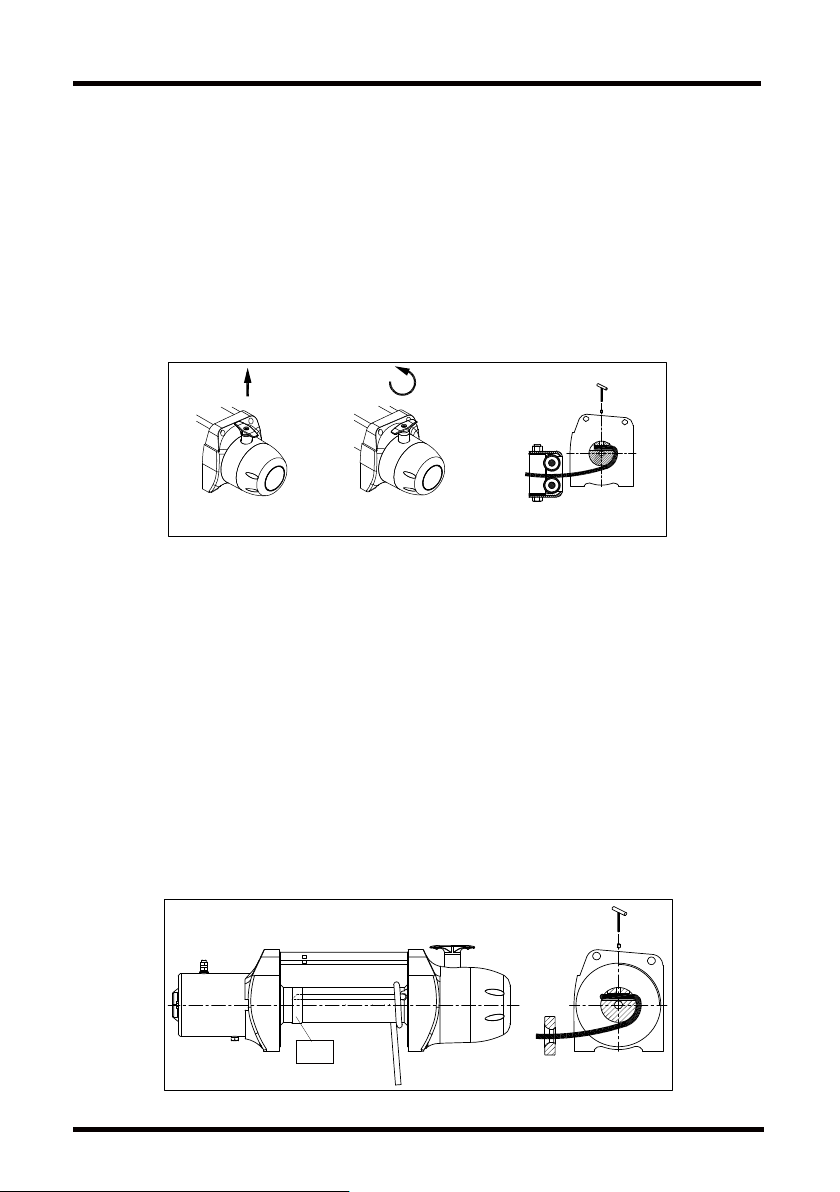

Motor Repositioning

Change the motor mounting direction according to the following steps

1. Use a piece of 11 mm wrench and loose 2 pieces of screw..

2. Hold the motor to avoid any escape. Loose and take away 2 pieces of screw located at motor

edge place.

3. Pull the motor backward by 5mm for escaping the positioning pin and rotate the motor by 90

degree increments to the required position.

4. Re-assembly 2 pieces of screw to the motor edge place and tighten them after the motor and

position pin reaching their positioning places.

(Disengage)(Engage)

Mounting Guide

8

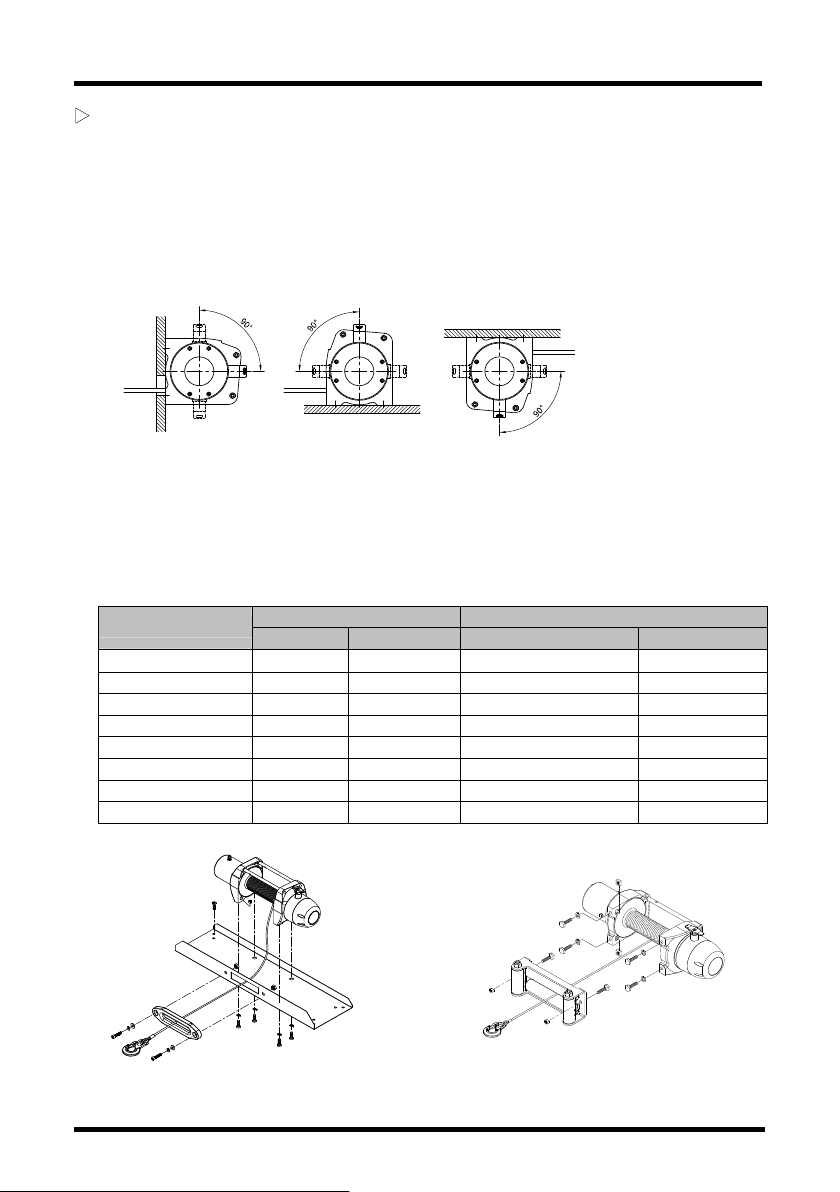

X Clutch Repositioning

Change the position of the Free-Spool T-handle according to the following steps.

1. Loosen and release the bolts on the brake rear cover for separating the brake rear cover away.

2. Loosen and release the bolts on the gearbox away for separating the gear box away (Only for

Seal series winches).

3. Rotate the gearbox by a proper angle increments mentioned on the below chart to the required

position.

4. Re-assembly the gearbox and rear brake cover.

X Mounting Configurations

The payout direction for wire rope/synthetic rope or the correct methods for mounting the winch

vary according to different winch model. Do wind the rope from the bottom of the drum for foot

down mounting winch. Do wind the rope from the top or bottom of the drum towards the direction of

the mounting base plate for foot forward mounting winch. At any condition, do not position the load

direction away from the mounting base plate.

Foot Down Mounting Position Foot Forward Mounting Position

Mounting Position Repositioning

Winch Model

Foot Down Foot Forward Clutch Angle Motor Angle

Seal 9.5/9.5s/9.5rs

V V

90∘ 90∘

Seal 9.5i/9.5si/9.5rsi

V V

90∘ 90∘

Seal 12.5/12.5s/12.5rs

V

90∘ 90∘

DV-18

V

36∘ 90∘

DV-12/15

V V

36∘ 90∘

DV-12 light/12s light

V

40∘ 90∘

DV-9/9s/9i/9si

V V

40∘ 90∘

DV-6000S

V V

90∘

Safety Requirements

9

In some cases, the operator of a winch may be required to have qualifications according to

applicable laws and ordinances.

Check safety and environmental conditions prior to and during use.

Only use correctly rated wire/synthetic rope in construction, strength.

Inspect for damage and/or defects before use.

Don’t use an unsuitable hook and snatch block for rope.

The operator must remain with the winch during operation.

The winch duty rating is S3 (intermittent-periodic).

Do not use the winch as a lifting device or a hoist for vertical lifting and moving people.

Ensure that the winch is connected to the correct voltage. 12/24 VDC only.

Do not exceed maximum line pull ratings. Shock load must not exceed these ratings.

Keep hands clear of rope and fairlead opening.

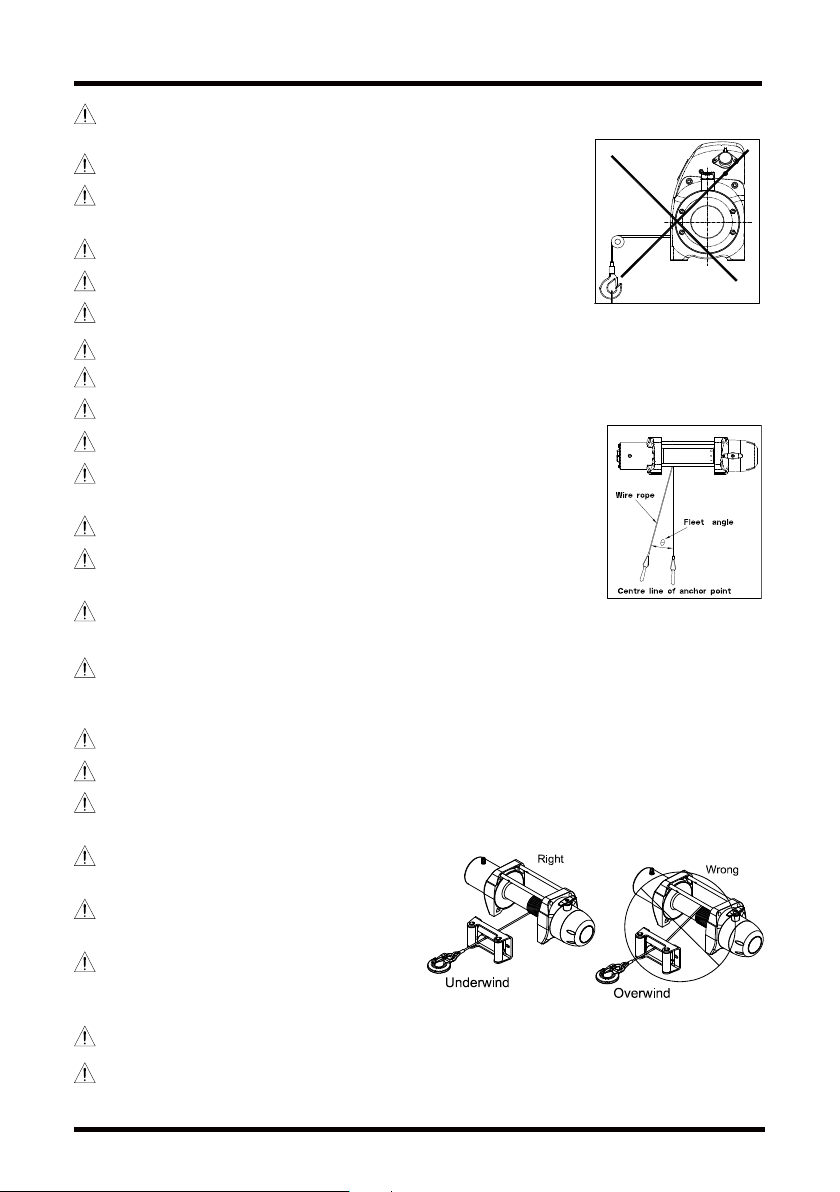

Pull from an angle below 15° in the horizontal plane to straighten up

the vehicle or load.

Always use leather gloves when handling the wire/synthetic rope.

When winching, always use a recovery damper. Place over the

wire/synthetic rope in the middle third of its length.

A rope should be replaced if it shows signs of excessive wear, broken strands, corrosion for wire

rope and excessive abrasion, broken strands, fused and melted fiber for synthetic rope.

If the winch fails to pull a load under normal conditions, stop the operation, otherwise motor

damage may occur. The thermal indicator LEDs in the control box or remote switch will indicate

RED as a warning.

Check that the clutch T-handle is in the “Engaged” position during and after use.

Remove the switch from the winch when not in use.

Do not wrap the wire/synthetic rope around the load and back onto itself. Always use a tree truck

strap.

Keep hands and clothes away from the winch,

rope, and roller/hawse fairlead.

Never unplug the remote control when winching

a load.

To avoid insufficient power when winching a

load, the vehicle should be running and in

neutral.

If noise or vibration occurs when running, stop the winch immediately and return it for repair.

The rope shall be wound in according to drum rotation sticker or refer to owners manual.

Winching Principles

10

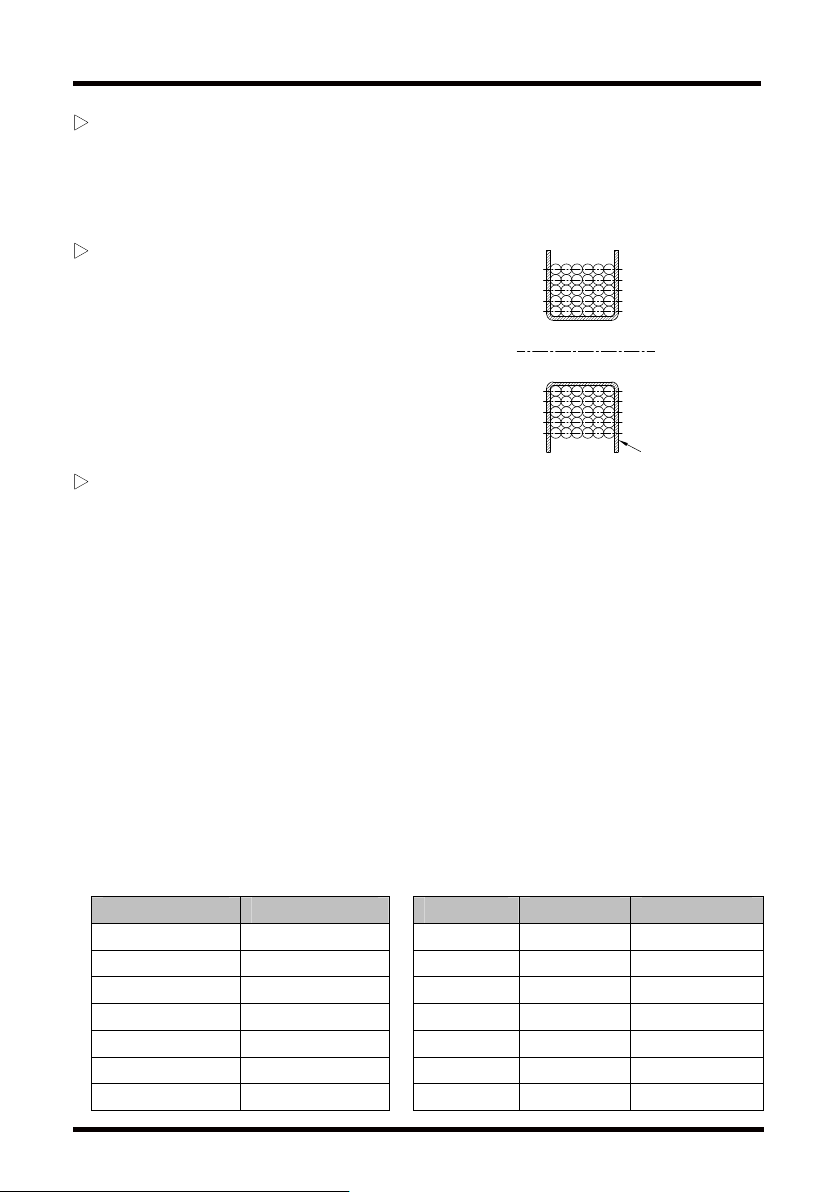

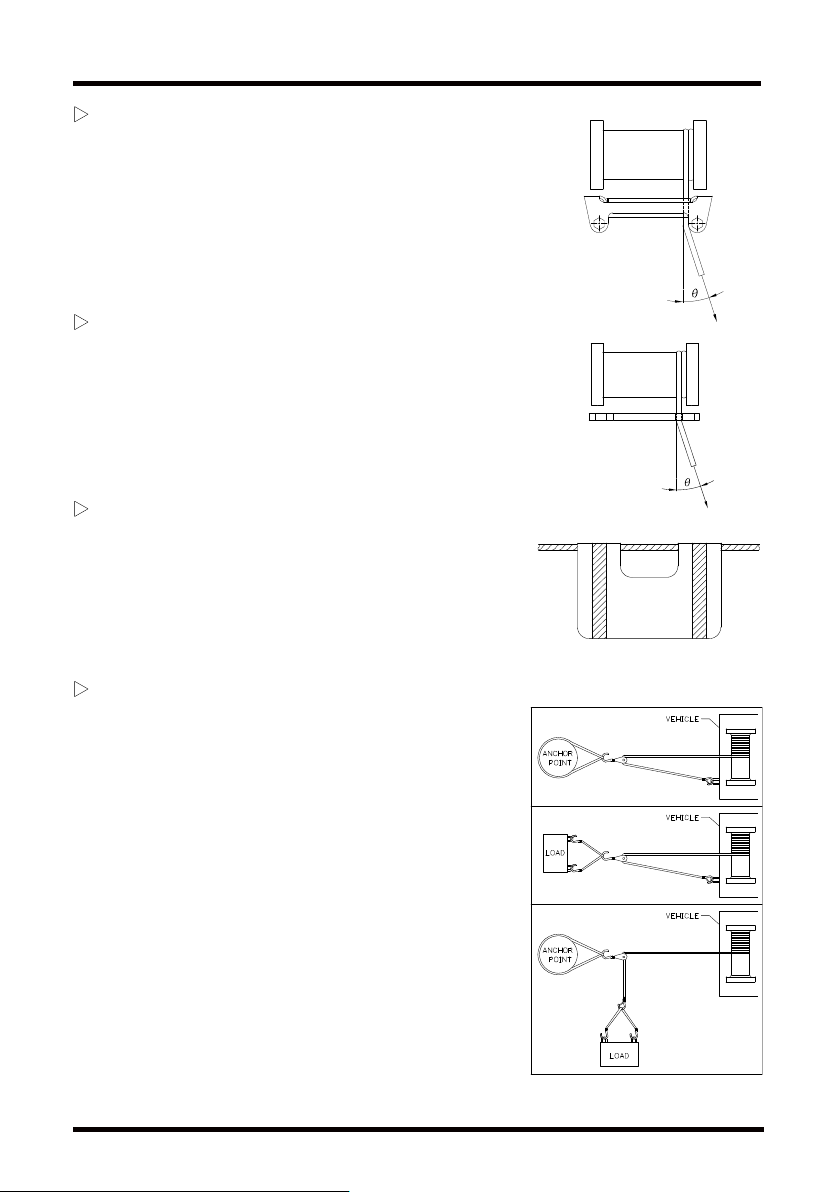

X Calculating Fleet Angle

To obtain the best wire/synthetic rope service, the direction of pull will be on a horizontal within

±15 degrees and perpendicular to be centerline of the winch drum within ±5 degrees. If the fleet

angle is bigger than the recommended angles, a good spooling cannot be obtained as the rope will

spoon onto one side of the rope drum and possible damage to the rope or winch.

X

Load Rating

Load and speed varies according to how much

wire/synthetic rope is on the drum. The first layer of rope

on the drum delivers the slowest speed and the maximum

load. A full drum delivers the maximum speed and the

minimum load.

For this reason, all automotive winches are rated at their

first layer capacities.

X

Required Pulling Force

You need a winch powerful enough to overcome the weight of your vehicle with the added

resistance caused by the obstacle, moving water, mud, snow, sand or on a steep hill.

As a general guide, you need a winch with a maximum line pull of at least 1.5 times greater than

the gross vehicle weight.

There are three factors listed that influence the line pull effect required to recover the vehicle. The

values and calculations in this section are approximate and are for reference only.

a). Gross vehicle weight

b). Type of the surface to be traversed

c). Gradient to overcome

In recovery and loading the winch is used to pull something, the required pulling force (RPF) can

be calculated according to the formula:

RPF = (Wt X S) + (Wt X G)

Where: Wt = The gross vehicle weight

S = The type of the surface to be traversed

G = The gradient to overcome

Surface Type Surface Drag (S)

Gradient Angle (θ) Gradient (G)

Metal 0.15

5% 3° 0.06

Sand 0.18

10% 6° 0.11

Gravel 0.20

20% 11° 0.2

Soft Sand 0.22

30% 17° 0.3

Mud 0.32

50% 26° 0.44

Marsh 0.52

70% 35° 0.58

Clay 0.52

100% 45° 0.71

Top layer (Max. speed Min. load)

Half layer (Med. speed Med. load)

First layer (Min. speed Max. load)

Flange of drum

Winching Principles

11

For example, if a vehicle weighing 3,000 kg is winched up an incline by 100% on the marsh road,

the above formula would be used as follows:

Where Wt: 3,000 kg, S: 0.52 G: 0.71

RPF = (Wt X S) + (Wt X G)

= (3,000 kg X 0.52) + (3,000 kg X 0.71)

= 1,560 kg + 2,130 kg

= 3,690 kg of effect required to recover the vehicle.

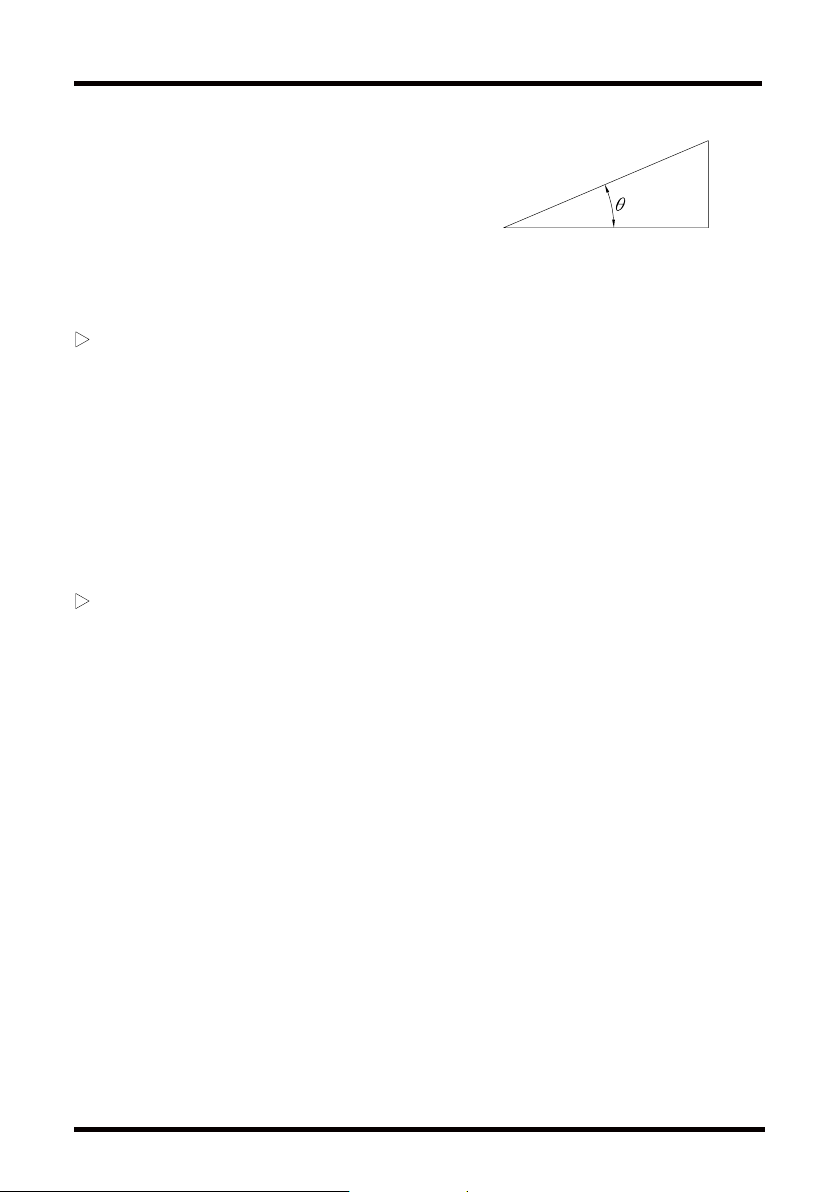

X

Securing Anchor Point

When choosing an anchor point, select a safe and firm point such as a tree, stump or rocks. If

using a winch to retrieve another vehicle, the rescue vehicle is considered the anchor point and

should be made secure.

The anchor point must be strong enough to hold the gross weight of the vehicle and be positioned

to keep the fleet angle between the centre of the anchor point and the wire/synthetic rope

maintained less than 15°. Always use a tree trunk protector strap to prevent ring barking the tree

and damaged to the wire/synthetic rope.

X Winching V.S. Hoisting. A pulling winch should not be used for lifting.

Please refer to our website to view our full range of lifting winches.

A gradient of 10% is a rise of one

meter in ten meters (High / Distance)

Slope

High

Distance

Accessories

12

X Roller Fairlead

The use of 4 ways roller fairlead can eliminate the contacting friction

because the fairlead rollers contact with the wire rope. But the

fairlead does not insure the wire rope will wind onto the drum in an

orderly manner. The proper fleet angle within 15° must be

maintained for the wire rope to wind onto the drum in an orderly

manner. If the proper fleet angle is not maintained, it can result in

damage to the winch and wire rope.

X

Hawse Fairlead

The basic hawse fairlead is designed to guide the synthetic rope to

and from the winch drum. Do not use cast steel hawse fairleads as

they have sharp edges and they do not have enough radius for the

rope to bend over.

X

Recovery Damper

A recovery damper is a safety device designed to help

eliminated the possibility of injury or property damage in the

event of a wire/synthetic rope failure. Place in the middle third

of a live rope. The damper can help absorb the energy in the

rope and reduce the likelihood of injury or damage.

X

Snatch Block

An important aid to successful winching is the use of snatch

block, which can be used to increase the pulling power of a

winch or change the direction of a pull.

A winch double lined with a snatch block creates a

mechanical leverage cutting the effort required by nearly half.

The double line pull shows self recovery using a snatch block

attached to an anchor point; the pull applied to the vehicle is

almost twice as much as the line pull of the winch.

The use of one snatch block shows an indirect pull where the

vehicle is limited due to unsuitable ground or obstruction. The

pull on the load is the actual line pull of the winch. If more

than one snatch block is used, they must be located at least

100 cm (40″) apart.

Fleet angle

Fleet angle

Winching Procedures

13

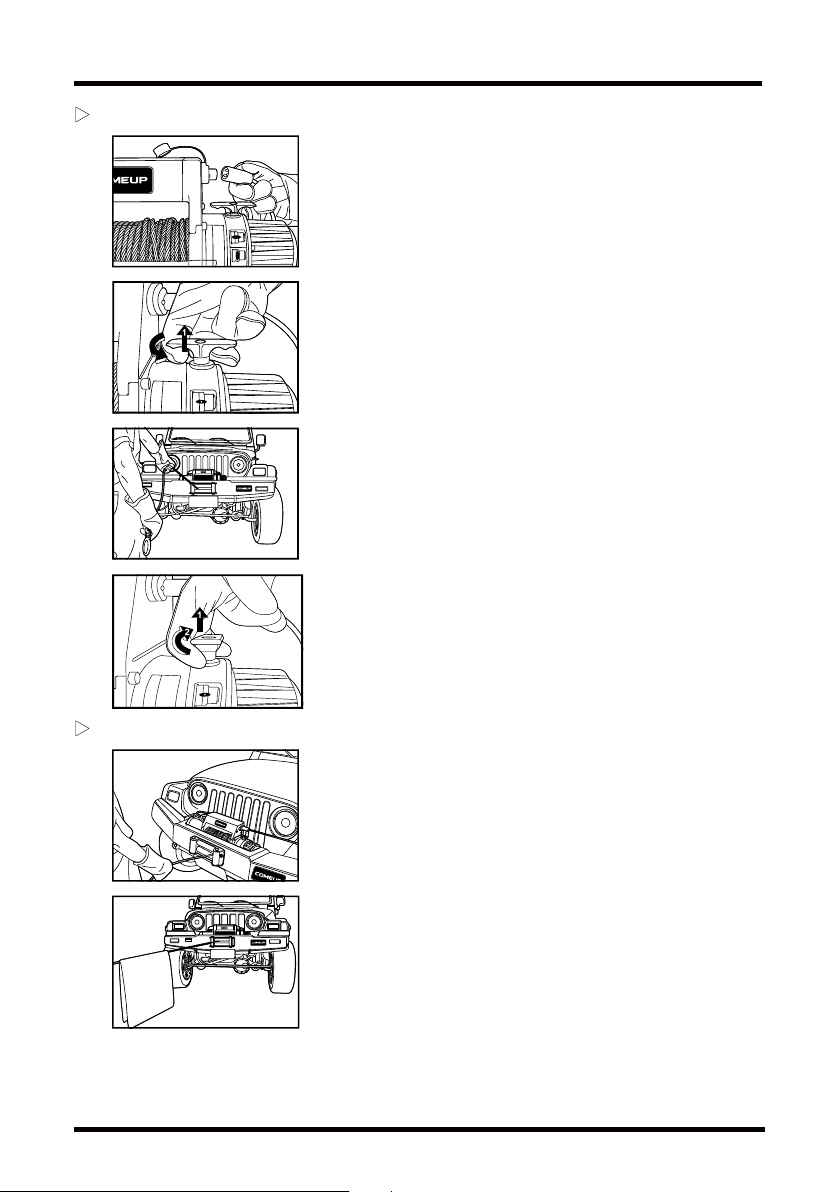

X Preparation before Winching

1). Connect the remote control

Always disconnect the remote control when not in use.

Always have the remote control kept free from winch,

wire/synthetic rope and roller/hawse fairlead.

2

2). Disengage clutch function

Lift the clutch T-handle up and turn it at 90°

counter-clockwise rotation to the “Disengaged” position,

rope can now clutch off the drum.

3). Pull the wire/synthetic rope to the anchor point

Wear leather gloves when handling wire/synthetic rope.

Pull out enough rope to reach the anchor point. Be careful

to keep the rope under tension.

4). Engage clutch function

To engage, lift the clutch T-handle up and turn it at 90°

clockwise rotation to the “Engaged” position. Never engage

the clutch while the drum is rotating.

X

Winching Operation

1). Check the wire/synthetic rope

Before winching, make sure the rope is wound on the drum

evenly. If there is a mixed winding, it is essential to rewind

it evenly.

2). Lay a recovery damper over the rope near the hook

end.

If a wire/synthetic rope failure occurs, the damper can

prevent the rope from whipping.

Winching Procedures

14

3). Secure anchor point

It is very important that an anchor point is strong enough to

hold the load while winching. Do not wrap the rope around

the load and back onto itself. Always use a strap to ensure

that the wire/synthetic rope does not fray or kink.

P

R

N

D

2

1

4). Setting the vehicle engine

The recovery vehicle engine should be running to provide

maximum power to the winch. The transmission shall be

set in neutral, hand brake applied ad wheel chocked or

vehicle anchored to prevent the vehicle from moving.

5). Attach shackle and hook

Use a shackle to lock both ends of tree trunk

protector, and then attach to the wire/synthetic rope

hook.

6). Begin winching

Keep force on the rope to ensure it winds onto the drum

evenly. Release hand brake and continue pulling until the

vehicle is recovered.

7). Secure vehicle

Once the vehicle is secured, wind the rope back onto the

drum evenly and secure the hook firmly.

8). Disconnect remote control

Take remote control out of the socket and store it in a safe

and dry place.

Winching Procedures

15

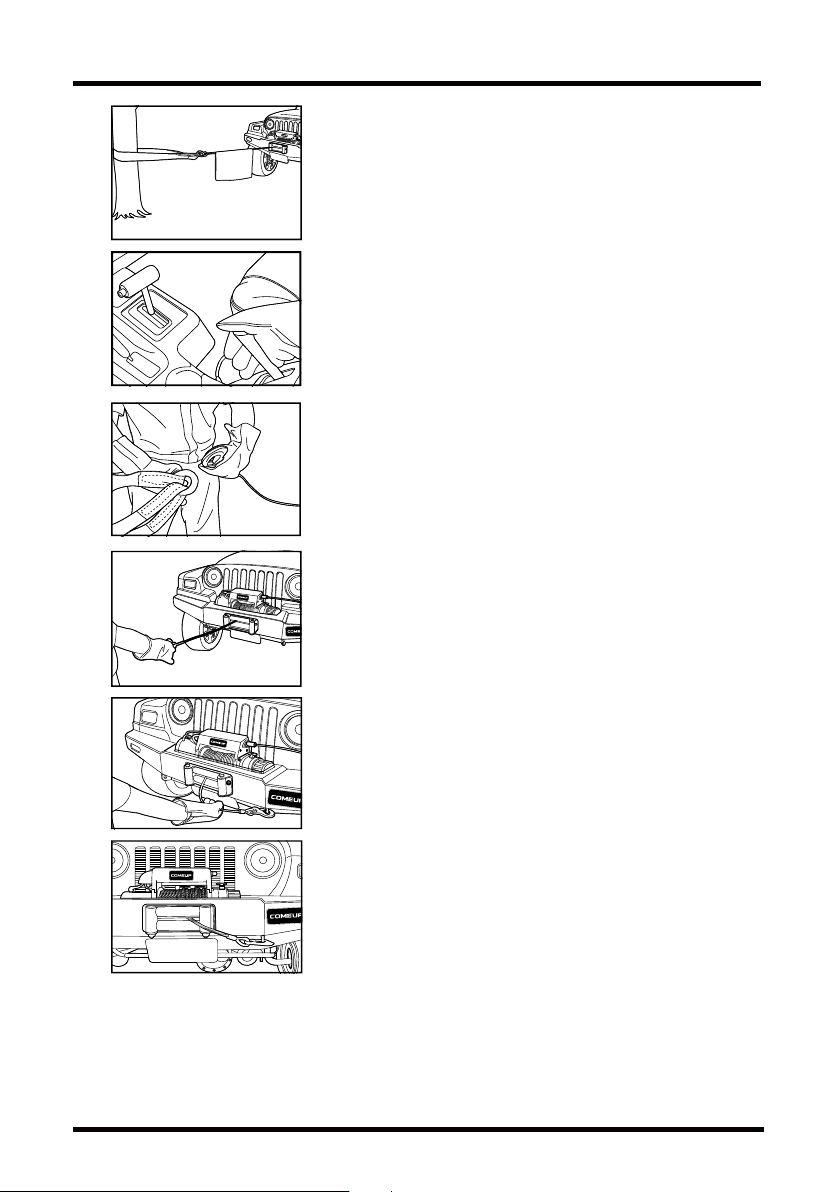

X Precaution while winching

Make sure the rope is wound on the drum evenly. A tightly

spiraled pig-tailed rope will damage the rope, shorten its

life.

Always keep clear of winch, rope, hook, and roller/hawse

fairlead during winching.

Keep winching area clear. Do not allow people to remain in

the area while winching.

Never guide a wire/synthetic rope onto the drum with your

hand, use a hand saver strap.

Avoid remote control cord from touching the wire/synthetic

rope.

A winching operation requires extra consumption of battery

power, so always keep your battery set in a good

condition.

Maintenance

16

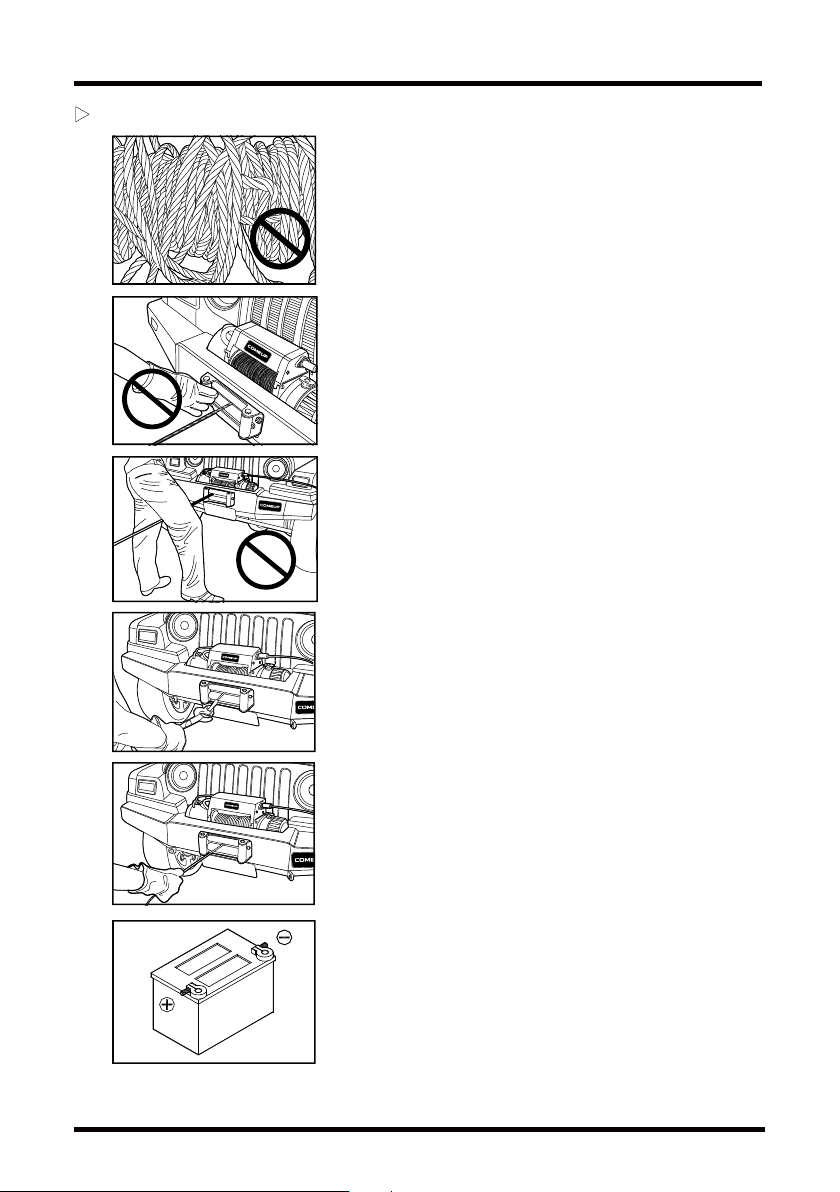

X Wire Rope Replacement

Do not wind out past the red paint section of the rope to secure the anchorage of the rope on the

drum.

1). Disengage the clutch T-handle.

2). Spool the entire rope, and then remove it from the drum.

3). Place the replacement rope through the roller fairlead opening, pass below the drum and insert

it into the hole on the drum core. Tighten the set-screw downwards to secure the wire rope.

4).A minimum of five (5) wraps of rope around the drum is necessary to support the rated load

X Synthetic Rope Replacement

Do not wind out past the red paint section of the rope to secure the anchorage of the rope on the

drum.

1). Disengage the clutch T-handle, remove existing rope and replace hawse if necessary.

2). Remove the set-screw on the drum and spool out the rope from the drum.

3). Cut the lateral side of the end by 45° and apply 2-3 wraps of electrical tape to hold cut strands

in place

4). Thread rope through a hawse fairlead and under the drum, insert the rope through the hole on

the drum with 15 – 20 cm / 6” – 8”.

5). Place rope across the drum and tape the end down to hold it in place. Lightly tighten the

set-screw to squeeze the rope, do not over tighten.

6). A minimum of ten (10) wraps of rope around the drum is necessary to support the rated load

Tape

(Engage)

(Disengage)

Maintenance

17

X Tip for prolonging the life of Synthetic rope

1. Regular maintenance and periodically check the rope for damage or wear

2. Since too much abrasion can damage or weaken your synthetic rope, protect your rope from

rubbing against sharp objects or edge

3. An aluminum hawse fairlead is highly recommended since it has no sharp edges and resists

damage more easily than a roller fairlead

4. Keeping your synthetic rope clean and dry. To clean it after a muddy ride, spool out the

5. rope, rinse it with a hose, and let it dry completely before re-spooling

X

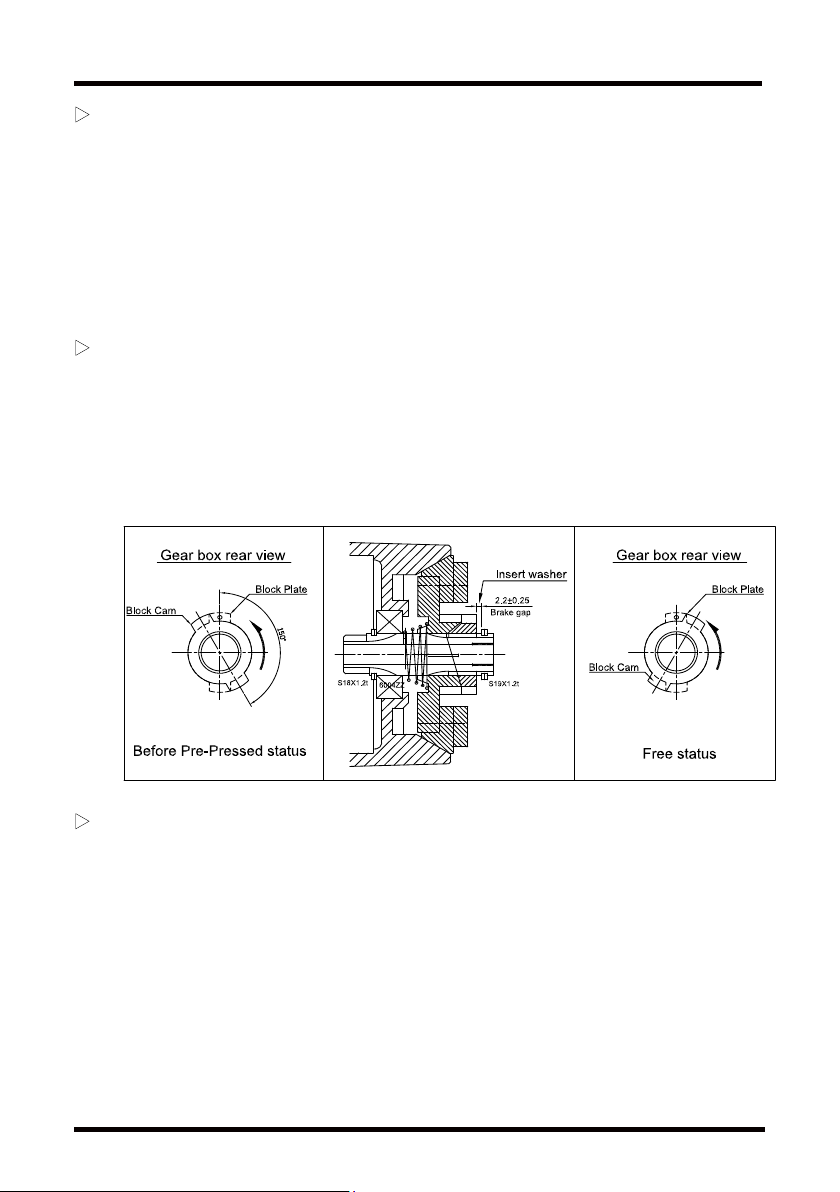

Brake Adjustment

Under normal use, the brake mechanism will not require any adjustment. If the brake fails to hold a

load, the brake disc may be worn and require replacement. When the brake wears to the point that

the load begins to slip, the brake can be adjusted as follows:

1). Loosen the bolt on the brake cover and take out the retaining rings

2). Insert spacers/washers to maintain the brake spacer between to be 2.2 ± 0.25 mm

3). Make sure to keep the clutch base plate is rotated counter-clockwise by 150 – 180 degree

X

Lubrication

All moving parts in the winch are permanently lubricated at the time of assembly. Under normal

conditions factory lubrication will suffice. If re-lubrication of gear box is necessary after repair or

disassembly use Shell EP2 or equivalent grease with enough quantity. Clutch T-handle lubricates

regularly with light oil. It is not allowed to have brake assembly lubricated.

Maintenance

18

FEDERAL COMMUNICATIONS COMMISSION INTERFERENCE STATEMENT

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates uses and can radiate radio frequency energy and, if

not installed and used in accordance with the instructions, may cause harmful interference to radio

communications.

However, there is no guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which can be determined

by turning the equipment off and on, the user is encouraged to try to correct the interference by one or

more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

-

Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

- Consult the dealer or an experienced radio / TV technician for help.

CE Mark Warning

• This is a Class B product, in a domestic environment, this product may cause radio

interference, in which case the user may be required to take adequate measures.

FCC and Industry Canada (IC) Warning:

• This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept

any interference received, including interference that may cause undesired operation.

CAUTION:

Any changes or modifications not expressly approved by the grantee of this device could void the

user's authority to operate the equipment.

Maintenance

19

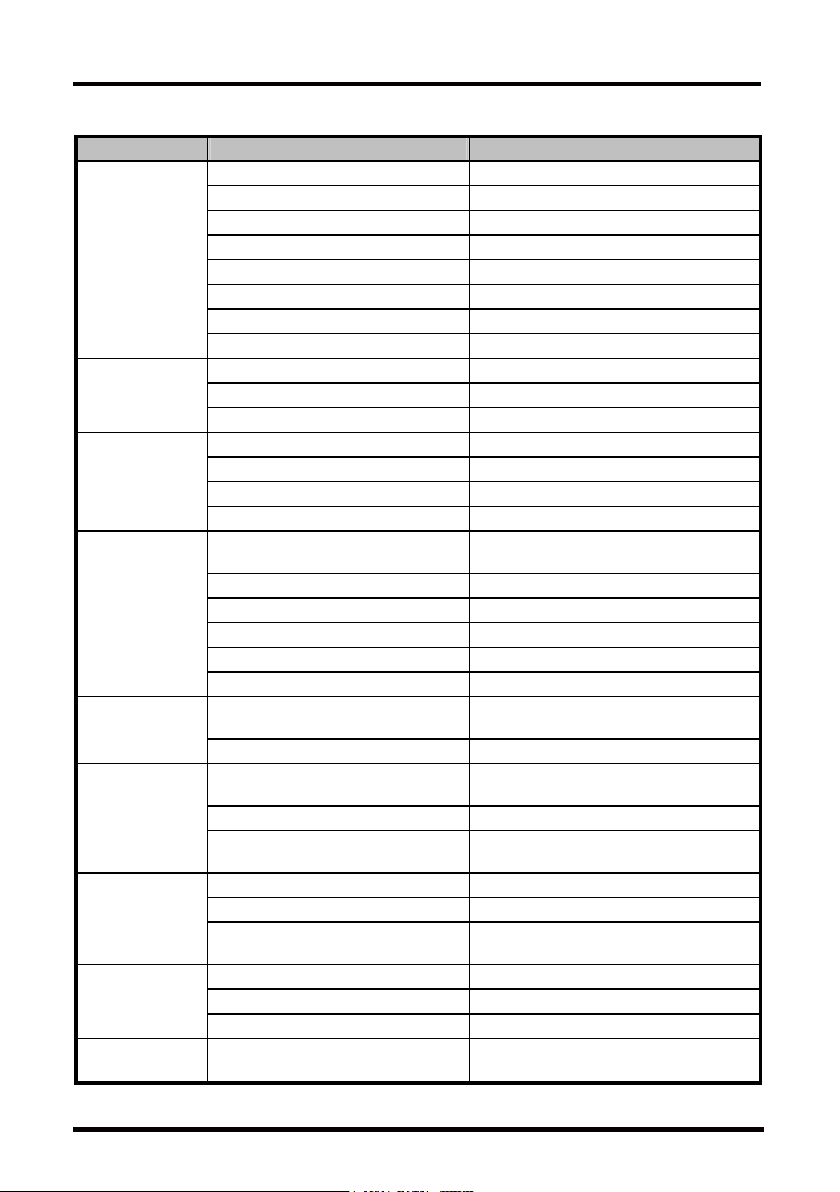

X Maintenance Schedule

Classification of check

Periodical

Daily

Monthly Quarterly

Item

Checking

method

Checking reference

c

Installation

Mounting bolts &

alignment

Bolt tension &

wear

Existence of abnormalities

c

Working Manual Reasonable actuation

c

Wearing in contact

points

Visual Free of wear or damage

c

Remote

control

LED lights red

Visual LED light green

c

Broken strands

Visual,

Less than 10%

c c

Decrease in rope

diameter

Visual,

measuring

7% of nominal diameter

max

c

Fastening

condition of end

Visual Existence of abnormalities

c

Wire

rope

Deforming or

corrosion

Visual Existence of abnormalities

c

Broken strands

Visual,

measuring

Two or more adjacent

strands are cut

c c

Decrease in rope

diameter

Visual,

measuring

25% of nominal diameter

max

c

Fused or melted

fibers

Visual Existence of abnormalities

c

Synthetic

rope

Fastening

condition of end

Visual Existence of abnormalities

c

Clutch

assembly

Damaged clutch

assembly

Visual evidence

of wear

Free of wear or damage

c

Motor Staining, damage

Visual evidence

of wear

Existence of abnormalities

c

Wearing of brake

disc

Visual evidence

of wear

Free of wear or damage

c

Brake

Performance Visual Reasonable actuation

c

Gear Damage, wearing

Visual evidence

of wear

Free of wear or damage

Trouble Shooting

20

If the winch fails to operate after several attempt, or if there is any fault whilst operation:

Symptom Possible Cause Remedy

Cut circuit Check battery lead

Weak battery Recharge or replace battery, 650CCA

Damaged over-load protector(option) Replace over-load protector(option)

Bad connection of wiring Reconnect tightly

Damaged contactor Replace contactor

Cut circuit on switch Replace switch

Damaged motor or carbon brush. Replace motor or carbon brush

Winch will not

operate

Poor or lost connections to motor Replace wiring or tighten it

Broken wiring or bad connections Reconnect or replace wiring

Damaged or stuck contactor Replace contactor

Motor runs in one

direction.

Switch inoperative Replace switch

Clutch does not disengage Replace clutch

Damaged 1

st

shaft Replace 1st shaft

Damaged brake cam and disc Replace brake cam and disc

Drum will not

clutch.

Damaged output shaft Replace output shaft

The gear train is mechanically binding

up

Check to insure the winch is mounted on

a flat, rigid surface

Damaged brake cam and disc Replace brake cam and disc

Damaged gear box Replace gear box

Broken retaining ring Replace retaining ring

Oil leakage into brake cavity Repair and clean oil leakage

No brake

Damaged or inoperative spiral spring

Replace and position spiral spring

Worn brake disc or loose brake

spacer

Replace brake disc or adjust brake spacer

according to brake adjustment procedures

Brake distance is

too long

Oil leakage into brake cavity Repair and clean oil leakage

Too much brake disc powder in the

brake hub

Clean brake hub

Over tensioned spiral spring Adjust tension on spiral spring

Brake will be

locked

Stuck between brake disc and gear

box

Replace with new brake assembly

Hit by certain exterior force Replace the damaged components

Damaged gear train Replace the damaged components

Damaged gear

box

Over load operation

Stop the winch operation and reduce the

load

Long period of operation Allow to cool

Damaged motor Replace or repair motor

Motor runs

extremely hot

Damaged or inoperative brake Replace or repair brake

LED lights red in

the remote switch

Overheating of the motor

Stop the winch operation and cool the

motor

21

Automotive Winch

Limited Lifetime Warranty for Mechanical Components

Limited One (1) Year Warranty for Electrical Components

WARRANTY

Comeup Industries Inc. (COMEUP) warrants to the original purchaser that the mechanical

components of the COMEUP Automotive Winch will be free of defects in material and workmanship for

the lifetime of the winch and the electrical components will be free of defects in material and

workmanship for a period of one (1) year from the original date of purchase. All COMEUP mounting

kits and other accessories carry a one (1) year limited warranty against defects in material

workmanship.

This warranty applies only to the original purchaser of the winch. To obtain any warranty service,

the purchaser under this Limited Warranty is requested to advise COMEUP or its authorized

distributors on any claim. The purchaser must provide a copy of the purchase receipt bearing the

winch serial number, date of purchase, owners name, email or Tel & Fax, address and purchaser

vehicle details. Any products that COMEUP determines to be accountable for defective will be

repaired or replaced or refund at COMEUP sole discretion without charge to buyer upon buyer’s

compliance with these procedures. In the event of repair or replace, purchaser must send the

defective winch or part, with freight prepaid, to COMEUP or its authorized distributor. And COMEUP

will send the serviced product back to purchaser on COMEUP’s cost. This warranty does not cover the

removal or reinstallation of the winch.

COMEUP takes the responsibility for COMEUP winch parts and components to be free from

defects in materials and workmanship, but the following portions are hereby excluded and disclaimed.

COMEUP or its authorized distributors may make reasonable charges for parts and labour for repairs

or resumption in the following portions not covered by this limited warranty.

(1). All warranties of wire rope and synthetic rope assemblies after initial use

(2). All warranties of fitness for a particular purpose

(3). All warranties of the product’s finish

(4). All warranties of merchantability

The limited warranty does not cover any failure that results from improper installation/operation,

third party part substitution, purchaser’s alteration or modification on COMEUP winch. This warranty is

void when COMEUP serial number plate is removed or defaced.

COMEUP’s liability to the purchaser under the winch purchases for any loss or damage howsoever

and whatsoever arising shall not exceed the price of the initial winch purchase receipt. COMEUP shall

not in any event be liable to the purchaser for any consequential and/or indirect loss or damage

whether for loss or for profit or otherwise, costs, expenses or other claims for consequential

compensation whatsoever and whether caused by negligence of COMEUP employees, distributors

and their employees or otherwise. COMEUP reserves the right to change product design without

notice. In situations in which COMEUP has changed a product design, COMEUP shall have no

obligation to upgrade or otherwise modify previously manufactured products.

22

Treuil Automobile

MODE D'EMPLOI

Anglais……………………………...1

Français……………………………..22

Espagnol………………………….…43

Allemand……………………………64

Italien……….……….…………….86

23

Treuil Automobile

Merci d'avoir acheté un treuil . Ce manuel couvre l'utilisation et l'entretien du treuil. Tous

les renseignements dans cette publication sont basés sur les informations de production les plus

récentes disponibles au moment de l'impression. Nous nous réservons le droit d'apporter des

modifications sans préavis en raison de l'amélioration continue des produits.

Le treuil a été conçu pour assurer un service sûr et fiable lorsqu'il est utilisé conformément aux

instructions. Veuillez lire et comprendre ce manuel avant l'installation et le fonctionnement du treuil.

Un treuillage imprudent peut entraîner des blessures graves ou des dommages matériels.

Chaque fois que vous aurez besoin de vous renseigner ou de commander des pièces de rechange,

veuillez toujours donner les informations suivantes:

1. Modèle du treuil et la tension

2. Numéro de série

3. Numéro de l’article et Référence

4. Description de la Référence

1. Le treuil est une machine très puissante. A manipuler avec extrême prudence en

respectant toutes les précautions et les avertissements.

2. Le treuil est évalué à la première couche du câble acier / corde synthétique sur le tambour

pour un fonctionnement intermittent et périodique.

3. Le treuil ne doit pas être utilisé pour soulever, supporter ou transporter du personnel.

4. Un minimum de cinq (5) tours de corde du câble d'acier et de dix (10) tours de corde

synthétique autour du tambour est nécessaire pour supporter la charge nominale.

5. Restez à l'écart du treuil, du câble, du crochet, et du chaumard pendant l’opération.

6. Le câble / corde synthétique peut briser sans avertissement. Toujours garder une distance

sécuritaire du treuil et la corde quand il est chargé.

7. Manquer d'aligner adéquatement, de soutenir ou de fixer le treuil à une base de montage

appropriée pourrait entraîner une perte d'efficacité de la performance ou des dommages au

treuil, du câble /de la corde synthétique, et de la chaîne de montage.

ATTENTION

Indicateur de Contrôle

24

Il y a trois modules de commande des treuils automobiles Comeup. Tous sont similaires dans la

configuration, mais n'ont pas les mêmes réponses en ce qui concerne leur type de contrôle.

Déterminer quel modèle vous avez et consulter les tableaux pour vos modèles particuliers ; vous

verrez une signalisation de son état par LED et sonnerie de buzzer.

X Câble de Module de commande à distance

Treuils disponibles Seal 9.5i/9.5si; DV-9i/9si

DEL sur le boîtier de commande de

pont

DELs sur la télécommande

Emplacements DEL

DEL gauche DEL droite DELs

Brancher connecteur Vert Vert Vert

Fonction Câble In/Out Vert Vert Vert

Signal de Surchauffe du moteur

Rouge Rouge Rouge

Débrancher connecteur DELs éteintes

Treuils disponibles

Seal 9.5 / 9.5s/12.5/12.5s

DV-18/15/12/9/9s

DV-12 light

X

Module de commande sans fil sur les deux modules de contrôle

Ils peuvent être commandés par le module de commande sans fil ou le module de commande à

distance par câble, mais seulement un type de commande peut activer le treuil en même temps.

Treuil disponible Seal 9.5rsi

DELs et buzzer sur la boîte de commande

de pont

DEL & Buzzer

DEL gauche

DEL droite Buzzer

DEL sur

l’émetteur sans fil

Appuyez sur l'émetteur pendant

5 secondes

Vert X X Vert

Fonction Câble In/Out Vert Bleu X Rouge

Câble In/out Bleu Rouge Signal de

Surchauffe du

moteur

Pas en

marche

Rouge

X

2 bips courts

toutes les 5

secondes

vert

Signal pour basse tension sur

l'émetteur

X X X clignotant vert

Signe de Faible signalisation X clignotant bleu

X clignotant rouge

Treuils Disponibles

Seal 9.5rs / 12.5rs

(Sonnerie dans le boîtier de

commande)

Indicateur de Contrôle

25

X Modules de commande sans fil sur les modules a double commande

Treuil disponible Seal 9.5rsi

DELs et buzzer sur la boîte de commande de

pont

DEL & Buzzer

DEL Gauche DEL Droite

Buzzer

sur la

télécommande

Branchez connecteur Vert X X Vert

Opération Câble In / Out Vert X X Vert

Avertissement : Surchauffe

du moteur

Rouge X

2 petites bips

toutes les 5

secondes

Rouge

débrancher Connecteur DEL s’éteint

Treuils disponibles

Seal 9.5rs / 12.5rs

(Buzzer dans le boitier de

commande)

Remarque:

1. Le voyant vert s'allume lorsque le treuil fonctionne dans des conditions normales de travail.

2. Le voyant rouge s'allume lorsque le treuil est en marche pendant surchauffe du moteur. Dans ce

cas arrêtez le fonctionnement pour permettre au treuil de se refroidir (DEL verte)

3. Les voyants s'allument ou bien le buzzer émet des bips lorsque le moteur est en surchauffe.

X

Récepteur et transmetteur sans fil Opération

1. Remplacement de la pile

Si le voyant clignote en vert, la batterie est faible et doit être remplacée.

a. Retirez les trois vis de l'émetteur sans fil.

b. Soulevez la partie supérieure et retirez la pile usagée et en disposez.

c. Insérez une nouvelle pile en lithium et relier la partie supérieure avec la partie inférieure.

d. Prenez le soin de bien serrer les trois vis.

2. Première installation / Reprogrammation du récepteur

L'émetteur est programmé à l'usine. Dans des circonstances normales, il n’est pas nécessaire

de le programmer. Suivez les procédures suivantes pour la programmation du récepteur.

a. Fixez le fil rouge (+) et noir (-) à la batterie du véhicule. Le boîtier bipera pendant 5 minutes et

la DEL droite sur le boîtier de commande du pont clignotera en bleu.

Pile en Lithium: CR2032

0678

Indicateur de Contrôle

26

b.Appuyez et maintenez enfoncé le bouton d'alimentation pendant 5 secondes environ ; le

voyant va donner une illumination verte permanente.

c. Appuyez soit sur câble In ou câble Out du bouton pour la programmation.

d.Après achèvement de la programmation, la sonnerie donnera un long bip dure pendant 5

secondes. Pour le treuil avec Seal 9.5rsi, la DEL droite s'éteint et la DEL gauche s'allume en

vert en permanence.

e.Le processus de la programmation doit être achevé dans 5 minutes. Si la programmation ne

réussit pas, éteignez-le et redémarrez la programmation.

3. Démarrez le treuil

․

Pour le treuil avec Seal 9.5rsi

Appuyez et maintenez enfoncé le bouton d'alimentation pendant 5 secondes pour démarrer le

fonctionnement du treuil. L'indicateur DEL et la DEL gauche s'allumeront en vert.

․

Pour Treuil avec Seal 9.5rs / 12.5rs

Appuyez et maintenez enfoncé le bouton d'alimentation pendant 5 secondes pour démarrer le

fonctionnement du treuil. L'indicateur LED s'allume en vert.

4. Arrêtez le treuil

a. Appuyez et maintenez enfoncé le bouton d'alimentation pendant 5 secondes pour arrêter le

fonctionnement du treuil.

b. Lorsque le fonctionnement du treuil est interrompu pendant plus de 5 minutes, le treuil et le

module s'éteignent automatiquement. Le voyant vert s'éteint également.

5. Unités de contrôle

Le module de commande sans fil et la télécommande sont compatibles pour activer le treuil,

mais il faut environ un intervalle de 10 secondes pour échanger la télécommande avec fil contre

le module de commande sans fil.

a. Un Clignotant rouge s'allume pour signaler une pauvre réception.

b. La télécommande peut être utilisée de façon autonome, sans la télécommande à fil.

c. Si le moteur est en surchauffe, la DEL gauche du Seal 9.5rsi s'allume en rouge et le buzzer

émet 2 bips courts toutes les 5 secondes jusqu'à ce que la température du moteur tombe

dans la marge de sécurité.

d. Une seule télécommande peut être programmée pour chaque récepteur.

X Schéma de câblage

Attacher le fil noir fermement à la borne négative (-) de la batterie et le fil rouge à la borne positive

de la batterie (+). La chute de tension pour le moteur du treuil ne doit pas excéder 10% de la

tension nominale de 12/24V DC.

bouton d'alimentation

Indicateur DEL

Câble Out

Câble In

DEL gauche

DEL droite

Seal 9.5rsi

Indicateur de Contrôle

27

X Recommandations de batterie et taille du fil

Une batterie bien chargée et une bonne connexion sont essentielles pour le bon fonctionnement de

votre treuil. L'exigence minimale pour la batterie est 650 ampères de démarrage à froid. La chute

de tension pour le moteur du treuil ne doit pas excéder 10% de la tension nominale de 12/24V DC.

Le fil de la batterie est de 2 calibres avec 1,83 m de longueur au plus, sinon une chute de tension

considérable peut se produire.

X

Opération Câble In / Câble out

Pour la télécommande avec fil

1. Pour "treuil ou câble - Out", déclencheur → out

2. Pour "treuil ou câble - In", déclencheur ← In

3. Pour arrêter le treuillage, relâchez la gâchette

Pour le module de commande sans fil:

1. Appuyez et maintenez enfoncé le câble dans le bouton de l'émetteur pour l'enroulement de la

corde en mode de fonctionnement.

2. Appuyez et maintenez le bouton Câble Out de l'émetteur pour l'enroulement de la corde quand

ce n’est pas en mode de fonctionnement.

3. Pour arrêter le treuillage, relâchez les boutons de câble In ou câble Out.

Câble -Out Câble -In

Guide de montage

28

X Fonction d'embrayage

1. L'embrayage permet au câble / corde synthétique de s'accrocher aisément à une charge ou

points d'ancrage, et est exploité par une poignée d’embrayage en T.

2. La poignée d’embrayage en T doit être en position "engagée" avant treuillage.

3. Pour débrayer, lever la poignée d’embrayage en T et la tourner à l'angle approprié mentionné

dans les graphiques de configurations de montage ci-dessous dans le sens inverse des aiguilles

d'une montre par rapport à la position «désengagé». Le câble / corde synthétique peut

maintenant être détaché de la bobine du tambour.

4. Pour l’engager, lever la poignée d’embrayage en T et la tourner à l'angle approprié mentionné

dans les graphiques de configurations de montage graphique ci-dessous dans le sens des

aiguilles d’une montre par rapport à la position "enclenché".

5. Si une poignée d’embrayage en T ne peut pas être correctement verrouillée dans la position

"engagé", faire tourner le tambour afin d'aider le dispositif d'embrayage d’engager le train

d'engrenages.

6. Porter des gants et utiliser une courroie de gain de main quand vous retirez le câble / corde

synthétique du tambour.

7. Ne jamais débrayer pendant que le câble / corde synthétique est en charge.

X Repositionnement du Moteur

Changer le sens de montage du moteur selon les étapes suivantes

1. Utilisez une clé de 11 mm et 2 vis.

2. Maintenez le moteur pour éviter toute fuite. Desserrer et enlever 2 vis situées sur le bord du

moteur.

3. Tirez le moteur vers l'arrière de 5 mm pour éviter la broche de positionnement et la rotez le

moteur de 90 degrés par rapport à la position souhaitée.

4. Remonter les 2 vis au bord du moteur et serrez-les de sorte que la broche du moteur et l’axe

retournent à leur position initiale.

(Désengagé)

(Engagée)

Guide de montage

29

X Embrayage Repositionnement

Changez la position de la poignée en T selon les étapes suivantes.

1. Desserrer et relâcher les boulons sur le couvercle de frein arrière pour écarter le couvercle

arrière du frein.

2. Desserrer et relâcher les boulons sur la boîte de vitesses pour séparer la boîte de vitesses

(Seulement pour les treuils de série).

3. Tournez la boîte de vitesses dans la position souhaitée en observant un incrément d'angle

approprié mentionné sur le graphique ci-dessous

4. Remonter la boîte et le couvercle de frein arrière.

X Configurations de montage

La direction de distribution du câble / corde synthétique ou les méthodes correctes pour le montage

du treuil varient en fonction des différents modèles de treuil. Enrouler la corde à partir du fond du

tambour de treuil vers le bas du pied de montage. Enrouler la corde à partir du dessus ou audessous du tambour dans la direction de la plaque de base de montage pour le montage de

l'avant-pied du treuil. En tout état, ne pas positionner le sens de la charge de façon à la distancer

de la plaque de base de montage.

Position Montage Pied à terre Pied en Avant Position de montage

Position de montage Repositionnement

Modèle de Treuil

Pied à terre Pied en avant Angle d’embrayage Angle du moteur

Seal 9.5/9.5s/9.5rs

V V 90∘ 90∘

Seal 9.5i/9.5si/9.5rsi V V 90∘ 90∘

Seal 12.5/12.5s/12.5rs

V 90∘ 90∘

DV-18 V 36∘ 90∘

DV-12/15 V V 36∘ 90∘

DV-12 light/12s light

V 40∘ 90∘

DV-9/9s/9i/9si V V 40∘ 90∘

DV-6000S V V 90∘

Loading...

Loading...