COMEUP Automotive Winch User Manual

1

Automotive Winch

Thank you for purchasing a

Winch. This manual covers operation and maintenance

of the winch. All information in this publication is based on the latest production information available

at the time of printing. We reserve the right to make changes without notice because of continued

product improvement.

The winch has been designed to give safe and dependable service if operated according to the

instructions. Please read and understand this manual before installation and operation of the winch.

Careless winch operation can result in serious injury or pro

perty damage.

When requesting information or ordering replacement parts, always give the following information:

1. Winch model and voltage

2. Serial Number

3. Item. No. and Part Number

4. Part Description

1. The winch is a very powerful machine. Treat with extreme care and observe all caution and

warnings.

2. The winch is rated at the first layer of wire/synthetic rope on the drum for intermittent-periodic

duty.

3. The winch is not to be used to lift, support or otherwise transport personnel.

4. A minimum of five (5) wraps of steel wire rope and of ten (10) wraps of synthetic rope around

the drum is necessary

to support the rated load.

5. Keep clear of winch, rope, hook, and fairlead while operating.

6. Wire/synthetic rope can break without warning. Always keep a safe distance from the winch

and rope while under a load

7. Failure to adequately align, support, or attach the winch to a suitable mounting base could

result in a loss of efficiency of performance or damage to the winch, wire/synthetic rope and

mounting channel.

WARNING

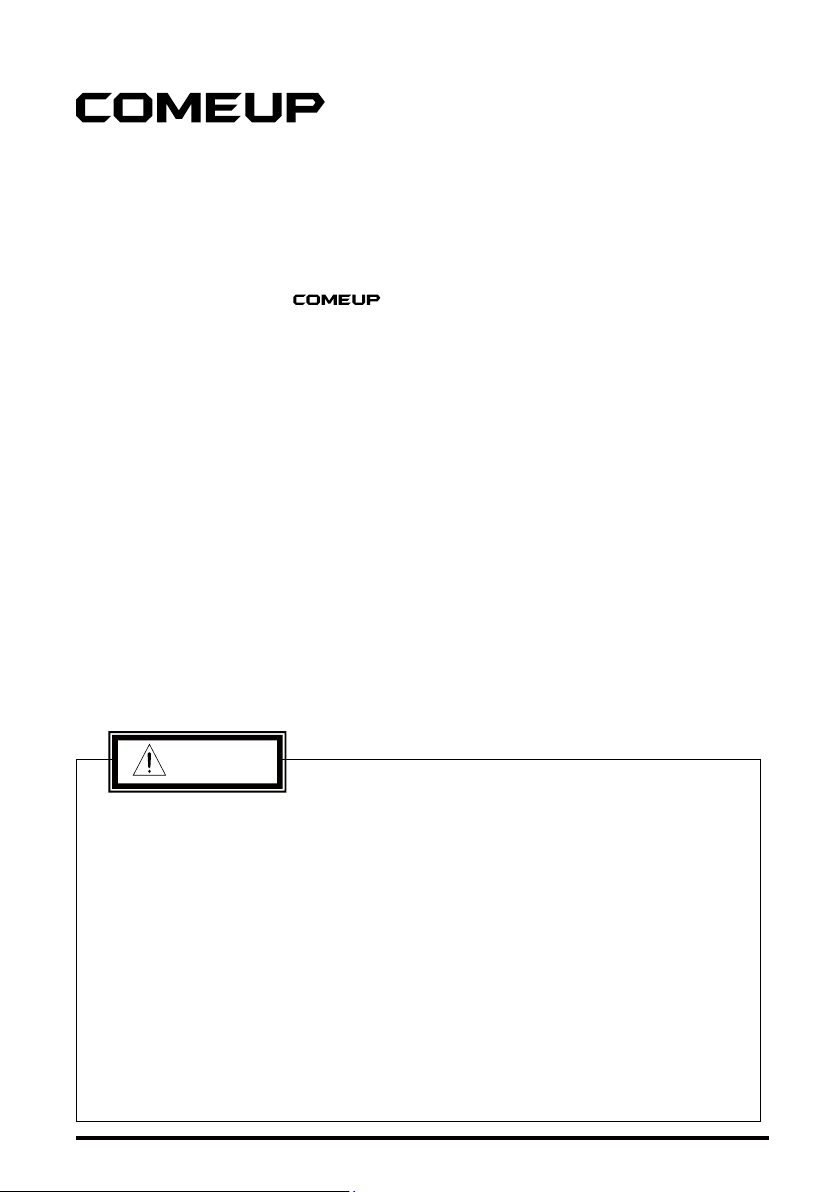

Control Indicator Guide

2

There are three control modules of the Comeup automotive winches. All are similar in setup, but have

differing responses in regards to their control type.

Determine which model you have and refer to the charts for you particular models signalling of its

condition through LED’s and buzzer

.

Wired Remote Control Module

Available Winches Seal 9.5i/9.5si; DV-9i/9si

LEDs on the bridge control box

LEDs on the remote control

LED Locations

Left LED Right LED LEDs

Plug in Connector Green Green Green

Cable In/Out Operation Green Green Green

Motor Overheating Warning Red Red Red

ffo snrut DEL rotcennoC tuO gulP

Available Winches

Seal 9.5 / 9.5s/12.5/12.5s

DV-18/15/12/9/9s

DV-12 light/12s light

Wireless Control Module on the dual control modules

They can be controlled by the wireless control module or the wired remote control module, but only

one control way can activate the winch at the same time.

isr5.9 laeS hcniW elbaliavA

LEDs and buzzer on the bridge control box

LED & Buzzer

Left LED Right LED Buzzer

LED on the

wireless

transmitter

Press Transmitter for 5 seconds Green X X Green

Cable In/Out Operation Green Blue X Red

deR eulB tuo/nI elbaC

Motor

Overheating

Warning

No Working

Red

X

2 short Beeps

every 5 seconds

Green

Low Voltage on Transmitter

Warning

X X X Blinking Green

Poor Signal Warning X Blinking Blue X Blinking Red

sehcniW elbaliavA

Seal 9.5rs / 12.5rs

(Buzzer in the control box)

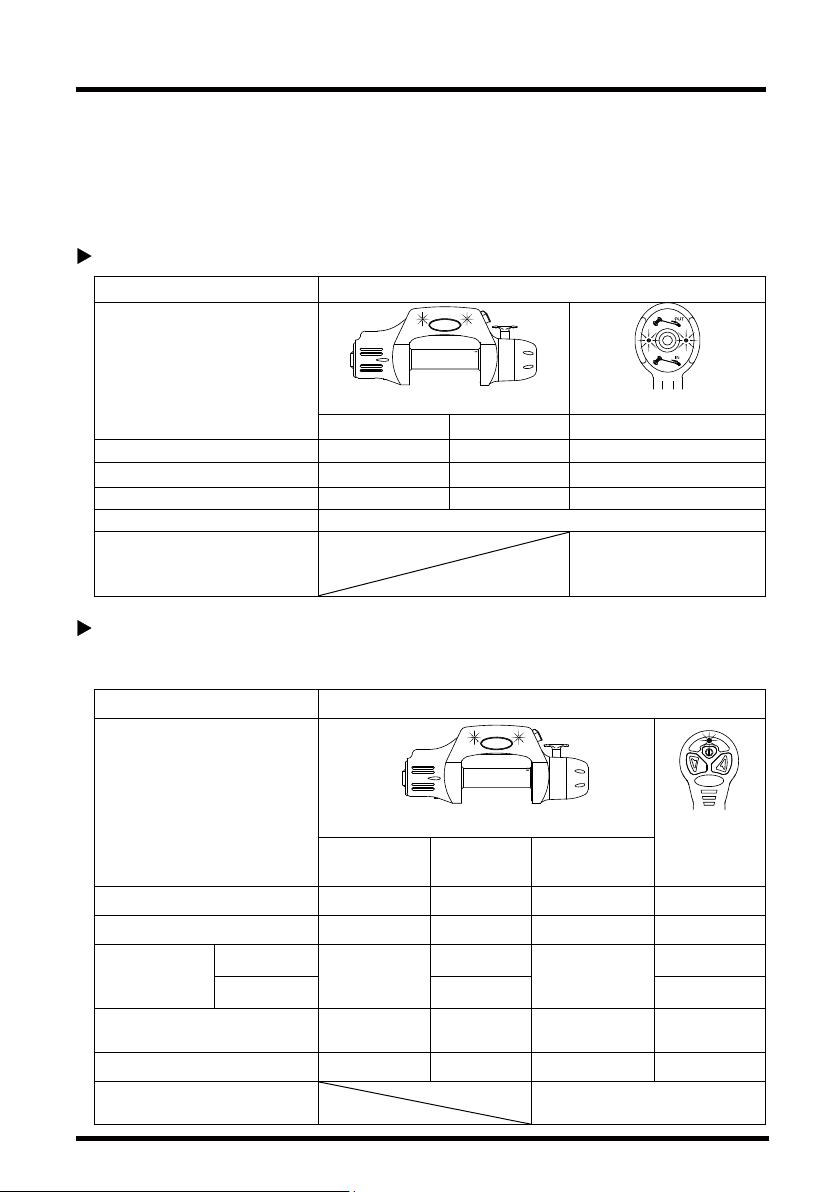

Control Indicator Guide

3

Wired Remote Control Module on the dual control modules

isr5.9 laeS hcniW elbaliavA

LEDs and buzzer on the bridge control box

LED & Buzzer

Left LED Right LED Buzzer

LEDs on the

remote control

Plug in Connector Green X X Green

Cable In/Out Operation Green X X Green

Motor Overheating Warning Red X

2 short Beeps

every 5 seconds

Red

Plug out Connector

LED turns off

sehcniW elbaliavA

Seal 9.5rs / 12.5rs

(Buzzer in the control box)

Remarks:

1. Green LED illuminates when the winch is operating under normal working conditions.

2. Red LED illuminates when the winch is operating when overheating of the motor. Stop operation

and allow winch to cool (Green LED)

3. The LEDs illuminate or the beeping buzzer alarms when the motor is overheating.

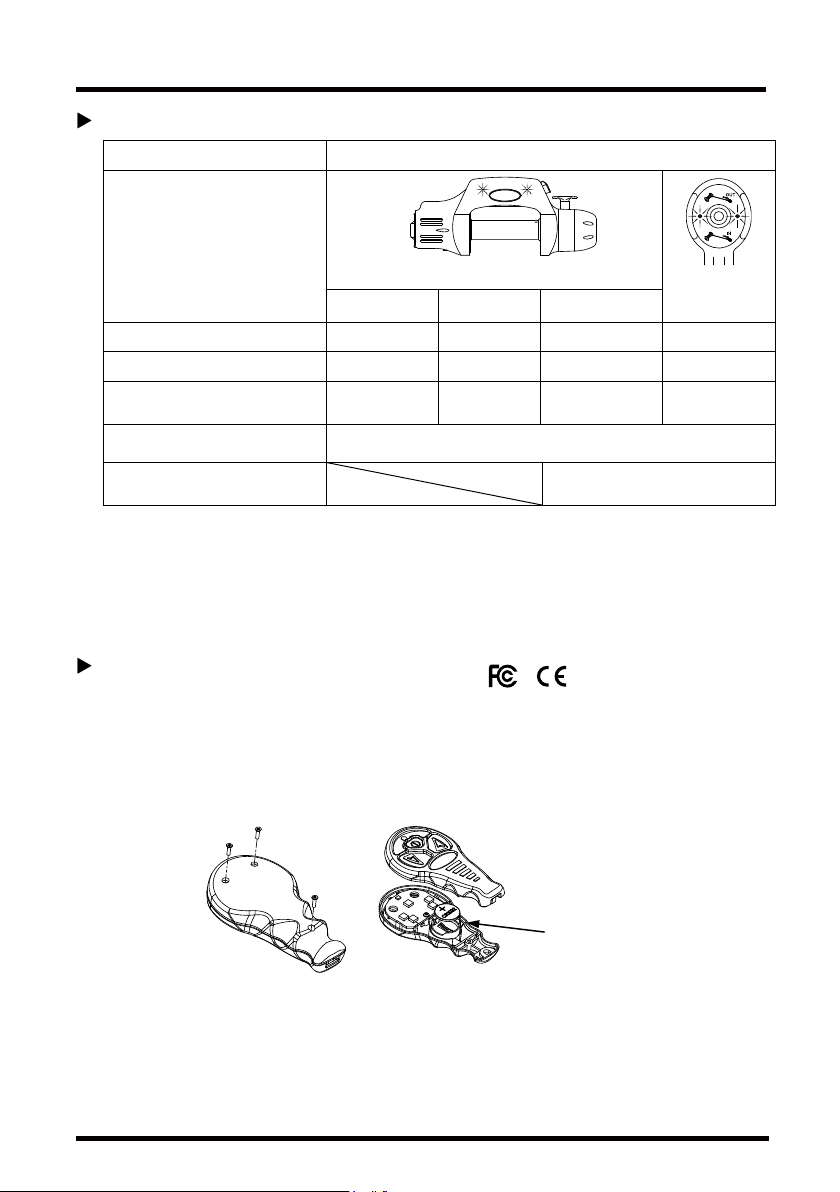

Wireless Receiver & Transmitter Operation

1. Replacing Battery

If the LED Indicator blinks Green, the battery is low and should be replaced.

a. Remove the three screws from the wireless transmitter.

b. Separate the top section and remove the old battery and dispose it.

c. Insert new lithium battery and join the top section with the bottom section.

d. Make sure to fasten the three screws.

2. First Installation/Re-programming the Receiver

The transmitter is programmed from the factory and under normal circumstances it won’t be

necessary to program it. Use the following proce

dures for any programming of the receiver.

a. Attach the red(+) and black(-) leads to battery set on the vehicle, then the buzzer beeps for 5

minutes and the Right LED on the bridge control box blinks Blue.

Lithium Battery: CR2032 (3V)

0678

Control Indicator Guide

4

b. Press and hold the Power Button for about 5 seconds, then the LED Indicator illuminates

Green permanently.

c. Press either Cable In Button or Cable Out Button for programming.

d. After the completion of programming, the buzzer sounds a long beep lasting for 5 seconds.

For Seal 9.5rsi winch, the Right LED turns off and the Left LED illuminates Green

permanently.

e. The process of the programming shall be completed within 5 minutes, if it fails to program,

turn off the power and restart the programming.

3. Start the Winch

․

For Seal 9.5rsi winch

Press and hold the Power Button for 5 seconds to start winch operation. The Left LED and

LED Indicator illuminate Green.

․

For Seal 9.5rs / 12.5rs winch

Press and hold the Power Button for 5 seconds to start winch operation. The LED Indicator

illuminates Green.

4. Shut down the Winch

a. Press and hold the Power Button for 5 seconds to stop winch function.

b. When operation of the winch is stopped for more than 5 minutes, the winch and the module

will turns off automatically. The Green LED Indicator also turns off.

5. Control Units

The wireless control module and remote control are compatible for activating the winch, but it

takes about a 10 second interval to exchange the wired remote control for the wireless control

module.

a. Blinking Red LED illuminate shows poor signal received.

b. The remote control can be used as a stand-alone, without the wired remote.

c.

If the motor is overheating, the Left LED of Seal 9.5rsi illuminates Red and the buzzer has 2

short beeps every 5 seconds until the temperature of the motor falls within the safety range.

d.

Only one remote can be programmed for each receiver.

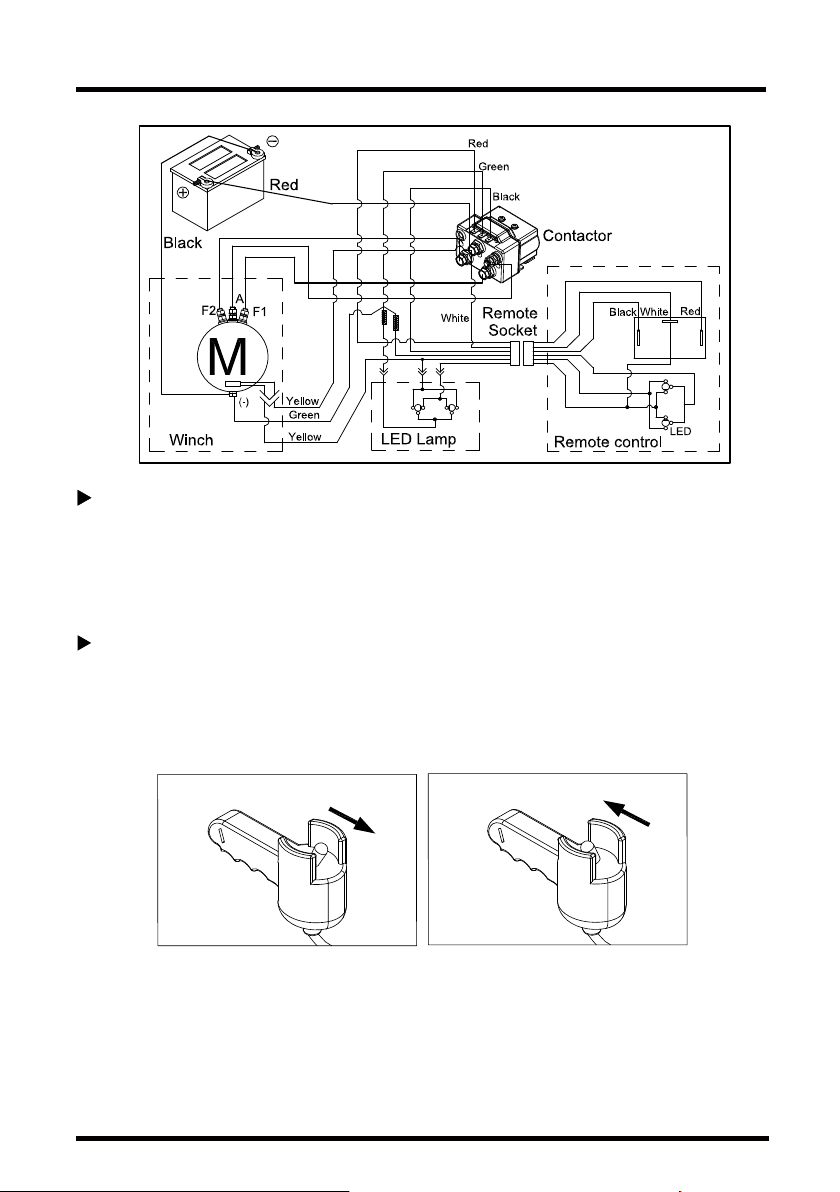

X Wiring Diagram

Attach the black lead firmly to the negative (–) battery terminal and red lead to the positive (+)

battery terminal. The voltage drop for the winch motor must not exceed 10% of the nominal voltage

of 12/24V DC.

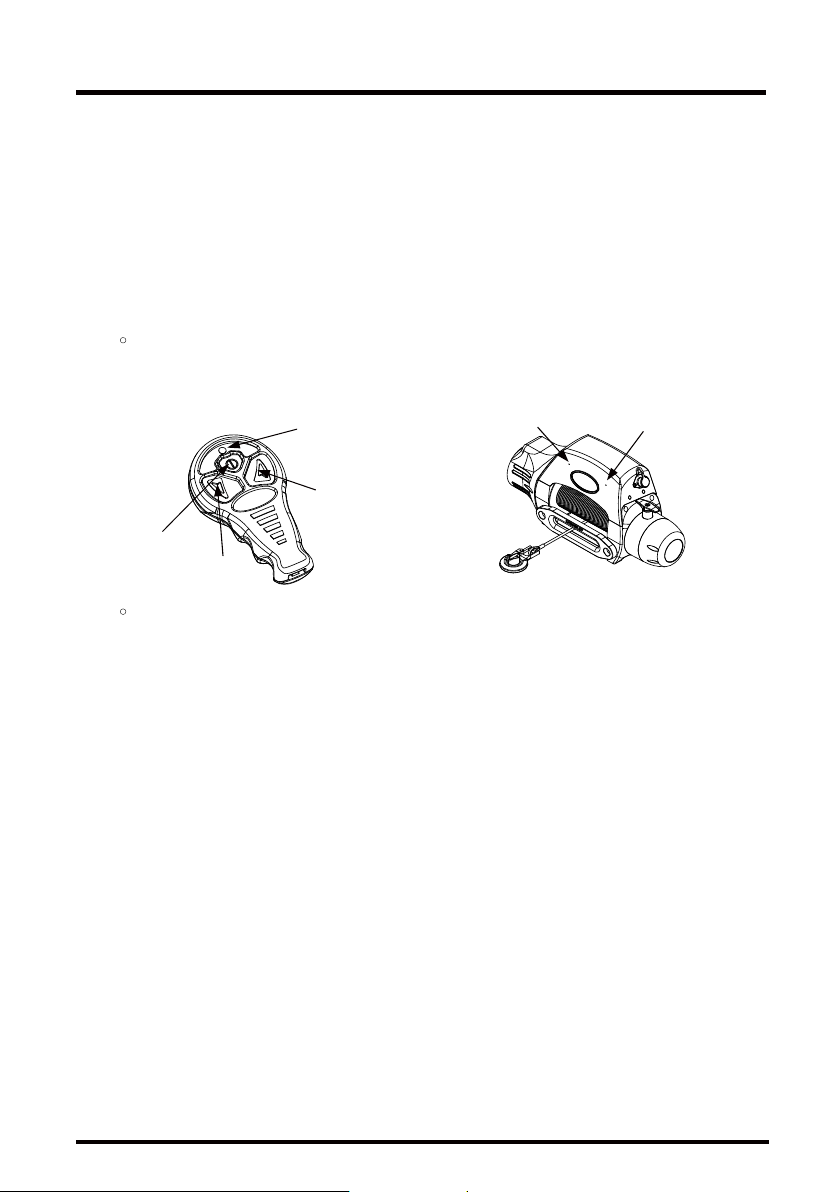

LED Indicator

Cable Out

Cable In

Power Button

Left LED

Right LED

Seal 9.5rsi

Control Indicator Guide

5

Battery Recommendations and lead size

A fully charged battery and good connections are essential for the proper operation of your winch.

The minimum requirement for battery is 650 cold cranking amp. The voltage drop for the winch

motor must not exceed 10% of the nominal voltage of 12/24V DC.

The battery lead shall be 2 gauge with 1.83 m in length at most, otherwise a considerable voltage

drop will be happened.

Cable-in / Cable-out Operation

For Wired Remote Control

1. To “ Winch or Cable - Out”, trigger → out

2. To “ Winch or Cable - In”, trigger ← in

3. To stop winching, release the trigger

For Wireless Control Module:

1. Press and hold the Cable In Button of the Transmitter for rope winding in operation.

2. Press and hold the Cable Out Button of the Transmitter for rope winding out operation.

3. To stop winching, release the Cable In or Cable Out Buttons.

Cable-Out Cable-In

Mounting Guide

6

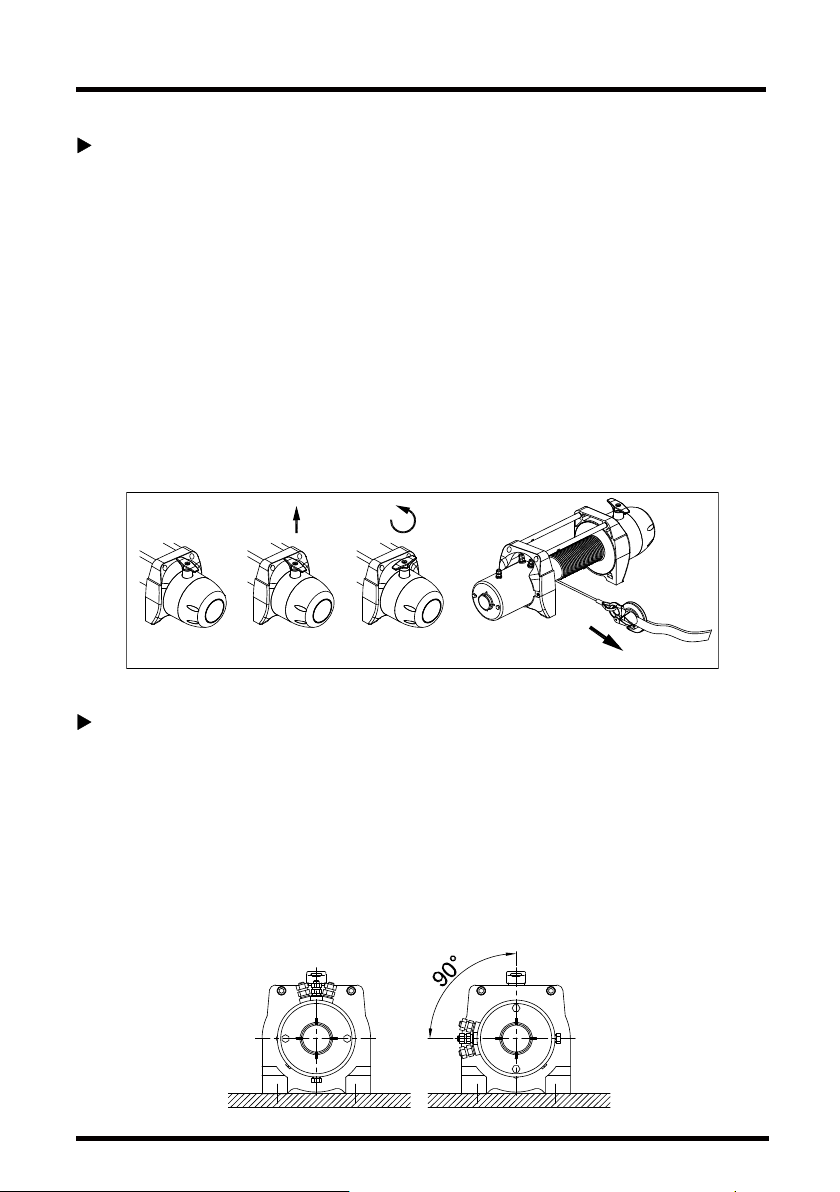

Clutch Function

1. The clutch allows rapid pay-out of the wire/synthetic rope for hooking onto a load or anchor

points and is operated by a clutch T-handle.

2. The clutch T-handle must be in the “Engaged” position before winching.

3. To disengage, lift the clutch T-handle up and turn it at the proper angle mentioned in the

mounting configurations chart below in a counter-clockwise direction to the “Disengaged”

position. Wire/synthetic rope can now free spool off the drum.

4. To engage, lift the clutch T-handle up and turn it at the proper

angle mentioned in the

mounting configurations chart below in a clockwise direction to the “Engaged” position.

5. If a clutch T-handle can’t be properly locked in the “Engaged” position, rotate the drum to help

the clutch device engage the gear train.

6. Wear gloves and use a hand saver strap when guiding the wire/synthetic rope off the drum.

7. Never disengage the clutch while wire/synthetic rope is under load.

Motor Repositioning

Change the motor mounting direction according to the following steps

1. Use a piece of 11 mm wrench and loose 2 pieces of screw..

2. Hold the motor to avoid any escape. Loose and take away 2 pieces of screw located at motor

edge place.

3. Pull the motor backward by 5mm for escaping the positioning pin and rotate the motor by 90

degree increments to the required position.

4. Re-assembly 2 pieces of screw to the motor edge place and tighten them after the motor and

position pin reaching their positioning p

laces.

(Disengage)(Engage)

Loading...

Loading...