Comeup 883423 User Manual

Utility Duty Winch

WARRANTY

Limited Lifetime Warranty for Mechanical Components

Limited One (1) Year Warranty for Electrical Components

Comeup Industries Inc. (COMEUP) warrants to the original purchaser that the mechanical

components of the COMEUP Utility Duty Winch will be free of defects in material and workmanship for

the lifetime of the winch and the electrical components will be free of defects in material and

workmanship for a period of one (1) year from the origin al date of purchase. All COMEUP mounting

kits and other accessories carry a one (1) year limited warranty against defects in material

workmanship.

This warranty applies only to the original purchaser of the winch. To obtain any warranty service,

the purchaser under this Limited Warranty is requested to advise COMEUP or its authorized

distributors on any claim. The purchaser must provide a copy of the p urchase receipt bearing the

winch serial number, date of purchase, owners name, email or Tel & Fax, address and purchaser

vehicle details. Any products that COMEUP determines to be accountable for defective will be

repaired or replaced or refund at COMEUP sole discretion without charge to buyer upon buyer’s

compliance with these procedures. In the event of repair or replace, purchaser must send the

defective winch or part, with freight prepaid, to COMEUP or its authorized distributor. And COMEUP

will send the serviced product back to purchaser on COMEUP’s cost. This warranty does not cover the

removal or reinstallation of the winch.

COMEUP takes the responsibility for COMEUP winch parts and components to be free from

defects in materials and workmanship, but the followi ng portions are hereby exc luded and dis claimed.

COMEUP or its authorized distributors may make reasonable charges for parts and labour for repairs

or resumption in the following portions not covered by this limited warranty.

(1). All warranties of wire rope and synthetic rope assemblies after initial use

(2). All warranties of fitness for a particular purpose

(3). All warranties of the product’s finish

(4). All warranties of merchantability

The limited warranty does not cover any failure that results from improper installation/operation,

third party part substitution, purchaser’s alteration or modification on C OMEUP winch. This warranty is

void when COMEUP serial number plate is removed or defaced.

COMEUP’s liability to the purchaser under the winch purchases for any loss or damage howsoever

and whatsoever arising shall not exceed the price of the initial winch purc hase receipt. COMEUP shall

not in any event be liable to the purchaser for any consequential and/or indirect loss or damage

whether for loss or for profit or otherwise, costs, expenses or other claims for consequential

compensation whatsoever and whether caused by negligence of COMEUP employees, distributors

and their employees or otherwise. COMEUP reserves the right to change product design without

notice. In situations in which COMEUP has changed a product design, COMEUP shall have no

obligation to upgrade or otherwise modify previously manufactured products.

Utility Duty Winch

.

WARNING

I. Safety Precaution

Precautions before using of winch are listing as follows:

Precautions at thetime of operation of winch are listing as follows:

Thank you for purchasing a Winch.

maintenance of the winch. All information in this publication is based on the latest

production information available at the time of printing. We reserve the right to make

changes without notice because of continued product improvement.

The winch has been designed to give safe and dependable service if operated according

to the instructions. Please read and understand this manual before installation and

operation of the winch. Careless winch operation can result in serious injury or property

damage.

When requesting information or ordering replacement parts, always give the following

information:

1. Winch model and voltage

2. Serial Number

3. Item. No. and Part Number

4. Part Description

1. The winch is a very powerful machine. Treat with extreme care and observe all

caution and warnings.

2. The winch is rated at the first layer of wire/synthetic rope on the drum for

intermittent-periodic duty.

3. The winch is not to be used to lift, support or otherwise transport personnel.

4. A minimum of five (5) wraps of steel wire rope and of ten (10) wraps of synthetic rope

around the drum is necessary to support the rated load.

5. Keep clear of winch, rope, hook, and fairlead while operating.

6. Wire/synthetic rope can break without warning. Always keep a safe distance from the

winch and rope while under a load

7. Failure to adequately align, support, or attach the winch to a suitable mounting base

could result in a loss of efficiency of performance or damage to the winch, wire rope

and mounting channel.

This manual covers operation and

The winch is designed to give safe and d ependable service of tr ouble-free operation. Pleas e read

and understand this Instruction Manual before installing your winch.

f

Confirm that the winch complies with the using conditions.

Because the maximum rope tensile force capable of loading decreases corresponding to the

increase of number of winding layers, please carry out rope winding according to the

instruction of this manual.

Don’t use rope that is unsuitable because of its construction, strength or having any defects.

Don’t use a hook or pulley block that is suited to the rope.

f

The operator of winch in some cases is required to hold qualifications according to applicable

laws and ordinances.

Prior to starting of use, carry out the daily checking without fail.

During use five(5) wraps of wire rope and ten (10) synthetic rope must remain on the drum at

all times. Even in the condition where the rope is feed out at most,

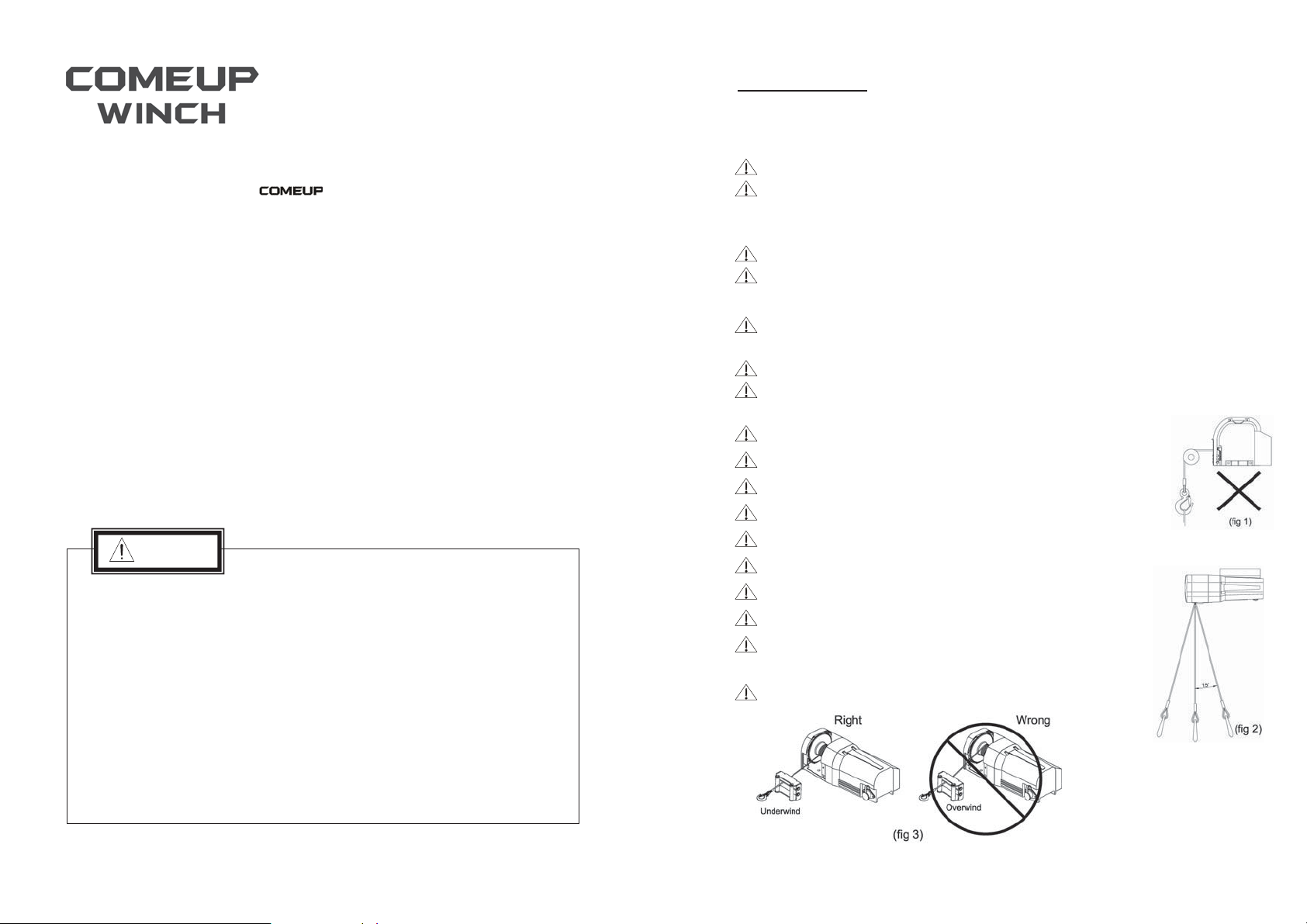

Do not use winch as a lifting device or a hoist for vertical lift (fig1).

Do not use winch to move people.

Do not exceed maximum line pull ratings shown. Do not shock load.

Keep hands clear of wire/synthetic rope.

Pull from an angle below 15 degree to straighten up the vehicle or boat (fig 2).

Run the engine during winching operations to keep battery charged.

Use leather gloves or a heavy rag when handling the wire rope.

Disconnect the remote switch from the winch when not in use.

When winching a heavy load, lay a heavy blanket over the wire/synthetic

rope near the hook end.

Always operate your winch in an underwound orientation only (Fig 3).

II. Winching Principles

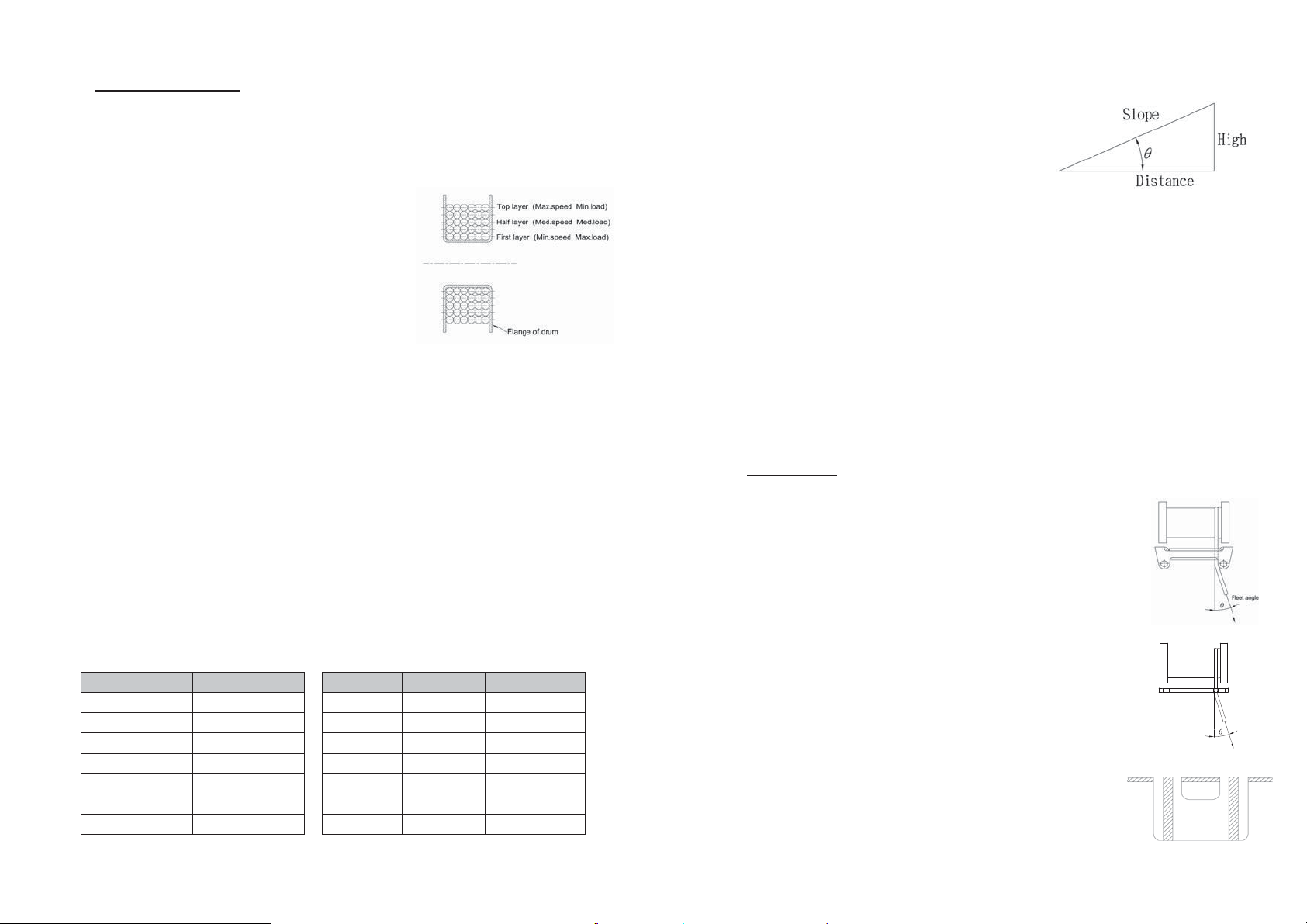

XCalculating Fleet Angle

X Load Rating

X Required Pulling Force

Surface Type Surface Drag (S) Gradient Angle (ș) Gradient (G)

X

SecuringAnchor Point

X Winching V.S.Hoisting. A pulling winch should not be used for lifting.

Pleaserefer to our websiteto view our full rang

e of lifting winches.

III. Accessories

X Roller Fairlead

X HawseFairlead

X Recovery Damper

Fleet angle

To obtain the best wire/synthetic rope service, the direction of pull will be on a horizontal within

±15 degrees and perpendicular to be centerline of th e winch drum within ±5 degrees. If the fleet

angle is bigger than the recommended angles, a good spooling cannot be obtained as the rope

will spoon onto one side of the rope drum and possible damage to the rope or winch.

Load and speed varies according to how much

wire/synthetic rope is on the drum. The first layer of rope on

the drum delivers the slowest speed and the maxim um loa d.

A full drum delivers the maximum speed and the minimum

load.

For this reason, all utility duty winches are rated at their first

layer capacities.

You need a winch powerful enough to overcome the weight of your vehicle with the added

resistance caused by the obstacle, moving water, mud, snow, sand or on a steep hill.

As a general guide, you need a winch with a maximum lin e pull of at least 1.5 ti mes great er than

the gross vehicle weight.

For example, if a vehicle weighing 1,200 kg is winc hed up an incline by 100% on the marsh road,

the above formula would be used as follows:

Where Wt: 1,200 kg, S: 0.52 G: 0.71

RPF = (Wt X S) + (Wt X G)

= (1,200 kg X 0.52) + (1,200 kg X 0.71)

= 624 kg + 852 kg

= 1,476 kg of effect required to recover the vehicle.

A slopeof 10% is a rise of one meter

in ten meters (High / Distance)

When choosing an anchor point, select a safe and firm point such as a tree, stump or rocks. If

using a winch to retrieve another vehicle, the rescue vehicle is considered the anc hor point and

should be made secure.

The anchor point must be strong enough to hold the gross weight of the vehicle and be

positioned to keep the fleet angle between the centre of the anchor poin t and the wire/synthetic

rope maintained less than 15°. Always use a tree trunk protector strap to prevent ring barking the

tree and damaged to the wire rope.

There are three factors listed that influence the line pull effect required to recover the vehicle.

The values and calculations in this section are approximate and are for reference only.

a). Gross vehicle weight

b). Type of the surface to be traversed

c). Gradient to overcome

In recovery and loading the winch is used to pull something, the required pul ling force (RPF) can

be calculated according to the formula:

RPF = (Wt X S) + (Wt X G)

Where: Wt = The gross vehicle weight

S = The type of the surface to be traversed

G = The gradient to overcome

Metal 0.15 5% 3° 0.06

Sand 0.18 10% 6° 0.11

Gravel 0.20 20% 11° 0.2

Soft Sand 0.22 30% 17° 0.3

Mud 0.32 50% 26° 0.44

Marsh 0.52 70% 35° 0.58

Clay 0.52 100% 45° 0.71

The use of 4 ways roller fairlead can eliminate the contacting

friction because the fairlead rollers contact with the wire/synthetic

rope. But the fairlead does not insure the wire/synthetic rope will

wind onto the drum in an orderly m anner. The proper fleet angle

within 15° must be maintained for the wire/synthetic rope to wind

onto the drum in an orderly manner. If the proper fleet angle is not

maintained, it can result in damage to the winc h and wire/synthet ic

rope.

The basic hawse fairlead is designed to guide the synthetic rope to

and from the winch drum. Do not use cast steel hawse fairleads as

they have sharp edges and they do not have enough radius for the

rope to bend over.

A recovery damper is a safety device designed to help eliminated

the possibility of injury or property damage in the event of a

wire/synthetic rope failure. Place in the middle third of a live rope.

The damper can help absorb the e ne rgy in the rope and reduce the

likelihood of injury or damage.

F

Loading...

Loading...