Page 1

www.cometsystem.com

User‘s Guide

U0110

U0111

U0121

U0122

U0141

U3120

U3121

U3631

U4130

U3430

U4440

U0541

U5841

U6841

U7844

USB Datalogger

Page 2

2 IE-LGR-Uxxxx-01

© Copyright: COMET System, s.r.o.

This User’s Guide may not be copied, and its contents may not be changed

in any way without explicit consent of COMET System, s.r.o.

All rights reserved.

The COMET System, s.r.o. company is continuously developing and

improving its product. COMET System, s.r.o. reserves the right to carry out

technical changes in equipment or product without any previous notice.

Contact address of this device’s producer:

COMET SYSTEM s.r.o.

Bezrucova 2901

756 61 Roznov pod Radhostem

Czech Republic

www.cometsystem.com

Page 3

IE-LGR-Uxxxx-01 3

List of contents

SAFETY MEASURES AND UNAUTHORIZED MANIPULATIONS ............. 6

GUIDE TO INSTALLATION AND USAGE OF THE DEVICE ...................... 7

Installing the datalogger, placing the probes ................................. 7

Device set-up ................................................................................ 8

Running the device ....................................................................... 9

Device disposal procedure ............................................................ 9

OPERATING THE DATALOGGER FROM THE KEYPAD ........................ 10

Displaying the device data .......................................................... 10

Menu Options ............................................................................. 14

MODELS PRODUCED ............................................................................. 15

U0110 One-channel thermometer ............................................... 15

U0111, U0121, U0141 One-, two- or four- channel thermometer for

external probes ........................................................... 15

U0122 Two-channel thermometer with external probe ................ 16

U3120 Compact thermometer - hygrometer ................................ 16

U3121 Thermometer – hygrometer for external probe ................ 17

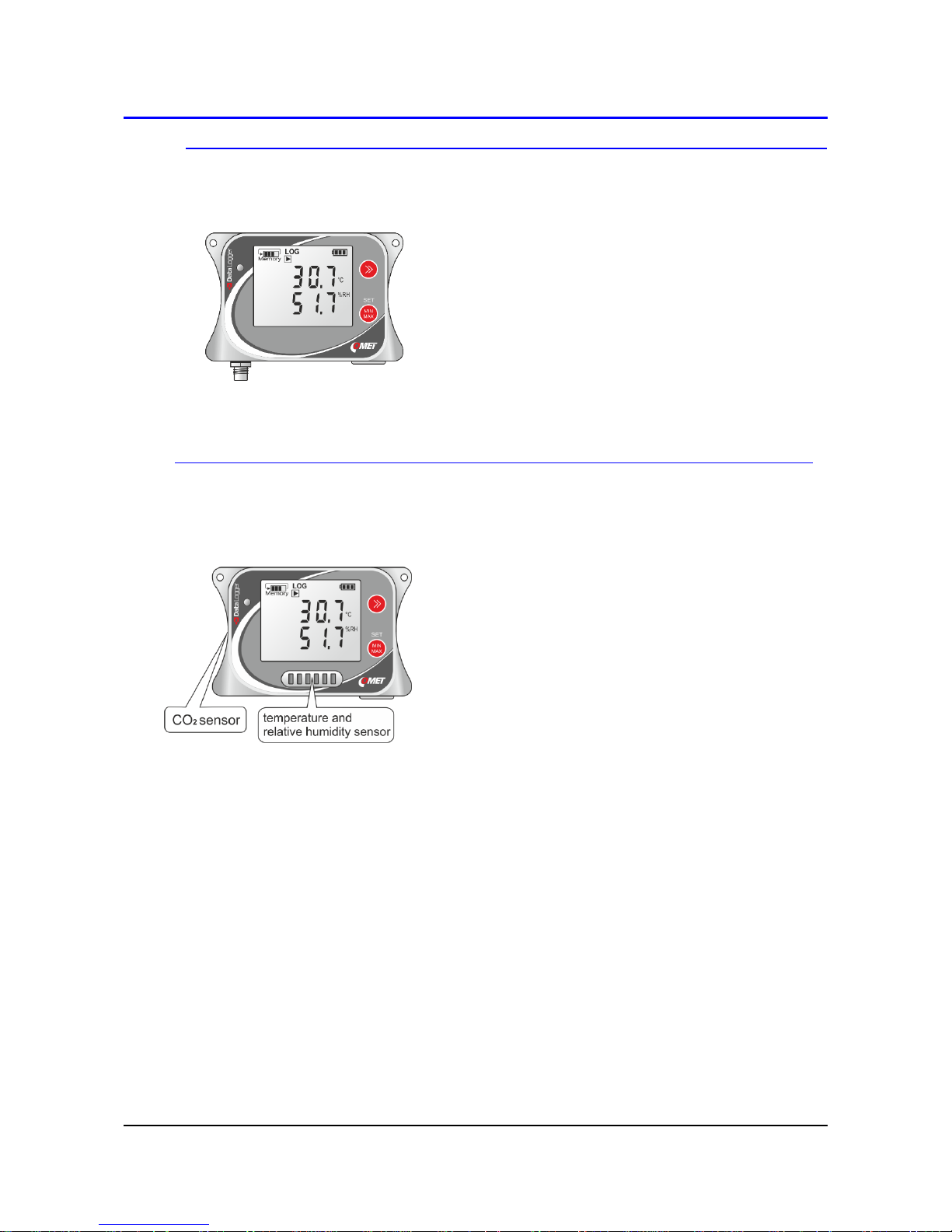

U3430 Compact thermometer – hygrometer - CO2 concentration

meter .......................................................................... 17

U3631 Compact thermometer – hygrometer with optional external

temperature probe ...................................................... 18

U4130 Compact thermometer - hygrometer - pressure gauge .... 19

U4440 Compact thermometer – hygrometer - pressure gauge -

CO2 concentration meter ............................................. 20

U0541 Two-channel thermometer for external probes with 2 inputs

0 - 10 V ....................................................................... 21

U5841 Datalogger with 3 inputs 0 - 10 V and 1 binary input ........ 22

U6841 Datalogger with 3 inputs 0 - 20 mA and 1 binary input ..... 23

U7844 Two-channel binary-input counter .................................... 24

COMET VISION PROGRAM .................................................................... 25

SETTING UP THE DEVICE ...................................................................... 26

How to set up the device by means of a program ........................ 26

The device setup from a program (Configuration) ....................... 26

APPLICATION NOTES ............................................................................. 32

RECOMMENDATIONS FOR OPERATION AND MAINTENANCE ........... 34

TECHNICAL PARAMETERS .................................................................... 37

Power supply .............................................................................. 37

USB communication interface ..................................................... 38

Measurement, data storage and real time circuitry ...................... 38

Parameters of datalogger inputs ................................................. 39

Operating and storage conditions ............................................... 51

Mechanical properties ................................................................. 51

ANNEXES ................................................................................................ 52

Annex 1: Selected error messages of the device ........................ 52

Annex 2: Connection of the Pt1000/E series probe connector ... 53

Annex 3: Connection of the Digi/E probe connector (female) ..... 54

Page 4

4 IE-LGR-Uxxxx-01

Annex 4: Accuracy of the dew-point temperature measurement 54

Annex 5: Connecting block ........................................................ 54

Introduction

This datalogger is designed for autonomous measurements and recording of

physical and electrical data, with the data recording interval from 1 s to 24 h.

The inputs and ranges of quantities to be measured are determined by the

model type the user has bought. The user cannot modify them. This portable

device can be mounted in a fixed-position. To set up datalogger, a PC with

a USB interface is needed.

This device allows:

- to measure and process input data coming from internal or external

sensors, binary inputs, counters and voltage or current inputs.

- to detect and log minimum and maximum values (existing since their last

manual resetting) of each quantity,

- to display the measured values on an LCD display. Some features can be

controlled by two push buttons situated next to the display (device

switching off and on, deactivation of alarm signalling, Min/Max value

resetting),

- to store an autonomous chronological record of measured values in

internal non-volatile memory. The values to be collected can be measured

at the instant of recording or as average or min/max values detected

during the recording interval. Recording can be performed continuously or

at the alarm time only. The recording mode can be also set optionally as

non-cyclic to stop at the memory filling up, or as cyclic. In this mode the

originally recorded values will be overwritten by fresh ones after the

memory unit getting filled up.

- to set up two alarm signalling limits for each quantity to be measured. The

alarm signalling can be realised visually, optionally by a symbol appearing

on the display or by a short blink of an LED, or acoustically

- to be supplied in autonomous manner from an internal primary lithium

battery, CO2 sensor models are powered by an internal Li-Ion accupack

that can be charged using a conventional USB charger. Other models can

not be charged.

- to communicate with a computer by means of a USB interface (all device

settings, recorded data downloading, and online monitoring). To

communicate, the datalogger utilises the HID USB standard, which does

not require additional controllers to be built into the PC.

Page 5

IE-LGR-Uxxxx-01 5

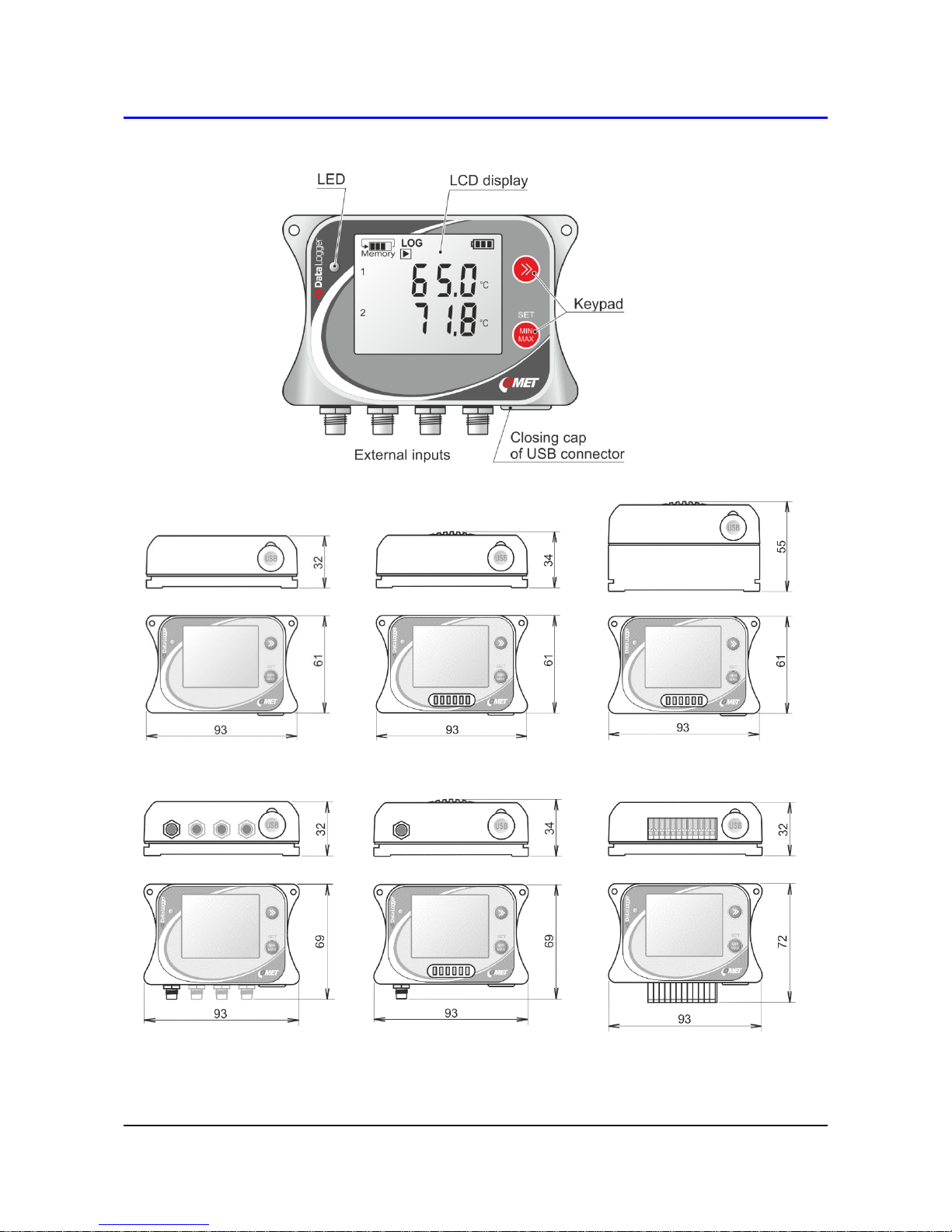

General view of a Uxxxx series datalogger (U0141 model):

Dimensional drawing:

U0110 U3120, U4130 U3430, U4440

U0111, U0121, U0122 U3631 U0541, U5841

U0141, U3121 U6841, U7844

Page 6

6 IE-LGR-Uxxxx-01

Safety measures and unauthorized manipulations

Read the following safety directions carefully before putting the device into operation.

Follow these instructions when using the device!

• Operating and storage conditions. Observe the recommended operating and storage

condition as quoted in the Technical parameters. Models with a CO2 sensor containing an internal

lithium-ion accupack should not be exposed to temperatures above 60 °C Do not expose the

device to direct radiation of heat sources and sun.

• Fire and explosion hazard. It is not allowed to use this datalogger within hazardous areas,

especially those endangered by a potential explosion of combustible gases, vapours or dust.

• Device cover. Do not operate the datalogger without the cover. Proceed always exactly

according to instructions that are given later in this User’s guide.

• Aggressive surroundings. Do not expose this device to any kind of aggressive surroundings,

to chemicals or mechanical shocks. Use soft tissue for cleaning. Do not apply solvents or similar

aggressive agents.

• Battery damage. Should the battery casing get damaged or should the whole device get

destroyed, carry it outside the fire, high temperature or water affected area to a safe fire-protected

place. Protect yourself and the environment against escaping gases and against being soiled

with the battery electrolyte.

• Failures and servicing. Do not try to repair the device yourself. If the device shows signs of

unusual behaviour, screw off the rear cover to remove battery or disconnect the accupack

connector. Avoid the removed battery contacting any metallic parts. Any repairs, including

accupack exchange by models with a CO2 sensor, may be carried out by suitably instructed

service personnel only. Contact the distributor you have bought the device from.

• Accumulator charging. Only models with internal CO2 sensors can be charged. Use the

charger that has been recommended to charge the accumulator. During the charging procedure

the device has to be located in an indoor room with a relative humidity (RH) up to 85 %. The

charging will proceed at an indoor temperature ranging between 0 °C and +40 °C.

• Protection against water and dust. The device will be protected against water and dust only

when all connectors are duly tightened, and the USB connector is provided with a closing cap.

The input connectors that are not used have also to be provided with closing caps.

• Recommended accessories. Use only accessories that are recommended by the producer

Page 7

IE-LGR-Uxxxx-01 7

Guide to installation and usage of the device

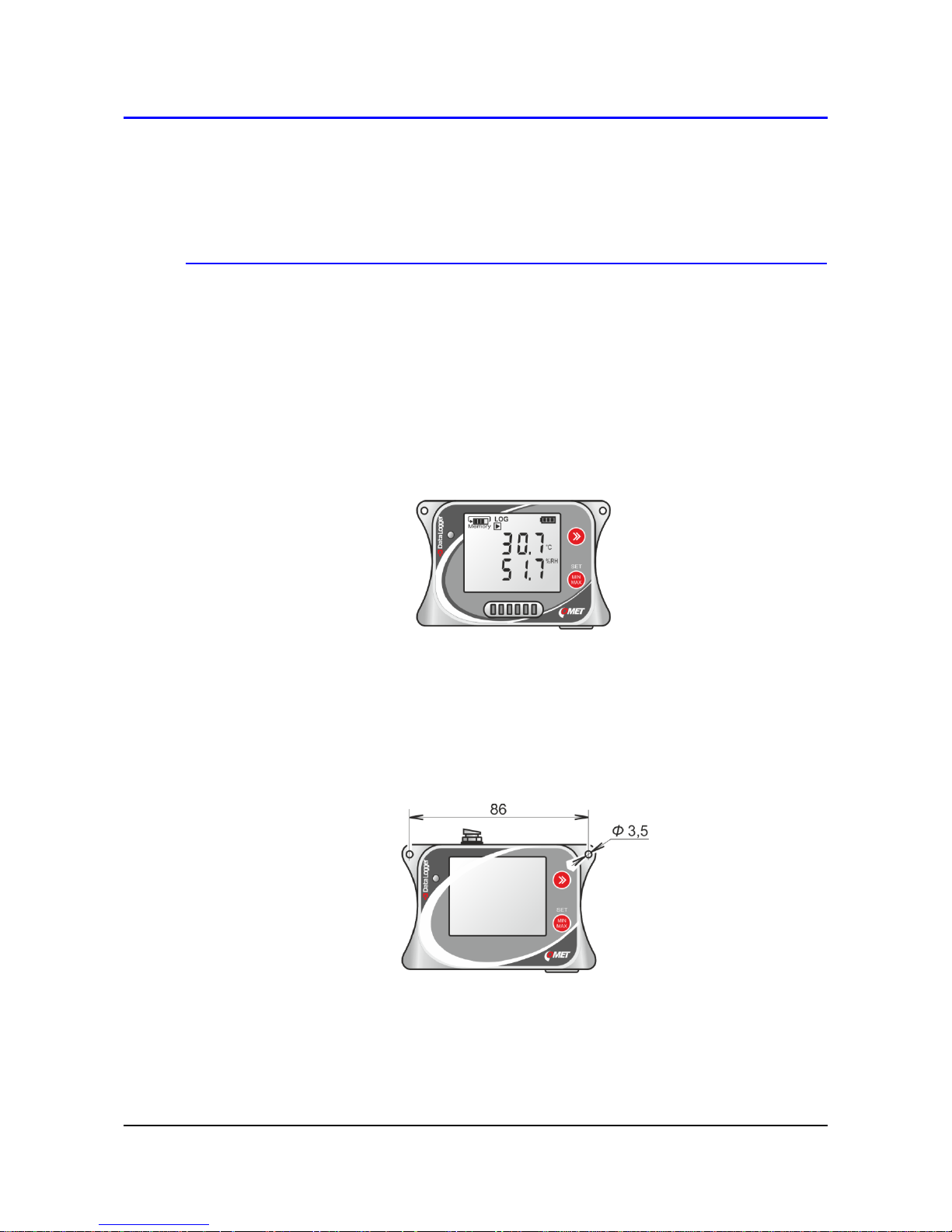

Installing the datalogger, placing the probes

• Choose a suitable location for installing the device - bear in mind that

the environmental conditions should be concordant with the Operating

conditions. Do not situate the device near sources of electromagnetic

interference.

• Recommended working position - for models with internal humidity

sensor (U3120, U3631, U4130, U3430 and U4440) with USB connector

down, for others any:

• This device may be operated as a portable one. In this kind of operation

avoid the device falling. Try to maintain the proper working position.

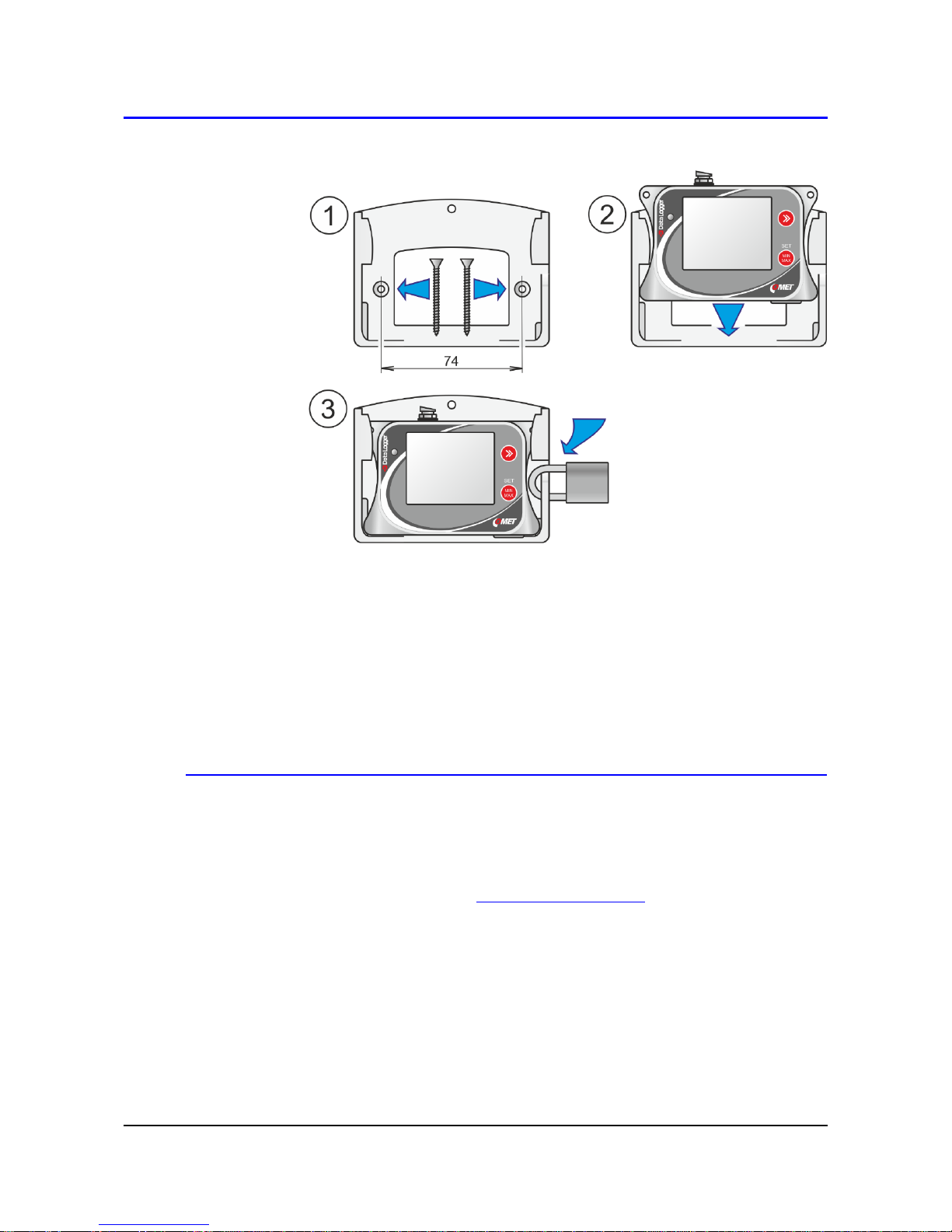

• You can screw the device on the wall or some other solid base

Page 8

8 IE-LGR-Uxxxx-01

• You can fix the device on the wall with the aid of a lockable holder

LP100 (optional accessory)

• Probe installation and cable routing - observe the installation

instructions, realize the recommended operating positions, avoid electric-

power distribution systems. See the chapter „MODELS PRODUCED“ for

more information.

• For the U3120, U3631, U4130, U3430 and U4440 device remove any

transport transparent foil from the front panel (otherwise it would prevent

air access to internal sensors)

Device set-up

• Connect the appropriate probes and signal leads to the device. For

more information refer to the chapter „MODELS PRODUCED“.

• Install the COMET Vision software into your computer - is available

for free on the address www.cometsystem.com.

• Run COMET Vision software

• Connect the device to the computer - on the datalogger side, use a

USB cable provided with a USB-C terminal.

• Setting up the device - with the aid of the COMET Vision program, set

up the device identification, the names of the points to be measured, the

recording mode, the alarms and there signalling.

• For more information, refer to the chapter „SETTING-UP THE DEVICE“.

Page 9

IE-LGR-Uxxxx-01 9

Running the device

• After the set-up - Disconnect the device from the computer and close the

USB connector with a closing cap. Check that all connectors are tightened

properly. The device may be operated with a permanently connected USB

cable. In this case the ingress protection will be reduced to IP 20.

• Operating the device by means of keys - In the main display mode you

can switch over between individual channels and the display mode

Current / minimum / maximum values by means of the keys. By pressing

a certain key combination, you will enter a menu in which you will be able

to switch the device on or off, to delete the Min/Max values and to disable

the alarm signalling. For more information, refer to the chapter

„OPERATING THE DATALOGGER FROM THE KEYPAD“.

• Charging the batteries - applies only to models with a CO2 sensor

(contains Li-Ion accupack), other devices cannot be charged. An internal

charger will be activated immediately after connecting the USB charger or

after connecting the datalogger to the computer. The datalogger contains

an intelligent charging circuitry evaluating the battery condition and

internal temperature. Charging time depends on the current battery

discharge status The battery charging process will be initiated only in the

case that the battery voltage is low and the internal temperature ranges

between 0 °C and 40 °C. Use the recommended charger type only. During

the charging period the ingress protection is reduced to IP 20; therefore,

do the charging under room (or similar) conditions only. If the battery is

very low, the charging process may be terminated with an error message.

In such a case contact the datalogger vendor to apply for battery

replacement. During the battery charging period the internal temperature

of the device may be slightly raised, which can, for a short period of time,

adversely influence the measurement values of the internal sensors.

Therefore, the charging speed with the power on is deliberately slowed

down to avoid excessive measurement influence. If you want to charge

the device as soon as possible, turn it off first. When the device is turned

off, the fast charging mode is automatically activated. Fully charged

battery is indicated on the display of the device usually within 6 hours.

• Maintenance and regular checks - for a reliable functioning of the device

it is advisable to perform its regular check-ups. For more details refer to

„RECOMMENDATIONS FOR OPERATION AND MAINTENANCE“.

Device disposal procedure

Screw-off the rear cover of the datalogger, take out the battery. The device

is disposed of as electronic waste. The battery must be disposed of as

hazardous waste.

Page 10

10 IE-LGR-Uxxxx-01

Operating the datalogger from the keypad

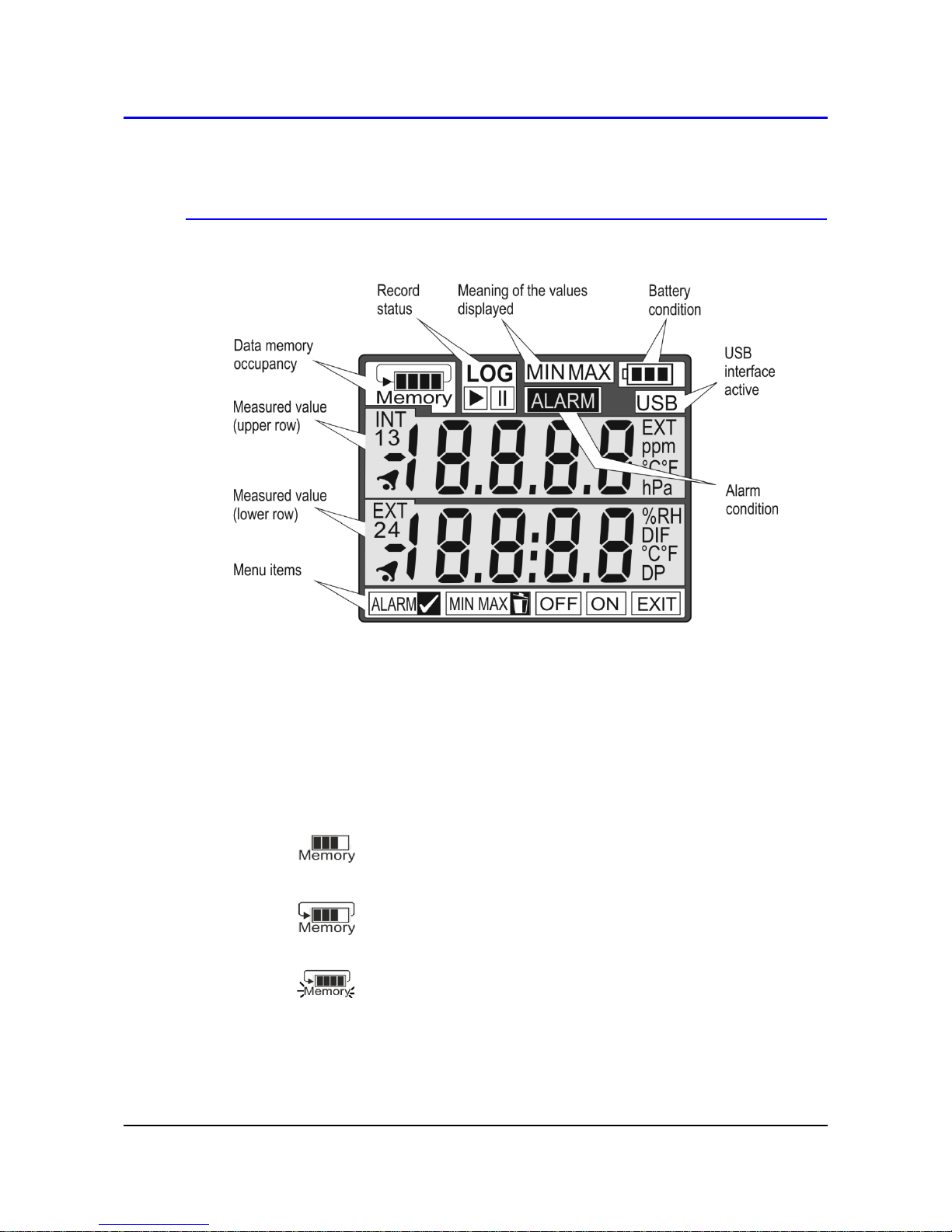

Displaying the device data

Data memory occupancy - this display section offers information about the

current condition of the free space existing in the data memory. The blinking

of the Memory symbol indicates that the preset memory occupancy limit has

been exceeded. This limit can be set up in the device’s configuration. Several

actions can be assigned to it (optical and acoustic signalling).

The memory occupancy is about 75 %, the device is in the non-

cyclic recording mode, i.e. the recording will be stopped as

soon as the memory capacity is full.

The memory occupancy about 75 %, the device is in the cyclic

recording mode, i.e. as soon as the memory capacity is full, the

oldest data will be overwritten.

The memory occupancy 100 %, the device is in the cyclic

recording mode. The preset memory occupancy limit has been

exceeded (The Memory symbol is blinking).

Record status - offers information on whether the recording is ON and

whether it is just running.

Page 11

IE-LGR-Uxxxx-01 11

A continuous recording with a preset interval is ON and running.

The recording is ON in the device and it is running at present. This

kind of display is utilized, when the record activity is dependent on

the alarm or the external input condition.

The recording is ON in the device but it is not running at present.

For instance, the rrecording is ON during an alarm only, and there

is no alarm just now. Or, a recording is ON that is controlled by an

external input which not active at the moment.

The LOG symbol is not displayed: The recording is OFF in the

device. The recording is not allowed in any channel in the device’s

configuration.

Meaning of the values displayed - this item specifies the meaning of the

measured values displayed in the two main rows. Beside the currently

measured values the device will also evaluate the minimum and maximum

values from their last resetting by the user. If the device is OFF and has not

been running for some time, then, after it is turning ON, the value of Min /

Max is then set to the values before switching OFF. It can be preset in the

device configuration, whether and in what manner these Min/Max values

will be displayed by the device. Remember that the Min/Max in question are

different from those being recorded.

Neither MIN nor MAX is displayed. You can see values that

have been currently measured.

In both display rows you can see the minimum values measured

since their last resetting by the user.

In both display rows you can see the maximum values measured

since their last resetting by the user.

Alarm condition - this item provides instant information that at least one of

the alarms which have been preset is active. Alarms can be generated by

exceeding the limits that have been preset in individual channels. Moreover,

they can notify of a device failure. In the device configuration you can preset

which conditions should be considered as alarm generating. By means of the

upper key you can easily browse through the values measured in all device

channels (if enabled in device configuration). In the case that the value is

preceded by a bell-like icon, the preset limits (alarms) have been exceeded

in this channel.

Page 12

12 IE-LGR-Uxxxx-01

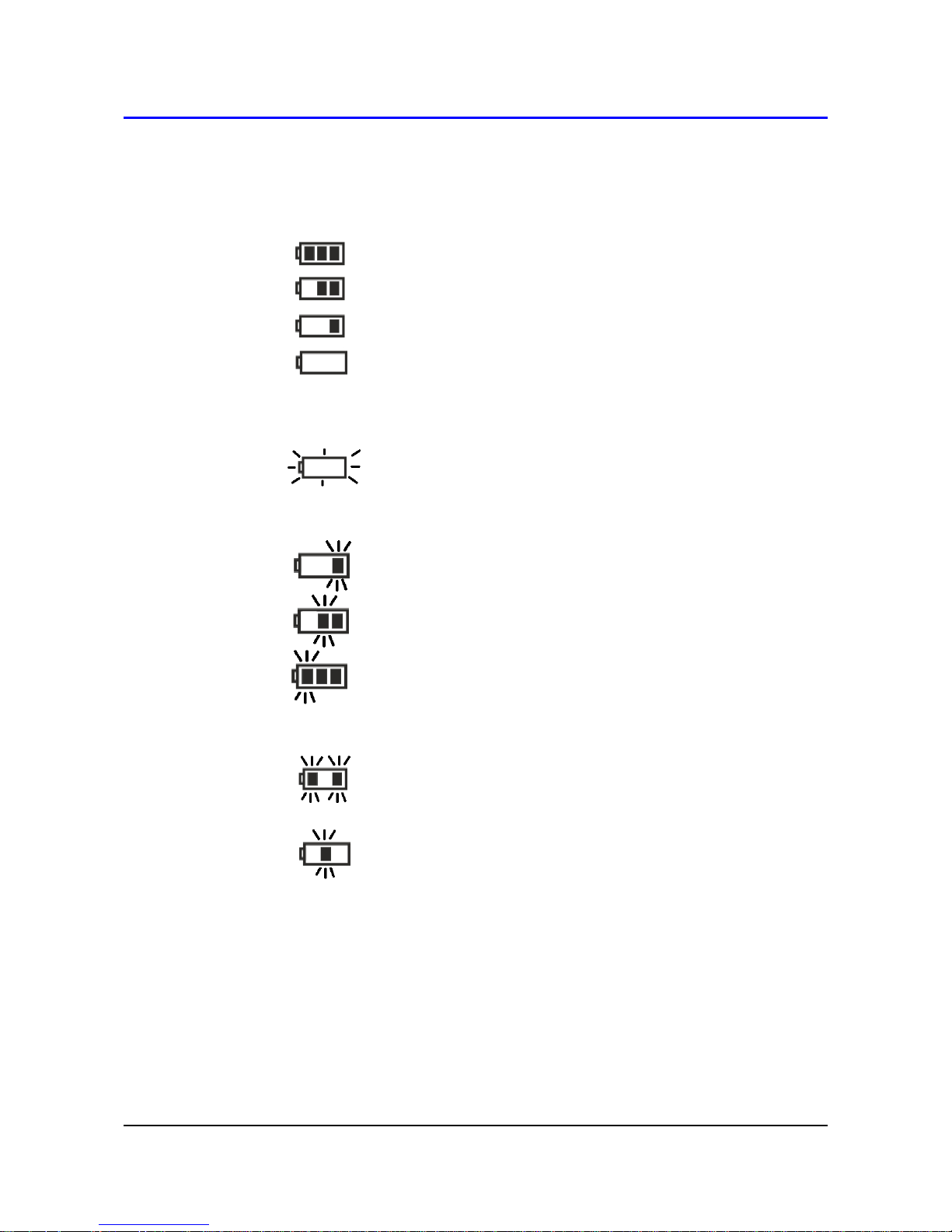

Battery condition - this symbol provides overview information about the

current battery charging condition. The charging is indicated by flashing one

of these symbols.

Battery conditions during battery operation of the device:

Fully charged battery

Partly discharged battery

Heavily discharged battery

Totally discharged battery, the device will be switched OFF.

Battery conditions with a charger connected to the battery:

Blinking symbol of an empty battery. There was a deep discharge

of the battery, the charger is attempting to recover battery. If this

condition persists for a long time and the standard charging

process is not renewed, contact your service department. The

battery will have to be replaced.

Indications of individual charging steps when the charging

process takes place in a standard way. If the display shows the

symbol of a full battery, the battery is fully charged and the

charger can be disconnected.

A failure has been detected during charging and the charging

process has been broken off. Try to remove the failure by

disconnecting and reconnecting the charger. If the problem

persists, call the service.

Wait, the charger performs internal testing, or the temperature

inside the device is not within the allowed charging range (0 to 40

°C).

USB interface active – the icon indicates that the device has been

connected to the computer.

Measured value (upper and lower row) - the currently measured value(s)

(or the Min/Max values) are displayed, if the corresponding symbols in the

upper display section are illuminated. The unit name and the measured value

symbol (1, 2, 3, 4, INT, EXT) are preset by the manufacturer, the user cannot

change them. In addition, it is factory preset whether the measured value of

a particular channel will be displayed in the lower or upper display unit row.

On the other hand, the user has many possibilities to adjust the appearance

Page 13

IE-LGR-Uxxxx-01 13

and behaviour of individual „screens“. Controlling them can take place only

manually by the aid of push buttons situated beside the display unit. The

upper push button serves to toggle between the measured values („the

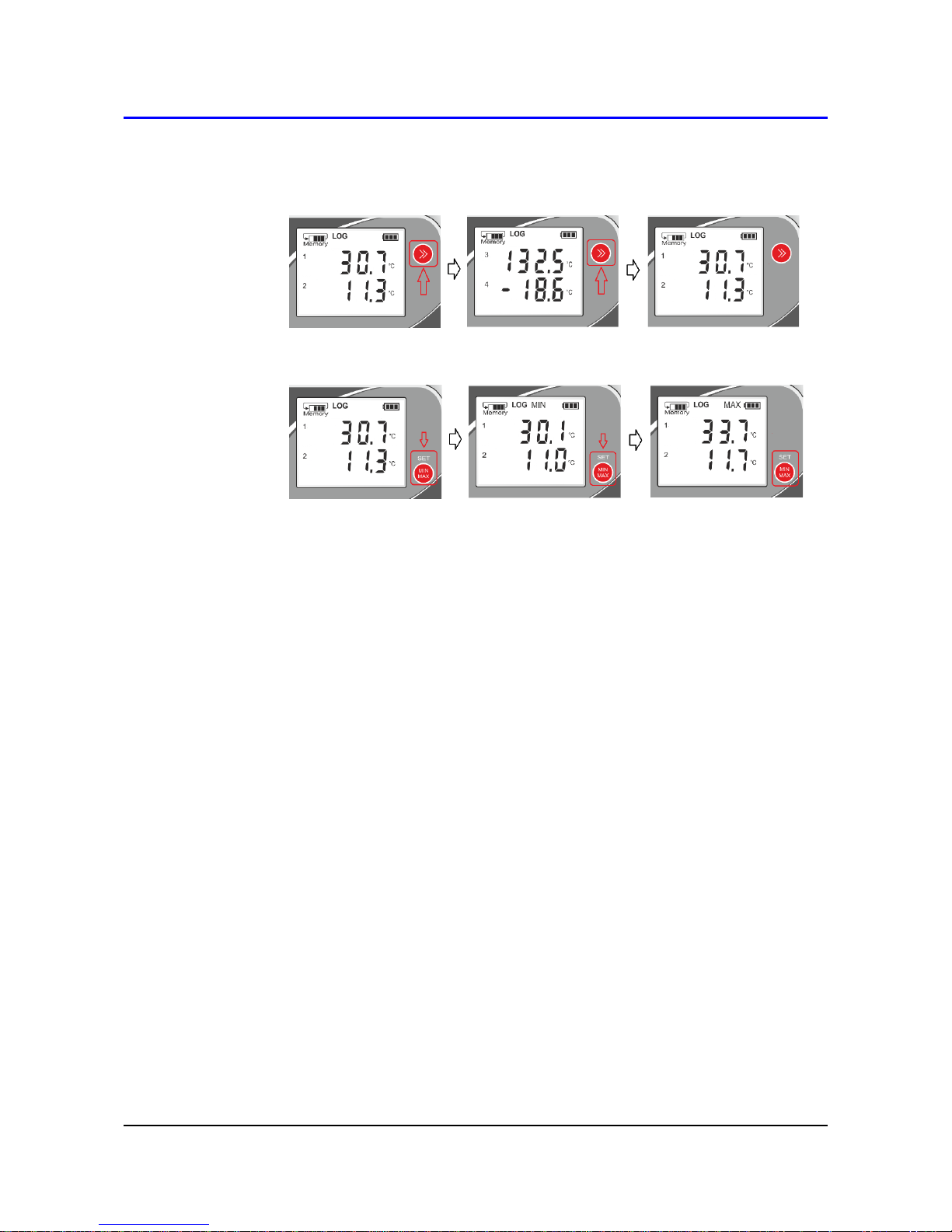

screens“):

The lower push button serves to toggle between the currently measured

values and the Min/Max values:

The device can also be set up to toggle the „screens“ automatically, in for

about 5 sec interval. The cycle can be interrupted by pressing a key. If you

do not want to use the keypad, you can disable it in the device settings.

Page 14

14 IE-LGR-Uxxxx-01

Menu Options

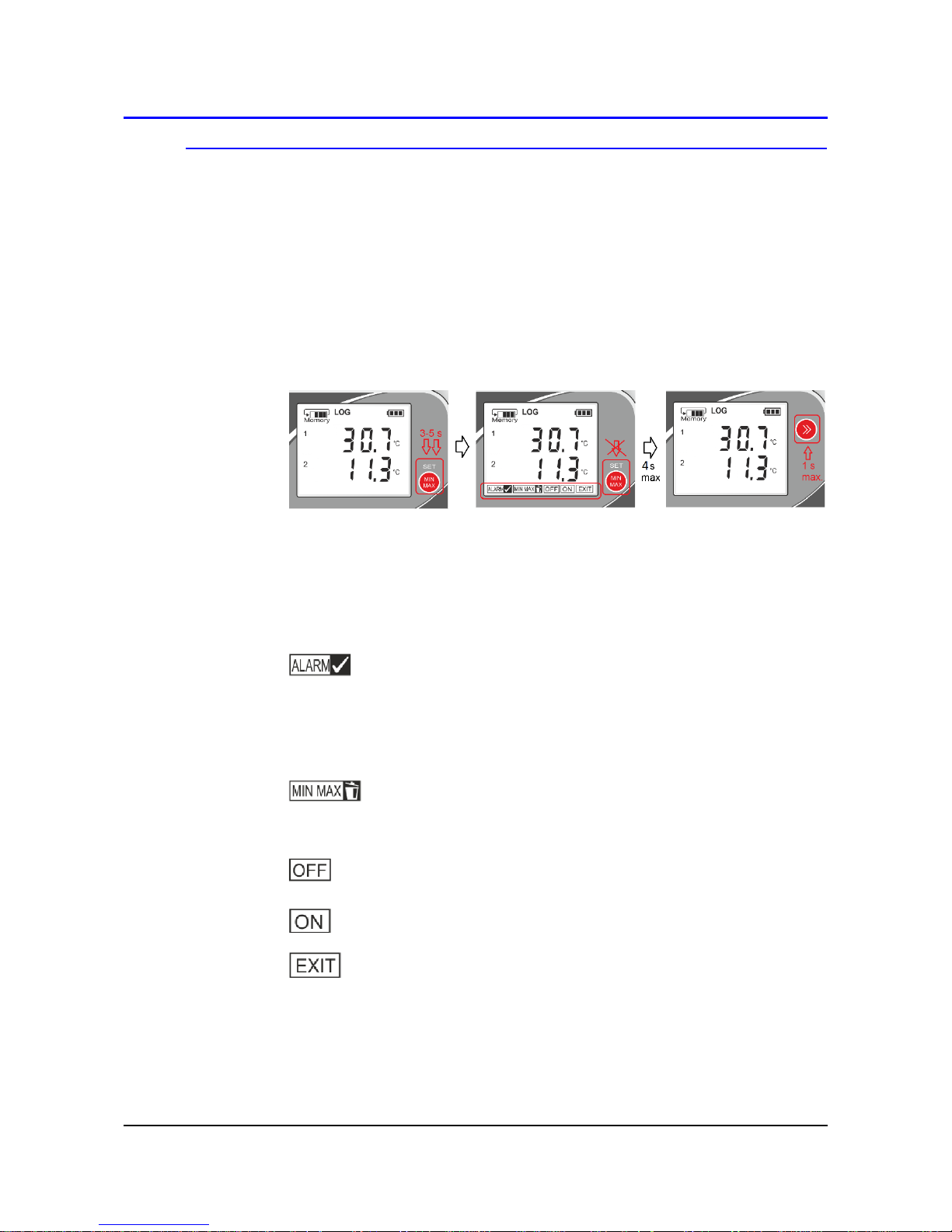

The menu can be entered by pressing a combination of both keys. In any

case, using the keypad must be enabled in the device configuration.

Individual menu items, too, may be disabled in the device setup. It is e. g.

possible to switch on the device in this way, but it is not possible to switch it

off.

To enter the menu:

Press the lower key and hold it pressed for about 3 s, until bottom menu line

appeared. Then release this key immediately and shortly press the upper key

during the following 4 s.:

You can now work with individual menu items. Press the upper key to scroll

through the menu items, press the lower key to confirm (SET). After

confirming certain choices, the menu will be quit automatically. If the keypad

is inactive for more than 20 s, the menu will close automatically.

Menu items:

Deactivation of the optical (LED diode) and acoustic alarm

signalling. In the case that the alarm signalling is active, it will be

terminated by generating a new alarm. In the device

configuration it must be allowed to disable this signalling from the

device keypad. If alarm memory (Latched alarms) is ON in the

device, the signalling will be deleted.

Deleting the Min/Max values in the device and it is related only to

values obtained since last reset. This does not concern those

recorded Min/Max values obtained in some other way. Option

must be enabled in the SW device configuration.

Switching the device off. This item is available only if the device

is ON. Option must be enabled in the SW device configuration.

Device switching-on. This item is available only if the device is

OFF. Option must be enabled in the SW device configuration.

Closing the menu.

Page 15

IE-LGR-Uxxxx-01 15

Models produced

The models produced differ from one another by types and ranges of values to be

measured. The datalogger’s input channels are invariably assigned to these values. The

user cannot change the type and range of the values to be measured.

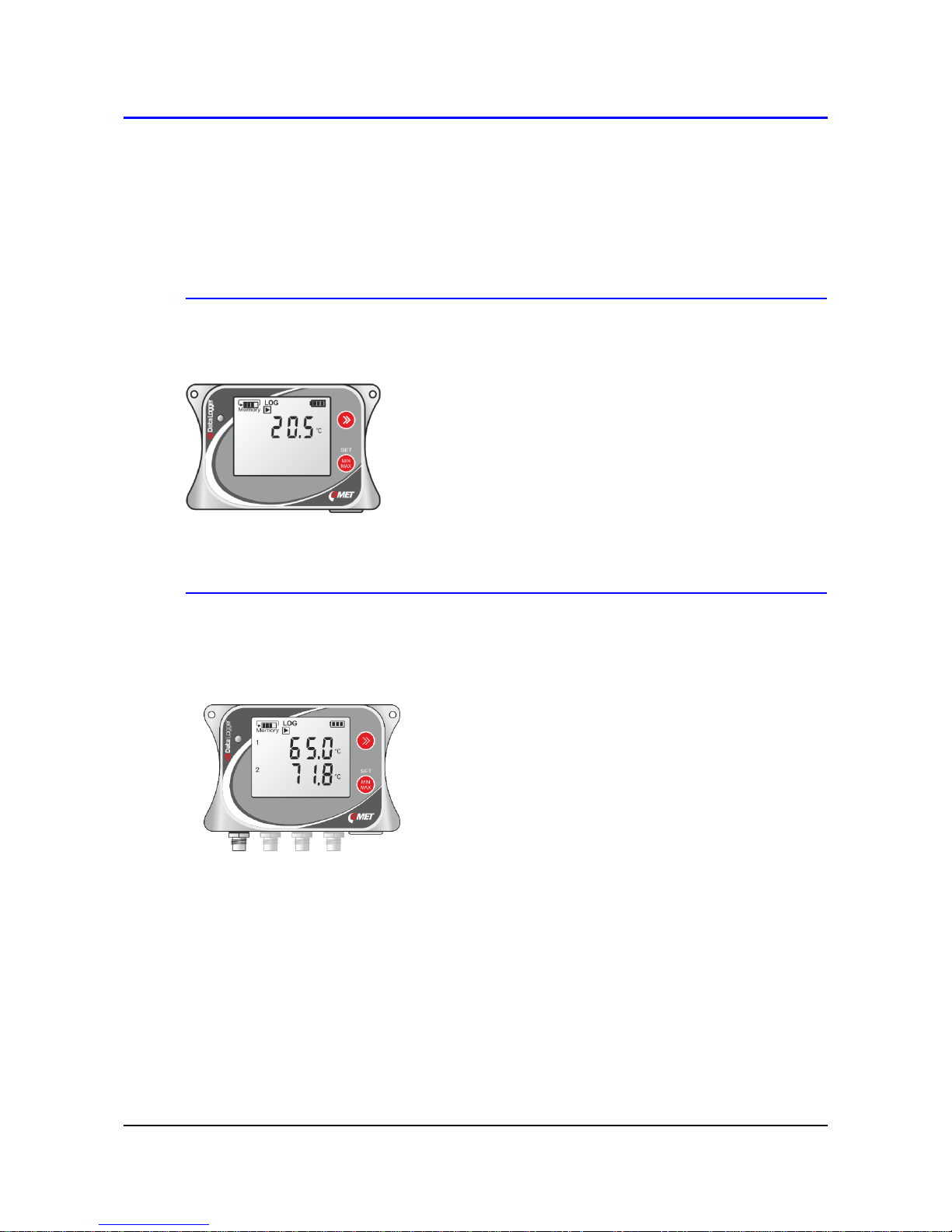

U0110 One-channel thermometer

This model is equipped with only one internal

temperature sensor, no additional probes and sensors

can be connected. It is characterized by a simple and

compact design and a relatively long response to a

temperature jump. The device is placed directly in the

measured space. The battery in the device cannot be

charged.

U0111, U0121, U0141 One-, two- or four- channel

thermometer for external probes

This model can measure one, two or up to four

temperature values transmitted by Pt1000/E series

external probes. The response to a temperature jump

depends on the connected probe design. As a rule, this

model is few times faster than that using the inner

sensor. It is often used to monitor locations where the

device itself is not directly in the measuring space and

only probes are in. The maximum length of each probe

lead should not exceed 15 m. It is recommended to use

shielded cables. To maintain the IP rating, the unused

probe connectors should be provided with a supplied

closing cap. The battery in the device cannot be

charged.

Page 16

16 IE-LGR-Uxxxx-01

U0122 Two-channel thermometer with external probe

This model allows to measure the temperature of the

internal sensor and one external probe series Pt1000/E.

The response to a temperature jump depends on the

connected probe design but is usually much faster than

the response of the internal sensor. It is often used,

among other things, to monitor large areas where a

device requiring individual monitoring is located. The

maximum length of each probe lead should not exceed

15 m. It is recommended to use shielded cables. To

maintain the IP rating, the unused probe connectors

should be provided with a supplied closing cap. The

battery in the device cannot be charged.

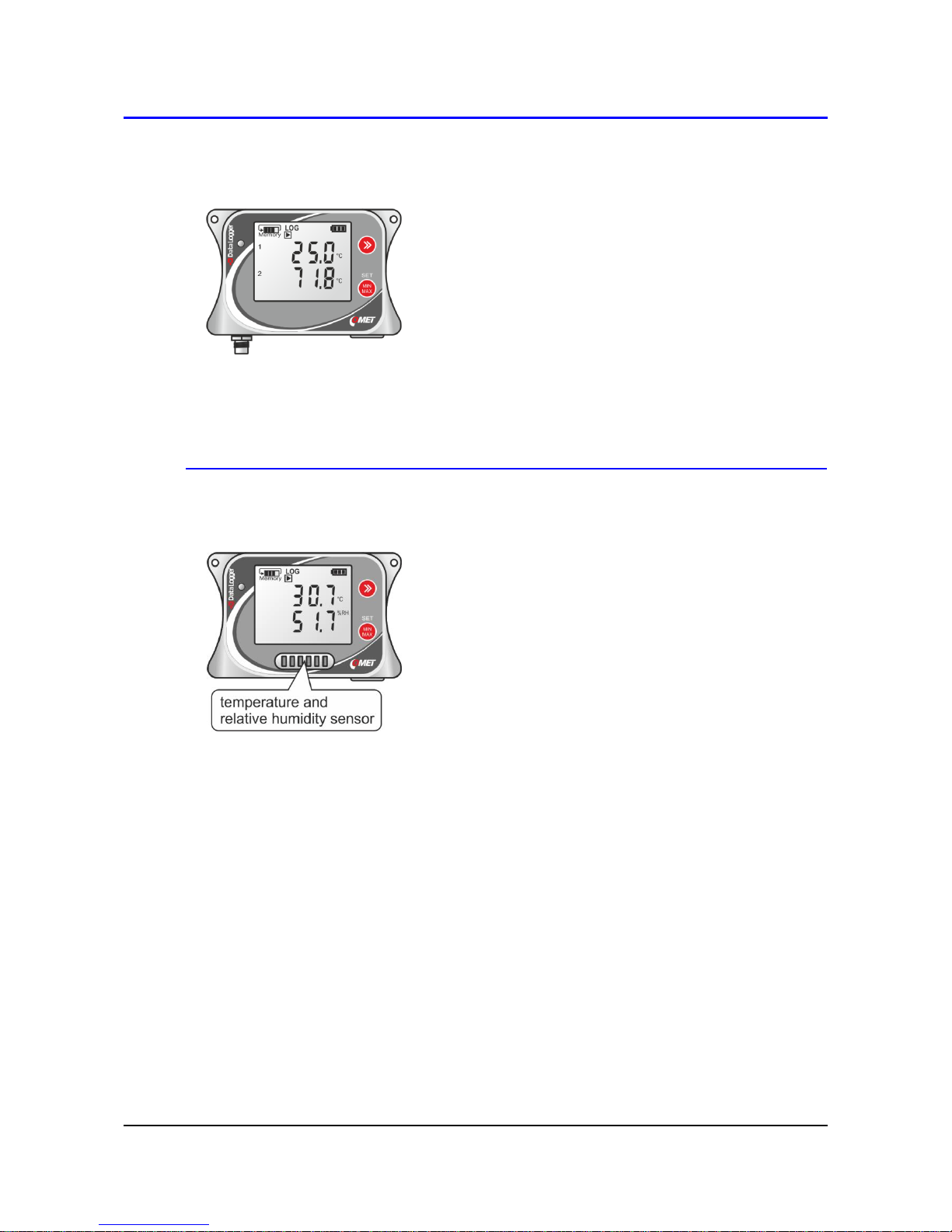

U3120 Compact thermometer - hygrometer

This model is designed to measure temperature, relative

humidity and dew-point temperature by internal sensor,

no additional probes or sensors can be connected. It is

characterized by a simple and compact design and a

relatively long response to a temperature and humidity

jump, compare to model with external probes. The

sensors are located under the grid on the front of the

unit and are protected with Teflon foil. Foil permits water

vapour but prevents water from permeating the liquid

state. The device is suitable for measuring in places

where there is no rapid change in temperature or

relative humidity, and there is no condensation of water

vapours. If water vapour condensation occurs inside the

datalogger, then the resulting water will remain there

and may damage its electronics. The device is placed

directly in the measured space. The battery in the device

cannot be charged.

It is recommended to calibrate this device in the

laboratory with the unscrewed bottom lid of the box to

allow the air to flow from the back of the electronics.

When air flow in the range of 0.5 - 1 m/s perform reading

after about 4 hours. The closed device reaches a

difference of approximately 2 %RH when inserted in the

humidity chamber, then dramatically slows down.

Precise reading takes many times longer time than with

the open rear lid.

Page 17

IE-LGR-Uxxxx-01 17

U3121 Thermometer – hygrometer for external probe

This model measures temperature, relative humidity

and dew point temperature using an outdoor Comet

Digi/E series probe. Its response to the temperature or

relative humidity jump is significantly faster than by

models with internal sensor. This model is often utilized

to monitor areas in which only the probe is installed,

whereas the main unit is installed elsewhere. When

monitoring remote areas, the maximum probe line wire

must not exceed 15 m. The Digi/E series probes provide

calibrated measurement values. Hence, they may be

replaced without having to modify the device setup.

The battery in the device cannot be charged.

U3430 Compact thermometer – hygrometer - CO2

concentration meter

This model is designed to measure temperature, relative

humidity, dew-point temperature and the concentration

of CO2 in the air by internal sensors. Barometric

pressure can be measured as absolute or recalculated

to sea level. No additional probes or sensors can be

connected. It is characterized by a simple and compact

design and a relatively long response in the measured

quantities, compare to model with external probes. The

sensors are located under the grid on the front and side

of the unit The device is suitable for measuring in places

where there is no rapid change in temperature or

relative humidity, and there is no condensation of water

vapours. The device is placed directly in the measured

space, Accupack in the device can be charged.

As the internal battery creates a parasitic heat during the

charging period, the measurement accuracy may be

affected by up to 1 º C. In battery mode, this model has

significantly shorter battery life than models without CO2

concentration measurement. For this reason, the

measurement of CO2 concentration does not occur as

often as the measurement of other variables. By default,

this is 2 minutes with the option of extending up to 10

minutes (option available in the COMET Vision SW).

We recommend calibration of the relative humidity and

temperature in the laboratory with the unscrewed

bottom lid of the box to allow the air to flow from the back

of the electronics. When air flow in the range of 0.5 - 1

m/s perform reading after about 4 hours.

Due to low IP20 protection, this device is not suitable for

dusty or water-borne areas.

Page 18

18 IE-LGR-Uxxxx-01

U3631 Compact thermometer – hygrometer with optional

external temperature probe

This model is designed to measure temperature, relative

humidity and dew-point temperature by internal sensor,

moreover one additional external temperature probe

Pt1000/E can be connected. Internal sensors are

located under the grid on the front of the unit and are

protected with Teflon foil. Foil permits water vapour but

prevents water from permeating the liquid state. The

device also measures the temperature from an external

probe and the difference between this temperature and

the dew point temperature. If the surface temperature of

the material is measured by an external probe, the risk

of condensation of water vapor on the surface to be

measured can be determined immediately. The device

alone is suitable for measuring in places where there is

no rapid change in temperature or relative humidity, and

there is no condensation of water vapours. If water

vapour condensation occurs inside the datalogger, then

the resulting water will remain there and may damage

its electronics. The device is placed directly in the

measured space. The battery in the device cannot be

charged.

It is recommended to calibrate this device in the

laboratory with the unscrewed bottom lid of the box to

allow the air to flow from the back of the electronics.

When air flow in the range of 0.5 - 1 m/s perform reading

after about 4 hours. The closed device reaches a

difference of approximately 2 %RH when inserted in the

humidity chamber, then dramatically slows down.

Precise reading takes many times longer time than with

the open rear lid.

The maximum length of each probe lead should not

exceed 15 m. It is recommended to use shielded cables.

To maintain the IP rating, the unused probe connector

should be provided with a supplied closing cap.

Page 19

IE-LGR-Uxxxx-01 19

U4130 Compact thermometer - hygrometer - pressure

gauge

This model is designed to measure temperature, relative

humidity, dew-point temperature and barometric

pressure by internal sensors. Barometric pressure can

be measured as absolute or recalculated to sea level.

No additional probes or sensors can be connected. It is

characterized by a simple and compact design and a

relatively long response in the measured quantities,

compare to model with external probes. The sensors are

located under the grid on the front and side of the unit

The device is suitable for measuring in places where

there is no rapid change in temperature or relative

humidity, and there is no condensation of water

vapours. The device is placed directly in the measured

space. The battery in the device cannot be charged.

It is recommended to calibrate this device in the

laboratory with the unscrewed bottom lid of the box to

allow the air to flow from the back of the electronics.

When air flow in the range of 0.5 - 1 m/s perform

reading after about 4 hours. The closed device reaches

a difference of approximately 2 %RH when inserted in

the humidity chamber, then dramatically slows down.

Precise reading takes many times longer time than

with the open rear lid.

Page 20

20 IE-LGR-Uxxxx-01

U4440 Compact thermometer – hygrometer - pressure

gauge - CO2 concentration meter

This model is designed to measure temperature, relative

humidity, dew-point temperature, barometric pressure

and the concentration of CO2 in the air by internal

sensors. Barometric pressure can be measured as

absolute or recalculated to sea level. No additional

probes or sensors can be connected. It is characterized

by a simple and compact design and a relatively long

response in the measured quantities, compare to model

with external probes. The sensors are located under the

grid on the front and side of the unit The device is

suitable for measuring in places where there is no rapid

change in temperature or relative humidity, and there is

no condensation of water vapours. The device is placed

directly in the measured space. Accupack in the device

can be charged. As the internal battery creates a

parasitic heat during the charging period, the

measurement accuracy may be affected by up to 1 º C.

In battery mode, this model has significantly shorter

battery life than models without CO2 concentration

measurement. For this reason, the measurement of CO2

concentration does not occur as often as the

measurement of other variables. By default, this is 2

minutes with the option of extending up to 10 minutes

(option available in the COMET Vision software).

We recommend that calibration of this device in the

laboratory be carried out with sufficient air flow (at least

1 m/s), but the reading should be carried out only after

a thorough settling, which may take up to 4 hours.

Due to low IP20 protection, this device is not suitable for

dusty or water-borne areas.

Page 21

IE-LGR-Uxxxx-01 21

U0541 Two-channel thermometer for external probes with

2 inputs 0 - 10 V

This model can measure up to two temperature values,

which are sensed by outdoor Pt1000/0 series probes. In

addition, it has two voltage inputs for monitoring voltage

signal changes. Input signals are connected to a

connecting block. The response to a temperature jump

depends on the probe design. As a rule, this device is

few times faster than the inner-sensor model. The

maximum length of the temperature probe should not

exceed 15 m; the maximum length of the voltage-input

cable should not exceed 30 m. It is recommended to use

shielded cables.

The device’s ingress protection is IP 20. Due to low

ingress protection the device is not suitable for using in

dusty rooms or rooms exposed to water ingress.

The battery in the device cannot be charged.

Connection mode:

For the procedure for connecting wires to the connecting

block refer to Annex 5.

Page 22

22 IE-LGR-Uxxxx-01

U5841 Datalogger with 3 inputs 0 - 10 V and 1 binary

input

This model is used to measure up to three voltage inputs

0 – 10 V DC while allowing one binary input to be

monitored. The voltage inputs are not galvanically

separated from one another. This means that the

negative terminals ("-") are connected to each other.

These facts must be taken into consideration when

designing the device into the circuit. Incorrect

connection may cause degradation of the measured

values. Binary input serves to monitor voltage signals or

signals coming from a voltage-free contact. The binary

input changes are registered immediately, irrespectively

of the recording interval setting. To safe record the input

status, the signal must be present for at least 1 s. Binary

input can capture connected/disconnected voltage

status.

Input signals are connected to a connecting block. The

device’s ingress protection is IP 20. Due to its low

ingress protection the device is not suitable for using in

dusty rooms or rooms exposed to water ingress. The

maximum length of the input wires should not exceed 30

m. It is recommended to use shielded cables. The

battery in the device cannot be charged.

Connection mode:

For the procedure for connecting wires to the connecting

block refer to Annex 5.

Page 23

IE-LGR-Uxxxx-01 23

U6841 Datalogger with 3 inputs 0 - 20 mA and 1 binary

input

This model is used to measure up to three signals from

current loops (0 to 20) mA DC while allowing one binary

input to be monitored. The current inputs are passive

and are not galvanically separated from one another.

This means that the connected sensors cannot be

powered by the current loop and the negative terminals

("-") are connected to each other. These facts must be

taken into consideration when designing the device into

the circuit. Incorrect connection may cause degradation

of the measured values. Standard outputs (4 to 20) mA

can also be measured with current inputs without any

problems.

Binary input serves to monitor voltage signals or signals

coming from a voltage-free contact. The binary input

changes are registered immediately, irrespectively of

the recording interval setting. To safe record the input

status, the signal must be present for at least 1 s. This

input can capture connected/disconnected voltage

status.

Input signals are connected to a connecting block. The

device’s ingress protection is IP 20. Due to its low

ingress protection the device is not suitable for using in

dusty rooms or rooms exposed to water ingress. The

maximum length of the input wires should not exceed 30

m. It is recommended to use shielded cables. The

battery in the device cannot be charged.

Connection mode:

For the procedure for connecting wires to the connecting

block refer to Annex 5.

Page 24

24 IE-LGR-Uxxxx-01

U7844 Two-channel binary-input counter

This model includes four inputs. Two of them can

function as counters, and all four inputs can function as

binary inputs. Both counter and binary inputs serve to

monitor voltage signals or signals coming from a

voltage-free contact. The binary input changes are

registered immediately, irrespectively of the recording

interval setting. To safe record the input status, the

signal must be present for at least 1 s. Binary inputs can

capture connected/disconnected voltage status. The

counter states are recorded according to the set Record

interval. Input signals are connected to a connecting

block. The device’s ingress protection is IP 20. Due to

its low ingress protection the device is not suitable for

using in dusty rooms or rooms exposed to water ingress.

The maximum length of the input wires should not

exceed 30 m. It is recommended to use shielded cables.

The battery in the device cannot be charged.

Optional input configurations:

• 2 x counter + 2 x binary input

• 1 x counter + 3 x binary input

• 4 x binary input

Connection mode:

For the procedure for connecting wires to the connecting

block refer to Annex 5.

Page 25

IE-LGR-Uxxxx-01 25

COMET Vision program

(this section could be for a short period outdated due to SW update)

Minimum HW and OS requirements _________________

• Windows 7 operational system and higher, or Windows Server

2008 R2 operational system and higher

• 1.4 GHz processor speed

• 1 GB memory

Program description ______________________________

The COMET Vision program is used to set up Comet devices, to obtain

the recorded data and the currently measured values.

The program is available free of charge (www.cometsystem.com),

any number of devices can be connected simultaneously (e. g. data

from several devices can be downloaded concurrently; several online

displays may be running at a time). Moreover, some advanced

features are available (e. g. graphs, statistic previews of registered

data, user-defined online display, export into a database etc.).

To run Uxxxx series dataloggers, version 2.0.xxxxx.xxxxx or higher

must be installed.

The starting point for the program control is the menu situated in the

left (optionally right) portion of the utility software and containing the

basic options „Home“, „Devices“, “Files”, „Online display“.

Adding the datalogger to a list of the Comet devices _____

The USB-connected device is automatically detected within approx. 5

seconds (required for connection initialization time). When connected

to a computer, the device is automatically added to the Comet device

list

A device can be added manually after clicking on the „Add device“

button. This can be found in the „Welcome“ screen, which is displayed

upon the first program launching, later in the „Home“ or „Device“ tabs .

A screen containing a connection type choice will appear. Here, USB

should be selected. Subsequently, after „Finish“ button confirmation,

the device will be added.

Page 26

26 IE-LGR-Uxxxx-01

Setting up the device

After the datalogger has been switched on, it starts measuring, data

recording and evaluating alarms according to the device’s setting up

performed by the user. Complete device setup can be performed by the aid

of the COMET Vision user software (hereinafter SW). During configuration

editing the device can work normally, nevertheless the access to some

functions (record download, contemporary configuration editing by other

users) is limited.

How to set up the device by means of a program

• Connect the datalogger to a computer, run the user SW.

• If you have not operated the device in the SW yet, add it to the list of your

Comet devices. For more details, see the chapter „CONNECTING THE

DATALOGGER TO A COMPUTER“.

• If the device is connected properly, its current status is displayed in the

Device Home panel.

• Click on the Configuration button. The device configuration will be

downloaded; you will be able to view it.

• If you change the setup of some item, the SW will pass over into the

editing mode. During the editing procedure the other users access to the

device will be limited.

• In case of a longer idle time the configuration editing mode will close

automatically.

• Finally save the new configuration into the device (Apply changes).

The device setup from a program (Configuration)

General - Information ______________________________

In this panel basic device information is available. Here is above all its

name (Device name), which serves to identify the device and the

measurement values it provides. You can name the device e.g.

according to its location or utilization, or you can leave its original

setting. The maximum length of this description, in which you can use

letters, numerals, underscores and further signs, is 31 characters.

More information, which is indicated in this panel, is the device’s serial

number, model and firmware version.

Page 27

IE-LGR-Uxxxx-01 27

General - Preferences _____________________________

In this panel you can choose the unit with which the device will measure

the temperature (Default temperature unit °C/°F). With some devices

the pressure unit can be chosen, too (Default atmospheric pressure

unit). When the device does not measure the atmospheric pressure,

but when it is necessary to know its value to measure some quantities

(calculated humidity and CO2), the atmospheric pressure value must

be entered (Default value of atmospheric pressure in the area

according to altitude).

With barometers, the correction constant can be entered here for

conversion to the equivalent sea level pressure. This constant can be

entered either as a current pressure converted to the sea level found

out e.g. at a near observatory, or through the medium of the elevation

above sea level.

General - Data and Time ___________________________

Here you can set the date and time running inside the device (Date and

Time). In the datalogger local current time is running according to your

setting. By means of the UTC Offset choice you can fix its relation to

the UTC. This information will be available for all time data provided by

the device. The device cannot automatically pass over between

summer and winter time.

CAUTION - after changing date and time the data

recorded by the device will be deleted!

Advanced - LCD Display ___________________________

In this panel you can set a variety of display and keypad behaviour

modes.

Advanced – Other settings (Keypad, Device start, Energy) _

In this panel you can set some functions of the datalogger’s buttons, a

delayed switching-on of the datalogger or the control of its switching-

on by a binary input (according to type). In addition, the datalogger‘s

switching-on and/or off by a button on the datalogger panel can be

enabled or disabled.

In the standard mode the datalogger measures all channels using an

interval of 10 s. This interval can be shortened to 1 s when a faster

measuring procedure is required. A disadvantage of this mode is a

higher power consumption. When the device is operated for a long

time, there is no need for a fast response to the change in the

measurement values and a long battery lifetime is what matters, you

can set the measurement interval to 1 minute. The CO2 concentration

channel measures with a 2-minute interval and can be extended up to

Page 28

28 IE-LGR-Uxxxx-01

10 minutes to save more battery life. For details concerning power

consumption, see Technical parameters.

Record _________________________________________

The choices that are available in this panel serve to control the device‘s

recording functions. The recording function may be switched on and off

when needed (Recording with interval). However, if you switch the

recording off and then you switch it on again, the memory free space

may be reduced by up to 0.2 % of its total capacity. Use Cyclic record

in the case that you require the device to continue recording even if the

measurement data memory is filled up with data. In this case the oldest

data is gradually overwritten by the newer data. If you do not use this

choice, the data recording will be stopped on reaching the full storage

capacity. Another important parameter is the Record interval. It can be

set from 1sec/10sec/1min (according to settings in Advanced – Other

settings (Energy) - Measurement Interval) to 24 hours (See Technical

parameters). The recording takes place every time at integer multiples

of the pre-set interval. For example, if you switch the device on at 5:05

and the recording interval has been set to 1 hour, the first data will be

recorded at 6:00, the following data at 7:00 and so on.

The data recording can take place either incessantly, or only in the

instant when some of the measurement values gets into an alarm

condition (system alarms do not trigger the recording). Choose Record

mode.

As a standard, the device records instantaneous measurement data

during a period defined by the recording interval and the actual time.

However, if continuous recording is enabled, the average, minimum

and maximum values can be selected in the Recorded values. Caution

– these Min/Max values apply only to the selected recording interval

and are different from the global Min/Max values displayed on the

device screen.

The record setting is completed by choosing measurement channels

that are supposed to be recorded.

CAUTION - After changing cyclic non-cyclic recording

(in either direction) the data recorded in the device is to be

deleted! SW warns you when saving a new configuration

and gives you the option to save data.

Channels_______________________________________

In this panel you can set all input channels. The assignment of the

measurement value and its range to a channel is factory-set and

cannot be changed. Supply a suitable name of the location to be

measured for each channel and decide whether it will be switched on

for measurement and for recording.

Further items, like those for entering the decimal place number, the

name of the physical unit and the conversion of the measurement

Page 29

IE-LGR-Uxxxx-01 29

values by means of the so-called User calibration are available in

channels with voltage and current inputs only. In these inputs no

physical quantity unit is displayed on the device’s LCD display. If a

value cannot be displayed because of a great number of digits, it is

substituted by an error message. Nevertheless, this error message

concerns only the device display, not the measurement or recording.

An example of user-defined calibration for a sensor having

a 4 to 20 mA current output. The sensor is connected to the

datalogger’s current input; the sensor’s measurement

range is -30 to +80 °C:

Lower point A: Input value: 20 will be shown as 80

Upper point B: Input value: 4 will be shown as -30

In a channel for external Pt 1000 probes there exists the possibility to

enter the probe parameters to correct the measurement error caused

by the probe cable.

In binary channels you can decide whether a voltage signal or a contact

(an open-collector transistor) will be connected to the input. Then enter

textual descriptions of the states for both input levels. In this way the

states will be displayed in the record and in the Online display. At the

same time, from the menu, choose symbols for displaying these states

by the device.

For a counter channel, decide whether to report an error or continue

from zero after it is overflowed.

In the next step, set alarm states for each measured variable. You can

set up to 2 alarms for each measured quantity (alarm 1 and alarm 2

buttons). Each alarm must be enabled (on/off) first.

Furthermore, choose whether the alarm should arise from exceeding

the limit value or from dropping under it (value is greater than / value is

lower than). Enter this limit value. In binary inputs, only the input state

must be defined. Subsequently, the alarm delay time must be entered

(for the duration of). This delay time serves to eliminate contingent

momentary overshoots of the limit value. The hysteresis, too, has a

similar significance (Alarm hysteresis). It prevents the alarm from

oscillating in the case that the measurement value varies around the

alarm limit value. It is not recommended to set it equal zero.

Thus, the setting for generating an alarm is completed. It remains to

decide, whether the alarm should be indicated optically by means of a

LED diode on the device (Optical signalling - LED) or acoustically

(Activate internal acoustic signalling)

Page 30

30 IE-LGR-Uxxxx-01

Alarm events ____________________________________

The device makes it possible to evaluate alarm situations, which can

either originate from the measurement data, or they can notify of a

certain device condition (exceeding the memory occupancy limit,

system alarms). The individual alarm situations can be assigned the

way of their signalling to the user.

An alarm originating from a measurement value is every time signalled

on the device display by means of a bell icon ahead of the

corresponding measurement value. General information about any

alarm occurring in the device is displayed by ALARM warning on the

device display (except for an exceeded memory occupancy limit, which

is signalled by a flashing Memory sign).

An alarm can be signalized by a fast flashing of the LED diode on the

device panel (Optical signalling - LED). In the case that only one alarm

originating from a measurement value is active, a yellow LED is

flashing. In the case that more alarms occur simultaneously, or a

system alarm or an alarm originating from an exceeded memory

occupancy limit occur, a red LED diode is flashing.

Besides, an alarm may be signalled acoustically by a characteristic

sound, which is repeated at regular intervals.

The operator alerted this way can confirm the acoustical or optical (LED

diode) signal and so mute it until a new alarm occurs (See the chapter

Controlling the datalogger from a keypad).

Alarm events - Preferences _________________________

In the standard mode the alarm lasts only during the time when the

measurement values lie outside the allowed limits. As soon as they

return inside the allowed limits, the alarm will cease. In some cases, it

is desirable for the user to be informed of an alarm that has occurred

during his absence. If you enable the Latched alarms choice in the

device setting, then every alarm occurring in the device remains active

until operator intervenes, irrespective of the measurement values (i.e.

until the time of manual cancel).

Moreover, alarm evaluation may be enabled here for selected days of

the week only and for certain hours of the day. This setting can also be

used for system alarms, but it should not be combined with the above

described option Latched alarms.

Page 31

IE-LGR-Uxxxx-01 31

Alarm events – Mute of signalling________________

In this panel you can enable the alarm to be deleted and deactivate the

alarm signalling both from the SW and from the device keypad.

Furthermore, optical (LED) or acoustical alarm signalling can be

enabled/disabled here.

Alarm events - Memory occupancy___________________

Use this panel setting, if an overrun of the pre-set limit value of the data

memory occupancy needs to be signalled. The signalling mode may

be selected optionally as optical (by means of a LED diode) or

acoustical.

Alarm events - System failure _______________________

These panel choices make it possible to set the so-called system

alarms, which indicate some technical failure of the datalogger or of

some of the probes connected to it. The signalling mode may be

selected optionally as optical (every time by means of a red LED diode)

or acoustical.

The device can respond to the following conditions:

a) Measurement error on any channel ...... e. g. a probe has been

disconnected or broken.

b) Device configuration error …... the device configuration has

been disturbed unexpectedly.

c) External power failure ...... the power supply has failed on

the USB connector (reserved for special events, when the

device is connected to a USB charger or a computer).

d) Low battery …. the battery is weak.

e) Time setting error or battery is discharged …. the battery has

run out of charge.

Summary _______________________________________

Printable summary of all device setting.

Page 32

32 IE-LGR-Uxxxx-01

Application notes

Operation with permanently connected USB cable ______

Datalogger is primarily intended to be operated as an autonomous unit

powered by its built-in batteries. Nevertheless, you can also operate it

with permanently connected USB cable. In this case the device is not

protected against dust and water ingress, and, consequently, it cannot

be operated in locations in which such ingress protection is required.

Models with CO2 concentration sensors include Li-Ion accupack that

can be charged from a PC or an external charger. The datalogger’s

internal charging circuitry controls the battery charging process based

on its instantaneous condition, thus protecting it against damage. The

charging process will run only if the device’s internal temperature

ranges between 0 °C and 40 °C. If this is not the case, the battery will

not charge even if the charger is connected. Other models equipped

with a primary lithium battery cannot be charged.

Device switching on and off_________________________

If you switch on and off the device frequently, then its keypad and both

functions, i.e. device switching on and off from the keypad, must be

enabled in the device settings. Another option is to set the date and

time when you want the device to turn itself on automatically. Once

reached, it will be permanently switched on. For binary input

dataloggers, it is possible to control the recording on and off by the

level at this input (voltage or contact).

Measuring calculated humidity values_________________

From among the calculated humidity values the device can provide the

dew-point temperature only. Other relevant calculated humidity values

can be obtained by subsequent data processing in the SW.

What is the purpose of the system alarms and how to work

with them _______________________________________

System alarms are useful for performing the functionality diagnosis of

the device and of the probes connected to it. A system alarm notifies

of a failure or damage of the device or of its probe. On the contrary,

alarms on measurement values indicate a failure of the technology the

device is monitoring.

Page 33

IE-LGR-Uxxxx-01 33

Problems with measurement correctness ______________

Incorrect measurement values of temperature or relative humidity may,

in most cases, be caused by an unsuitable probe location or improper

methodology. Some notes concerning these problems are mentioned

in the following chapter Recommendations for operation and

maintenance. In probes using current and voltage outputs incorrect

measurement results may be induced by latent coupling between

individual components, e.g. across supply sources or through

improperly connected cable shielding.

If the device indicates an error condition, see detailed information in

Annex 1, selected error messages.

Another problem area relates to random peaks occurring within the

measurement values. Their most frequent reason is a source of

electromagnetic interference situated near the device or the pertaining

cables. Attention must be paid also to possible damaged portions of

the cable insulation. Prevent accidental contacts between wires and

adjacent conductive parts.

Problems arising during communication with a computer __

For communication with a computer a cable should be used that is not

longer than 5 m. Check that all connectors are properly seated. It is

especially the USB-C connector that must be properly pushed into the

receptacle. Cable disconnecting and subsequent connecting during

communication can cause a temporary non-availability of the USB

equipment in the computer. This may be corrected by closing the

COMET Vision utility program (including the communication service)

and starting it subsequently. Restart the computer, if the above

mentioned measure is not the proper remedy. Check whether new HID

equipment will appear in Device administrator after the device has

been connected to the computer.

Page 34

34 IE-LGR-Uxxxx-01

Recommendations for operation and maintenance

Datalogger operation in several application areas________

Before putting the device into operation, it should be considered, if its

usage is suitable for the intended purpose. In connection with this

consideration the device‘s optimum settings should be determined. In

the case that the device is part of a larger measurement system,

instructions for its metrological and operational checks should be

developed

Inadvisable or hazardous applications:

This datalogger is not intended for such applications in which the failure

of its functioning could directly endanger life and health of humans and

animals, or the functioning of other equipment with life-sustaining

functions. In applications the failure or malfunction of which could result

in severe property damage it is recommended to provide the system

with suitable and independent signalling equipment which is able to

evaluate such a condition and, in case of failure, to prevent the above

mentioned damages (See the chapter „Safety measures and

unauthorized manipulations“).

Device positioning:

Adhere to principles and procedures mentioned in this manual. Try to

choose such a place to position the device, where the negative

influence caused by environment is as low as possible. When

performing measurements in refrigerators, metal boxes, metal

chambers and the like, it is every time advisable, as far as the device’s

operation and reliability is concerned, to place the device outside,

leaving only the sensors and probes inside the measured environment.

Positioning of temperature sensors:

These sensors should be placed in locations where sufficient air

circulation is ensured and where the most critical location is supposed

(according to the application requirements). To prevent heat

conduction through the sensor cables from undesirable influencing the

measurement value, the sensor must be properly inserted into the

measured environment. If you follow the temperature distribution in an

air-conditioned storehouse, do not place the sensor into the direct air

stream generated by the air-conditioning unit. As a matter of fact, the

temperature distribution in large-chamber refrigerators may be quite

inhomogeneous, the temperature differences reaching up to 10 °C.

Similar dispersion can be found inside deep-freezing boxes (e.g. in

those used for blood preservation by deep freezing).

Page 35

IE-LGR-Uxxxx-01 35

Positioning of humidity sensors:

The positioning of humidity sensors depends again on the application

requirements. Humidity measurements in refrigerators without

additional humidity stabilization can be very questionable. When the

cooling is switched on/off, there may be significant changes in humidity

in the range of tens of percent, even if the mean value is correct.

Moisture condensation on the ventricle walls is common.

Recommendations for metrological checks ____________

Metrological verification is carried out according to the requirements of

the particular application at intervals fixed by the user. In some cases,

calibration must be performed by an independent laboratory that is

accredited by the government.

Recommendations for regular checks _________________

It is recommended to check the system in which the instrument is

incorporated at regular intervals. Checking interval and inspection

scope depend on the particular application and the user’s internal

regulations. In fixed installations following checks are recommended to

be performed:

• Metrological verification;

• Regular checks fixed by the user;

• Judgement of all problems that has occurred since the last check;

• Visual check of the device, connectors condition, cover integrity;

• Functionality check (checking of features utilized by the application):

a) Check of the transfer of the actual recorded value into the

computer, record evaluation

b) Functionality check of individual alarms. This should be done

by changing the input quantity to give rise to an alarm. Then

check it visually on the display.

c) Judgement of the battery condition on the display.

• Check of the cabling. To be checked: Condition of cable

connections and cable surface integrity, proper cable routing, no

additional parallel heavy-current conductors.

• Check of all sensors. This is to be performed visually. Check for

water ingress, check for suitable sensor location with respect to

correct measurement conditions and possible signal deteriorating

by interference.

• The check results are to be recorded.

Page 36

36 IE-LGR-Uxxxx-01

Battery replacement procedure_____________________

WARNING - Models with CO2 concentration

measurement (U3430, U4440) are powered by an internal

rechargeable Li-ion accupack. Its exchange is possible

only by the manufacturer or authorized service!

Battery replacement on other models can be performed only person

who knows the principles of safe handling of lithium primary batteries.

Do not dispose of batteries in a fire, expose them to high

temperatures, low air pressure, and do not mechanically damage

them. Used batteries should be taken to hazardous waste.

If a weak battery symbol appears on the display during operation, it is

advisable to replace the battery within 2-3 weeks. A weak battery

indication may also occur if the sensor is operated at low

temperatures even when the battery is still usable (outdoor use

usually at night). During the day (after increasing temperatures), the

low battery indication disappears. In this case, it is not necessary to

change the battery.

A critically weak battery that can fail at any time is indicated by the

blinking empty battery symbol on the display. Replace the battery as

soon as possible.

Note: When the device is operating at very low temperatures, the

empty battery symbol on the sensor display may not be visible.

To replace the battery, unscrew the backside lid, remove the old

battery by pulling it behind the clip, and insert the new battery with the

correct polarity. Refer to the battery symbol + (plus pole) printed on

the electronics board at the battery location.

If you order a new battery from the manufacturer of the device

(Comet System, s.r.o., order code A4203), you will also receive it with

the clip. Check the seal integrity in the encoder housing and reinstall

the cover.

Service recommendations ________________________

Engineering support and service activities are provided by the device

distributor. His contact person‘s address is given in the Certificate of

warranty included with the product.

WARNING - Unskilled intervention into the device may

lead to loss of warranty!

Page 37

IE-LGR-Uxxxx-01 37

Technical parameters

Power supply

The device is powered by an internal lithium battery, accessible after

unscrewing the cover (see Battery replacement procedure). Models with

CO2 concentration measurement (U3430, U4440) are powered by an

internal rechargeable Li-ion accupack. Its exchange is possible only by the

manufacturer or authorized service!

Battery _________________________________________

Battery model used:

U3430, U4440 models: BAT26001S2P Li-ion 2 pack

US18650VTC5 5200 mAh SONY (2x 2600mAh)

Other: Primary 3.6 V lithium battery, size AA, capacity

2200 mAh, recommended type: Tadiran SL-760 / S, 3.6

V, 2200 mAh

Operating time: Months to several years according to the device

setting. Devices with a CO2 concentration sensor have a higher

battery consumption, so they are fitted with a charging module

and accupack. Follow the battery status, replace it if necessary,

recharge the U3430, U4440.

Battery charger (models U3430, U4440 only)_____________

Recommended charger type:

Commonly used chargers, such as mobile phone

chargers with a USB type C connector, such as Sunny

SYS 1561-1105

Maximum current from the USB connector:

• Provided that the datalogger is connected to the

computer and a successful enumeration takes place,

the input current limit will be set to 500mA.

• If no successful enumeration takes place within

10 s after powering up the device (the device is not

connected to the computer), then the input current limit

is increased to 1000 mA. However, when the input

voltage drops, the current drawn from the connector

will decrease automatically.

Charging time:

Charging time depends on the current battery discharge

level. Since the parasitic heat is generated when the

internal battery is charging, the charging speed with the

power on is deliberately slowed down to prevent

Page 38

38 IE-LGR-Uxxxx-01

excessive influence of measured values. If you want to

charge the device as soon as possible, turn it off first.

When the device is turned off, the fast charging mode is

automatically activated. Fully charged battery is

indicated on the display of the device usually within 6

hours.

Charging conditions:

The charging process only runs when the internal

temperature ranges between 0 °C and 40 °C.

USB communication interface

Compatibility:

USB1.1 and USB 2.0

Connector:

USB-C

Measurement, data storage and real time circuitry

Measurement Interval:

10 s as standard (CO2 sensor 2 min)

1 s in fast mode

1 minute in economic mode (CO2 sensor 10 min)

Recording interval:

(1 s, 2 s, 5 s, 10 s, 15 s, 30 s)

1 min, 2 min, 5 min, 10 min, 15 min, 30 min,

1 h, 2 h, 3 h, 4 h, 6 h, 8 h, 12 h, 24 h

You cannot select a shorter Recording interval than the

Measurement interval

Storage capacity:

Maximum 500 000 values in non-cyclic record

Maximum 350 000 values in cyclic record

Page 39

IE-LGR-Uxxxx-01 39

Parameters of datalogger inputs

U0110 ________________________________________

Measured value:

Internal temperature

Temperature range:

(-30 to +70) °C

Accuracy:

± 0.4 °C

Response time:

T63 < 6 min, t90 < 15 min (temperature jump 20 °C, air

circulation ca 1 m/s)

Display resolution:

0.1 °C

Recommended calibration interval:

2 years

U0122__________________________________________

Measured values:

Internal temperature

1x External temperature sensed by an external Comet

Pt1000/E series probe

Range:

Internal temperature: (-30 to +70) °C

External temperature input:

(-90 to +260) °C, Pt1000/3850 ppm sensor

Meas. current: ca 0.5 mA with ca 60 ms pulses

Accuracy:

Internal temperature: ± 0.4 °C

External temperature input (without probe):

±0.2 °C in a range of -90 to +100 °C

±0.2 % of the measurement value in a range

of +100 to +260 °C

The accuracy of the device with a temperature

probe connected to it is determined by the above

input accuracy and the accuracy of the probe

employed.

Connection mode (external probe):

Two-wire connection with the possibility of

compensation of the error caused by the cable

Page 40

40 IE-LGR-Uxxxx-01

resistance. The probe is provided with a 3-pin M8 ELKA

3008V connector. Its connection mode is shown in

Annex 2.

The recommended length of the Pt1000/E probe cable

is maximum 15 m, a length of 30 m must not be

exceeded. Shielded cables are recommended.

Response time:

Internal temperature: T63 < 6 min, t90 < 15 min

(temperature jump 20 °C, air circulation ca 1 m/s)

External temperature input: Is determined by the

response time of the used probe.

Display resolution:

Internal temperature: 0.1 °C

External temperature input: 0.1 °C, 16-bit converter

range

Recommended calibration interval:

2 years

U0111, U0121, U0141_____________________________

Measured values:

1, 2 or 4 x temperature sensed by an external Comet

Pt1000/E series probe

Temperature range:

(-90 to +260) °C, Pt1000/3850 ppm sensor

Measuring current: ca 0.5 mA with pulses of ca 60 ms

length

Input accuracy (without probes):

±0.2 °C in a range of -90 to +100 °C

±0.2 % of the measurement value in a range of +100

to +260 °C

The accuracy of the device with a temperature probe

connected to it is determined by the above input

accuracy and the accuracy of the probe employed.

Connection mode:

Two-wire connection with the possibility of

compensation of the error caused by the cable

resistance. The probe is provided with a 3-pin M8 ELKA

3008V connector. Its connection mode is shown in

Annex 2.

The recommended length of the Pt1000/E probe cable

is maximum 15 m, a length of 30 m must not be

exceeded. Shielded cables are recommended.

Page 41

IE-LGR-Uxxxx-01 41

Response time:

Is determined by the response time of the used probe.

Display resolution:

0.1 °C

Recommended calibration interval:

2 years

U3120 ________________________________________

Measured values:

Internal temperature, relative humidity.

Dew-point temperature calculated from the internal

temperature and relative humidity.

Ranges:

Temperature: (-30 to +70) °C

Relative humidity: (0 to 100) %RH without lasting

condensation

(*2)

Dew-point temperature: -90 to +70 °C

Accuracy:

Temperature: ± 0.4 °C

Relative humidity:

- sensor accuracy ±1.8 %RH

(at 23 ºC in the range of 0 to 90 %RH)

- hysteresis < ±1 %RH

- non-linearity < ±1 %RH

Dew-point temperature: ±1.5 °C at an ambient

temperature of T< 25 °C and RH >30 %.

For details see diagrams in Annex 4.

Response time (air streaming velocity approx. 1 m/s)

(*2)

:

Temperature: t63 < 2 min, t90 < 8 min (temperature

jump 20 °C)

Relative humidity: t63 < 45 s, t90 < 4 min, t99 <4 h.

(humidity jump 30 %RH, constant

temperature)

Display resolution:

Temperature incl. dew-point temperature: 0.1 °C

Relative humidity: 0.1 %RH.

Recommended calibration interval:

1 year

(*2)

Important information is provided in the chapter

Manufactured models – U3120

Page 42

42 IE-LGR-Uxxxx-01

U3121 ________________________________________

Measured values:

Temperature and relative humidity measured by an

external Digi/E series probe. The dew-point temperature

is calculated from the measured temperature and the

relative humidity.

Range, accuracy and response time:

Depending on the connected Digi/E series probe.

Connection mode:

Digi/E series probe. The probe is provided with a 4-pin

M8 ELKA 4008V connector. Its connection mode is

shown in Annex 3. The length of the Digi/E probe cable

must not exceed 15 m.

Display resolution:

Temperature incl. dew-point temperature: 0.1 °C.

Relative humidity: 0.1 %RH.

Recommended calibration interval:

1 year (according to the connected probe)

U3631 ________________________________________

Measured values:

Internal temperature, relative humidity.

1x External temperature measured by an external

Comet Pt1000/E probe.

Dew-point temperature calculated from the internal

temperature and relative humidity.

Difference of external temperature and dew point

temperature.

Ranges:

Internal temperature: (-30 to +70) °C

Relative humidity: (0 to 100) %RH without lasting

condensation

(*2)

.

Dew-point temperature: -90 to +70 °C

External temperature input:

(-90 to +260) °C, Pt1000/3850 ppm sensor

Measuring current: approx. 0.5 mA in pulse

length approx. 60 ms

Accuracy:

Internal temperature: ± 0.4 °C

Relative humidity:

- sensor accuracy ±1.8 %RH

(at 23 ºC in the range of 0 to 90 %RH)

- hysteresis < ±1 %RH

- non-linearity < ±1 %RH

Page 43

IE-LGR-Uxxxx-01 43

Dew-point temperature: ±1.5 °C at an ambient

temperature of T< 25 °C and RH >30 %.

For details see diagrams in Annex 4.

External temperature input (without probe):

± 0.2 °C in the range -90 °C to +100 °C

± 0.2 % of the measured value in the range

+100 ° C to +260 ° C

The accuracy of the device with attached

temperature probe is determined by the above