Page 1

MONITORING, DATA LOGGING AND

CONTROL SYSTEM

MS5, MS5D

INSTRUCTION MANUAL

Basic Part

SYSTEM s.r.o.

Page 2

2 ie-ms2-MS5-02

CONTENT: page

INSTRUCTION MANUAL........................................................................................................... 1

INTRODUCTION ............................................................................................................................. 3

1. GENERAL SAFETY PRECAUTIONS ........................................................................................ 5

2. WIZARD for INSTALLATION and CONFIGURATION of DATA LOGGER.......................... 5

3. RULES for MOUNTING and CONNECTION of DATA LOGGER...........................................7

3.1. Mechanical location of data logger and the way of cable routing...................................... 7

3.2. Data logger interface connectors......................................................................................11

3.3. Mounting and connection of output relays module MP018............................................. 13

3.4. Mounting and connection of external terminal with display............................................ 14

3.5. Connection of data logger to the computer ...................................................................... 14

3.6. Wiring of data logger with supported SMS messages...................................................... 20

3.7. Connection of data logger to power ................................................................................. 21

4. USER PROGRAM and CONFIGURATION OF DATA LOGGER ......................................... 21

4.1. Program features............................................................................................................... 21

4.2. Installation of program..................................................................................................... 21

4.3. Setting of communication with data logger ..................................................................... 21

4.4. Basic items in menu program........................................................................................... 26

5. DESCRIPTION of CONFIGURATION and DATA LOGGER MODES .................................. 27

5.1. Bookmark Common.......................................................................................................... 27

5.2. Bookmark Communication............................................................................................... 28

5.3. Bookmark Profile............................................................................................................. 29

5.4. Bookmark Ch.. Identity & Calculations........................................................................... 30

5.5. Bookmark Ch.. Measuring & recording .......................................................................... 31

5.6. Bookmark Ch..Conditions............................................................................................... 33

5.7. Bookmark Ch..Alarms and indication............................................................................. 38

6. CONTROL and INDICATION COMPONENTS of DATA LOGGER...................................... 40

7. APPLICATION NOTES.............................................................................................................. 45

7.1. Processes and how to work with ...................................................................................... 45

7.2. Configuration Profiles and how to work with.................................................................. 46

7.3. SMS message and how to work with ................................................................................ 46

7.4. Possibilities of setting Logging interval........................................................................... 46

7.5. Identification of person, who deactivated alarm.............................................................. 47

7.6. Way of entering PIN code from data logger keyboard..................................................... 47

7.7. Sharing of Display mode on several computers together with automatic storing of data

on network.................................................................................................................................... 47

7.8. How to ensure alarm report, in case of power failure..................................................... 48

7.9. Back-up of data logger configuration and its restoring................................................... 48

7.10. Other possibilities in data logger configuration.............................................................. 48

7.11. What to do if data logger does not work .......................................................................... 48

7.12. Self test error.................................................................................................................... 48

7.13. Problems with correct measurement................................................................................ 48

7.14. Problems in communication with computer..................................................................... 49

8. RECOMMENDATION FOR OPERATION AND MAINTENANCE...................................... 50

9. TECHNICAL DESCRIPTION AND PARAMETERS OF DATA LOGGER ........................... 52

Note: Manual Appendixes are available in electronic pdf format.

Page 3

ie-ms2-MS5-02 3

INTRODUCTION

Data loggers are designed for measurement, record, evaluation and consequent processing of input

electrical signals, characterized by relatively slow changes (>1s). Together with proper transmitters and

transducers are suitable for monitoring of physical values.

Device enables:

• to measure and process 1 to 16 input signals

• to acquire autonomous time record of measured values

• create alarm states

• to perform other actions based on created alarms (audible, visual indication, controlling of

relay outputs, sending SMS message, controlling of telephone dialer etc.)

• to monitor on-line measured values and states

The basic model is data logger MS5. Data logger MS5D is equipped on the top of it with and

display and simple keyboard.

Drawing (MS5D):

Items marked Accessory are not included in delivery and it is necessary to order separately.

Page 4

4 ie-ms2-MS5-02

Architecture of measuring system with data logger MS5:

Page 5

ie-ms2-MS5-02 5

1.GENERAL SAFETY PRECAUTIONS

The following list of precautions serves to reduce risk of injury or damage of described

instrument. To prevent injuries use instrument accordingly with rules in this manual.

• Follow rules specified in part Not allowed manipulations and notice

• Service should be performed only by qualified person.

• Use suitable power source. Use only source with power voltage recommended by the

manufacturer and approved in accordance with proper standards. Pay attention, the source has

undamaged cables or cover.

• Connect and disconnect correctly. Do not connect and disconnect cables, if device is under

electrical voltage.

• Do not use instrument without covers.

• Do not use instrument, if it does not work correctly. If you mean instrument does not correctly,

let it check by qualified service person.

• Do not use instrument in environment with danger of explosion.

2.WIZARD for INSTALLATION and CONFIGURATION of DATA LOGGER

2.1.1

Mounting of data logger and its accessory

• Select suitable location for placing data logger – pay attention to parameters of ambient

environment, minimize the number of cables, avoid sources of interference

• Mounting of sensors and routing of cables – pay attention to rules of theirs installation, use

recommended working positions, avoid devices and distribution of power electricity

• Check proper connection – before first switching on. If data logger controls other actuating

devices of regulation, it is recommended to put them out of operation before configuration of

data logger.

Detailed rules for mounting of data logger including different ways of connection to the

computer are described in chapter RULES for MOUNTING and CONNECTION DATA

LOGGER.

2.1.2

Basic activation of data logger

• Connection of data logger to power - connect data logger to power and visually check its

function (indication of power, optionally the display and keyboard)

• Installation of software - install user program to the PC (see part PROGRAM for DATA

LOGGER)

Configuration of data logger communication with computer – in user SW in part

Configuration-Setting of communication configure and test the data logger connection to

computer. Detailed description of Setting of communication interface is in chapter

RULES for MOUNTING and CONNECTION of DATA LOGGER.

Program enables to work simultaneously with several data loggers, that are connected to the

computer in different ways.

2.1.3

Configuration of data logger – read and change the data logger configuration by means of

the SW in part Configuration – Configuration of data logger (icon i). Detailed description

of data logger configuration is in

part DESCRIPTION of CONFIGURATION and MODES of

DATA LOGGER.

• set data logger Name, Date and Time in data logger

!

Page 6

6 ie-ms2-MS5-02

• assign names to each measured point and optimize the display for your requirements (signal

conversions, decimal point position etc.)

• switch on each input channel needed and set record function:

- on channels where recorded value with fixed interval is required, use Continuous record

with fixed interval.

- if record with fixed interval only under certain conditions is required, use Conditional

record.

- if only values and time under defined conditions are required, use Sampled record

- each type of record can be limited in time

- different record modes can be combined

• if needed set alarm functions

- first define conditions for consequent actions

- assign to each alarm conditions for creation of alarm

- assign to each alarm actions to be performed in alarm creation (lightening of LED diode

on data logger panel, activation of ALARM OUT output, activation of audible

indication, sending SMS message, sending e-mail etc.)

- maximum four conditions and two different alarm actions on one channel can be

defined; if there is a need for one channel to link several alarms (maximum four), it is

enabled to use available alarms from different channels

- activity of output ALARM-OUT can be cancel by the user directly from data logger or

remotely, at the same time it is possible to record it (including information on way of

canceling)

- changes of state for each alarms can be recorded separately

• if there is a need during data logger operation to describe from its keyboard parts of record

with predefined notes, it is enabled by means of Processes.

• if there is a need during data logger operation to change entire data logger configuration from

its keyboard, it is enabled by means of storing several configuration Profiles.

• if it is required to secure data transfer and access to data logger and program functions,

system of passwords and access rights can be used

2.1.4

Usual work with data logger

• reading, viewing, archiving and print/export recorded data from selected data logger or from

file on disk

• on-line viewing of measured values – Display mode, enables to watch simultaneously all

connected data loggers

• Display mode can be shared simultaneously on several computers in the network

Instructions for regular check and maintenance of data logger are specified in part

RECOMMENDATIONS for OPERATION and MAINTENANCE.

Page 7

ie-ms2-MS5-02 7

3.RULES for MOUNTING and CONNECTION of DATA LOGGER

3.1. Mechanical location of data logger and the way of cable routing

Location of data logger must match the operating conditions and not allowed manipulations.

Working position of data logger:

• data logger lies on horizontal nonflammable surface

• data logger is fixed by means of mounting consoles on the wall from nonflammable

material or at low current switchboard – working position is with input connectors

downward

The way of mounting of consoles to data logger and mounting holes dimensions:

• data logger is fixed by means of the holder on DIN rail at low current switchboard -

working position is with input connectors downward

The way of mounting the holder to data logger:

Page 8

8 ie-ms2-MS5-02

Mechanical drawing (without cables and connectors):

Connection terminals and connectors can be protected by magnetically fixed side covers MP027.

Recommendations for mounting:

• do not mount data logger near sources of interference (data logger must not be

mounted directly to power switchboard nor to its nearness. Also do not mount data logger

near power contactors, motors, frequency converters and other sources of strong

interference).

• In cable routing follow rules of standards for installation of low current distribution (EN

50174-2), especially it is necessary to pay attention to avoid electromagnetic interference

intrusion to the leads, transmitters, transducers and sensors. Do not locate cabling near

sources of interference.

!

Page 9

ie-ms2-MS5-02 9

• Do not use leads in parallel with power distribution network leads

• Do not use outdoor leads without corresponding protection against effects of static

electricity

• if not necessary, do not connect system with other circuitry

• fundamentally use shielded cables - e.g. SYKFY n pairs x 0.5, shielding at data logger side

connect properly

• do not create earth loops - it concerns both measuring circuits and cable shielding.

• do not create hidden earth loops - do not connect cable shielding at end device side, if these

device do not have terminal designed for shielding. Shielding must not be connected to outer

metal parts of the device nor with other devices. Do not use shielding as a signal lead.

Page 10

10 ie-ms2-MS5-02

• Do not use common leads for several channels

• It is recommended to earth data logger at one point – there is a special terminal on power

terminal. This earthing will work correctly, if system would not be grounded at other point at

the same time.

Page 11

ie-ms2-MS5-02 11

3.2. Data logger interface connectors

Connectors

Each signal is connected to self-locking terminal WAGO located on the side of the case. Insert flatbladed screwdriver to rectangle terminal hole and push screwdriver towards away from you - contact is

released. Connect wire to released terminal (circular hole behind the rectangular one) and close the terminal

by removing the screwdriver. Connect positive pole of dc voltage of input signal to terminal IN, negative to

COM, shielding to GND.

Notice: The entire input terminal block is possible to remove from data logger by pulling it up from the

connector.

Connection of leads:

Connection of transducers with current output powered by current loop

In case of connection of channels with current loop powered from data logger (inputs A0)

it is possible to insert other devices (panel meters, measuring computer cards, etc.) to

current loop. In this case it is necessary to consider, if undesirable current coupling will not

cause measurement inaccuracy. All inserted devices must be galvanic isolated from other

circuits. In case, it is not possible to ensure this, use galvanic isolated inputs A1G and power loops from

external source. Connection of input part of the module A0 including connection to two-wire probes is

described in appendix 2.

!

Page 12

12 ie-ms2-MS5-02

Connection of thermocouple probes

For connection of thermocouples use appropriate extension cable. Continuity of material of

thermocouple wire should be kept along the line up to data logger connector. Extension (compensation)

cable for thermocouples type S (PtRh-Pt) is used from different materials (due cost reasons).

Marking of subminiature thermocouple connectors and wires manufactured by OMEGA (in

accordance with US standard):

Type of

thermocouple

Connector color + wire color - wire color

K (NiCr-Ni) Yellow Yellow Red

J (Fe-Co) Black White Red

S (Pt10%Rh-Pt) Green Black Red

B (Pt30%Rh-Pt) White Black Red

T (Cu-CuNi) Blue Blue Red

If there are more thermocouple inputs in data logger not galvanic isolated, avoid thermocouples to be

mutually connected. If hazard of current leakage exists (mostly between thermocouple welded point and

surrounding metal framework), thermocouple probes with galvanic isolated weld from outer probe shield or

galvanic isolated input modules should be used. In other case high measuring errors can appear. It is

recommended to use shielded thermocouple cables for longer distance (depending on possible interference

sources).

Connection of temperature resistance transducers

• data logger enables only two-wire connection

• choose wires of maximum diameter and minimum length. In Appendix 6 additional errors

caused by leads resistance are specified.

• measurement error caused by wire resistance can be compensated by suitable configuration

of data logger

Connection of transmitters with digital output RS485 to RP input

• For connection of RS485 link for input module RS use e.g. shielded cable 2x2x0.5 mm2,

where one pair can be used for power of transducers and second pair for link RS485.

• It is recommended to terminate the link by resistor 120 Ω at the beginning and end of the

cable.

ATTENTION - it is recommended to connect to one RP module only devices

communicating with the same communication speed and the samem communication

protocol!

Connection of output ALARM OUT

This output is dual:

• switching-over galvanically isolated relay contact

• voltage (galvanically connected to data logger)

The output is set from the manufacturer, that in case of selected alarm voltage appears at the output

and simultaneously relay closes. It is enabled to set opposite behavior in data logger configuration

(service menu).

Activity of this output can be cancelled from data logger keyboard by the user or remotely from the

PC. It is enabled to identify by proper data logger configuration, who cancelled the alarm.

It is possible to connect to this output:

!

Page 13

ie-ms2-MS5-02 13

• External audio indication unit - use shielded cable up to 100m from data logger. Connect

terminal ALARM OUT and GND on data logger with the audio unit in corresponding

polarity. Connector CINCH of audio indication unit has positive pole on its central lead.

• Telephone dialer – in case of alarm telephone dialer dials specified telephone number and

announces voice message. In dialer configuration first select user mode, then store phone

number (or numbers) and record voice message. Then it is recommended to set delay of

transmitting after activation at least 10 seconds (Function 4 1). After completing of all

settings connect dialer to phone line and check the function.

• Simultaneously galvanically isolated contact relay can be used for control of other devices.

If indication controls external circuitry, it is recommended to set delay after activation at least

10 seconds to prevent possible false alerts.

3.3. Mounting and connection of output relays module MP018

Module contains 16 output relays with switching-over contact, which can be used for control of

external devices (see parameters of relay and not allowed manipulations precautions). It is possible to assign

any number of relays to any alarm to be closed if alarm appears. Relay are identified by numbers 1 to 16.

Each relay has three self-locking terminals (switching-over contact). Activity of relay can be checked

visually on assigned LED diodes.

Mounting:

Relay module is designed for mounting to switchboard with corresponding protection.

Fix module (140x211 mm) by means of DIN rail holder MP019 or screw by means of

side wall holders MP013 with four suitable screws (mounting holes are identical as for

data logger with wall holders MP013, see figure above).

Connection:

Connect module to data logger with special cable MP017 (wiring diagram is specified

in Appendix 10). Plug one cable end to corresponding connector on relay module,

second end to data logger, connector Ext. Display & Relays (upper or lower connector

half can be used, both parts are connected identically). Connect slave device on output

terminals of relay. Pay attention to necessary safety (depending on the character of

connected device).

Configuration:

Activate relay module function for proper operation in service menu of user SW. If data

logger is delivered together with relay module, this function is activated already from the

manufacturer.

Relay module layout:

Page 14

14 ie-ms2-MS5-02

3.4. Mounting and connection of external terminal with display

External terminal with display is designed for visualization of measured values, alarms and for data logger

controlling from point up to maximum 50 m from data logger. Its function is identical with internal built-in

display of MS5D (keyboard and display work in parallel).

Mounting:

External terminal with display is designed for mounting to suitable case. It can be

mounted to low-current switchboard lid where data logger itself is located or to a

separate case. Cut rectangular hole 133 x 94 mm to the lid. Insert terminal unit and four

screws from the front side and screw by means of metal holders from the back side.

Tighten slightly.

Connection:

Connect external terminal to data logger with special cable (wiring diagram is specified

in Appendix 10). Follow identical rules for cable routing as for input signals. Plug one

cable end to corresponding connector on display unit, second end to data logger,

connector Ext. Display & Relays (upper or lower connector half can be used, both parts

are connected identically).

Configuration:

Activate display module for proper operation in service menu of user SW. If data logger

is delivered together with display module, this function is activated already from the

manufacturer. Newer displays are equipped with internal audio indication. Audio

indication behaves in the same way as

External audio indication unit

connected to the

output ALARM OUT. This function can be enabled or disabled in service menu of the

SW.

3.5. Connection of data logger to the computer

Data logger contains for communication with computer one internal communication interface, which is

separated to several external interfaces:

Page 15

ie-ms2-MS5-02 15

Do not connect to these connectors simultaneously more than one device!

3.5.1 Connection of data logger to the computer by means of interface RS232

Application:

• only short distance between data logger and master device up to approximately 10 m

• 2 meters cable is included in delivery (wiring diagram is specified in Appendix 4).

3.5.2 Connection of data logger to computer by means of USB interface

Application:

• only short distance between data logger and master device up to approximately 5 m

• Use usual USB cable A-B

• Before Setting of communication in user SW it is necessary to connect converter physically to

the computer to allow operating system to create virtual communication port. Drivers are

installed to your computer during installation of user SW for data logger (valid for Windows

2000 and higher).

!

Page 16

16 ie-ms2-MS5-02

3.5.3 Connection of data logger to the computer by means of Ethernet interface

Parameters:

• Access enabled from different computers also via Internet

• Near data logger Ethernet network socket is available. Connection cable is not included in

delivery

• data logger configuration and data download is not enabled simultaneously for several

users

3.5.4 Connection of data loggers to the computer by means of interface RS485

Parameters:

Page 17

ie-ms2-MS5-02 17

• designed for long distance communication up to 1200m in indoor environment

• enables to communicate via one RS485 link with 32 data loggers

• necessary RS485 port in computer or suitable converter to other interface (RS232, USB, Ethernet)

• see detailed wiring diagrams of connection cables for recommend types of converters in Appendix

4

• recommended cable – shielded twisted two-wire, e.g. cable SYKFY n x 0.5, connect RS485 link

(lead A and B) and cable shielding. Cable shielding is not connected to any circuitry of data logger,

only continues on parallel terminal. Ground shielding near converter at the computer side,

preferably to the PC frame.

• termination resistor - see Appendix 4.

• if using several data loggers connected to one RS485 network, then all must be set to the same

communication speed and each unit must have its own address (no data logger in the network with

the same address is allowed). This configuration can be changed both from user SW and directly

from the data logger keyboard.

• do not connect to network of data loggers MS5 RS485 any other device, than data logger MS5,

MS2+, MS3+ or MS4+

Page 18

18 ie-ms2-MS5-02

Drawing of connection by means of converter RS232/RS485 (recommended type E06D):

Drawing of connection by means of converter USB/RS485 (recommended type: E214):

Page 19

ie-ms2-MS5-02 19

Drawing of connection by means of converter Ethernet/RS485 (recommended type:

UDS100,UDS1000):

3.5.5 Connection of data logger via modem

Parameters:

• Computer is far from data logger

• In data logger and PC location is covering by GSM signal of the operator

• Possible work with SMS messages

• Except described GSM connection dialed connection via land line is enabled

Parameters:

• at the data logger side and PC side suitable modem must be used (recommended type: Wavecom

M1306B)

• WARNING – data logger must be connected first by means of RS232 interface and configured, then

connected to the modem! Detailed description is specified in the following chapter with the

description of Configuration of communication.

• connect interface RS232 of data logger with modem by cable, delivered with modem !

• Used SIM card must enable data transfers (verify at your operator, not every operator

automatically supports).

Page 20

20 ie-ms2-MS5-02

Drawing of data logger connection to the PC by means of GSM modem:

3.6. Wiring of data logger with supported SMS messages

There are two possibilities of connection with supported SMS messages:

a) if data logger is connected to the PC by means of GSM modem – SMS message are sending and

receiving when data logger does not communicate with the PC, drawing connection see above

b) data logger is connected to the PC in different way than by means of GSM modem

• data logger must be equipped with independent SMS port

• this independent SMS port must be connected to GSM modem (recommended type

Wavecom M1306B), use original connection cable delivered with modem

• modem must contain SIM card enabling transfer of SMS messages. Must not be blocked by

PIN code

• area must be covered by GSM signal

Drawing of connection:

Page 21

ie-ms2-MS5-02 21

3.7. Connection of data logger to power

Data logger is powered from suitable power source (can be ordered). When powered from a different

source it is necessary to use dc voltage at range specified in technical parameters of data logger and take

into attention data logger consumption (see Appendix 1). In some applications it is necessary record runs

correctly even in case of mains failure. In this case it is necessary to use back-up source UPS as for the

computer. Above solution is necessary in cases power mains has extreme fluctuations and interference.

4.USER PROGRAM and CONFIGURATION OF DATA LOGGER

The following text describes especially possibilities of data logger setting and some procedures of work

with data. More detailed information on program is in Program Help.

4.1. Program features

Software for data logger enables to configure data logger and process measured data. It is delivered

on the CD or can be download freely from www.cometsystem.cz. After installation program can run in

two modes as:

• basic (unregistered) version – enables configuration of data loggers and table processing of

data. It does not enable graphic processing of data, administration of users and passwords,

automatic data download, storing of data outside of local computer, www display

• optional (registered) version – after entering of purchased registration key optional

functions of the SW are enabled. Entering of key is enabled in installation of the SW or

anytime later.

Hardware requirements:

• recommended configuration: processor Pentium 1 GHz and higher, 512 MB RAM, Windows 2000

and higher

4.2. Installation of program

Insert disk with programs for Comet instruments to the CD drive and run program setup.exe.

Installation wizard appears to perform all installation. Run installed program from menu Start-Program

files-CometLoggers-MSPlus (if you did not change its location during installation).

Drivers for data logger USB interface are installed automatically for operation systems Windows

2000 and higher. For other USB devices, e.g. ELO214, installation of proper drivers to these devices is

necessary.

4.3. Setting of communication with data logger

User SW enables to work simultaneously with several data loggers connected in different ways to

the computer. Configuration is performed in two steps:

• selection of communication device of the computer

• assignment of data logger to selected communication interface

If SW serves simultaneously to several data loggers, user is invited before each communication with data

logger to select data logger from the list. In Display mode all data loggers are displayed simultaneously

(except those connected via modem).

Page 22

22 ie-ms2-MS5-02

Configuration of data logger must correspond with configuration in the computer.

E.g. if data logger is set to RS232 interface and the SW is set to network serial

interface, data logger will not communicate.

4.3.1 Communication with data logger connected by means of interface RS232

• connect data logger to the computer and switch on its power

• In the software select menu item Configuration –Communication settings and continue in options

New communication device - Simple serial without addressing

•

In the next window select number of COM port and enter your name of the device (selectable,

from letters and digits)

•

Confirm window and choose selection Search. Program goes through all used communication

speeds and displays found data loggers in bottom window part (Dataloggers). Finally confirm

window Setting of communication (OK).

!

Page 23

ie-ms2-MS5-02 23

4.3.2 Communication with data logger connected by means of interface USB

• procedure is the same as in previous case. USB interface is interpreted in the computer as Virtual

COM port. Drivers would be installed automatically during installation of the SW. Drivers are

available also on installation CD or at www.cometsystem.cz .

If you disconnect the converter from the computer, it can happen, data logger will not be found in the

next communication. The cause is, operation system assigned to converter different number of

communication port. You can change it in the above window of communication device or in operation

system – Device Administrator, COM and LPT ports – Parameters – Specify.

4.3.3 Communication with data logger connected by means of Ethernet interface

• connect data logger to the computer and switch on the power

• Select software menu item Configuration –Communication settings and continue in selections New

communication device - Simple serial without addressing

• select in the following window type of interface Ethernet/RS232, enter your name of device

(selectable, from letters and digits)

• enter IP address of data logger (if you do not know you can search the network by button Search)

and number of port (10001)

• Confirm window and enter selection Search. Program goes through all used communication speeds

and displays found data loggers in the bottom window part (Dataloggers). Confirm finally

Communication settings (OK).

• In menu Configuration – Datalogger setting or directly on data logger by means of the keyboard

and display switch communication interface to Ethernet. If you have set to RS232, data logger will

work, but items referred to Ethernet interface will not be displayed (warning e-mails, traps etc.)

Then again verify functionality of the connection.

4.3.4 Communication with data loggers connected by means of interface RS485

• connect data logger to computer and switch on the power

• check on display of data loggers, if the same communication speed and different addresses are set

• In the software select menu item Configuration –Communication settings and continue in options

New communication device - Net serial

Page 24

24 ie-ms2-MS5-02

• in the following window enter your name of the device (selectable, from letters and digits) and

accordingly with the type of used converter enter next configuration:

• for converter RS232/RS485 (E06D):

• for converter USB/RS485 – configuration is analogical as in previous case, after first connection of

the converter to the PC corresponding driver to converter must be installed.

• for converter Ethernet/RS485

More details – see chapter 5.3.3.

Used converter must support interface RS485 and be switched to interface RS485!

• Confirm window and enter selection Search. Program goes through all addresses and displays

found data loggers in the bottom window part (Dataloggers). Finally confirm window

Communication settings (OK).

Page 25

ie-ms2-MS5-02 25

4.3.5 Communication with data logger connected by means of modem

• connect data logger to the computer by means of interface RS232, switch on the power and set

connection with the computer to RS232 in accordance with above instructions

• read configuration of data logger and set communication interface data logger RS232-modem.

Depending on the modem type select preset configuration string for its configuration, store to data

logger

• connect data logger to the modem (use original modem cable), on computer side connect to its

serial interface second modem

• connect modem to power and after about 10s connect data logger to power. This way it is ensured

data logger after first switching on will configure the modem.

• In the software select menu item Configuration –Communication settings and continue with

selection New communication device - Modem

• In the next window select number of COM port, where modem is connected and enter your name of

the device (selectable, from letters and digits). Some modem types work only on speed 9600 Bd.

• confirm window and in part Dataloggers enter selection New, select communication device and

enter telephone number of modem at data logger

Page 26

26 ie-ms2-MS5-02

• perform Test of connection

SIM cards of both modems must enable data transfers and must not be blocked by PIN code. More

information concerning solution of problems is specified in Appendix 5.

4.4. Basic items in menu program

Item menu File:

• reading stored file from disk to table

Data in files are stored on disk in a special binary format, which is not compatible with standard

formats. In case, value in table is not available or is not correct, error message is displayed – more

information see in Appendix 7

• reading data from data logger

After this selection window for selection of data logger is displayed (if there are more than one) ,

user can select name of file, where data will be stored and after if data logger will be erased after

data transfer

• configuration of the printer

• print – if graph was created, first query is displayed, if printing of table or graph is required

• configuration of program Options – only in optional version of program

• configuration of language localization

• logout of user – only in optional version of program

Item menu Show:

• table – displays measured values, can be set different numbers of channels. Exports to dbf and xls

format are available

• graph – only in optional version of program

• Event viewer – here actions are stored run by the SW with data logger and theirs result

Item menu Configuration:

• Datalogger settings – detailed description will follow

• Erase datalogger memory – after confirmation erasing is performed

Page 27

ie-ms2-MS5-02 27

• Reset counter inputs and erase memory - after this selection counter in counter modules (CTU,

CTK) are reset and consequently data logger data memory is erased totally.

• Reading configuration from file – reads configuration from already downloaded file with data

record. It is possible to restore configuration to data logger memory.

• Deactivate alarm signalisation – if enabled, it is possible to cancel activity of ALARM OUT output

remotely from the PC.

• Communication settings – configuration was described above

Item of menu Display - online visualization of measured values on the computer, reading interval can be set

in section File-Options, bookmark Display (in basic version it is fixed to 10s, in optional version can be

set from 10 s). In suitable configuration the mode can be shared on several computers. See Application

notes.

5. DESCRIPTION of CONFIGURATION and DATA LOGGER MODES

Use menu item Configuration – Datalogger configuration to configure data logger parameters. After

reading of configuration window is displayed with several bookmarks. If you work with Profiles, window

with Profile offer is displayed before.

5.1. Bookmark Common

• enter data logger name – maximum length is 16 characters, use letters (no diacritic marks),

digits, underline.

A folder under this name is created in computer, to store downloaded files with recorded

data in. Data logger name is displayed on the display after switch on and is available in data

logger Menu. The name is used for identification in user SW.

• check if Date and time in data logger is set correctly

When changing time in data logger, always all recorded data erasing will be

required by the SW.

• Security

– if need to secure data transfer by a password, tick Communication data encryption with

password and enter password (8 characters)

– if you need to define names and rights users of the system, first tick Communication data

encryption with password, enter password and then switch on Protection of access to HW

functions and define each system user.

– if you need to assign PIN codes to users for theirs identification in canceling of alarms or

optionally other rights, do it in window Users and password – Parameters – Details and

switch on Alarm confirmation with PIN and create new PIN code. Then switch on

Confirmation of alarm signalisation protected by user PIN or Condition setting from PC

protected by user PIN.

– if you need to secure some menu items of data logger against arbitrary overwriting, tick

proper selection and enter PIN. This PIN is different from users PIN.

If you use Communication data encryption with password and forget the

password, then it is not possible to recover the communication in simple way!

• if you will need to mark parts of record with your notes during operation from data logger

keyboard, use Processes. More detailed description is specified in chapter Application notes.

• if you will need to swap between different configurations during data logger operation, use

Profiles. More detailed description is specified in chapter Application notes.

!

!

Page 28

28 ie-ms2-MS5-02

• if you will use alarm output ALARM OUT, define, if and how data logger user can cancel its

activity. If you need to identify person, alarm was cancelled by, proceed in accordance with

chapter Application notes.

5.2. Bookmark Communication

Here you can set:

• Datalogger communication interface - you can change the type of used data logger

communication interface

Change of communication interface can cause after storing data logger configuration

you would have to physically connect via this interface and change data in

Ccommunication setting. If data logger has display with keyboard, you can change it

directly on data logger. If you set on data logger interface RS485, you must assign the

same interface also in SW, otherwise data logger will not communicate!

If you set Ethernet communication interface, you will be able to use data logger www

pages, send warning e-mails and traps. (Condition is to have installed Ethernet

interface in data logger).

• Baudrate – preset value is 115 200 Bd. If you use classic connection via RS232 (COM port), then

this is the highest available speed. For USB connection you can use higher speed. For Ethernet

interface cannot be changes (fixed to 115 200 Bd). For RS485 with larger networks a need to

decrease the speed can appear.

• RS485 network address – relevant in communication via RS485, each data logger in the network

must have different address!

• Datalogger responds to incoming SMS messages – if data logger is connected to GSM modem,

you can get actual measured values and alarm states by sending SMS from mobile telephone to

number of modem. Data logger reacts on three texts of received SMS messages: Info, Alarm, Ch1

to Ch16. For more details see chapter Application notes.

• Datalogger sends SMS message when selected alarms are activated – if data logger is connected

to GSM modem, you can assign one to four telephone numbers to each alarm states warning SMS

message containing description of created alarm is sent to.

Quick and reliable SMS message delivery depends on quality of GSM network.

Features and settings of data logger Ethernet interface:

If data logger is connected to the computer via Ethernet interface, then functions of this interface can be set

at the right part of the window. Some setting is necessary to perform in cooperation with your network

administrator.

It is possible to set:

IP address of data logger – it must be unique address in your network, assigned by your network

administrator (if you use DHCP, tick this selection, address then will be presented as 0.0.0.0.)

IP address of gateway – address of gateway or router, providing communication with other LAN

segments. Address of gateway must be at the same network segment as data logger.

Mask of subnetwork – defines range of possible IP addresses in local network, e.g. 255.255.255.0

Configuration password - password for access to setting of transmitter

Size of MTU – size of packets, default is 1400 bytes. It is possible to lower it with some networks.

Sending of warning e-mails - if ticked, warning e-mails will be sent to below specified addresses

Sending of traps - if ticked, warning SNMP traps will be sent to below specified addresses

SysLog - if ticked, warning messages will be sent to below address of SysLog server

Web enabled

– if ticked, www pages of data logger will be created

!

Page 29

ie-ms2-MS5-02 29

Soap – if ticked, actual measured values will be sent to below address of Soap server (in mode

„Display“)

Bookmark Emails:

IP address of SMTP server - If needed to send e-mails by the data logger, it is necessary to set

correctly the address.Administrator of your network gives you the value of the address.

Recepient of e-mails 1-3 - e-mail addresses of recepients. E-mails will be sent to those adresses in

case of selected alarms

Sender - enables to set addresses of the e-mail sender. Selection Original sender sets sender name to

MS5@IP address

Send testing e-mail - sends testing e-mails to selected addresses

Bookmark SNMP:

Recepient of trap 1 – 3: IP addresses of recepients of SNMP traps.

Password for reading - setting of password for access to SNMP MIB tables.

Password for write - setting of password for write do SNMP MIB table of data logger.

Send testing trap - sends testing trap of 1/0 type to specified IP addresses.

Bookmark Web

Refresh - refresh time of automatic pages reading (update of displayed measured

values). Range 10-65535 s.

Bookmark Syslog

IP address of SysLog server – IP address of server, messages are sent to.

Bookmark SOAP

IP address of SOAP server – IP address of server, on-line measured values, messages with data

logger and alarms state are sent to (similar to the „Display“ mode)

Target web page – name of pages, where server has running script for incoming message processing

Source port – port number, data logger sends SOAP message from. Default set to 8080

Target port – port of server, where SOAP message is expected

Sending interval – how often data logger sends data to server

Note: MIB tables are downloadable free at the manufacturer´s www pages.

5.3. Bookmark Profile

• Cyclic record – if it is not ticked, then after fulfilling of memory data record ends. Measurement

and evaluation of alarms continues. If it is ticked, then after fulfilling of memory

oldest data are overwriting with newest.

• Alternative record times – record must not run in fixed time intervals, but it is enabled also to

define up to four times in day, when measured values will be stored.

• Language – language localization of fixed messages on data logger LCD. It does not concerns

language localization of program

• Alarm signalisation – alarms can also be signalized acoustically or by ALARM OUT output.

Signalization of alarm can be deactivated (cancelled) by the user, if it is enabled. It can be done in

several ways:

- by pressing of the ENTER key on data logger

- by means of data logger menu with possibility to require PIN of user

- remotely from the computer

In case alarm which activated the indication is cancelled and appears again, indication is activated

again. Canceling (deactivation) of indication simultaneously refers to internal audible indication

and to ALAM OUT output.

Page 30

30 ie-ms2-MS5-02

- if there is a need to indicate acoustically some alarms directly in data logger, tick Internal acoustic

alarm signalisation and specify for each alarm, if alarm is indicated this way.

- If there is a need to activate ALARM OUT output, tick ALARM OUT and specify for each alarm,

if alarm is indicated this way.

- changes of ALARM OUT output state can be recorded and it is enabled consequently to identify the

user canceling the alarm by means of Administration of users and passwords.

- if there is a need to record changes of all alarm states, tick selection Recording of ALARM OUT

state changes and Recording of all alarms changes

- if there is a need to indicate acoustically the state of memory occupation, tick this selection

• SMS phone number list – if you use sending of SMS messages after alarm creation, then enter here

telephone numbers for sending messages. Enter numbers in international format with country code,

e.g. 0049... or +49....

• Critical states actions – it is enabled to assign actions similar to alarms to some error states,

evaluated by data logger (error of measurement on some of input channels, error in configuration of

data logger, reaching of specified occupation of data memory and self test error). Do not use zero

duration time of critical state for evaluation of the action. Use at least 10s delay. If this state lasts

this time without interruption, selected actions will be performed.

5.4. Bookmark Ch.. Identity & Calculations

This and the following bookmark refer to data logger input channels to be switched over in left lower

window corner.

Set your own identification of measured points and optional conversion of measured values at this

bookmark:

• in upper part of bookmark name and range of installed input module is specified for information.

• Channel name: - enter name of measured points in length of maximum 16 characters.

• Physical unit (except binary inputs) – you can select from the list or write your own in length of

maximum 6 characters

• Description of state open/closed (in binary inputs) – user selectable strings in length 16 of

characters to describe state „closed“/ „open“ (input S,SG) resp. „without voltage“/ „with voltage“

(input S1)

• Number of decimal places (except binary inputs) – you can set maximum 5 digits behind decimal

point.

• Recalculation (except binary inputs)- measured value from input module can be recomputed by

means of two-point linear transformation to other value. Default state is set to conversion 1:1 and

full scale points of module input range module or value 0-0, 1-1 are used. Value can be arbitrary

with the exception of state, both input values are the same.

Example: data logger with current input 4 - 20 mA is connected to temperature transducer with

current output, which generates at temperature -30°C output current 4 mA and at

temperature 80°C current 20 mA. Enter following values to the table:

Measured value 4.000 [ mA] will be shown as -30.0 [°C].

Measured value 20.000 [ mA] will be shown as 80.0 [°C].

• Processes (except binary inputs) – allow which processes are enabled to use. See Application notes.

• Show increments (only CTU, CTK inputs) – LCD displays always absolute, resp. converted

absolute counter value. It is enabled to display in record table only increments between consequent

measurements in accordance with adjusted logging interval.

Page 31

ie-ms2-MS5-02 31

• Bouncing filter (only CTU, CTK inputs) – designed to avoid possible transient effects during

change of logical level of the input signal. Filter parameters are specified in description of input

modules.

• Address of connected device, Maximum waiting etc. – setting of RP/RS input module, for more

information see Appendix 3.

5.5. Bookmark Ch.. Measuring & recording

• tick Input channel is measuring and fires alarms to enable this channel for measuring,

• if there is a need record measured value, select one from three available record mode.

These modes can be combined. Binary inputs S, S1, SG enable only the third mode –

record of state changes on input.

A)

Continuous record

- if there is a need to record measured value to the instrument memory

without respecting any other conditions, use this selection and select suitable logging interval.

Logging function can be limited in time both globally (i.e. Date and time from ...to) and daily (daily

from...to).

If no from offered logging intervals suit you, use record in alternative daily times, defined before

on bookmark Profile.

Example of table with continuous record:

Date and time Channel 1: T[°C]

1.1.2004 08:00:00 23,8

1.1.2004 08:30:00 24,5

1.1.2004 09:00:00 26,8

1.1.2004 09:30:00 33,2

1.1.2004 10:00:00 37,5

1.1.2004 10:30:00 42,3

1.1.2004 11:00:00 45,1

1.1.2004 11:30:00 45,2

1.1.2004 12:00:00 44,1

1.1.2004 12:30:00 40,1

1.1.2004 13:00:00 35,2

1.1.2004 13:30:00 30,1

B)

Conditional record– if there is

need to record measured value to the instrument memory only in

case, if defined conditions are valid, then use this selection. Select suitable logging interval and

assign conditions for the record. Logging function can be limited in time both globally (i.e. Date

and time from ...to) and daily (daily from...to).

If no from offered logging intervals suit you, use record in alternative daily times, defined before

on bookmark Profile.

Example of measured values list (condition for record – temperature is higher than 40°C):

Date and time Channel 10: T[°C]

1.1.2004 10:55:00 40,1

1.1.2004 11:00:00 41,3

1.1.2004 11:05:00 40,2

1.1.2004 11:30:00 40,3

1.1.2004 11:35:00 42,5

1.1.2004 11:40:00 40,1

Page 32

32 ie-ms2-MS5-02

By means of continuous and conditional record situation can be solved, when device operation is

monitored. In case of its trouble-free operation record with long logging interval is sufficient, but in

case of failure there is a need to have detailed record with failure.

Example of list of measured values (continuous record with interval 30 minutes and conditional

record with interval 5 minutes at temperature higher than 40°C):

Date and time Channel 1: T[°C]

1.1.2004 08:00:00 23,8 continuous

1.1.2004 08:30:00 24,5 continuous

1.1.2004 09:00:00 26,8 continuous

1.1.2004 09:30:00 33,2 continuous

1.1.2004 10:00:00 37,5 continuous

1.1.2004 10:30:00 39,3 continuous

1.1.2004 10:55:00 40,1 conditional

1.1.2004 11:00:00 41,3 continuous +conditional

1.1.2004 11:05:00 40,2 conditional

1.1.2004 11:30:00 40,3 continuous +conditional

1.1.2004 11:35:00 42,5 conditional

1.1.2004 11:40:00 40,1 conditional

1.1.2004 12:00:00 34,1 continuous

1.1.2004 12:30:00 30,1 continuous

1.1.2004 13:00:00 25,2 continuous

1.1.2004 13:30:00 20,1 continuous

Conditional record can be linked to a simple Condition or on logical Combination of conditions

(maximum four conditions from different channels linked by operators AND and OR).

Example of conditional record in case of logical combination of conditions:

C) Sampled record - if there is a need to know time and measured value when certain event appeared

defined by Condition or Combination of conditions, use this selection. Work with conditions is

similar as in previous case. Always time and value is stored when defined state of conditions started

or was terminated.

Example table with sampled record:

Date and time Channel 1: T[°C]

1.1.2004 08:01:11 23,8

condition

3 at channel 2

condition

2 at channel

5

conditio

n 4

at channel

1

condition

1 at channel

2

record will run, if equation is valid:

(condition 3 at channel 2 AND condition 2 at channel 5)

OR

(condition 4 at channel 1 AND condition 1 at channel 2)

Conditioned

record

at channel 10

runs

Page 33

ie-ms2-MS5-02 33

1.1.2004 08:40:23 24,5

1.1.2004 09:05:07 26,8

1.1.2004 09:12:44 33,2

1.1.2004 10:08:09 37,5

1.1.2004 10:32:48 42,3

Record of binary channels behaves analogically as sampled record, when each change on binary

inputs is stored. Value is replaced by text description, which corresponds with user configuration.

5.6. Bookmark Ch..Conditions

Condition defines certain state of measured value (exceeding of adjusted limit

upwards/downwards, defined state of binary input) on specified input channel. It can have two

states: valid-invalid. Up to four independent conditions at one channel can be defined. Creation of

alarm states depends on state of conditions and sampled and conditional record can be controlled

by them:

Data logger enables to set condition depending on measured value, on time and condition, which validity is

remotely controlled from the computer. Each from four conditions it is possible to switch on for evaluation.

Binary inputs has lower number of possibilities to set conditions, setting is analogical.

A) If there is a need to activate some actions dependent on Measured value, select Start of validity: Input

value

Example:

Select, if condition will be valid, if measured (Input) value is higher or lower than adjusted limit (170) and

how long must this state last without interruption. Than condition becomes valid (30s, maximum 65535s).

Define further circumstances for termination of condition validity. If no validity termination is defined,

condition remains permanently valid (till change of data logger configuration). You can select validity

termination after value return back with hysteresis (2) OR (optionally AND) if defined time expired

(maximum 65535 s).

You can also define, how the state of the condition works if measurement error appears:

measured

value,

channel state

or time value

condition

1 valid/invalid

condition

2 valid/invalid

condition

3 valid/invalid

condition

4 valid/invalid

conditioned data

record

sampled data

record

ALARM 1

ALARM 2

Page 34

34 ie-ms2-MS5-02

If other devices are controlled based on validity of the condition (relay outputs, sending

of SMS message, audible indication etc.), always use nonzero hysteresis and nonzero

time delay for creation of condition validity to avoid false alarms at transient effects of

input value.

Description of function:

Area 1... measured value exceeded limit, but was not over this limit for required duration, condition invalid.

Area 2 ... measured value exceeded limit and was over this limit for required duration. After finishing

adjusted condition became valid.

Area 3 ... measured value is still over limit, condition is valid

Area 4 ... measured value already dropped below limit, but nonzero hysteresis is adjusted, for finishing of

condition validity measured value must drop of adjusted hysteresis value

Area 5 ... measured value dropped below limit decreased of hysteresis, condition is invalid

Switching of data logger power in different condition states:

1. if power of data logger is switched OFF in area 2, after switching ON measured value si still over

limit and required delay is not over, data logger continues in testing on, as no power failure would

appear.

2. if power of data logger is switched OFF in area 2, after switching ON measured value is still over

limit and required delay is over already, condition becomes valid immediately

3. if power of data logger is switched OFF in area 2 and after switching ON measured value is not

over limit, cycle of time testing is interrupted (similarly as in area 1).

4. if power of data logger is switched OFF in area 3 or 4, after switching ON measured value is over

limit decreased of hysteresis, condition stays valid. But if measured value does not match this,

condition is invalid immediately.

Other examples of configuration of conditions depended on measured value:

• Setting of condition validity at measured value drop:

30s

30s

2.0

170

t

[s]

condition invalid

measured

value

condition valid

!

Page 35

ie-ms2-MS5-02 35

• Condition with fixed specified time validity

30s

30s

1.0

170

t

[s]

condition invalid

measured

value

condition valid

Page 36

36 ie-ms2-MS5-02

To renew validity of condition measured value first must drop below specified limit and then to

exceed the limit.

• Combination of condition validity termination with hysteresis OR after specified delay

30s

30s

170

t

[s]

condition invalid

measured

value

3600s

condition valid

Page 37

ie-ms2-MS5-02 37

To renew validity of condition measured value first must drop below specified limit and then to

exceed the limit.

Combination of condition validity termination with hysteresis AND after specified

delay

30s

30s

170

t

[s]

condition invalid

measured

value

3600s

1.0

condition valid

30s

30s

170

t

[s]

condition invalid

measured

value

3600s

1.0

condition valid

Page 38

38 ie-ms2-MS5-02

B)

if there is a need to control validity of condition only by date, time and day in the week, use

selection

Valid in time interval

Example:

C) if there is a need to control validity of condition directly from computer, use selection

Set

remotely from PC. In

this case authorized access by user PIN code entering is enabled (if using

Administration of users and passwords).

Example:

5.7. Bookmark Ch..Alarms and indication

Two alarm states for each channel are enabled to define. Several actions are enabled to assign to each

alarm. Alarms are defined based on validity of Conditions or based on logical Combinations of conditions

(maximum four conditions from different channels).

Wiring diagram of possibility of alarm states creation and associated actions:

30s

30s

170

t

[s]

condition valid

condition invalid

measured

value

3600s

1.0

Page 39

ie-ms2-MS5-02 39

Example of alarm creation at used logical combination of conditions:

Alarm is active, if input conditions are valid. By means of combination of conditions you can solve also

complex situations including remote control. Some actions last during all alarm time (audible indication,

ALARM OUT output activity, visual indication, relay closing), other actions last only at the moment of

alarm creation (SMS message, e-mails).

alarm is activated, if equation is valid:

(condition 3 on channel 2 AND condition 2 on

channel 5)

OR

(condition 4 on channel 1 AND condition 1 on

channel 2)

ALARM2

on channel 10

activated

measured

value

condition num. 1

(2,3,4)

is valid

ALARM 1

activated

yellow LED shines (always)

internal audio indication

activate ALARM OUT sig.

SMS & e-mail sending

selected relay activation

condition num. 2

(1,3,4)

is valid

ALARM 2

activated

red LED shines (always)

internal audio indication

activate ALARM OUT sig.

SMS & e-mail sending

selected relay activation

Page 40

40 ie-ms2-MS5-02

6. CONTROL and INDICATION COMPONENTS of DATA LOGGER

6.1.

Indication of power and state of output ALARM OUT

Indication is performed visually by LED diodes located at case side next to power terminals (see

Drawing). Green LED indicates the presence of power voltage, red LED activity of output ALARM OUT.

6.2.

Display and keyboard (only for models equipped with this accessory)

Left from display are three indication LED diodes:

• Power - indication of presence of power voltage

• Alarm - indication of activity of output ALARM OUT. Its function is identical to LED

from case side

• Error – lights, if configuration violence of data logger appears or error in self test

appears

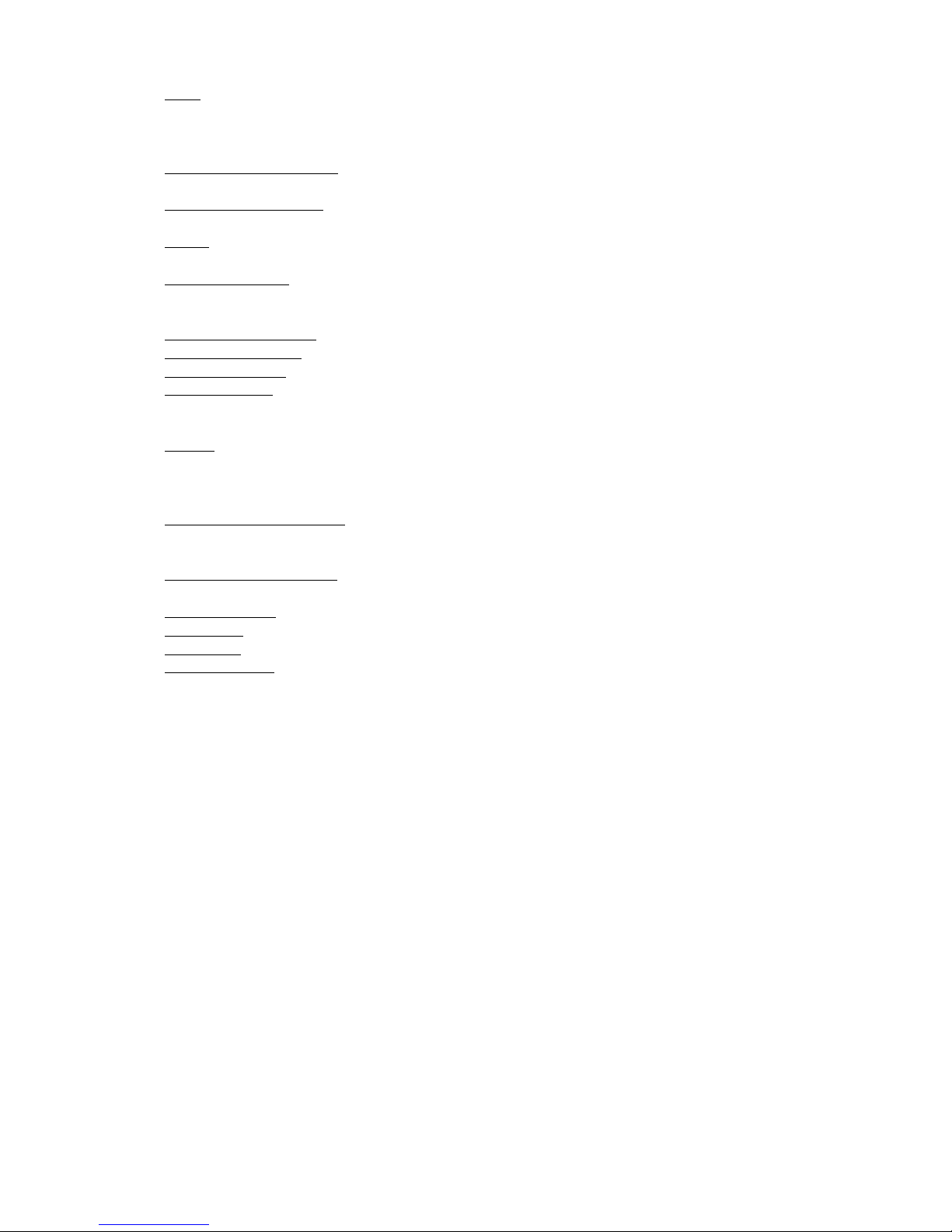

Display is dual line, display can be controlled by means of four button keyboard located next below it

(buttons MENU, , ,ENTER). After connection of data logger to power self test of several internal

voltages is performed first. If everything correct, data logger starts to display values.

Display after connection power to data logger.

Datalogger model and name is displayed for several seconds.

Then data logger evaluates self test of internal voltages. If

everything correct, data logger starts to display values. If self test

is not correct, data logger reports Self Test Error with specified

voltage, which is not correct (power voltage, internal battery and

source of negative voltage). The failure is necessary to fix. If

specified error message is confirmed by pressing ENTER key,

data logger goes on to basic display.

Basic display on the LCD

In basic display upper line displays user specified name of

measuring point, adjusted from user program. Lower line

displays measured value with physical unit respective state of

input channel. All active channels can be checked by keys , .

Error message can occur instead of measured value. Binary

inputs display at the whole LCD bottom line user defined

description of state closed/open. In case value is not available or

is not correct error message is displayed – see Appendix 7.

ENTER

MENU

Unit name: MS5

Laboratory

ENTER

MENU

Temperature 1

-12.6 [°C]

Page 41

ie-ms2-MS5-02 41

Deactivation of audible alarm and output ALARM OUT by

pressing ENTER key

If is these function is enabled, then in basic display of measured

values short pressing of this key deactivates audible indication

and ALARM OUT output. In case another alarm appears with

requirement for audible indication, alarm is activated. Similarly,

if data logger deactivates alarm, which activated audible

indication and consequently this alarm appears again, it is

activated.

Display of adjusted process

If using Processes, shortly press ENTER key in basic display

mode on required channel to display actual process in progress.

Selection of new process

If using Processes, press and hold for about 5s ENTER key in

basic display to enter selection of preset processes. Use ,

keys to go through process names enabled for input channel. If

no process is needed use selection No process. Press ENTER key

to activate selected process.

Press MENU key to leave the display without storing new

process.

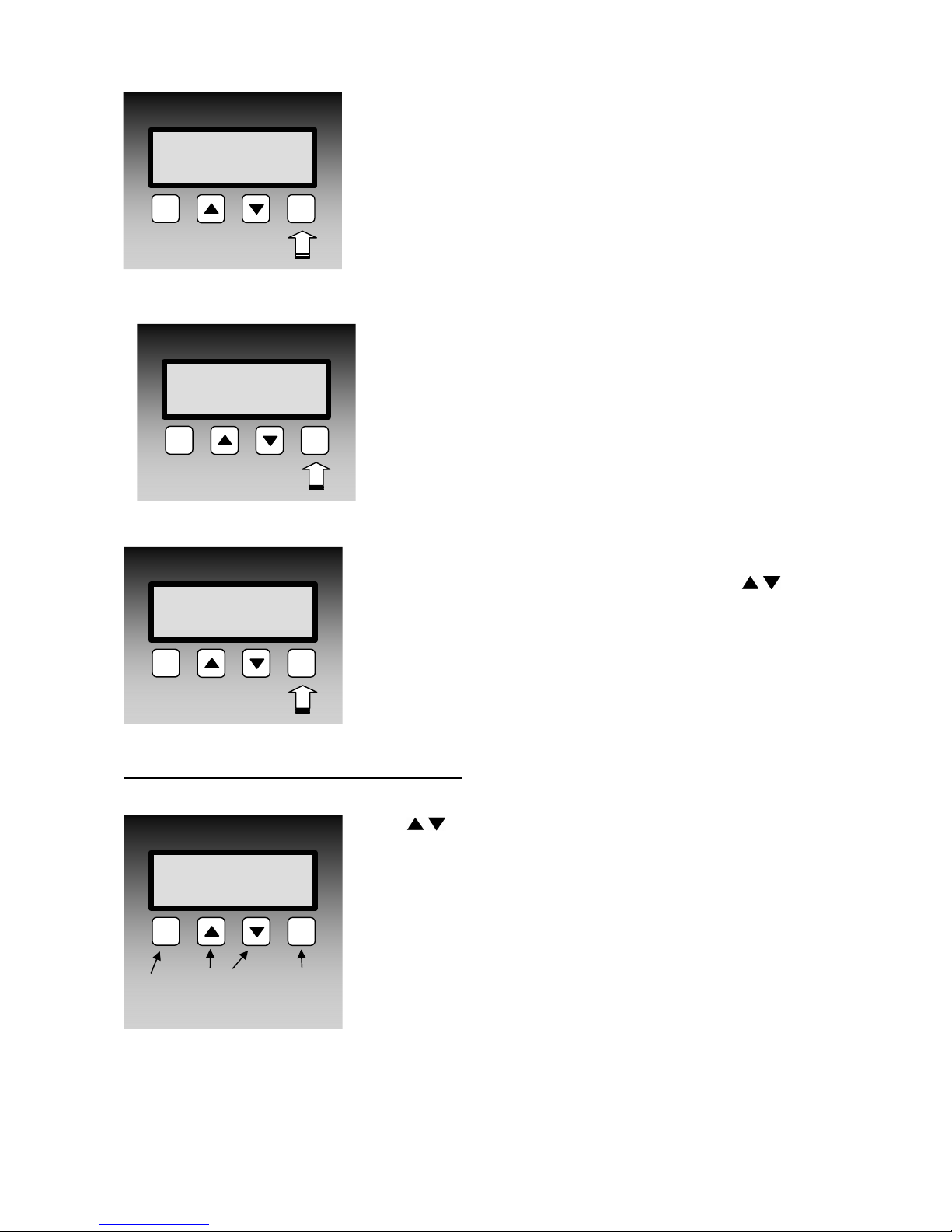

Items and function available in Menu data logger

Press MENU key in basic display to enter the data logger Menu.

Use , keys to go through all menu items. Press MENU key

to leave menu to the basic display.

ENTER

MENU

Temperature 1

-12.6 [°C]

ENTER

MENU

Process:

Smoked Ham

ENTER

MENU

Select process:

Smoked Ham

cca 5 s

ENTER

MENU

Menu item

>>>

one step

back

another menu

item

enter to

submenu

Page 42

42 ie-ms2-MS5-02

Menu item Information

Item Information contains another Sub-Menu. Press ENTER key

to enter sub-menu and use , keys to move between items.

Leave Sub-Menu by pressing MENU key.

In submenu Information it is possible to display one fixed

message after another Data Logger Model, Data Logger Name,

Serial number, Record mode (cyclic/non-cyclic), Memory

occupation, Date and time in data logger, Language .

Menu item Communication

Submenu Communication – enables to display and change

Setting of communication interface, Communication speed and

Data logger address in the RS485 network. Displayed items in

menu depends on actually adjusted communication interface and

optionally on implemented HW.

Change of configuration can be selectable protected by PIN

code, entered by the user. Way of entering PIN code is specified

in Application notes.

Change of data logger communication interface

Press ENTER key to enter selection of communication

interface. Use , keys to select required communication

interface and press ENTER key to confirm the selection.

Adjusted communication interface must correspond with

physical connection and with SW configuration. If you

choose selection Ethernet, corresponding items in Data

Logger Configuration become active.

Change of data logger communication speed

Press ENTER key to enter selection of communication speed.

Use , keys to select required communication speed and

press ENTER key to confirm the selection. This selection is

not available for some communication interface.

ATTENTION – standard computer COM port does not

support communication speed 230 400 Bd. This highest speed

you can use at USB connection.

ENTER

MENU

Information

>>>

ENTER

MENU

Communication

>>>

ENTER

MENU

Com. port:

RS232, USB

ENTER

MENU

Com. speed

115200 Bd

Page 43

ie-ms2-MS5-02 43

Change of data logger RS485 address

Press ENTER key to enter address selection. By means of

, keys select new address and press ENTER key to

confirm selection. This selection is available only for active

RS485 interface.

Menu item Acoustic signalisation & ALARM OUT

Submenu for switch OFF the audio indication. This item appears

only, if user allowed in Common parameters Alarm

Confirmation via menu. After entering actual states of audio

indication and ALARM OUT output are displayed. If in active

state, it is possible to deactivate by pressing ENTER key. In case

password requirement function is activated in SW, it is necessary

to enter password first. Way of entering PIN code is specified in

Application notes.

Menu item Configuration

Submenu enables to set data logger to another predefined

configuration – Profile. This item of menu is displayed only, if

user enabled in Common parameters administration of

Profiles and allowed to change configuration from keyboard

of data logger. Change of configuration can be secured by PIN

code. Way of entering PIN code is specified in Application

notes..

Change of configuration profile

Press ENTER key to enter selection of configuration profiles.

By means of , keys select new profile and confirm by

pressing ENTER key. This action also causes reset of all

conditions, which were created or were preparing to be created.

ENTER

MENU

Logger address

in net: 02

ENTER

MENU

Acoustic sign.

&ALARM OUT >>>

ENTER

MENU

Configuration

>>>

ENTER

MENU

Select config.:

Profile 1

Page 44

44 ie-ms2-MS5-02

Menu item Service

Submenu enabling to display value of some Service parameters

of data logger.

Service – display of self test of internal voltages

Self test of data logger internal voltage. First value indicates

approximate power voltage (9 to 30 V, see technical

parameters). Second value is voltage of negative source (-2V to

-6V) and third value is voltage of internal back-up battery (2,6V

to 3,3 V).

Service – display of firmware version and uP speed

Service – display of cold junction temperature of

thermocouple

ENTER

MENU

Service

>>>

ENTER

MENU

Selftest:

24V -3.7V 3.0V

ENTER

MENU

Firmware ver.:

5.2.1 6MHz

ENTER

MENU

Cold junction:

25.5 [°C]

Page 45

ie-ms2-MS5-02 45

Service – display of state of processing SMS

Actual state of communication with GSM modem is displayed

on the LCD. Press ENTER key to enter directly the display of

receiving and sending SMS buffer.

Service – display of A/D converter values for measured

channels

Value read from A/D converter of analog inputs at range 0 to

65535. Limit value 0 indicates converter lower limitation

(corresponds to Error1) and value 65535 (corresponds to Error

2) indicates converter upper limitation. With counter inputs

binary state of counter is displayed. With binary inputs state of

input (ON/OFF) is displayed and with RS input symbols „---“

are displayed.

7. APPLICATION NOTES

7.1. Processes and how to work with

Process is the name of action recorded by data logger in time. User of data logger can enter from its

keyboard to each input channel different previously preset names of processes and such way to

distinguish in record, which action was performed at that time. Example can be smoke-box for

meat. During one working shift different products are processed consequently (names are known

before and stored in data logger).

Way of work with processes:

• In configuration of data logger write to Process label list all processes (e.g. kind of products)

meant for the data logger. Maximum processes is 16 and each process name can contain

maximum 16 characters

• select for each channel, which processes will be used (all-some-no). This selection simplifies

choosing process (kind of product), when only relevant processes will be offered for the

channel.

• at the beginning of the process (e.g. after inserting one kind of product to the meat smoke-

box) user finds the desired input channel and presses and holds ENTER key on the data

logger keyboard. The name of the first process is displayed. By means of arrow keys preset

name corresponding with the product can be selected. By pressing ENTER key again this

process in data logger will be activated.

• when the operation is finished and user requires another process (e.g. another kind of product

is inserted to the meat smoke-box), it is activated in similar way. Optionally no process is

assigned.

• after recorded data download to the PC each time section of the record will be described with

name of process, which was active in specified time

• by short pressing of ENTER key on data logger it is possible to display actually active

process

ENTER

MENU

SMSStatus:00:56

SMS: Waiting...

ENTER

MENU

Temperature 1

ADC: 37782

Page 46

46 ie-ms2-MS5-02

Using of Processes is not possible with binary channels (S, SG, S1).

7.2. Configuration Profiles and how to work with

Configuration Profiles are designed for applications, where it is required data logger is portable and

quick change of configuration is enabled without necessity to erase actual record and without

necessity to use computer. User stores required Configuration Profiles to data logger in advance.

Maximum number of Configuration profiles is 20, minimum number is 6. Each Configuration

profile has its name defined by the user (12 characters).

Profile management– enables user to work with several predefined configurations of data logger

and change them.

Enable profile change from datalogger keyboard – data loggers with display enables to swap each

Configuration Profiles from data logger keyboard without necessity of connection to the computer.

If administration of profiles is active, then after reading of data logger configuration always

window with list of existing profiles appears first enabling to create new, edit or remove actual

profile. Before storing of edited profile or removing profile erasing of all measured data is

necessary. So optional data download to the PC is useful before erasing.

7.3. SMS message and how to work with

If data logger is connected to modem with support SMS function, it is possible enable the following

action:

response on incoming SMS queries, when following possibilities exist:

a) Info – if SMS is sent to modem with this text (both capital/lower-case letters are allowed), SMS

response is received containing basic information on data logger (type, name, memory occupation,

channel names, measured values and alarm states). This SMS can consist of up to four partial SMS

messages depending on configuration of data logger. One long SMS can be displayed on mobile

telephones with support of long SMS.

b) Alarm - if SMS is sent to modem with this text (both capital/lower-case letters are allowed), SMS