Page 1

INSTRUCTION

INSTRUCTIONINSTRUCTION

INSTRUCTION

MANUAL

MANUALMANUAL

MANUAL

FOR

FORFOR

FOR

POT WASHING

POT WASHINGPOT WASHING

POT WASHING

-------------------------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------------------------------------

Mod.

Mod.Mod.

Mod.

GE605 rcd

GE605 rcdGE605 rcd

GE605 rcd

GE755 rcd

GE755 rcdGE755 rcd

GE755 rcd

GE805 rcd

GE805 rcdGE805 rcd

GE805 rcd

GE1005 rcd

GE1005 rcdGE1005 rcd

GE1005 rcd

GE1255 rcd

GE1255 rcdGE1255 rcd

GE1255 rcd

Page 2

INSTRUCTIONS FOR THE USER

2

FOREWORD

1. Read the instructions contained in the present booklet carefully, because

they supply important information on installation, operation and

maintenance safety. Store this booklet carefully for any further

consultation by other operators.

2. Having removed the packing material, check that all the equipment is

present.

If there is any doubt, do not use it and contact qualified personnel.

The packing elements (plastic bags, foam polystyrene, nails, etc.) should

be kept away from children, because they are dangerous.

3. Before switching the equipment on, make sure that the model plate data

conforms to that of the electrical and water distribution network.

4. Installation should be carried out by qualified personnel according to the

manufacturer's instructions.

5. This equipment should be destined to the use which it has been conceived

for. Any other application should be considered improper and

consequently dangerous.

6. The equipment should only be used by personnel trained for its use.

7. Operators must strictly follow all hygienic requirements in the handling of

clean dishware and cutlery.

8. Do not leave the machine in an environment at temperatures lower than

0°C.

9. The protection of the machine is IP X4, therefore it should not be washed

with high pressure directed water jets.

10.Qualified personnel only can access the control panel, after having

disconnected the machine from the primary current supply.

11.The appliance is made according to EEC 89/336 regarding radio noise

suppression and electromagnetic compatibility.

12.According to EEC directive nr.23 of 19/02/1973 and the law of actuation

nr.791 of 18/10/1987, our appliances are built-up according to the good

technique norms in force in Italy and abroad.

13.Noise level of the machine, less than 70dB(A)

Page 3

INSTRUCTIONS FOR THE USER

3

INSTRUCTIONS FOR USE

Page 4

INSTRUCTIONS FOR THE USER

4

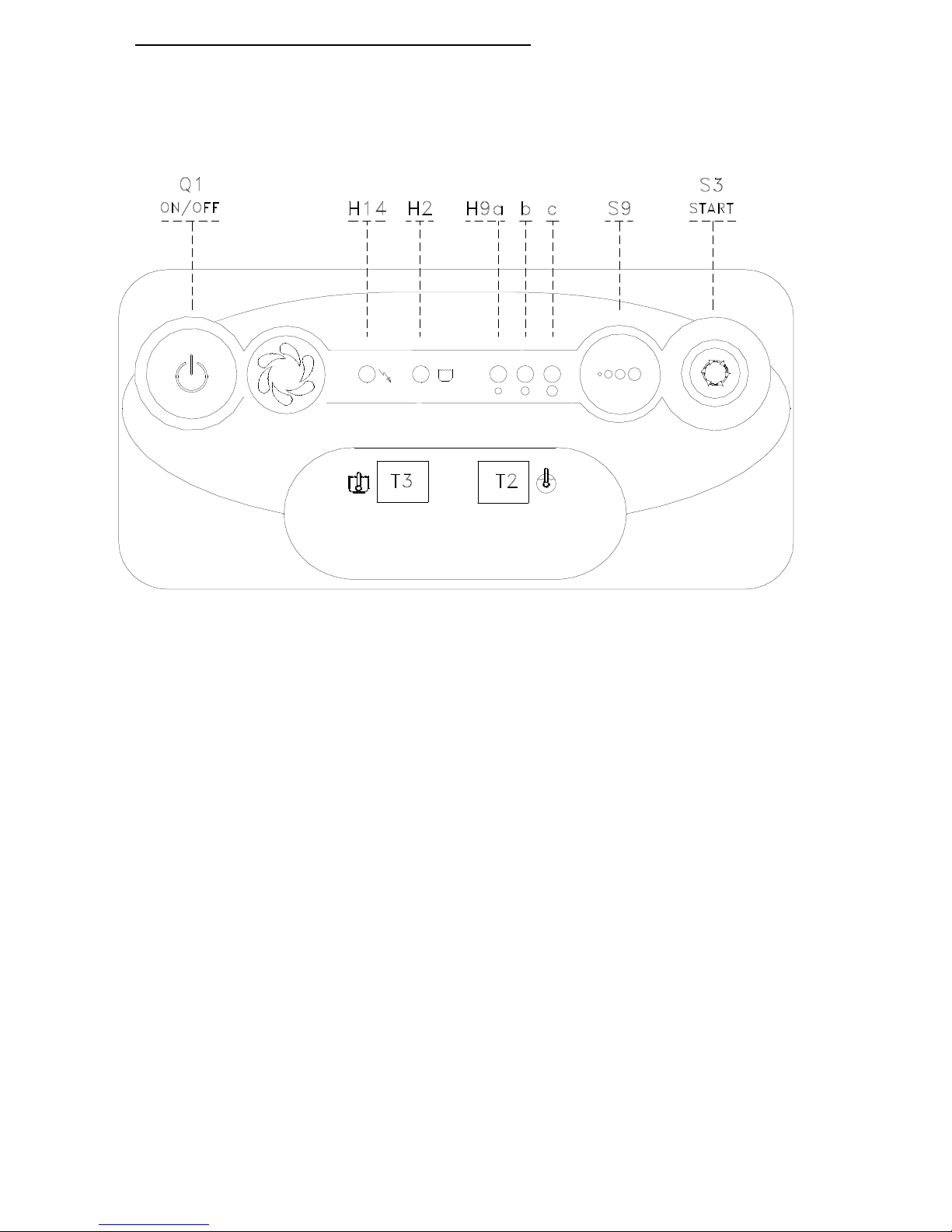

CONTROL PANEL

CONTROL PANELCONTROL PANEL

CONTROL PANEL

Q1

Main switch

H14

Pilot lamp " check "

H9a-b-c

Pilot lamp "cycle"

H2

Pilot lamp "machine ready"

S3

Push button "WASH or DRAIN CYCLE START"

S9

Cycle selector / AUTOMATIC or MANUAL startup

T2 B

oiler thermometer

T3

Tank thermometer

Page 5

INSTRUCTIONS FOR THE USER

5

OPERATION AND USE

1. Before washing make sure that:

• the wall-mounted on/off switch is switched on;

• the water tap is open;

• water is present in the distribution network;

• the pump protection filters are installed in their respective positions;

• the overflow in inserted;

• all rotating parts are free;

• the rinse aid dispenser is full;

• make sure that dishware is in good conditions as it may cause cleaning

difficulty and haven bacteria.

2. Press the "Q1 on/off" button ("H14" ON) to enable the automatic wash

tank filling and the consequent triggering of the heating element.

Wait that the temperatures are 55°C for washing "T3" and 80-85°C

for rinsing "T2" (the lamp"H2" ON).

3. Pour about 30 gr. of detergent directly into the tank, paying attention to

distribute it uniformly on the filters, the quantity being according to

supplier's instructions. Add 15 gr. every 4 cycles to achieve a concentration

of 1,5 gr./lt. In order to respect our environment, use only the correct amount

of detergent.

When using chlorinated detergent, it is suggested to use an automatic

dispenser; otherwise, brownish spots might appear on the surfaces due to

chlorine reactions. Detergent should always be placed near the pump filter.

4. Then, introduce the glasses or the cups to wash, after having removed the

solid waste and having placed them into the proper racks. The cups and the

glasses should be turned upside down, while the cutlery should be put

vertically into the proper container, and the same applies to dishware.

Page 6

INSTRUCTIONS FOR THE USER

6

5. Press the "S9" button to select the wash cycle according to conditions of

the dishware:

• (H9a ON ) ................short cycle ............ for glasses and cups

• (H9b ON).................medium cycle........ with normally dirty dishes

• (H9c ON) .................long cycle.............. with particularly dirty dishes or

. deep dishes

• (H9a-b-c ON)...........intensive wash...... max 8 min.

6. Close the door and press the "S3 start" button to start cycle.

The lamp flashes.

The activation of a cycle is shown by the flash of the lamp:

H9a for the short cycle

H9b for the medium cycle

H9c for the long cycle

H9a-b-c alternating for the intensive wash (max 8 min.).

It is possible to perform an intensive wash (lamp "H9a-b-c" OFF) that will

remain activated until the "S3 start" button is pressed again or a maximum

time of 8 min. is reached; the pause, rinse and drain (if required) phases will

follow.

To opening the door, the lamp "H14" flashes quickly.

To start up the the cycle AUTOMATICALLY (by opening and closing the

door), you will need to change the cycle start up mode. Press and hold the

"S9" button (approx. 10sec) until the pre-selected cycle lamp remains

blinking lite and the washing cycle will then start up AUTOMATICALLY

when the door is closed.

ATTENTION: Machine in conformity with the existing hygienic

standards, guaranteeing a final rinse at 85°C. Wash cycle automatically

lengthened if final rinse temperature is not reached.When this auto-cycle

intervenes and the cycle is pro-longed, after 8 minutes the "H14"

indicator flashes to indicate this intervention and the cycle continues

(water supply temperature is likely to be the problem, otherwise contact

an assistance center since it is a rinse water heating intervention.).

Page 7

INSTRUCTIONS FOR THE USER

7

7. Remove the rack and slightly incline it to permit a perfect drain; allow

dishware to dry and after having washed one’s hands, handle the rack in

order not to touch the dishware inside then place the rack on hygienically

clean shelves.

To change the tank water if necessary.

8. DRAIN CYCLE

At the end of washing, with the machine off, take out the overflow pipe

from the tank and wait until it is completely empty then close the door

and turn on the machine for a few minutes to wash the machine.

Then again press the switch "Q1 on/off" to turn off the machine and wait

until the tank is completely empty.

For machines with drain pump, open the front door, pull out the

overflow pipe, turn ON the machine, and press the "S3 start" button for

start the drain cycle. The lamp "H14" and "H9" flashes.

The machine will carry out the drain cycle for 2 min. and 20 sec.

At this point, the tank filter can be taken out, in order to be washed, then

replace it with the overflow in its place.

SELF CLEANING AND DRAIN CYCLE

For machines with drain pump, turn OFF the machine, pull out the

overflow pipe, close the front door and press the "S3 start" button for start

the cycle. The lamps “H9a-H9c” and "H14" flashes.

The machine will carry out the drain cycle for 2 min. and 20 sec.

At this point, the tank filter can be taken out, in order to be washed, then

replace it with the overflow in its place.

(For further use , first switch off the machine).

For any further information concerning equipment cleaning, read chapter

"USEFUL SUGGESTIONS".

DEACTIVATING THE DISHWASHER AT THE END OF THE DAY

9. At the end of service, turn off by using the main wall switch and close the

water and steam* valve.

(*) for steam machines only

Page 8

INSTRUCTIONS FOR THE USER

8

INSTRUCTIONS DURING THE WASHING

1)Do not plunge bare hands into the water containing the detergent. If this

happens, wash them immediately and abundantly with fresh water.

2)When the machine is operating, do not open the door too rapidly.

3)Use only specific anti-foaming detergents.

4)Disconnect the equipment in case the machine is out of order or it does

not work properly. For the repairs consult a technical assistance centre

authorised by the manufacturer and ask only for an original spare parts.

5)Never modify the thermostat settings.

6)Check that the wash temperature is 55-60°C.

7)Wash tank water should be changed at least twice a day or according to

daily wash requirements.

8)Do not subject clean dishware to any further cleansing treatment such as

brushes or drying towels.

If these instructions are not followed, the safety of the equipment can be

compromised.

ALARMS

ALARM A4

Tank temperature probe not connected.

Boiler temperature probe not connected.

ALARM A5

Tank temperature probe in short circuit or the

temperature exceeds 99°C.

Boiler temperature probe in short circuit or the

temperature exceeds 99°C.

Page 9

INSTRUCTIONS FOR THE USER

9

USEFUL SUGGESTIONS

1) MAINTENANCE

IMPORTANT: Before carrying out the cleaning and maintenance

operations, disconnect the equipment from the electric supply.

Frequently check and clean the nozzles. The frequency of this operation will

depend on the quantity of residues, which may result in an unsatisfactory

washing result.

♦ For the inside and outside cleaning of the machine, do not use corrosive

products such as sodium hypochlorite (bleach) savelling water and

hydrochloric acid, acids, steel wool or steel brushes.

♦ The presence of calcium and magnesium salt in the water can

compromise machine performance, thus ask qualified personnel to

remove the deposits periodically.

♦ In order to avoid some oxidation risks, or chemical reactions, generally

the stainless steel surfaces have to be well cleaned.

2) OPTIMAL RESULTS:

A possible wash deficiency can be noticed when residue remains.

Marks can be caused by an insufficient rinse: in this case check

that the rinse nozzles are clean and that there is sufficient water supply

pressure.

In case of dishware residue check that:

• the washing nozzles are clean

• the water temperature is around 60°C

• there is detergent

• the pump suction filter is clean

• the racks are suitable for the dishes and cutlery that are to be washed

• the position of the cutlery and the dishes in the racks are correct

3) TEMPORARY MACHINE NON-USE

In case the machine is stopped for some weeks, it is recommended before

closing it to fill the tank and run the machine with clean water, then empty it

out, in order to avoid the forming of bad odour and that any residue remains

in the pump.

If necessary repeat this operation until the water leaving the machine is

clean.

If the machine is stopped for many weeks, it is recommended to oil the

stainless steel surfaces with paraffin oil and to discharge the water from the

boiler and the electric pump.

Page 10

INSTRUCTIONS FOR THE USER

10

4)SANITIZING THE MACHINE

Sanitizing the machine at least once a week is of the utmost importance in

order to guarantee hygiene even when the machine is not in use.

It is advisable to use a disinfecting product suggested by an authorised

detergent dealer.

The use of this product will satisfy hygienic requirements, even during

machine non use.

Before switching off the machine run the machine briefly with clean

water.

5)HARD WATER CONDITIONS

If a hard water supply is present, mineral deposits will form within the

machine and also on dishware.

In order to avoid the above conditions a periodic removal of these deposits is

necessary.

The frequency and method of this operation upon consultation by your

detergent supplier.

Page 11

11

INSTALLATION AND MAINTENANCE

INSTRUCTIONS

The following instructions are addressed to a qualified personnel the only

one authorised to carry out checks and repairs, if any.

The manufacturer declines any responsibility in the case of interventions

made by a non qualified personnel or the use of spare parts other than those

supplied by the Manufacture.

Page 12

INSTRUCTIONS FOR TECHNICAL PERSONNEL

12

INSTALLATION

During installation, carry-out a good machine levelling, which is a

prerequisite for a correct operation thereof. In order to prevent any damages

caused by vapours going out of the machine, make sure that the surrounding

materials don't deteriorate in their presence.

1)ELECTRICAL CONNECTION

The electrical power supply shall be fed to the machine by connecting it to a

wall-mounted differential magneto-thermal on/off switch, with a contact

aperture distance equal to or greater than 3 mm.

The said magnetothermal on/off switch should be rated according to the

following table, as a function of the power supply voltage, the machine

model, and the heating type (electrical or steam heating).

Modèle Type de

chauffage

Branchement

électrique (V)

Puissance

totale (kW)

Absorption

électrique (A)

Section câble

alimentation

(mm²)

Interrupteur

a mur

(A)

GE605 RCD électrique

380-400V/3N

9 13,7 2,5 16.0

GE755 RCD électrique

380-400V/3N

9 13,7 2,5 16.0

GE805 RCD électrique

380-400V/3N

9 13,7 2,5 16.0

GE1005 RCD électrique

380-400V/3N

15 23,0 4 32.0

GE1255 RCD électrique

380-400V/3N

15 23,0 4 32.0

N.B.: Check that the voltage which the machine is set to correspond to the

power supply voltage available.

Power cable cross section must not be less then that indicated in the table. If

the cables are not protected by a sheathing, use a flexible, protected cable in

Polychloroprene with equivalent H07RN-F characteristics.

Check the line length; should it be too long, conform the line cross section to

such line length and to current drain; don't submit the power supply cable to

traction.

Cable must be connected to X1 terminal block passing through the cable

brake (see refer to electrical diagram).

Page 13

INSTRUCTIONS FOR TECHNICAL PERSONNEL

13

The electrical safety of this equipment is only assured if it is connected as

follows.

It is necessary to connect the equipment to an effective ground installation,

as specified by the electrical safety regulations in force.

Check that this basic requirement is complied with and, in case of doubt, ask

for a careful check of the installation by a qualified personal.

In addition, the equipment shall be part of an equipotential system, the

effectiveness of which should be checked according to the regulations in

force.

The connection should be made at the screw marked by the respective label

located on the equipment back side. ( )

The manufacturer declines any responsibility for any damages caused by lack

of an effective ground installation.

2)WATER CONNECTION

Install a water cock in a well accessible place, terminating in a 3/4" gas

fitting, which the draining pipe shall be connected to.

Carefully comply with any national or regional regulations in force.

The operating pressure should not be less than 2 bar nor greater than 4 bar

(200/400 kPa). In order to get a good result, it is suggested that the feeding

water has an hardness not greater than 5/10°F and a temperature of 55°C 0+10°C.

3)STEAM FEEDING (*)

As far as steam feeding is concerned, connect to the machine fittings

indicated in the installation drawings. In order to make the equipment

independent from the general steam distribution network, it is necessary to

use gate and 1”gas on/off valves.

This type of feeding should be supplied at a pressure ranging from 0.5bar

(110,8°C-50kPa) to 2bar (132,9°C-200 kPa).

The steam used should be absolutely saturated and dry.

4)WATER DRAIN

Install a water drain at the floor level, complete with siphon, and connect to

the drain through a flexible pipe, making sure that there are no throttlings

along it. Make sure that the draining pipe is resistant at a temperature of

70°C.

Page 14

INSTRUCTIONS FOR TECHNICAL PERSONNEL

14

5) STEAM EXHAUST (*)

The condensed steam exhaust shall have an appropriate slope toward the

recovery installation or a blow-by pump, in order to guarantee an

autonomous scavenging of the condensed steam.

_______________________

(*) for steam machines only

6) LOADING AND UNLOADING OF THE MACHINE

For the transportation of the machine from the delivery point to the final

installation position, use a fork lift or adequate lifting equipment used by

authorised staff. Lift the machine by its frame, taking care that any

protruding parts are not damaged (discharges, wiring etc.).

7) MACHINE DISMANTLING

At the end of its normal lifetime, the machine has to be taken apart according

to the local regulations in force by separating the components as follows:

• metal parts: hood, platforms, frames, filters

• electrical parts: motors, remote control switches, microswitches, wiring

• plastic parts: racks, connections

• rubber parts: tubes, sleeves

Page 15

INSTRUCTIONS FOR TECHNICAL PERSONNEL

15

WIRING DIAGRAM

B2

Boiler temperature probe

B3 Tank temperature probe

C1 Anti noise filter

E2 Booster heater

E3 Tank heater

K1 Relais

K2 Tank filling relay

KS1 Door switch relay

KE2 Booster heater contactor

KE2b Safety contactor of booster heater

KE3 Tank heater contactor

KM2 Rinse pump contactor

KM3 Wash pump contactor

KM3a Wash pump contactor

M2 Rinse pump

M2a Rinse pump

M3 Wash pump

M3a Wash pump

M5 Drain pump (if required)

MD Detergent dispenser (if required)

S1 Door switch

S2 Tank pressure switch

S11a RCD pressure switch

SE2 Booster thermostat

SE2a Booster thermostat

SE2b Booster safety thermostat

SE3 Tank thermostat

Y11 RCD filleng solenoid valve

Y2 Tank filling solenoid valve

X1 Junction

The manufacturer declines any resonsibility for any printing errors contained

in this booklet. The manufacturer also reserves the right to make any

modifications to its products that do not affect the basic characteristics

thereof.

Page 16

GE…-eng

12-2010

Loading...

Loading...