Page 1

Model 0616X

0816X

Electronic Key Systems

This manual applicable for the following key system models:

l 0616X Manufacturing Code

Codes

and Later

J

66-031.04

Page 2

TABLE OF CONTENTS

Table of Contents

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . .

MANUAL SCOPERELATEDPUBLICATioN’S

. . . . . . . . . . . . . . . . . .

. . . . . .

REGARDING FCC RULES AND ‘REGULATIONS . . . . . . . . . . . . . . . . . l-l

CHAPTER 2 INSTALLATION

l

l .

. l

. . . .

. . . . . . . . . . . . . .

. . . . . . . .

.

MOUNTING PROCEDURE . . . . . . . . . . . . . . . . . . . . . . .

SYSTEM WIRING . . . . . . . . . . . . . . . . . . . . . . . . . .

CHECKOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

CHAPTER3 SYSTEM PROGRAMMING . . . . . . . . . . . . . . . . . . . . . . . . 3-l

GENERAL INFORMATION

BASE LEVELPROGRAM ENTRY

CLASS OF SERVICE DEFAULT

. . . . . . . . . . . . . . . . . . . .

: : : :

: : : : : :

: : : : : . .

.

PROGRAMMING KEYS

SYSTEM COS

.

: : : :

:

: : :

:

: . .

LINE COS PROGRAMMING PROCEDURE

PROCEDURE . : : :

: : : : : :

: : : :

SMDR AND COS PRINTOUT

SYSTEM SPEED

CHAPTER 4 MAINTENANCE

TECHNICAL ASSISTANCE AND REPAIR SERVICE

PROGRAMMING . . . . . . . . . . . . . . . . . . . 3-12

...

FUSE LOCATION

: : : : : : :

FAILURE ISOLATION. : : : : : : : : : : : : : : : : : :

PAIRED STATIONS

.........................

: :

: : : : : : : : . 3-11

.......

..........................

.......

FAILURE ANALYSIS

.

:

: :

: :

:

:

2-l

Cl

..............................

LIST OF TABLES

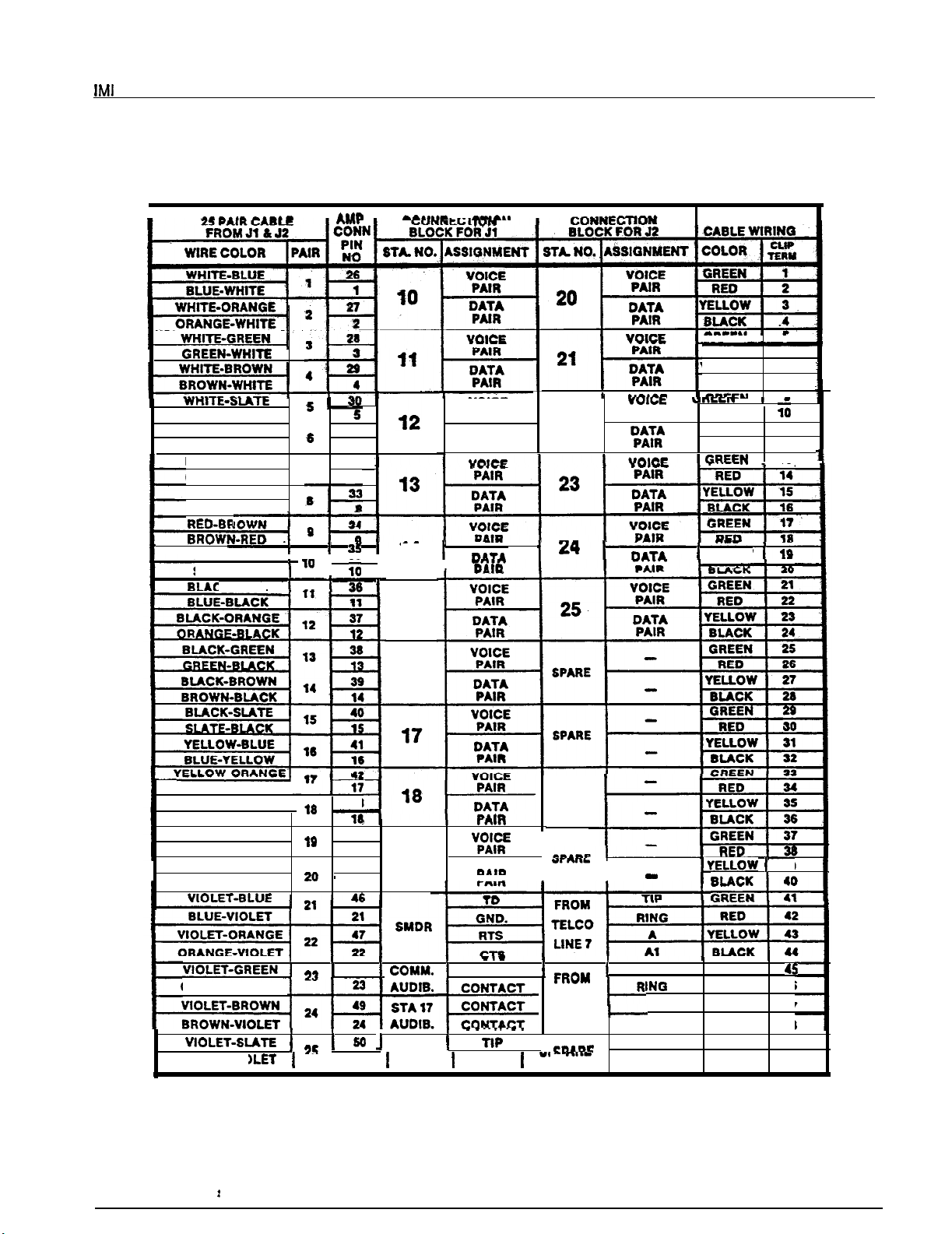

Table 2-l. KSU to Station Wiring

Table 3-l. System COS Programming Reference .

. . . . . . . . . . . . .

. . . . . . . . . . . . . 3-13

Table 3-2. tine COS Programming Reference . . . . . . . . . . . . . . . . .

Table 3-3. Station COS Programming Reference

Table 34. Toll Restriction

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

Table 4-1. Station Pairing . . . . . . . . . . . . . . . . . . . . . . . . .4-3

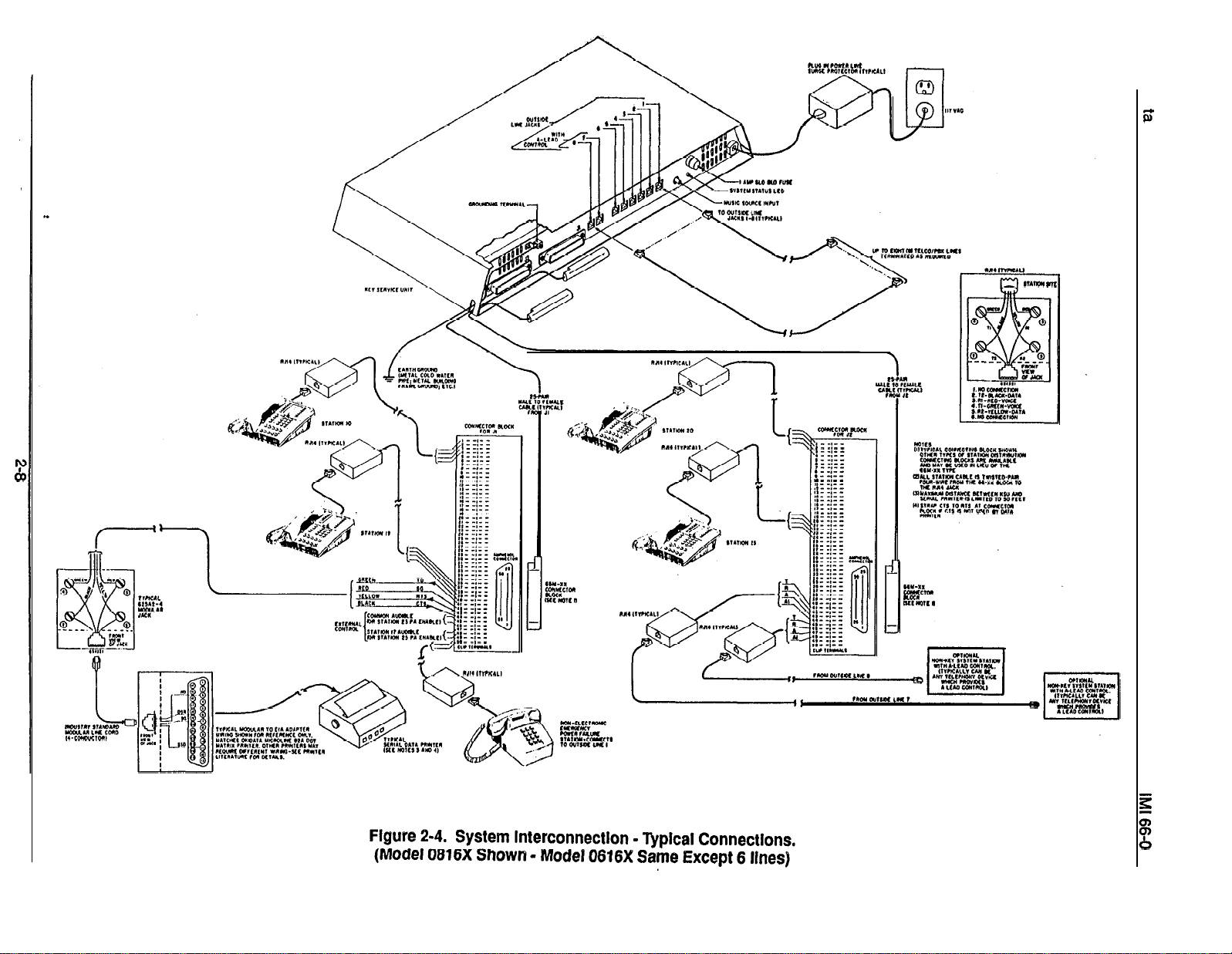

LIST OF ILLUSTRATIONS

Figure 2-l.

Figure 2-2.

Figure 2-3.

Figure 2.4.

Figure

Figure 3-2.

Figure 3-3.

Figure 3-4.

Figure 4-l.

Figure 4-2.

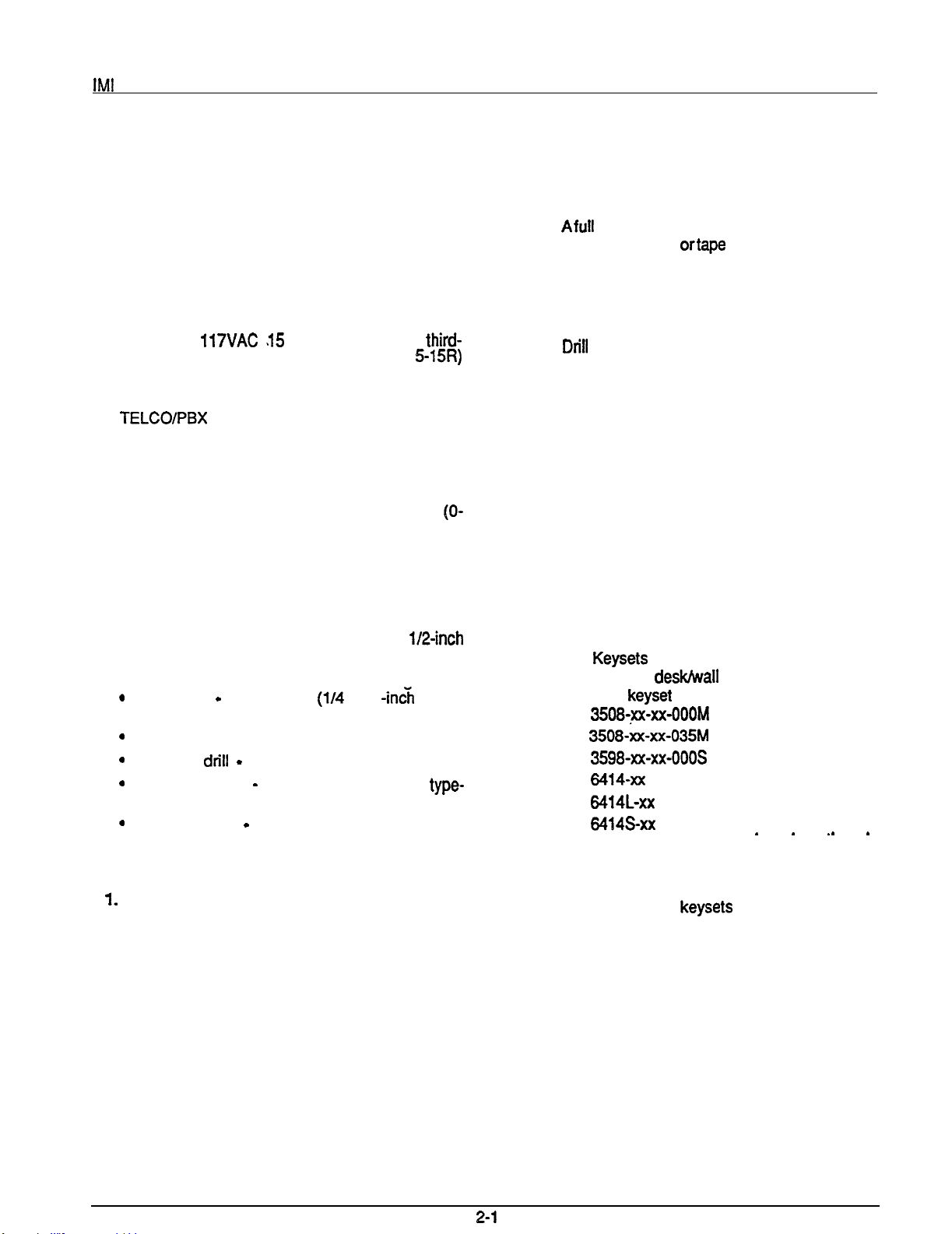

Mounting Dimensions

External Signalling

Typical Connection

PA Connections

System Interconnection

Station Programming Keys

Station Message Detail Record

Typical COS Printouts

Programming Flow

. :

Failure Analysis Flow Chart

Station Wall Mounting Details

.. ..

...................................................

..............

.

....................

.

......

.....

Format.

.....

................

.3-2

3-l 0

Page 3

CHAPTER 1

INTRODUCTION

Introduction

MANUAL SCOPE

This publication contains installation, programming,

and maintenance information for the following Execu-

Tech electronic key systems and the associated

telephone equipment.

ber, the model number, and the serial number or produc-

tion date of the system.

NOTIFICATION TO TELEPHONE COMPANY

Unless a telephone operating company provides and in-

stalls the system, the telephone operating company

l

Model 0616X

later

l

Model 0816X

This system is fully protected, and therefore the instal-

lation does not require the services of an authorized

agent. However, the installation procedures detailed in

this manual should only be performed by individuals

manufacturing code

all manufacturing codes

which provides the lines must be notified before a connection is made to them. The lines (telephone num

bers) involved, the FCC registration number, and the

ringer equivalence number must be provided to the

telephone company. The FCC registration number and

the ringer equivalence number of this equipment are

provided on the label attached to the KSU.

familiar with general telephone installation procedures.

The end user may perform routine maintenance proce-

dures. such as the following listed ones, but all other

servicing must be performed by factory authorized per-

sonnel

company when final disconnection of this equipment

from the telephone company line occurs.

COMPATIBILITY WlTH TELEPHONE NETWORK

When necessary, the telephone operating company

l

Place or replace any designation strips on the

face of the telephone stations.

l

Replace the line cord or handset coiled cord.

l

Replace complete stations and station handsets.

The handset is a special Comdial type. Other

handset types will not work properly.

provides information on the maximum number of

telephones or ringers that can be connected to one fine,

as well as any other applicable technical information.

The telephone operating company can temporarily discontinue service and make changes which could effect

the operation of this equipment. They must, however,

Relocate the station when it is plugged into the

proper system jacks.

ment changes that would make the system incompatible.

RELATED PUBLICATIONS

01-001, Compliance Requirements To FCC Rules

and Regulations Part 68 and 15

Handling Of Electrostatically Sensitive

Components

GCA 70-011, Station User’s Guide

INSTALLATION REQUIREMENTS

Connection of the electronic key system to the

telephone lines must be through a universal service

order code (USOC)

telephone operating company. If the installation site

does not have the proper outlet, ask the telephone corn

pany business office to install one. The correct outlet

GCA 70-044, Attendant Guide

jack for this system is a type RJ21X.

jack supplied by the

PARTY LINES AND COIN LINES

INSTALLER/USER INFORMATION

Local telephone company regulations may not permit

connections to party lines and win lines by anyone ex-

REGARDING FCC RULES

AND REGULATIONS

cept the telephone operating company.

TROUBLESHOOTING

This electronic key system complies with Federal Communications Commission (FCC) Rules, Part 68.

If a service problem occurs, first try to determine if the

trouble is in the on-site system or in the telephone com-

The FCC registration label on the KSU contains the

pany equipment.

FCC registration number, the ringer equivalence num-

Page 4

Introduction

IM!

66-031

Disconnect all equipment not owned by the telephone

company. If this corrects the problem, the faulty equip-

ment must not be reconnected to the telephone line until

the problem has been corrected. Any

causes improper operation of the telephone network

may require the telephone company to discontinue service to the trouble site after they notify the user of the

reason.

REPAIR

FCC regulations do not permit repairof customer owned

equipment by anyone except the manufacturer, their

the FCC. However, routine repairs can be made according to the maintenance instructions in this publication, provided that all FCC restrictions are obeyed.

RADIO FREQUENCY INTERFERENCE

The electronic key system contains incidental radio fre-

quency generating circuitry and, if not installed and

used properly, may cause interference to radio and

television reception. This equipment has been tested

and found to comply with the limits for a Class A corn

puting device pursuant to Subpart J of Part 15 of FCC

Rules. These limits are designed to provide reasonable

protection against such interference when operated in

a commercial environment.

AUTHORIZATION

that

Operation of this equipment in a residential area may

cause interference to radio and television reception: in

which case the user is encouraged to take whatever

measures may be required to correct the interference.

If this equipment does cause interference to radio or

television reception, which can be determined by tum-

ing the equipment off and on, the user is encouraged to

try to correct the interference by one or more of the following measures: Reorient the television or’ radio’s

receiving antenna, and/or relocate the KSU, the individual telephone stations, and the radio or TV with

respect to each other.

If necessary, the user should consult the manufacturer

or an experienced radio/television technician for addi-

tional suggestions.

booklet prepared by the Federal Communications

mission helpful: “How to Identify and Resolve Radio-N

Interference Problems.” This booklet is available from

the Government Printing Office, Washington DC.

20402. Stock No. 004-000-00345-4.

RINGER

The REN of each line is 0.4B. The FCC requires the installer to

record it at the equipment.

user may find the following

NUMBER

the total REN for each line, and

l-2

Page 5

66-031

installation

CHAPTER 2

INSTALLATION

MOUNTING CONSIDERATIONS

l

The KSU should be attached vertically to any sturdy, flat, surface. It may be vertically rack mounted

if desired.

l

The KSU must be located within six (6) feet of a

proper electrical outlet. The power supply requires

a dedicated 117VAC

AMP circuit, with a third-

wire ground, supplied to a standard (NEMA

electrical outlet.

l The distance between the KSU and the

FCC requirements. A nominal distance of 7 feet is

recommended.

.

The mounting location must be secure and dry and

have adequate ventilation. The temperature range

of the location must be within 32-122 degrees F

50 degrees C), and the relative humidity must be

less than 90 percent non-condensing.

.

If the mounting surface is damp or if it is concrete

or masonry material, a backboard must be attached

to the mounting surface to be used for KSU mounting. Suitable mounting backboards are available

commercially or can be constructed out of

plywood cut to size.

l

Tools and hardware reauired for mountina include:

Fasteners

wood screws

x 1

round

head), toggle bolts, or wall anchors

Screwdriver -to match fasteners

Electric drill

Connecting tool

if prepared holes are required

for fastening wires to a type-

66 connector block.

Crimping tool

for 623-type modular plugs

MOUNTING PROCEDURE

Unpack, and carefully inspect all equipment for

shipping damage. Notify the shipper im-

mediately of any damages found. Verify that

the packages contain all parts and accessories

needed for proper installation and operation.

3.

scale mounting template is supplied in the

packing box. Hold ortape it to the mounting sur-

face, and mark the location of the mounting

holes on the mounting surface as they are located on the template. The mounting dimensions are shown on Figure 2-l . .

4.

size to accommodate the hardware being used.

If necessary, prepare these holes with inserts,

anchors or other attachment devices as dic-

tated by the type of mounting surface.

Attach the KSU to the mounting surface with

5.

four (4) screws installed through the KSU

mounting flange and into the mounting surface

holes. Note that the flange holes are elongated

with an enlargement at one end. This feature

allows the mounting screws to be partially installed in the mounting surface before the

cabinets are hung on them.

6.

Place the individual telephone stations as

desired and in keeping with accepted industry

and office standards. Currently produced 8

tine Keysets can be wall mounted if necessary

as they are

reversible. Currently

produced keyset models include:

l

l

l

l

l

l

Refer to Chapter 4, Maintenance, for instructions in

preparing a desk/wall reversible station for wall mounting.

Any previously produced keysets which may currently

still be in service can also be wall mounted if necessary.

Use a wall mounting bracket (part number 701032-056)

for this purpose.

2.

If a backboard is required at the mounting loca-

tion, attach it securely to provide a stable

mounting surface for the equipment.

Page 6

Installation

---o--

l

I

Figure 2-1. Mounting

SYSTEM WIRING

System cabling may be routed concealed or visible as

the installation location requires, Good engineering

practices must be observed

codes must be adhered to.

through 2-4 illustrate the system wiring and connection

points for the key system.

AC Power Connection

The AC power is applied to the system by connecting

the AC power cord to the standard (NEMA

electrical outlet which supplies the dedicated 117VAC

The following precautions should be taken to help

prevent damage to the system which could be caused

by an electrical over-voltage condition.

and

all applicable building

Table 2-l and Figures 2-2

l

A plug-in, powerline surge protectof should be

installed between the KSUpowercordand the

AC power eiectrkai outlet.

The KSU interface connections for the COlPBX lines

are individual

connectors and the demarcation point connectors is via

standard modular line cord.

tip/ring loop resistance is 1900 ohms from the KSU

modular jack to the CO/PBX equipment.

To help Insure that foreign voltages, which could

appear on the CO lines, do not damage the system,

verify that gas discharge tubes orsimiiarprotection

devices are installed, and properly grounded, in all

connected CO lines.

l

Do not connect the ACpower cord until the installation has been checked per the SYSTEM

CHECKOUT instructions given at the end of

this Chapter.

l

Employ a dedicated lVL!AC

AMP circuit,

with a third-wire ground, supplied to a stand-

ard (NEMA

electrical outlet for the

AC

power connection.

Statlon Connection

Connections between the KSU and the stations are typically via type 66M-xx connector blocks which are cable

connected to the KSU

maximum distance allowed from the KSU to a station is

1500 feet using #I24 gauge, twisted-pair cable.

If spare conductors exist in the cables that are run between the KSU 66M-xx connector block and the station

jacks. Wiring between the KSU

maximum allowed

male connectors. The

.

Page 7

Installation

jacks, it is a good practice to connect them to earth

ground. Doing this may help prevent them from induc-

ing radio frequency and/or AC interference into the

tern

can be connected to any odd or even station port in the

system per the following guidelines.

The polarity between the individual wires in a particular voice or data pair is not critical; however do

not connect the voice circuits to the data

Cable

Each cabinet-mounted

equipped with a retaining clip. This clip is designed to

secure the matted connection once it is made. The clip

does this by snapping into a slot on the cable-mounted

connector when it is pressed together with the cabinet-

mounted connector. This retaining clip must be pulled

back slightly to un-snap it before the connectors can be

separated.

Console Connection

The optional DSS/BLF console may be installed at any

station port to work in conjunction with a companion station connected to the adjacent port (e.g.; port 10 for station and port 11 for console).

The installed distance limit between the KSU and a con-

sole is the same as that specified for a regular station.

Connect all four wires (voice pair and data pair) of the

console cable to the station connector block.

The voice pair connections of the console can be used

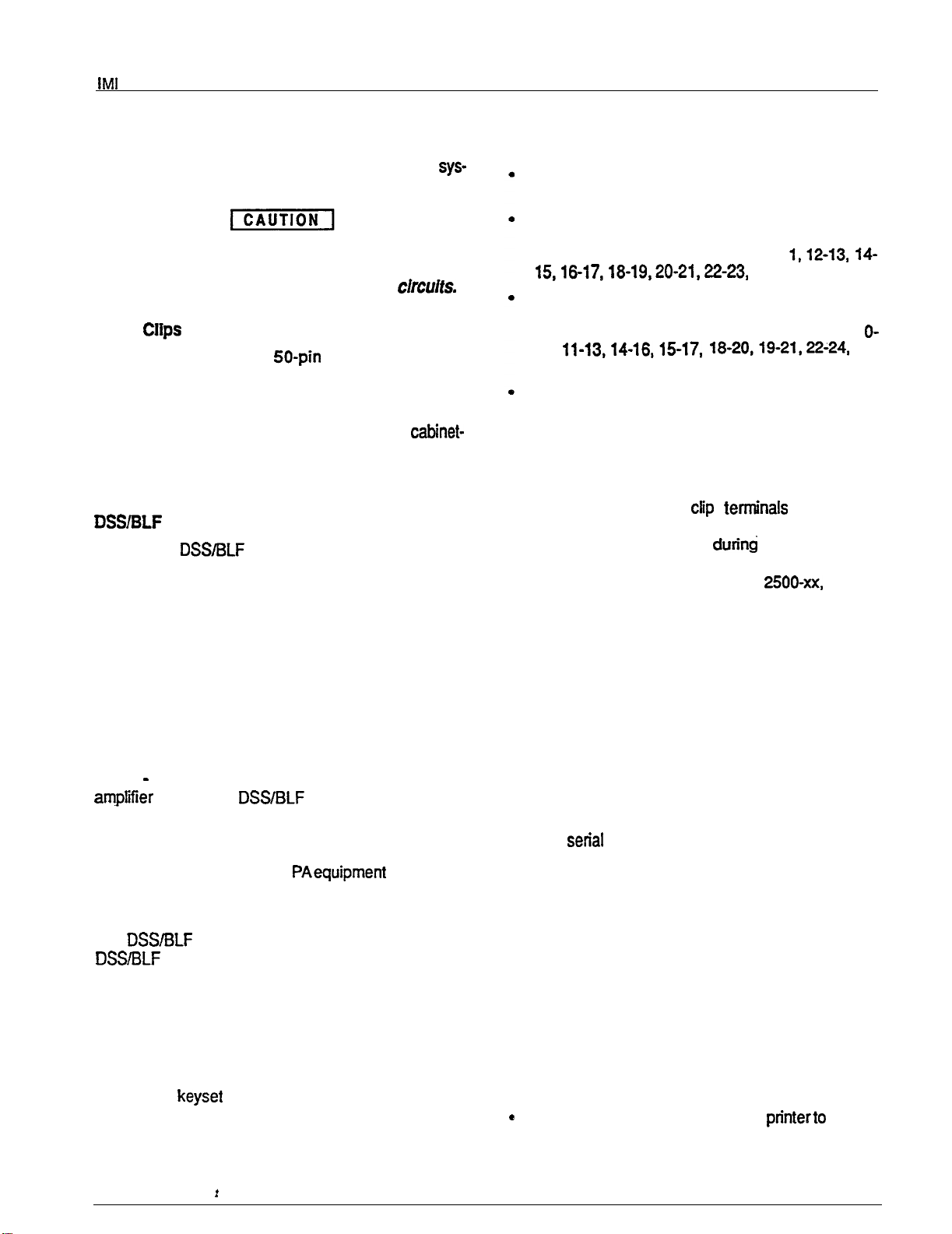

simultaneously to enable a PA port function. Refer to

the paragraph in this chapter headed Area Paging In-

terface

Station PA Port. Per that discussion, wire a PA

male connector is

Power Failure Station Connection

The system provides a tip and ring-pair connected to

line 1 as an emergency power failure circuit. This power

failure pair is available at clip terminals on connector

block J-l as detailed on Table 2-l and Figure 2-4. A

power failure pair is only active durfng a commercial

power failure. An industry standard, single-line

telephone, such as a Comdial model 2500-xx, can be

connected to a power failure pair and used to provide

communications capability until the AC power to the

system is restored.

A-Lead Control Device Connection

The KSU can detect an A-lead

nal when it is applied to lines 7 and 8. An A-lead con-

trol device can be bridge-connected to these lines via

clip terminals on connector block J-2 as detailed on

Table 2-1 and Figure 2-4.

The installed distance between the KSU and the

BLF station must be limited to 1000 feet or less.

The data-line paired station port cannot be used as

a BLF station connection or as a regular station

connection. Data-line pairing is: 1 O-l 1,12-13,

The overload paired station port cannot be used as

a BLF station connection but can be used as a

regular station connection. Overload pairing is: 1

12, 1%13,14-16,15-17, 18-20,19-21,22-24, and

23-25.

A port, paired in either manner with a BLF station,

can be used as a PA port if desired.

AC

(A

and Al) control sig-

connector block clip terminals. Use an audio matching

transformer, as discussed in the referenced paragraph

and Figure 2-3, to provide isolation. If an enable signal

is required with the particular PAequipment being used,

the console and PA equipment connections are limited

to station ports 23 and 25.

The DSS/BLF console port must be programmed as a

before console operation can take place. The console

port must be also programmed as a PA port if a PA

amplifier has been connected to the voice pair as part

of the system.

Busy Lamp Field Stations

An optional keyset is available which is equipped with

a 14 station Busy Lamp Field (BLF). Up to eight BLF

stations can be connected to the system. A BLF station

Data Device Connection

When a serial data printer is used for SMDR and COS

printout, connect it to clip terminals on connector block

J-l as detailed on Table 2-1 and Figure 2-4.

The distance between the device and the KSU can be

up to 500 feet in a quiet electrical environment.

Shielded cable may be required at some sites for long

runs. For longer distances, a limited distance modem

must be used to relay the data communications between the KSU and the data device.

When preparing a cable for connection to a data device,

refer to the manufacturer’s manual for the equipment

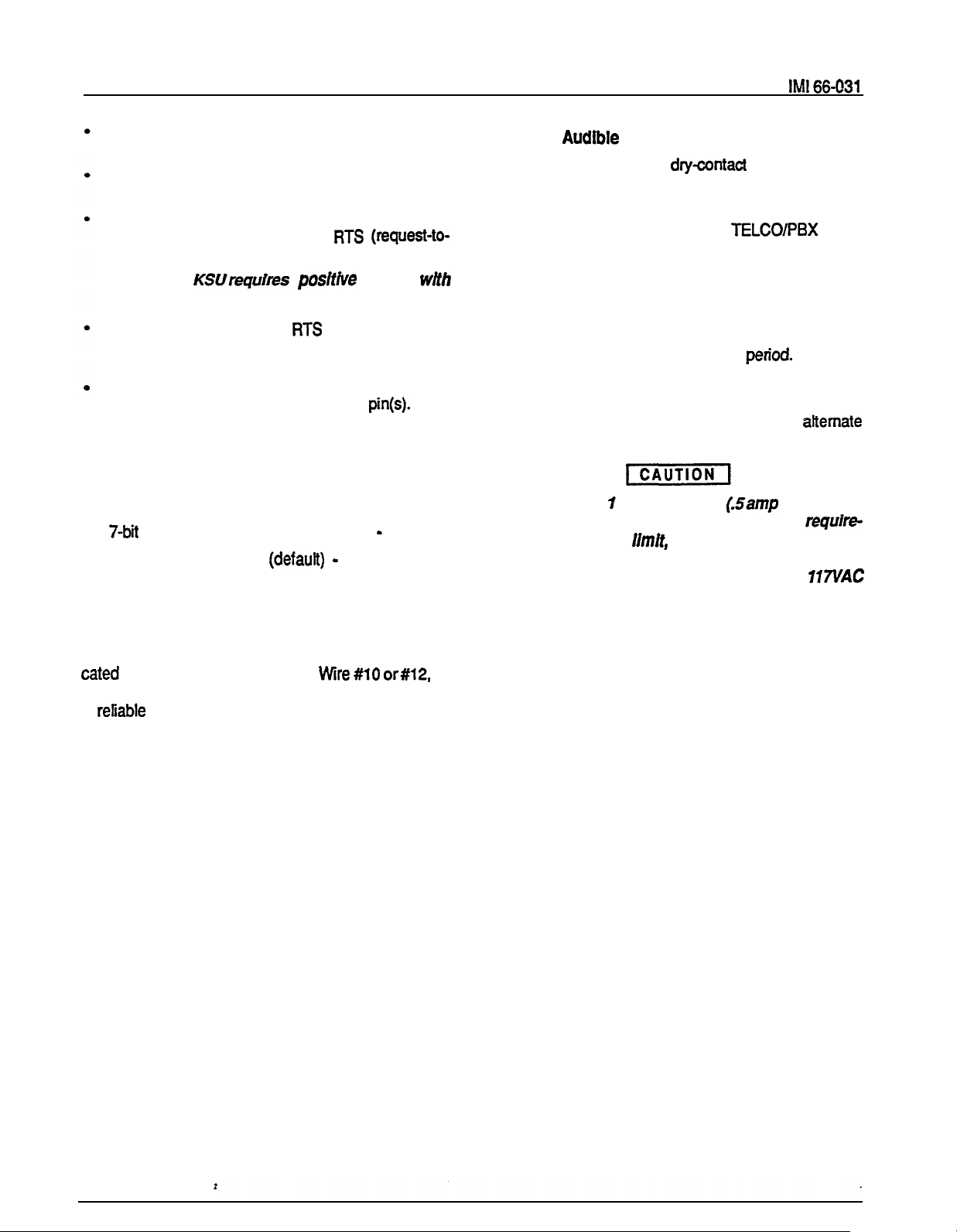

being interfaced, and make the following wiring connections:

2-3

Wire the KSU RD line (data from printerto wmmon

equipment) to the device TD (transmit data) output

pin,

Page 8

Installation

Wire the KSU TD (data to device from KSU) pin to

the device RD (receive data) pin.

Wire the KSU SG (signal ground) pin to the device

SG (signal ground) pin.

Wire the KSU CTS (clear-to-send status from

device to KSU) pin to the device FITS (request-to-

send) output pin.

NOTE: The

a

voltage,

Common

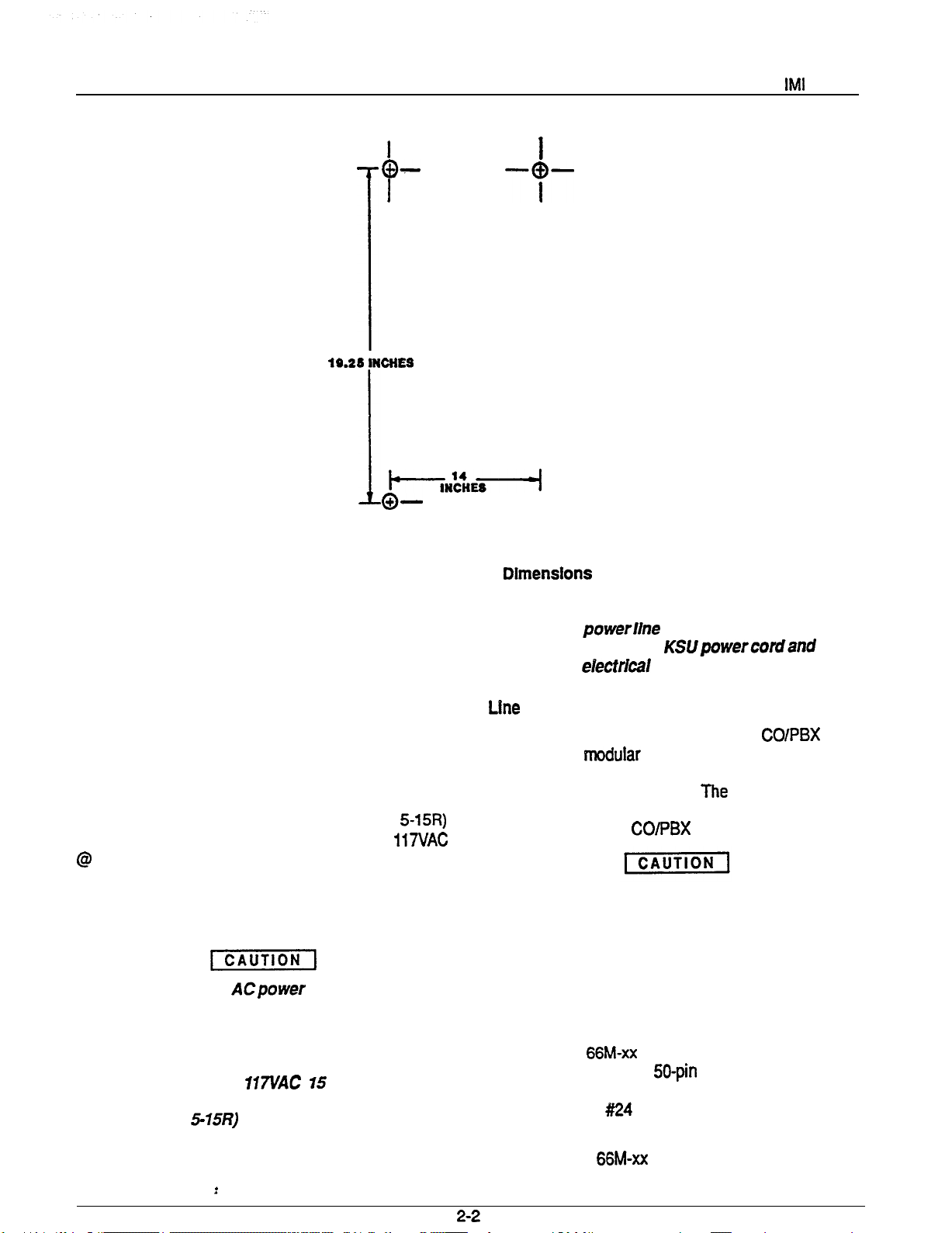

Two sets of relay closure drycontact points are available at the J-l station connector block.

l

l

respect to signal ground, in order to send data.

If required, wire the KSU

status signal from the KSU to the device) pin to the

device DSR (data-set-ready) input pin.

If required, wire the KSU PG (protective ground)

tine(s) to the device protective ground pin(s).

Data Format

Configure the data device to match the following data

format and to receive data at the baud rate that is set

by COS programming.

l

l

Baud rate of 110 baud (defautt)

to 300 baud through class of service programming.

(request-to-send

fixed

can be changed

These contact closures track the ringing pattern in both

cases. The contacts are closed during the ringing

period and are

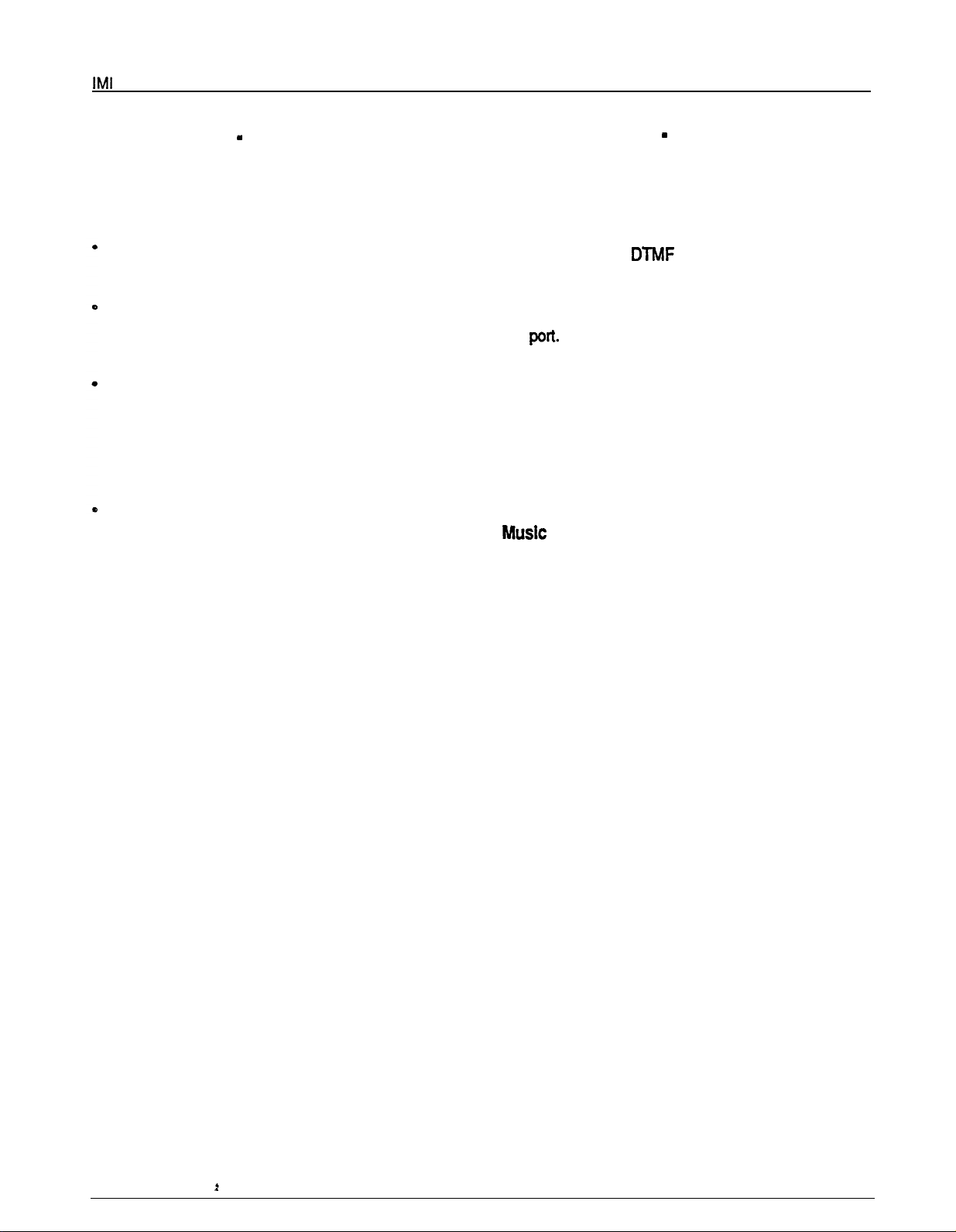

A typical connection is illustrated in Figure 2-2. Refer

to the paragraph headed Area Paging Interface for a

discussion for using these terminals in the

paging function.

Do not exceed a

load on these control terminals.

ments exceed thls

an external slave relay.

CONTROL TERMINALS DIRECTLY TO THE 117VAC

LINE.

System Grounding

and Auxiliary Station interface

One set (J-l connections) provides a dry-contact

closure whenever any of the

connected to the KSU, ring.

The other set provides a dry-contact closure whenever system station 17 rings.

open

during the silent perfod.

amp at 24 volts

If the load

connect the load through

DO NOT CONNECT THESE

lines,

at 48 volts)

It is required that a grounding wire, separate from the

three wire AC line cord, be used. A ground stud is tosulated, solid copper wire between the ground stud and

a reliable earth ground such as a metal cold water pipe

or a building frame ground.

in-

24

Page 9

Installation

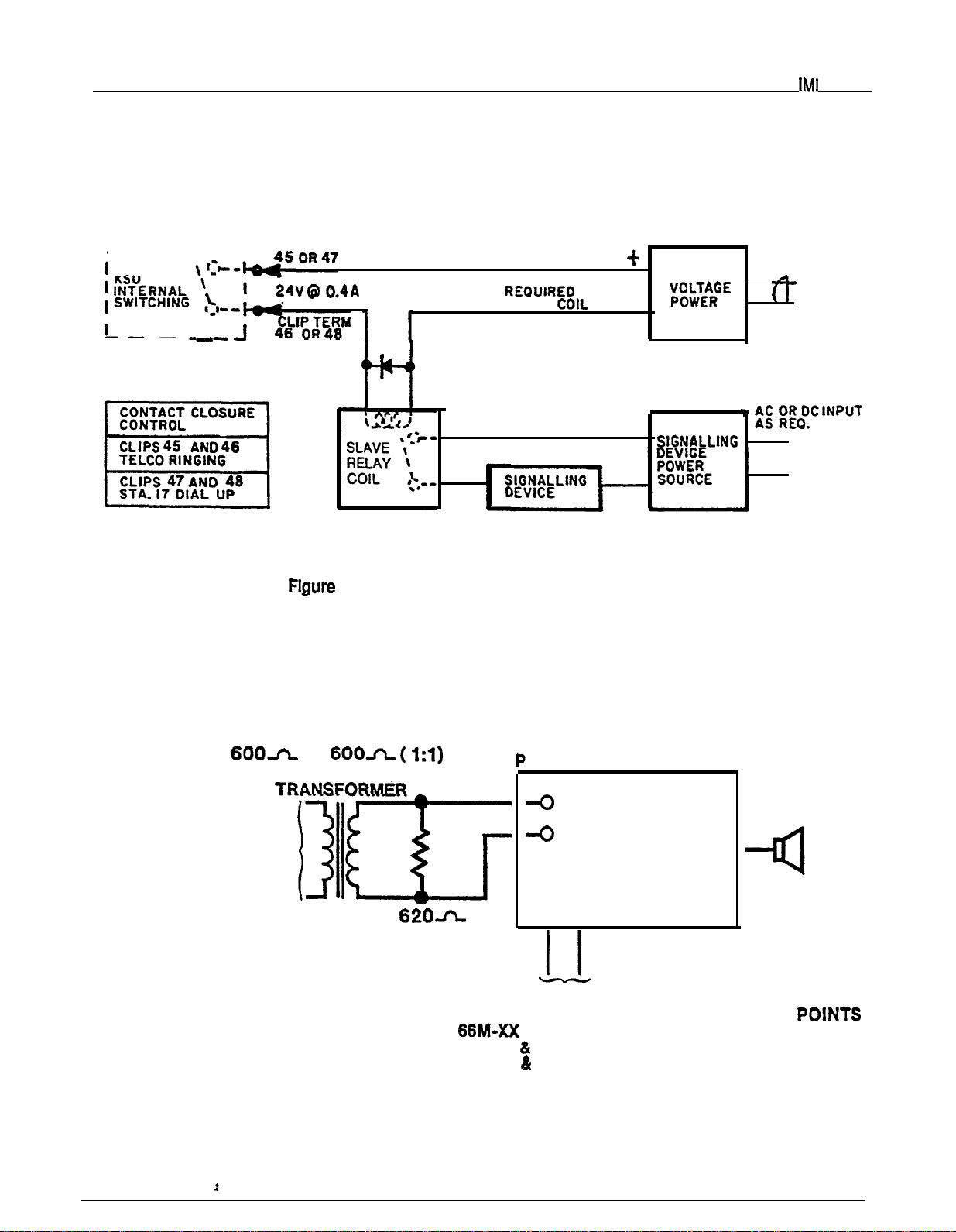

Area

Paging

Interface

Station PA Port

A station port can be configured by class of service

programming to be a PA port. As a PA port, it can be

used to couple a station voice path to an external device

(see Chapter 3 for programming details).

The audio input of an external paging amplifier can

be connected to the audio pair of the station port as

illustrated in Figure 2-3.

The audio input connection must be isolated with a

Area Paging Interface - Llne Port

A fine port can be configured by COS programming to

be an AUXILIARY port. As an AUXILIARY port, it can

be used to couple a station voice path to an external

device. This is done from any station with that tine ap-

pearance by pressing the proper line key to select the

AUXILIARY port.

dialed through the AUXILIARY port as needed.

l

600 ohm to 600 ohm audio matching transformer.

Terminate the audio input of the paging amplifier

with a 620 ohm (nominal value) resistor.

l

If station port 23 is programmed as a PA port, the

Common Audible contact points are automatically

reconfigured as PA enable terminals. The contact

closure now occurs when PA station 23 is dialed.

The normal common audible function, as discussed

previously, is disabled as long as station 23 is a PA

station.

A DTMF tone select, zone-paging amplifier can be

employed if desired. If used, the zone-select code must

be dialed after the AUXILIARY port line select key is

pressed.

If station port 25 is programmed as a PA port, the

Auxiliary Station Interface (station 17 audible) con-

tact points are automatically reconfigured as PA

enable terminals. The contact closure now occurs

when PA station 25 is dialed. The normal auxiliary

station interface function, as discussed previously,

is disabled as long as station 25 is a PA station.

If music on hold is to be part of the system, connect a

KX registered music source to the KSU input jack

(phono jack) provided for this purpose. The impedance

of this input is approximately 500 ohms. Level adjust-

ment of the music source may be necessary. This may

be done during system checkout.

The audio input of an external paging amplifier can

be connected to the tip and ring leads of the line

The audio input connection must be isolated with a

600 ohm to 600 ohm audio matching transformer.

Terminate the audio input of the paging amplifier

with a 620 ohm (nominal value) resistor.

2-5

Page 10

Installation

l----1

--

CLIP TERM .

MAX

VOLTAGE CLAMPING DIODE

RECOMMENDED

OUTPUT AS

RELAY

BY

LOW

SUPPLY

2-2. External Signalling-Typical Connection.

AC

.

0

0

TO KSU STATION

PORT 23 OR 25 IF

ENABLE IS REQUIRED

OR TO ANY UNUSED

STATION PORT IF

ENABLE IS

NOT REQUIRED.

TO

AUDIO

A SYSTEM

AUDIO

ENABLE INPUT

QQ

TO KSU EXTERNAL CONTROL CONNECTION

ON

l CLIPS 45

l CLIPS 47

Figure 2-3. PA Connections.

CONNECTOR BLOCK.

46 FOR STATION PORT 23 PA ENABLE

48 FOR STATION PORT 25 PA ENABLE

INPUT

2-6

Page 11

Installation

I

SLATE-WHITE

RED-ORANGE

ORANGE-RED

RED-GREEN

GREEN-RED

RED-SLATE

RED-BLUE

BLUE-RED

SLATE-RED

:K-BLUE

7 7

,

__

Table 2-l.

l

31

6

32

KSU To

I

.

14

I

Station Wring.

I

VOICE

PAIR

DATA

PAIR

_____

22 .

STATION

GREEN 5

RED

YEUDW 7

PAIR

BLACK 6

YEUOW 11

BLACK 12

YEUDW

RED

6

.

l *

15

16

ORANGE-YELLOW1

YELLOW-GREEN ,6

GREEN-YELLOW

YELLOW-BROWN.

BROWN-YELLOW

YELLOW-SLATE

.

SLATE-YELLOW

GREEN-VIOLET

SLATE-VIC RED

--

43

U

19

45

20

48

I 25

19

I

POWER

FAIL

DATA

CONTACT

RING

I

I

,

I

SPARE

TELCO

LINE6

I

I

TIP GREEN

RI

A YELLOW

Al

RED

BLACK

GREEN

29

46

47

46

49

56

2-7

Page 12

Page 13

Installation

CHECKOUT

UNIT

TEST

Check the KSU and telephone installation for proper

operation by performing the following actions.

Resistance

Check

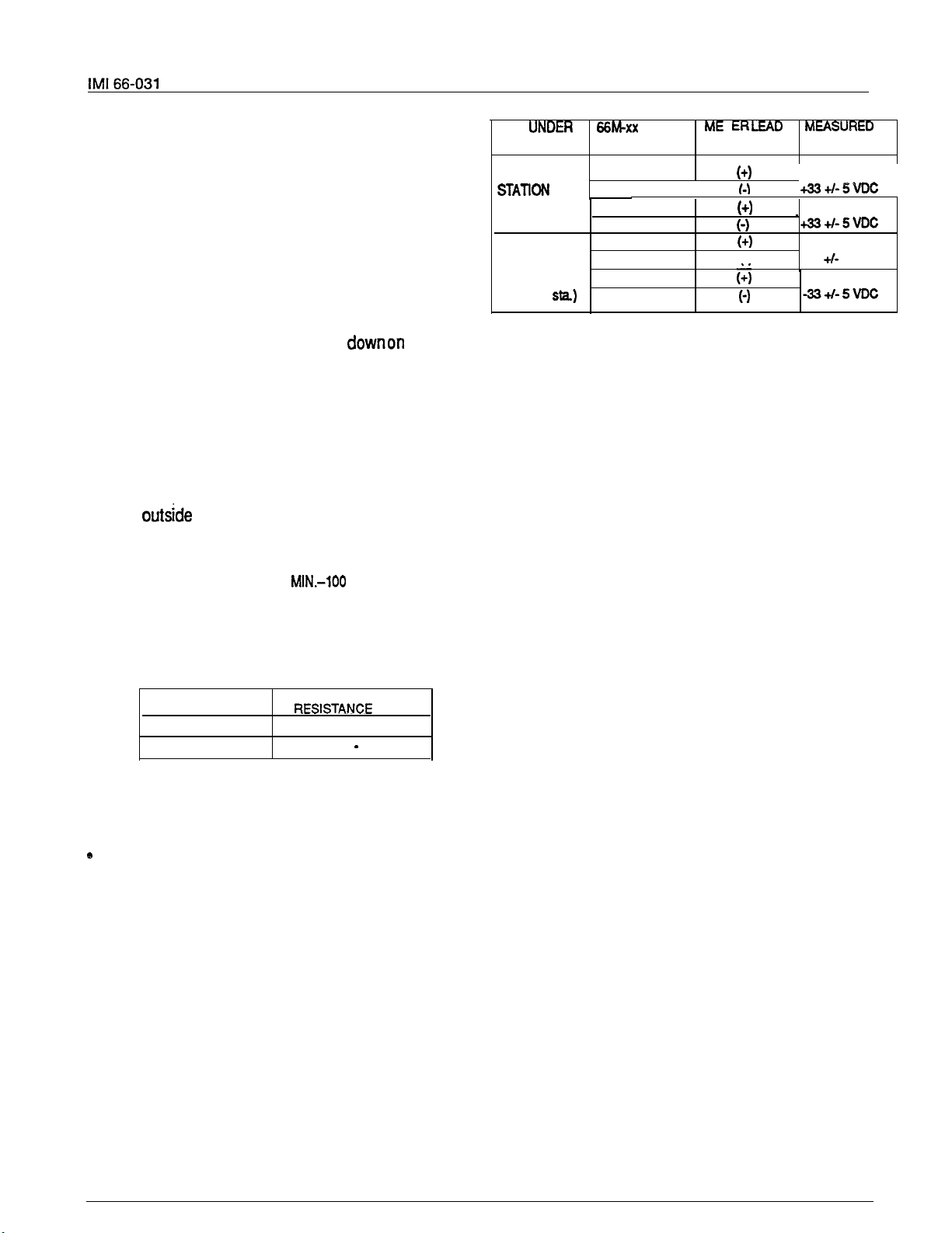

Make the following resistance measurements at the Sta-

tion connector blocks under the following conditions.

l

AC power cord disconnected from electrical outlet.

l

KSU connected to station connector blocks.

l

Stationswired, and wiring punched downon blocks.

l

Bridging clips removed from blocks to isolate sta-

tions from common equipment.

1.

Measure the resistance of each installed sta-

tion

and wiring from the station side of the con-

TYPICAL EVEN

(Repeat for

each even sta.)

TYPICAL ODD

STATION

(Repeat for

each odd

Variant readings can indicate a possible wiring, station,

or common equipment problem.

General Check

1.

nector blocks. Resistance values will vary with

cable length and station type but should be

within the following limits. Readings which are

or station problem.

VOICE PAIR:

DATAPAIR:

2.

Measure the resistance of the KSU and cables

(40 OHMS MIN.-150 OHMS MAX.)

(0.3 OHMS MIN.-100 OHMS MAX.)

2.

from the KSU side of the station connector

blocks. Resistance values should be within the

following limits.

MEASURED KSU

40-50

0.3

0.5

3.

Voltage

MEASURFD PAIR

VOICE PAIR

DATA PAIR

Check

I

CONNECTION POLARITY VOLTAGE

Voice 1

Data 3

voice2

Data 4

Voice

Data

Voice 6

Data 8

I

5

7

LtAD MEASURtD

.

I-) -335VDC

I

Check the red light emitting diode (LED) sys-

tem status indicator.

Be sure that it is on steady. If it is off or flashing, disconnect and reconnect the AC power

plug. If the indicator is still not on steady, refer

to the Failure Analysis Flow Chart found in

Chapter 4.

Refer to the station User’s Guide for operating

information.

Perform a general operational test of the sys-

tem by exercising the systemfeaturesfrom sta-

tion port 10 or 11. Operational parameters are

per the system default conditions as detailed in

Chapter 3 until COS programming is per-

formed.

Once the basic system is verified as operational, perform the COS programming.

Make the following voltage measurements at the station

connector blocks under the following conditions:

Bridging clips installed

l

AC power connected to the common equipment

Measure the voltage across one voice line and one data

line and then across the other voice line and the other

data line for each even and odd station. The measured

voltage must be as follows:

:

2-9

Page 14

CHAPTER 3

SYSTEM PROGRAMMING

GENERAL INFORMATION

Class Of Service (COS) programming consists of

setting the Class Of Service (COS) operating conditions. COS programming is divided into the following three major categories: System COS, tine

COS, and Station COS.

All COS programming commands must originate at

station 10. No COS programming commands can

be accepted from any other station connected to the

system. COS programming causes station 10 to

default to a square condition (line select key 1

selects line

mended that station 10 always remain in a square

conditionto avoid possible programming confusion.

COS programming does not require that a sequential process be followed once the base level

program entry mode has been established except

where noted herein.

The system defaults to preset characteristics when

it is initially powered up or whenever programmed

to do so. If the default characteristics, or any other

previously set characteristics, are satisfactory,

those portions of the programming sequence may

be omitted.

Prior to taking any programming action, record the

system, line and station COS conditions on Table

ter). Also, record all toll restdction requirements on

Table 3-4.

THE PROGRAMMING STEPS MUST BE PER-

FORMED WITH LESS THAN 17 SECONDS OF

DELAY TIME BETWEEN KEYSTROKE OPERA-

TIONS. A delay of longer that 17 seconds causes

the KSU programming mode to time out.

Flgure 3-3 found at the end of this chapter provides

a quick-reference flow diagram of the class of ser-

vice programming requirements.

Programming is the same for both the model 0616X

and 0816X key systems. The only difference be-

tween these two models is the number of lines

which each serves (six or eight).

key 2 selects line 2, etc.). It is recom-

The system can be defaulted to a standard class of

The following system default conditions are set:

BASE LEVEL PROGRAM ENTRY MODE

The first step in a COS programming sequence is to

enter the base level programming mode. Once in

this mode, COS can be set as desired.

entered.

3.

Press

tion that the base level mode is active.

The dial tone will return as a confirma-

CLASS OF SERVICE DEFAULT

service per the following procedure.

1. Press

2.

Press the following keys:

3. Press MONITOR.

All lines are DTMF

Voice signalling attempted first when inter-

com call is made

sec. pause time

2 sec. dial tone recall time

30 sec. recall from hold

All lines private

All lines are CO lines

No toll restriction set

300 msec. held call abandon time

No ringing line preference enabled

No prtme line is chosen

port is disabled

PA port is disabled

No delayed ringing enabled

No access denied

No origination denied

No automatic privacy released

Day and night ringing patterns set as follows:

station 10,

System-wide, all call paging in zone D

Printer port set for 110 baud data rate

Line select keys l-n selects lines l-n

(squared pairing)

7, and 24 all lines

7 4 6

# 0

2. Press the following keys in sequence:

The dial tone stops and a tone burst sounds to in-

:

7 4 6.

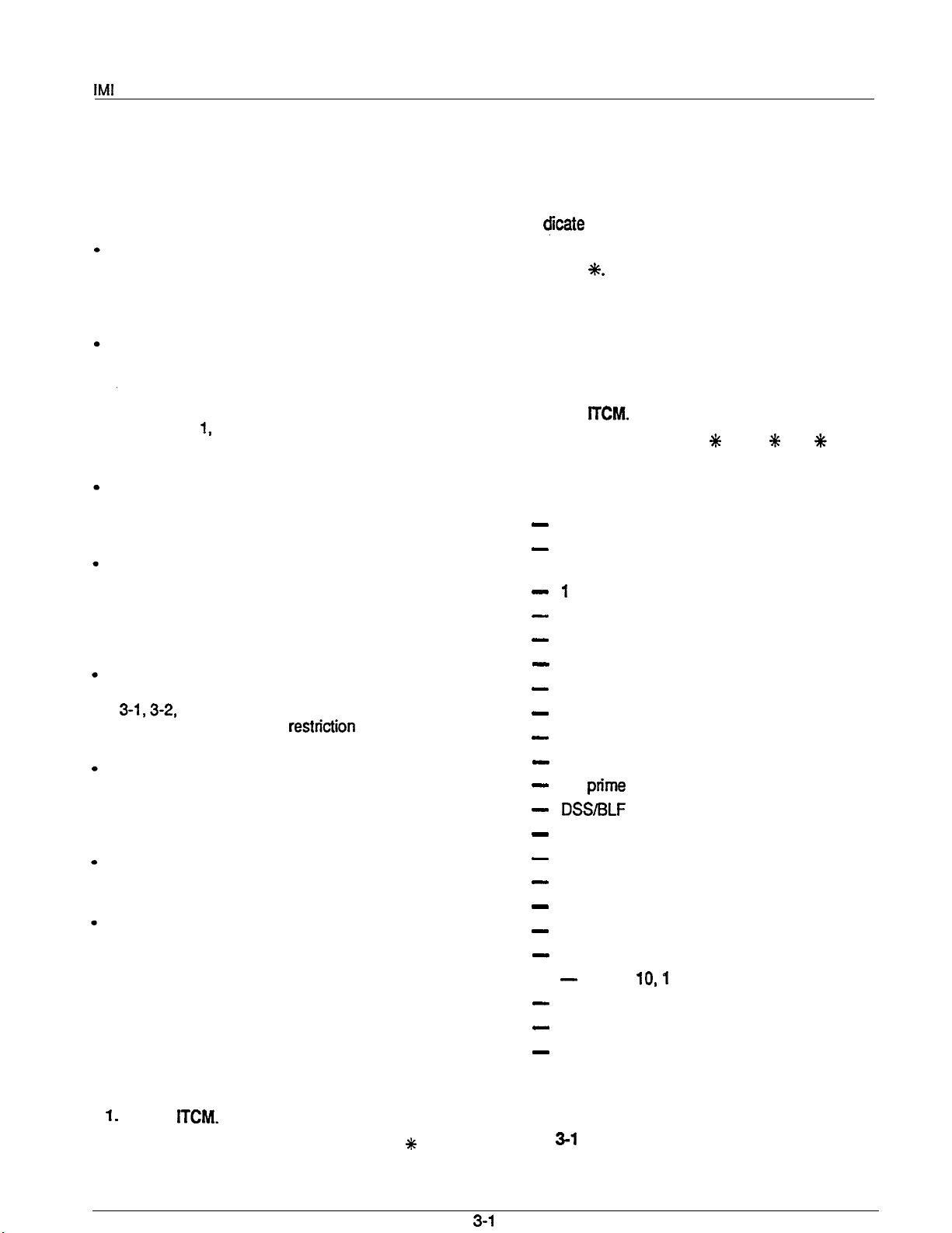

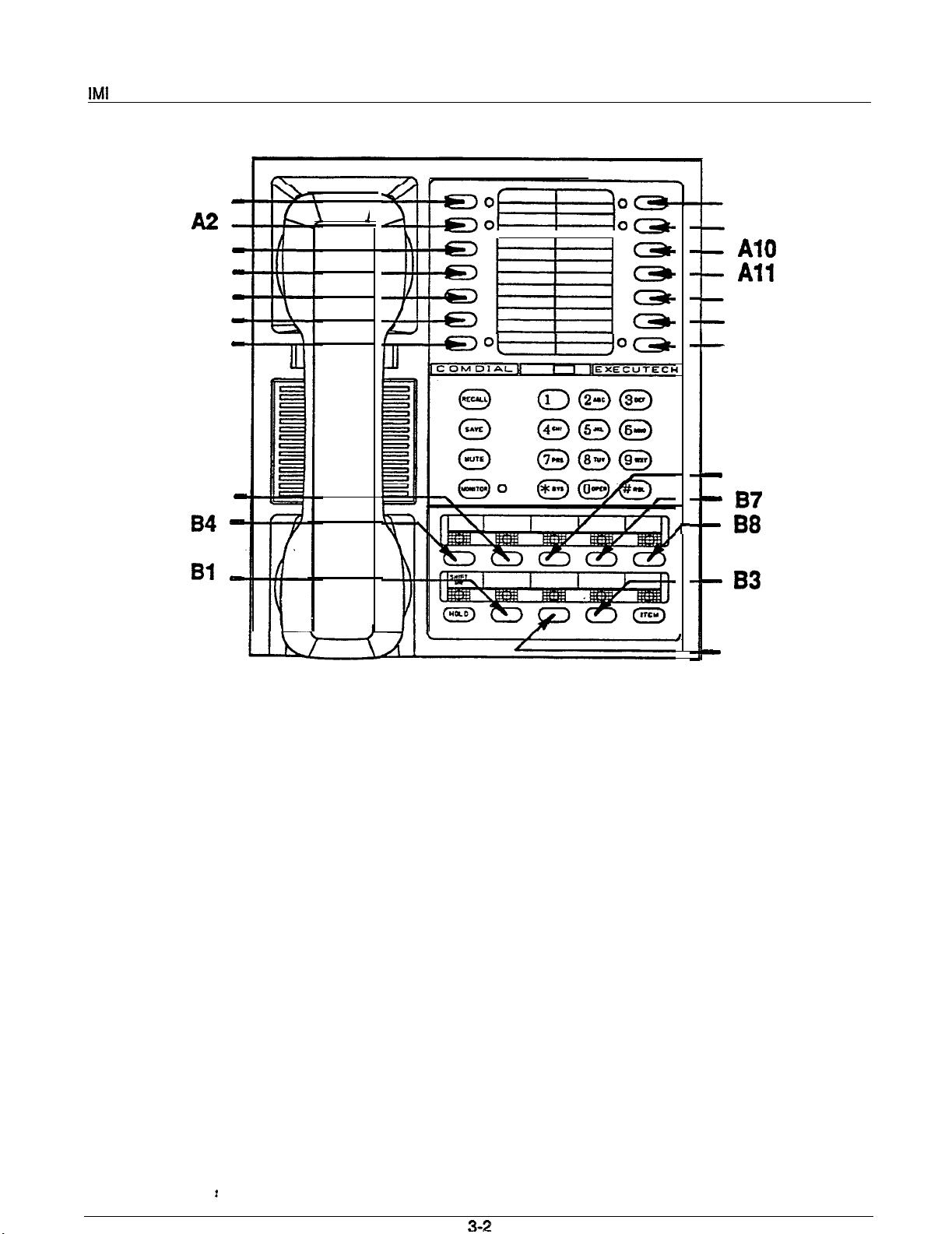

PROGRAMMING KEYS

Figure

out in the following procedures.

illustrates the programming keys called

Page 15

Al -

A3

A4

A5

A6 -

A7 -

B5

0

0 0

0

0

A8

A9

0

0

A12

0

Ad3

Al4

B6

B2

Figure 3-l. Programming Key Layout

Page 16

SYSTEM DEFAULTS

All lines are DTMF

Voice signalling attempted first when inter-

com call is made

1 sec. pause time

2 sec. dial tone recall time

30 sec. recall from hold

All lines prfvate

All lines are CO lines

No toll restriction set

Printer port set for 110 baud data rate

2 sec. automatic pause insertion wait time

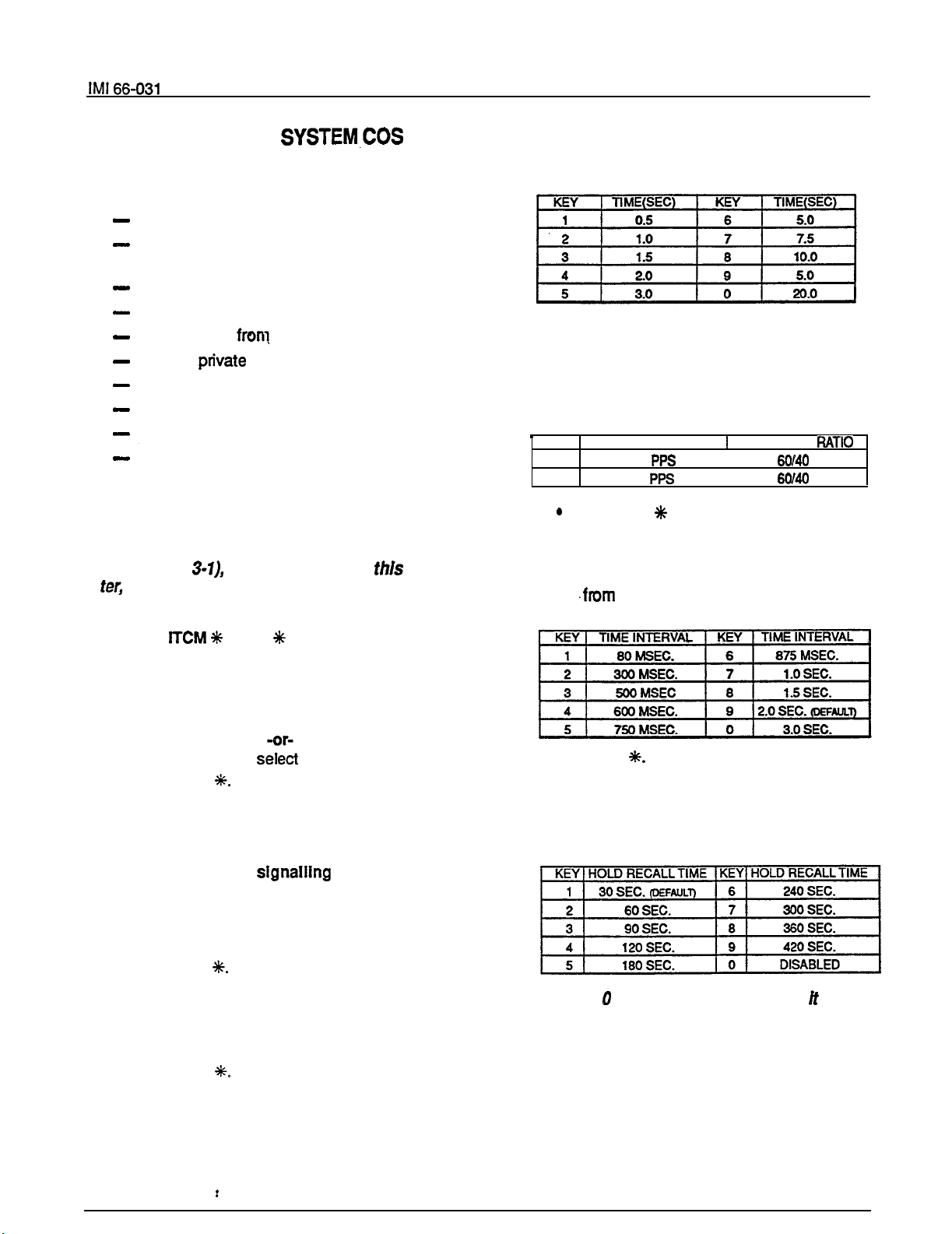

PROCEDURE

NOTE: Before performing this procedure, turn

to the System COS Programming Reference

Chart (Table

and record all system COS requirements on

it.

locatedat the end of this chap

5. Select pulse dial operatlng characteristics.

l

Press 5. Dial tone will stop.

l

Press keypad key to select operating

characteristic per chart. Tone burst con-

firms selection.

KEY PULSES PER SECOND

1

2

10

20

Press the % key. Dial tone will sound.

6.

Select

flash/dial tone recall time

l

Press 6. Dial tone will stop.

l

Press keypad key to select time interval

BREAK/MAKE

I

interval.

1. Press

2.

Select the

7 4 6

(base level entry)

PULSE/TONE

or TONE ONLY dialing

system default characteristics.

l

Press #. Dial tone will stop.

l

Press 0 to select

l

Press 1 to

l

Press

Dial tone will return.

TONE ONLY.

PULSE/TONE.

NOTE: In addition to setting the dialing mode,

the above action defaults the system, line and

station COS.

3. Select Intercom

first performed

when intercom call is placed.

l

Press Al3 for tone signalling.

-or-

.

Press Al4 for voice signalling.

l Press

4.

Select time interval for programmed pause.

l

Press 4. Dial tone will stop.

l

Press key to select time interval per

chart. Tone burst confirms selection.

l

Press

Dial tone will sound.

l

7.

Press

Select

hold

l

Press 7. Dial tone will stop.

l

Press keypad key to select hold recall in-

Dial tone will sound.

recall

time

interval.

terval from chart.

NOTE: The

program selection makes

possible for an exclusive hold condition, when set

at a station, to place a line on a pennanent hold

thaf cannot be released at any other station.

3-3

Page 17

System Program-

l

Press

Select

toll restriction table entries. Refer to

Dial tone will sound.

programming table (Table 3-4) to preselect entry

requirements.

l

Select table with memory key. The dial

tone will stop when the selection is made.

AlAl

A2A2 22 A6A6

A3A3 33 A7A7

A4A4 44 A8A8

l

Select

11

A5A5 55

mode of table

66

77

88

with keypad key.

Tone burst conforms selection.

l

Select

entry line on table

with memory

key. Action clears any current entry and

causes continuous busy tone to sound.

l

Dial

number for entry line. Press

key

to enter “match anything” digit. Tone

burst sounds after each key is pressed.

NOTE: An entry line can contain a maximum of

16 digits.

When the maximum number of digits

are entered, the system sounds a fast

tone, and steps to the next entrypoint on a table

or to the next table.

If less than sixteen digits are entered on

line, select next entry location with

memory key.

l

Repeat procedure for each desired toll

restriction table.

NOTE: Select an

quired.

This action insures that any previous

line even if no input is re-

entry is cleared. Select a table and then select

each line in the table to clear the table of

entries.

Do not dial any numbers after the entry

line selections.

l Press

9.

Program

10. When the system stores a dialed number for later

the user waits a period of time between digits.

(The length of the stored pause was programmed

in step 4.) To program

11. Press

ming mode.

data speed baud rate

l

Press 3 to set data speed of 300 baud.

for printer port.

-or-

*

Press 0 to set data speed of 110 baud

l Press

l

Press

length of time to

is inserted, proceed as follows:

7 4 6

to enter program-

ming mode.

l Press RECALL..

l

Press keypad key 1 to set wait time to

750 milliseconds.

-or-

*

Press keypad key 2 to set wait time to 2

seconds.

l Press

to exit system COS program-

.

3-4

Page 18

System Programming

LINE COS PROGRAMMING PROCEDURE

LINE DEFAULTS

5.

All lines private

All lines are CO lines

No toll restriction Set

Dialing mode is tone only

300

msec.

held call abandon time

6.

PROCEDURE

NOTE: Before performing this procedure, turn

the Line COS

(Table

located at the end of this chapter,

Reference Chart

and record all line COS requirements on it.

l Press

will sound.

2.

Choose

privacy

l

Press 8. Dial tone will stop. This action

initializes all lines as private. This condi-

tion is also system default value.

l

Press line select key of each line which

is to be non-private.

A tone burst sounds after each selection

for confirmation.

l

Press

Press tine select key (program keys Bl-B6 for

model 0616X or

to be programmed. Dial tone will stop.

7 4 6

status

The dial tone

of each line.

Dial tone will sound.

-B8 for model 0816X) for line

NOTE: Selecting a line forprogramming clears

all assigned toll restriction tables.

7.

8.

NOTE: There are a

programmed on a model 0616X system and a

maximum of eight lines on an 0816X system-

9.

Press memory

keys to assign toll restriction

tables to

KEY

Al

A2

A3 3

A4

TABLE

1

2

4 A8 8

Specify dialing mode per

KEY

A6 6

A6

A7 7

chart

A tone burst will confinn selection.

Press keypad key to restore after hold is aban-

doned.

KEY TIME INTERVAL

8

9

MSEC.

300 MSEC.

Repeat procedure from step 3 for next fine to be

programmed.

of

Press& MONtTOR to exit line COS programming.

Dial tone will sound.

TABLE .

6

with keypad key.

lines

be

4. Specify line type per chart with keypad key. Atone

burst will confirm selection.

3-5

Page 19

STATION COS PROGRAMMING PROCEDURE

System Programming

STATION DEFAULTS

No ringing line preference enabled

No prime line is chosen

DSS/BLF port is disabled

PA port is disabled

No delayed ringing enabled

No access denied

No

denied

No privacy released

Day and night ringing patterns set as follows:

station 10, 17, and 24 all lines

System-wide, all call paging in zone D

tine select keys 1 -n selects lines 1 -n

(squared pairing)

PROCEDURE

NOTE: Before

to the Station COS Programming Reference

Chart (Table 3-3), located at the end of this chap-

ter, and record ail station COS requirements on

1.

Enter the base programming mode:

l

Press ITCM

sound.

2.

Press a two-key sequence on keypad to choose

station port for programming (i. e.,to choose station 11 press 11). Tone burst sounds to confirm

selection. Improper selection results in dial tone.

NOTE: Station port selection defaults the foi-

lowing features:

enable, prime line selection, and ringing line

preference enable. Pius, toil restriction table

assignments are disabled.

3. Configure port as DSS/BLF console

sole port is required).

.

Press RECALL. Tone burst sounds to

confirm selection.

l

Skip this step if DSS/BLF console is not

installed at station port currently being

programmed.

l

If enabled, do not proceed beyond this

step unless port is also to be

programmed as PA port.

4.

Configure port as

PA

Press 9. Tone burst confirms selection.

this procedure, turn

7 4 6

Dial tone will

enable,

port

(if PA port is desired).

port

(if con-

Skip this step if PA port is not desired.

l

Do not proceed beyond this step if PA

port selection

5. Choose prime line or prime

is

made.

Tone

burst confirms selection.

l

Press tine select key for line desired.

-or-

* Press

NOTE: if more than one iine selection key is

pressed, the last one pressed selects the

cep ted prime line.

6. Enable

ringing line preference.

l Press 1.

7. Press memory keys to assign toll restriction

tables to station.

l

At this point, there are no toll restriction

tables assigned.

l

Tone burst confirms each selection.

Skip to step 16 after programming the toll restric-

tion table assignments unless other station COS

programming

l

must be performed.

is recommended that programming steps

8-14 be performed in the order that they

are presented below. In steps 8-14, the

whenever the program selection key is

pressed. This default value is overridden

by the subsequent programming action.

l

During subsequent reprogramming of a

station, any step, controlling a feature

that does not need to be reprogrammed,

can be skipped over thus leaving the current COS condition intact. It is not necessary to return to the base programming

mode to shift from one programming step

to another except when performing step

15. Program step 15, which sets the line

appearance to key assignment, must be

followed by a return to base level

programming (press

8. Program

NOTE: A

direct ringing

assignments.

may be programmed for direct

ringing or delayed ringing but not for both ring-

:

3-6

Page 20

System Programming

features.

delayed rtngtng

dtrect rtngtng

selected, delayed rtngtng wttt

be disabled.

Press 2 for direct tinging.

sounds to confirm.

condition of no ringing enabled

now set on all iines.

Press line select

B6 for 0616X and

each line on which direct ringing

desired. Tone sounds after each selection.

9. Program

10. Choose

11. Program

12.

Set access to

13. Set night ringing status.

delayed ringing

l

Press 3 for delayed tinging. Tone burst

sounds to confirm.

l

Press Iine select key (program keys

B6 for 0616X and

each line on which delayed n’nging is

desired.

l

Tone sounds after each selection. Delay

time is 15 seconds.

access

Press 4. Tone burst sounds. Defauft

condition of access not denied set on all

lines.

l

Press line select key (program keys

B6 for 0616X and

each line on which access is to be

denied.

l

Tone burst sounds after each selection.

call origination denled

l

Press 5. Tone burst sounds. Default

condition of call origination not denied set

on all lines.

l

Press line select key (program keys

B6 for 0616X and

each line on which call origination is to

be denied. Tone burst sounds after each

selection.

privacy release.

l

Press 6. Tone burst sounds. Defauit

condition of no access to privacy release

set on all lines.

l

Press line select key (program keys

B6 for 0616X and Bl -B8 for 0816X) for

each line on which access is to be

denied. Tone burst sounds after each

selection.

l

Press 8. Tone burst sounds. Defauit condition of no night ringing

lines.

Press line select key (program keys

B6 for 0616X and

each line on which night ringing is

desired. Tone burst sounds after each

selection.

setected after

Tone burst

key

(program

-B8 for 0816X)

assignments.

-B8 for 0816X) for

status.

-B8 for 0816X) for

-B8 for 0816X) for

-B8 for 0816X) for

keys

is

status.

be set on all

for

14. Set all-call and zone paglng

capability. Default

value is all-call at all stations in system.

l

Press 1. Tone burst sounds. Clears sta-

tion from paging zones A, B,

l

Press ITCM to clear station from atl-catl

and C.

(if required).

l

To assign reception by zone,

l

Press line select key for zone A

l

Press tine select key 2 (B2) for zone B

l

Press line select key 3 (B3).for zone

l

Press line select key 4 (84) for all-call (if

C.

it was previously cleared).

l

To enable origination by zone,

l

Press line select key 5 (B5) for zone A

.

Press line select key 6 (B6) for zone B

l

Press line select key 7 (B7) for zone C

l

Press line select key 8 (B8) for all-call (if

it was previously cleared).

NOTE:Step

a

15.

to bass level.

Set

appearance to key assignment if cur-

tmmedtapty fottowedby

rent settings are not correct. System default configures line appearance to key assignment so that

ment has tines l-6 assigned to keys Bl-B6 for

model 0616X, and lines l-8 assigned to keys

B8 for model 816X.

l

To re-assign line/key configuration,

l

Press 7. Tone burst sounds.

l

Press Gne key

Tone burst

sounds.

l

Press keypad key

for

number of line

6). Tone burst sounds.

l

Press next line key and keypad key com-

bination. Repeat for each line. All iine

select keys can be programmed to select

same tine if such a condition is desired.

l

To disable line select key and indicator

tight for any lines which are unassigned

to a particular station,

l

Press line select key for unassigned line.

l Press 9.

l

Repeat for each unassigned line.

16. Press % to return to base programming mode.

17. Repeat steps 1 through 16 for each station connected to the system.

18. Press MONITOR to exit programming

mode.

Page 21

SMDR

COS PRINTOUT

SMDR

PRINTOUT

A data printer can be connected to the system to be

To obtain the COS printout,

l

used for printing station message detail recording

(SMDR) information. The SMDR data is provided

automatically as it is generated. No intervention is

required to obtain the printout. The data is formatted as shown in Figure 3-2. Either an 80

column or a 40-column printout line can be

selected through the system COS programming.

l

The COS printout will begin immediately.

COS PRINTOUT

When a data printer is connected to the system to be

used for printing SMDR data, it can be commanded

from station 10 to also print a record of the current

COS configuration. Partial or complete printouts can

be obtained. When the printer is being used to obtain

a COS printout, the SMDR printout is temporarily

halted; however, SMDR data collection is continued

by the system during a COS printout operation. If

more than two calls are logged for any one tine

during the halt, call records may be lost. Typical COS

printouts are shown in Figure 3-3.

To abort printout,

l

To exit COS prfntout mode,

l

Press ITCM

PRINT SYSTEM AND LINE COS PLUS TOLL RESTRICTIONS

7 4 6

(base level if not active)

Press memory key to select type of printout desired.

Press memory key A9.

Press

MONITOR.

3-8

Page 22

STATION NUMBER

I-

MONTH/DAY/YEAR

40 COLUMN

PRINTOUT

LINES

1

2

NOTES

1. CARRIAGE RETURN AND LINE FEED IMMEDIATELY

LAST PRINTED CHARACTER ON EACH

INITIATE TIME-HOUR : MINUTE

(24 HOUR REAL TIME CLOCK)

[CARRIAGE RETURN!

-,

1 I-

J

DIALED DIGITS-UP TO MAXIMUM OF 32

(ACCOUNT CODES ARE ISOLATED BY l OR # SYMBOLS

Flgure

9782200

OUTGOING CALL

(WITH ACCOUNT CODES)

AC POWER FAILURE AND

RESTORATION

24 2

l *

Station Message Detail Record Prlntout Format

Page 23

System Programming

SYSTEM COS

PAUSE TIRE 2.0 SEC

PULSE DIAL 20 PPS

FLASH TIME 720 MSEC

HOLD RECALL 240 SEC

LINE

LINE PRV TYPE PU- HOLD TOLL

RLS LSE.SOMS

1

2

3

4 x

5 x

6

7

8 X

STATION 13

TOLL RESTRICTION

LINE

DELAY RING X

NITE RING

ACCESS DENY

ORIGIN DENY

PRIVACY

AUX

NONE

x

x

P.A. ENABLE

PRIME LINE

12345678

RING X

TABLES

123 6

123 6

123 6

123 6

X

X

123

1

456

456

78

TOLL RESTRICTION TABLES

TABLE

11

2 0

3

4

TABLE 2 ALLOW

1 17034344664

2 17039493113

3 1985

4 1831

TABLE3

1 8313

2 5891

3

4

TABLE 4 DENY

1 91

2 90

TABLE 5 ALLOW

1 91804

2 917034341133

3

4

TABLE6 ALLOW

1 1800

2 91800

1

DENY

ALL CALL

GROUP

BUTTON

LINE NO. 2 3 4 1 6 7 8 5

RECEIVE

ABCD

X

12345678

ORIGIN

ABCD

Figure 3-3. Typical COS Printout

(Model 0616X Shown. Model 0616X same except six lines)

X

3-10

TABLE 7 DENY

11

2 2

3 3

4 91985

TABLE 8 ALLOW

14

2 5

3 6

4 17039491234

Page 24

System Programming

SYSTEM CLOCK INFORMATION

THE CLOCK

1.

Press ITCM, then dial

2.

Dial clock date with keypad keys.

l

Values less than 10 must be dialed as

#.

ox.

l

Hours must be expressed in 24-hour format.

.

Enter: YEAR MONTH DAY HOUR

MINUTE

Example: 8808061530 (August

PM)

3. If SMDR printer is installed and operating, clock

date will be printed as illustrated in following typical example:

01/08/86 16:00

4. Reset minutes setting, if necessary, as follows:

l

Repeat step

l

Dial new digits, and press #.

l

A new clock date printing will occur.

CHECKING THE TIME SETTING

A printing of the current clock date can be obtained

from station 10 whenever needed as follows:

l

Press ITCM and dial

# #.

A clock date printing will automatically occur once

each 24-hour period. This daily, automatic printing

will formatted as follows:

(current date and

hours)

POWER

The system clock will continue to run for at least 30

minutes after AC power has been removed form the

system. If power is restored within the 30-minute

backup period, the following.printing sequence will

occur:

OFF

TIME

iiR:Mti

(time of power outage)

If power is not restored within the backup period, the

following printing sequence will occur when the

power is restored.

CLOCK

The clock will begin running from the default date. It

must be reset to the current date per the instructions

above.

HR:MN (time of poker return)

VALID

(default clock date)

3-l 1

Page 25

66-031

System Programming

SYSTEM SPEED DIAL PROGRAMMING

Ten (10) system speed dial numbers can be stored

from station 10 for use at all stations in the system.

To store speed dial numbers,

l Press

l

Perform the following steps:

l Press SAVE.

l

Press line select key (program keys

l

.

to identify line to be preselected during opera- 3

tion (otherwise system will pick prime line or

last line used).

Dial speed dial number from keypad (up to

31 digits).

Dial 1

l

Press HOLD to store pause if required.

0, #, and

as required.

Press RECALL to store flash if required.

Repeat the preceding steps for each number

to be stored. 9

To end procedure,

l Press MONITOR

SYSTEM SPEED DIAL INDEX

(enter programmed numbers)

1

2

4

5

6

7

3-12

Page 26

System Programming

Table

System COS Programming Reference

PROCEDURE

Note: Circle the record values at right

before performing the procedure given below.

BASE

LEVEL ENTRY

.

.

.

Press 0 for tone dialing

. Press

.

3. FIRST ATEMPTED INTERCOM SIGNALING MODE

Press Al3 for tone signalling.

. Press Al4 for voice signalling

. Press*

. Press4

. Press one key

pulse/tone dialing

FOR PROGRAMMED PAUSE

RECORD

(Shading Denotes Default Value)

Note: Circle the desired value

for the system being programmed.

PULSE/TONE SWITCHABLE

. . . . . . . . .

. . .

. . ..: :..

TONE

SECONDS

0.5

1.5 1 2.0 1 3.0 5.0 7.5 10. 15.

I

KEY 1 1 1 2 1 3 1 4 1 5 1 6 1 7 1 8

SEC.

. Press

5.

PULSE DlAL CHARACTERISTICS

. Press5

. Press

. Press

.

6. HOOKSWITCH FIASHIRECALLTIME INTERVAL

. Press6

KEY

SEC.

. Press one key:

. Press*

7. HOLD RECALL TIME INTERVAL

. Press7

. Press one key:

KEY 1 1

SEC. 30 80 90 120 180 240 300 360 420

. Press

10 PPI and

PPI and

1 1

2 1 3

PPI AND MAKE/BREAK

1.0 1.5 2.0 3.0

4

5

6

7 1 8

9

9

0

SECONDS

90 1120118012401300

0

3-13

Page 27

66-031 System Programming

TOLL RESTRICTION

.

Set system toll restriction requirements per instructions

given on Table 3-4

9. SMDR DATA SPEED BAUD RATE

.

.

Press

. Press1

.

Press

baud

sec.

I

If a timeout occurs during the programming sequence, perform base level entry again

and proceed at any program step.

Record

toll restricbn data on table

Page 28

66-031

System Programming

Table 3-2. Line COS Programmlng Reference

PROCEDURE

the information In the box at right before

performing the pfugram pfucadwes givan below

BASE LEVELENTRY

.

Press ITCM

PRNACY STATLJS

.

Press 6. All line6 private

.

Press keys for non-private.

.

.

. Press*

3. SELECT LINE FOR PROGRAMMING

.

Press 81-88 (model 0816X)

.

Press

4. SPECIFY LINE TYPE

.

5.

ASSIGN TOLL TABLES TO LINE

. Press

746

(model 0616X)

= Auxiliary Line

keys:

RECORD

Check each line number block for rhe fine featwu that is

in the calling number and locaffon status.

NON-PRIVATENON-PRIVATE

I

I

6. DIALING MODE OF LINE

.

Press 6 = pulse/tone

.

Press 7 = ton8

7. ABANDONED HOLD RECALLTIME

.

. Press

8. SELECT NEXT LINE FOR PROGRAMMING

.

Press Bl-B8 (model 0616X)

.

Press

9. END LINE

. Press S MONITOR

NOTE:

a timeout occurs during the

dialing

(model 0616X)

PROGRAMMING

RESTRICTIONRESTRICTION

CALLING NO.CALLING NO.

Change page

Page 29

System Programming

Table 3-3. Statlon COS Programming Reference

(Copy this sheet as required)

PROCEDURE

2.

. Press RECALL

4.

PA PORT

right before

RECORD

Enter lnfotmstion or circle desin?d

INTERCOM NUMBER

(3

below before

. . . .

..:..:c..

. . . . . . . . . . . .

. Press4

. Press6

.

Press Bl-B6 (model D616X)

.

Press

(model 0816X)

(0816X)

(4

Page 30

66-031

PROCEDURE

System Programming

Table 3-3, STATION COS PROGRAMMING REP ERENCE (Continued)

(Copy this sheet as required)

or enter the

14. ALL

.

.

.

Dial

. Dial

Press #

Press keys:

Press keys:

(0616X)

used key and light

at right

ZONE PAGING

to clear allcall.

= receive A. B, C, and all-call

= originate A. B. C and allcall

. Press*

17. PROGRAM NEXT

.

Repeat procedure from step 2

18. END

. Press MONITOR

sequence, perform base level entry again and

proceed at any progmm step.

a timeout occurs during the

3-17

Page 31

Table

Chanae

Toll RestrIctIon ProgrammIng Reference

TABLE ENTRY PROCEDURE

Determine the types of dialing restrictions which

must be imposed on the system.

this includes access codes which result in toll charges,

and certain local numbers as desired.

If the restricted dialing codes will be imposed consistently on most or all stations in the system, list

them on one or two tables. If wide variation in the

dialing restrictions is planned, spread the listing

out across several tables.

3.

Strategically group the listings on the tables so

that a list of restrictions can be applied to a particular station or group of stations.

4.

Designate each table as a DENY table or as an

ALLOW table. The numbers entered in a DENY

table are prevented from being dialed. ALLOW

tables take precedence over DENY tables.

Therefore, an entry in an allow table will provide

an expticit exception to an entry in a DENY table.

Note that the system always permits the dialing of

any number not explicitly denied.

6. Since it is important that emergency numbers

never be restricted, always create an allow table

tables that have been created.

7. If the system is installed behind a PBX, include an

access code as part of every table entry.

8. Once these tables are completely filled out, enter

the restriction pfanning tables on the line, and station programming reference charts to record the

planned toll restrictions for the system.

PROGRAMMING PROCEDURE

1.

Select toll restriction table

KEY

Al

A2 2 A6

A3 3 A7 7

A4 4 A8 8

2.

Select table type

TABLE KEY

1

A5

TABLE

5

6

Example A:

Provide a simple and broad toll

restriction format by creating a DENY table with

two entries: ENTRY (1) = 1 ENTRY (2)

0.

This format prevents all long distance and

operator calls.

Example B: Prevent the dialing of all numbers

within the (804) area code, while allowing the

dialing of one specific number within that area

code, by entering 1804 in a DENY table and

18049782200 in an ALLOW table.

5.

Enter the # character in place of a particular digit

to condense a range of numbers into one entry.

The # character is a “match-anything” digit, and

can be included in an entry in either a DENY table

or an ALLOW table.

Example

A:

If

and 397 dialing

is to be prohibited, list one entry of 3#7 on a

DENY table to cover them all.

Example

B:

Since area codes typically have

a 1 or a 0 as a middle digit, prevent long dis-

tance calls to those area codes by entering

3.

Select entry line

4.

Dial entry number (16 digits max). Press

enter “match anything” digit.

5.

Repeat procedure for each table.

6.

Press

MONITOR.

key to

3-18

Page 32

TOLL RESTRICTION TABLE 1

TYPE: ALLOW DENY

ENTRY

ENTRY NUMBER (16 MAXIMUM)

System Programming

TABLE ASSIGNMENT: LINES

TOLL RESTRICTION TABLE 2

TYPE: ALLOW DENY

ENTRY

ENTRY NUMBER (16 MAXIMUM)

I7

STATIONS

I I I I I I I I

TABLE ASSIGNMENT: LINES

TOLL RESTRICTION TABLE 3

TYPE: ALLOW DENY

ENTRY ENTRY NUMBER (16

TABLE ASSIGNMENT: LINES

STATIONS

STATIONS

MAXIMUM)

I

TOLL RESTRICTION TABLE

TYPE: ALLOW DENY

ENTRY

ENTRY NUMBER (16 MAXIMUM)

I

TABLE ASSIGNMENT: UNES

TOLL

ALLOW DENY

ENTRY

I

TABLE

,

I

I

ENTRY NUMBER (16

5

I

I I

MAXIMUM)

I

I I

I

I I I

TOLL RESTRICTION TABLE

TYPE: ALLOW

ENTRY ENTRY NUMBER

TABLE ASSIGNMENT: LINES

DENY

4

STATIONS

MAXIMUM)

TOLL RESTRICTION TABLE

NPE: ALLOW

ENTRY

I

TABLE ASSIGNMENT: LINES

3-19

8

DENY

ENTRY NUMBER (16 MAXIMUM)

STATIONS

I

Page 33

NG KEY LAYOUT

EXECUTECH MODELS 0616X, 0816X

CLASS OF SERVICE PROGRAMMING

-SYSTEM

AS

616X

SEE

-AT ENTRY T

AS

LINE

STATIONS. BY

RECEIVE.

Flgure

LINES.

TO

EXT.

LINES

616X KEY

A

9

NO

AT

TO

C.

NO

KM

m LINE

m

USES

TO

NO

REMAIN INTACT.

TO

ONLY SPECIFIES

IS

LINE, NO

NO

Programming Flow Dlagram

Page 34

CHAPTER 4

MAINTENANCE

Maintenance

TECHNICAL ASSISTANCE

AND REPAIR SERVICE

right side of the KSU cabinet. Always replace this

fuse with one of the same value

equipment damage could result.

Technlcal Assistance

Should you expen’ence difficulty with installation,

checkout, or programming, and have made an at-

System Status indicator

tempt to isolate the problem using information

provided herein; or should you encounter problems at

a later date which cannot be resolved by referring to

this manual, call the Comdial Technical Service staff.

They can be reached between the hours of 8:00 AM

and 8:00 PM Eastern time, Monday through Friday.

The red LED located near the fuse holder is the sys-

tem status indicator. This indicator should turn on

steady when AC power is applied to the KSU. If the

indicator flashes after power up, it could be indicating

a processor failure. Unplug and reconnect the AC

power to the KSU and observe the LED indication. If

Technical Services: l-800-366-8224

When calling for technical assistance, you should be

at the job site and you should have in your possession, as a minimum, an accurate volt-ohm meter and

it still shows a flashing indication, refer to Figure 4-l.

Station Self Test

Exercise the station self test feature as follows:

a copy of this manual.

Repair Senrlce

If your KSU or an individual station needs repair, it

may be returned to Comdial. Comdial will, at their op

tion, either repair the defective equipment or replace

it with a remanufactured unit. This repair will be done

for a fixed charge. For information on this charge,

please call or write to the address given below.

Comdial

Charlottesville, VA 22906

Attention: Repair Department

Telephone: (804) 978-2400

When returning equipment for repair, pack it carefully

to prevent damage. Any damages during shipment

will be the responsibility of the purchaser. The equip-

ment should be shipped freight or postage prepaid.

The shipping address is:

Comdial

1180 Seminole Trail

Charlottesville, VA 22901

Attention: Repair Department

and type;

FAILURE ISOLATlON

1.

Disconnect the line cord at the station base.

NOTE:

EVEN STATION WILL BE DISABLED DURING

TIME THAT THE

BEING DISCONNECTED OR RECONNECTED.

2.

Press and hold the MUTE key, and reconnect the

line cord to the station connector. The station will

automatically perform a

the MUTE key as soon as the test begins. The

sequence of the test is as follows:

l

The tine select indicators will light in se-

quence from 1 to 8.

l

The intercom select indicator will light.

l

The speaker indicator will light.

l

All indicators will turn off in the same sequence.

l

ringer volume control is set to the

medium or high volume setting.

3.

Replace any station that does not pass the Self

test.

ADJACENT ODD OR

CORD IS

test routine. Release

Be sure that the

FUSE LOCATION

The KSU is protected against short circuit damage by

Test the DSS/BLF Console for proper lamp operation

per the following procedure.

a fuse located in the primary of the AC transformer

winding. The fuse is a 1 amp,

SLO-BLO type

fuse. The fuse holder is located near the top of the

Change page

4-d

1. Disconnect the console line cord plug from the

fne.

Page 35

66-031

Maintenance

Press and hold the station 10 select key while

2.

reconnecting the line cord plug to the line.

IMPORTANTNOTE: THE COMPANION STATtON

WILL BE DISABLED DURING THE

THE CONSOLEIS BEING DISCONNECTED AND

RECONNECTED.

Release the station 10 select key, and note

3.

the BLF indicators will each

beginning with the station 10 indicator. The in-

dicators will then turn off and the console will become operational.

turn

on in sequence

Paired Stations

. .

ne

All stations are even/odd paired on the data lines as

shown in Table 4-l. Station 10 is paired with station

etc. If erratic light indications or ring signals occur

at a paired station, an open data pair at either station

may be the fault. A station with an open data line

may work properly on a short loop but fail on a long

loop. Test the station wiring per the checkout procedure given in Chapter 2.

Overload Paultlg

. .

that

Failure Analysis

Figure 4-l details a failure analysis flow chart to assist a service technician in isolating a failure in a

defective system. One way to isolate a failure is to

substitute a known good assembly for a suspected

one, This is the recommended failure isolation

method to use with the system.

Connecting and disconnecting stations

does not affect the stored station auto/speed dial

memory data. This data is stored in the KSU memory

and not at the individual stations. Replacing the

KSU, however, causes all stored memory to be lost.

This includes all memory dialing numbers as well as

all COS programming data.

Table

Station Pairing

to the

system

All stations are paired as shown in Table 4-l for overload current protection. If a fault occurs which

causes more than 300 ma. of current to be drawn, the

paired stations are disabled by circuit action. Disconnect the disabled stations and reconnect them one at

a time

to

isolate the faulty one.

4-2

Page 36

FAILURE

.

PERFORM

SELF TEST

YES

YES

INPUT FOR FAILED

UNUSED TELCORSX

JACK ON PSX

REPLACE KSU AND

PERFORM

Page 37

Index

66-031

.

A

A-LEAD CONTROLDEVICE CONNECTlON

AC POWER CONNECTION

ACCESS DENIED

ALL CALL PAGING

AREA PAGING INTERFACE

AREA PAGING INTERFACE

BASE LEVEL PROGRAM ENTRY MODE

BUSY LAMP FIELD STATlONS

...................

...............

..................

UNE PORT

STATlON PA PORT . .

..............

............

C

.....................

CALL ORIGINATION DENIED

CHECKOUT

CLASS OF SERVICE DEFAULT

COMMON AUDIBLE AND

CONNECTION, PA

CONNECTION, A-LEAD CONTROL DEVICE

CONNECTION. AC POWER

CONNECTION. UNE

CONNECTION, POWER FAILURE STATIONS

CONNECTION. DATA DEVICE

CONNECTION. DSSIBLF CONSOLE

CONNECTIONS. STA-IION

......................

.................. 26

.................

...................

............

........... 3-l

.........

..............

............

.........

..............

D

DATA LINE PAIRING

DATADEVICE CONNECTION

DATASPEED BAUD RATE

DEFAULT, CLASS OF SERVICE

DEFAULTS, SYSTEM

DEFAULTS, STATION

DELAYED RINGING ASSIGNMENT

WALL MOUNTING, STATlONS

DIALING MODE

DIRECT RINGING ASSIGNMENT

.................

............ 23

..............

...........

.................

................. 38

.........

...........

....................

..........

.........

..............

.....

......

......

.....

....

INDEX

2-3

2-2

3-7

3-7

2-5

2-5

3-4

3-l

2-3

3-7

2-3

2-4

l-l

2-3

2-2

2-2

2-3

2-3

2-3

2-2

3-3

4-2

3-4

3-1

3-3

3-7

4-4

3-3

........... 4-l

E

.................

F

FAILURE ISOLATION

FAILURE ANALYSIS FLOW CHART

FAILURE ANALYSIS

FCC RULES AND REGULATlONS

G

GENERAL CHECK

GENERAL INFORMATlON, PROGRAMMlNG

.................

........

..................

..........

...................

..................

.... 3-l

................

H

HELD CALL ABANDON TlME

I

INDICATOR, SYSTEM STATUS

INSTALLATION

INTERCOM SIGNALUNG MODE

INTERCONNECTION. SYSTEM

INTRODUCTION

....................

...................

.............

.................

.....

............ 4-l

..........

...........

............

K

KSU TO STATlON WlRlNG

..............

L

LINE COS PROGRAMMING REFERENCE

LINE CONNECTIONS

......................

LINE DEFAULTS

LINE COS PROGRAMMING PROCEDURE

MAINTENANCE

MANUAL SCOPE

MOUNTING CONSIDERATIONS

MUSIC ON HOLD

.................

...................

.................... 4-l

................... l-l

..............

..............

...........

...................

N

NIGHTRINGING

...................

......

.....

....

4-l

4-2

l-l

4-l

2-3

3-3

3-3

2-l

3-3

2-7

l-l

3-15

2-2

3-5

2-2

2-l

2-l

2-5

3-7

.

Page 38

66-031

Index

0

OVERLOAD PAIRING

..................

4-2

P

PA CONNECTlON

PAIRED STATIONS

PARTY LINES AND COIN LINES

POWER FAILURE STATION CONNECTION

PRIME LINE/INTERCOM

PRINTOUT, SMDR AND COS

PRIVACY RELEASE

PRIVACY STATUS OF LINE

PROGRAMMED PAUSE

PROGRAMMING REFERENCE, LINE COS

PROGRAMMING REFERENCE,

TOLL RESTRICTION

PROGRAMMING. SYSTEM

PROGRAMMING REFERENCE, STATION COS

PROGRAMMING KEYS

PROGRAMMING REFERENCE,SYSTEM COS

PROGRAMMING, SYSTEM SPEED DlAL

PROGRAMMING FLOW DIAGRAM

PROGRAMMING PROCEDURE, STATION COS . . 3-6

PULSE DlAL CHARACTERISTICS

RADIO FREQUENCY 1NTERFERENCE

RELATED PUBLlCATlONS

REPAIRSERVICE

REPAIR AUTHORlZATlON

RESISTANCE CHECK

RINGER EQUIVALENCE NUMBER

...................

.......................

...................

........... l-l

.....

...............

...............

.............

..................

.............

...............

.....

.................

..............

....

..................

................

.............

...... 512

.........

..........

....... l-2

..............

..............

.........

4-2

2-3

3-8

3-7

3-5

3-3

... 33

3-15

3-18

3-l

...

3-16

3-l

...

3-13

3-21

3-3

1-l

4-1

2-8

l-2

SELF TEST, STATION-

SMDR AND COS PRINTOUT

STATION

STATION COS PROGRAMMING REFERENCE

STATION dONNECTlON

STATION MESSAGE DETAIL

RECORD PRINTOUT FORMAT

STATlON DEFAULTS

STATlON COS PROGRAMMING PROCEDURE . .

STATION WALL MOUNTING DETAILS

SYSTEM COS PROGRAMMING PROCEDURE

SYSTEM STATUS INDICATOR

SYSTEM PROGRAMMING

SYSTEM COS PROGRAMMING REFERENCE

SYSTEM SPEED DIAL PROGRAMMING

SYSTEM CLOCK INFORMATION

SYSTEM INTERCONNECTION

SYSTEM WIRING

SYSTEM GROUNDING

SYSTEM DEFAlJLlS

................ 4-l

...................

.............

.................

...

...............

............

.................

........

. 3-3

............

..............

. 3-13

.......

...........

............

....................

................

.................

3-8

2-2

3-9

3-6

3-6

4-4

4-l

3-l

3-12

3-11

2-7

2-2

24

T

TECHNICALASSISTANCE

TOLL RESTRICTION

PROGRAMMING REFERENCE

TOLL RESTRICTION TABLES

TROUBLESHOOTING

TYPICAL COS PRINTOUT

.............. 4-l

...........

............

................. l-l

..............

3-18

V

VOLTAGE CHECK

...................

2-8

W

WALL MOUNTING DETAILS, STATlON

WIRING, KSU TO STATlON

..............

........ 44

2-6

S

SELF TEST, DSS/BLF CONSOLE

.......... 4-l

ZONE PAGING

....................

3-7

Page 39

Page 40