Comchip CDSW300W Service Manual

CD-SW300W

SERVICE MANUAL

No. S6620CDSW300W

MINI COMPONENT SYSTEM

CONTENTS

CHAPTER 1. GENERAL DESCRIPTION

[1] Precaution for using lead-free solder............ 1-1

[2] Safety precaution for service manual .... 1-2

[3] Voltage selection........................................... 1-2

[4] AC power supply cord....................................1-2

[5] Specifications.................................................1-3

[6] Names of parts...............................................1-4

CHAPTER 2. ADJUSTMENTS

[1] Mechanism section ........................................ 2-1

[2] Test mode ...................................................... 2-2

[3] CD section ..................................................... 2-4

[4] CD Changer mechanism section................... 2-5

MODEL

CD-SW300W Mini Component System consisting of

CD-SW300W

and CP-SW300 (subwoofer).

In the interests of user-safety the set should be restored to its

original condition and only parts identical to those specified be

used.

CHAPTER 5. CIRCUIT DESCRIPTION

[1] Waveforms of CD circuit................................5-1

[2] Voltage..........................................................5-2

CHAPTER 6. CIRCUIT SCHEMATICS AND PARTS

LAYOUT

[1] Notes on schematic diagram.........................6-1

[2] Types of transistor and LED..........................6-1

[3] Schematic diagram........................................6-2

[4] Wiring side of PWB .....................................6-10

CHAPTER 7. FLOWCHART

[1] Troubleshooting.............................................7-1

CD-SW300W

(main unit) and CP-S300 (front speaker)

CHAPTER 3. MECHANISM BLOCKS

[1] Caution on disassembly................................. 3-1

[2] Removing and reinstalling the main parts ........ 3-4

CHAPTER 4. DIAGRAMS

[1] CD Block Diagrams .......................................4-1

[2] Main Block Diagrams.....................................4-2

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

CHAPTER 8. OTHERS

[1] Function table of IC.......................................8-1

[2] FL Display .....................................................8-8

Parts Guide

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

CD-SW300W

SC

HAPTER 1: GENERAL DE

RIPTION

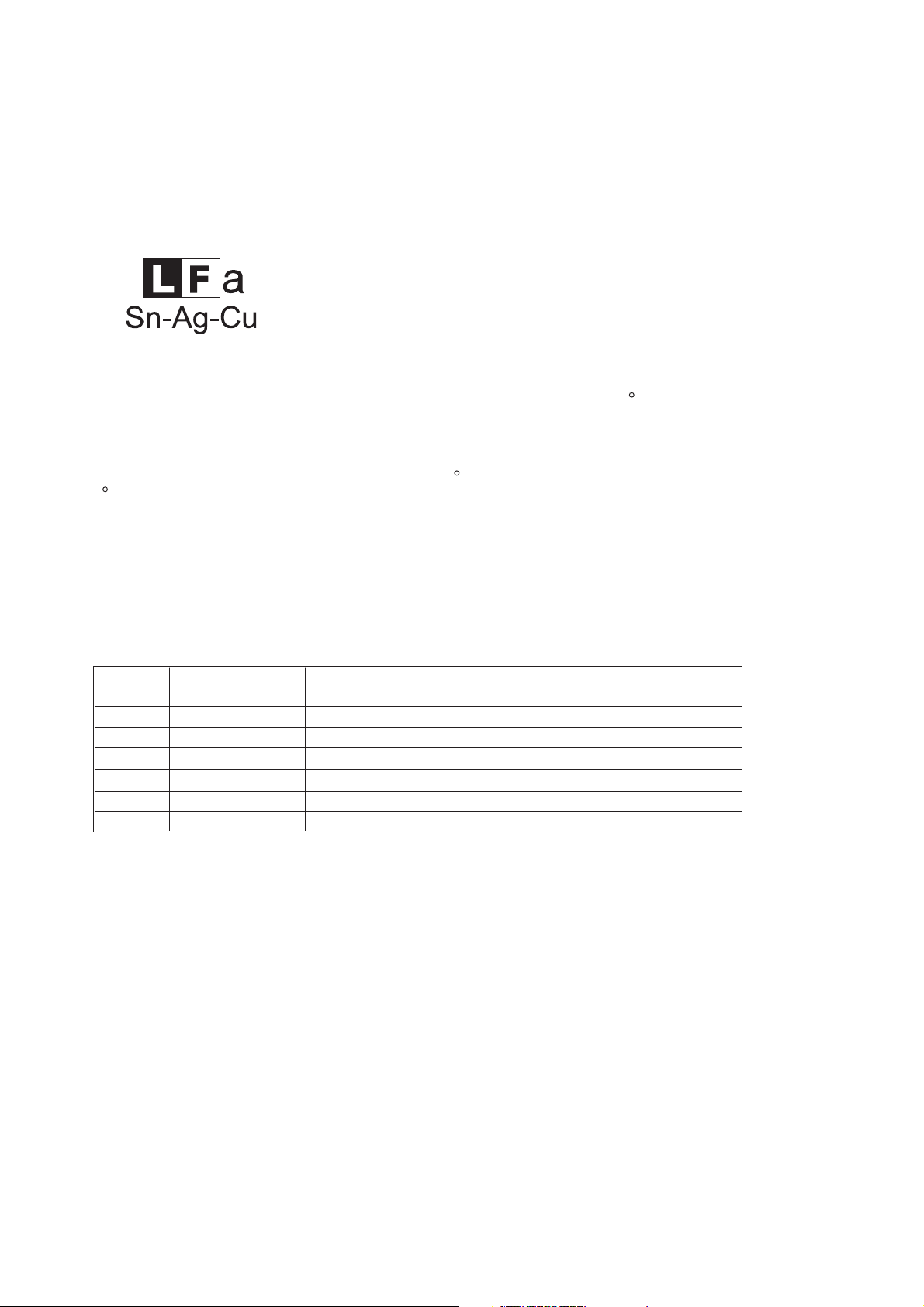

[1] PRECAUTIONS FOR USING LEAD-FREE SOLDER

1. Employing lead-free solder

"MAIN, POWER, DISPLAY, GAME INPUT, CD SERVO, FRONT SPEAKER LED, CD MOTOR (PWB ONLY), CD

CHANGER MOTOR (PWB ONLY), SUB WOOFER LED " of this model employs lead-free solder.

The LF symbol indicates lead-free solder, and is attached on the PWB and service manuals. The alphabetical character

following LF shows the type of lead-free solder.

Example:

Indicates lead-free solder of tin, silver and copper.

2. Using lead-free wire solder

When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional lead wire

solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 C, we recommend you to

dedicated soldering bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit, contact our

use a

service station

3. Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 C which is higher than the conventional lead solder

by 40 C,

extended period of

of parts may be exceeded,

Lead-free solder contains more tin, and the end of the soldering bit may be easily corrected. Make sure to turn on

and off the

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after

every use

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Ref No.

PWB-A 92LPWB6516MANS

PWB-B 92LPWB6516DPLS

PWB-C

PWB-D

PWB-E

PWB-F

PWB-H

or service branch in your area.

and as it has poor solder wettability, you may be apt to keep the soldering bit in contact with the PWB for

time. However, since the land may be peeled off or the maximum heat-resistance temperature

remove the bit from the PWB as soon as you confirm the steady soldering condition.

power of the bit as required.

of it.

Parts No.

92LPWB6514CDUS

92LPWB6514LEDS

QPWBF0027AWZZ

QPWBF1055AWZZ

92LPWB6230LEDS

MAIN (A1), POWER (A2)

DISPLAY (B1), GAME INPUT (B2)

CD SERVO

FRONT SPEAKER LED

CD MOTOR (PWB ONLY)

CD CHANGER MOTOR (PWB ONLY)

SUB WOOFER LED

Description

1 – 1

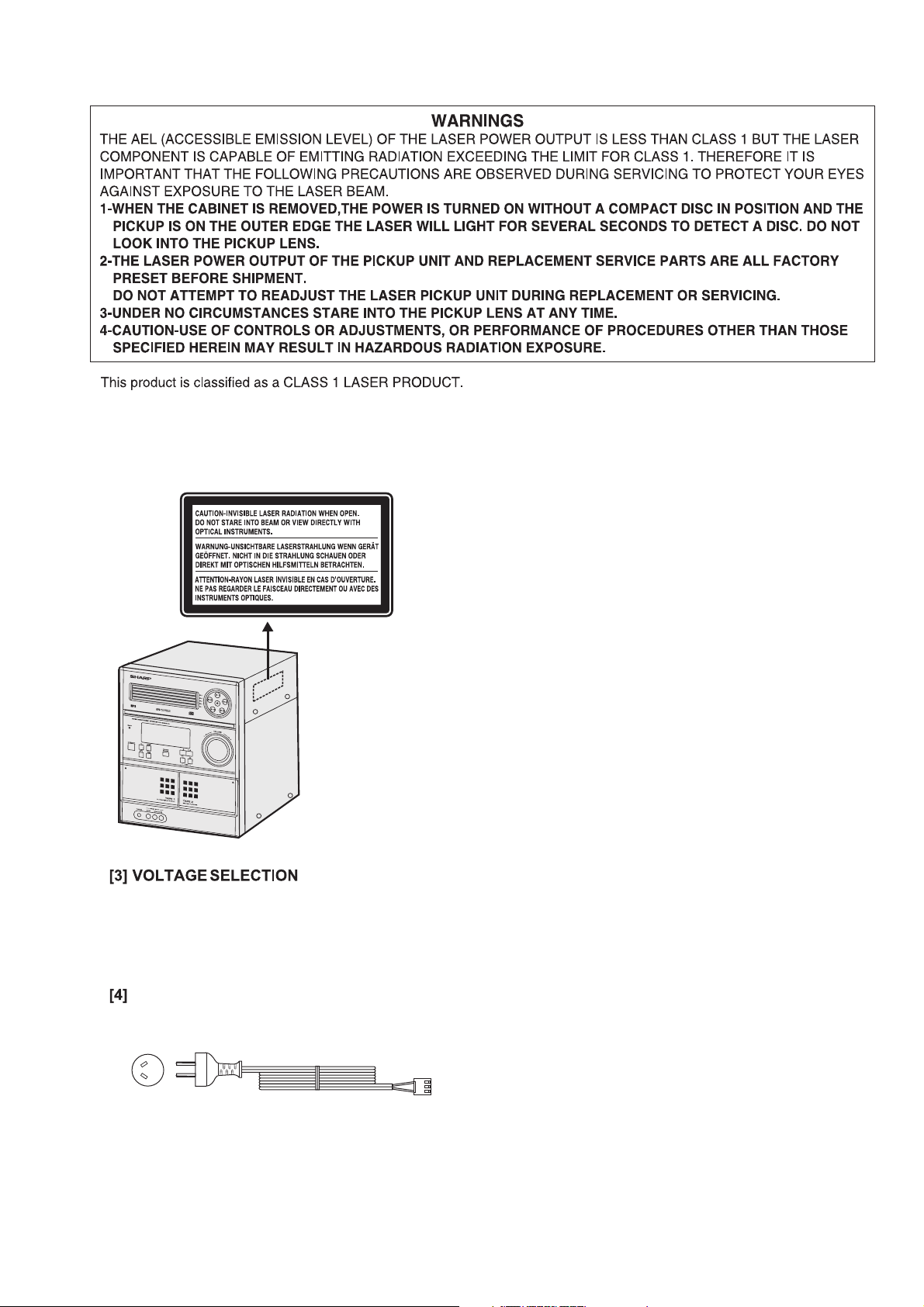

[2] SAFETY PRECAUTION FOR SERVICE MANUAL

Laser Diode Properties

Material: GaAIAs

Wavelength: 795 nm

Emission Duration: continuous

Laser Output: max. 0.6 mW

CD-SW300W

Before operating the unit on mains, check the preset voltage. If the voltage is different from your local

voltage, adjust the voltage as follows. Turn the selector with a screwdriver until the appropriate voltage

number appears in the window (110V, 127V, 220V or 230V - 240V AC).

AC POWER SUPPLY CORD

QACCZ0013AW00

1 – 2

–2

CD-SW300W

[5] SPECIFICATIONS

FOR A COMPLETE DESCRIPTION OF THE OPERATION OF THIS UNIT, PLEASE REFER

TO THE OPERATION MANUAL.

As part of our policy of continuous improvement, SHARP reserves

the right to make design and specifcation changes for product

improvement without prior notice. The performance specifcation

figures indicated are nominal values of production units .There may

be some deviations from these values in individual units.

General

■

Power source AC 110/127/220/230 - 240 V, 50/60 Hz

Power consumption

Dimensions Width: 260 mm (10 - 1/4")

Weight 9.97 kg (21.98 lbs.)

Amplifier

■

Output power Front Speaker:

Output terminals Front Speakers: 6 ohms

Input terminals Game/Auxiliary (audio signal):

CD player

■

Type 5-disc multi-play compact disc player

Signal readout Non-contact, 3-beam semiconductor laser

D/A converter 1-bit D/A converter

Frequency

response

Dynamic range 90 dB (1 kHz)

165 W

Height: 330 mm (13")

Depth: 323 mm (12 - 7/8")

MPO: 400 W (200 W + 200 W) (10% T.H.D.)

RMS: 200 W (100 W + 100 W) (10% T.H.D.)

RMS: 160 W (80 W + 80 W) (0.9% T.H.D.)

Subwoofer:

MPO: 400 W (10% T.H.D.)

RMS: 200 W (10% T.H.D.)

RMS: 165 W (0.9% T.H.D.)

Subwoofer: 12 ohms

Headphones: 16 - 50 ohms

(recommended: 32 ohms)

Video output: 1Vp-p

500 mV/ 47 k ohms

Game/Video: 1Vp-p

pickup

20 - 20,000 Hz

Tuner

■

Frequency range FM: 88.0 - 108.0 MHz

Cassette deck

■

Frequency

response

Signal/noise ratio 55 dB (TAPE 1, playback)

Wow and flutter 0.3 % (WRMS)

Front Speaker

■

Type 3-way type speaker system

Maximum input

power

Rated input power 100 W

Impedance 6 ohms

Dimensions Width: 200 mm (7 - 7/8")

Weight 3.3 kg (7.3 lbs.) /each

Subwoofer

■

Type Full Range

Maximum input

power

Rated input power 200 W

Impedance 12 ohms

Dimensions Width: 250 mm (9 - 13/16")

Weight 5.9 kg (13 lbs.)

AM: 531 - 1602 kHz

50 - 14,000 Hz (normal tape)

50 dB (TAPE 2, recording/playback)

Super tweeter

5 cm (2") tweeter

16 cm (6 - 5/16") woofer

200 W

Height: 330 mm (13")

Depth: 231 mm (9 - 1/8")

20 cm (8") subwoofer

400 W

Height: 330 mm (13")

Depth: 294 mm (11 - 9/16")

1 – 3

– 4

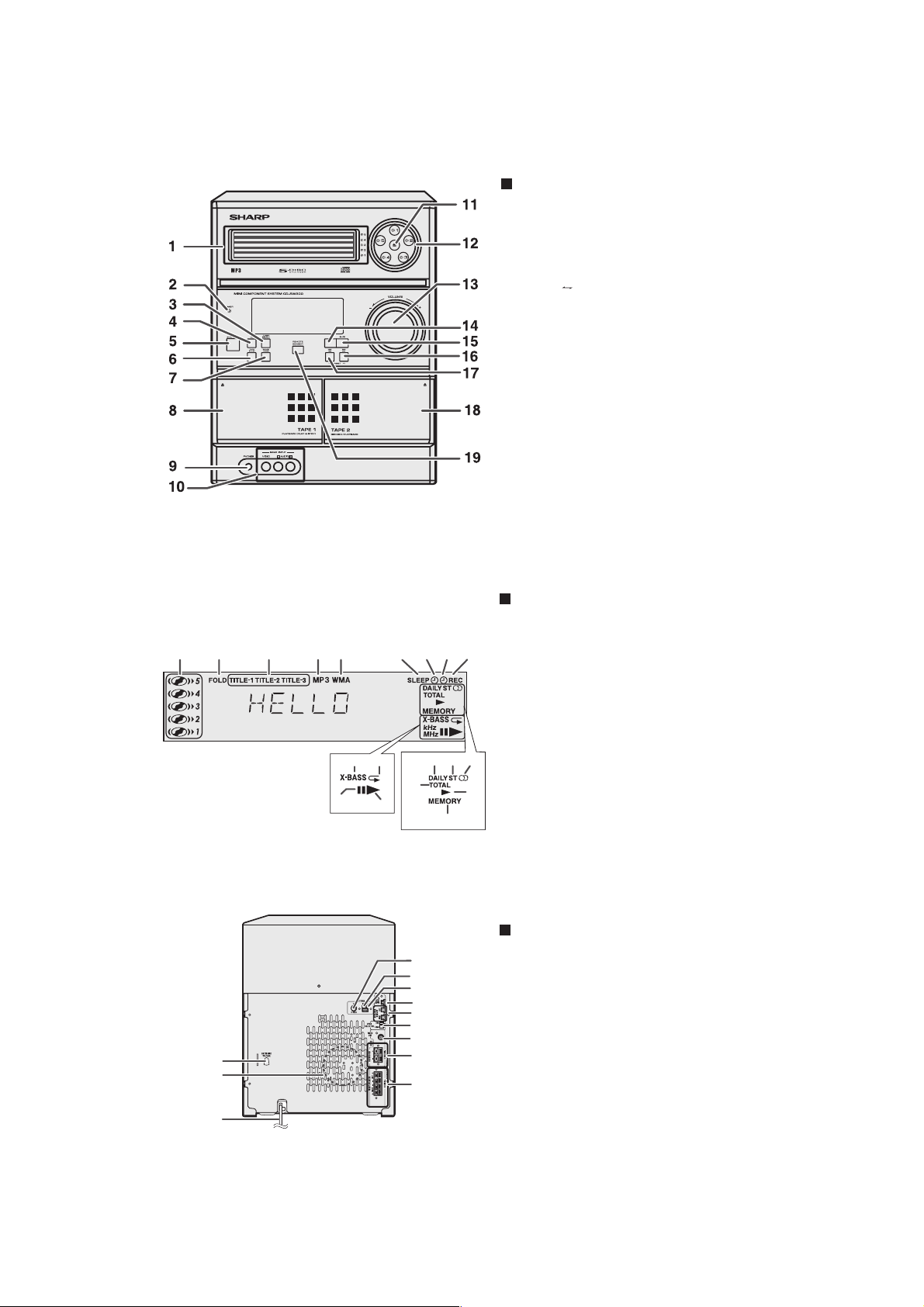

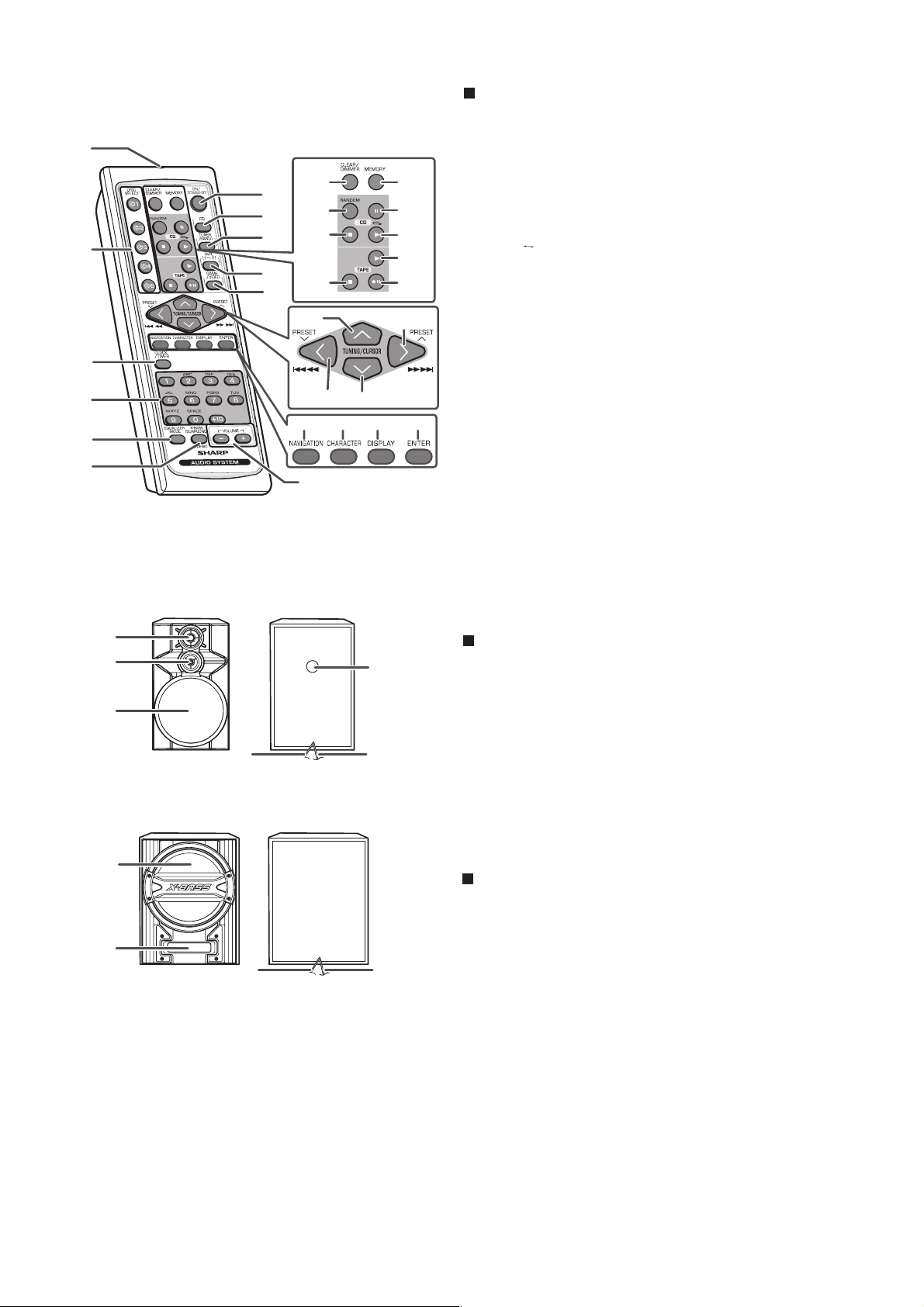

[6] NAMES OF PA RTS

CD-SW300W

Front panel

1. Disc Trays

2. Timer Indicator

3. Tuner (Band) Button

4. CD Button

5. On/Stand-by Button

6. Tape (1 2) Button

7. Game/Video Button

8. Tape 1 Cassette Compartment

9. Headphone Jack

10. Game/Video Input Jacks

11. Disc Tray Open/Close Button

12. Disc Number Select Buttons

13. Volume Control

14. CD or Tape Stop Button

15. CD Play or Repeat, Tape Play Button

16. CD Track Up or Fast Forward, Tape 2 Fast Forward,

Tuner Preset Up, Time Up Button

17. CD Track Down or Fast Reverse, Tape 2 Rewind,

Tuner Preset Down, Time Down Button

18. Tape 2 Cassette Compartment

19. Remote Sensor

Display

1. Disc Number Indicators

2. MP3/WMA Folder Indicator

2

13456789

16 17

11 12 13

10

18

19

15

3. MP3/WMA Title Indicators

4. MP3 Indicator

5. WMA Indicator

6. Sleep Indicator

7. Timer Play Indicator

8. Timer Recording Indicator

9. Tape 2 Record Indicator

10. MP3/WMA Total Indicator

11. Daily Timer Indicator

12. FM Stereo Mode Indicator

14

13. FM Stereo Receiving Indicator

14. Tape Play Indicator

15. Memory Indicator

16. Extra Bass Indicator

17. Disc Repeat Play Indicator

18. Disc Pause Indicator

19. Disc Play Indicator

Rear panel

4

5

6

7

8

9

10

1

2

AC INPUT

11

12

3

1. AC Voltage Selector

2. Cooling Fan

3. AC Power Lead

4. FM 75 Ohms Aerial Socket

5. AM Aerial Earth Terminal

6. AM Loop Aerial Terminal

7. Subwoofer Light-up Socket

8. Speaker Light-up Sockets

9. Span Selector Switch

10. Video out Socket

11. Subwoofer Terminals

12. Front Speaker Terminals

1 – 4

–2

CD-SW300W

1

2

3

4

5

6

13

7

14

8

15

9

10

16

11

22

24

25

26 27 28 29

12

23

17

18

19

20

21

Remote control

1. Remote Control Transmitter

2. Disc Number Select Buttons

3. Clock/Timer Button

4. Character Input/Disc Direct Search Buttons

5. Equalizer Mode Select Button

6. Extra Bass (Surround)/Demo Button

7. On/Stand-by Button

8. CD Button

9. Tuner (Band) Button

10. Tape (1 2) Button

11. Game/Video Button

12. Volume Up and Down Buttons

13. Disc Clear/Dimmer Button

14. Disc Random Button

15. Disc Stop Button

16. Tape Stop Button

17. Memory Button

18. Disc Pause Button

19. Disc Play or Repeat Button

20. Tape Play Button

21. Tape 2 Record Pause Button

22. Tuning Up, Cursor Up Button

23. Disc Track Up or Fast Forward, Tape Fast Forward,

Tuner Preset Up, Time Up, Cursor Right Button

24. Disc Track Down or Fast Reverse, Tape Rewind,

Tuner Preset Down, Time Down, Cursor Left Button

25. Tuning Down, Cursor Down Button

26. MP3/WMA Navigation Mode Select Button

27. Character Button

28. MP3/WMA Display Button

29. Enter Button

11

2

4

3

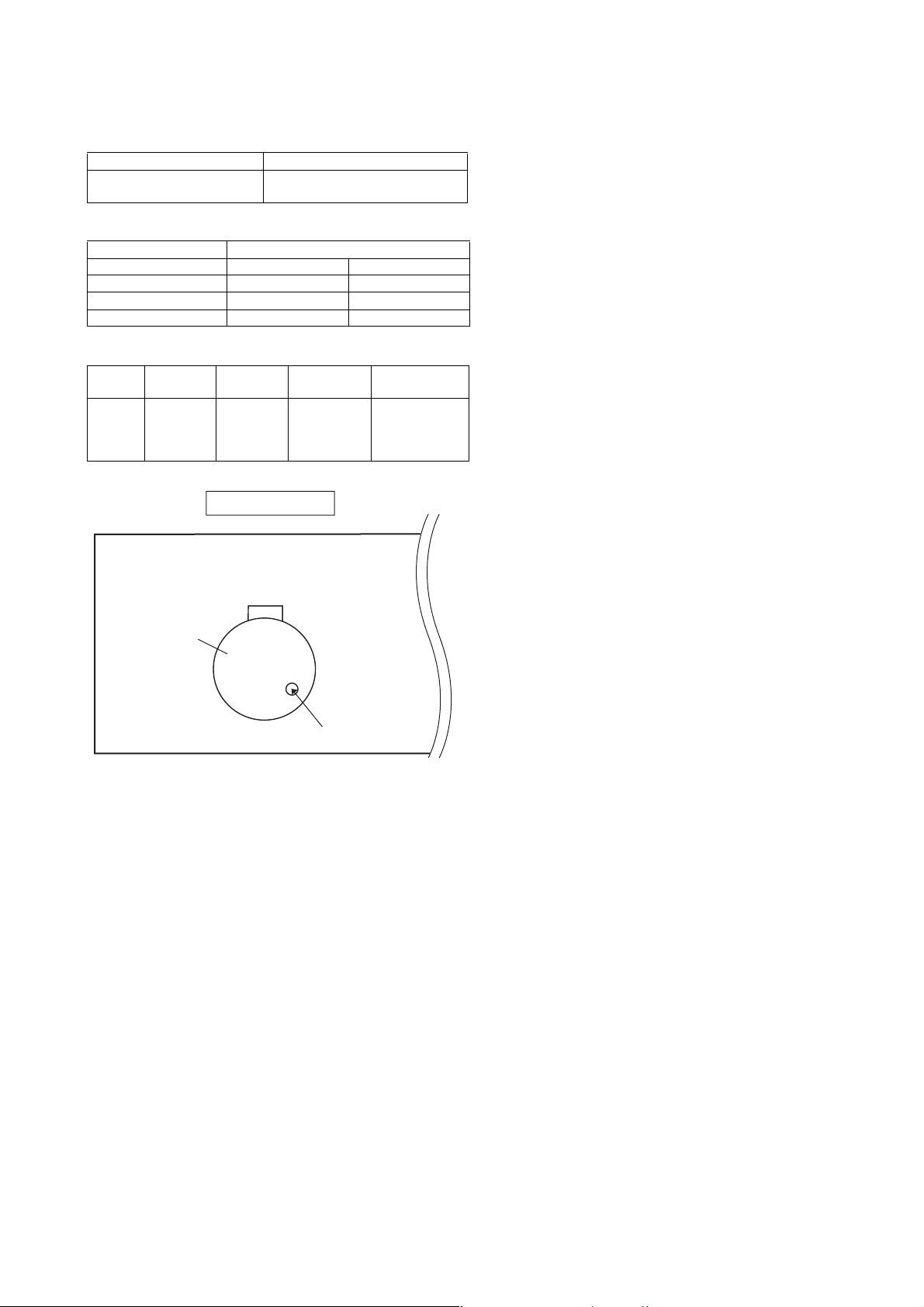

Front Speaker

1. Tweeter

2. Super Tweeter

3. Woofer

4. Bass Reflex Duct

5. Speaker Wire

6. Speaker Light-Up Wire

56

11

Subwoofer

1. Subwoofer

2. Bass Reflex Duct

3. Subwoofer Light-Up Wire

2

3

4

4. Speaker Wire

1 – 5

– 4

CD-ES700/CD-ES77CD-ES700/CD-ES77Service ManualCD-ES700/CD-ES77MarketE

CHAPTER 2. ADJUSTMENTS

[1] Mechanism section

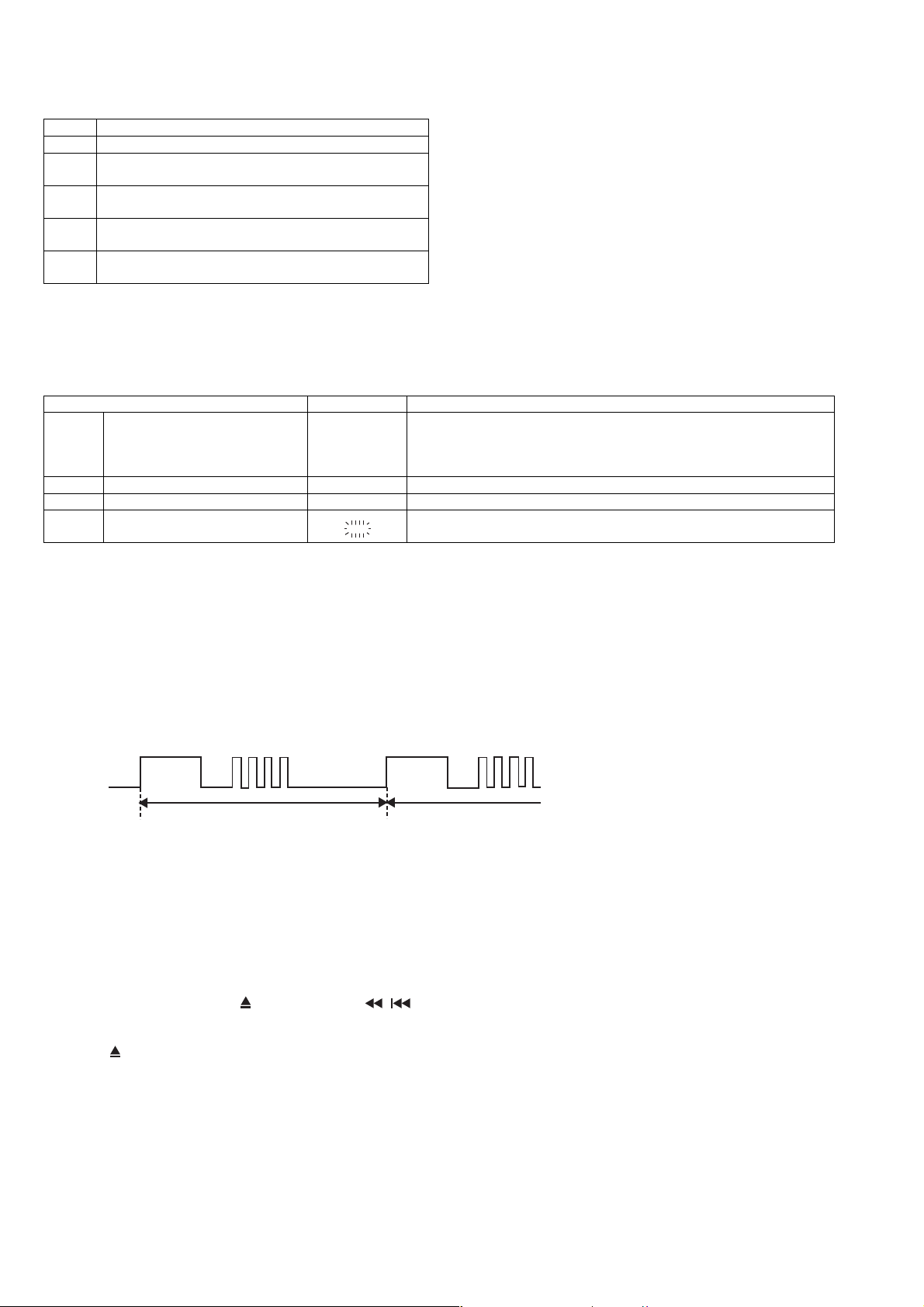

• Driving Force Check

Torque Meter Specified Value

Play: TW-2111 Tape 1: Over 80 g

Tape 2: Over 80 g

• Torque Check

Torque Meter Specified Value

Tape 1 Tape 2

Play: TW-2111 30 to 80 g.cm 30 to 80 g.cm

Fast forward: TW-2231 — 70 to 180 g.cm

— 70 to 180 g.cm

• Tape Speed

CD-SW300W

Test Tape Adjusting

Normal

speed

MTT-111 Variable

Tape

Motor

Figure 1

Point

Resistor

in motor.

TAPE MECHANISM

Variable Resistor in motor

Specified

Value

3,000 ± 30 Hz

Speaker

Instrument

Connection

Speaker

Terminal (Load

resistance: 6

ohms)

2 – 1

CD-SW300W

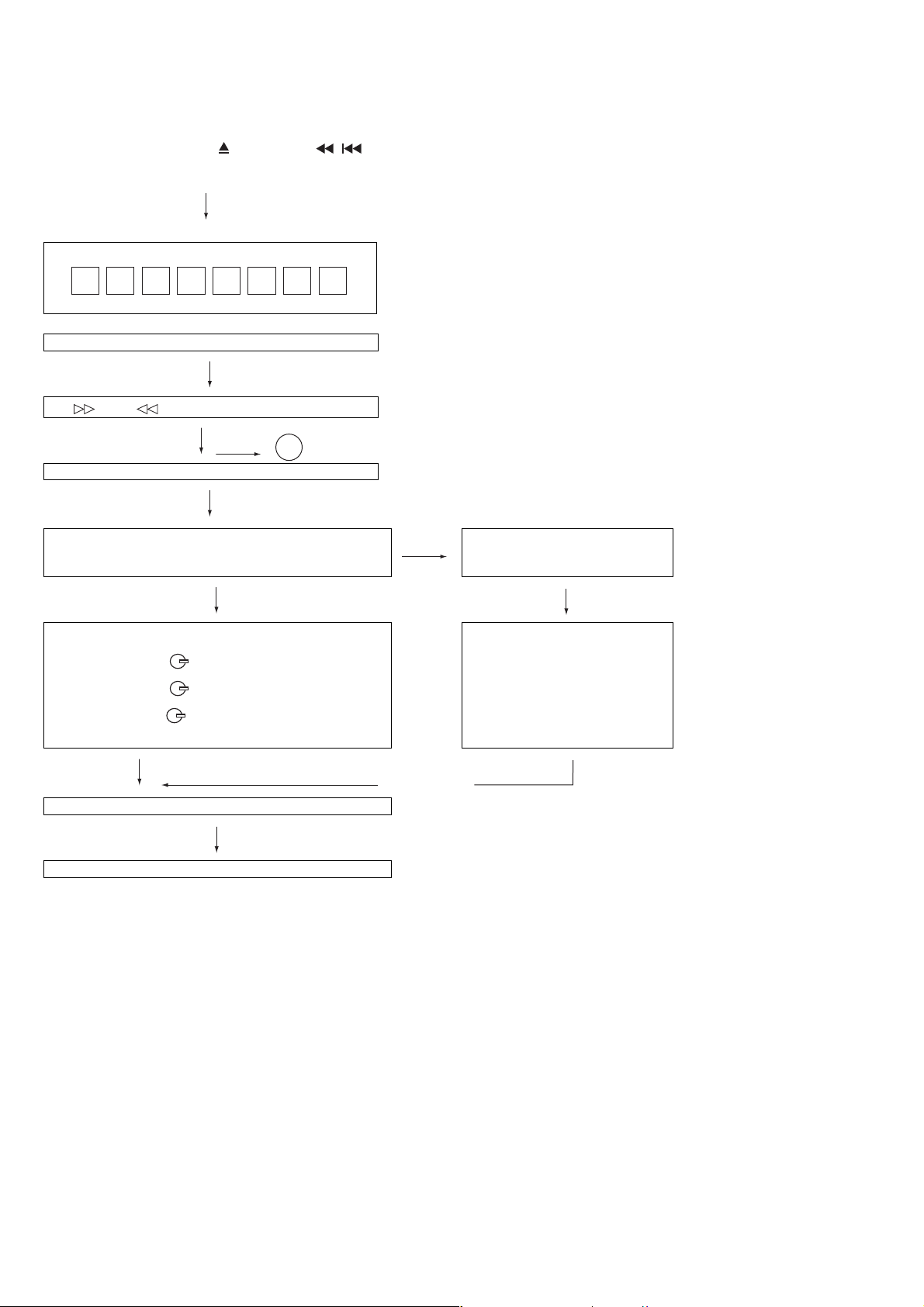

[2] Test mode

• Setting the test mode

During stand-by mode, press GAME/VIDEO button

while pressing down the button and button.

then, press the CD button to enter the test mode.

C D T E S T

OPEN/CLOSE operation is using manual. IL isn’t done

<< >>,<< >>buttons make pick's slide possible.

to page 2-3

<<PLAY>> key input.

Do TOC IL. Do normal play.

When these following key is input into PLAY key, track number can be appoint directly.

<< 1>> key: Track 4

<< 2>> key: Track 9

<< 3>> key: Track 15

A

IL isn’t done

IL isn’t done

<<MEMORY>>

key input.

Adjustment result automatically will

display as below for each 2 sec:

a) "FOF_XXXX"

b) "TOF_XXXX"

c) "TBAL_XX"

d) "TGAN_XX"

f) "FGAN_XX"

g) "RFLS_XX"

<<STOP>> key input.

STOP

explanation:

a) Focus off set = "FOF_XXXX"

b)Tracking off set = "TOF_XXXX"

c)Tracking balance = "TBAL_XX"

d)Tracking Gain = "TGAN_XX"

f) Focus Gain = "FGAN_XX"

g) RF level shift = "RFLS_XX"

VOL — Last memory

P.GEQ — FLAT

X-BASS — OFF

To cancel : Power OFF

––––––––

2 – 2

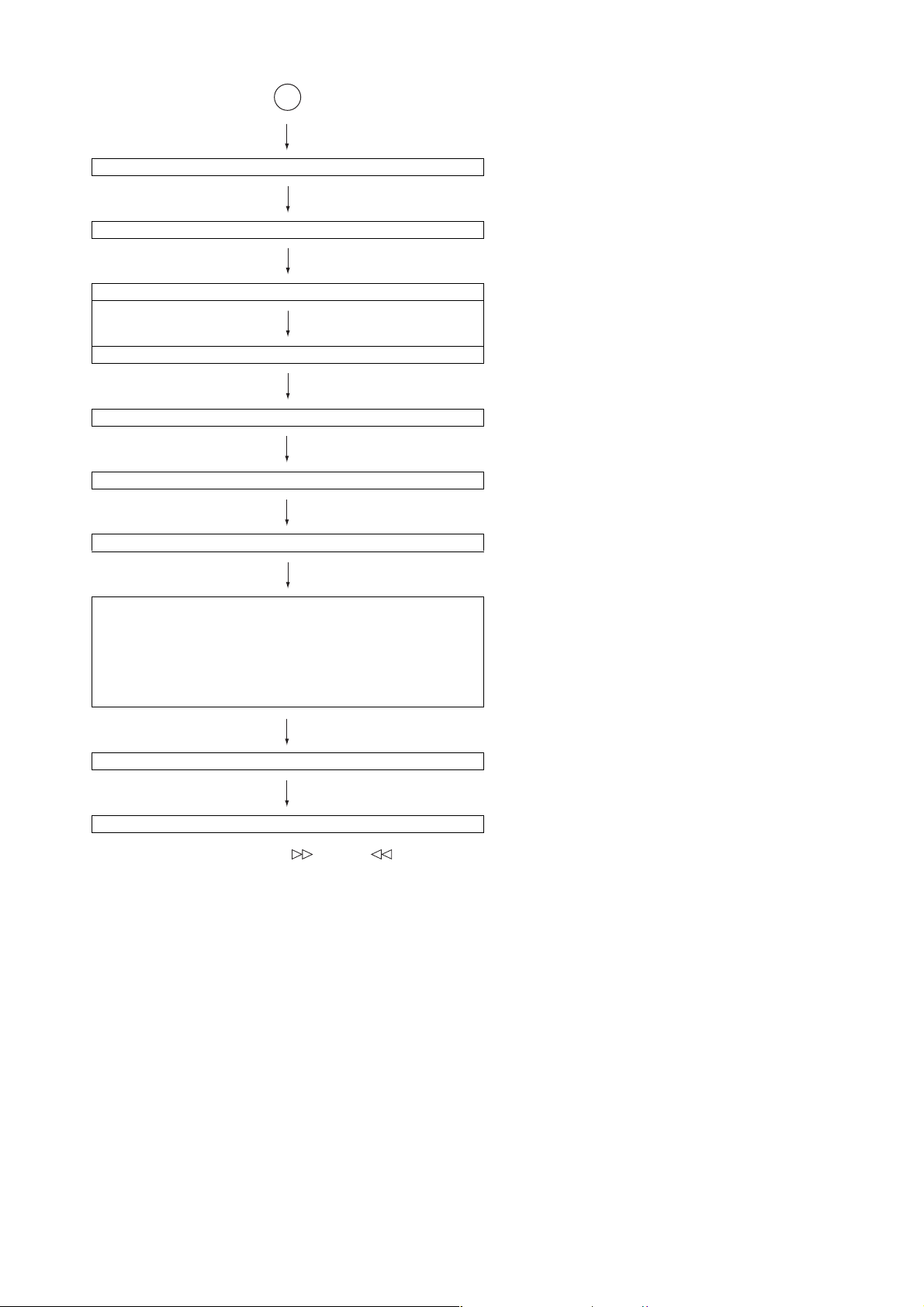

A

<<MEMORY>> key input.

Laser ON.

<<MEMORY>> key input.

Tracking OFF play at that specific point.

<<MEMORY>> key input.

Tracking ON play from that specific point.

CD-SW300W

<<MEMORY>> key input.

Adjustment result automatically will display as below for each 2 sec :

a) "FOF_XXXX"

b) "TOF_XXXX"

c) "TBAL_XX"

d) "TGAN_XX"

f) "FGAN_XX"

g) "RFLS_XX"

<<STOP>> key input.

STOP

Sliding the PICKUP with<< >>, << >> button

must only be in STOP mode.

explanation:

a) Focus off set = "FOF_XXXX"

b)Tracking off set = "TOF_XXXX"

c)Tracking balance = "TBAL_XX"

d)Tracking Gain = "TGAN_XX"

f) Focus Gain = "FGAN_XX"

g) RF level shift = "RFLS_XX"

VOL — Last memory

P.GEQ — FLAT

X-BASS — OFF

To cancel : Power OFF

2 – 3

CD-SW300W

[3] CD section

CD Error code description

Error Explanation

10* CAM error. Can't detect CAM switch when CAM is moving.

11* When it detect cam operation error during initialize

process.

20* TRAY error. Can't detect TRAY switch when TRAY is

moving.

21* When it detect TRAY operation error during initialize

process.

31 When it change to CD function, DSP cannot read initial

data.

* 'CHECKING'

If Error is detected, 'CHECKING' will be displayed instead of 'ER-CD**'. 'ER-CD**' display will only be displayed

when error had been detected for the 5

Standard Specification of Stereo System Error Message Display Contents

Error Contents Display Notes

CD CD Changer Mechanism Error. 'ER-CD**' (*) 10: CAM SW Detection NG during normal operation.

CD DSP Communication Error. 'ER-CD31' DSP COMMUNICATION ERROR.

Focus Not Match/IL Time Over. 'NO DISC'

TUNER PLL Unlock. PLL Unlock.

th

times.

FM 87.5 MHz

11: CAM SW Detection NG during initialize process.

20:TRAY SW Detection NG during normal operation.

21:TRAY SW Detection NG during initialize process.

(*) CHECKING:

If CD changer mechanism error is detected, 'CHECKING' will be display instead of 'ER-CD**'. 'ER-CD**' display will

only be display when error had been detected for the 5

th

times.

Speaker abnormal detection and +B PROTECTION display

In case speaker abnormal detection or +B PROTECTION had occurred, the unit will automatically enter to stand - by

mode and Timer indicator will be flashing as below.

Example : In case of speaker abnormal

TIMER

LED

ON

OFF

NO. 1

NO.1 : +B Protection

NO.2 : Speaker abnormal

OFF

FLASHING

NO. 2

1 FRAME

OFF

ON

NO. 1

FLASHING

OFF

NO. 2

(REPEAT)

+B PROTECTION is condition when irregular process occur on power supply line.

BEFORE TRANSPORTING THE UNIT

The following process need to be taken after set tapering/parts replacement.

1. Press the ON/STAND-BY button to enter stand-by mode.

2. While pressing down the button and the button, press the GAME/VIDEO button. The Micro Computer

version number will be displayed as "CM*****".

3. Press button until "WAIT"→ "FINISHED" appears.

4. Unplug the AC cord and the unit is ready for transporting.

2 – 4

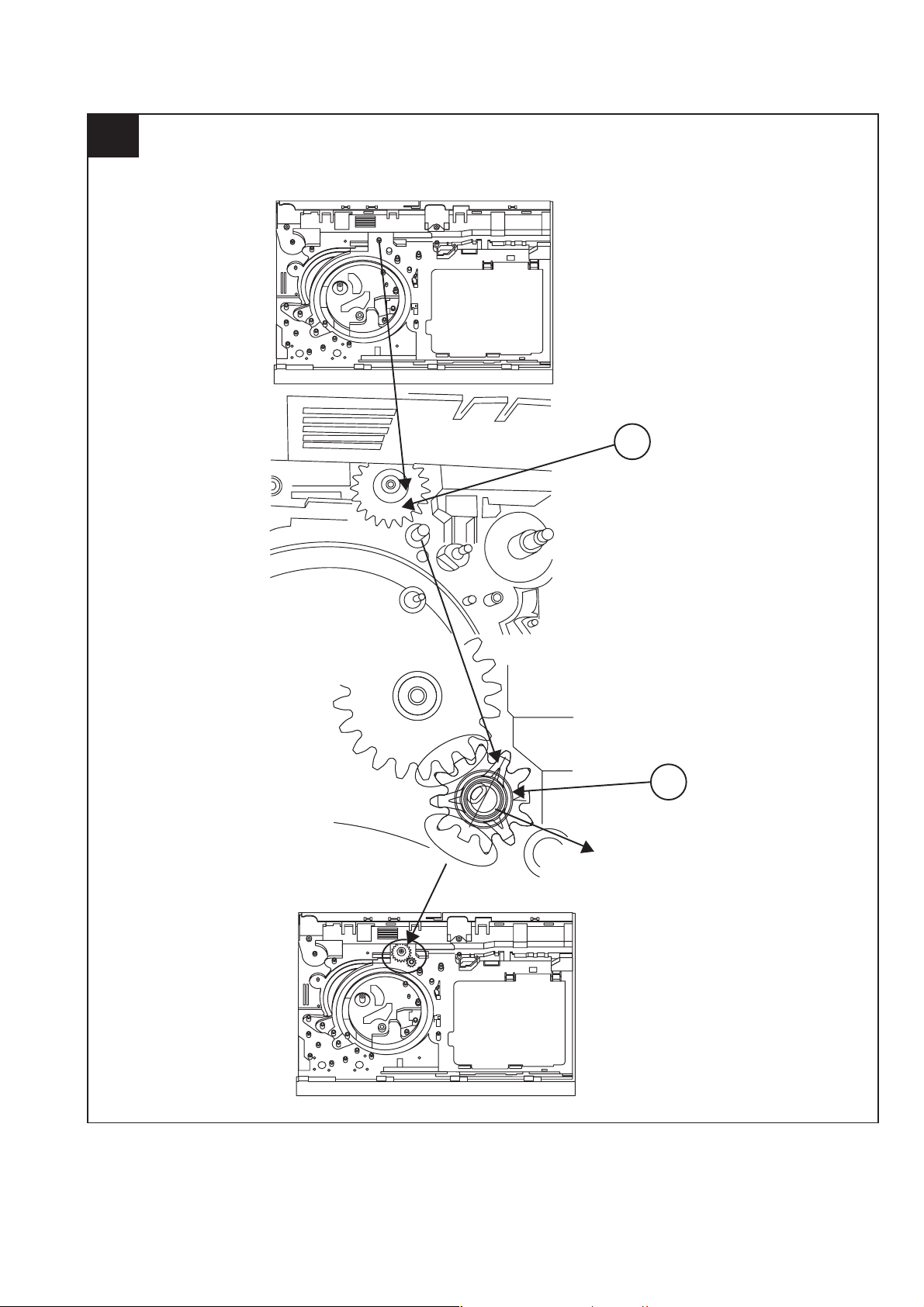

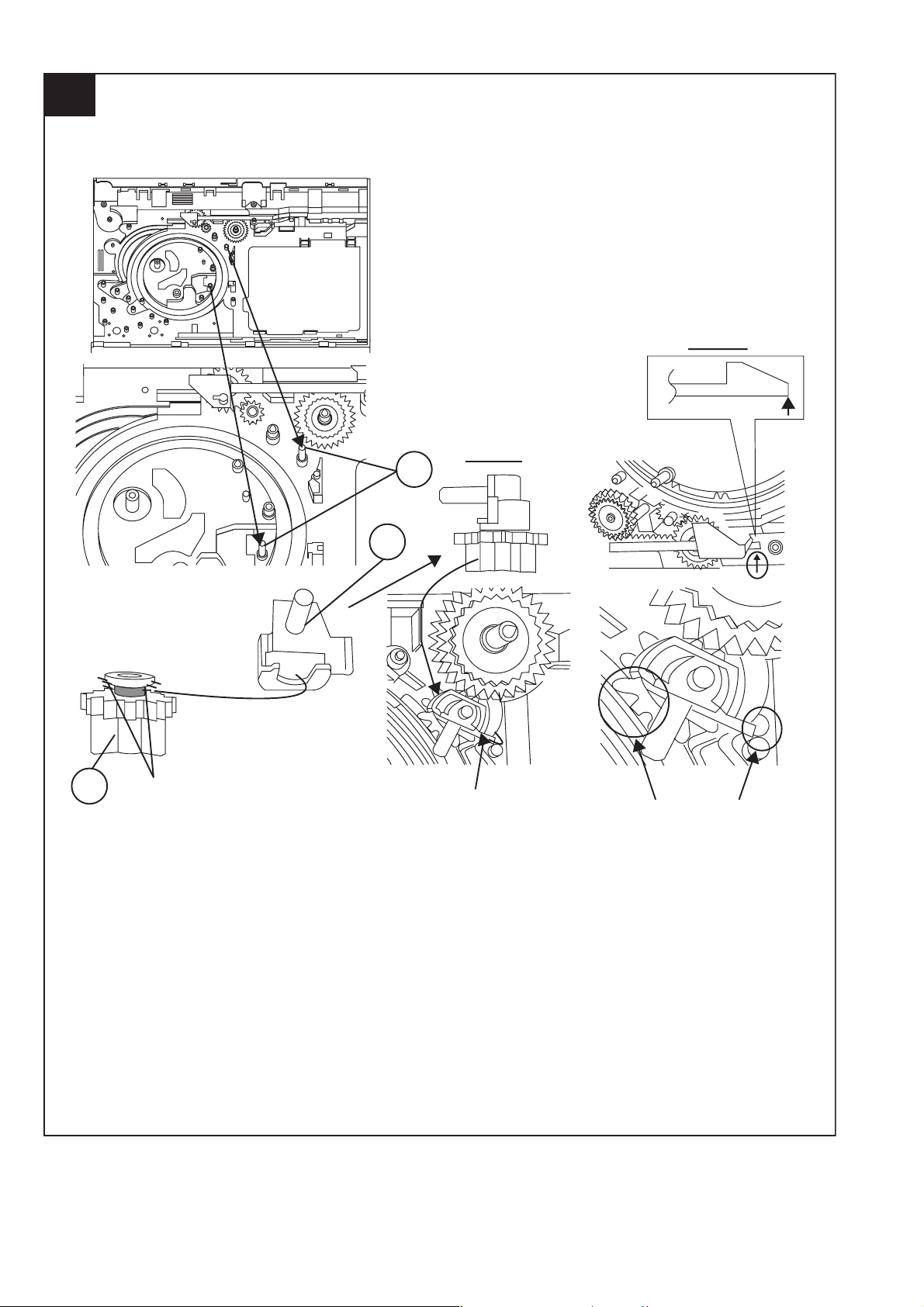

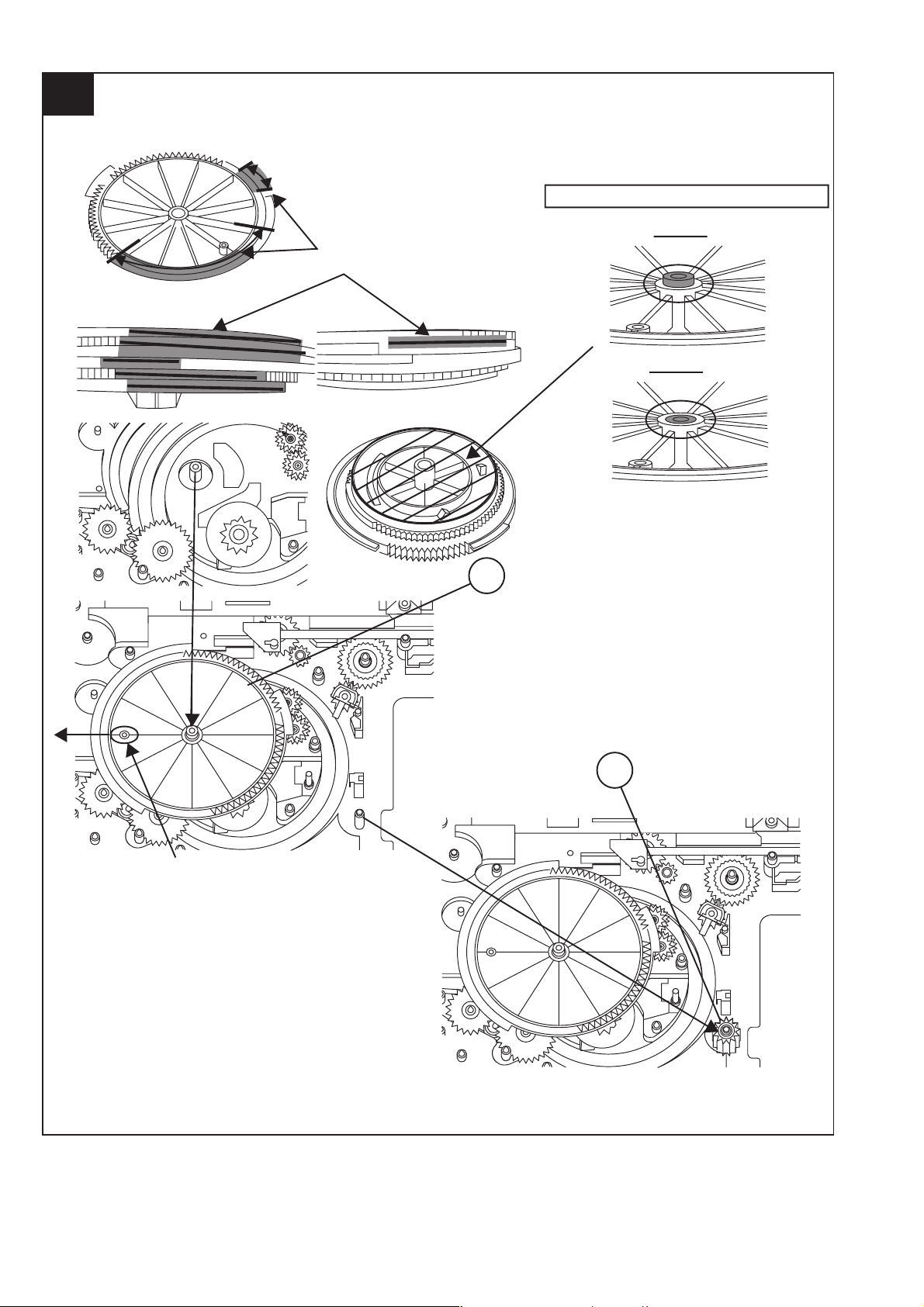

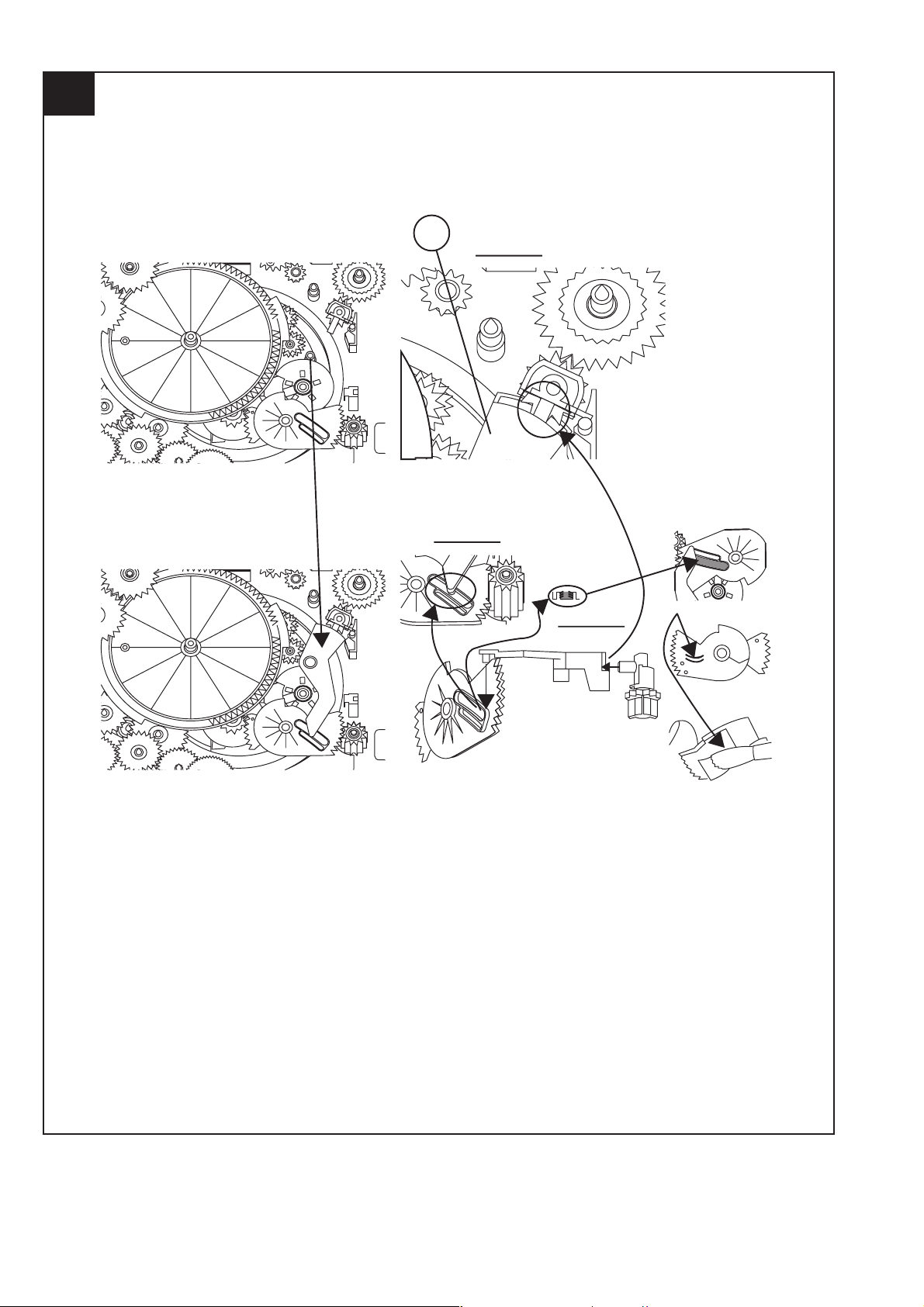

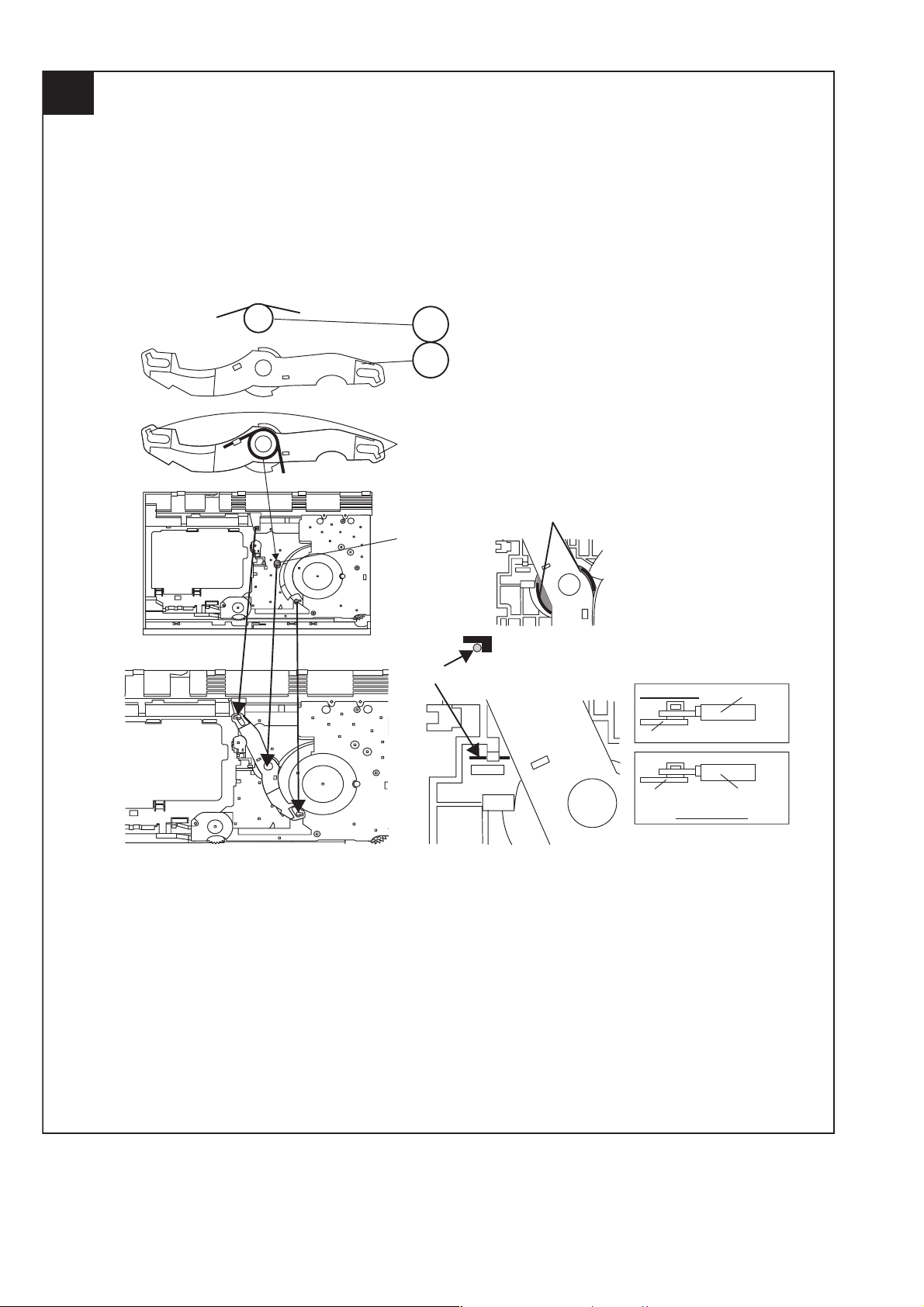

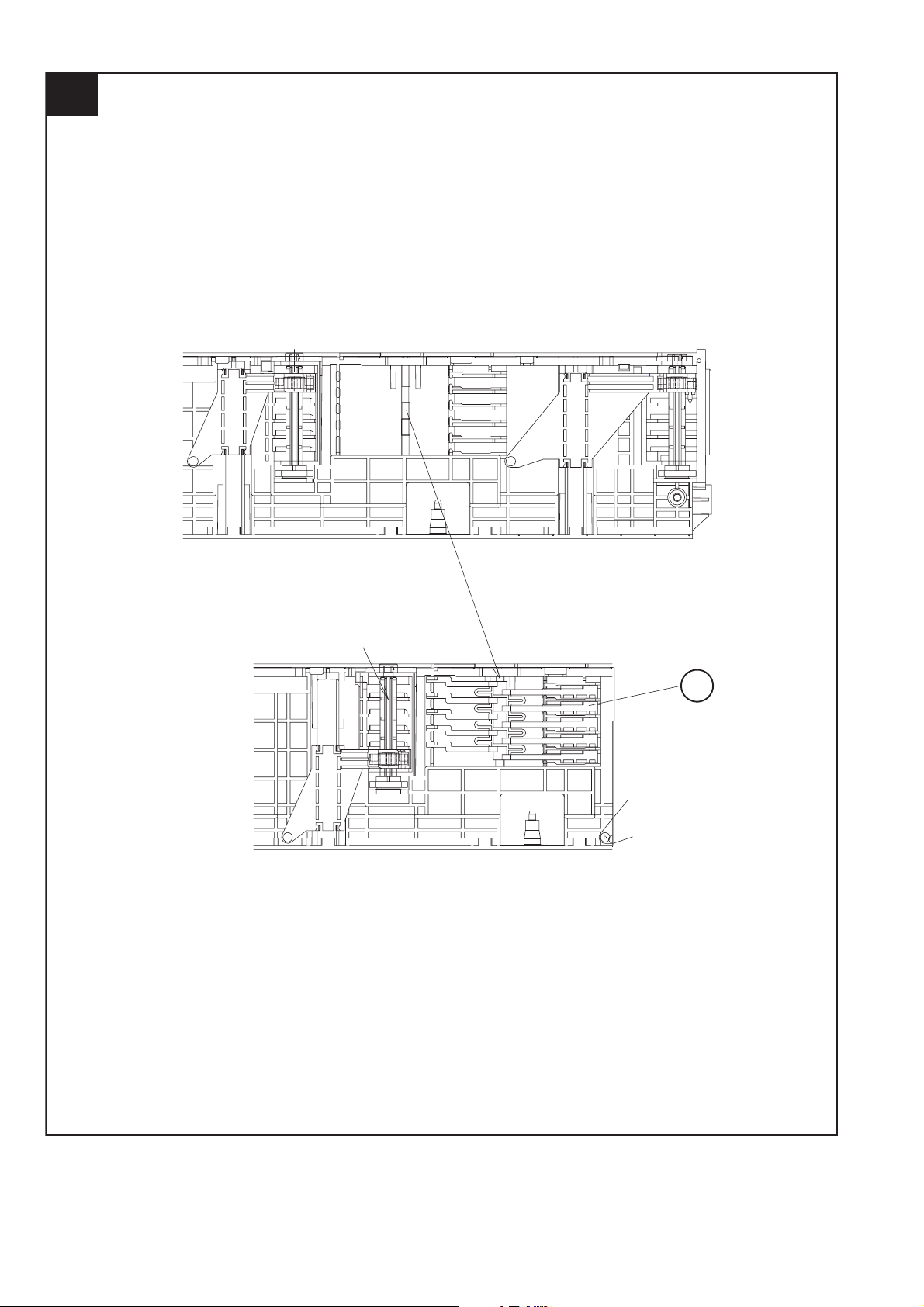

[4] CD Changer mechanism section

• All numbers in the drawing correspond to those in parts guide (CHANGER MECHANISM PARTS).

1

141

CD-SW300W

140

HALF GEAR

MUST BE ARRANGED AS SHOWN

2 – 5

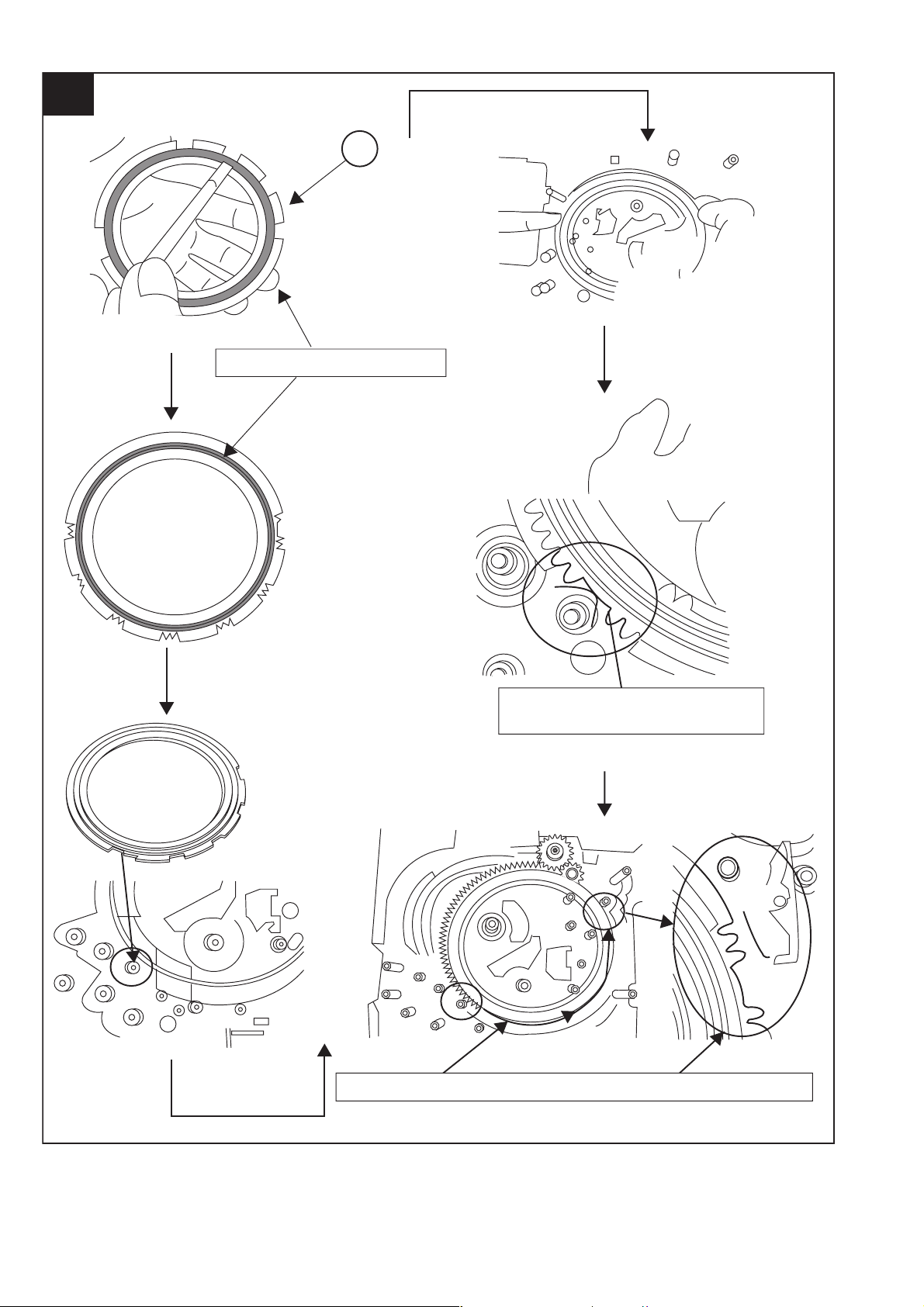

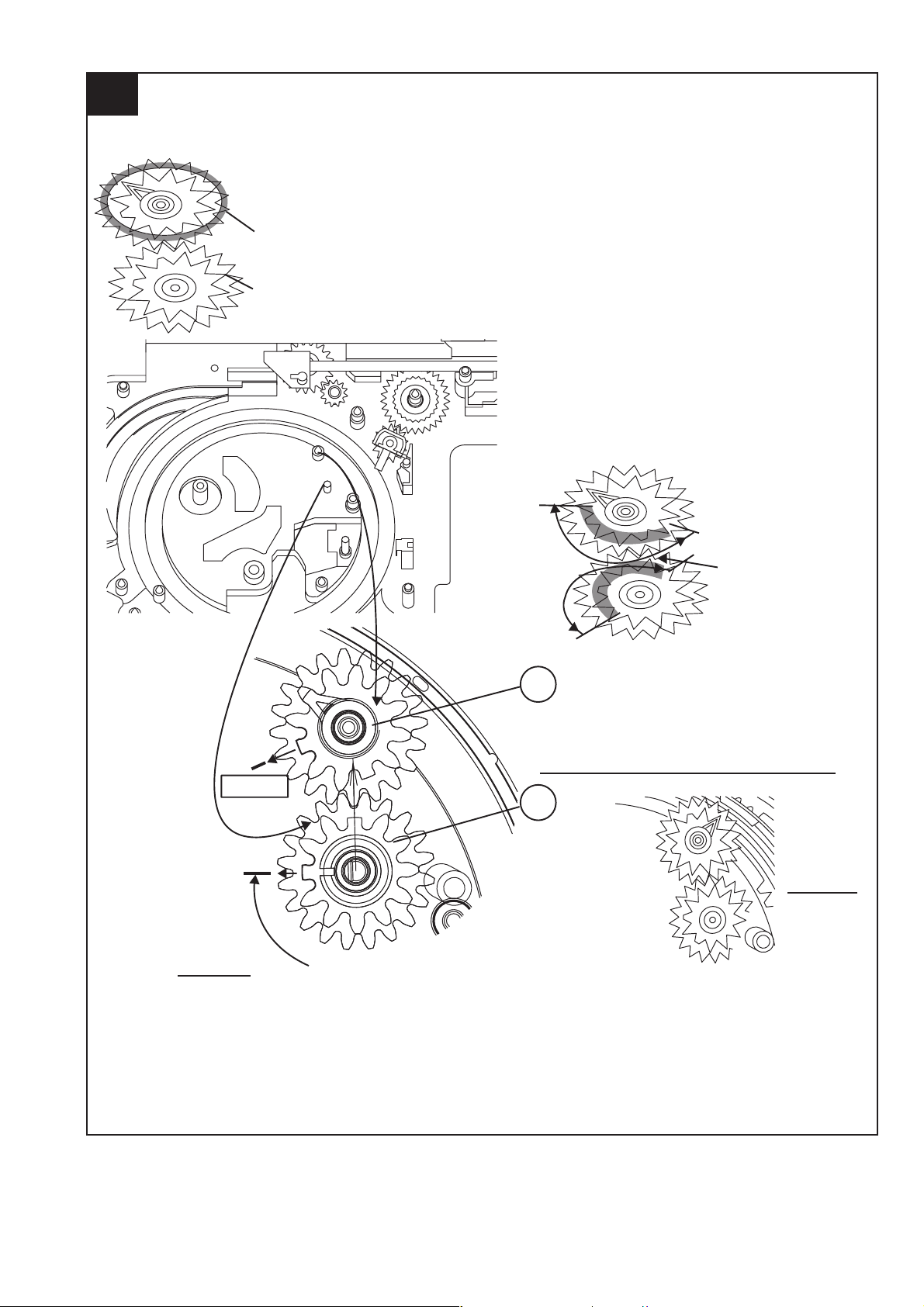

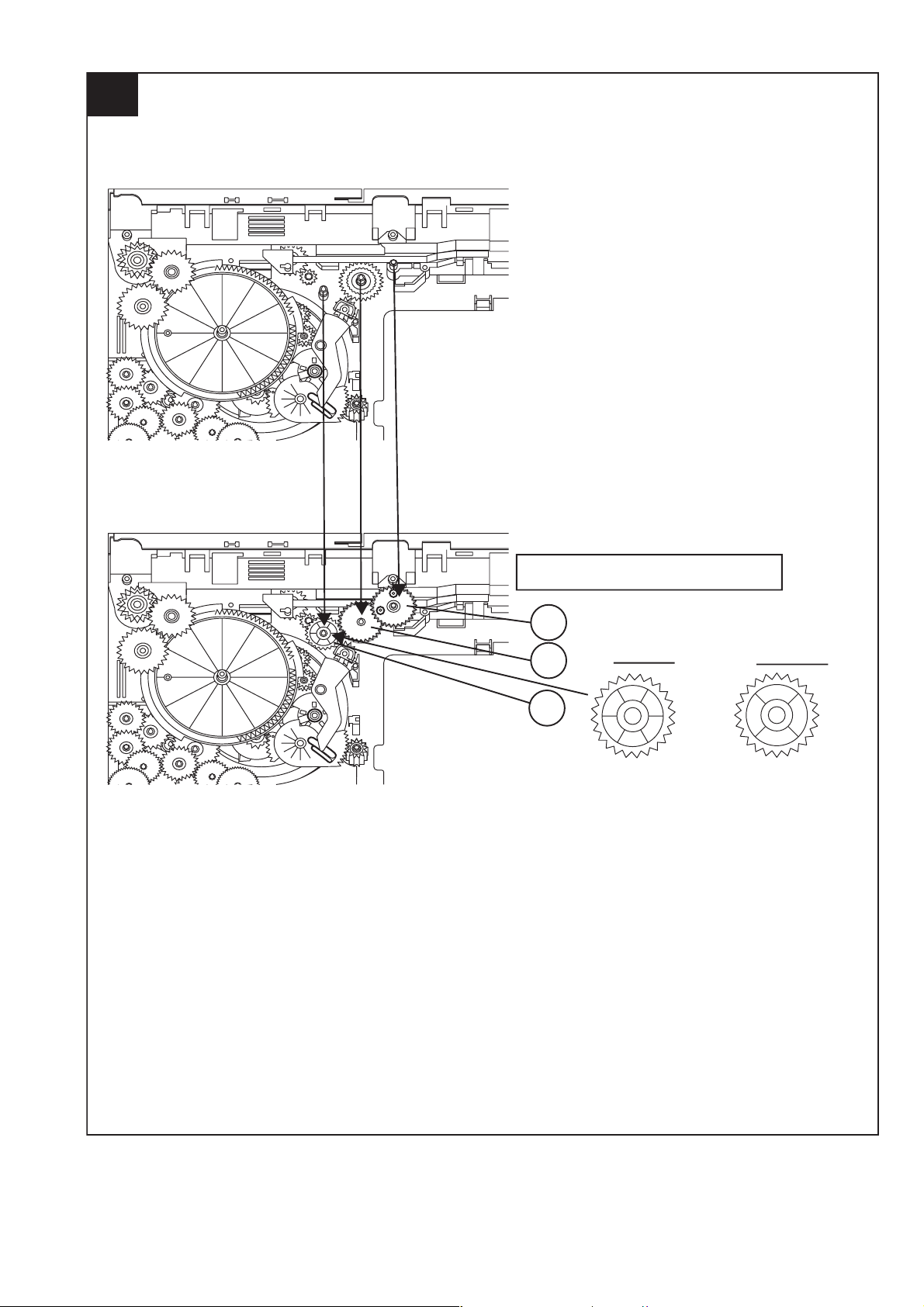

CD-SW300W

2

139

APPLY SANKOL SHS1001 BEFORE FIX

FIX ITEM 139 ACCORDING TO THE

PICTURE AS SHOWN ABOVE

ROTATE MODE BIG GEAR UNTIL REACH AS SHOWN IN PICTURE

2 – 6

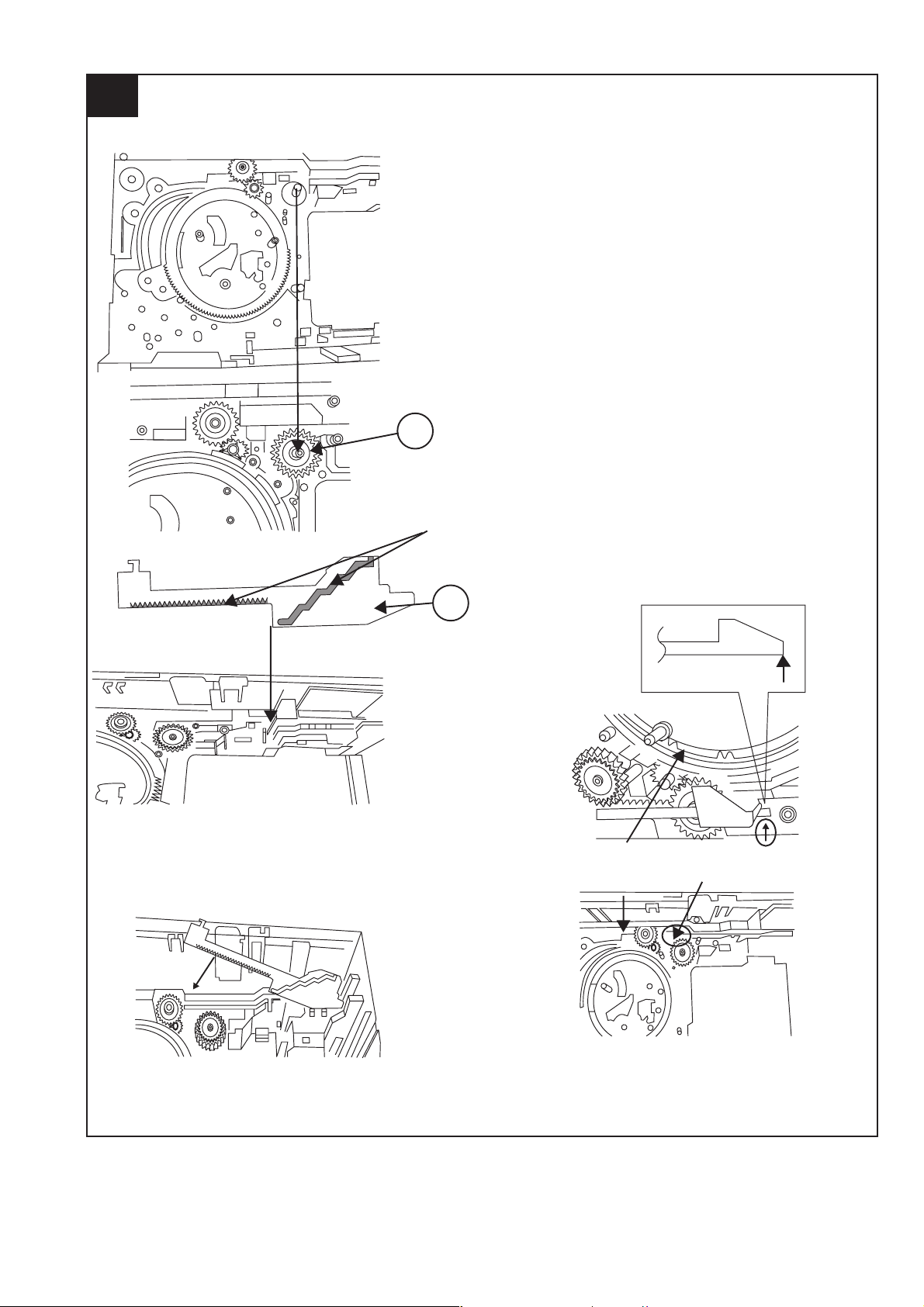

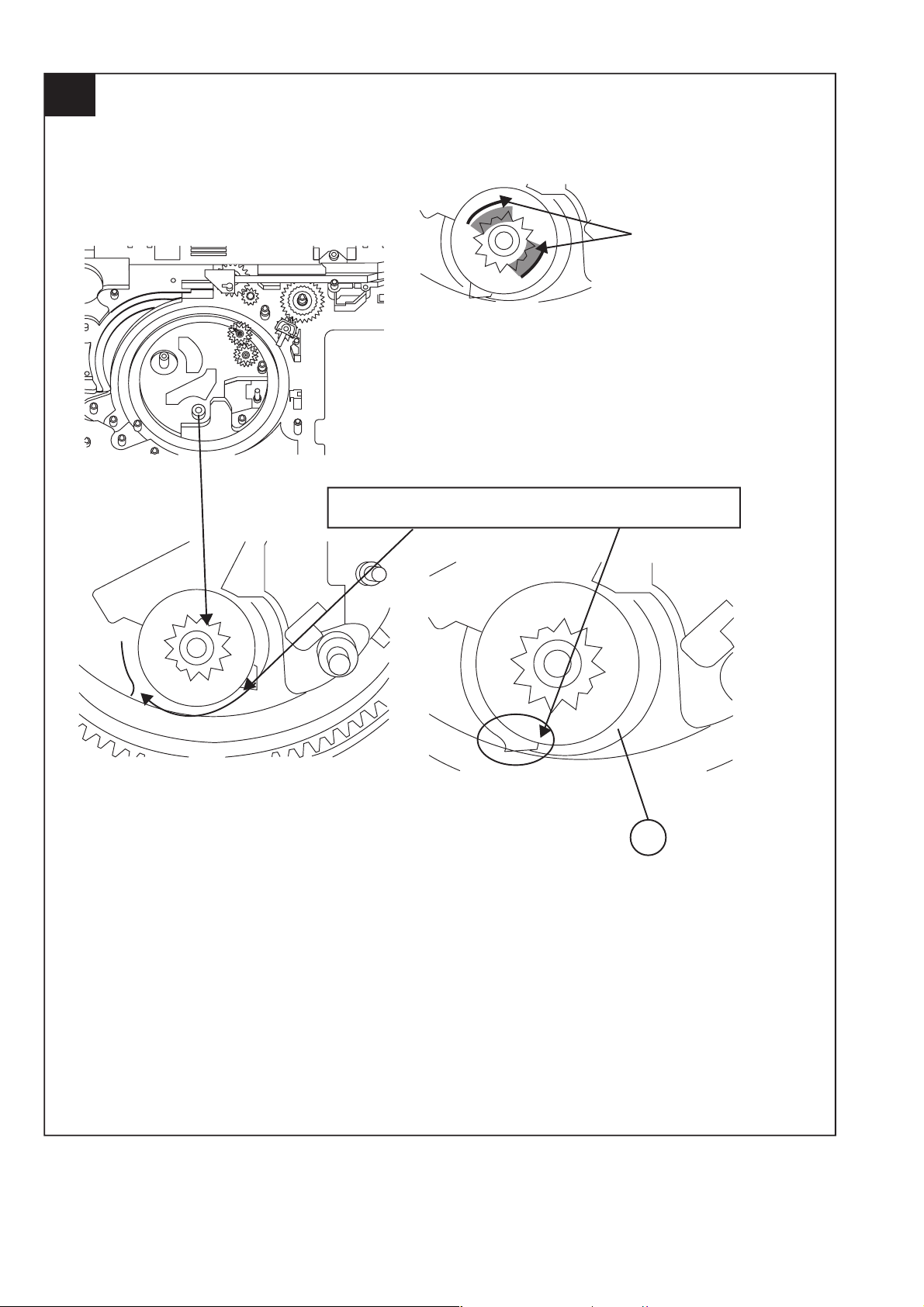

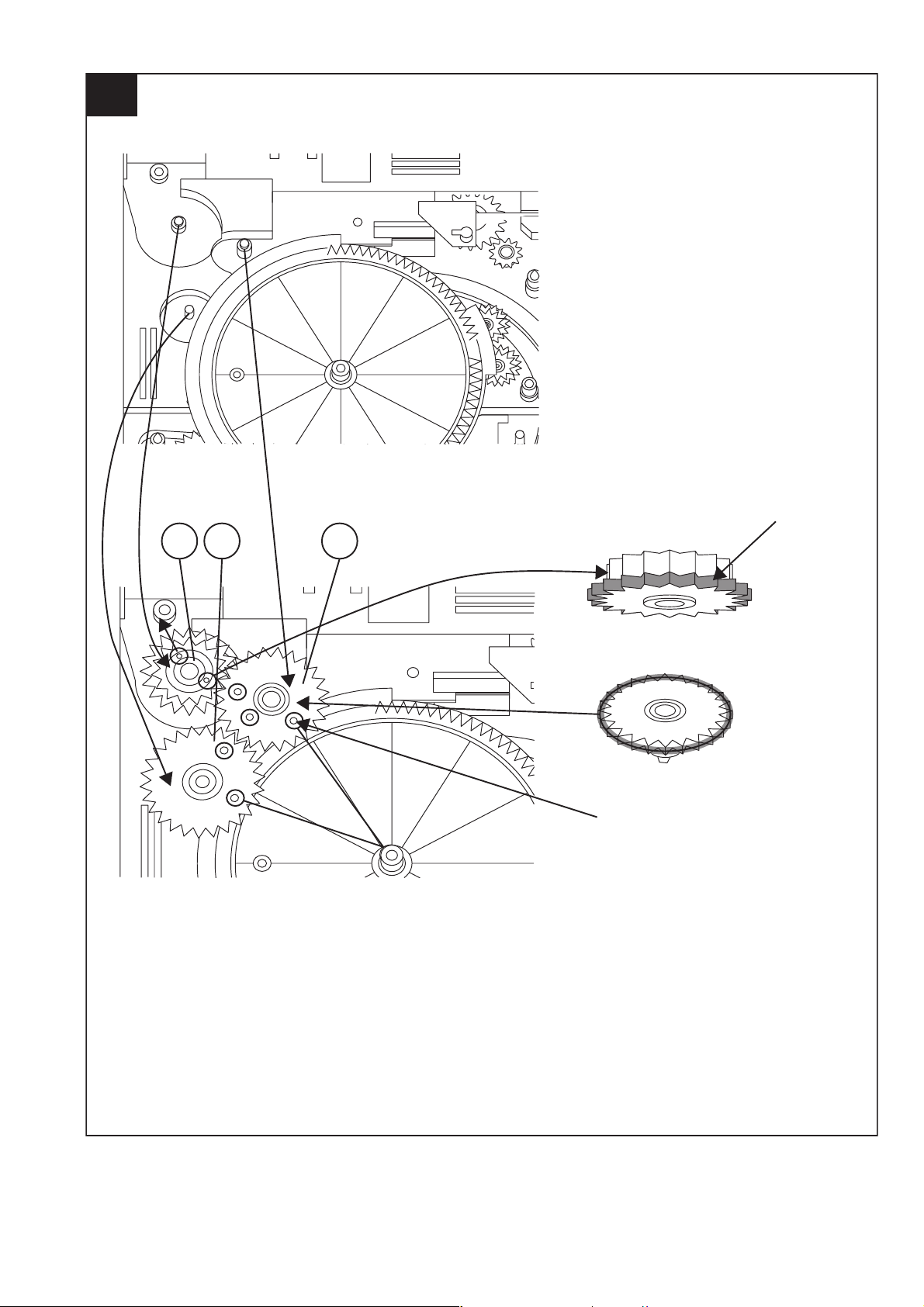

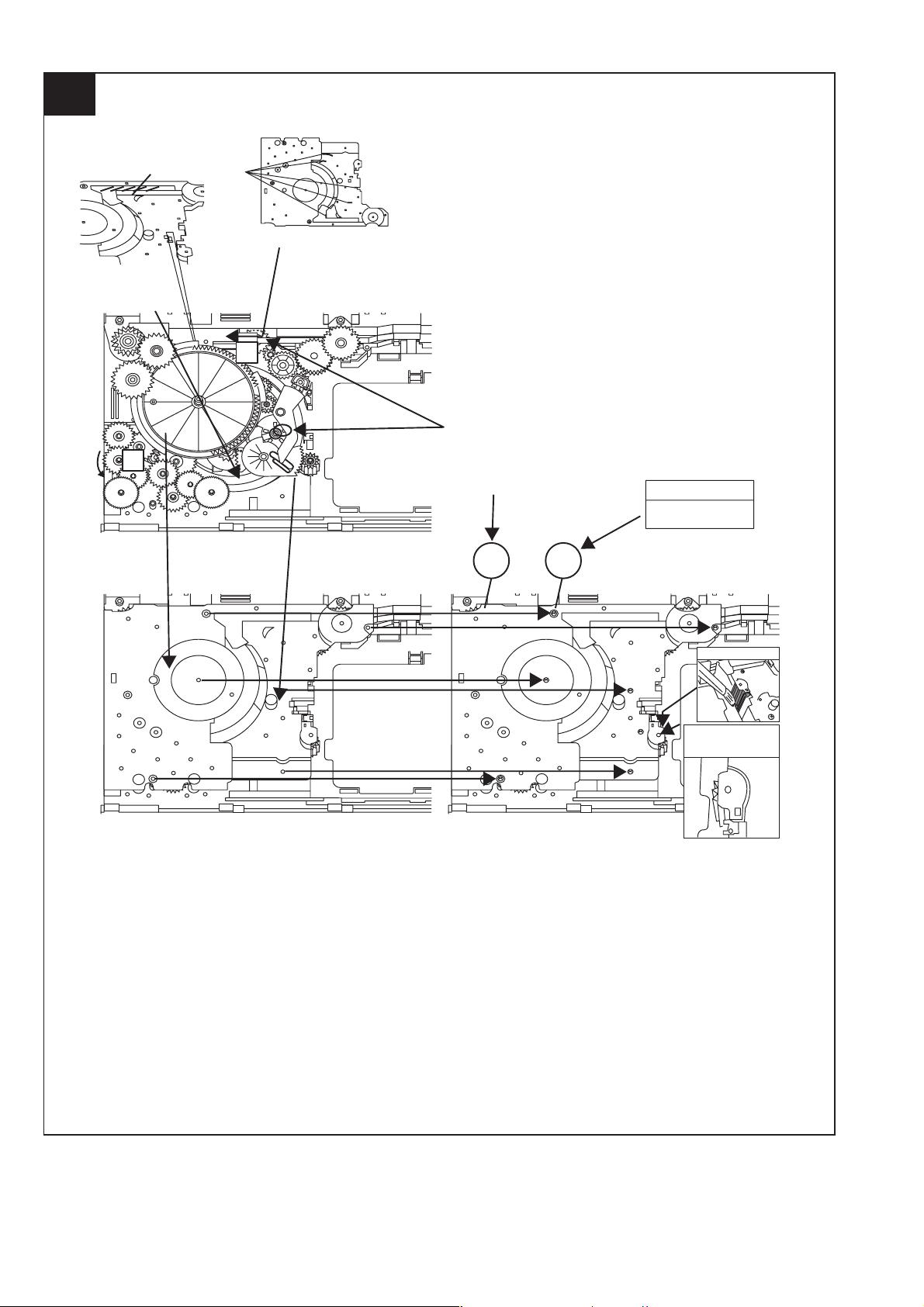

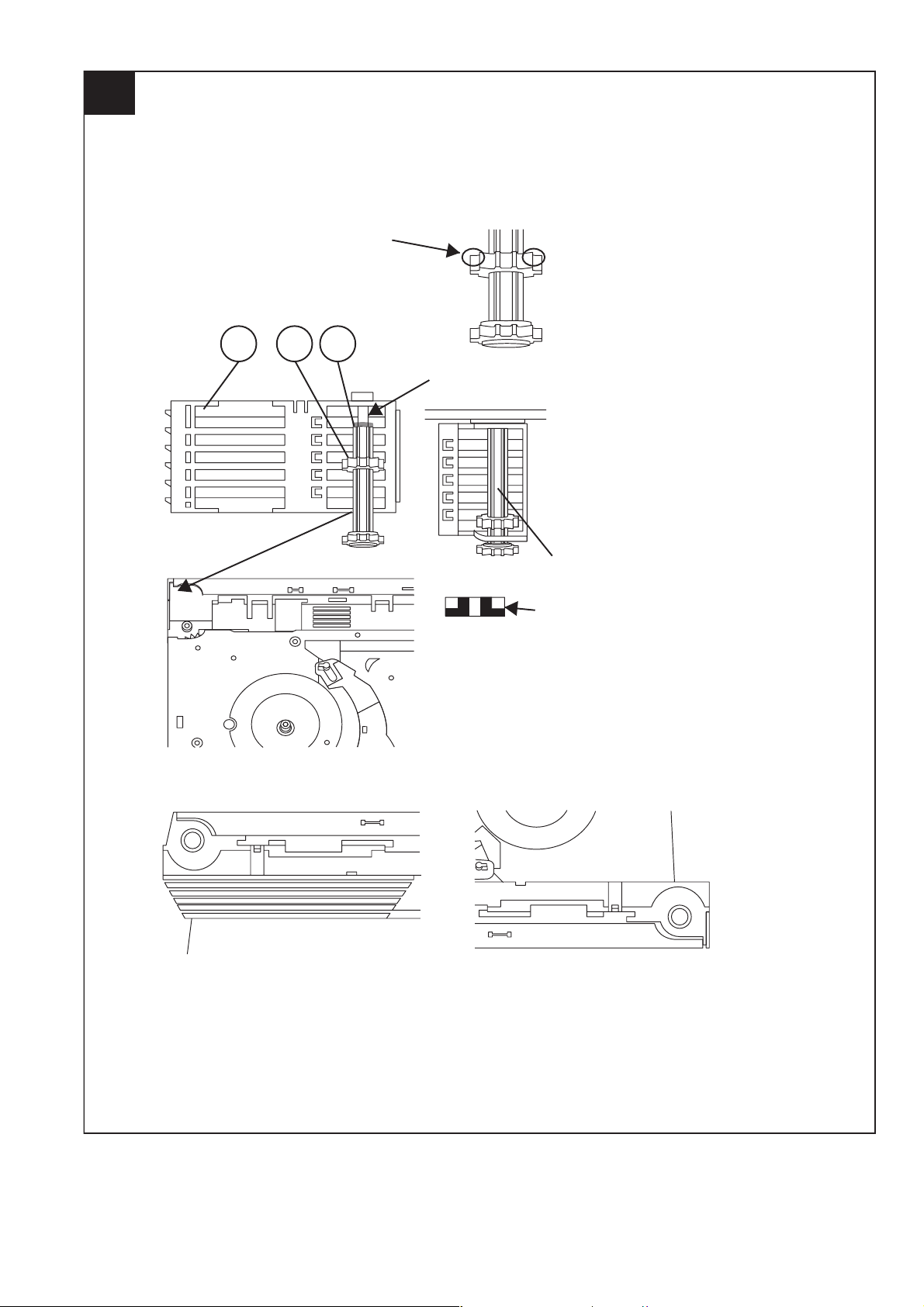

3

CD-SW300W

143

APPLY GREASE SC141

112

PULL THE LEVER UNITIL

REACH THE ARROW MARK

2 – 7

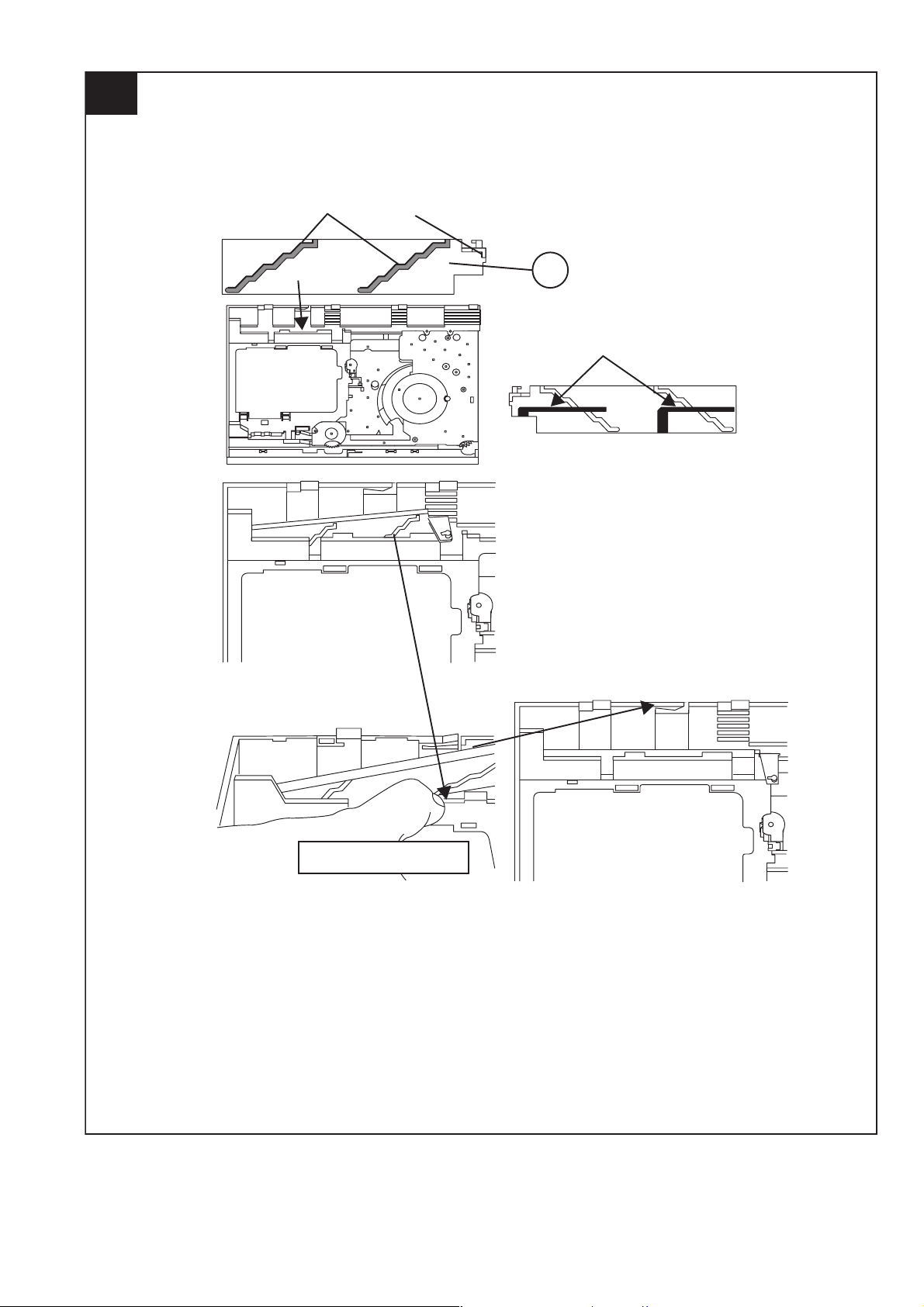

CD-SW300W

4

FIGURE 2

FIGURE 1

152

142

APPLY GREASE SC141

118

SLOT CLAMP

SWITCH ARM INSIDE BASE SLOT

HALF GEAR MUST BE

ARRANGED AS SHOWN

2 – 8

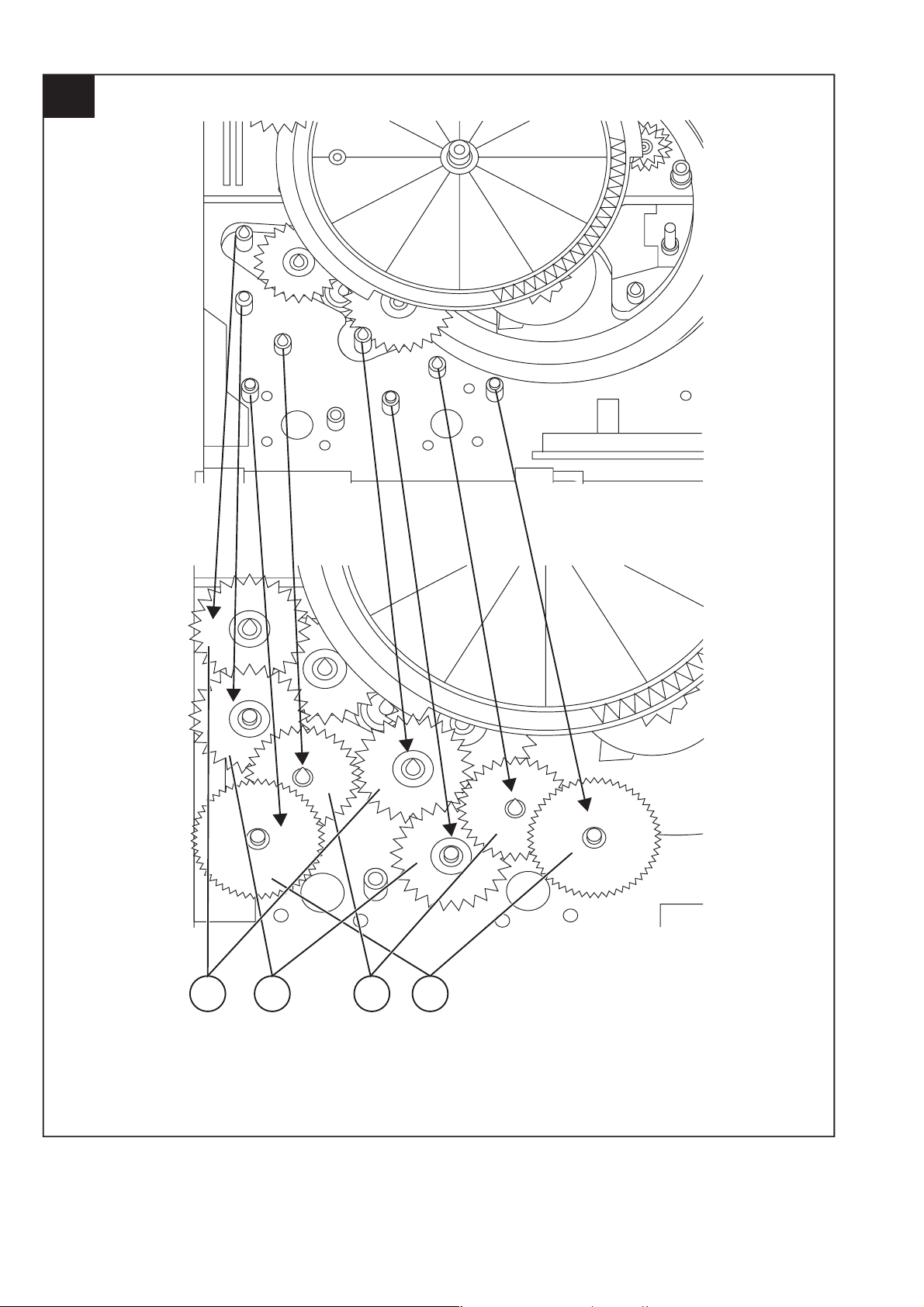

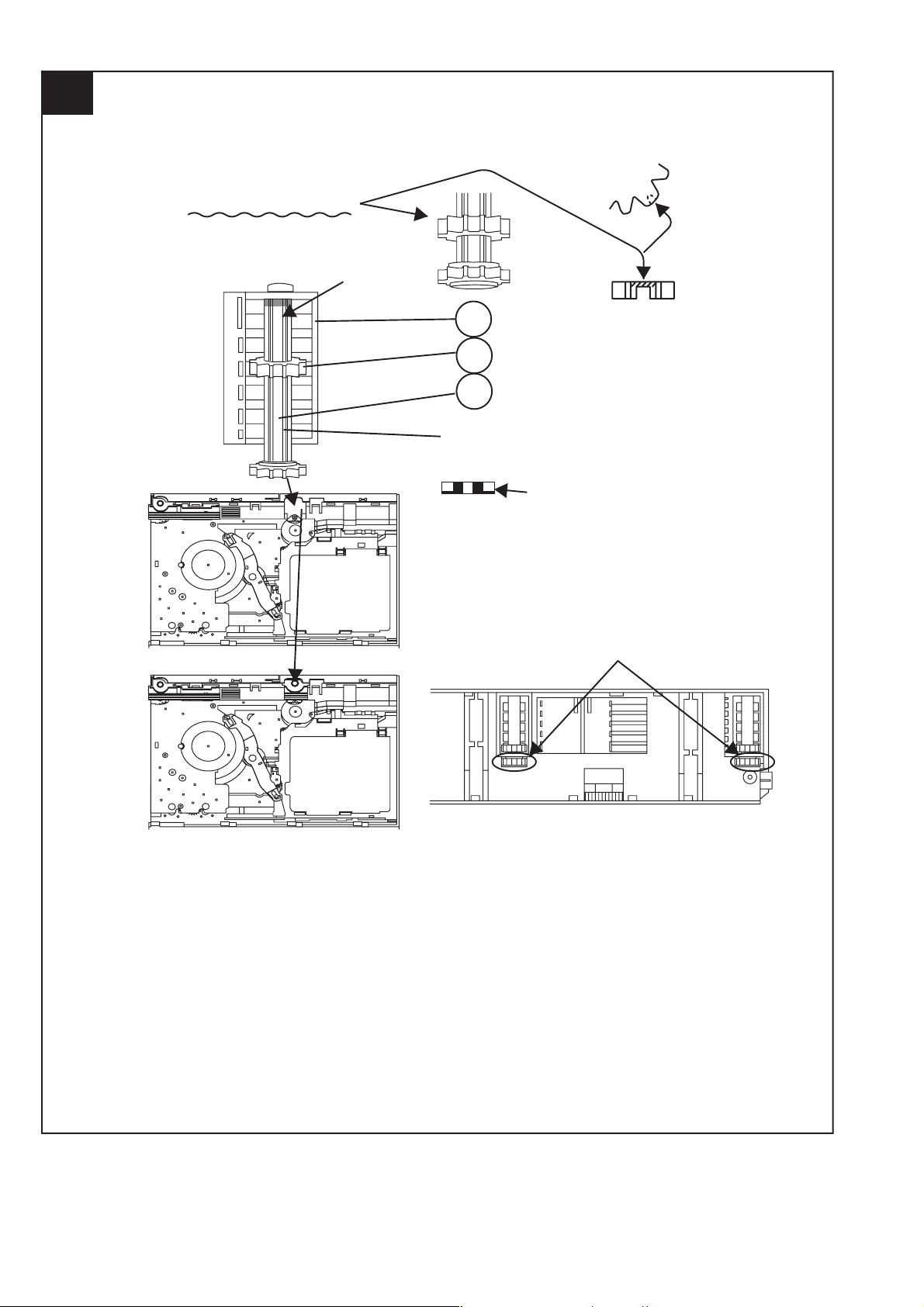

5

CD-SW300W

APPLY GREASE SC141 AT BOTTOM SIDE

OF GEAR FOLLOW MARKING (REFER TO GRAY AREA)

NO NEED TO APPLY GREASE AT BOTTOM

SIDE

FIGURE 1

APPLY GREASE SC141

AT TOP SIDE OF GEAR

FOLLOW MARKING

(REFER TO GRAY AREA)

127

IF DIRECTION IS OTHER THAN DIRECTION

SHOWN IN FIGURE 1, IT IS INCORRECT

CORRECT

128

INCORRECT

BLACK MARK

2 – 9

CD-SW300W

6

APPLY GREASE SC141 AT

HALF GEAR AREA

ROTATE CLOCKWISE UNTIL REACH HERE (MAXIMUM)

129

2 – 10

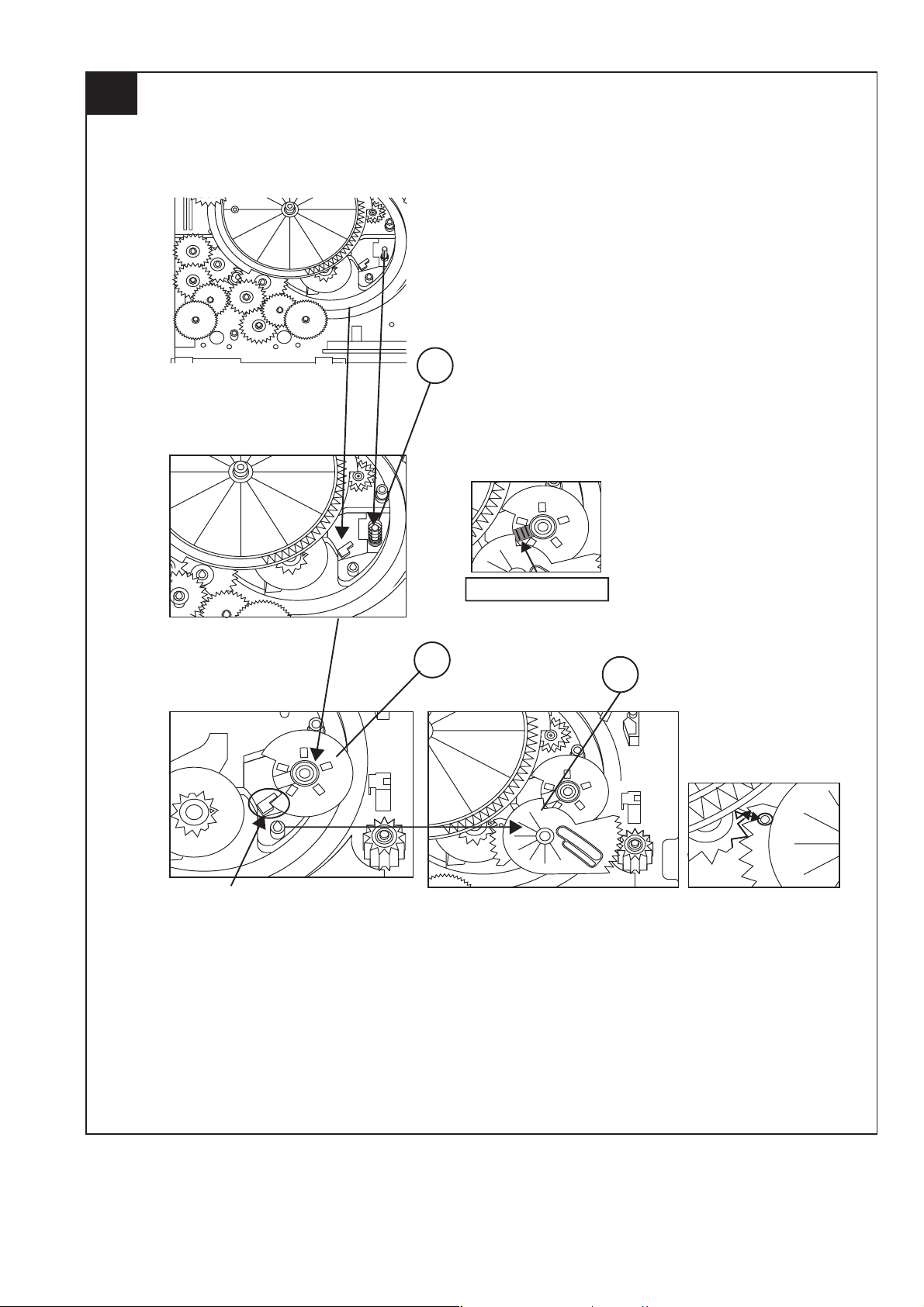

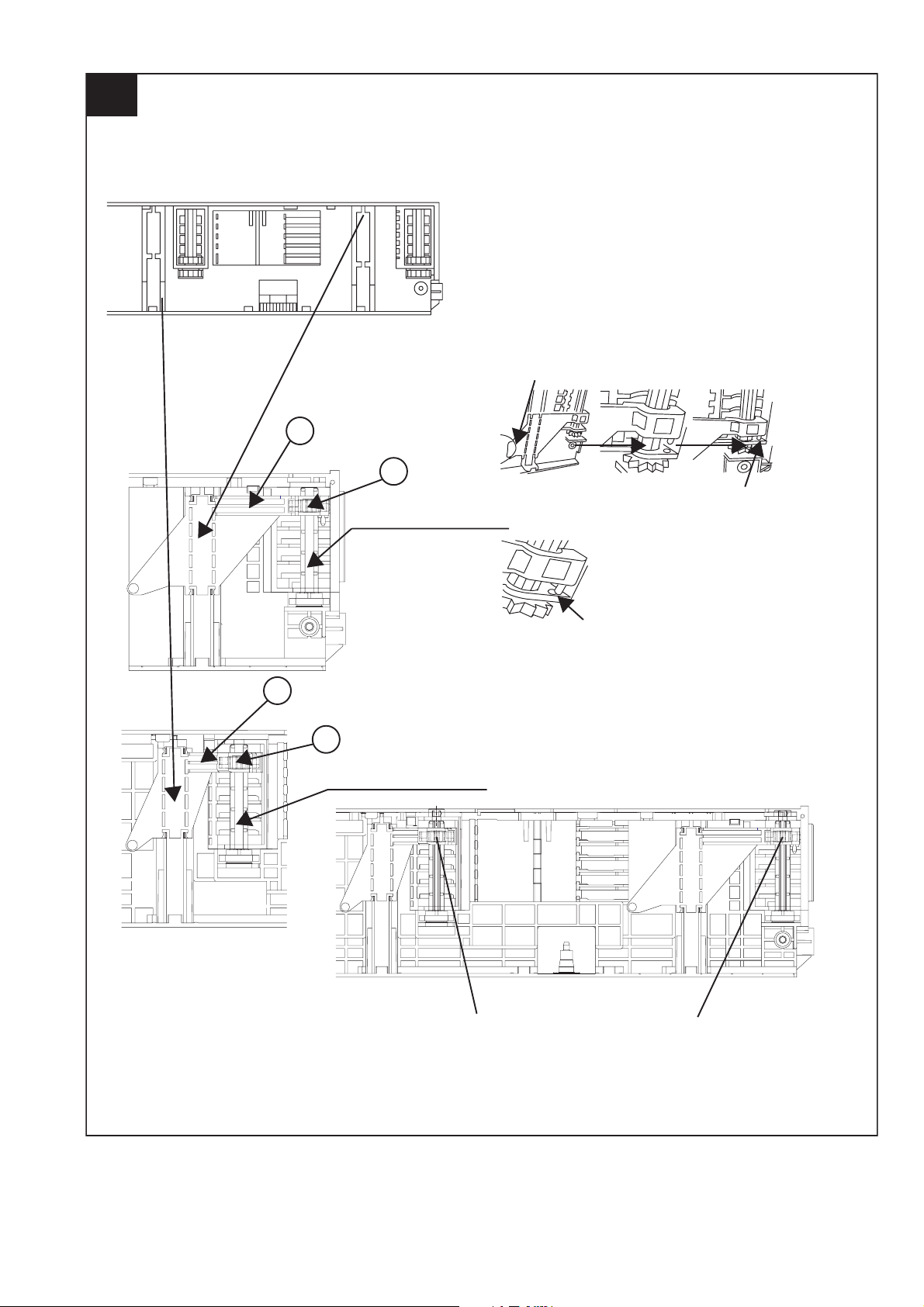

7

CD-SW300W

151150149

2 – 11

CD-SW300W

8

THE SHOWN AREA MUST FREE FROM GREASE

CORRECT

GREASE SC141 APPLICATION LENGTH

GREASE APPLICATION PORTION

INCORRECT

SHOWN HOLE MUST FACING ARROW DIRECTION

124

131

2 – 12

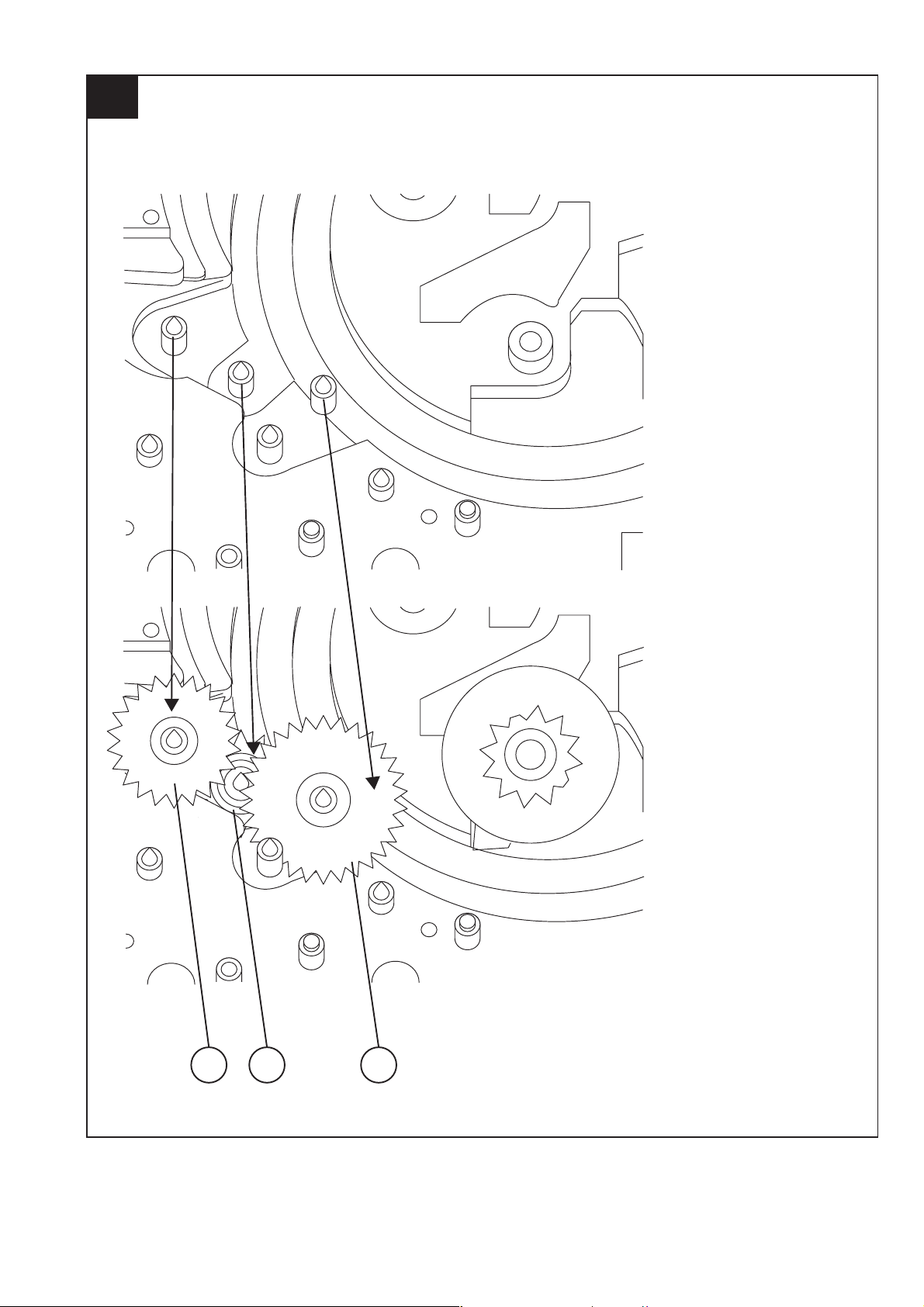

9

138 126 125

CD-SW300W

APPLY GREASE SC141

AT BOTTOM SIDE

ONLY

TR-RE JOINT GEAR C

APPLY GREASE SC141 ONLY AT TOP SIDE GEAR

MUST BE FIXED ACCORDINGLY TO

THE HOLE'S

2 – 13

CD-SW300W

10

148 147 146 145

2 – 14

11

CD-SW300W

121

144

WHEN FIXING ITEM 144 MUST FOLLOW AS SHOWN

APPLY GREASE SC141

130

2 – 15

CD-SW300W

12

117

FIGURE 2

FIGURE 1

APPLY GREASE

SC141

FIGURE 3

APPLY GREASE SC141

2 – 16

13

CD-SW300W

ITEM 133 , 134 MUST APPLY GREASE SC141

ON TOP SIDE GEAR ONLY

134

GEAR 112 GEAR 112

133

132

CORRECT

TOP VIEW AFTER

BEING ASSEMBLED

INCORRECT

IT IS INCORRECT TO

FIX IT IN REVERSED

DIRECTION

2 – 17

CD-SW300W

14

APPLY GREASE SC141

BEFORE FIX

A

MOVE 112 UNTIL TOUCH THE WALL

B

DURING GEAR A ROTATE

MUST PRESS SHOWN AREA

AND LEVER B WILL MOVE

ARROW DIRECTION THEN

FIX PART 108

SCREW TORQUE

+0.5

2 kgf-cm

- 0

108 803 x6

APPLY GREASE SC141

CONFIRM WHETHER

FIXED

PROPELY OR NOT

2 – 18

15

CD-SW300W

APPLY GREASE SC141

113

BEHIND THE LEVER NEED TO APPLY GREASE SC141

PULL IT THEN LEVER WILL

MOVE IN

2 – 19

CD-SW300W

16

123

115

APPLY GREASE SC141

APPLY GREASE SC141 BEFORE FIX

APPLY GREASE

SC141 AT BOSS

SPRING MUST BE ARRANGED UNDER THE HOOK

CORRECT LR JOINT LEV

BOARD R

BOARD R

LR JOINT LEV

INCORRECT

2 – 20

17

CD-SW300W

IT IS INCORRECT IF ASSEMBLED

IN A REVERSED DIRECTION

103 137 136

APPLY GREASE SC141

BIG SLOT MUST FACING OUT

WHEN FIX AND AFTER FIXED TO BASE CHASSIS.

AFTER ASSEMBLY, CONFIRM WITH FREE DROP TEST

GEAR POSITION DURING FIXING

2 – 21

CD-SW300W

18

IT IS INCORRECT IF ASSEMBLED IN

A REVERSED DIRECTION

APPLY GREASE SC141

104

135

136

BIG SLOT MUST FACING OUT

WHEN FIX AND AFTER FIXED TO BASE CHASSIS

AFTER ASSEMBLY, CONFIRM WITH FREE DROP TEST

GEAR POSITION DURING FIXING

CONFIRM BOTH GEARS SIT PROPERLY AND LOCKED

2 – 22

19

120

CD-SW300W

AFTER FIX OUTER UP/DOWN LEVER HOLD AS SHOWN PORTION AND

MOVE UP/DOWN THEN CONFIRM WHETHER LEVER GO INSIDE THE HOLE OR NOT

137

IT IS CORRECT IF THE LEVER HOLD

BIGGER SLOT FACING OUT

ENTERS THE HOLE

119

IT IS INCORRECT IF THE LEVER HOLD DOES NOT

ENTER THE HOLE

135

BIGGER SLOT FACING OUT

ALL OF THIS 135 AND 137 GEAR FIX TOGETHER WITH 119

AND 120 LEVER ( MOVE TOGETHER )

2 – 23

CD-SW300W

20

BIG SLOT FACING OUT

110

2 – 24

Loading...

Loading...