CriticalPoint Public Safety BDA

UHF PUBLIC SAFETY

BI-DIRECTIONAL

AMPLIFIER

USER MANUAL

Public Safety BDA RX-4122 Class A & Class B

QE: 1-0-1

Comba Telecom Ltd.

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 2

The information contained herein is the responsibility of and is approved by the

following, to whom all enquiries should be directed:

This is an unpublished work the copyright in which vests in Comba International

("Comba"). All rights reserved.

The information contained herein is confidential and the property of Comba and is

supplied without liability for errors or omissions. No part may be reproduced,

disclosed or used except as authorized by contract or other written permission. The

copyright and the foregoing restriction on reproduction and use extend to all media

in which the information may be embodied.

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 3

Section

Page

0.1 CONTENTS

0.1 CONTENTS ................................................................................................................................. 3

0.2 INDEX TO FIGURES AND TABLES ......................................................................................... 5

0.3 HISTORY ..................................................................................................................................... 6

0.4 GLOSSARY OF TERMS ............................................................................................................ 7

0.5 SAFETY NOTICES AND ADMONISHMENTS ......................................................................... 8

1 GENERAL INFORMATION ................................................................ ........................................ 9

2 EQUIPMENT DESCRIPTION .................................................................................................. 10

2.1 FUNCTIONAL BLOCK DIAGRAM ........................................................................................... 10

2.2 EQUIPMENT LAYOUT ................................................................ ............................................. 11

2.3 EQUIPMENT CONSTITUTION ................................................................................................ 12

3 INSTALLATION ......................................................................................................................... 13

3.1 WARNINGS AND ALERTS ................................................................ ...................................... 13

3.2 SITE PLANNING CONSIDERATIONS .................................................................................... 14

3.2.1 SITE PLANNING ....................................................................................................................... 14

3.2.2 INSTALLATION CHECKLIST................................................................................................... 15

3.3 INSTALLATION PROCEDURES ............................................................................................. 16

3.3.1 GOODS INWARDS INSPECTION........................................................................................... 16

3.3.2 TOOLS ....................................................................................................................................... 16

3.3.3 PREPARATION ......................................................................................................................... 16

3.3.4 WALL MOUNTING .................................................................................................................... 17

3.3.5 DRIP-LOOP ............................................................................................................................... 17

3.4 EQUIPMENT CONNECTORS ................................................................................................. 18

3.4.1 PS BDA CONNECTORS .......................................................................................................... 18

3.4.2 PS BDA LED Indicators ............................................................................................................ 20

3.4.3 GROUNDING CONNECTION .................................................................................................. 20

3.4.4 RF CABLE CONNECTION ................................ ....................................................................... 20

3.4.5 ETHERNET CONNECTION ..................................................................................................... 20

3.4.6 DRY CONTACT CABLE CONNECTION ................................................................................ 21

4 COMMISSIONING .................................................................................................................... 23

4.1 PRE-COMMISSIONING TASKS .............................................................................................. 23

4.2 COMMISSIONING PROCEDURE ........................................................................................... 24

5 WEB GUI ................................................................................................................................... 26

5.1 WEB GUI CONNECTION ......................................................................................................... 26

5.2 WEB GUI INTRODUCTION ..................................................................................................... 27

5.2.1 [DEVICES] ................................................................................................................................. 27

5.2.2 [COMMISSIONING] .................................................................................................................. 29

5.2.3 [FIRMWARE] ............................................................................................................................. 29

5.2.4 [MANAGEMENT]....................................................................................................................... 31

5.3 COMMISSIONING PROCEDURE ........................................................................................... 41

6 MAINTENANCE ................................................................................................ ........................ 48

7 APPENDICES ........................................................................................................................... 49

7.1 APPENDIX A: ............................................................................................................................ 49

7.2 APPENDIX B: TOOLS .............................................................................................................. 51

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 4

7.3 APPENDIX C: DECLARATION OF HARMFUL SUBSTANCES AND CONTENT ............... 52

7.4 APPENDIX D: RMA (RETURN MATERIAL AUTHORIZATION) ........................................... 53

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 5

0.2 INDEX TO FIGURES AND TABLES

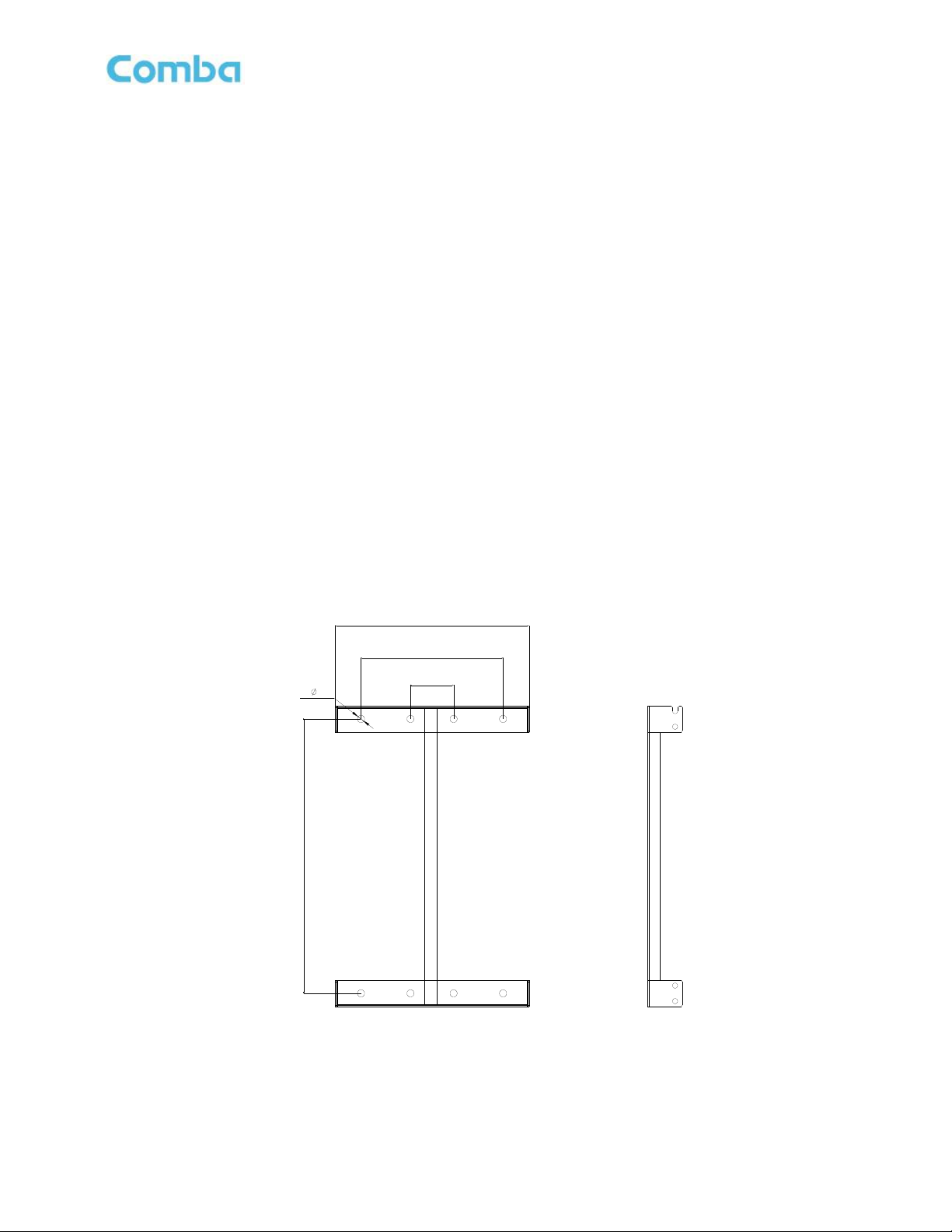

Figure 1: Front, Side and Bottom Views of the PS BDA Enclosure ................................................................ 9

Figure 2: PS BDA Functional Block Diagram ............................................................................................... 10

Figure 3: Layout of the PS BDA .................................................................................................................. 11

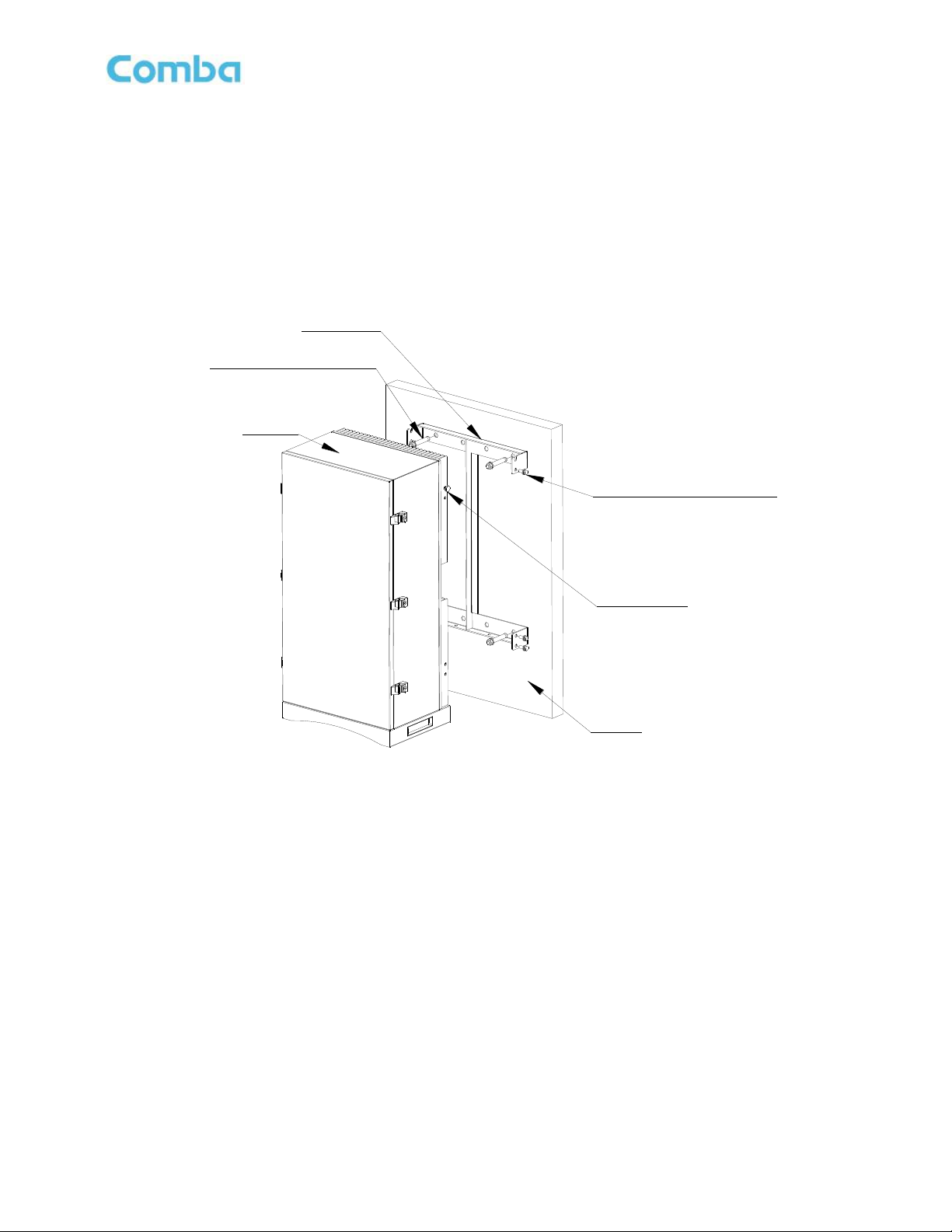

Figure 4: Mounting Rack Overview ................................ ............................................................................. 16

Figure 5: PS BDA Wall Mounting ................................................................................................................ 17

Figure 6: Equipment Connectors................................................................................................................. 18

Figure 7: Commissioning Procedure ........................................................................................................... 24

Figure 8: Input IP Address .......................................................................................................................... 26

Figure 9: Input Domain Name ..................................................................................................................... 26

Figure 10: Input User Name and Password ................................................................................................. 26

Figure 11: Web GUI Main Screen ............................................................................................................... 27

Figure 12: Overview Screen........................................................................................................................ 27

Figure 13: 400MHz Screen 1 ...................................................................................................................... 28

Figure 14: 400MHz Screen 2 ...................................................................................................................... 28

Figure 15: 400MHz Screen ......................................................................................................................... 29

Figure 16: [Commissioning] Screen ............................................................................................................ 29

Figure 17: [Firmware] Screen – MCU Firmware Upgrade ............................................................................ 30

Figure 18: [Firmware] Screen – Firmware Swap .......................................................................................... 30

Figure 19: [Firmware] Screen – Module Update ................................................................ .......................... 30

Figure 20: [Management] Screen ................................................................................................................ 31

Figure 21: Management – Import & Export .................................................................................................. 32

Figure 22: Management – IP Setting ........................................................................................................... 33

Figure 23: Management – Comm. Setting ................................................................................................... 34

Figure 24: Management – Security ................................................................ ............................................. 35

Figure 25: Modify Password........................................................................................................................ 36

Figure 26: Management – Device Reset ..................................................................................................... 36

Figure 27: Management – Device Info ........................................................................................................ 37

Figure 28: Management – Isolation ............................................................................................................. 37

Figure 29: Management – RF Setting ......................................................................................................... 38

Figure 30: Management – Alarm Setting ................................................................................................ ..... 38

Figure 31: Management – Report ............................................................................................................... 39

Figure 32: Management – Alarm Log .......................................................................................................... 39

Figure 33: Management – Clear History Alarm ............................................................................................ 40

Figure 34: Commissioning Procedure – Start .............................................................................................. 41

Figure 35: Commissioning Procedure – Site Info. Setting ............................................................................ 41

Figure 36: Device Information Setting ......................................................................................................... 42

Figure 37: Device Sub Band Setting-Class A .............................................................................................. 42

Figure 38: Channel parameters setting-Class A ................................................................ .......................... 43

Figure 39: Device sub-band setting-Class B................................................................................................ 44

Figure 40: Commissioning Procedure – Isolation Detection ......................................................................... 44

Figure 41: Commissioning Procedure – Isolation Detection Confirm ............................................................ 45

Figure 42: Commissioning Procedure – Isolation Detection Failed .............................................................. 45

Figure 43: Commissioning Procedure – Isolation Detection Finish ............................................................... 46

Figure 44: Commissioning Procedure – Center Frequency Setting .............................................................. 46

Figure 45: Commissioning Procedure – Channel Number Setting ............................................................... 46

Figure 46: Commissioning Procedure – Finish ............................................................................................ 47

Table 1: Equipment Connectors .................................................................................................................. 19

Table 2: LED Indicators .............................................................................................................................. 20

Table 3: Pin Definition of Dry Contact Cable ............................................................................................... 21

Table 4: Commissioning Task Explanation .................................................................................................. 25

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 6

Change No.

ENU

Details Of Change

1

1-0-0

This manual first created and issued in Jan. 2018.

2

1-0-1

Update to add the part for Class B in

.

0.3 HISTORY

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 7

Abbreviation

Definition

ALC

Automatic Level Control

ATT

Attenuator

BTS

Base Transceiver Station

CH

Channel

CSA

Cross Sectional Area

dB

Decibel

dBm

Decibels relative to 1 milliwatt

DL

Downlink

DT

Donor Terminal

DPX

Duplexer

FS

Frequency Selection

Hz

Hertz

ID

Identification

IF

Intermediate Frequency

LNA

Low Noise Amplifier

LOS

Line-of-Sight

MCU

Main Control Unit

MHz

Megahertz

MT

Mobile Terminal

MTBF

Mean Time Between Failures

NF

Noise Figure

OMC

Operation & Maintenance Center

OMT

Operation & Maintenance Terminal

PA

Power Amplifier

PLL

Phase Locked Loop

PSU

Power Supply Unit

RF

Radio Frequency

SMA

Sub-Miniature A Connector

UL

Uplink

VAC

Volts Alternating Current

VDC

Volts Direct Current

VSWR

Voltage Standing Wave Ratio

0.4 GLOSSARY OF TERMS

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 8

0.5 SAFETY NOTICES AND ADMONISHMENTS

This document contains safety notices in accordance with appropriate standards. In the interests of conformity

with the territory standards for the country concerned, the equivalent territorial admonishments are also shown.

Any installation, adjustment, maintenance and repair of the equipment must only be carried out by trained,

authorized personnel. At all times, personnel must comply with any safety notices and instructions.

Specific hazards are indicated by symbol labels on or near the affected parts of the equipment. The labels

conform to international standards, are triangular in shape, and are colored black on a yellow background. An

informative text label may accompany the symbol label.

Hazard labeling is supplemented by safety notices in the appropriate equipment manual. These notices contain

additional information on the nature of the hazard and may also specify precautions.

Note: The grantee is not responsible for any changes or modifications not expressly approved by the party

responsible for compliance. Such modifications could void the user’s authority to operate the equipment.

For compliance with the general population RF exposure limits, each individual antenna used for this

transmitter must be installed to provide a separation distance greater than 60.62cm or more from all persons

during normal operation and must not be co-located with any other antenna for meeting RF exposure

requirements.

Warning Notices:

These draw the attention of personnel to hazards that may cause death or injury to the operator or others.

Examples of use are cases of high voltage, laser emission, toxic substances, point of high temperature, etc.

WARNING. This is NOT a CONSUMER device. It is designed for installation by FCC LICENSEES and

QUALIFIED INSTALLERS. You MUST have an FCC LICENSE or express consent of an FCC Licensee to

operate this device. The PS BDA can be configured as Class A or Class B Signal Booster. You MUST

register Class B signal boosters (as defined in 47 CFR 90.219) online at

www.fcc.gov/signal-boosters/registration. Unauthorized use may result in significant forfeiture

penalties, including penalties in excess of $100,000 for each continuing violation.

Note: The grantee is not responsible for any changes or modifications not expressly approved by the party

responsible for compliance. Such modifications could void the user’s authority to operate the equipment.

Alert: These draw the attention of personnel to hazards that may cause damage to the equipment. An example

of use is the case of static electricity hazard.

Caution notices may also be used in the handbook to draw attention to matters that do not constitute a risk of

causing damage to the equipment but where there is a possibility of seriously impairing its performance, e.g. by

mishandling or gross maladjustment. Warnings and Cautions within the main text do not incorporate labels and

may be in shortened form.

Disconnection of the 2 RF connectors may cause damage to the equipment when power is on.

The application antenna and RF cable are not provided.

WARNING!

Use only authorized and approved antennas, cables and/or coupling devices! The use of unapproved antennas,

cables or coupling devices could cause damage and may be of violation of FCC regulations. The use of

unapproved antennas, cables and/or coupling devices is illegal under FCC regulations and may subject the

user to fine.

End of Section

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 9

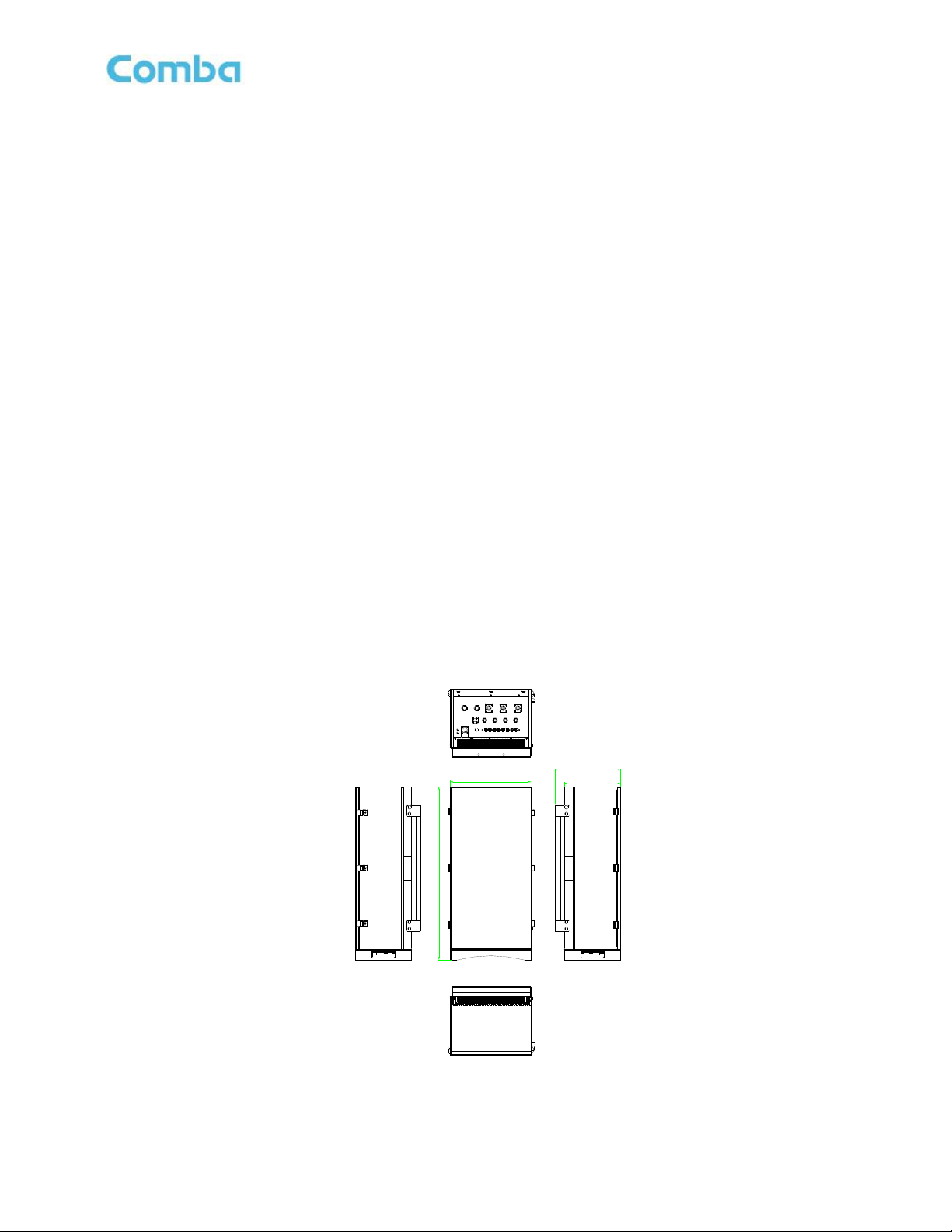

390

315

270

800

1 GENERAL INFORMATION

The RX-4122 is a new digital public safety Bi-Directional repeater (hereafter referred to as PS BDA) designed

to protect the lives of first responders and building occupants. Through the use of digital filtering technology,

the RX-4122 helps eliminate adjacent channel interference to allow band selectivity and support 400MHz

rebanding.

Main Features

PS UHF 400MHz.

Support 32 channels total (Class A) or dual sub-bands(Class B).

Channel selective or band selective, software programmable.

Auto diagnostic.

Uplink squelch, per channel (Class A).

User adjustable gain control (AGC), UL and DL independent per channel.

Built in isolation testing (Mandatory prior to commissioning the PS BDA).

Easy commissioning and setup via Web-based GUI.

Weatherproof enclosure, IP65/NEMA4X.

Fully compliant with the 2016 NFPA 1221 Code, FCC and UL standard.

Low power consumption: less than 85W

Weight: 77 lbs (not including mounting bracket and duplexers)

Alarming output to supervised circuits for: antenna failure, signal booster failure, and etc.

The following figure shows the enclosure of the PS BDA.

Figure 1: Front, Side and Bottom Views of the PS BDA Enclosure

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 10

Mobile

Ant

Donor

Ant

Mobile

Power

Supply

Alarm

Indicator

Main Control Unit

OMT

LAN

DT

MT

BTS

DL Subband 01

BIAS

Tee

DL Subband 02

PA

PA

DL_01

DL_02

UL_01

UL_02

DL_01

DL_02

UL Subband 01

UL Subband 02

UL_01

UL_02

Digital

Integrated

module

LNA

DL_01

DL_02

LNA

UL_01

UL_02

DL_01

DL_02

UL_01

UL_02

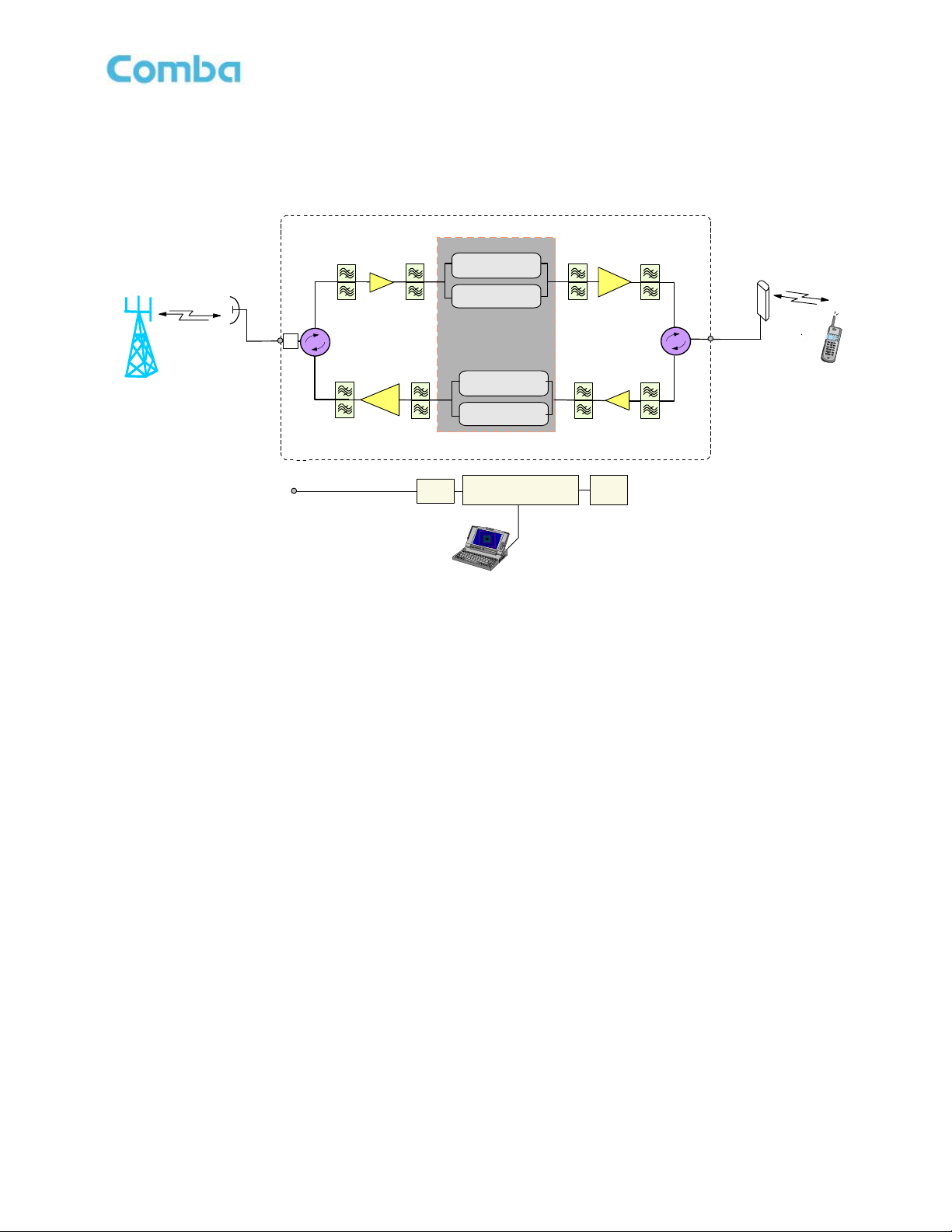

2 EQUIPMENT DESCRIPTION

2.1 FUNCTIONAL BLOCK DIAGRAM

Figure 2: PS BDA Functional Block Diagram

In the downlink path, the BTS signals are received by the donor antenna of the repeater. After the circulator, the

signals are sent to downlink filter and then the LNA module for pre-amplification and to the digital RF integrated

module for digital filtering and frequency conversion. Then the DL signals will be sent to the downlink PA to

amplify power, and filter via downlink filter, the circulator, and last, the signals are transmitted at the MT port to

the service antenna.

In the uplink path, the mobile signals are received by the service antenna. After the circulator, the signals are

sent to uplink filter, and then to LNA, digital integrated module for digital filtering, then to the PA for power

amplification and to the uplink filter, the circulator, after that, the uplink signals are sent to the donor antenna for

transmission back to the BTS.

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 11

黑色开关

MT

DT

避雷器

DL FilterUL Filter

DL FilterUL Filter

DT

/DL INMT/DL OUT UL IN UL OUT

Front Side of 3rd Layer

(Passive Unit)

Back Side of 2nd

Layer

Front Side of 2nd Layer

(Passive Unit)

Loop

Circulator

Circulator

UL Filter DL Filter

DL FilterUL Filter

PSU

Distribution

Board

MCU

+28V

+28V

GND

RF OUT

RF IN

+28V

GND

RF OUT

RF IN

DL PA

Digital Integrated

Module

+28V

Ref IN

LNA1 OUT

LNA1 IN

LNA2 IN

LNA2 OUT

UL IN

UL OUT

DL OUT

DL IN

UL PA

OUT4

IN4

OUT3IN3OUT2

IN2

OUT1

IN1

LAN

RUN

ALM

PWR

OMT

2.2 EQUIPMENT LAYOUT

Shown below is the internal layout of the PS BDA.

Figure 3: Layout of the PS BDA

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 12

2.3 EQUIPMENT CONSTITUTION

The typical PS BDA unit consists of the following components:

Downlink Power Amplifier (DPA): It provides power amplification for DL branches.

Uplink Power Amplifier (UPA): It provides power amplification for UL branches.

Main Control Unit (MCU): The MCU is used to monitor and control the operation of the repeater. It also

provides the communication interface for remote control and status indication. LED indicators provide the

operation status of the MCU.

Downlink Filter: The filter is used to restrain the uplink signals to achieve a better isolation between downlink

path and uplink path, to make sure the device can work in a normal duplex mode.

Uplink Filter: The filter is used to restrain the downlink signals to achieve a better isolation between downlink

path and uplink path, to make sure the device can work in a normal duplex mode.

Digital Integrated Module: Consists of RF module, digital process module and monitoring modules. The RF

module amplifies and converts the RF signal to IF signal. The Digital process module converts the IF signal into

baseband signal via AD conversion and extraction, and filtering. After that, the IF signal will be amplified and

converted to an RF signal by the RF module for RF filtering and amplification. The Monitoring module monitors

and controls the system parameters and it is the interface for both remote monitoring and local commissioning,

and at the same time control the charge and discharge of the backup battery.

Power Supply Unit (PSU): The PSU converts the input voltage into a stable DC supply to provide power for

the internal functional modules.

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 13

3 INSTALLATION

3.1 WARNINGS AND ALERTS

Radio Frequency Energies

There may be situations, particularly for workplace environments near high-powered RF sources, where

recommended limits for safe exposure of human beings to RF energy could be exceeded. In such cases,

restrictive measures or actions may be necessary to ensure the safe use of RF energy.

High Voltage

The equipment has been designed and constructed to prevent, as far as reasonably practicable danger. Any

work activity on or near equipment involving installation, operation or maintenance must be, as far as

reasonable, free from danger.

Where there is a risk of damage to electrical systems involving adverse weather, extreme temperatures, wet,

corrosive or dirty conditions, flammable or explosive atmospheres, the system must be suitably installed to

prevent danger.

Protective Earthing

Equipment provided for the purpose of protecting individuals from electrical risk must be suitable for the

purpose and properly maintained and used.

Handling Precautions

This covers a range of activities including lifting, lowering, pushing, pulling, carrying, moving, holding or

restraining an object, animal or person from the equipment. It also covers activities that require the use of force

or effort, such as pulling a lever, or operating power tools.

Where some of the abovementioned activities are required, the equipment must be handled with care to avoid

being damaged.

Electrostatic Discharge (ESD)

Observe standard precautions for handling ESD-sensitive devices. Assume that all solid-state electronic

devices are ESD-sensitive. Ensure the use of a grounded wrist strap or equivalent while working with

ESD-sensitive devices. Transport, store, and handle ESD-sensitive devices in static-safe environments.

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 14

3.2 SITE PLANNING CONSIDERATIONS

3.2.1 SITE PLANNING

Site Considerations

Outdoor equipment are designed to be waterproof, rainproof, and with snow protection. Temporary protection

should be taken when the equipment enclosure is opened for installation or maintenance in an outdoor

environment. The equipment must not be opened for installation or maintenance in bad weather (e.g. gale,

storm rainfall, extreme temperatures and high humidity)

Installation Location

Mounting surface shall be capable of supporting the weight of the equipment.

In order to avoid electromagnetic interference, a proper mounting location must be selected to minimize

interference from electromagnetic sources such as large electrical equipment.

Environmental

Humidity has an adverse effect on the reliability of the equipment. It is recommended to install the equipment in

locations having stable temperature and unrestricted air-flow.

The installation location for the product should be well ventilated. The equipment has been designed to operate

at the temperature range and humidity level as stated in the product specifications in the datasheet.

Direct sun light exposure to the equipment should be avoided. Provide additional shelter if necessary.

Power Supply

The power supply unit (PSU) provides power to all modules within the equipment. Depending on the product

variant, it is recommended that the PSU be operated on a dedicated circuit breaker or fused circuit.

Grounding Requirement

Verify that the equipment has been well grounded. This includes antennas and all cables connected to the

system. Ensure lightning protection for the antennas is properly grounded.

Cable Routing

Depending on equipment configuration, a variety of types of cables are required. Where applicable, ensure

cables are properly routed and secured so that they are not damaged.

Manual Handling

During transportation and installation, take necessary handling precautions to avoid potential physical injury to

the installation personnel and the equipment.

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 15

3.2.2 INSTALLATION CHECKLIST

Working space available for installation and maintenance for each mounting arrangement. Ensure

unrestricted airflow.

Ensure earth ground point is within reach of the ground wire.

Ensure a power source is within reach of the power cord and the power source has sufficient capacity.

Where appropriate, ensure unused RF connectors are terminated.

Do not locate the equipment near large transformers or motors that may cause electromagnetic

interference.

Reduce signal loss in feeder cable by minimizing the length and number of RF connections.

Ensure VSWR of antennas system < 1.5:1.

Ensure equipment will be operated within the stated environment (see datasheet)

Observe handling of all cables to prevent damage. Donor antenna should have a narrow beamwidth and

positioned in line-of-sight (LOS) to the donor BTS site so that the donor signal level is maximized. This

allows the use of minimum gain to achieve the maximum DL output power. The UL gain is typically set

lower than or equal to the DL gain to minimize noise interference to the donor BTS

Service antennas should be selected based on the type of service area, e.g., indoor antenna for indoor

application, and panel antenna for outdoor application.

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 16

382

280

85

8-

14

530

3.3 INSTALLATION PROCEDURES

3.3.1 GOODS INWARDS INSPECTION

Verify the number of packages received against the packing list.

Check all packages for external damage; report any external damage to the shipping courier. If there is

damage, a shipping agent should be present before unpacking and inspecting the contents because

damage during transit is the responsibility of the agent.

Open and check each package against the packing list. If any items are missing, contact Comba.

Do not remove items from anti-static packing until ready for installation. If damage is discovered at the

time of installation, contact the shipping agent.

3.3.2 TOOLS

See Appendix A for a full list of the recommended tools required for installation and routine maintenance.

3.3.3 PREPARATION

Wall mounting with the masonry bolts supplied, which make use of the outer holes.

Figure 4: Mounting Rack Overview

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 17

Mounting Rack

Expansion Bolt

M10X110

Chassis

M8X25,Hexagon

Head,

Flat Gasket,Pad

Pylons Screw

Wall

3.3.4 WALL MOUNTING

Drill four holes on the wall using the position of four holes on the mounting rack as a guide. Fix the

mounting rack to the wall using four masonry bolts (M10x110mm).

Install the Mounting Rack to the wall.

Hang the equipment and secure the enclosure to the mounting rack.

3.3.5 DRIP-LOOP

Comba recommends that every horizontal cable entry to the equipment forms a 'U' before its entry to the

equipment. Water on the cable will drip down at the bottom of the loop and will not accumulate at the equipment

connectors.

Figure 5: PS BDA Wall Mounting

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 18

OMT

LAN ALM1 ALM2

AUX

RUN

PWR

ALM

DT/DL IN

MT/DL OUT UL OUT

IN1

OUT1

IN2

OUT2 IN3 OUT3

IN4

OUT4

3.4 EQUIPMENT CONNECTORS

3.4.1 PS BDA CONNECTORS

The PS BDA is designed for all cable entries from the right or left of the enclosure, as shown in the following

figure.

Figure 6: Equipment Connectors

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 19

Identifier

Descriptions

Power1

Power cable connector for a pre-installed power cord for connection to AC

(e.g. AC 100-240V 50Hz/60Hz).

DT /DL IN

N-Female connector, It is downlink input port and uplink output port for Duplex mode; It is

downlink input port only for Simplex mode.

MT/DL OUT

N-Female connector, It is downlink output port and uplink input port for Duplex mode; It is

downlink output port only for Simplex mode.

UL IN

N-Female connector, It is uplink input port for Simplex mode; It is useless for Duplex

mode.

UL OUT

N-Female connector, It is uplink output port for Simplex mode; It is useless for Duplex

mode.

INxx/OUTxx

Reserved for extension

ALM1

Connector for connection to dry contact alarm 1, 2 and 3

ALM2

Connector for connection to dry contact alarm 4, 5 and 6.

AUX

External alarm 1, 2, 3 and 4.

LAN

RJ45 connector for internet connection (Ethernet type only).

OMT

RJ45 connector for local connection by WEBOMT

1

Table 1: Equipment Connectors

The voltage identification is a variant due to electricity system diversity of global regions. The power cable connector might

be identified for AC 110V, AC 220V, AC 110V/220V, or DC -48V respectively. Please refer to specific product or contact

local sales if any doubt.

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 20

Identifier

Colour

Indication

PWR

Green

Power indicator. ON = power on; OFF = power off.

RUN

Green

Operation indicator, flashes every second to indicate normal operation.

ALM

Red

Alarm indicator. ON = alarm; OFF = no alarm.

3.4.2 PS BDA LED Indicators

The LED indicators help user to check the equipment status easily.

Table 2: LED Indicators

3.4.3 GROUNDING CONNECTION

Ground Connection

To ensure safe operation of the product, a ground (earth) connection is required. For single phase AC power

source, the product must be grounded by connecting the “earth wire” of the power cord to the ground terminal

of the AC supply. For operating this product with DC power system (such as rectifiers), the product should not

be connected to power systems that switch open the return lead because the return lead could function as the

ground (earth) connection for the equipment.

Protective Ground Connection

The enclosure must be grounded securely by connecting a copper wire (CSA 16mm2) to the grounding terminal

on the equipment/rack, and the other end to a protective ground (i.e. building earth point). An internationally

acceptable color code of the ground connection wire is green/yellow.

Such a ground connection implements the “Protective Ground Connection”, and must be connected to the

equipment at the designated ground point. In general, do not connect the supply before establishing an

adequate ground (earth) connection.

Construct the ground wire, and use appropriate crimp connectors where necessary. Locate and connect the

equipment grounding terminal to a protective ground (i.e. building earth point).

3.4.4 RF CABLE CONNECTION

Single band PS BDA RF cables connection is as follows:

PS BDA MT port Connects to the feeder cable from service antennas.

PS BDA DT port Connects to the feeder cable from donor antennas.

3.4.5 ETHERNET CONNECTION

Connect Ethernet with ‘LAN’ port in the panel, Ethernet type only.

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 21

Pin NO.

Pin

Input

ALM1

1

CLOSE1

1

2

COM1

2

3

OPEN1

3

4

CLOSE2

4

5

COM2

5

6

OPEN2

6

7

CLOSE3

7

8

COM3

8

9

OPEN3

9

ALM2

1

CLOSE4

1

2

COM4

2

3

OPEN4

3

4

CLOSE5

4

5

COM5

5

6

OPEN5

6

7

CLOSE5

7

8

COM5

8

9

OPEN5

9

AUX

1

EXT ALM1

1

2

EXT ALM2

2

3

EXT ALM3

3

4

EXT ALM4

4

5

GND

5

6

GND

6

7

GND

7

8

GND

8

9

NC

9

3.4.6 DRY CONTACT CABLE CONNECTION

Below please find the pin definitions of dry contact cables.

Table 3: Pin Definition of Dry Contact Cable

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 22

Dry contact status:

Main Power Normal/Lost dry contact status:

Pin definition of ALM and AUX connectors:

End of Section

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 23

4 COMMISSIONING

4.1 PRE-COMMISSIONING TASKS

After equipment installation, perform the following steps before equipment powering and commissioning:

Verify that the expected voltage, current and power levels do not violate any ratings.

Visually inspect the power connection within the equipment. Ensure that the power cable is correctly and

securely connected, including the grounding wire, RF cable and other cables.

Check the grounding connection and verify that the ground resistance is less than 5Ω.

Test the antenna system and ensure that the echo loss within working frequency is less than -14dB

(VSWR<1.5).

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 24

Start commissioning guide in WEB GUI

Sub Band Setting

RF Setting

End

Isolation Detection

Site Information Setting

4.2 COMMISSIONING PROCEDURE

Perform the following procedures for system commissioning.

Figure 7: Commissioning Procedure

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 25

Commissioning Tasks

Observation

1. Site Information Setting

Site ID, Dev ID, Dev Info, Longitude , Latitude, Date/time setting

2. Sub Band Setting

Sub Band Frequency setting.

3. Isolation detection

Detect isolation of service antenna and donor antenna.

4. RF Setting

DL_Target and the DL frequency center, the filter bandwidth setting

and the switch setting.

5. Recommended DL and UL

gain parameters

The commissioning guide will provide recommended DL/UL gain

settings.

Users will still need to set all the gains manually in the “Device” pages,

and the frequencies for all the independent channels in the same

“Device” pages after the commissioning process is finished.

Table 4: Commissioning Task Explanation

End of Section

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 26

5 WEB GUI

The PS BDA can be monitored and controlled via the WEB GUI; use the following guide to finish system

parameter setting and commissioning.

5.1 WEB GUI CONNECTION

Step 1: Connect the OMT port to the PC RJ45 port with the supplied RJ45 cable to set up a physical

connection.

Step 2: Open a browser (browser IE7.0, IE8.0, Chrome or Firefox, suggested display resolution is 1024×768),

input Web GUI IP address: 192.168.8.101, click [Enter].

NOTE:

DHCP and DNS are also available to login to the Web GUI. The domain name is: www.combaomt.com.

Advise to clear all the history record of Browse before connecting BDA every time.

Figure 8: Input IP Address

Figure 9: Input Domain Name

Step 3: Input User Name: admin; Password (default password: admin). Click [Log in].

Figure 10: Input User Name and Password

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 27

Shows the basic information

about the PS BDA

Indicates the

equipment status

Indicating

alarm status

Click to enable

/disable alarm

Indicating

alarm status

Click to enable

/disable alarm

5.2 WEB GUI INTRODUCTION

After log in, the Web GUI main screen will appear.

Figure 11: Web GUI Main Screen

On Comba Web GUI Home Screen, there are four Menu bars:

[Devices], [Commissioning], [Firmware] and [Management].

5.2.1 [DEVICES]

The [Devices] Screen shows the equipment status, such as PA status, alarm information, etc.

Overview Screen

Figure 12: Overview Screen

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 28

Selecting

sub band

Frequency

information

RFparameters

Click to set

frequency

information, ,

enable/disable

RF switch.

Selecting

sub band

Click to set

bandwidth,

UL/DL ATT,

enable/disable

RF switch.

Sub band switch

status

Center frequency

of channel

Channel bandwidth

Sub band switch

status

400MHz Screen-Class A

This screen is only available for 400MHz PS BDA Class A

Figure 13: 400MHz Screen 1

400MHz Screen-Class B

Figure 14: 400MHz Screen 2

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 29

Click to set Freq Low and

High, DL/UL Gain,

Enable/disable RF switch.

DL Freq Low

and High of

sub-bands

RF parameters

of sub-bands

Sub-bands

switch status

Figure 15: 400MHz Screen

5.2.2 [COMMISSIONING]

A work flow of the commissioning process is shown on [Commissioning] Screen. Click the [Start] button, the

software will guide you through the commissioning step by step. For details, please refer to chapter 5.3.

Figure 16: [Commissioning] Screen

5.2.3 [FIRMWARE]

There are two functions on the [Firmware] bar: [upgrade] and [swap]. [Upgrade] is used to upgrade software,

and [Swap] is to replace the current firmware version with the previous one.

Follow the steps shown below figure to upgrade the firmware.

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 30

Step 1: Click to select the

file for upgrading.

Step 2: Click to finish the

software upgrading.

Click to swap the firmware

to the previous version

Step 2: Click to

select the file.

Step 3: Click to finish

the upgrading.

Step 1: Check the

module that needs to be

updated.

Figure 17: [Firmware] Screen – MCU Firmware Upgrade

Figure 18: [Firmware] Screen – Firmware Swap

Figure 19: [Firmware] Screen – Module Update

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 31

Management menu, click

Enter to each page for

parameters setting.

5.2.4 [MANAGEMENT]

Other parameters can be configured on the [Management] Screen.

Figure 20: [Management] Screen

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 32

Click to import/export the

configuration parameters.

There are nine function bars list on the left side of the [Mangement] Screen.

Inport&Export

Figure 21: Management – Import & Export

The parameters that can be imported / exported include sub band, alarm enable, ATT value, RF switch, and DL

output power.

This function can help users quickly configure PS BDA parameters. For example, if one PS BDA is finished

configuration, users can export the parameters and save it as a file on the PC, and then import this file to other

PS BDAs for faster set up of additional PS BDAs.

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 33

Configure the IP

address for remote

monitoring.

IP Setting

Figure 22: Management – IP Setting

Note: For remote monitoring, the IP Address must be set correctly based on the location IP of the remote

connection. If more than one piece of equipment is connected to the public network through the same router,

the router’s local IP CANNOT be set as 192.168.8.*.

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 34

Comm. Setting

Figure 23: Management – Comm. Setting

Note: There are 4 available communication types: SMS, PS, SNMP and ETHERNET. You can choose a

suitable type for remote monitoring.

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 35

Security

Figure 24: Management – Security

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 36

Click , [Modify Password] window will pop-up.

Figure 25: Modify Password

Note: Username cannot be modified.

Device Reset

Note: Click , all the parameters and alarms will be reset to factory default value. The Device Reset

process will last about 2~4 minutes. For PMU monitor reset, users need to re-login to the WEB GUI.

Figure 26: Management – Device Reset

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 37

Click here to get

PC time.

Input device

information.

Device Info

Figure 27: Management – Device Info

Note: Users can input a maximum of 30 characters in Device Info.

Isolation

Note: This Step is the same as step 5 of [Commissioning]. Users can check isolation again by clicking the

Check button, the detection range is from 65dB to 125dB.

Figure 28: Management – Isolation

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 38

Click to start

the alarm test.

RF setting

Alarm Setting

Figure 29: Management – RF Setting

Figure 30: Management – Alarm Setting

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 39

Click to export alarm

log or clear alarm log

Report

Figure 31: Management – Report

Note: Click Create to create the report (the report can’t be created in IE browser) and make sure that PDF

Reader software is installed on the computer. If not, the report will not be visible.

The device basic information, an overview of RF information and sub-band RF information are included in this

report. Please refer to appendix D for an example of device report.

Alarm Log

Figure 32: Management – Alarm Log

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 40

Click to clear history alarm

Clear History Alarm

Figure 33: Management – Clear History Alarm

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 41

5.3 COMMISSIONING PROCEDURE

To complete the installation and commissioning, users need to follow the steps below.

Step 1: Click the Menu bar [Commissioning] on home screen, a work flow will be displayed.

Figure 34: Commissioning Procedure – Start

Step 2: Click to start the process.

Figure 35: Commissioning Procedure – Site Info. Setting

Step 3: Click , to set the site information.

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 42

Figure 36: Device Information Setting

It is mainly used to record device location and Date/Time provides a time reference. Clicking the Config Value

of Date/Time will update the Date/Time automatically.

Step 4 :

a. Click to enter to Sub Band Setting/Channel parameters setting-Class A

Figure 37: Device Sub Band Setting-Class A

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 43

Figure 38: Channel parameters setting-Class A

Reminder:

Make sure the frequency of sub-bands match the actual frequency of filters, or BDA cannot work normally.

If the frequency is within [450MHz,470MHz], the bandwidth between DL Freq Low and DL Freq High can

be adjusted from 0.2 to 5MHz only. If the frequency is within[ 470,512], the bandwidth between DL Freq

Low and DL Freq High can be adjusted from 0.2-3MHz.

The frequency edges of two sub bands can be overlap, but they cannot be cross-contained.

The total channel quantity is 32CH within 4 sub-bands.

The channel center frequency must be within the frequency range of its relative sub-band, if it is not within

the range, the system will show a reminder window to show the setting unsuccessful.

If the sub band is off, all the channels belong to the sub band are auto set to off.

The procedure of sub band switch on: sub band 1 is first, and then 2, 3, 4. The procedure of sub band

switch off: sub band 4 is first, and then 3, 2, 1. And the isolation use sub band 1 to test, so make sure sub

band 1 is always on when BDA is working.

b. Click to enter to Sub Band Setting/Channel parameters setting-Class B

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 44

Figure 39: Device sub-band setting-Class B

Reminder:

Make sure the frequency of sub-bands match the actual frequency of filters, or BDA cannot work normally.

If the frequency is within [450MHz,470MHz], the bandwidth between DL Freq Low and DL Freq High can

be adjusted from 0.2 to 5MHz only. If the frequency is within[ 470,512], the bandwidth between DL Freq

Low and DL Freq High can be adjusted from 0.2-3MHz.

The frequency edges of two sub bands can be overlap, but they cannot be cross-contained.

NOTE: Make sure the device is connected with appropriate donor and service antennas before

proceeding to step 5.

Step 5: Click to enter to Isolation Detection Screen.

Click to start Isolation Detecting, then a [Confirm] window will pop-up.

Figure 40: Commissioning Procedure – Isolation Detection

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 45

Click to continue. If isolation detection passes, the process will go to Isolation Detection Finish

shown as Figure 43 If failed, a Tips window will pop-up, users need to check whether the system isolation

is adequate.

NOTE: At the end of the first frequency band commissioning, users can start other frequency band

commissioning.

Figure 41: Commissioning Procedure – Isolation Detection Confirm

Figure 42: Commissioning Procedure – Isolation Detection Failed

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 46

Step 1: Click to

open the

parameter setting

page.

Step 2: Input the

desired value.

Step 3: Click to

finish the setting.

Step 4: Click next to

continue RF setting.

Step 1: Click to

open the

parameter setting

page.

Step 2: Input the

desired value.

Figure 43: Commissioning Procedure – Isolation Detection Finish

Step 6: RF Setting Screen for setting the center frequency.

Figure 44: Commissioning Procedure – Center Frequency Setting

Figure 45: Commissioning Procedure – Channel Number Setting

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 47

Step 7: Click to finish the commissioning. In this window, a summary of device setting is shown.

Figure 46: Commissioning Procedure – Finish

End of Section

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 48

6 MAINTENANCE

The PS BDA is designed for trouble-free operation and generally does not need maintenance. Maintenance

activities should only be carried out by trained personnel.

Periodic inspection of the repeater equipment(s) is recommended, the recommended tasks includes:

Verify the direction and position of antennas. Re-align if necessary.

Make sure the cable connector and sealing on the RF cable connectors are not damaged.

Verify lightning and grounding protection is in good condition.

End of Section

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 49

No. of Antennas

Cable losses

Max Allowed Antenna Gain

4

3

39.1-(36-6-3)=12.1dBi

1

3

39.1-(36-0-3)=6.1dBi

10

3

39.1-(36-10-3)=15.1dBi

Equation (1) – Max Service antenna gain

Max Service antenna gain (dBi) = 39.1-(36dBm-# of antennas in dB – cable losses in dB).

Equation (2) – Input Noise to service antenna

Input Noise to service antenna:

-31dBm – antenna splitter losses in dB – out of band rejection of filters - cable loss in dB

7 APPENDICES

7.1 APPENDIX A:

Antenna installation:

Installation of an antenna must comply with the FCC RF exposure requirements. The antenna used for this

transmitter must be mounted on permanent structures.

The FCC regulations mandate that the ERP of type B signal boosters should not exceed 5W, this is equivalent

to 8.2W EIRP (39.1dBm).

Therefore the max antenna gain allowed for this type of signal booster should be limited to the values given by

equation 1 (below) for the service antenna.

For example:

Compliance with FCC deployment rule regarding the radiation of noise

Good engineering practice must be used in regard to the signal booster’s noise radiation. Thus, the gain of the

signal booster should be set so that the ERP of the output noise from PS BDA should not exceed the level of

-43 dBm in 10 kHz measurement bandwidth.

In the event that the noise level measured exceeds the aforementioned value, the PS BDA gain should be

decreased accordingly.

In general, the ERP of noise on a spectrum more than 1 MHz outside of the pass band should not exceed -70

dBm in a 10 kHz measurement bandwidth.

RX-4122 PS BDA has a noise level of -21 dBm in 100 kHz (equals to -31dBm in 10kHz) measurement at 1 MHz

spectrum outside the pass band of BDA and an in-band noise level at around -50 dBm in a 10 kHz bandwidth.

Therefore, the noise at the antenna input port should be calculated based on equation (2).

For example: in band noise

RX-4122 PS BDA connected to 10 service antennas with a 100m long ½ inch cable.

Losses of such a cable with the connectors = ~ 12dB

Assuming 10 service antennas: antenna splitter losses = 11 dB

Based on equation (2) Input antenna noise (to the antenna) = – 51 – 12 – 0 –11=-74 dBm ERP

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 50

The in-band input noise to the antenna should be – 51 – 12 – 0 – 11= -63dBm ERP

For example: Out of band noise

RX-4122 PS BDA connected to 10 service antennas with a 100m long ½ inch cable.

Losses of such a cable with the connectors = ~ 12dB

Assuming 10 service antennas: antenna splitter losses = 11 dB

Out of band rejection of filters: more than 45dBc

Based on equation (3) Input antenna noise (to the antenna) = – 31 –12 – 45 – 11= – 99dBm ERP

The Out of-band input noise to the antenna should be – 31 –12 – 45 – 11= – 99dBm ERP

Conclusion:

Good engineering practice requires that in general when the out of band noise measured at the service

antenna input is more than -70 dBm per 10 kHz measurement bandwidth, an external band pass filter should

be added to attenuate the out of band noise level.

All Comba BDAs include high selectivity duplexers and filters to attenuate the out of band noise.

Compliance with FCC Part 90.219 (d)(6)(i)

The deployment rules require that the ERP of intermodulation products should in general not exceed -30dbm.

This is not a formidable task since in the vast majority of the passive DAS installations; the signal loss in the

DAS due to splitting to multiple antenna and cable losses is significant.

As well as the above RX-4122 PS BDA is more likely to be used in a multicarrier environment (more than 2

carriers), which in turn will reduce the intermodulation products produced by the device.

The following statement is already in the user manual to highlight the requirement to the installer for the

instances where the above does not reduce the ERP of the intermodulation products to -30dBm.

‘The installation procedure must result in RX-4122 PS BDA complying with FCC requirements 90.219(d). In

order to meet FCC requirements 90.219(d), it may be necessary for the installer to reduce the UL and/or DL

output power for certain installations.’

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 51

7.2 APPENDIX B: TOOLS

The following are the recommended list of tools for new installation and routine maintenance.

Slotted Screwdriver

Philips Screwdriver

Ring Spanner (Assorted size: 12~20mm)

Electrically operated drill and masonry drill bits 12mm

Anti-static Wrist Strap

Side Cutter

Frequency Counter (e.g. FLUKE PM6685R)

RF Power Meter (e.g. Bird 5000)

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 52

Part Name

Harmful Substance

Pb

Hg

Cd

Cr (VI)

PBB

PBDE

A

× ○ ○ ○ ○

○

B

× ○ ○ ○ ○

○

Note: Above table complies with SJ/T 11364.

○: Indicates that the harmful substance content in all homogeneous materials for corresponding part is under the limited

requirement of GB/T 26572.

×: Indicates that the harmful substance content in at least one single homogeneous material for the corresponding part exceeds the

limited requirement of GB/T 26572.

Remark: The content of the parts marked with “×”above exceeds the requirement as there is still no mature alternative

technologies to achieve the replacement of poisonous and harmful materials or elements.

7.3 APPENDIX C: DECLARATION OF HARMFUL SUBSTANCES AND

CONTENT

Product Name: Public Safety BDA

Model: RX-4122

Harmful substance and content of this product as below table shown:

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 53

7.4 APPENDIX D: RMA (RETURN MATERIAL AUTHORIZATION)

End of Section

INSTALLATION GUIDE FOR RX-4122

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 54

Loading...

Loading...