mBDA Indoor Series

EAWS DIGITAL BAND

SELECTIVE REPEATER

USER MANUAL

mBDA-EAWS QE: 1-0-2

Comba Telecom Inc.

The information contained herein is the responsibility of and is approved by the

following, to whom all enquiries should be directed in the first instance:

This is an unpublished work the copyright in which vests in Comba International

("Comba"). All rights reserved.

The information contained herein is confidential and the property of Comba and

is supplied without liability for errors or omissions. No part may be reproduced,

disclosed or used except as authorised by contract or other written permission.

The copyright and the foregoing restriction on reproduction and use extend to all

media in which the information may be embodied.

USER MANUAL FOR MBDA INDOOR SERIES

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 3

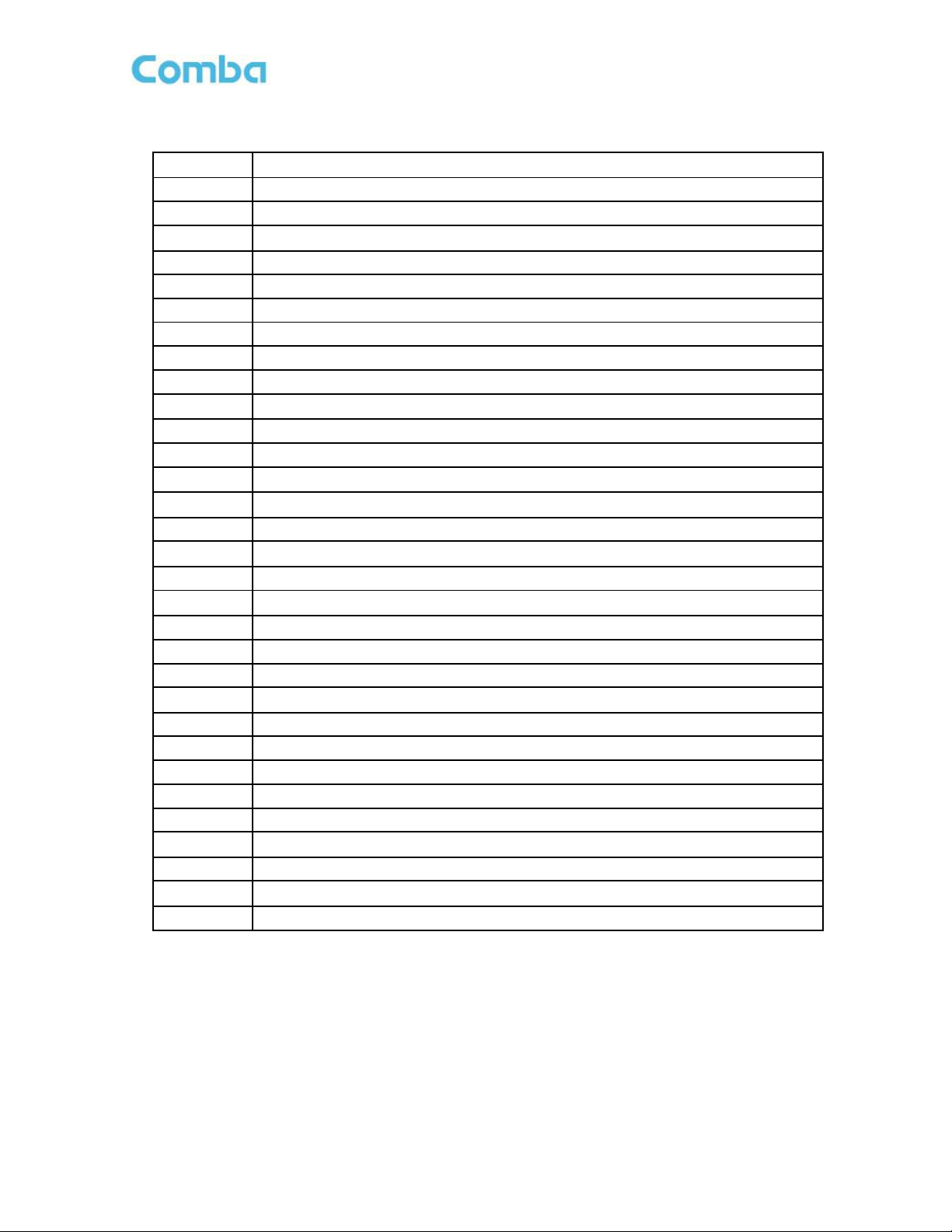

Section

Page

0.1 CONTENTS

.............................................................................................................................................................................. 2

0.1 CONTENTS .................................................................................................................................................... 3

0.2 INDEX TO FIGURES AND TABLES ................................................................................................................... 5

0.3 HISTORY ....................................................................................................................................................... 7

0.4 GLOSSARY OF TERMS .................................................................................................................................... 8

0.5 SAFETY NOTICES AND ADMONISHMENTS ..................................................................................................... 9

1 GENERAL INFORMATION ............................................................................................................................ 10

2 EQUIPMENT DESCRIPTION .......................................................................................................................... 12

2.1 SYSTEM DIAGRAM ...................................................................................................................................... 12

2.2 EQUIPMENT LAYOUT .................................................................................................................................. 13

2.3 EQUIPMENT CONSTITUTION ....................................................................................................................... 14

2.4 KIT OF PART ................................................................................................................................................ 14

3 INSTALLATION ............................................................................................................................................ 15

3.1 WARNINGS AND ALERTS ............................................................................................................................. 15

3.2 SITE PLANNING CONSIDERATIONS .............................................................................................................. 16

3.3 INSTALLATION PROCEDURES ...................................................................................................................... 17

3.4 EQUIPMENT CONNECTORS ......................................................................................................................... 27

3.5 EQUIPMENT CONNECTION ......................................................................................................................... 29

4 COMMISSIONING ....................................................................................................................................... 31

4.1 PRE-COMMISSIONING TASKS ...................................................................................................................... 31

4.2 LED INDICATORS ......................................................................................................................................... 31

4.3 COMMISSIONING PROCEDURE ................................................................................................................... 32

5 WEB GUI ..................................................................................................................................................... 34

5.1 WEB GUI CONNECTION ............................................................................................................................... 34

5.2 WEB GUI INTRODUCTION ........................................................................................................................... 35

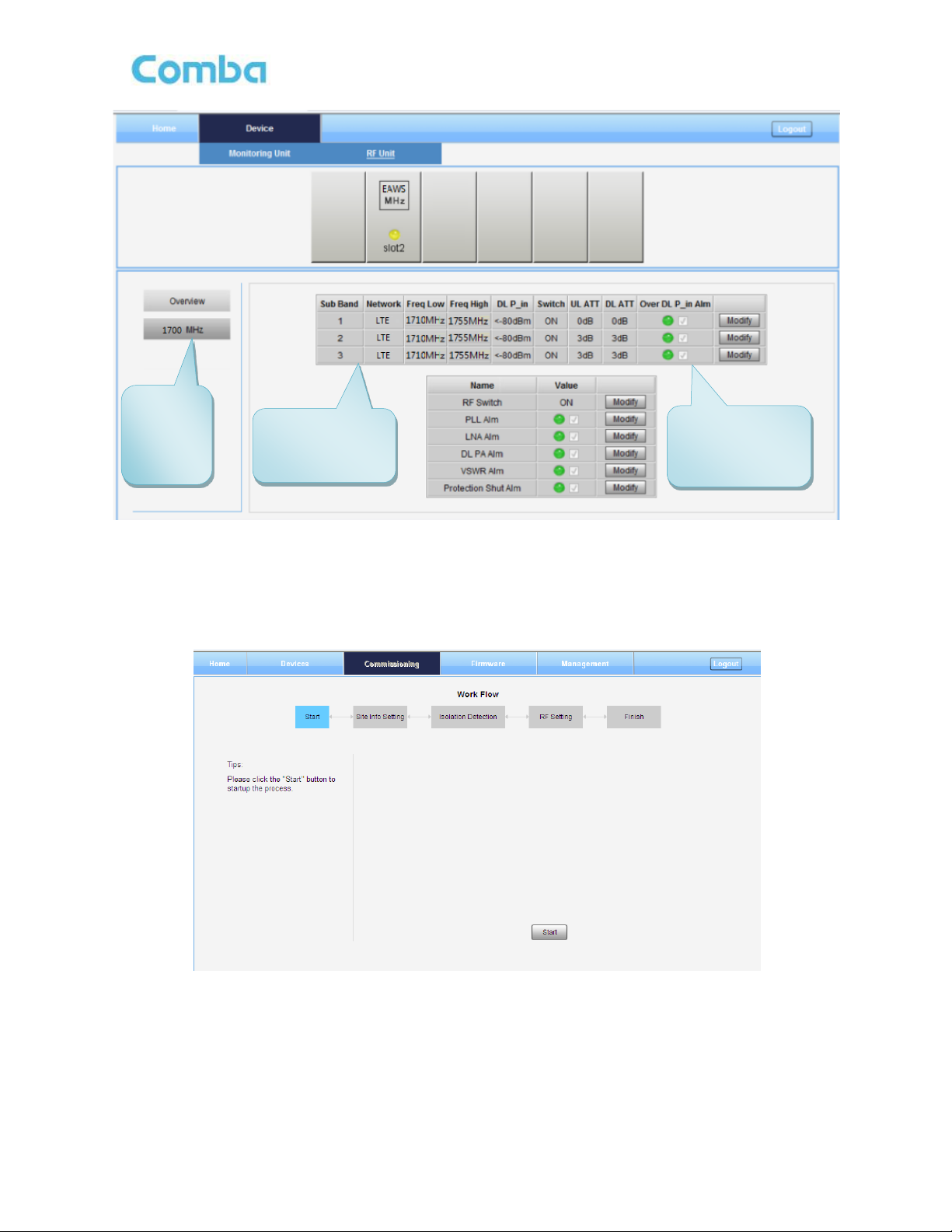

5.2.1 [DEVICES] ............................................................................................................................................... 35

5.2.2 [COMMISSIONING] ................................................................................................................................ 38

5.2.3 [FIRMWARE] .......................................................................................................................................... 38

5.2.4 [MANAGEMENT] .................................................................................................................................... 40

5.3 COMMISSIONING PROCEDURE ................................................................................................................... 46

6 MAINTENANCE ........................................................................................................................................... 53

6.1 ALARMS ...................................................................................................................................................... 53

USER MANUAL FOR MBDA INDOOR SERIES

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 4

6.2 TROUBLESHOOTING ................................................................................................................................... 53

7 APPENDICES ............................................................................................................................................... 55

7.1 APPENDIX A: TOOLS FOR INSTALLATION AND MAINTENANCE .................................................................... 55

7.2 APPENDIX B: RMA (RETURN MATERIAL AUTHORIZATION) ......................................................................... 56

USER MANUAL FOR MBDA INDOOR SERIES

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 5

0.2 INDEX TO FIGURES AND TABLES

Figure 1:mBDA-EAWS ............................................................................................................................................. 11

Figure 2: 2 Bands System Diagram for Example ................................................................................................. 12

Figure 3: Layout of mBDA ....................................................................................................................................... 13

Figure 4: mBDA Screen ........................................................................................................................................... 18

Figure 5: mBDA with 4 RFU and Combiners Configuration ............................................................................... 18

Figure 6: mBDA Rack ................................................................ ................................................................ ............... 19

Figure 7: Remove Cover Plates .............................................................................................................................. 19

Figure 8: PMU Installation ....................................................................................................................................... 20

Figure 9: Combiner Installation ............................................................................................................................... 20

Figure 10: RF Unit Installation ................................................................................................................................ 21

Figure 11: Completed mBDA with Six RFU Installation ...................................................................................... 21

Figure 12: Completed mBDA with Six RFU Installation ...................................................................................... 22

Figure 13: Completed mBDA of Four RFU and Two Combiners Installation ................................................... 22

Figure 14: Equipment Cabinet with Pallet ............................................................................................................. 23

Figure 15: mBDA Installation .................................................................................................................................. 24

Figure 16: Secure the Screws ................................................................................................................................. 24

Figure 17: Finish Installaiton ................................................................................................................................... 25

Figure 18: Rack Mounting........................................................................................................................................ 26

Figure 19: mBDA Front Panel Connectors ........................................................................................................... 27

Figure 20: mBDA Rear Panel Connectors ............................................................................................................ 27

Figure 21: mBDA Grounding (mBDA Rear Panel) ............................................................................................... 29

Figure 22: mBDA Power Connection (Rear Panel) ............................................................................................. 30

Figure 23: Pins Allocation for “EXT_ALM” Port for mBDA ................................................................................. 30

Figure 24: Commissiong Flow Chart ...................................................................................................................... 32

Figure 25: Input IP Address ..................................................................................................................................... 34

Figure 26: Input Domain Name ............................................................................................................................... 34

Figure 27: Input User Name and Password .......................................................................................................... 34

Figure 28: Web GUI Main Screen .......................................................................................................................... 35

Figure 29: [Devices] Sceen ..................................................................................................................................... 36

Figure 30: Power & Monitoring Unit ....................................................................................................................... 36

Figure 31: RF Unit..................................................................................................................................................... 37

Figure 32: RF Unit Detail Information .................................................................................................................... 38

Figure 33: [Commissioning] Screen ....................................................................................................................... 38

Figure 34: [Firmware] Screen – Upgrade .............................................................................................................. 39

Figure 35: [Firmware] Screen – Pop-up Window 1 .............................................................................................. 39

Figure 36: [Firmware] Screen - Swap .................................................................................................................... 40

Figure 37: [Management] Sceen ............................................................................................................................ 40

Figure 38: Management – Import&Export ............................................................................................................. 41

Figure 39: Management – IP Setting ..................................................................................................................... 41

Figure 40: Management – SNMP Setting.............................................................................................................. 42

Figure 41: Management – Security ........................................................................................................................ 42

Figure 42: Modify Password .................................................................................................................................... 43

Figure 43: Management – Device Reset ............................................................................................................... 43

Figure 44: Management – PA Reset ...................................................................................................................... 44

Figure 45: Management – Device Info ................................................................................................................... 44

Figure 46: Management – Isolation ........................................................................................................................ 45

Figure 47: Management – Report................................................................................................ ........................... 45

Figure 48: Commissioning Procedure – Start ....................................................................................................... 46

Figure 49: Commissioning Procedure – Site Info. Setting .................................................................................. 46

Figure 50: Dev Info & Date/Time ............................................................................................................................ 47

Figure 51: Commissioning Procedure – Isolation Detective ............................................................................... 48

Figure 52: Commissioning Procedure – Isolation Detective Confirm ................................................................ 48

Figure 53: Commissioning Procedure –Isolation Detection Failed .................................................................... 48

Figure 54: Commissioning Procedure –Isolation Detection Finish .................................................................... 49

USER MANUAL FOR MBDA INDOOR SERIES

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 6

Figure 55: Commissioning Procedure – Subband bandwidth and Switch Setting .......................................... 49

Figure 56: Commissioning Procedure – DL Output Power Setting Screen ..................................................... 50

Figure 57: Commissioning Procedure – DL Output Power Setting ................................................................... 51

Figure 58: DL Output Power Over Exceed ........................................................................................................... 51

Figure 59: Commissioning Procedure – Finish .................................................................................................... 52

Table 1: mBDA Components .................................................................................................................................. 14

Table 2: KOP ............................................................................................................................................................. 14

Table 3: mBDA Connections ................................................................................................................................... 28

Table 4: Pin Definition of “EXT_ALM” Port for mBDA ......................................................................................... 30

Table 5: LED Indications .......................................................................................................................................... 31

Table 6: Commissioning Procedure ....................................................................................................................... 33

Table 7: Monitoring Unit Alarm List ........................................................................................................................ 53

Table 8: RF Unit Alarm List ..................................................................................................................................... 53

Table 9: Monitor Unit Alarms Diagnosis ................................................................................................................ 54

Table 10: RF Unit Alarms Diagnosis ...................................................................................................................... 54

USER MANUAL FOR MBDA INDOOR SERIES

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 7

Change No.

ENU

Details Of Change

1 2

1-0-0

1-0-1

This user manual first created in Aug 2014.

Minor updates per revised QIG 1-0-2 in Mar 2015

3

1-0-2

Update the WEB photos in May 2018

0.3 HISTORY

USER MANUAL FOR MBDA INDOOR SERIES

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 8

ALC

Automatic Level Control

ATT

Attenuation

BDA

Bi-direction Amplifier

BS

Base Station

BTS

Base Transceiver Station

DL

Downlink

DT

Donor Terminal

FOU

Fiber Optical Unit

GUI

Graphic User Interface

ID

Identification

LNA

Low Noise Amplifier

MCU

Main Control Unit

MT

Mobile Terminal

MTBF

Mean Time Between Failures

MBDA

Master Unit

NC

Normally Closed

NF

Noise Figure

NO

Normally Open

OMC

Operation & Maintenance Center

OMT

Operation & Maintenance Terminal

PA

Power Amplifier

POI

Point of Interconnects

PSU

Power Supply Unit

RF

Radio Frequency

RFU

Radio Frequency Unit

RU

Remote Unit

SMA

Sub-Miniature “A” Connector

TX/RX

Transmit/Receive

UL

Uplink

VAC

Volts Alternating Current

VSWR

Voltage Standing Wave Ratio

WCDMA

Wideband Code Division MBDAltiple Access

0.4 GLOSSARY OF TERMS

USER MANUAL FOR MBDA INDOOR SERIES

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 9

0.5 SAFETY NOTICES AND ADMONISHMENTS

This document contains safety notices in accordance with appropriate standards. In the interests of

conformity with the territory standards for the country concerned, the equivalent territorial admonishments

are also shown.

Any installation, adjustment, maintenance and repair of the equipment must only be carried out by trained,

authorized personnel. At all times, personnel must comply with any safety notices and instructions.

Specific hazards are indicated by symbol labels on or near the affected parts of the equipment. The labels

conform to international standards, are triangular in shape, and are colored black on a yellow background.

An informative text label may accompany the symbol label.

Hazard labeling is supplemented by safety notices in the appropriate equipment manual. These notices

contain additional information on the nature of the hazard and may also specify precautions.

Warning Notices:

These draw the attention of personnel to hazards that may cause death or injury to the operator or others.

Examples of use are cases of high voltage, laser emission, toxic substances, point of high temperature,

etc.

WARNING. This is NOT a CONSUMER device. It is designed for installation by FCC LICENSEES and

QUALIFIED INSTALLERS. You MUST have an FCC LICENSE or express consent of an FCC Licensee to

operate this device. Unauthorized use may result in significant forfeiture penalties, including penalties in

excess of $100,000 for each continuing violation.

For compliance with the general/uncontrolled population RF exposure limits, each individual antenna

used for this transmitter must be installed to provide a separation distance greater than 40cm or more

from all persons during normal operation and must not be co-located with any other antenna for meeting

RF exposure requirements.

Alert Notices:

These draw the attention of personnel to hazards that may cause damage to the equipment. An example

of use is the case of static electricity hazard.

Caution notices may also be used in the handbook to draw attention to matters that do not constitute a

risk of causing damage to the equipment but where there is a possibility of seriously impairing its

performance, e.g. by mishandling or gross maladjustment. Warnings and Cautions within the main text do

not incorporate labels and may be in shortened form.

The application antenna and RF cable are not provided. Since the antenna and RF cable are excluded, if

it needs to use the antenna, the antenna gain should not exceed 10 dBi, the installation height of antenna

for AWS 1710-1755 MHz band operations is limited to 10 meters above ground, for compliance with

Section 27.50.And the RF cable should be complied 50 ohms.

End of Section

USER MANUAL FOR MBDA INDOOR SERIES

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 10

Band

Downlink (DL)

Uplink (UL)

FCC ID

700MHz Upper C

746-757

776-787

PX8MBDA-200S

700MHz Lower ABC

728-746

698-716

850MHz

869-894

824-849

1900MHz

1930-1995

1850-1915

2600MHz

2620-2690

2500-2570

AWS

2110-2155

1710-1755

EAWS

2110-2180

1710-1755

PX8MBDA-EAWS

(Applying)

800MHz (ESMR)

862-869

817-824

PX8MBDA-800

1 GENERAL INFORMATION

The mBDA Indoor Series Digital Band Selective Repeater (hereinafter called “mBDA Indoor Series”) is

designed for indoor network. It can wireless transmit, three-way amplify BTS uplink and downlink signals

and enlarge coverage range. Digital band selective technology effectively amplifies the desired BTS

signals and provides superior out-of-band rejection, avoid cell interference and improve call quality.

The certified bands of FCC for this product as below and all of the bands can be choosen to be an

combination flexibly.

Main Features

It supports six wideband channels; each channel can turn off separately. Operation band is 3MHz-

20MHz adjustable.

High power bandwidth linear PA ensures signals no distortion amplification.

The system gain is compensated automatically according to the temperature variation within the

enclosure, which ensures stable operation under ambient temperature.

Has off-line isolation testing, downlink VSWR alarm, downlink input filed intensity and output power

testing function, which is convenient for installation and commissioning.

Supports multi-band expansion, convenient for configuration and upgrade.

Monitoring master unit software remote download function enables remote software upgrade.

Local Operation and Maintenance Terminal (OMT): operating status and parameters can be set or

monitored by OMT PC locally.

Operation Maintenance Center (OMC): system working parameters and communication configuration

can be set or inquired remotely through the build-in WCDMA modem. If alarm is generated, the

equipment will dial up to OMC automatically.

Build-in Li-ion battery ensures that alarm information can automatically report to OMC in case of

equipment power failure.

Designed for all weather outdoor installation – waterproof, damp-proof and omni-sealed.

USER MANUAL FOR MBDA INDOOR SERIES

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 11

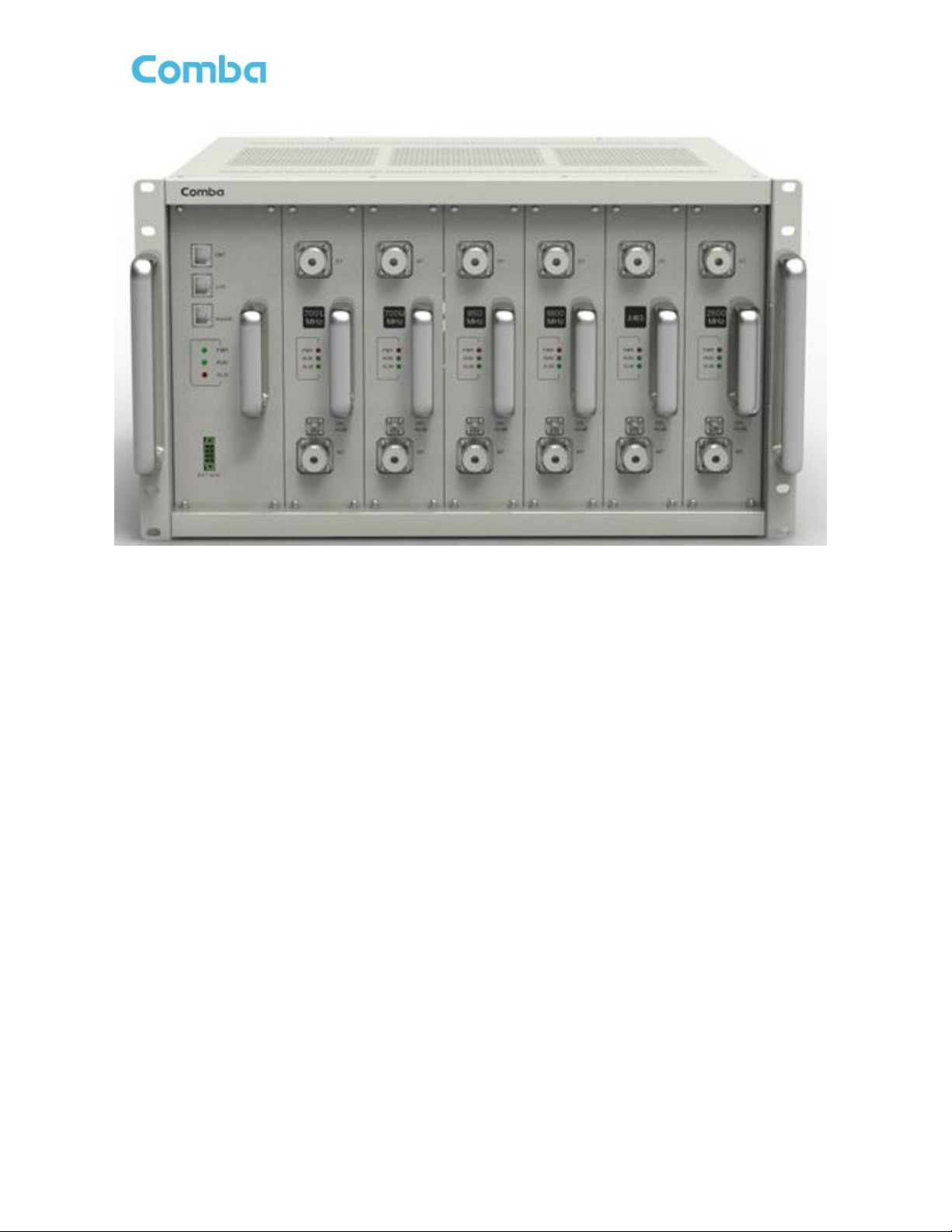

The figure below shows the enclosure of the mBDA indoor series..

NOTE: RF module is slot undependent.

Figure 1:mBDA indoor series

End of Section

USER MANUAL FOR MBDA INDOOR SERIES

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 12

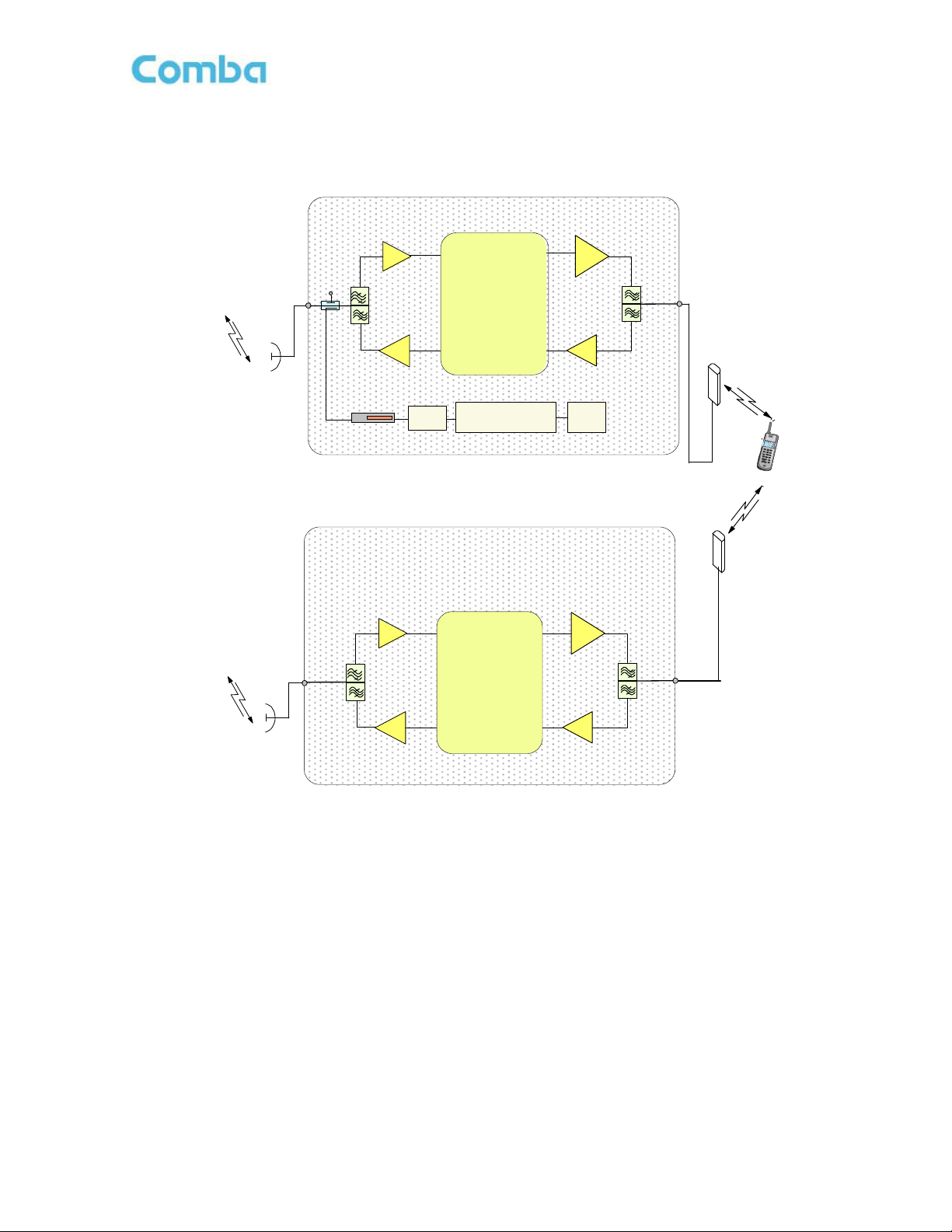

Donor

Ant

Modem

Power

Supply

Alarm

Indicator

DL PA

UL PA

UL LNA

DL LNA

Main Control Unit

DT

MT

Mobile

Mobile

Ant

Digital Frequency

Selective Module

DL PA

UL PA

UL LNA

DL LNA

Digital Frequency

Selective Module

DT

MT

Ant

Mobile

2 EQUIPMENT DESCRIPTION

2.1 SYSTEM DIAGRAM

In the downlink, the BTS signals are received by donor antenna of the repeater. After the duplexer, the

Figure 2: 2 Bands System Diagram for Example

signals are sent to the LNA module for pre-amplification and digital RF integrated module for digital

filtering and frequency conversion. Then the DL signals will be sent to downlink PA to amplify power and

filter via duplexer. After amplification, the signals are transmitted via the MT port to the service antenna.

In the uplink, the mobile signals are received by the service antenna. After the MT port integrated

duplexer, the signals are sent to the LNA, integrated module for digital filtering, then to PA for power

amplification and to duplexer. After that, the uplink signals are sent to the donor antenna for transmission

back to the BTS.

USER MANUAL FOR MBDA INDOOR SERIES

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 13

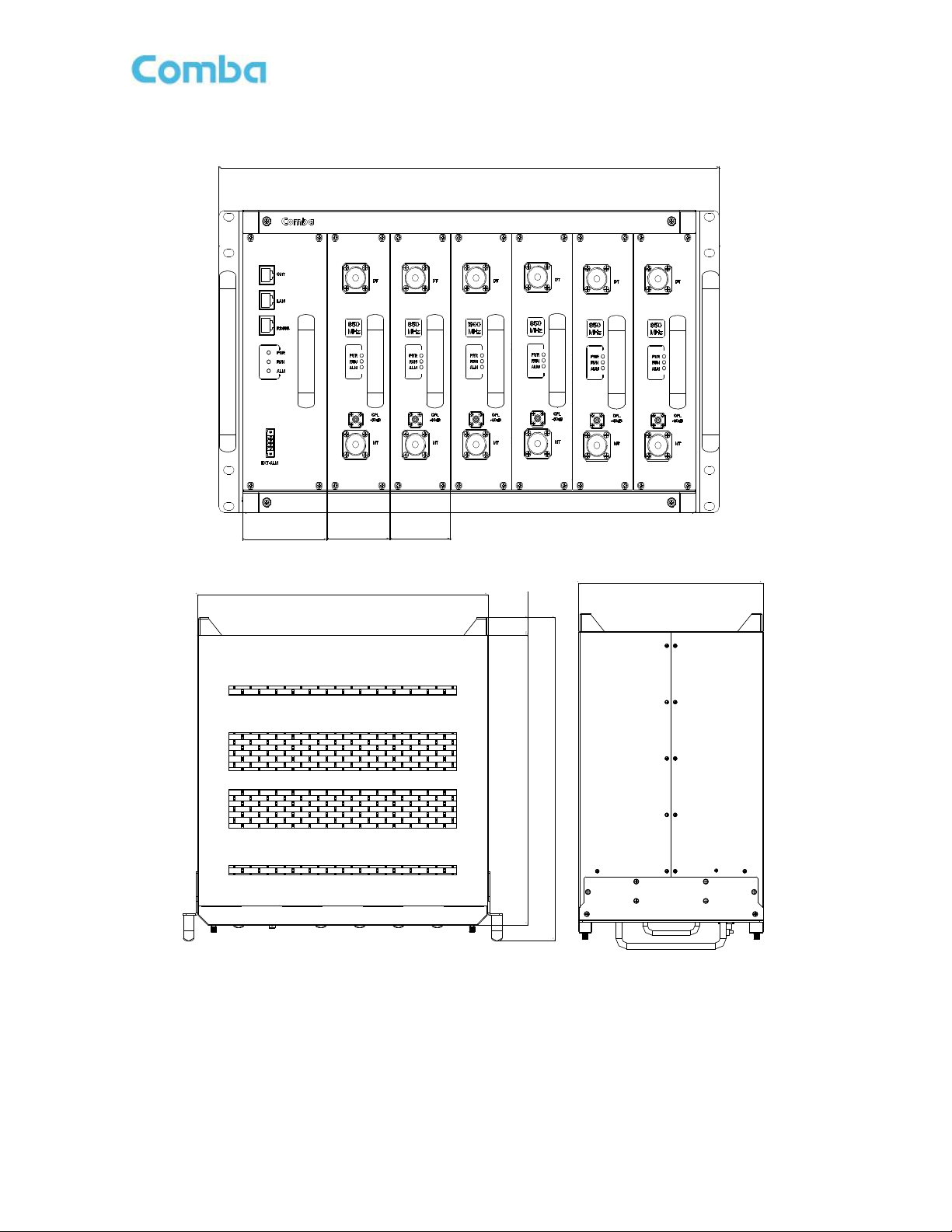

58.6

81.4

482

58.6

26.1436

485.6

439

265.2

2.2 EQUIPMENT LAYOUT

Figure 3: Layout of mBDA

USER MANUAL FOR MBDA INDOOR SERIES

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 14

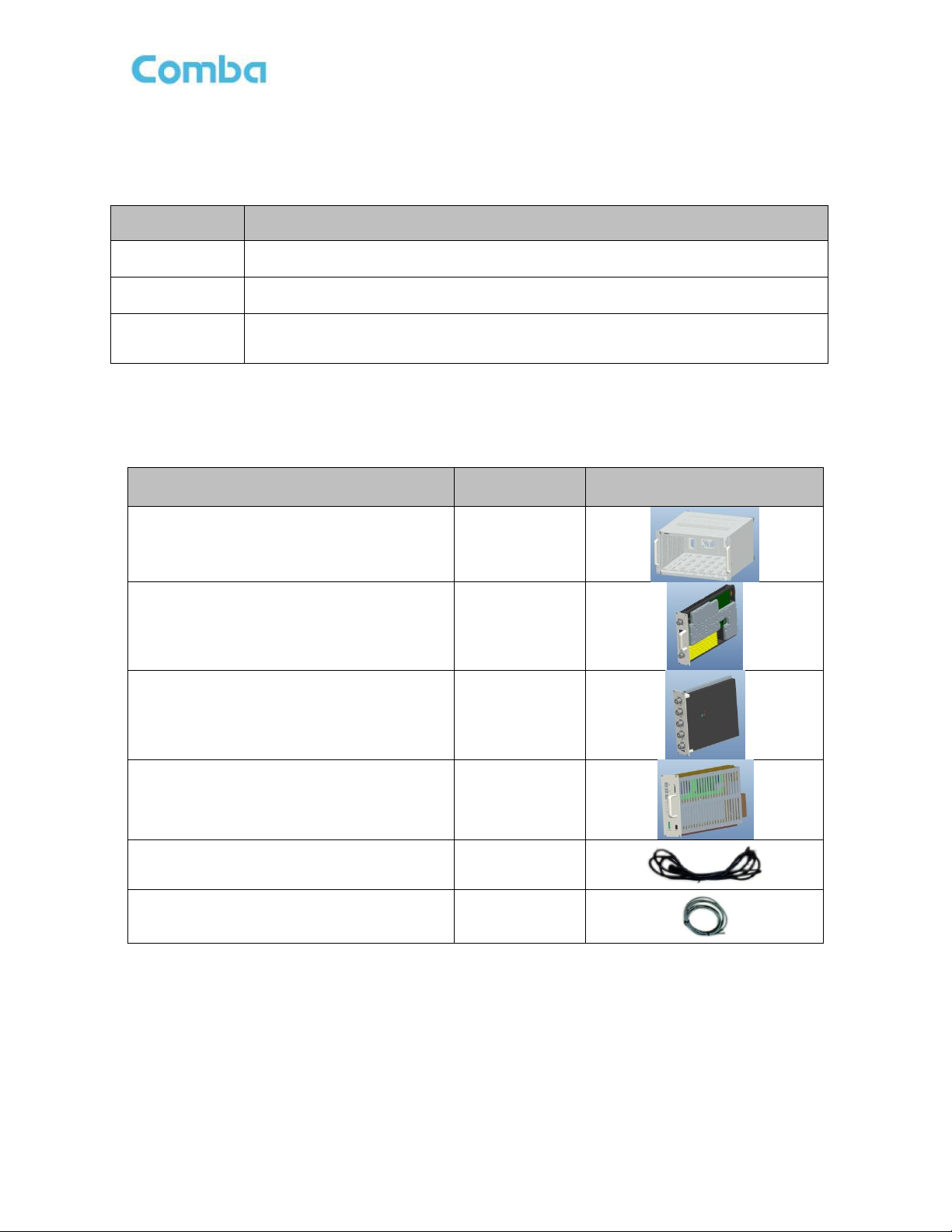

Module

Description

mBDA-RACK

There are total 7 slots in the main chassis, where six slots for RF Units and

Combiner Units, first slot is for Power & Monitoring Unit.

mBDA-PMU

Power & Monitoring Unit (PMU) converts the input voltage into stable DC to supply

power for each RF module and provides monitor control.

mBDA-RFU

RF Unit processes UL/DL signal and amplifies the signal for coverage.

Item

Qty

Image

Rack

1

RF Unit (RFU)

(Packing separately)

1~6

Combiner Unit (CB)

(Optional and Packaged separately)

0~2

Power & Monitoring Unit (PMU)

(Packing separately)

1

Power Supply Cable

(13 Feet 1 inch)

1

Communication Cable

1

2.3 EQUIPMENT CONSTITUTION

mBDA consists of the following parts:

Table 1: mBDA Components

2.4 KIT OF PART

Table 2: KOP

End of Section

USER MANUAL FOR MBDA INDOOR SERIES

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 15

3 INSTALLATION

3.1 WARNINGS AND ALERTS

Radio Frequency Energies

There may be situations, particularly for workplace environments near high-powered RF sources, where

recommended limits for safe exposure of human beings to RF energy could be exceeded. In such cases,

restrictive measures or actions may be necessary to ensure the safe use of RF energy.

High Voltage

The equipment has been designed and constructed to prevent practicable danger, as far as reasonably

possible. Any work activity on or near equipment involving installation, operation or maintenance must be

free from danger, as far as reasonably possible.

Where there is a risk of damage to electrical systems involving adverse weather, extreme temperatures,

wet, corrosive or dirty conditions, flammable or explosive atmospheres, the system must be suitably

installed to prevent danger.

Protective Earthing

For the purpose of protecting individuals fromelectrical risk, the equipment provided must be safety in

design and properly maintained and used.

Handling Precautions

This covers a range of activities including lifting, lowering, pushing, pulling, carrying, moving, holding or

restraining an object or person. It also covers activities that require the use of force or effort, such as

pulling a lever, or operating power tools.

Electrostatic Discharge (ESD)

Observe standard precautions for handling ESD-sensitive devices. Assume that all solid-state electronic

devices are ESD-sensitive. Ensure the use of a grounded wrist strap or equivalent while working with

ESD-sensitive devices. Transport, store, and handle ESD-sensitive devices in static-safe environments.

USER MANUAL FOR MBDA INDOOR SERIES

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 16

3.2 SITE PLANNING CONSIDERATIONS

3.2.1 SITE PLANNING

Site Considerations

There may be situations, particularly for workplace environments near high-powered RF sources, where

recommended limits for safe exposure of human beings to RF energy could be exceeded. In such cases,

restrictive measures or actions may be necessary to ensure the safe use of RF energy.

Installation Location

Mounting surface shall be capable of supporting the weight of the equipment.

In order to avoid electromagnetic interference, a proper mounting location must be selected to minimize

interference from electromagnetic sources such as large electrical equipment.

Environmental

Humidity has an adverse effect on the reliability of the equipment. It is recommended to install the

equipment in locations having stable temperature and unrestricted air-flow.

The installation location for the system should be well ventilated. The equipment has been designed to

operate at the temperature range and humidity level as stated in the product specifications.

Powering

The power & monitoring unit (PMU) provides power to all modules within the equipment. Depending on

the product variant, it is recommended that the PMU operates on a dedicated AC circuit breaker or fused

circuit.

Grounding Requirement

Verify that the equipment has been well grounded. This includes antennas and all cables connected to

the system. Ensure lightning protection for the antennas is properly grounded.

Cable Routing

Depending on equipment configuration, a variety of types of cables are connected to the equipment:

coaxial cables, power cable, communication cable, and commissioning cable. Where applicable, ensure

cables are properly routed and secured so that they are not damaged.

Manual Handling

During transportation and installation, take necessary handling precautions to avoid potential physical

injury to the installation personnel and the equipment.

USER MANUAL FOR MBDA INDOOR SERIES

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 17

3.2.2 SYSTEM INSTALLATION CHECKLIST

Working space available for installation and maintenance for each mounting arrangement. Ensure

unrestricted airflow.

Ensure earthing point is within reach of the ground wire. (2m; 6 ft. 10 in.).

Ensure a power source is within reach of the power cord and the power source has sufficient

capacity.

Where appropriate, ensure unused RF connectors are terminated.

Where appropriate, ensure unused optical fiber connectors are protected.

Do not locate the equipment near large transformers or motors that may cause electromagnetic

interference.

Reduce signal loss in feeder cable by minimizing the length and number of RF connections.

Ensure the equipment will be operated within the stated environment (refer to datasheet).

Where appropriate, confirm available of suitably terminated grade of RF.

Observe handling of all cables to prevent damage.

3.3 INSTALLATION PROCEDURES

3.3.1 GOODS INWARDS INSPECTION

mBDA was factory tested, inspected, packed, and delivered to the carrier with utmost care. Do not accept

shipment from carrier which shows damage or shortage until the carrier’s agent endorses a statement of

the irregularity on the face of the carrier’s receipt. Without documentary evidence, a claim cannot be

processed.

Open and check each package against the packing list. For any shortage, contact Comba Telecom

Systems. Do not remove items from packing materials until installation.

3.3.2 TOOLS

See Appendix A for a full list of tools required for installation and maintenance.

USER MANUAL FOR MBDA INDOOR SERIES

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 18

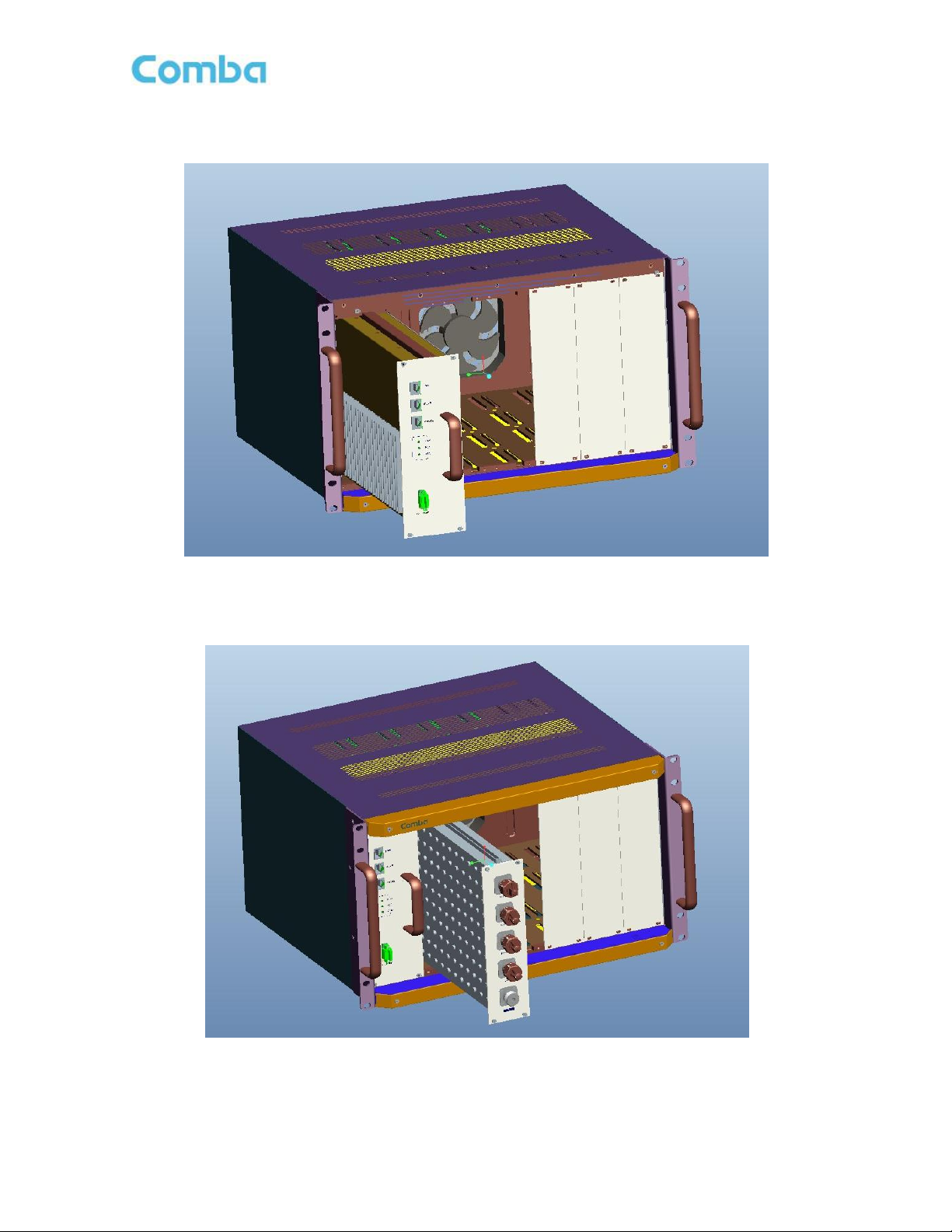

3.3.3 ASSEMBLING

mBDA consists of one Rack and three different modules including PMU ,RFUs and CBs (CB is optional).

All the units are packed separately. Follow the steps below to assemble.

Figure 4: mBDA Screen

Note: PMU must be installed in the leftmost slot; RF Units are independent and can be installed in any of

the remaining six slots.

Figure 5: mBDA with 4 RFU and Combiners Configuration (example)

PMU must be installed in the leftmost slot. When assembling an mBDA system with DT Combiner and MT

Combiner modules, CBs and RFUs can be installed in any of the remaining six slots.

With typical configuration of quad band RFU plus two CB, we recommend inserting CBs and RFUs in the

order as shown in Figure 2 to have a better internal cabling. Starting from the left, the mBDA rack should

have PMU, DT Combiner (mBDA-CB-ABPK4ID1), the certified RFUs which can choose 700U MHz, 700L

MHz, 800MHz (ESMR) , 850MHz, 1900MHz, 2600MHz, AWS and EAWS and MT Combiner (mBDA-CBABPK4ID2).

USER MANUAL FOR MBDA INDOOR SERIES

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 19

Step1: The rack with cover plates is shown in Figure 3. Please remove the cover plates before installing

related modules.

Figure 6: mBDA Rack

Figure 7: Remove Cover Plates

USER MANUAL FOR MBDA INDOOR SERIES

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 20

Step 2: PMU installation: Insert PMU and fasten the screws.

Figure 8: PMU Installation

Step 3: Combiner Installation: When Combiners are required, insert Combiners and fasten the screws

(see below Figure)

Figure 9: Combiner Installation

USER MANUAL FOR MBDA INDOOR SERIES

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 21

Step 4: RF Units installation: Insert RFUs into any slot and fasten the screws.

Figure 10: RF Unit Installation

Note: Make sure the DIP switch (located towards the rear of the RFU) is set to the ON position (see below

Figure)

Figure 11: Completed mBDA with Six RFU Installation

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 22

Step 5: Finish Installation.

USER MANUAL FOR MBDA INDOOR SERIES

Figure 12: Completed mBDA with Six RFU Installation

Figure 13: Completed mBDA of Four RFU and Two Combiners Installation

USER MANUAL FOR MBDA INDOOR SERIES

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 23

3.3.4 mBDA IN NORMAL EQUIPMENT CABINET

mBDA is an indoor type device. It can be installed in normal equipment cabinet, the installation

procedures are shown as below:

Step 1: Make sure the equipment cabinet is available with pallet, and the pallet is fixed steadily

(Equipment Cabinet nuts, screws and pallet are not provided.). Use cabinet nuts, screws and pallet as

recommended by rack manufacturer.

Figure 14: Equipment Cabinet with Pallet

Step 2: Install the mBDA on to the pallet.

USER MANUAL FOR MBDA INDOOR SERIES

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 24

Figure 15: mBDA Installation

Step 3: Attach the mBDA onto the cabinet with the recommended rack screws.

Figure 16: Secure the Screws

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 25

Step 4: Finish installation.

USER MANUAL FOR MBDA INDOOR SERIES

Figure 17: Finish Installaiton

USER MANUAL FOR MBDA INDOOR SERIES

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 26

3.3.5 mBDA IN 19” RACK MOUNTING

mBDA can also be installed in 19’’ rack mounting, the installation procedures are shown as below:

Step 1: Install right angle bracket and left angle bracket on back of the mounting rack (Rack nuts and

screws are not provided). Use rack nuts and screws as recommended by the rack manufacturer.

Step 2:Slide themBDA-EAWS on to the angle brackets and confirm it is level.

Step 3:Attach themBDA-EAWS onto the rack with the recommended rack screws.

Figure 18: Rack Mounting

USER MANUAL FOR MBDA INDOOR SERIES

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 27

3.4 EQUIPMENT CONNECTORS

The figure below presents the connectors of mBDA.

Figure 19: mBDA Front Panel Connectors

Figure 20: mBDA Rear Panel Connectors

USER MANUAL FOR MBDA INDOOR SERIES

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 28

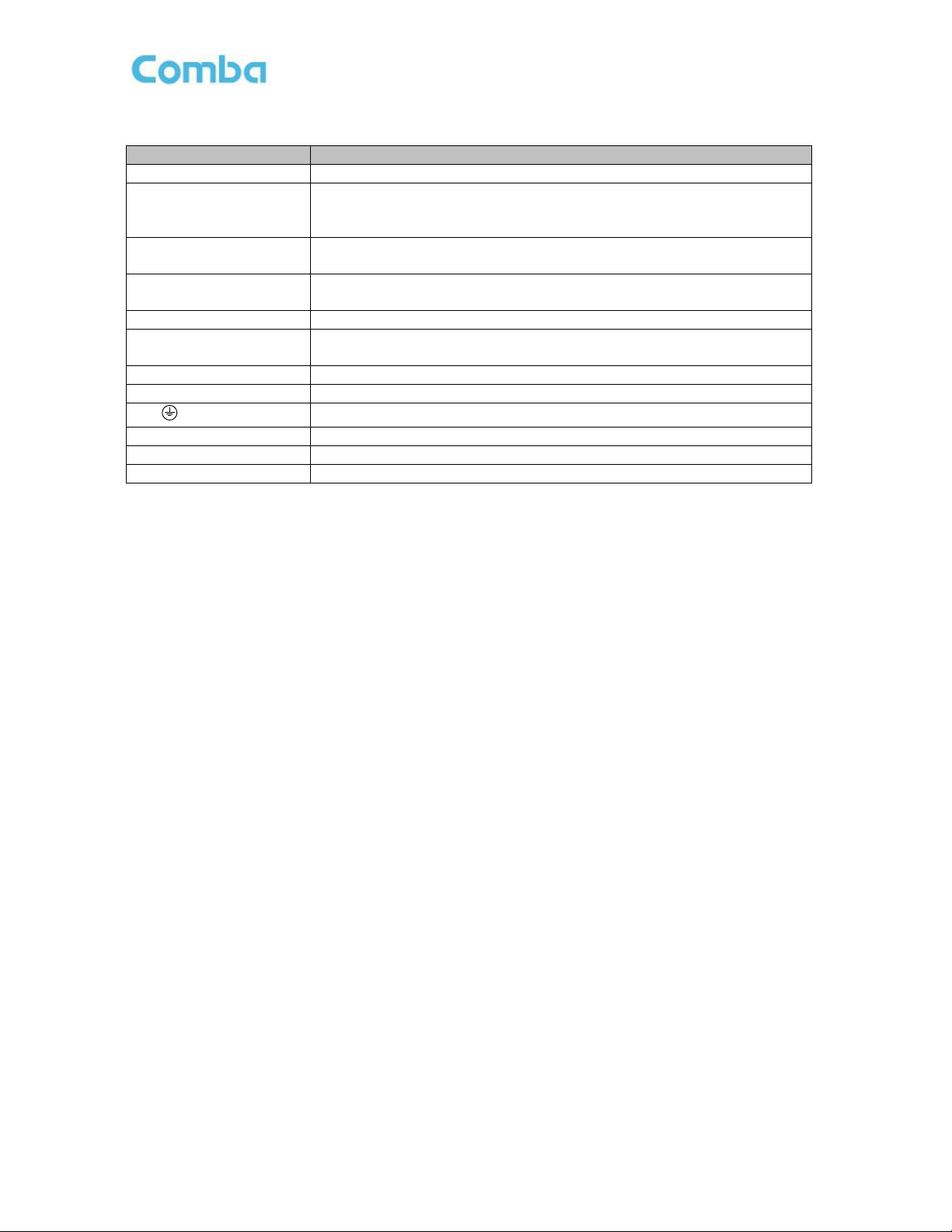

Identifier

Functional Description

1 & 3. LED indicator

LED indicator. Refer to Table 6 for more detailed information.

2. OMT/LAN/RS485

OMT port is for local commissioning; LAN port is for remote

connection; RS485 is for extension connection when adding extended

equipment.

4.EXT_ALM

External alarm connector with 4 pins. Refer to Table 4 for more

detailed information.

5. DT Combiner

Donor signal input port and split relative signal to RF modules. Mini

DIN female.

6. DT

RF input port, connects to DT combiner, Mini DIN female.

7. MT Combiner

Combined signals output port, connects to cover system, signals are

from relative RF modules. Mini DIN female.

8.CPL

Output coupler port, -40dB, QMA female, DL only.

9.MT

RF output port, Mini DIN female, connect to Service Antenna.

10.

Grounding connector.

11. FAN

Fan inside

12. POWER

Power switch.

13. AC100~240V

AC power supply connector.

Table 3: mBDA Connections

Step 1: a) For systems without CB modules installed

Connect RFU module’s DT port to an external combiner or donor antenna.

Connect RFU module’s MT port to an external combiner or service antenna.

b) For systems with CB modules installed

Connect donor antenna to DT port of the DT Combiner.

Connect each RFU module’s DT port to their respective port on the DT Combiner.

Connect each RFU module’s MT port to their respective port on the MT Combiner.

Connect the service antenna to MT port of the MT Combiner.

Step 2: Connect the power cable to the power supply port (100-240VAC, 3.5Amp maximum).

USER MANUAL FOR MBDA INDOOR SERIES

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 29

WARNING!

This unit must always be grounded. Consult an appropriate electrical

inspection authority or an electrician if you are uncertain that suitable

grounding is available.

Do not connect power before grounding.

Grouding Connector

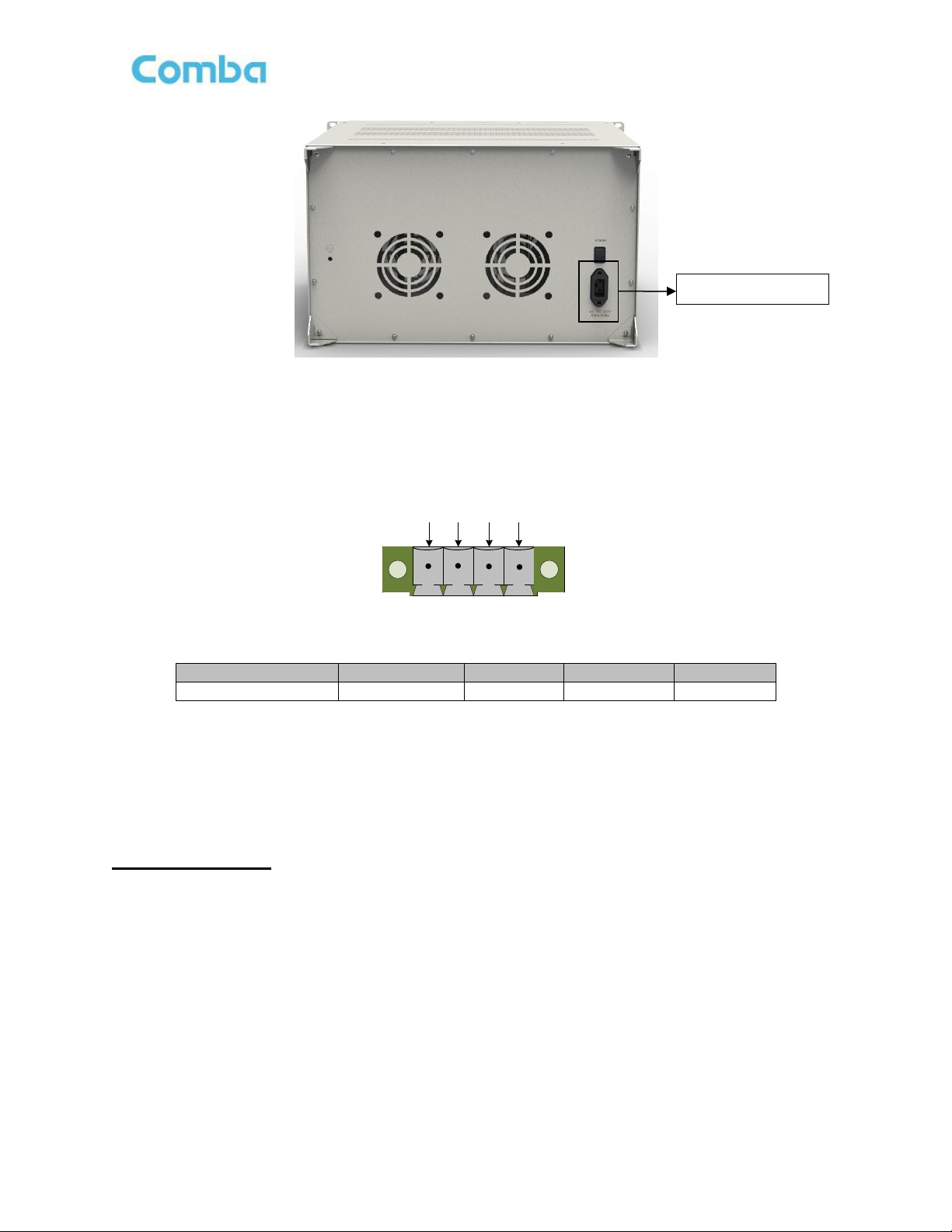

3.5 EQUIPMENT CONNECTION

3.5.1 GROUNDING CONNECTION

3.5.2 mBDA GROUNDING CONNECTION

Step 1: Connect the GND cable to the GND connector and the building EARTH. Recommended GND

cable size is # 12 AWG.

Step 2: Ensure the GND cable is connected to building GND.

Figure 21: mBDA Grounding (mBDA Rear Panel)

3.5.3 mBDA CONNECTIONS

Step1: Connect the mBDA DT port to the RF Source downlink, and then connect mBDA MT port with RF

Source uplink.

Step 2: Connect the power cable to the power supply port (100-240VAC, 1Amp maximmum).

USER MANUAL FOR MBDA INDOOR SERIES

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 30

123

4

Pin number

1 2 3

4

Alarm definition

EXT. Alarm 1

GND

EXT. Alarm 2

GND

Power Connector

Figure 22: mBDA Power Connection (Rear Panel)

3.5.4 EXTERNAL ALARM CONNECTION

For EXT-ALM, this is a 4-pin connector. The following figure and table show the pin allocation and

definition. Pin numbering are shown looking-into the connector on the enclosure.

Figure 23: Pins Allocation for “EXT_ALM” Port for mBDA

Table 4: Pin Definition of “EXT_ALM” Port for mBDA

Note: Users need to configure Ext Alm 1~2 on WEB GUI to realize External Alarm (Refer to Chapter 5).

3.5.5 CONNECT TO PC

The local commissioning and management for mBDA is achieved through connecting to the WEB based

GUI.

Connect mBDA to PC

Connect mBDA “OMT” port (RJ45) to the RJ45 port of PC with supplied Ethernet cable to achieve local

monitoring and management.

End of Section

USER MANUAL FOR MBDA INDOOR SERIES

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 31

LED Indicator

Normal Status

Indication

PWR

Steady green

Power indicator. If LED is off, it indicates the

system has no power.

RUN

Flashing green

(1 time/sec)

mBDA operation indicator. After initialization

(1~2 minutes), the LED should flash at once per

sec. (When upgrade firmware, LED will flash

rapidly)

ALM

OFF

Alarm indicator. If LED is RED, there is an

alarm.

4 COMMISSIONING

4.1 PRE-COMMISSIONING TASKS

After equipment installation, perform the following steps before equipment powering and commissioning,

check that the expected voltage, current, and power levels do not violate any ratings. Double check all

connections including ground before applying power. Do not manipulate circuits or make changes when

power is applied:

Visually inspect the power connection within the equipment. Ensure that all cables are correctly and

securely connected, including power cables, grounding wires and RF cables.

Check grounding connection and verify that the ground resistance is less than 5Ω.

Connect the equipment to the PC.

Power on equipment.

Monitor the initialization of the equipment though the LEDs on the panel. Refer to detailed LEDs

information in the next section.

4.2 LED INDICATORS

Diagnostic LEDs are located on the equipment front panel; each indicates the status of a particular

function:

Table 5: LED Indications

USER MANUAL FOR MBDA INDOOR SERIES

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 32

Connect and inquiry status

Set channel No.

Input power detection and adjust the direction of

Donor Antenna

Output power confirmation

Drive test and adjust the direction of Service

Antenna

Adjust UL ATT and confirm the call quality

Double check the status of BTS Uplink and the isolation

between Donor Antenna and Service Antenna

End

Set monitor parameters

Isolation detection

4.3 COMMISSIONING PROCEDURE

System commissioning can commence after the monitoring system has completed self initialization. The

commissioning procedure is shown below:

Figure 24: Commissiong Flow Chart

USER MANUAL FOR MBDA INDOOR SERIES

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 33

Commissioning Tasks

Observation

1. On-line and Inquiry status

Activate the OMT Main window. The system Initialization will

completed in about 2 minutes.

Click “Connect” button to enquire the repeater’s status. Proceed if

there is no alarm; else check the failure and attend to the alarm.

2. Isolation detection

Detect isolation of service antenna and donor antenna.

3. Set Channel No.

Keep RF switch ON and set the channel number of the repeater’s

operating frequency.

4. Adjust Downlink Output

Power and align donor

antenna

Observe DL input power from measured value. Align the direction

of donor antenna until the DL input power reading is maximized.

Note: To ensure that the measured DL input power is accurate,

one should set the DL ATT to “0” before performing the check.

5. Configure [Equipment ID]

Go to [Properties Info] and set [Equipment ID].

6. Comm. Config

Enable the power supply by selecting “On” in [RF] -> [Switch]; go to

[Properties Info.] -> [Comm. Config.] and set OMC Phones No. ,

the service No. of SMSC, Report Mode.

7. Select Monitoring

Parameters

Select the equipment controlled and monitored parameters.

If the external devices are connected to the equipment for

management, please enable in the [External Alarm Info.] Interface.

8. Test coverage area field

intensity and adjust

service antenna.

Use test-handset to verify field intensity within the coverage area. If

needed, realign the service antenna to achieve the desired

coverage.

Note: If during operation, the equipment gain could not be set to

maximmum or the output power is not high enough due to

insufficient donor and service antennas isolation, then the

antennas’ position should be changed to increase isolation. If the

output power is too high and ALC is activated, then adjust the DL

ATT to achieve optimal DL Gain.

9. Verify UL gain and ensure

test call produces good

voice quality and there is

no interfering BTS

Adjust UL gain and perform test calls. Typically, the UL gain is set

around 5dB less than DL gain. Perform test calls in the coverage

area while adjusting UL gain if required.

Note: If the repeater is near the BTS and the test call performance

is poor, this may be due to UL noise interference to the BTS. Users

can calculate and determine if the repeater UL noise will interfere

with the BTS.

Verify again that there is no unacceptable interference to BTS.

Table 6: Commissioning Procedure

End of Section

5 WEB GUI

mBDA can be monitored and controlled by WEB GUI, follow below contents to achieve system parameter

setting and commissioning.

5.1 WEB GUI CONNECTION

Step 1: Connect PMU OMT port to PC RJ45 port with the supplied Ethernet cable to set up a physical

connection.

Step 2: Open browser (browser IE7.0, IE8.0, Chrome or Firefox, suggest disply resolution is 1024×768),

input Web GUI IP address: 192.168.8.101, click [Enter].

Figure 25: Input IP Address

NOTE: DHCP and DNS are also available to login Web GUI. The domain name is: www.combaomt.com.

Input User Name: admin; Password (default password: admin). Click [Log in].

Figure 26: Input Domain Name

Figure 27: Input User Name and Password

USER MANUAL FORMBDA-EAWS

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 35

5.2 WEB GUI INTRODUCTION

After log in, the Web GUI main screen will appear. We take dual bands products for example.

Figure 28: Web GUI Main Screen

On Comba Web GUI Home Screen, there are four Menu bars:

[Devices], [Commissioning], [Firmware] and [Management].

5.2.1 [DEVICES]

The [Devices] Screen shows the actual active modules of mBDA.

USER MANUAL FORMBDA-EAWS

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 36

This part shows

PMU alarm status

This part shows

PMU basic

This part shows

configuration of PMU

Click here to

enable/disable

PMU Main Management Screen

Figure 29: [Devices] Sceen

RF Unit Management Screen

Figure 30: Power & Monitoring Unit

USER MANUAL FORMBDA-EAWS

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 37

PA

informati

RFU

Slot

RFU

RF

Commission

Figure 31: RF Unit

NOTE: There are three statuses for PA Service: Normal, Recovery and Shutdown. If PA output power

or reflected power exceeds the threshold, software will trigger Recovery:

It will reset PA and then re-detect the PA output power and reflected power, if they are normal, the PA

Service Status will turn to Normal, if PA output power or reflected power is still over the threshold, PA

Service Status will turn to Recovery again.

If PA output power or reflected power is still over the threshold after six times of PA Recovery, PA

Service status will be Shutdown which will need to be reset manually. Reset at Management > PA

Reset.

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 38

RF parameter

850MHz RFU

Click

check

band

Alarm

configuration

relative

USER MANUAL FORMBDA-EAWS

information and

setting table of

Figure 32: RF Unit Detail Information

5.2.2 [COMMISSIONING]

A work flow of the commissioning process is shown on [Commissioning] Screen. Click the [Start] button,

the software will guide you through the commissioning step by step. For details, please refer to chapter

5.3.

Figure 33: [Commissioning] Screen

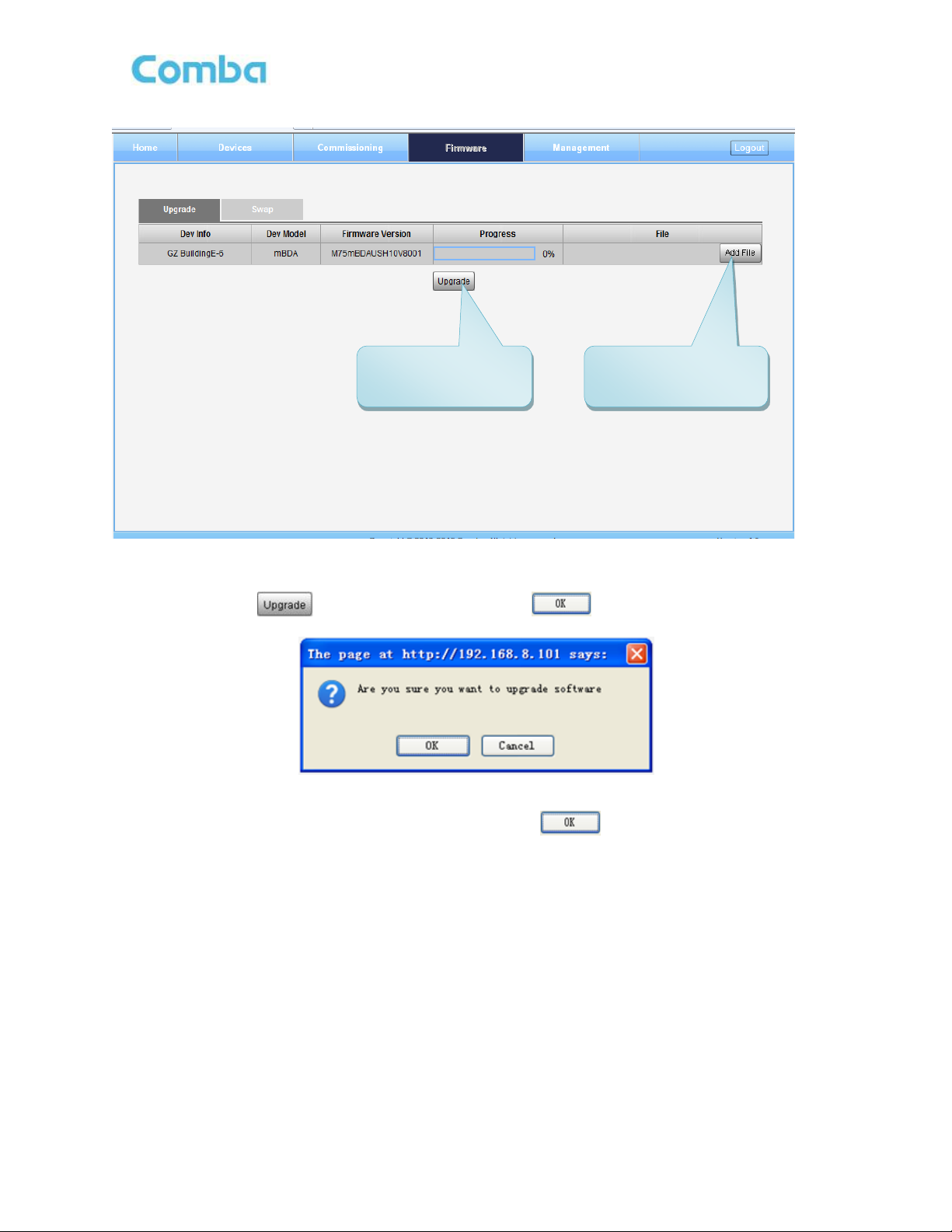

5.2.3 [FIRMWARE]

There are two functions on the [Firmware] bar: [upgrade] and [swap]. [Upgrade] is used to upgrade

software, and [Swap] is to replace current firmware version to the previous one.

USER MANUAL FORMBDA-EAWS

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 39

Step 1: Click to select

software to be updated

Step 2: Click to

upgrade software

Follow steps shown in below figure to upgrade firmware.

Figure 34: [Firmware] Screen – Upgrade

Step 4: After clicking , a window will pop up and click .

Figure 35: [Firmware] Screen – Pop-up Window 1

Step 5: Wait for 2~4 minutes while mBDA is being reset. Click to continue.

Step 6: Clear browsing history and cookies from browser.

NOTE: For PMU software upgrade, users need to re-login Web GUI after reset is done.

Follow steps shown in below figure to Swap firmware.

USER MANUAL FORMBDA-EAWS

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 40

Figure 36: [Firmware] Screen - Swap

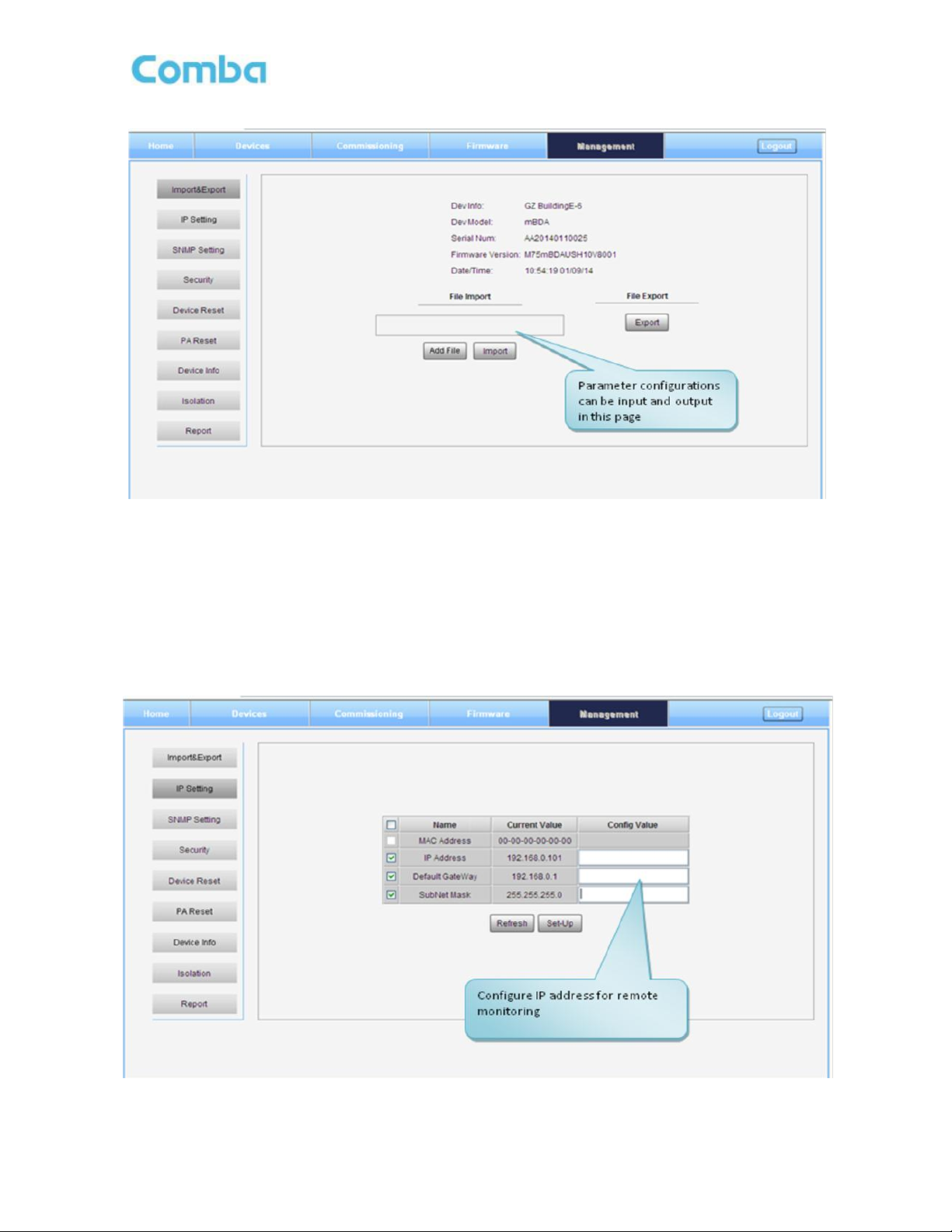

5.2.4 [MANAGEMENT]

Other parameters can be configured on [Management] Screen.

There are nine function bars list in the left side of the [Mangement] Screen. Below figures are the

introduction of each function bar.

Inport&Export

Figure 37: [Management] Sceen

USER MANUAL FORMBDA-EAWS

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 41

Figure 38: Management – Import&Export

The parameters that can be import/export as below: sub band, alarm enable, ATT value, RF switch, DL

output power and so on.

Import and Export can help users quickly configure mBDA parameters. For example, if one mBDA

finished configuration, users can export its parameters and save as a file in PC, and then import this file to

other mBDA to fast finish the device parameter setting.

IP Setting

Figure 39: Management – IP Setting

USER MANUAL FORMBDA-EAWS

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 42

Note: For remote monitoring, the IP Address must be set correctly according to the location IP of remote

connection. If more than one equipment is connected to the public network through the same router, the

router’s local IP CANNOT be set as 192.168.8.*.

SNMP Setting

Figure 40: Management – SNMP Setting

Security

Figure 41: Management – Security

Click , [Modify Password] window will pop-up.

USER MANUAL FORMBDA-EAWS

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 43

Note: Username cannot be modified.

Device Reset

Figure 42: Modify Password

Note: If users click , all the parameter and alarm will set to factory default value. Device Reset

process will last about 2~4 minutes. For PMU monitor reset, users need to re-login WEB GUI.

Figure 43: Management – Device Reset

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 44

PA Reset

USER MANUAL FORMBDA-EAWS

Figure 44: Management – PA Reset

Note: PA will be turned off by software when PA output power or (VSWR) reflected power is exceed the

threshold. Users need to reset PA after debugging.

Device Info

Figure 45: Management – Device Info

USER MANUAL FORMBDA-EAWS

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 45

Note: Users can input maximum 30 bytes characters in Device Info.

Isolation

Figure 46: Management – Isolation

Note: This Step is the same as step3 of [Commissioning]. Users can check isolation again by clicking

Check button.

Report

Figure 47: Management – Report

USER MANUAL FORMBDA-EAWS

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 46

Note: Click Create to create report (The report cann’t create in IE browser.) and make sure the computer

has installed PDF Reader software. If no, users will see nothing.

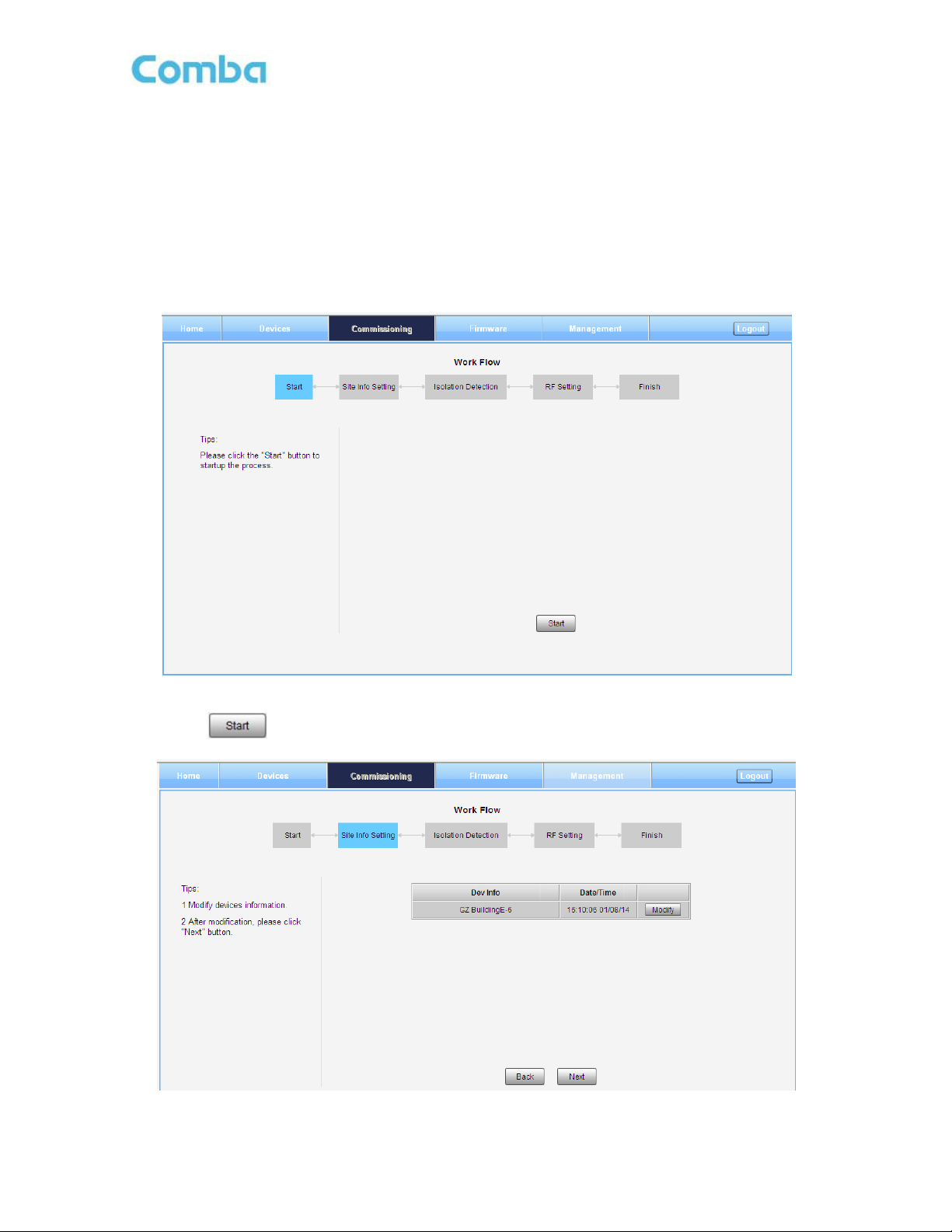

5.3 COMMISSIONING PROCEDURE

To complete the installation and commissioning, users need to follow the steps below.

Step 1: Click Menu bar [Commissioning] on home screen, a work flow will show up.

Figure 48: Commissioning Procedure – Start

Step 2: Click to start the process.

Figure 49: Commissioning Procedure – Site Info. Setting

USER MANUAL FORMBDA-EAWS

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 47

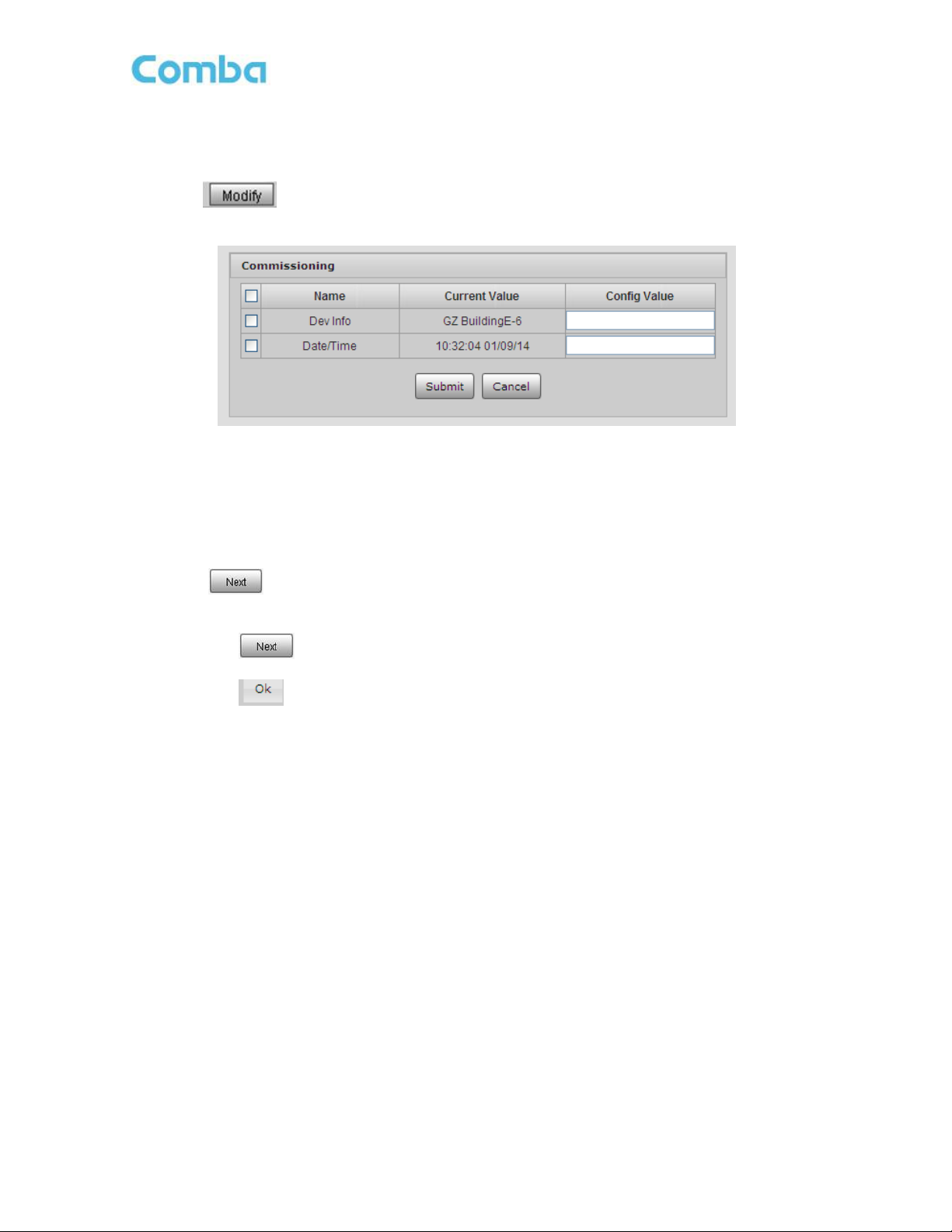

Step 3: Click , users can set the site information.

Figure 50: Dev Info & Date/Time

Dev Info mainly used to record device location and Date/Time provid a time reference. Click the Config

Value of Date/Time, will update Date/time automatically.

NOTE: Make sure the device is connected with appropriate donor and service antennas before

proceeding to step 4.

Step 4: Click to enter to Isolation Detection Screen shown as Figure 52.

Select a frequency band (RFU) that need to commission.

Click to start Isolation Detecting, then [Confirm] window will pop-up shown as Figure

53.

Click to continue. If isolation detection success, the process will go to RF Settiing

Screen shown as Figure 55. If failed, a Tips window will pop-up shown as Figure 54, users

need to check whether the system isolation is very weak.

NOTE: At the end of first frequency band commissioning, user can start other frequency band

commission.

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 48

USER MANUAL FORMBDA-EAWS

Figure 51: Commissioning Procedure – Isolation Detective

Figure 52: Commissioning Procedure – Isolation Detective Confirm

Figure 53: Commissioning Procedure –Isolation Detection Failed

USER MANUAL FORMBDA-EAWS

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 49

Step1: Select a sub

band to modify RF

Step2: Configure RF

parameter in this table

Step 3: Click submit to finish

RF setting of selected sub

Figure 54: Commissioning Procedure –Isolation Detection Finish

Step 5: RF Setting Screen for setting subband bandwidths and switchs.

Figure 55: Commissioning Procedure – Subband bandwidth and Switch Setting

USER MANUAL FORMBDA-EAWS

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 50

NOTE: For each RF module, the 3 subband bandwidth setting should not be overlap each other, if yes,

only 1 subband can be turn on, other overlap subband is forbided to switch on by equipment.

Step 6: Click to enter to DL output power setting after finishing subband bandwidths and switchs

setting.

Figure 56: Commissioning Procedure – DL Output Power Setting Screen

USER MANUAL FORMBDA-EAWS

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 51

Step1: Select a

channel with switch on

Step2: Fill the value of

parameter

Step 3: Click submit to

finish DL output power

Figure 57: Commissioning Procedure – DL Output Power Setting

NOTE: For each RF module, the total target output power of all subbands which channel switch is on

must not exceed the nominal downlink output power (27, 30, 33dBm); if yes, Tips window will pop-up

shown as Figure 59. Finish the output power setting, click button , go to Finish Screen shown as

Figure 60.

Figure 58: DL Output Power Over Exceed

Step 7: Click to commission other RFUs parameters. Click to finish the

commissioning.

USER MANUAL FORMBDA-EAWS

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 52

Figure 59: Commissioning Procedure – Finish

End of Section

USER MANUAL FORMBDA-EAWS

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 53

Alarm List

Alarm Condition

RF Unit Alarm

Alarm when any RF unit is alarm, otherwise normal;

Alarm judgment period: Immediately;

Ext Alarm

Alarm status when the external terminals have the same H/L level with alarm

level, otherwise normal;

Alarm period: 10s by default.

Fan Alarm

Alarm when the Fan has broken, otherwise normal; Fan2 is close to MCU.

Another one is Fan1;

Alarm period: 10s by default.

Over-Temperature

Alarm

Alarm when equipment temperature is higher than the threshold, otherwise

normal;

Alarm judgment period: 3 minutes by default;

Alarm threshold : 80℃ by default.

Alarm List

Alarm Condition

Over DL P_in

Alarm

Alarm when DL input power is higher than the threshold, otherwise normal;

Alarm judgment period: 3 minutes by default;

Alarm threshold: -30dBm by default.

PLL Alarm

Alarm when PLL circuit is broken, otherwise normal;

Alarm judgment period: 3 minutes by default;

LNA Alarm

Alarm When LNA is broken, otherwise normal;

Alarm judgment period: 3 minutes by default;

DL PA Alarm

Alarm when PA Over-temperature Alarm, PA DL output power overload

Alarm, Reflection Power Alarm happens, otherwise normal;

Alarm judgment period: 3 minutes by default.

VSWR Alarm

Alarm when the DL reflection power is higher than the threshold, otherwise

normal;

Alarm judgment period: 3 minutes by default;

Alarm threshold: 2.0 by default.

Protection Shut

Alarm

Alarm when the PA status is off itself, otherwise normal;

Alarm judgment period: 10s by default.

6 MAINTENANCE

The mBDA is designed for trouble-free operation and generally does not need maintenance. Maintenance

activities should only be carried out by trained personnel.

The equipment operation status can be observed remotely through OMC.

Periodic inspection of the repeater equipment(s) is recommended, the recommended tasks includes:

Inspect and record operation status and output power of the repeater from OMC or OMT.

Verify the direction and position of antennas. Re-align if necessary.

Make sure the cable gland and sealing on the RF cable connectors are not damaged.

Verify lightning and grounding protection is in good condition.

6.1 ALARMS

Table 7: Monitoring Unit Alarm List

6.2 TROUBLESHOOTING

Table 8: RF Unit Alarm List

USER MANUAL FORMBDA-EAWS

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 54

Alarm condition

Diagnosis

RF Unit Alarm

Check RF Unit alarm on WEB GUI.

Ext Alarm

Check to make sure if the external device connected is working normally.

Fan Alarm

Check to make sure the fan is working normally.

OverTemperature

alarm

Check temperature on WEB GUI

If device temperature is over threshold, make sure environment temperature is within the

envireonment temperature range that device supported (-20~40℃). Apply climatic protection

to the system under severe environment.

Alarm condition

Diagnosis

Over DL P_in

Alarm

Test DL input power of the alarm RF Unit, if it is higher than threshold, changing the threshold

value; when the DL input power is more than -40dBm, it is recommended to add an external

attenuator with proper attenuating value.

PLL Alarm

Check device on WEB GUI;

Restart the device, if the PLL alarm is not fixed, replace the RF Unit.

LNA Alarm

Check device on WEB GUI;

Restart the device, if the LNA alarm is not fixed, replace the RF Unit.

DL PA alarms

Check PA Service Status on WEB GUI RU page,

If it is [Recovery], reset PA on WEB GUI Management page, then read RF Unit output power:

If output power is exceed threshold, need to reduce gain or input power; if output power is

normall, check whether antenna port VSWR is too high.

If it is [Shutdown], Refer to Protection Shut Alram

Protection Shut

Alarm

Make Sure the environment temperature is -20~40℃

Reset PA, if PA service status turns to [Recovery], and then refer to DL PA Alarms. If PA still

shutdown, the PA part maybe broken, please replace the RU.

Following installation and commissioning, occasional operation tasks to handle alarms may be required:

Table 9: Monitor Unit Alarms Diagnosis

Table 10: RF Unit Alarms Diagnosis

End of Section

USER MANUAL FORMBDA-EAWS

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 55

7 APPENDICES

7.1 APPENDIX A: TOOLS FOR INSTALLATION AND MAINTENANCE

The following tools (not included in package) are required for installation or routine maintenance:

Power Drill (for wall mount)

Adjustable Wrench (0.31 inch~0.79 inch)

Philips Screwdriver

Allen wrench (M6)

Signal generator support output power 10dBm.

Site Master

USER MANUAL FORMBDA-EAWS

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 56

7.2 APPENDIX B: RMA (RETURN MATERIAL AUTHORIZATION)

FOR NAM OFFICE EMAIL, PLEASE INSERT: support.us@comba-telecom.com

End of Section

End of Document

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 57

USER MANUAL FORMBDA-EAWS

USER MANUAL FORMBDA-EAWS

ENU STATUS : 1-0-1

Copyright - refer to title page

Page 58

Loading...

Loading...