Page 1

InteliSys-NTC

Hybrid

Hybrid Master Controller

SW version 2.2.0

1 Document information 6

2 System overview 10

3 Installation and wiring 13

4 Controller setup 26

5 Technical data 157

6 Appendix 158

Copyright © 2020 ComAp a.s.

Written by Vladimír Zubák

Prague, Czech Republic

ComAp a.s., U Uranie 1612/14a,

170 00 Prague 7, Czech Republic

Tel: +420 246 012 111

E-mail: info@comap-control.com, www.comap- control.com

Global Guide

Page 2

Table of contents

1 Document information 6

1.1 Clarification of Notation 6

1.2 About this guide 6

1.3 Legal notice 6

1.4 Dangerous voltage 8

1.4.1 Adjust the setpoints 8

1.5 Document history 8

1.6 Firmware and Archives 9

1.6.1 BaseBox type controllers 9

2 System overview 10

2.1 What is a Hybrid application? 10

2.1.1 How do ComAp controllers support Hybrid applications? 10

2.1.2 How the InteliSys NTC Hybrid controller works? 11

2.2 Configurability and monitoring 11

2.2.1 GenConfig 11

2.2.2 InteliMonitor 12

2.2.3 WinScope 12

2.2.4 WebSupervisor 12

3 Installation and wiring 13

3.1 General 13

3.1.1 Wiring 13

3.1.2 Grounding 14

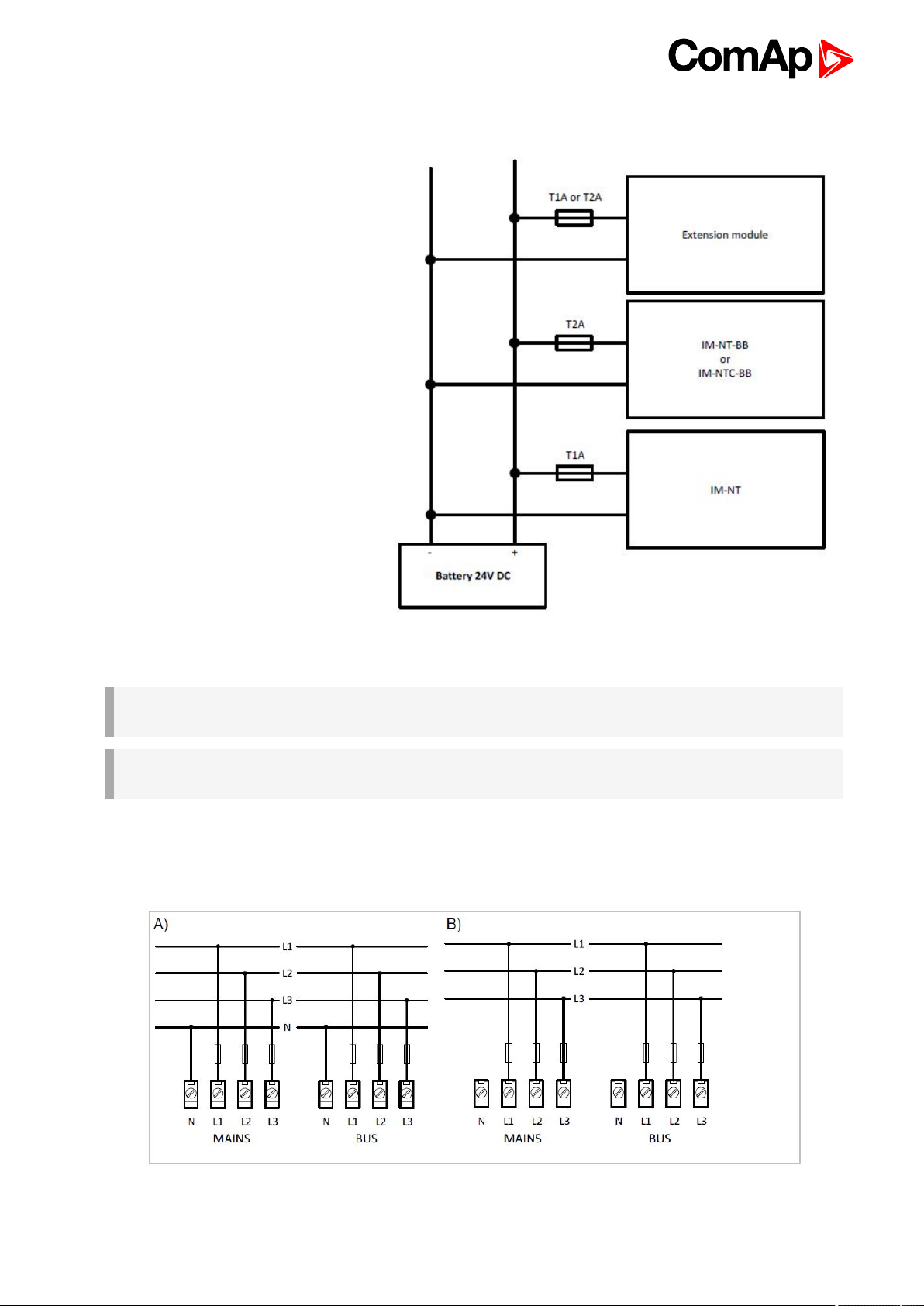

3.1.3 Power supply 14

3.1.4 Power supply fusing 15

3.1.5 Voltage and current inputs 15

3.2 InteliSys NTC Hybrid Installation Instructions 16

3.2.1 Mounting 16

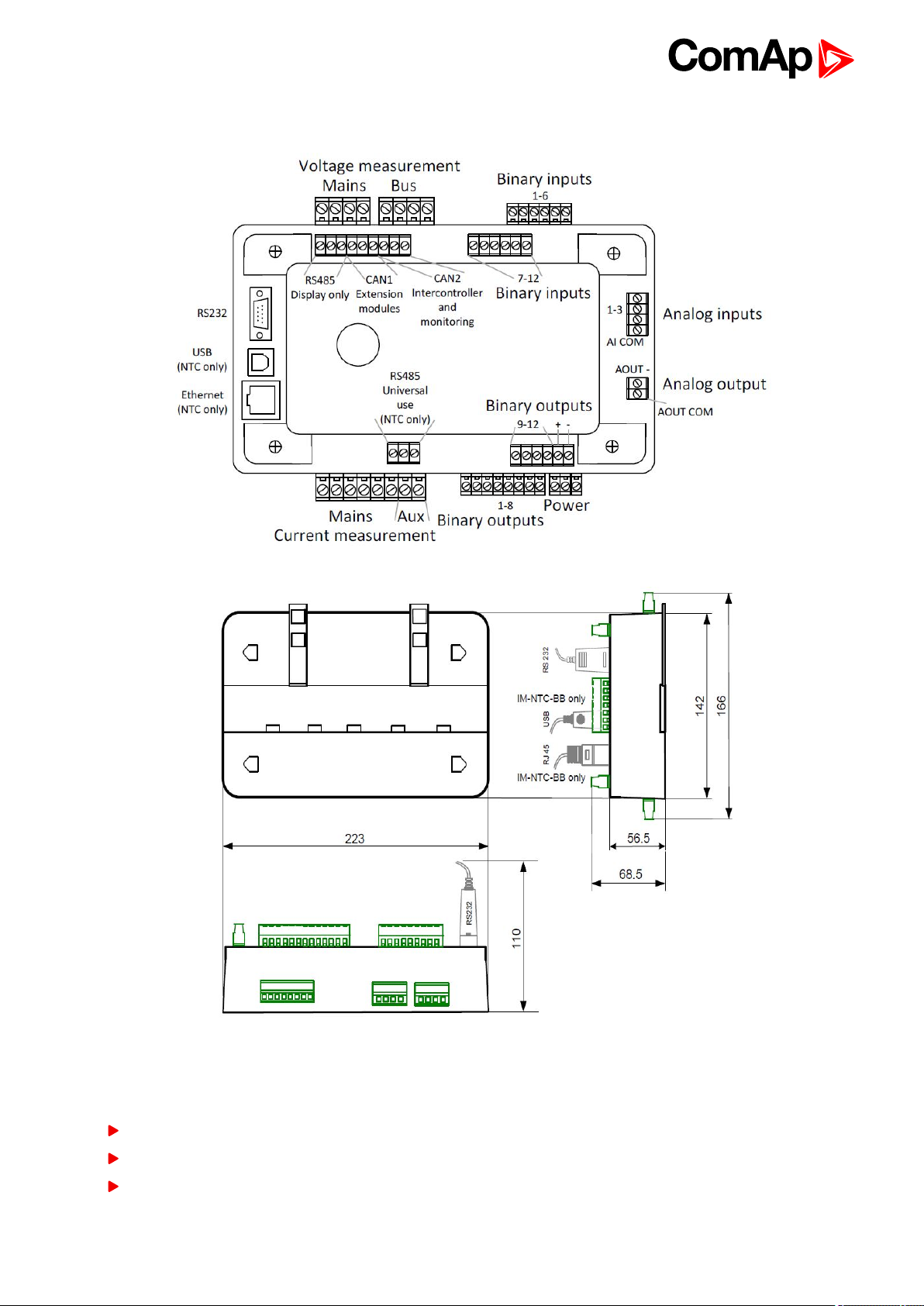

3.2.2 Terminal diagram, Dimensions 18

3.2.3 Package contents 18

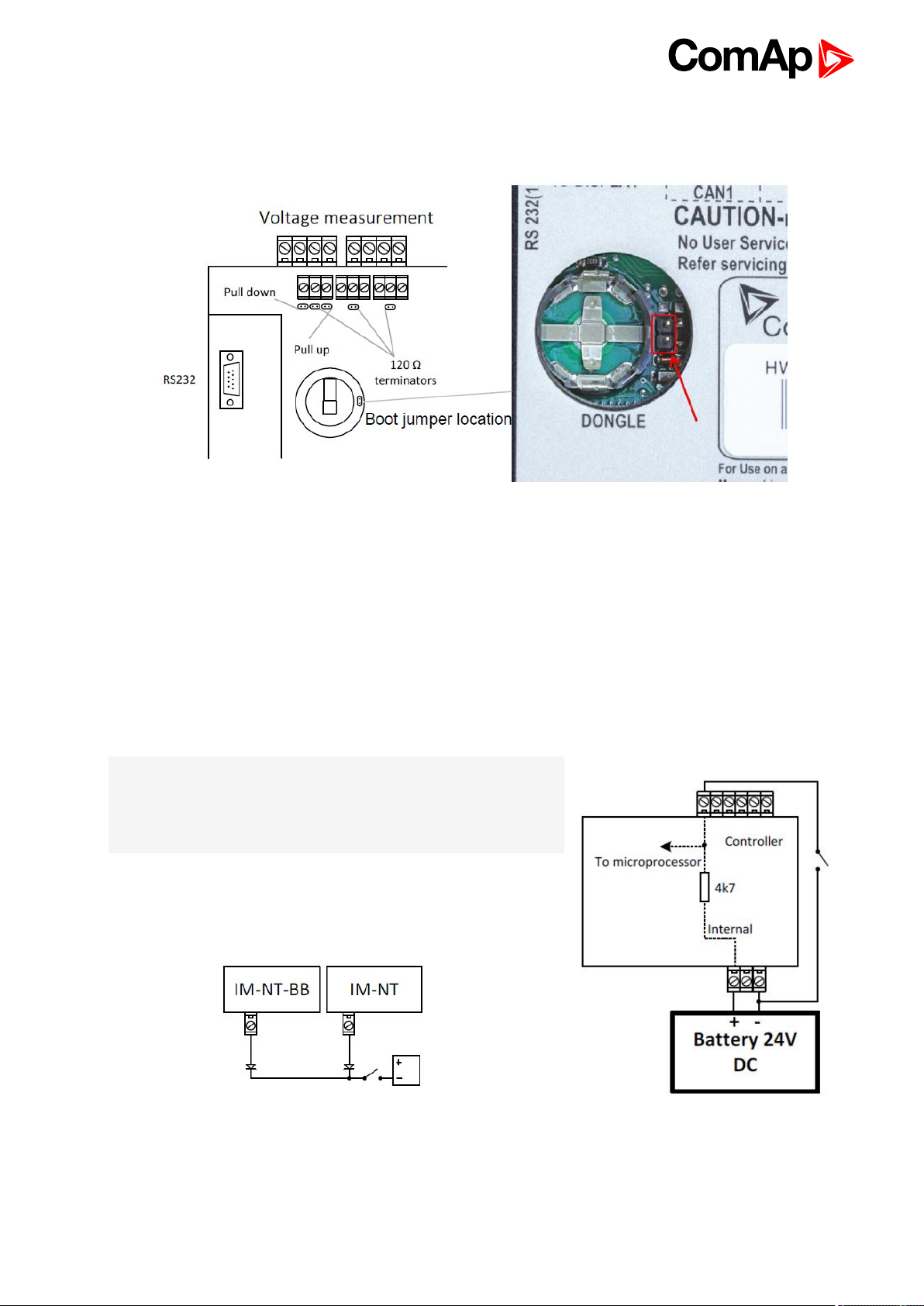

3.2.4 Jumper settings 19

3.3 Binary Input wiring 19

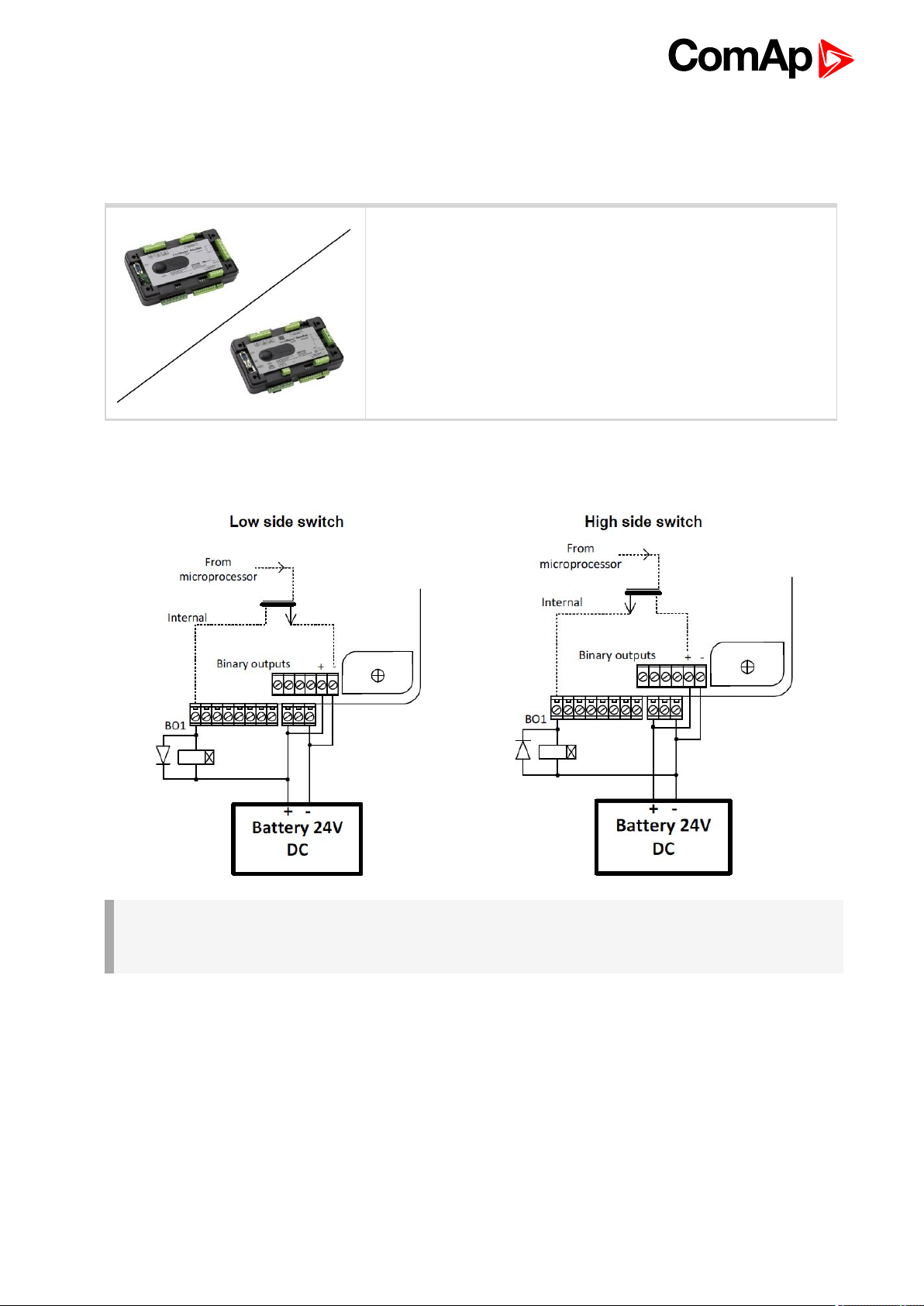

3.4 Binary Output wiring 20

3.4.1 IM-NT-BB and IM-NTC-BB 20

3.5 Analog Input and Output wiring 21

3.6 CAN and RS485 bus wiring 23

InteliSys-NTC Hybrid 2.1.0 Global Guide

2

Page 3

3.6.1 Wiring examples 24

4 Controller setup 26

4.1 Connection to a controller usingPC 26

4.1.1 Direct connection 26

4.1.2 Modem connection 27

4.1.3 Internet connection 28

4.1.4 Airgate connection 29

4.1.5 Connection to multiple controllers 29

4.2 Modification of configuration, setpoints etc 30

4.3 Programming of a controller 31

4.3.1 Standard programming 31

4.3.2 Programming of non-responsive controller 32

4.4 Changing the language 34

4.4.1 Selection of the language in InteliSysNTC Hybrid 34

4.5 Password management 35

4.5.1 User administration 35

4.5.2 Access group setting in GenConfig 36

4.5.3 Password break protection 37

4.6 Related tools 37

4.7 Functions 39

4.7.1 Overview 40

4.7.2 Modes 54

4.7.3 Process Limitation 58

4.7.4 System start 64

4.7.5 StartUpSynchronization 65

4.7.6 Power management 65

4.7.7 Dynamic Spinning Reserves 97

4.7.8 Remote Alarm Messaging 97

4.7.9 Controller Redundancy 99

4.7.10 System load control modes 100

4.7.11 Managing system load control modes 103

4.7.12 Renewables Active Power Control 108

4.7.13 Renewables Reactive Power Control 111

4.7.14 Multiple Mains Feeders Support 113

4.7.15 System PF control modes 115

4.7.16 Automatic Mains Failure function 117

4.7.17 Regulation loops 119

4.7.18 Force value – step by step guide 121

4.7.19 Values for continuous writing from external sources 123

InteliSys-NTC Hybrid 2.1.0 Global Guide

3

Page 4

4.7.20 General Purpose Timers 124

4.7.21 History Related functions 125

4.7.22 User Buttons 127

4.7.23 Remote Control Function 128

4.7.24 Virtual Peripheral Inputs-Outputs (VPIO) module 129

4.7.25 Shared Inputs and Outputs 129

4.7.26 Distributed Binary Inputs and Outputs 131

4.7.27 MODBUS 132

4.7.28 Analog Input Sensors and User Sensors 134

4.7.29 Languages and Translator tool in GenConfig 134

4.7.30 System Start/Stop 135

4.7.31 Power Formats 135

4.7.32 Soft Unload with support of IAux measurement 136

4.7.33 System Isolated 138

4.7.34 User Mask function 138

4.7.35 Switchable Current measurement ratio 139

4.7.36 PLC functions 139

4.8 Renewables Interface 139

4.8.1 Required communication lines 139

4.8.2 Configuration for communication with the InteliFieldbus Gateway 140

4.9 Protections and Alarm management 142

4.9.1 Supported protections 142

4.9.2 Protection groups 143

4.9.3 Protection types 143

4.9.4 Default protections in MCB/MGCB applications 144

4.9.5 Mains voltage and frequency protections - limits and indications 144

4.9.6 Bus voltage and frequency protections - limits and indications 145

4.9.7 User configurable protections 146

4.9.8 Reset Actual Alarms selection 148

4.9.9 Bus Measurement Error detection 149

4.9.10 Peripheral Modules Error detection 149

4.10 MGCB/MCB fail detection 149

4.10.1 MCB fail Information 149

4.10.2 General Information 150

4.10.3 Function for breaker control in AUT mode 155

4.10.4 Function for breaker control in MAN mode 155

4.11 Controller operation states 156

5 Technical data 157

InteliSys-NTC Hybrid 2.1.0 Global Guide

4

Page 5

6 Appendix 158

Controller objects 159

6.1 List of controller objects types 159

6.1.1 Setpoints 160

6.1.2 Values 349

6.1.3 Logical binary inputs 415

6.1.4 Logical binary outputs 462

6.1.5 Logical analog inputs 500

InteliSys-NTC Hybrid 2.1.0 Global Guide

5

Page 6

1 Document information

1.1 Clarification of Notation 6

1.2 About this guide 6

1.3 Legal notice 6

1.4 Dangerous voltage 8

1.5 Document history 8

1.6 Firmware and Archives 9

1.1 Clarification of Notation

Note: This type of paragraph calls the reader’s attention to a notice or related theme.

IMPORTANT: This type of paragraph highlights a procedure, adjustment etc., which can cause a

damage or improper function of the equipment if not performed correctly and may not be clear at

first sight.

Example: This type of paragraph contains information that is used to illustrate how a specific function

works.

1.2 About this guide

Pressing F1 in the GenConfig and InteliMonitor Setpoints, Values or configuration window will open the help

with the context of currently selected Setpoint, value and binary input or output function.

1.3 Legal notice

This End User's Guide/Manual as part of the Documentation is an inseparable part of ComAp’s Product and

may be used exclusively according to the conditions defined in the “END USER or Distributor LICENSE

AGREEMENT CONDITIONS – COMAP CONTROL SYSTEMS SOFTWARE” (License Agreement) and/or in

the “ComAp a.s. Global terms and conditions for sale of Products and provision of Services” (Terms) and/or in

the “Standardní podmínky projektů komplexního řešení ke smlouvě o dílo, Standard Conditions for Supply of

Complete Solutions” (Conditions) as applicable.

ComAp’s License Agreement is governed by the Czech Civil Code 89/2012 Col., by the Authorship Act

121/2000 Col., by international treaties and by other relevant legal documents regulating protection of the

intellectual properties (TRIPS).

The End User and/or ComAp’s Distributor shall only be permitted to use this End User's Guide/Manual with

ComAp Control System Registered Products. The Documentation is not intended and applicable for any other

purpose.

Official version of the ComAp’s End User's Guide/Manual is the version published in English. ComAp reserves

the right to update this End User's Guide/Manual at any time. ComAp does not assume any responsibility for its

use outside of the scope of the Terms or the Conditions and the License Agreement.

Licensed End User is entitled to make only necessary number of copies of the End User's Guide/Manual. Any

translation of this End User's Guide/Manual without the prior written consent of ComAp is expressly prohibited!

InteliSys-NTC Hybrid 2.1.0 Global Guide

6

Page 7

Even if the prior written consent from ComAp is acquired, ComAp does not take any responsibility for the

content, trustworthiness and quality of any such translation. ComAp will deem a translation equal to this End

User's Guide/Manual only if it agrees to verify such translation. The terms and conditions of such verification

must be agreed in the written form and in advance.

For more details relating to the Ownership, Extent of Permitted Reproductions Term of Use of the

Documentation and to the Confidentiality rules please review and comply with the ComAp’s License

Agreement, Terms and Conditions available on www.comap-control.com.

Security Risk Disclaimer

Pay attention to the following recommendations and measures to increase the level of security of ComAp

products and services.

Please note that possible cyber-attacks cannot be fully avoided by the below mentioned recommendations and

set of measures already performed by ComAp, but by following them the cyber-attacks can be considerably

reduced and thereby to reduce the risk of damage. ComAp does not take any responsibility for the actions of

persons responsible for cyber-attacks, nor for any damage caused by the cyber-attack. However, ComAp is

prepared to provide technical support to resolve problems arising from such actions, including but not limited to

restoring settings prior to the cyber-attacks, backing up data, recommending other preventive measures against

any further attacks.

Warning: Some forms of technical support may be provided against payment. There is no legal or factual

entitlement for technical services provided in connection to resolving problems arising from cyber-attack or

other unauthorized accesses to ComAp's Products or Services.

General security recommendations and set of measures

1. AccessCode

• Change the AccessCode BEFORE the device is connected to a network.

• Use a secure AccessCode – ideally a random string of 8 characters containing lowercase, uppercase letters

and digits.

• For each device use a different AccessCode.

2. Password

• Change the password BEFORE the device enters a regular operation.

• Do not leave displays or PC tools unattended if an user, especially administrator, is logged in.

3. Controller Web interface

• The controller web interface at port TCP/80 is based on http, not https, and thus it is intended to be used only

in closed private network infrastructures.

• Avoid exposing the port TCP/80 to the public Internet.

4. MODBUS/TCP

• The MODBUS/TCP protocol (port TCP/502) is an instrumentation protocol designed to exchange data

between locally connected devices like sensors, I/O modules, controllers etc. From it’s nature it does not

contain any kind of security – neither encryption nor authentication. Thus it is intended to be used only in closed

private network infrastructures.

• Avoid exposing the port TCP/502 to the public Internet.

5. SNMP

• The SNMP protocol (port UDP/161) version 1,2 is not encrypted. Thus it is intended to be used only in closed

private network infrastructures.

• Avoid exposing the port UDP/161 to the public Internet.

InteliSys-NTC Hybrid 2.1.0 Global Guide

7

Page 8

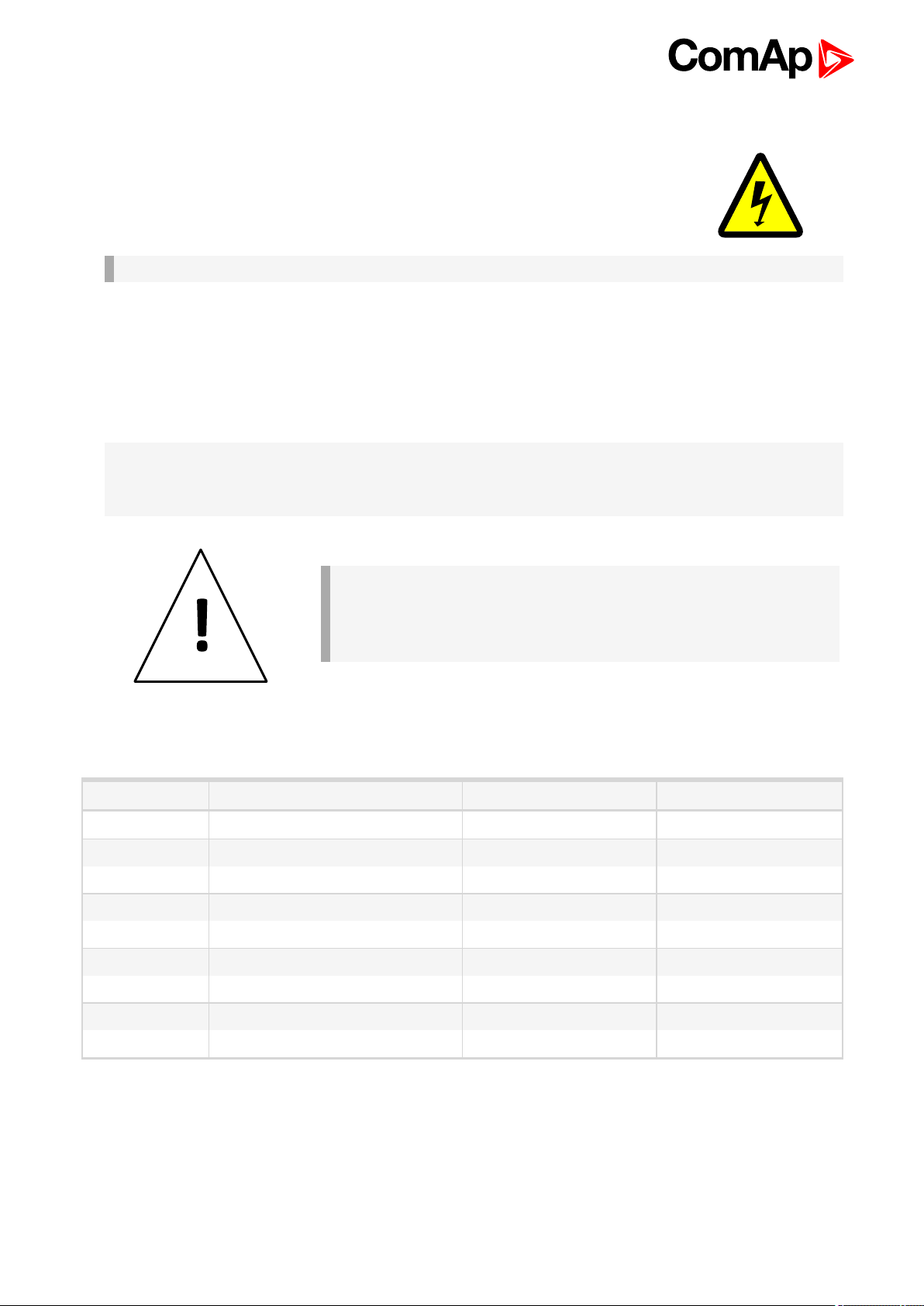

1.4 Dangerous voltage

In no case touch the terminals for voltage and current measurement!

Always connect grounding terminals!

In any case do not disconnect controller CT terminals!

IMPORTANT: InteliSys-NTC Hybrid can be installed only in an area inaccessible by a layman!

1.4.1 Adjust the setpoints

All parameters are adjusted to their typical values. However the setpoints has to be checked and adjusted to

their real values before the first starting of the gen-set.

The following instructions are for qualified personnel only. To avoid personal injury do not perform any action not

specified in related guides for product.

Note: ComAp believes that all information provided herein is correct and reliable and reserves the right to

update at any time. ComAp does not assume any responsibility for its use unless otherwise expressly

undertaken.

IMPORTANT: Warning!

There is a fire hazard risk in case of changing battery of wrong type

or polarity!

Disposal of batteries must be done according to their instructions.

1.5 Document history

Revision Related SW version Date Author

9 2.1.0 25.6.2020 Vladimír Zubák

8 2.1.0 November 2019 Lukáš Vančura

7 2.1.0 15.10.2019 Lukáš Vančura

6 2.1.0 18.9.2019 Vladimír Zubák

5 2.1.0 2.8.2018 Vladimír Zubák

4 3.5.0 14.3.2017 Pavel Mareš

3 3.4.0 6.11.2015 Tomáš Vydra

2 3.3.1 4.9.2015 Tomáš Vydra

1 3.2.0 30.3.2015 Tomáš Vydra

InteliSys-NTC Hybrid 2.1.0 Global Guide

8

Page 9

1.6 Firmware and Archives

Since the version 3.0, controller firmware was differentiated for BaseBox type controllers and GC (Graphical

Character, with built-in display) controllers. These firmwares are compatible but their functions differ slightly. It

is not possible to upload BaseBox type firmware to GC controller and vice versa.

1.6.1 BaseBox type controllers

InteliSys-NTC Hybrid-BaseBox and InteliSys-NTC Hybrid-

BaseBox

The firmware for these controllers has specific functions available which are not available in Graphical

Character type controllers. The list of BaseBox-exclusive function is as follows:

Peak Shaving based on kVA

Distributed Binary Inputs and Outputs

User Modbus

InteliSys-NTC Hybrid 2.1.0 Global Guide

9

Page 10

2 System overview

2.1 What is a Hybrid application? 10

2.2 Configurability and monitoring 11

6 back to Table of contents

2.1 What is a Hybrid application?

Hybrid application combines conventional and non-conventional source for power generation. The most typical

application is with diesel gen-sets and photovoltaic plant as illustrated below.

Information about ComAp solution for hybrid applications can be found here: Hybrid power plant using ComAp’s

hybrid solution.

For complete description of hybrid applications see our Hybrid Application Guide.

2.1.1 How do ComAp controllers support Hybrid applications?

There are two different scenarios based on the position ComAp controllers are in – master or slave. This

document refers to and provides assistance with the set up of applications where ComAp InteliSys-NTC Hybrid

controller works as a master controller providing interface to gen-set controllers, as well as to renewable energy

source, and as such provides overall control of the hybrid application. Power management is provided by “slave”

InteliSys and InteliGen-set controllers with the IGS-NT-Hybrid firmware, which receives required value of

Dynamic Spinning Reserve from the InteliSys-NTC Hybrid.

Information about suitable genset controllers for hybrid applications and instructions for setup can be found in

the IGS-NT-Hybrid User guide.

InteliSys-NTC Hybrid 2.1.0 Global Guide

10

Page 11

2.1.2 How the InteliSys NTC Hybrid controller works?

The main duty of the IS-NTC-Hybrid is to collect information from the PV inverters (status, actual PV output,

statics, etc.), calculate accordingly the required DSR and share it with the other ComAp genset controllers over

CAN bus. The gen-set controllers are then responsible for optimum power management of the gen-sets with

respect to the renewable energy source, which output utilization must be maximized, and only in case the gen-

sets face the thread of being underloaded, the IS-NTC-Hybrid would curtail the output from the PV plant. The

limitation of the renewable energy source is based on a calculation considering the minimum allowed genset

loading level (Min GS Power setpoint) to prevent the gen-sets from underloading, resp. to protect the wind

turbine in high wind speeds.

2.2 Configurability and monitoring

One of the key features of the controller is the system’s high level of adaptability to the needs of each individual

application and wide possibilities for monitoring. This can be achieved by configuring and using the powerful

ComAp PC/mobile tools.

Supported configuration and monitoring tools:

GenConfig (page 11) – complete configuration and firmware upgrade

InteliMonitor (page 12) – multiple site monitoring and setpoint setting

WinScope (page 12)– special graphical monitoring software

WebSupervisor (page 12) – web-based system for monitoring and controlling

WebSupervisor mobile – supporting application for smartphones

Note: Use the GenConfig PC software to read, view and modify configuration from the controller or disk and

write the new configuration to the controller or disk.

2.2.1 GenConfig

Configuration and monitoring tool for InteliSys-NTC Hybrid, InteliGenNT and other controllers.

Functions provided by GenConfig

Direct, modem or internet communication with the controller

Offline or online controller configuration

Controller firmware upgrade

Reading/writing/adjustment of setpoints

Binary/Analog Inputs and Outputs logical functions adjustments

Exporting data into a XLS file

Controller language translation

Screen Editor for editing InteliVision 5 a 8 screens

PLC Editor for editing built-in PLC functions

Updating and configuration of InteliVision 8 firmware

User Protections, User sensor curves, password protection and

history management

InteliSys-NTC Hybrid 2.1.0 Global Guide

11

Page 12

2.2.2 InteliMonitor

PC Monitoring tool for Inteli controllers.

Functions provided by InteliMonitor

Online monitoring of a controller or whole site

Fully customizable SCADA diagram

Reading/writing/adjustment of setpoints

Reading of measured values

Browsing of controller history records

2.2.3 WinScope

Special graphical controller monitoring software.

Functions provided by WinScope

Monitoring and archiving of ComAp controller’s parameters and

values

View of actual/historic trends in controller

On-line change of controllers’ parameters for easy regulator

setup

2.2.4 WebSupervisor

Web-based system for monitoring and controlling ComAp controllers.

Functions provided by WebSupervisor

Site and fleet monitoring

Reading of measured values

Browsing of controller history records

On-line notification of alarms

E-mail notification

Also available as a smartphone application

6 back to System overview

InteliSys-NTC Hybrid 2.1.0 Global Guide

12

Page 13

3 Installation and wiring

3.1 General 13

3.2 InteliSys NTC Hybrid Installation Instructions 16

3.3 Binary Input wiring 19

3.4 Binary Output wiring 20

3.5 Analog Input and Output wiring 21

3.6 CAN and RS485 bus wiring 23

6 back to Table of contents

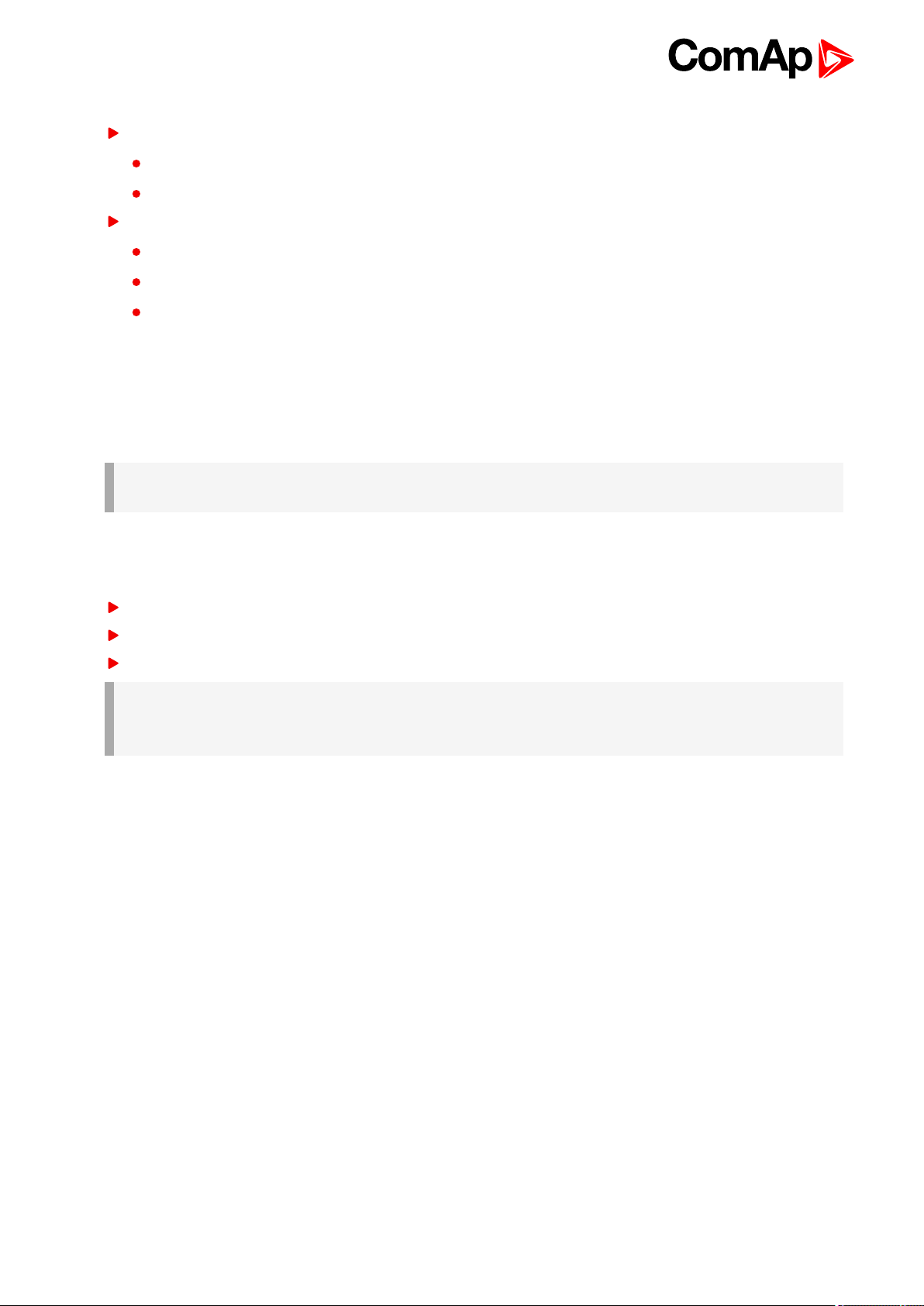

There are currently three HW versions of InteliSys-NTC Hybrid controller. Please refer to the corresponding

portion of this chapter for installation instruction for your particular controller type. Chapters relevant for both

HW configurations are marked as “(general)”.

3.1 General

Controller type Hardware features

12 Binary Outputs

12 Binary Inputs

3.1.1 Wiring

To ensure proper function:

3 Analog Inputs

1 Analog Output

Mains and Bus Voltage measurement (3-phase)

Mains Current measurement (3-phase)

Auxiliary Current measurement (1-phase)

RS485 Communication port dedicated for display

RS485 Communication port for universal use with galvanic

separation

RS232 Communication port

CAN1 Communication port (for extension modules)

CAN2 Communication port (for intercontroller

communication and monitoring)

USB Communication port

RJ45 (Ethernet) Communication port

Use grounding terminals.

Wiring for binary inputs and analog inputs must not be run with power cables.

Analog and binary inputs should use shielded cables, especially when the length is more than 3 m.

InteliSys-NTC Hybrid 2.1.0 Global Guide

13

Page 14

Tightening torque, allowable wire size and type, for the Field-Wiring Terminals:

For Mains(Bus) Voltage, Generator Voltage a Current terminals

Specified tightening torque is 0.56Nm (5.0 In-lb)

Use only diameter 2.0-0.5mm (12-26AWG) conductor, rated for 90°C minimum.

For other controller field wiring terminals

Specified tightening torque 0.79Nm (7.0 In-lb)

Use only diameter 2.0-0.5mm (12-26AWG) conductor, rated for 75°C minimum.

Use copper conductors only.

3.1.2 Grounding

The shortest possible piece of wire should be used for controller grounding. Use cable min. 2.5 mm2. A brass

M4x10 screw with star washer securing ring type grounding terminal shall be used.

The negative “-” battery terminal must be properly grounded.

IMPORTANT: Switchboard and engine must be grounded at a common point. Use as short a cable

as possible to the grounding point.

3.1.3 Power supply

To ensure proper function:

Use power supply cable min. 2.5mm

Use fuse 2 amps

Maximal continuous DC power supply voltage is 36VDC.

IMPORTANT: Switchboard lightning strikes protection according standard regulation is expected!!!

The maximum allowable current through the controller negative terminal is 3 to 8A (depends on

the controller type and binary output load).

2

InteliSys-NTC Hybrid 2.1.0 Global Guide

14

Page 15

3.1.4 Power supply fusing

Always use according fuse (1Amp or

2Amps) when connection controller,

extension modules or relays to a power

source.

3.1.5 Voltage and current inputs

IMPORTANT: Risk of personal injury due to electric shock when manipulating voltage terminals

under voltage! Be sure the terminals are not under voltage before touching them.

IMPORTANT: Do not open the secondary circuit of current transformers when the primary circuit is

closed!!! Open the primary circuit first!

Use 1.5 mm2cables for voltage connection and 2.5 mm2for current transformers connection.

Adjust nominal voltage, nominal current, CT ratio and PT ratio by appropriate setpoints in the Basic Settings

group.

InteliSys-NTC Hybrid 2.1.0 Global Guide

Image 3.1 Voltage measurement wiring

15

Page 16

IMPORTANT: Check measurement connections carefully! Failure is possible if phases are

connected in wrong order (WrongPhSequence detected by the controller) but this is not detected if

the phases are just rotated (i.e. instead of phase sequence L1, L2, L3, phase sequence is e.g. L2,

L3, L1.

3.2 InteliSys NTC Hybrid Installation Instructions

This portion of Instalation instructions is dedicated to the InteliSys-NTC Hybrid-

BaseBox and InteliSys-NTC Hybrid-NTC-BaseBox controllers without built-in

display. If you have version with built-in display of the controller, please refer to

the section 3.1.

3.2.1 Mounting

BaseBox units are prepared for mounting on DIN rain mount (35mm).

Locate two plastic holders on the back side of the

controller

Mount the unit on the DIN rail and secure by pressing

two plastic holder until they click and fix the unit into

position

Make sure both holders are in open position (right

image). If not (left image) open them by pulling them

slightly out

InteliSys-NTC Hybrid 2.1.0 Global Guide

16

Page 17

BaseBox units may also be mounted on InteliVision 5 and together with it mounted into cut-out in a

switchboard.

Use the rail provided on the back side of InteliVision 5 and

Mount InteliVision 5 into the switchboard cut-out (for

more information on InteliVision 5 mounting please

refer to the InteliVision 5 Reference Guide)

mount the controller to it while following the same steps

when mounting on standard rail (rail openings on

InteliVision 5 are fixed so there is only one possible way

how to mount the controller to it)

Locate four screw holes on the front of the controller

Insert provided screws and use them to secure the

controller mounted to InteliVision 5 (screws fit into

InteliVision 5 holder pieces)

InteliSys-NTC Hybrid 2.1.0 Global Guide

17

Page 18

3.2.2 Terminal diagram, Dimensions

3.2.3 Package contents

The package contains:

Controller

Mounting holders

Terminal blocks

InteliSys-NTC Hybrid 2.1.0 Global Guide

18

Page 19

3.2.4 Jumper settings

There are several jumpers available on the unit. Their location and purpose is described below:

Use boot jumper if controller is not responding to communication (e.g. due to faulty programming sequence).

Take off the rubber cover using screwdriver to acces boot jumper next to dongle slot.

Use 120 Ω terminators at the end of CAN1, CAN2 or RS485 buses. Do not use these terminators on units that

are not terminating the bus.

Use pull up and pull down resitors on RS485 to bias the line when no device is active on the bus to prevent noise

from undriven line to be interpreted as data.

3.3 Binary Input wiring

Use min. 1 mm2cables for wiring of binary inputs.

Note: The name and function or alarm type for each binary input

have to be assigned during the configuration. Binary inputs may be

used in built-in PLC as well. Please refer to the manual of GenConfig

for more information.

It is recommended to use separation diodes when multiple binary input

terminals are connected together to prevent unwanted activation of

binary input when one of the controllers is switched off.

InteliSys-NTC Hybrid 2.1.0 Global Guide

19

Page 20

3.4 Binary Output wiring

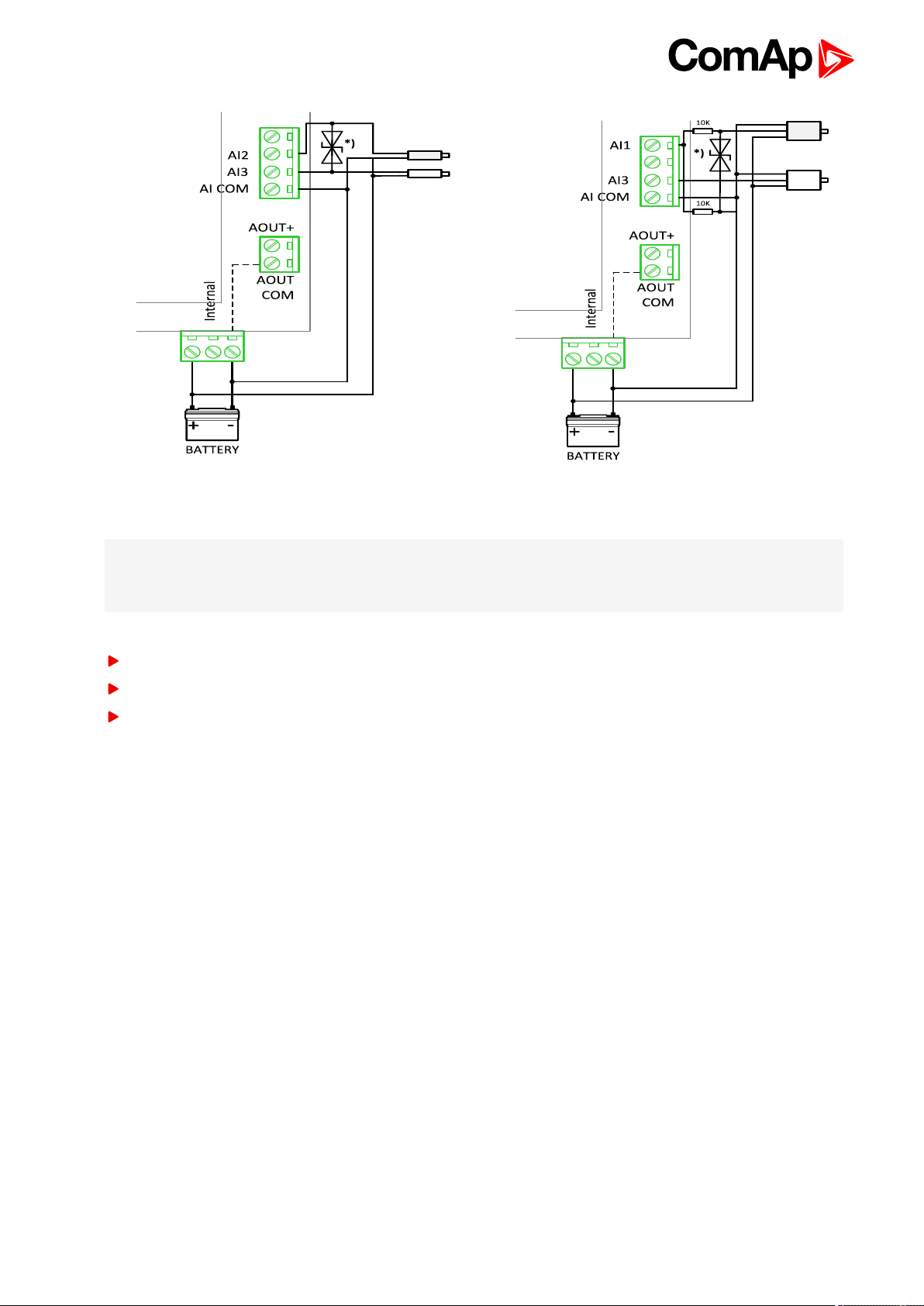

3.4.1 IM-NT-BB and IM-NTC-BB

This portion of Installation instructions is dedicated to the InteliSys-

NTC Hybrid-BaseBox and InteliSys-NTC Hybrid-BaseBox

controllers without built-in display. If you have version with built-in

display of the controller, please refer to the section 3.8.1.

It is possible to use binary outputs as low side switch or high side switch in BaseBox type of controller. For

correct wiring in both cases please refer to the following diagrams.

IMPORTANT: Both power supply sockets for binary outputs need to be connected to ensure proper

function of binary outputs.

Never use DC relays without protection diodes!

InteliSys-NTC Hybrid 2.1.0 Global Guide

20

Page 21

Low side or High side function of binary outputs can be chosen in configuration tool GenConfig in Modules tab.

This configuration is used for all binary inputs available on the controller.

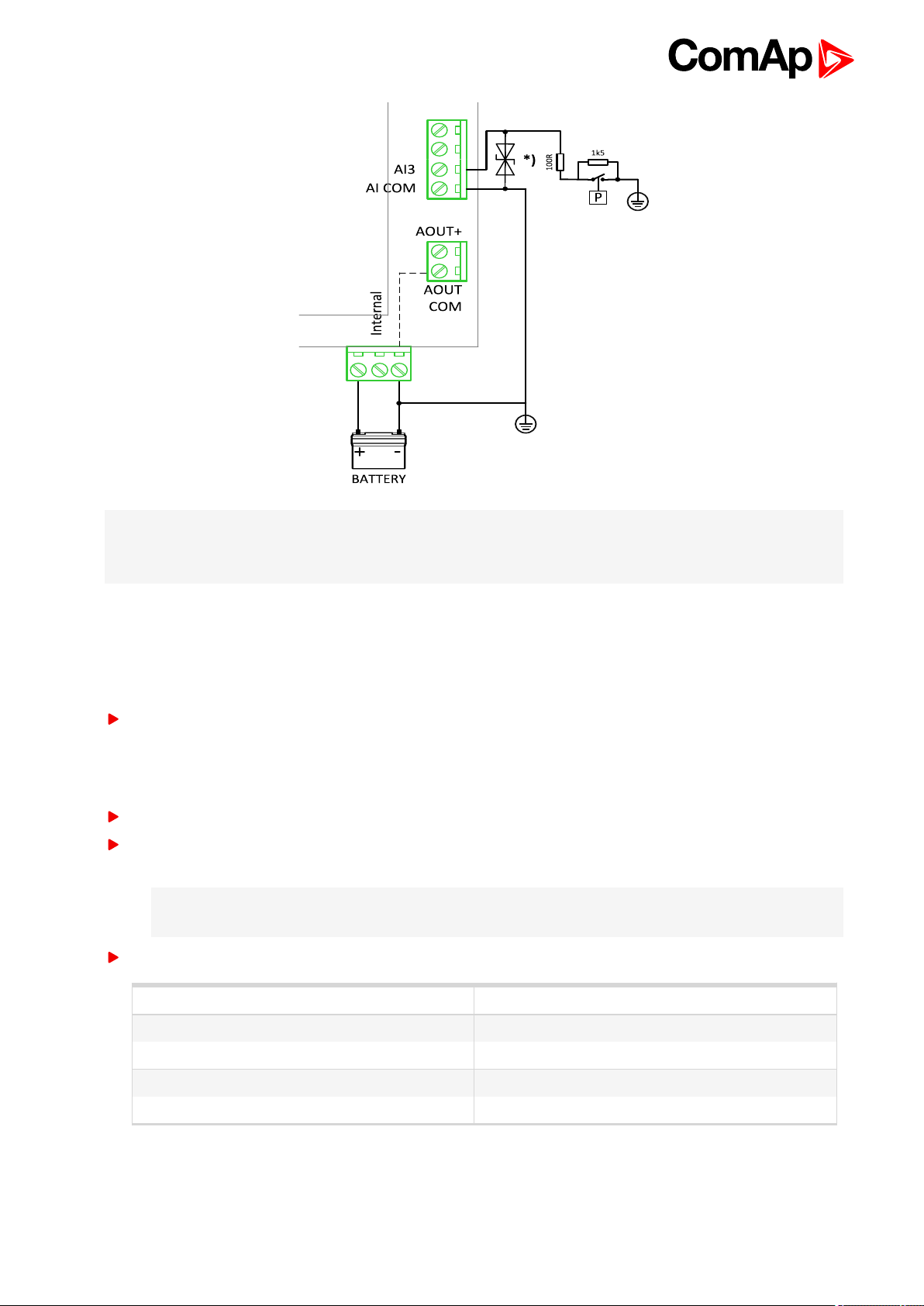

3.5 Analog Input and Output wiring

This portion of Installation instructions is dedicated to the InteliSys-

NTC Hybrid-BaseBox and InteliSys-NTC Hybrid-BaseBox

controllers without built-in display. Analog inputs and output are not

available in InteliSys-NTC Hybrid-GC.

Note: For more information on technical data regarding supply, inputs, outputs etc. please refer to For jumper

setting of Analog inputs please refer to the section 3.2.4 Jumper settings.

Resistive sensor with grounding on Analog input 3

Resistive sensor on Analog input 3 and Analog output wiring

and Analog output wiring. Note, that battery

should be also grounded to common ground in all

cases!

InteliSys-NTC Hybrid 2.1.0 Global Guide

21

Page 22

Passive Current sensor on Analog input 3 and Active Current

sensor on Analog input 2

Note: *)

Transient Voltage Suppressor Diode parameters: 12 V, 600 W, through hole TVS diode type, bidirectional.

Transient Voltage Suppressor Diode is used only when the installation is to be according to IEC 60255-1.

Tristate sensor (binary sensor with fail detection) on Analog input 3

Below 750Ω = Inactive

Between 750Ω and 2400Ω = Active

Below 10Ω or Over 2400Ω = sensor failure (wire shorted or interrupted)

Voltage sensors on Analog input 1 and 3

InteliSys-NTC Hybrid 2.1.0 Global Guide

22

Page 23

Note: *)

Transient Voltage Suppressor Diode parameters: 12 V, 600 W, through hole TVS diode type, bidirectional.

Transient Voltage Suppressor Diode is used only when the installation is to be according to IEC 60255-1.

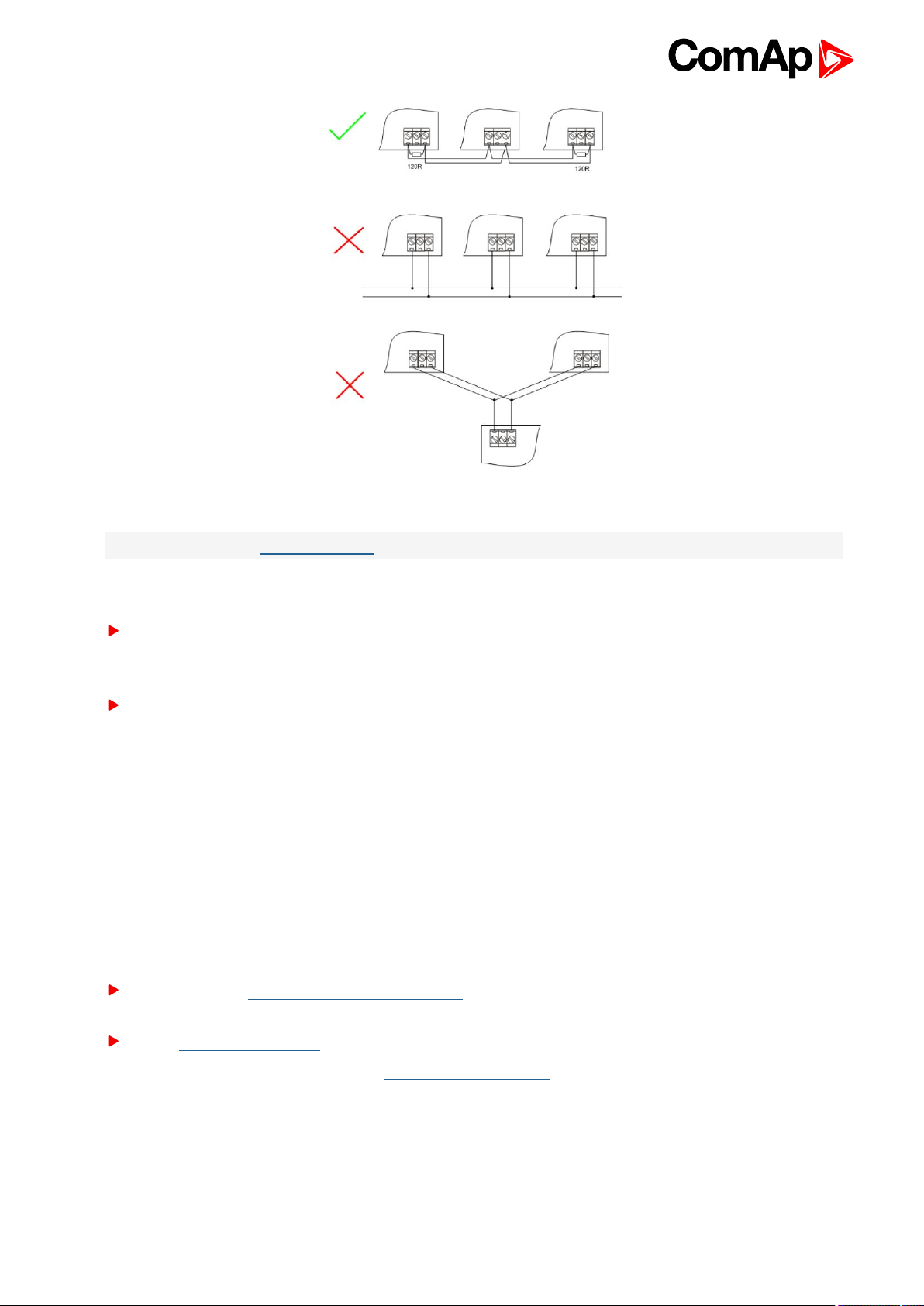

3.6 CAN and RS485 bus wiring

The wiring of the CAN bus communication should be provided in such a way that the following rules

are observed:

The maximum length of the CAN bus depends on the communication speed. For a speed of 250 kbps, which

is used on the CAN1 bus (extension modules, ECU) and CAN2 bus if it is switched to 32C mode, the

maximum length is 200 m. If the CAN2 bus is switched to 8C mode the speed is 50 kbps and the maximum

length is 800 m.

The maximum length of the RS485 bus is 1000 m

The bus (CAN and RS485) must be wired in linear form with termination resistors at both ends. No nodes are

allowed except on the controller terminals.

Note: A termination resistors at the CAN and RS485 are already implemented on the PCB. For

connecting, close the jumper near the appropriate CAN or RS485 terminal.

Use a cable with following parameters:

Cable type Shielded twisted pair

Impedance 120 Ω

Propagation velocity ≥75% (delay ≤4.4 ns/m)

Wire crosscut ≥0.25 mm

Attenuation (@1MHz) ≤2dB / 100 m

InteliSys-NTC Hybrid 2.1.0 Global Guide

2

23

Page 24

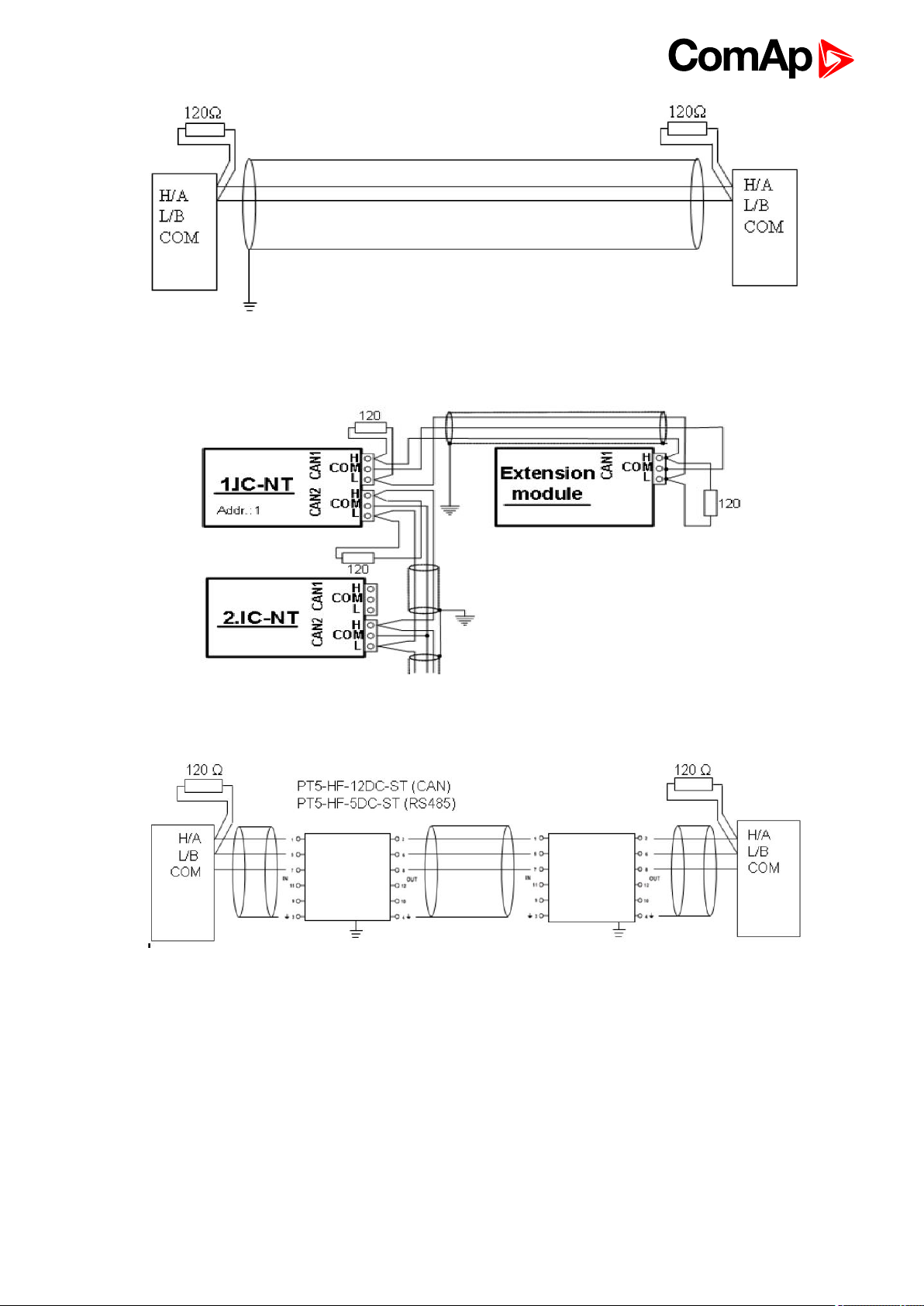

Image 3.2 CAN and RS485 BUS topology

Note: See the website www.can-cia.org for information about the CAN bus, specifications, etc.

According to the certification of the non-galvanical isolated RS485 (marked RS485 (1), Display) due to the IEC

60255-1 have in mind following:

It's possible connect directly to the controller maximally 3 devices by shielded communication cable with

maximum bus length 150m using bi-directional transils 68V 600W on each signal (A, COM, B) against

ground.

If the condition above is not fulfilled, it is necesary to use external separator with galvanic isolation minimally

2000V, surge resistant (e.g. CommFront RS485 / RS422 ISOLATOR / REPEATER / CONVERTER –

INDUSTRIAL, designation type RPT-485_422-4)

3.6.1 Wiring examples

1. For shorter distances (all network components within one room) – picture 1 interconnect A and B; shielding

connect to PE on controller side

2. For longer distances (connection between rooms within one building) – picture 2 interconnect A, B, COM;

shielding connect to PE at one point

3. In case of surge hazard (connection out of building in case of storm etc.) – picture 3

We recommend using the following protections:

Phoenix Contact (http://www.phoenixcontact.com): PT 5-HF-5DC-ST with PT2x2-BE (base element)(or

MT-RS485-TTL)

Saltek (http://www.saltek.eu): DM-006/2 R DJ

Recommended data cables: BELDEN (http://www.belden.com)

1. For shorter distances: 3105A Paired – EIA Industrial RS485 PLTC/CM (1x2 conductors)

2. For shorter distances: 3105A Paired – EIA Industrial RS485 PLTC/CM (1x2 conductors)

3. In case of surge hazard: 3106A Paired – EIA Industrial RS485 PLTC/CM (1x2+1 conductors)

InteliSys-NTC Hybrid 2.1.0 Global Guide

24

Page 25

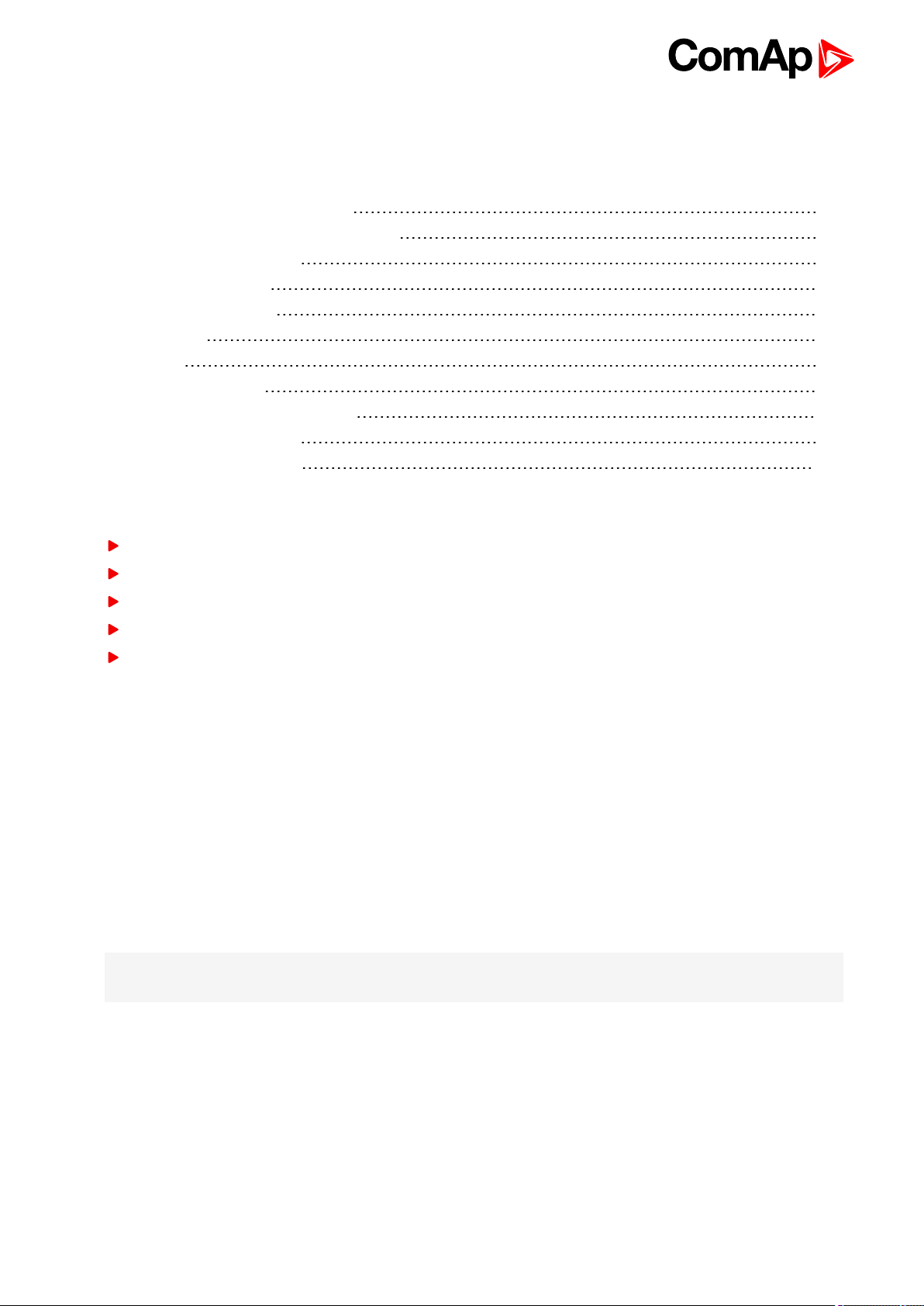

Image 3.3 Shorter distances (all network components within one room)

Image 3.4 Longer distances (connection between rooms within one building)

Image 3.5 Surge hazard (connection out of building in case of storm etc.)

6 back to Installation and wiring

InteliSys-NTC Hybrid 2.1.0 Global Guide

25

Page 26

4 Controller setup

4.1 Connection to a controller usingPC 26

4.2 Modification of configuration, setpoints etc 30

4.3 Programming of a controller 31

4.4 Changing the language 34

4.5 Password management 35

4.6 Related tools 37

4.7 Functions 39

4.8 Renewables Interface 139

4.9 Protections and Alarm management 142

4.10 MGCB/MCB fail detection 149

4.11 Controller operation states 156

6 back to Table of contents

In this section brief introduction is presented how to

Connect to a controller,

Modify various settings,

Program controller and reprogram non-responsive controller,

Manage passwords and password protections and

Operate related tools (ScreenEditor, PLC Editor etc.).

is presented.

4.1 Connection to a controller usingPC

There are several available ways to connect to controller using PC for monitoring, control or

configuration/programming. For more information on related PC tools see Configurability and monitoring on

page 11.

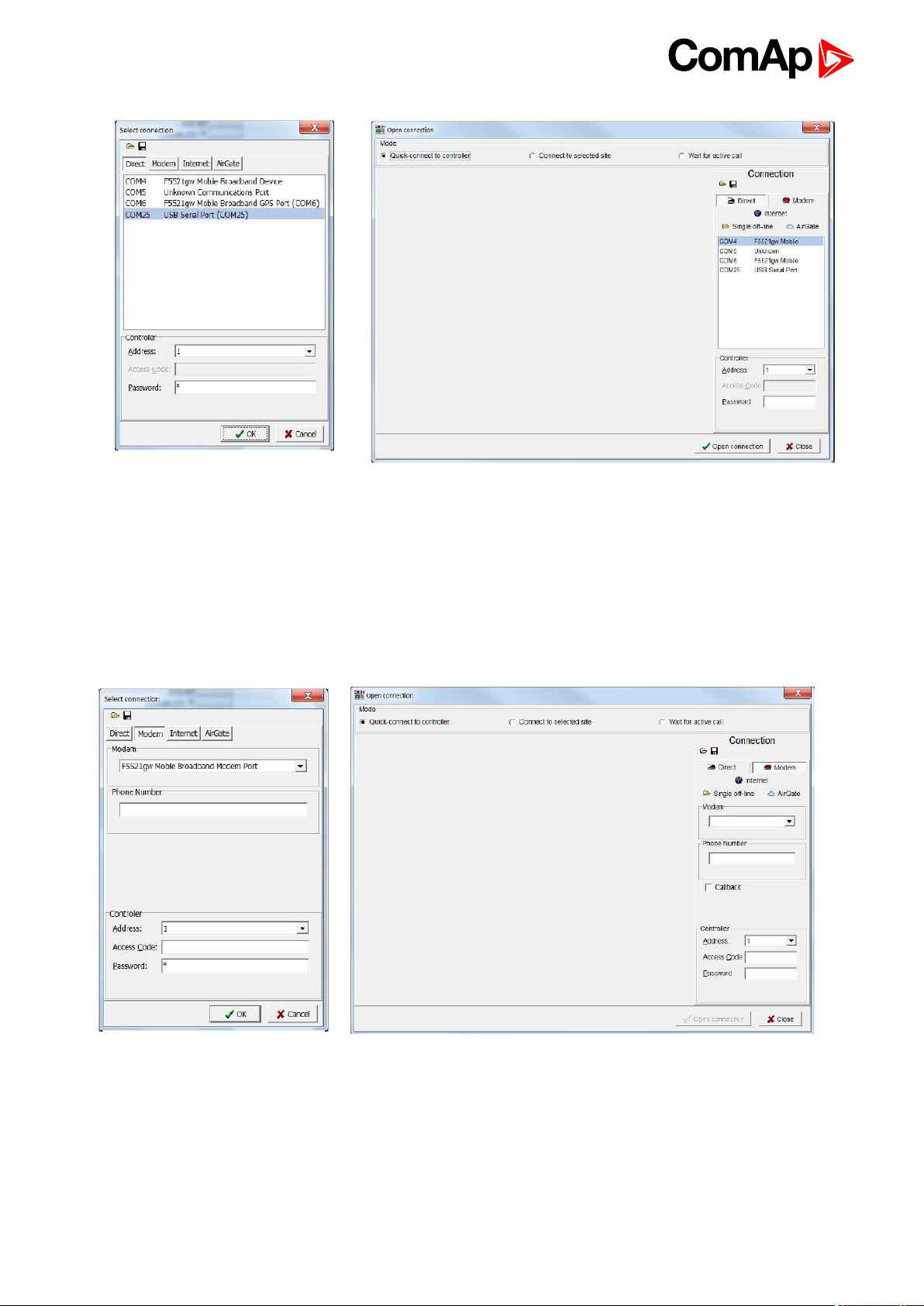

4.1.1 Direct connection

A direct connection can be realized by RS232 connection or USB connection (available on NTC BaseBox only).

Figures below illustrate the connection setting in GenConfig and InteliMonitor.

Note: RS232 can be used only for configuration, not operation communication when installation is to be

according to IEC 60255-1

InteliSys-NTC Hybrid 2.1.0 Global Guide

26

Page 27

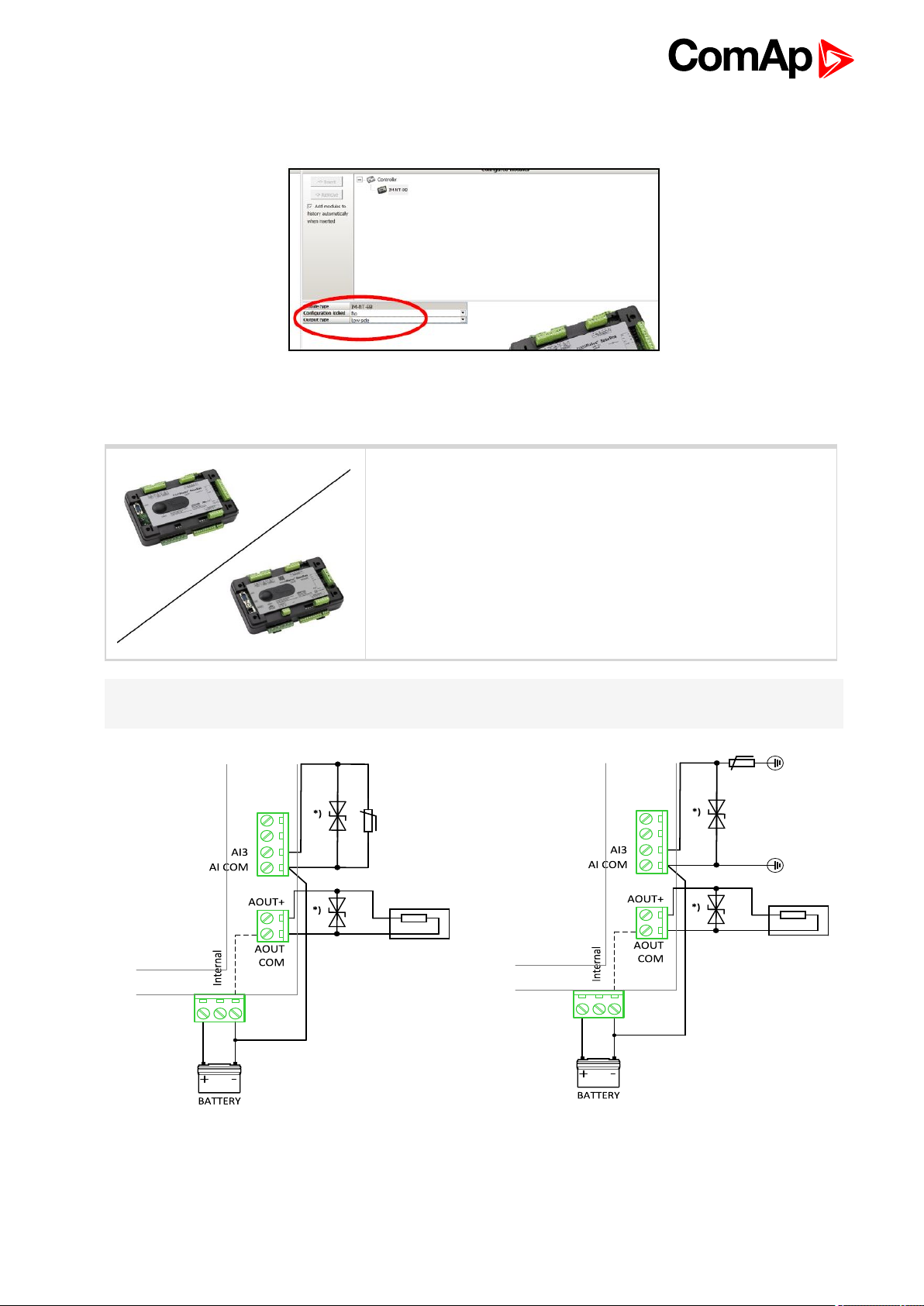

Image 4.1 GenConfig

Select according COM port, adjust CAN address and enter password (optional for locked configuration).

Image 4.2 InteliMonitor

4.1.2 Modem connection

A modem connection can be realized by suitable modem connected to the controller. Figures below illustrate the

connection setting in GenConfig and InteliMonitor.

Image 4.3 GenConfig Image 4.4 InteliMonitor

Select connected modem, adjust Phone number and enter CAN address and enter correct Access Code for

remote connection. Enter password (optional for locked configuration).

It is possible to adjust number of rings before the controller accepts the connection from modem – use Comms

settings:NumberRings AA.

InteliSys-NTC Hybrid 2.1.0 Global Guide

27

Page 28

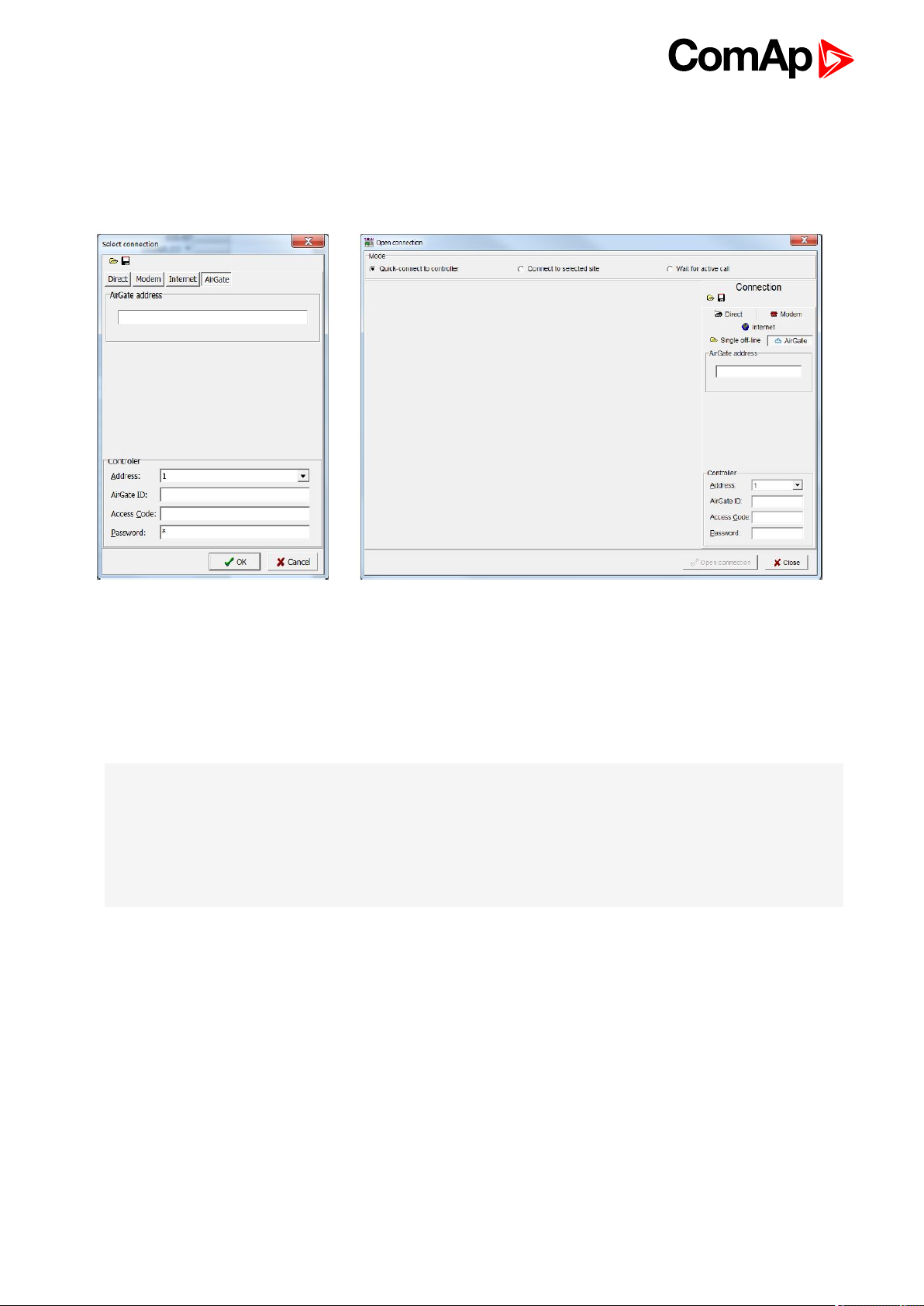

4.1.3 Internet connection

Internet (Ethernet) connection can be used directly in NTC BaseBox version of the controller. For connection to

other versions, use InteliBridge-NT device. Figures below illustrate the connection setting in GenConfig and

InteliMonitor.

Image 4.5 GenConfig Image 4.6 InteliMonitor

Adjust IP address of the controller (InteliBridge-NT) you want to connect to. Select CAN address of the

controller. Enter Access Code for remote connection. Enter password (optional for locked configuration).

Note: The controller must have public IP address or it must be reachable for connection in the specific network.

InteliSys-NTC Hybrid 2.1.0 Global Guide

28

Page 29

4.1.4 Airgate connection

AirGate connection can be used directly in NTC BaseBox version of the controller. For connection to other

versions, use InternetBridge-NT device. Figures below illustrate the connection setting in GenConfig and

InteliMonitor.

Image 4.7 GenConfig Image 4.8 InteliMonitor

Enter AirGate address of a server with AirGate service (currently airgate.comap.cz). Select CAN address of the

controller you want to connect to. Enter AirGate ID of the controller (InteliBridge-NT) you want to connect to

(AirGate ID is assigned automatically if the controller is properly connected to the Internet and corresponding

AirGate setting is enabled. You can find AirGate ID in controller values.). Enter Access Code for remote

connection. Enter password (optional for locked configuration).

Note: What is AirGate service? AirGate is a service provided for free by ComAp which allows users to connect

to controllers even though they are not assigned public IP address or if there are behind corporate firewalls.

Controller connects to the AirGate server (secure and fast server located in Central Europe) and obtains

AirGate ID (used in the connection, see above). Then it communicates with the server on a secure line and any

user that know AirGate ID and access code for that particular controller can connect from anywhere (Internet

access needed) to the controller and monitor and control it.

4.1.5 Connection to multiple controllers

Connection to multiple controller is available in InteliMonitor. It is possible to connect to multiple controller using

Direct connection to I-LB+, using Internet connection to NTC BaseBox controllers or to InteliBridge-NT, using

modem connection capable of multiple connections or AirGate connection to multiple NTC BaseBox controllers

or to InteliBridge-NT.

InteliSys-NTC Hybrid 2.1.0 Global Guide

29

Page 30

Image 4.9 Direct multiple connection

Image 4.10 Internet multiple connection (use InternetBridge-NT IPs for connection to NTC

BaseBox controllers as well)

Image 4.11 AirGate multiple connection (fill in AirGate IDs for each controller, when using

InteliBridge-NT fill in InteliBridge-NT AirGate ID for each controller)

4.2 Modification of configuration, setpoints etc

For full configuration of controller configuration use GenConfig. You may open archive prepared for specific

application and upload it to the controller. You may also change:

Controller type (Modules tab)

Extension modules (Modules tab)

Binary Input and Output logical functions and protections (I/O tab)

Analog input sensor type, logical functions and protections (I/O tab)

Analog output function, conversion, normalization, resolution (I/O tab)

Setpoints and password level for particular setpoint (Setpoints tab)

Commands password protection (Commands tab)

InteliSys-NTC Hybrid 2.1.0 Global Guide

30

Page 31

Prepare custom protections (Protections tab)

Modify History data selection (History tab)

Prepare custom user sensor characteristics (User Sensor tab)

Modify languages settings (Languages tab)

Translate corresponding names to other language prepared in Languages tab (Translator tab)

Prepare complex logical functions with built-in PLC functions (PLC Editor tab)

Modify screens for InteliVision 5 and 8 (ScreenEditor tab)

Review and modify assigned logical binary functions (LBI tab)

Review and modify assigned logical analog functions (LAI tab)

Select power format, rename Pulse counters and Remote switches (Miscellaneous tab)

IMPORTANT: Do not forget that changes in GenConfig are not sent to the controller unless you

write them to the controller.

In InteliMonitor it is possible to configure:

Setpoints (multiple setpoint configuration in several controllers at once)

Set/Reset statistics

Administrate users and their rights

IMPORTANT: Do not forget that all changes in InteliMonitor are sent to the connected controller

and controller immediately acts on it. Do not change CAN address of the controller or connection

is lost and need to be re-established with new CAN address.

4.3 Programming of a controller

4.3.1 Standard programming

For programming GenConfig is used. Select correct connection mode and then select the following option:

InteliSys-NTC Hybrid 2.1.0 Global Guide

31

Page 32

You may use “FW upgrade (from default configuration)” (this will overwrite all of the settings in the controller with

default settings. If you need to upgrade firmware from existing configuration, select “FW upgrade (from existing

configuration)”. This function will automatically open wizard which will help you update the existing configuration

to be compatible with the newly selected firmware.

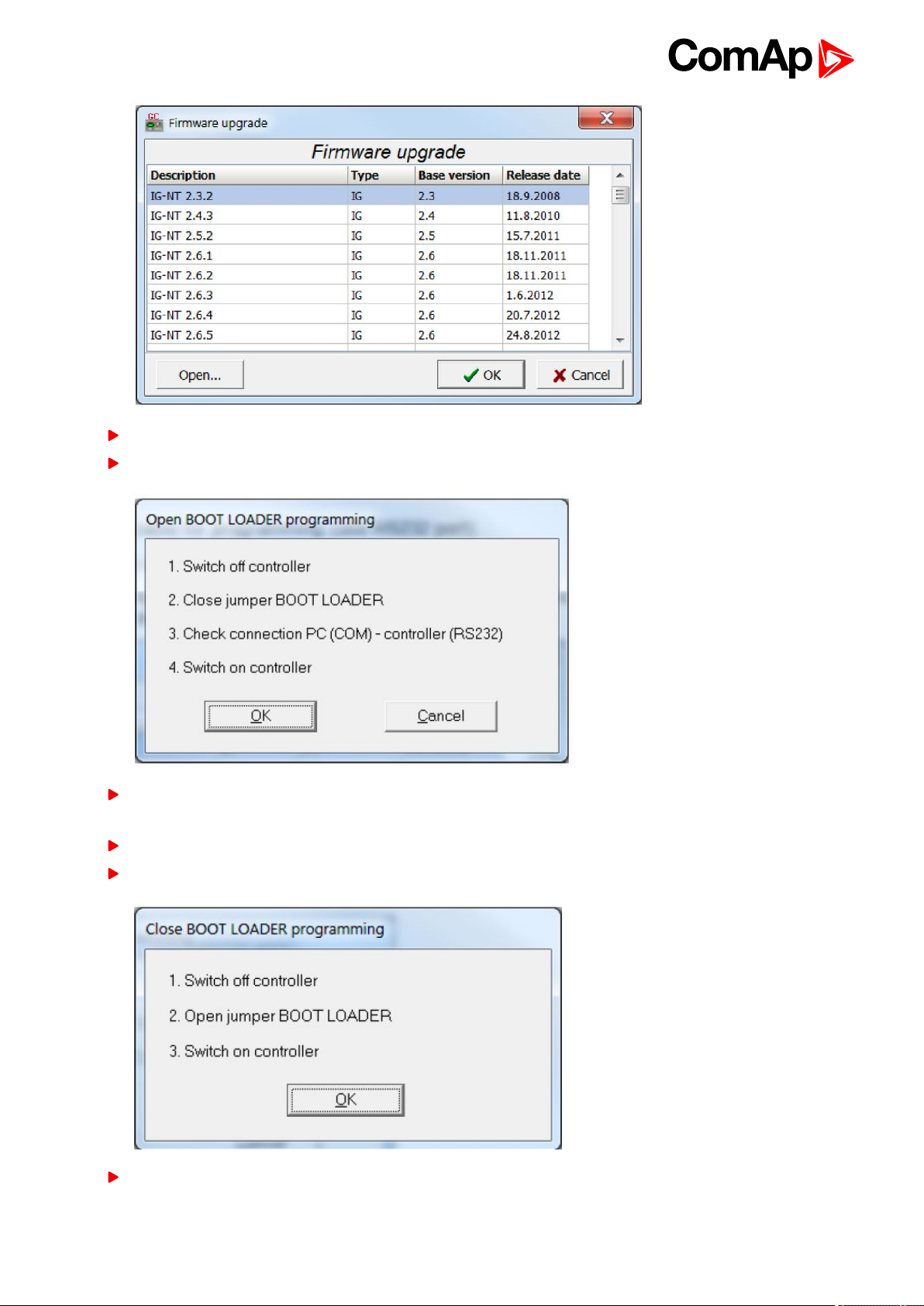

4.3.2 Programming of non-responsive controller

If the controller does not contain valid firmware, new firmware cannot be programmed in the standard way. This

situation can occur if the connection between the PC and the controller was interrupted e.g. during a previous

firmware upgrade. In such case the controller may have a blank display or connection to InteliVision may not be

established and it does not communicate with the PC. The bootjumper must be used to get valid firmware into

the controller.

Connect proper cable for programming (use RS232 port).

Open GenConfig and select “FW upgrade (default configuration)”

From the following table select FW that is required or click open and browse your files to find firmware in

non-default location

InteliSys-NTC Hybrid 2.1.0 Global Guide

32

Page 33

Click OK

Wait until the connection times out and following dialog appears

Follow the instructions and then click OK (information regarding the location of boot jumper can be found in

section 3.1.4 (IM-NT GC) or 3.2.4 (IS-NTC HYBRID and IS-NTC HYBRID)

Programming starts momentarily

When the programming is done following dialog appears

Follow the instructions and press OK. Following diagram will appear and programming is done

InteliSys-NTC Hybrid 2.1.0 Global Guide

33

Page 34

Additional dialog warns you that the setpoints may have improper values. Change the configuration in

normal way.

4.4 Changing the language

There is step-by-step guide in GenConfig help available for the Languages and Translator tabs which contains

all the information on how to prepare new languages in the configuration (press F1 in Languages or Translator

tab or go to Help->GenConfig Help and locate corresponding chapters).

4.4.1 Selection of the language in InteliSys

This portion of instructions is dedicated to the InteliSys-NTC Hybrid

controller without built-in display. If you have version with built-in

display of the controller, please refer to the section 4.4.2.

NTC

Hybrid

InteliSys-NTC Hybrid 2.1.0 Global Guide

34

Page 35

If using BaseBox version of the controller you may use InteliVision 5, InteliVision 8 or InteliVision 17 Touch. If

you need to use for some reason IG or IS-Display please refer to the chapter 4.4.1 for the instructions regarding

built-in display which works the same as the external displays.

For InteliVision 5 an 8 go to main menu and select Help/Others and Languages. Scroll up and down and select

preferred langugue. Confirm by pressing enter.

If you are using InteliVision 17, it is running standard InteliMonitor software. Please refer to the manual of

InteliMonitor how to change fonts in InteliMonitor and in custom SCADA.

Note: you need to use graphical language you may need to upload correct set of characters into the InteliVision

via controller. By default Chinese character set is uploaded in the controller. If you need to use for example

Korean characters (Hangul), in GenConfig select following menu while connected to the controller: File ->

Firmware upgrade and Cloning -> Display GC font change / FW upgrade. GenConfig connects to the controller

and new fonts may be uploaded to the controller as well as new firmware for the built-in display.

4.5 Password management

Password management requires InteliMonitor for user names, passwords and rights modification. It also

requires GenConfig for assigning corresponding setpoints and command to correct right groups.

4.5.1 User administration

User administration is available only when logged in as an Administrator. Once logged in select “Admin users…”

as shown on the right.

Following dialog is displayed:

Enable or disable users. Change user names and by double clicking change the access groups that are

accessible by particular user. Hold CTRL and click separate access groups to select only several of them with

no access to lower groups.

Log in as a different user to change password for that particular user.

Note: Newly enabled user has always default password “0”.

InteliSys-NTC Hybrid 2.1.0 Global Guide

35

Page 36

4.5.2 Access group setting in GenConfig

To assign particular setpoint to access group use the following function in GenConfig (by clicking select the

correct access group).

Note: Each setpoint may be assigned to only one access group. This setpoint can be changed by all users with

activated corresponding access rights.

To assign particular command to access group use the following function in GenConfig (by clicking select the

correct access group).

Note: Each command may be assigned to only one access group. This command can be used by all users with

activated corresponding access rights.

InteliSys-NTC Hybrid 2.1.0 Global Guide

36

Page 37

4.5.3 Password break protection

Password break protection (PBP) can be adjusted to ENABLED or DISABLED by a tick box in password

management in InteliMonitor (see the figure below). Default value is ENABLED.

Warning “PassInsertBlck” is displayed in alarm list during the blocking period.

Controller does not accept attempts to insert correct or incorrect password during the blocking period. In

case of this attempt there is a message displayed in InteliMonitor, GenConfig and InteliVision 5 and 8 which

states the remaining time of blocking.

Controller is blocked for 5 minutes if there were 6 attempts to insert incorrect password. In case of another six

failed attempts (after the period of blocking elapses) the blocking period is 30, 60, 120 and 240 minutes long

respectively.

History record “Incorrect password” is written after the 6th failed attempt to enter password (i.e. this record is

written once the PBP is activated). During the blocking no history records of inserting incorrect or correct

password are written.

Entering of passwords during the blocking period does not prolong the blocking period (passwords are not

actually entered because they are rejected by the controller at all).

When the controller is switched OFF and ON again (i.e. power down and up again) during the blocking period,

the blocking period is reset back to the full length of currently active PBP (e.g. if there is 24 minutes remaining

out of 30 minutes after the controller reset there will be again 30 minutes remaining).

After the correct password is inserted the PBP blocking period for next 6 failed attempts is reverted back to 5

minutes.

4.6 Related tools

There are two tools available for user regarding the configuration of the controller:

ScreenEditor – it can be used to modify screens in InteliVision 5 and 8

InteliSys-NTC Hybrid 2.1.0 Global Guide

37

Page 38

PLC Editor – it can be used to create and modify built-in PLC functions

Note: For more information on ScreenEditor use help in GenConfig (Help -> ScreenEditor Help).

For more information on PLC Editor use GenConfig Reference Guide.

InteliSys-NTC Hybrid 2.1.0 Global Guide

38

Page 39

4.7 Functions

4.7.1 Overview 40

4.7.2 Modes 54

4.7.3 Process Limitation 58

4.7.4 System start 64

4.7.5 StartUpSynchronization 65

4.7.6 Power management 65

4.7.7 Dynamic Spinning Reserves 97

4.7.8 Remote Alarm Messaging 97

4.7.9 Controller Redundancy 99

4.7.10 System load control modes 100

4.7.11 Managing system load control modes 103

4.7.12 Renewables Active Power Control 108

4.7.13 Renewables Reactive Power Control 111

4.7.14 Multiple Mains Feeders Support 113

4.7.15 System PF control modes 115

4.7.16 Automatic Mains Failure function 117

4.7.17 Regulation loops 119

4.7.18 Force value – step by step guide 121

4.7.19 Values for continuous writing from external sources 123

4.7.20 General Purpose Timers 124

4.7.21 History Related functions 125

4.7.22 User Buttons 127

4.7.23 Remote Control Function 128

4.7.24 Virtual Peripheral Inputs-Outputs (VPIO) module 129

4.7.25 Shared Inputs and Outputs 129

4.7.26 Distributed Binary Inputs and Outputs 131

4.7.27 MODBUS 132

4.7.28 Analog Input Sensors and User Sensors 134

4.7.29 Languages and Translator tool in GenConfig 134

4.7.30 System Start/Stop 135

4.7.31 Power Formats 135

4.7.32 Soft Unload with support of IAux measurement 136

4.7.33 System Isolated 138

4.7.34 User Mask function 138

4.7.35 Switchable Current measurement ratio 139

4.7.36 PLC functions 139

6 back to Table of contents

InteliSys-NTC Hybrid 2.1.0 Global Guide

39

Page 40

4.7.1 Overview

Note: There are numerous built-in functions in the controller that can be modified or combined to produce new

functions for specific uses. Note that it is not possible to describe all the combinations or modifications in detail

in this manual. Users are encouraged to find new way of how to use existing functions to their benefit.

Function Name Brief Description Related Setpoints, Inputs and Outputs

There are vast options regarding

access restrictions in the

controller. It is possible to lock:

Access locking

from various

sources

Active call,

emailing and SMS

service

Buttons for various

commands on the terminal.

External buttons for various

commands on binary inputs.

Built-in terminal or terminal

#1 to monitoring mode only.

External local terminal or

terminal #2 to monitoring

mode only.

All external remote

terminals (PC connection,

displays on all buses except

on RS485 dedicated port).

This function allows user to choose

under which conditions active

emailing happens, what is the type

of the message and separate

addresses or numbers. Learn more

about these functions in a separate

chapter.

Local buttons

ACCESSLOCK INT

ACCESSLOCKD#2

ACCESSLOCK D#3

ACCESSLOCK EXT

FAULTRESBUTTON

HORNRESBUTTON

STOPBUTTON

History record

Alarm only

Warning

Mains protect

MainsP w/Reset

AcallCH1-Type

AcallCH2-Type

AcallCH3-Type

AcallCH4-Type

AcallCH5-Type

AcallCH1-Addr

STARTBUTTON

MCBBUTTON

MGCBBUTTON

ActCallAttempt

Acall+SMS lang

ISSUEACTCALLC1

ISSUEACTCALLC2

ISSUEACTCALLC3

ISSUEACTCALLC4

ISSUEACTCALLC5

SMTP authent

SMTP user name

SMTP password

Alternative

brightness for

built-in InteliGen

display

InteliSys-NTC Hybrid 2.1.0 Global Guide

It is possible to choose two

different levels of brightness and

switch them with logical binary

input.

AcallCH2-Addr

AcallCH3-Addr

AcallCH4-Addr

AcallCH5-Addr

Alt brightness

SMTP address

Contr mailbox

Time zone

40

Page 41

Function Name Brief Description Related Setpoints, Inputs and Outputs

It is possible to leave the

assignement of CAN addresses on

controllers themselves. If the

function is activated controllers will

Automatic CAN

address

assignement

Automatic display

backlight timeout

look for possible collisions of CAN

bus communication and they will

change their addresses

accordingly. This function need to

be activated or deactivated in all

controllers on CAN bus. It is

available only in some

applications.

It is possible to adjust timeout for

backlight of built-in display of the

controller. When using InteliVision

display the backlight timeout is

adjusted separately in the the

display.

CANnegotiation

DispBaklightTO

Automatic Mains

Failure function

Automatic

synchronization

This is a complex function that

ensures correct reaction of the

system to detected Mains Failure.

For more information please refer

to a separate chapter.

Controller automatically performs

synchronization sequence

including corresponding regulations

to achieve correct phase and

voltage on both synchronized

sides. It possible to set phase shift

caused by transformers to be taken

into acount during synchronization.

Synchronization automatically

closes corresponding breaker if the

voltages on both sides do not differ

more than Voltage window and

their phases do not differ more than

Phase window for time equal to

Dwell time. For regulation loops

MFStart enable

EmergStart del

FwRet break

MCB close del

MCB opens on

MGCB Close del

ReturnWithIntr

BreakerOverlap

RetFromIsland

ReturnTo mains

Mains ret del

Voltage window

BtoM AngleReq

Phase window

Dwell time

Sync timeout

FORWARDSYNCHRO

REVERSESYNCHRO

IN SYNCHRONISM

InteliSys-NTC Hybrid 2.1.0 Global Guide

41

Page 42

Function Name Brief Description Related Setpoints, Inputs and Outputs

functions please refer to a separate

chapter.

In the controller there are many

parameters that are used for

Basic Voltage and

Current settings

entering of nominal values of Mains

and Bus characteristics. It also

allows users to set measurement

transformers ratio and select range

of voltage measurement. All of

these parameters are crucial for the

right function of the controlle since

regulations, protections and other

function are directly dependant of

these settings. For additional

information on protections please

refer to separate chapter

Protections and Alarm

Management.

Vm VT ratio

Vm InpRangeSel

Bus VT ratio

BusInpRangeSel

MainsNomV

MainsNomVph-ph

BusNomV

BusNomVph-ph

Nomin current

NominMainsImp

MainsCTprim

MainsCTsec

AuxCurrCTprim

AuxCurrCTsec

Nominal freq

Nom frq offset

CAN bus

communication

mode

Circuit Breaker

control

Circuit breaker

feedback sensing

It is possible to change speed of

communication on CAN2 bus

(Intercontroller and Monitoring) to

lower (longer distance, limited to 8

controllers) or to higher (shorter

distance, limited to 32 controllers).

Circuit Breaker control depends on

many various parameters. Please

refer to a separate chapter.

Lear more about circuit breaker

feedback sensing in a separate

chapter.

CAN bus mode

MCB CLOSE/OPEN

MCB ON COIL

MCB OFF COIL

MCB UV COIL

MCB STATUS

MGCB CLOSE/OPEN

MGCB ON COIL

MGCB OFF COIL

MGCB UV COIL

MGCB STATUS

MGCB FEEDBACK

MGCB FDB NEG

MCB FEEDBACK

MCB FDB NEG

Communication

log in controller

history

InteliSys-NTC Hybrid 2.1.0 Global Guide

It is possible to log communication

events into the controller history

(e.g. opened new communication,

communication closed etc.).

LB/UART Log

42

Page 43

Function Name Brief Description Related Setpoints, Inputs and Outputs

Controller modes

of operation

Controller

Redundancy

Detection of

communication

error of peripheral

modules

Controller can be switched to

several modes of operation. It is

possible to switch modes using

buttons on terminal, using buttons

in InteliMonitor, changing of a

setpoint or activation of binary

inputs for remote change of the

mode of operation. For more

information on modes of operation

please refer to a separate chapter.

It is possible to use redundant

controller which is in monitoring

mode only unless the primary

controller fails. This is a complex

function and it is described in a

separate chapter.

Controller detects any problems in

communication with extension

modules (it is possible to adjust

corresponding level of protection in

GenConfig) and issues alarm

based on it.

ControllerMode

REMOTE OFF

REMOTE MAN

REMOTE AUT

REMOTE TEST

OFF MODE

MAN MODE

AUT MODE

TEST MODE

Watched Contr

CTRLHEARTBEAT

CTRLHBEAT FD

EMERG. MANUAL

CTRLHBEAT SENS

PeriphCommErr

Detection of empty

CAN bus

Disable Circuit

breaker function

Evaluation of

CAN2

communication

collision

External values

available for

repeated writing

This function can be used to detect

failed communication via CAN2

bus. If no other controllers are

found on CAN2 bus, alarm is

issued.

It is possible to disable one or both

breakers via InteliSys-NTC Hybrid.

Disabled circuit breaker opens (if

previously closed) and InteliSys-

NTC Hybrid keeps it open under

any conditions.

Controller automatically detects

possible collisions on CAN2 bus

(e.g. same shared binary outputs

are broadcasted by two controllers

on one CAN bus).

It is not possible to repeatedly write

setpoints from external device

(although it is possible to

repeatedly force different values or

continuously changing values into

CAN2emptDetect

MGCB DISABLE

MCB DISABLE

MGCB OPEN

SHxOcol detect

ExtValue1deflt

ExtValue2deflt

ExtValue3deflt

ExtValue4deflt

ExtValue1LoLim

EXTVALUE1 UP

EXTVALUE2 UP

EXTVALUE3 UP

EXTVALUE4 UP

EXTVALUE1 DOWN

InteliSys-NTC Hybrid 2.1.0 Global Guide

43

Page 44

Function Name Brief Description Related Setpoints, Inputs and Outputs

ExtValue2LoLim

setpoint because forced value is

not stored in the memory) because

of possible memory damage. If

continuous writing of some value

into a setpoint from external device

is needed, External values should

be used and their value should be

subsequently forced to the setpoint

for safe operation. For detailed

guide to the usage of external value

please refer to a separate chapter.

ExtValue3LoLim

ExtValue4LoLim

ExtValue1HiLim

ExtValue2HiLim

ExtValue3HiLim

ExtValue4HiLim

ExtValue1 rate

ExtValue2 rate

ExtValue3 rate

ExtValue4 rate

EXTVALUE2 DOWN

EXTVALUE3 DOWN

EXTVALUE4 DOWN

EXTVALUE1RESET

EXTVALUE2RESET

EXTVALUE3RESET

EXTVALUE4RESET

Forcing of a value

to the setpoint

Group Link

function for

complex

installations (Bus

Tie Breaker)

It is possible to force up to 16

different values to one setpoint to

change various functions of the

controller. Any suitable setpoint or

value can be forced into the

setpoint provided that this setpoint

is forcable. There are 16 Force

value setpoints designed just for

forcing (if correct value for forcing

is not available in any other

setpoint or value). For detailed

step-by-step instruction on how to

use value forcing please refer to a

separate chapter.

Group Link function enables

ComAp controllers to work

independently or together

dependent on the state of a Bus Tie

Breaker. For more information refer

to the chapter Power

management.

Force value 1

Force value 2

Force value 3

Force value 4

Force value 5

Force value 6

Force value 7

Force value 8

Force value 9

Force value 10

Force value 11

Force value 12

Force value 13

Force value 14

Force value 15

Force value 16

GROUPLINK

Control group

GroupLinkLeft

GroupLinkRight

FORCEVALUEIN 1

FORCEVALUEIN 2

FORCEVALUEIN 3

FORCEVALUEIN 4

FORCEVALUEIN 5

FORCEVALUEIN 6

FORCEVALUEIN 7

FORCEVALUEIN 8

FORCEVALUEIN 9

FORCEVALUEIN 10

FORCEVALUEIN 11

FORCEVALUEIN 12

FORCEVALUEIN 13

FORCEVALUEIN 14

FORCEVALUEIN 15

FORCEVALUEIN 16

It is possible to modify history

History related

functions

InteliSys-NTC Hybrid 2.1.0 Global Guide

records layout and set periodic

time stamping in history. Controller

has adjustable time and date

setpoints (time is update each

Time stamp act

Time Stamp Per

#SummerTimeMod

#Time #Date

44

Page 45

Function Name Brief Description Related Setpoints, Inputs and Outputs

second) and there is inbuilt

summer time mode function. Read

about history layout modification in

separate chapter.

TIME STAMP ACT

IP Addr mode

Internet related

communication

functions

Language selection

It is possible to connect controllers

to Internet. AirGate function is also

available when Internet connection

is established. Active emails may

be sent upon various reasons. For

more information on these

functions please refer to a separate

chapter.

InteliSys-NTC Hybrid can change

language in its built-in display as

well as in attached displayes by

activation of binary inputs.

IP address

Net mask

Gateway IP

ComApProtoPort

AirGate

AirGate IP

DNS IP

NumberRings AA

LANG SEL INT A

LANG SEL INT B

LANG SEL INT C

LANG SEL D#2 A

LANG SEL D#2 B

LANG SEL D#2 C

LANG SEL D#3 A

LANG SEL D#3 B

LANG SEL D#3 C

Load shedding

function

Mains Coupling

Complex load shedding and

reconnection function is available

in the controller. It is described in

the separate chapter.

This function defines if Mains

Coupling is enabled via controller

Ld shed active

Ld reconLevel1

Ld reconLevel2

LdShedBased on

Ld reconLevel3

Ld shed mode

LdRecon f lvl1

Ld shedStages

LdRecon f lvl2

Ld shedLevel1

LdRecon f lvl3

Ld shedLevel2

Ld reconDelay1

Ld shedLevel3

Ld reconDelay2

Ld shed f lvl1

Ld reconDelay3

Ld shed f lvl2

AutoLd recon

Ld shed f lvl3

LDSHED STAGE 1

Ld shedDelay1

LDSHED STAGE 2

Ld shedDelay2

LDSHED STAGE 3

Ld shedDelay3

MANUALLDRECON

Mains coupling

InteliSys-NTC Hybrid 2.1.0 Global Guide

45

Page 46

Function Name Brief Description Related Setpoints, Inputs and Outputs

breakers. It should be enabled only

if two or more Mains incommers

are in phase and it is allowed by

local authorities.

I/E-Pm meas

Measurement of P

and Q selection

Minimum required

power in parallel to

Mains operation

Modbus switches

You may select the source of

Mains current measurement or

disable this measurement.

This function sets minimal power

produced by gen-set group in

parallel to Mains operation in % of

nominal power of each gen-set

regardless of Import/Export limit.

This function is active only if

InteliSys-NTC Hybrid plays active

role in load sharing.

There are two Modbus registers

containing 16 bits each that can be

easily written using Modbus. Their

values are available in the form of a

Value (BINARY) and in the form of

logical binary ouputs that can be

used further in the configuration.

I/E-Qm meas

MLC:I/E-PM

MPF:I/E-QM

Min Power PtM

MODBUSSW1-32

ModbusSw1

ModbusSw2

Overheat

Protection

Peak Shaving

function

Permanent logical

0 or 1 outputs

This function is used to protect

system from overheating. If the

temperature rises above given

limit, mode of load control is

changed to prevent overheating.

When temperature returns back the

previous mode of load control is

restored. For exact function of

Temperature By Power control see

separate chapter System Load

Control.

Peak Shaving function can be

based on active power (kW) or

reactive power (kVA). It is

described in a separate chapter.

It is possible to use permanent

logical binary function that is

always logical 0 or logical 1. It may

Overheat prot

TempByPwr Treq

MLC:TBYPWR

PeakLevelStart

PeakLevelStop

PeakAutS/S del

Peak kVA Start

Peak kVA Stop

PeakKVAS/S del

LOGICAL 0

LOGICAL 1

InteliSys-NTC Hybrid 2.1.0 Global Guide

46

Page 47

Function Name Brief Description Related Setpoints, Inputs and Outputs

used for various purposes.

Power Management

Power management is a very

complex function with many

settings that is used if the gen-sets

are in AUT mode of operation (and

other requirements are fulfilled) to

start and stop engines accordingly

to set parameters for more efficient

function of the system. Part of

Power Management consists of

automatic priority swapping for

extended efficiency of the system.

For complete information of all

Power Management function

please refer to a separate chapter.

#Pwr mgmt mode

#PriorAutoSwap

Priority ctrl

#SysAMFstrtDel

#SysAMFstopDel

LoadResStrt 1

LoadResStop 1

LoadResStrt 2

LoadResStop 2

LoadResStrt 3

LoadResStop 3

LoadResStrt 4

LoadResStop 4

%LdResStrt 1

%LdResStop 1

%LdResStrt 2

%LdResStop 2

%LdResStrt 3

NextStopDel

SlowStopDel

MinRunPower 1

MinRunPower 2

MinRunPower 3

RunHrsMaxDiff

PwrBandContr 1

PwrBandContr 2

PwrBandContr 3

PwrBandContr 4

PwrBnChngDlUp

PwrBnChngDlDn

LOAD RES 2

LOAD RES 3

LOAD RES 4

SYSTREADY

SYST RES OK

SYST RES 1 OK

Process limitation

control

Protections

This function is used to limit

process (e.g. parallel operation is

not allowed). This function is

complex and it is described in a

separate chapter.

Protections in the controller are

very complex function with many

settings. Please refer to a separate

chapter for more information about

protection functions in InteliSys-

NTC Hybrid.

%LdResStop 3

%LdResStrt 4

%LdResStop 4

NextStrt Del

OverldNext Del

Island enable

ParallelEnable

Synchro enable

Horn Timeout

BinInp delay 1

BinInp delay 2

BinInp delay 3

ForceBlockDel1

ForceBlockDel2

ForceBlockDel3

ResetActAlarms

SYST RES 2 OK

SYST RES 3 OK

SYST RES 4 OK

ALLAVAILGS RUN

ENGINES SWAPPED

COMMONACTLEV2

COMMONALLEV2

Mns2POvrldProt

OverldStrtEval

2POvrldStEvDel

Mns2Inom prot

Mains2Inom del

Mains >V MP

InteliSys-NTC Hybrid 2.1.0 Global Guide

Force block 1

Mains <V MP

47

Page 48

Function Name Brief Description Related Setpoints, Inputs and Outputs

Force block 2

Force block 3

VMAINS <>

VMAINS <>

FMAINS <>

FBUS <>

MAINSFAIL

BUS FAIL

VECTORSHIFTTP

VMAINS <>

HORN

ALARM

HORN LASHING

ALARM FLASHING

COMMON WRN

COMMON MPR

COMMON FLS

COMMON MP

COMMON AL

COMMON HST

Mains V del

Mains Avg>V MP

Mains >f

Mains <f

Mains f del

VectorS prot

VectorS CB sel

VectorS limit

ROCOF Win

ROCOF df/dt

Bus >V

Bus <V

Bus V del

Bus >f

Bus <f

Bus f del

BusMeasError

Pulse Counters

Regulation

functions

The controller offers up to 4 pulse

counters that can count incomming

pulses of at least 100 ms (high and

low) length with various

conversion. The counted value is

stored in the controller and can be

displayed.

There is whole variaty of regulation

functions in the controller. Please

refer to a separate chapter to find

out more.

COMMONACTLEV1

COMMONALLEV1

ConvCoefPulse1

ConvCoefPulse2

ConvCoefPulse3

ConvCoefPulse4

PULSECOUNTER 1

PULSECOUNTER 2

PULSECOUNTER 3

PULSECOUNTER 4

Freq gain

Freq int

Angle Gain

Load Ramp

Load gain

Load int

Voltage gain

InteliSys-NTC Hybrid 2.1.0 Global Guide

Voltage Int

48

Page 49

Function Name Brief Description Related Setpoints, Inputs and Outputs

PF gain

PF int

REMOTECONTROL1

Remote Control

Function

Remote start and

stop of the system

RS232 and RS485

communication

functions

This particular function enables

user to close or open binary output

assigned to RemoteControl

function from InteliMonitor or via

Modbus commands. For more

information please refer to a

separate chapter.

System controlled by InteliSys-

NTC Hybrid can be started and

stopped based on

activation/deactivation of binary

input Rem start/stop. Behavior of

the system then depends on load

control mode, power management,

process control and other factors.

The controller has several settings

regarding RS232 and RS485

functions. It is possible to set

mode of communication on

particular port, speed of

communication and AT commands

for modem connection.

REMOTECONTROL2

REMOTECONTROL3

REMOTECONTROL4

REMOTECONTROL5

REMOTECONTROL6

REMOTECONTROL7

REMOTECONTROL8

REM START/STOP

RS232(1) mode

RS232(2) mode

RS232(1)MBCSpd

RS232(2)MBCSpd

RS232(1)MdmIni

RS232(2)MdmIni

RS485(1) conv.

Soft unloading and

Soft unloading

based on Auxiliary

measurement

Start Blocked

indication

Soft unloading can be performed in

the standard way or it can be

performed based on actual current

to the load or through MGCB

measurement to prevent sudden

overloading of gen-sets because of

other loads on bus. This function is

using Auxiliary current

measurement to ensure that soft

unloading is performed correctly in

case of complex installations (e.g.

two Mains incommers).

The controller indicates blocked

start of the gen-set group based on

process limitation setpoints by

RS485(2) conv.

Soft Unload

AuxCurrCTprim

AuxCurrCTsec

MGCB open lev

MGCB open del

START BLOCKED

InteliSys-NTC Hybrid 2.1.0 Global Guide

49

Page 50

Function Name Brief Description Related Setpoints, Inputs and Outputs

activation of logical binary output

START BLOCKED (previously it

was indicated by alarm list

message).

StartUpSynchro

nization

Synchronization of

separate gensets

directly to the

Mains voltage

System Isolated

StartUpSynchronization is now

supported in InteliSys-NTC Hybrid

controllers.

This function enables or disables

the direct synchronization of each

gen-set to Mains voltage. This is

beneficial for faster system

reaction time after startup.

Moreover, you can use this

function to distribute Mains voltage

along bus even if no gen-set is

running.

There are two logical binary inputs

that can be used for secondary CB

feedbacks. When these binary

inputs get activated the

corresponding breakers are

considered opened no matter what

is the position of feedbacks of

MCB or MGCB.

MultiSoftStart

MGCBparalClose

MCBISOLATED

MGCBISOLATED

System Load

Control

System starting

impuls

System Load is a complex function

and it is described in a separate

chapter.

This is multipurpose starting

SysBaseLoad

SysPwrFactor

SysLdCtrl PtM

SysPFCtrl PtM

Import load

Import PF

MLoad ctrl PtM

PF ctrl PtM

Export limit

TempByPwr Treq

TempByPwr gain

TempByPwr int

MLC:ANEXSYSBLD

MLC:ANEXI/E

MLC:TBYPWR

MPF:ANEXI/E

SYS START/STOP

InteliSys-NTC Hybrid 2.1.0 Global Guide

50

Page 51

Function Name Brief Description Related Setpoints, Inputs and Outputs

impulse which serves as a starting

input for genset controllers in the

system.

Using force value function on

MainsCTprim, the controller can

Switchable Current

measurement ratio

effectively switch the ratio of the

current measurement on the fly (if

the measurement transformers can

switch their amplification).

MainsCTprim

TEST ON LOAD

Parallel enable

Test on load and

Test on load with

break

Time

synchronization

and GPS

positioning with

InternetBridge- NT

InteliSys-NTC Hybrid can perform

controlled test on load in TEST

mode. For detailed description of

Test on load please refer to a

separate chapter.

InteliSys-NTC Hybrid obtains data

about precise time and GPS

position from InternetBridge-NT-

2.0 (and higher) connected to the

CAN. Time is broadcasted to all

the controllers on CAN bus.

Position is available for monitoring

and for WebSupervisor.

Synchro enable

Island enable

FwRet break

ReturnWithIntr

BreakerOverlap

RetFromIsland

ReturnTo Mains

Latitude

Longitude

Timer channel 1

Timer channel 2

Timer channel 3

TIMERACT 13-16

TIMERACTIVECOM

TIMER BLOCK 1

Up to 16 timers are provided in the

controller (with 4 combined

outputs). They can be used to

Timers

InteliSys-NTC Hybrid 2.1.0 Global Guide

trigger various internal functions as

well as external devices. Please

refer to a separate chapter for

detailed information.

Timer channel 4

Timer channel 5

Timer channel 6

Timer channel 7

Timer channel 8

Timer channel 9

Timer channel 10

Timer channel 11

Timer channel 12

Timer channel 13

Timer channel 14

TIMER BLOCK 2

TIMER BLOCK 3

TIMER BLOCK 4

TIMER BLOCK 5

TIMER BLOCK 6

TIMER BLOCK 7

TIMER BLOCK 8

TIMER BLOCK 9

TIMER BLOCK 10

TIMER BLOCK 11

TIMER BLOCK 12

51

Page 52

Function Name Brief Description Related Setpoints, Inputs and Outputs

User Buttons

User Configurable

protections

It is possible to use up to 16 user

buttons. User buttons can be for

example assigned to software

buttons in InteliVision displays.

Pressing of corresponding button

then activates the output with

function that is chosen in the

configuration. For more information

on how to use User Buttons please

refer to a separate chapter.

There are several prepared user

configurable protections in default

archive. Please refer to a separate

chapter for complex step-by-step

instructions on user configurable

protections.

Timer channel 15

TIMER BLOCK 13

Timer channel 16

TIMER BLOCK 14

TIMERACT 1-4

TIMER BLOCK 15

TIMERACT 5-8

TIMER BLOCK 16

TIMERACT 9-12

UserBtn pulse

USER BUTTON 9

USER BUTTON 1

USER BUTTON 10

USER BUTTON 2

USER BUTTON 11

USER BUTTON 3

USER BUTTON 12

USER BUTTON 4

USER BUTTON 13

USER BUTTON 5

USER BUTTON 14

USER BUTTON 6

USER BUTTON 15

USER BUTTON 7

USER BUTTON 16

USER BUTTON 8

Batt >V

Batt <V

Batt volt del

Mains I unbal

Mains Iunb del

Mains V unbal

Mains Vunb del

Bus V unbal

User Mask

User MODBUS

It is possible to use four separate

Logical Binary Inputs to show or

hide particular objects in

InteliVision 5 and 8. It is possible to

use these inputs to show particular

screens in InteliVision 5. For more

information on this function please

refer to the separate chapter.

Modbus registers (up to 128) can

be defined for every value and