Page 1

InteliLite NT

®

Operator Guide

December 2008

Copyright © 2007 ComAp s.r.o.

Written by Adela Prochazkova

Prague, Czech Republic

ComAp, spol. s r.o.

Kundratka 2359/17, 180 00 Praha 8, Czech Republic

Tel: +420 246 012 111, Fax: +420 246 316 647

E-mail: info@comap.cz, www.comap.cz

Page 2

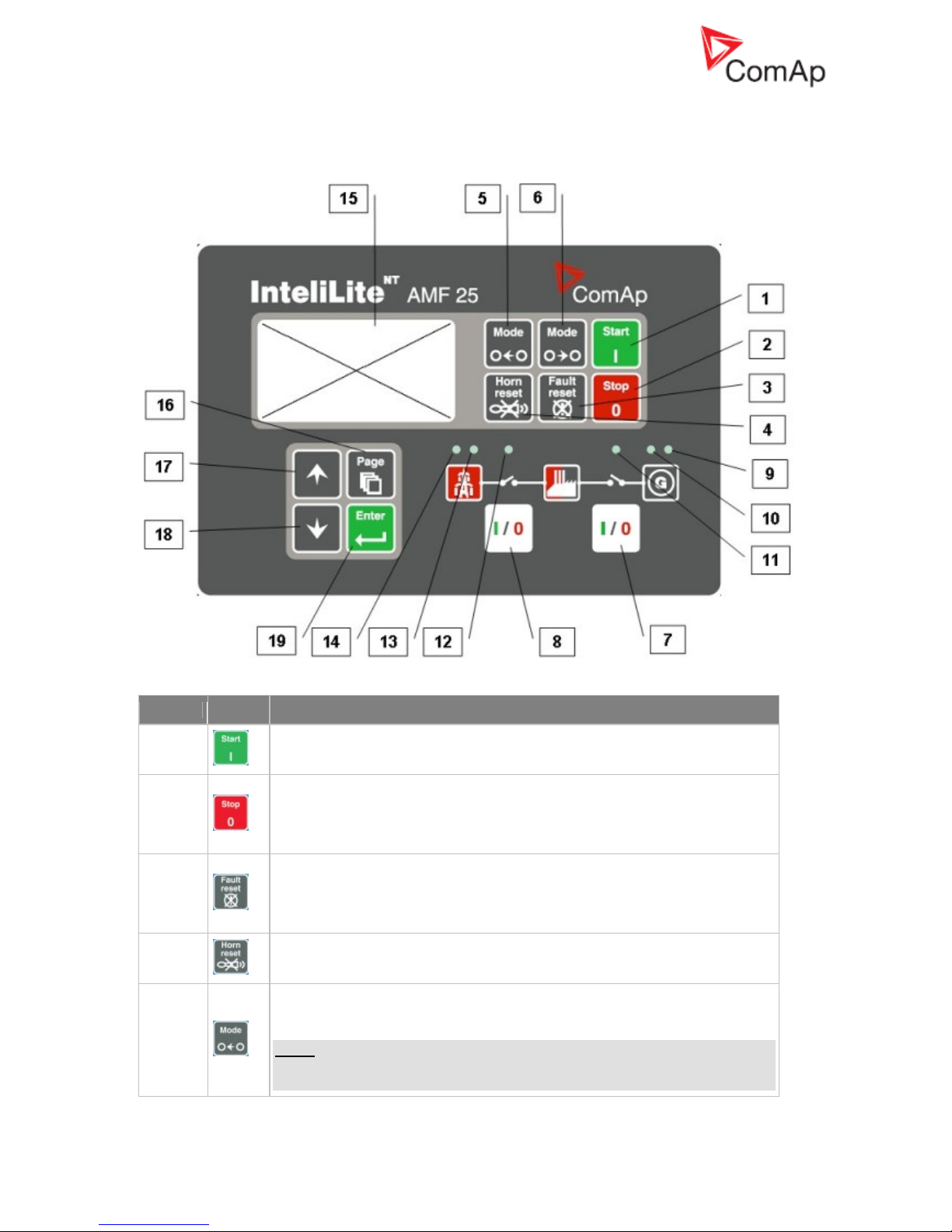

Operator Interface AMF

GEN-SET CONTROL BUTTONS

POSITION BUTTON DESCRIPTION

1

START button. Works in MAN mode only. Press this button to initiate the

start sequence of the engine.

2

STOP button. Works in MAN mode only. Press this button to initiate the stop

sequence of the gen-set. Repeated pressing or holding the button for more

than 2s will cancel current phase of stop sequence (like ramping the power

down or cooling) and next phase will continue.

3

FAULT RESET button. Use this button to acknowledge alarms and

deactivate the horn output. Inactive alarms will disappear immediately and

status of active alarms will be changed to "confirmed" so they will disappear

as soon as their reasons dismiss.

4

HORN RESET button. Use this button to deactivate the horn output without

acknowledging the alarms.

5

MODE LEFT button. Use this button to change the mode. The button works

only if the main screen with the indicator of currently selected mode is

displayed.

NOTE:

This button will not work if the controller mode is forced by one of binary

inputs Remote OFF, Remote MAN, Remote AUT, Remote TEST.

IL-NT Operator Guide

©ComAp – December 2008 2

Page 3

6

MODE RIGHT button. Use this button to change the mode. The button works

only if the main screen with the indicator of currently selected mode is

displayed.

NOTE:

This button will not work if the controller mode is forced by one of binary

inputs Remote OFF, Remote MAN, Remote AUT, Remote TEST.

7

GCB button. Works in MAN mode only. Press this button to open or close

the GCB manually. Note that certain conditions must be valid otherwise GCB

closing is blocked.

8

MCB button. Works in MAN mode only. Press this button to open or close

the MCB manually.

CAUTION!

You can disconnect the load from the mains supply with this button! Be sure

you know well what you are about to do!

GEN-SET OPERATION INDICATORS

POSITION INDICATOR DESCRIPTION

9

Gen-set failure. Red LED starts flashing when gen-set failure occurs. After FAULT

RESET button is pressed, goes to steady light (if an alarm is still active) or is off (if no

alarm is active).

10

Gen-set voltage OK. Green LED is on if the generator voltage is present and within

limits.

NOTE:

The limits for the generator voltage and frequency are given by setpoints in the Gener

Protect group.

11

GCB ON. Green LED is on, if GCB is closed. It is driven by GCB CLOSE/OPEN

output (AMF 8/9) or by GCB feedback signal (AMF 20/25).

12

MCB ON. Green LED is on, if MCB is closed. It is driven by MCB CLOSE/OPEN

output (AMF 8/9) or by MCB feedback signal (AMF 20/25).

13 Mains voltage OK. Green LED is on, if mains is present and within limits.

14

Mains failure. Red LED starts blinking when the mains failure is detected and after

the gen-set has started and connected to the load it lights permanently until the mains

failure disappears.

E

N

DISPLAY AND CONTROL BUTTONS

POSITION BUTTON DESCRIPTION

15 Graphic B/W display, 128x64 pixels

16

PAGE button. Use this button to switch over display pages. See Display

Screens and Pages Structure chapter below this table for more details.

17

UP button. Use this button to move up or increase a value.

18

DOWN button. Use this button to move down or decrease a value.

19

ENTER button. Use this button to finish editing a setpoint or moving right in

the history page.

IL-NT Operator Guide

©ComAp – December 2008 3

Page 4

Operator Interface MRS

GEN-SET CONTROL BUTTONS

POSITION BUTTON DESCRIPTION

1

START button. Works in MAN mode only. Press this button to initiate the

start sequence of the engine.

2

STOP button. Works in MAN mode only. Press this button to initiate the stop

sequence of the gen-set. Repeated pressing or holding the button for more

than 2s will cancel current phase of stop sequence (like ramping the power

down or cooling) and next phase will continue.

3

FAULT RESET button. Use this button to acknowledge alarms and

deactivate the horn output. Inactive alarms will disappear immediately and

status of active alarms will be changed to "confirmed" so they will disappear

as soon as their reasons dismiss.

4

HORN RESET button. Use this button to deactivate the horn output without

acknowledging the alarms.

5

MODE LEFT button. Use this button to change the mode. The button works

only if the main screen with the indicator of currently selected mode is

displayed.

NOTE:

This button will not work if the controller mode is forced by one of binary

inputs Remote OFF, Remote MAN, Remote AUT.

IL-NT Operator Guide

©ComAp – December 2008 4

Page 5

6

MODE RIGHT button. Use this button to change the mode. The button works

only if the main screen with the indicator of currently selected mode is

displayed.

NOTE:

This button will not work if the controller mode is forced by one of binary

inputs Remote OFF, Remote MAN, Remote AUT.

7

GCB button. Works in MAN mode only. Press this button to open or close

the GCB manually. Note that certain conditions must be valid otherwise GCB

closing is blocked.

GEN-SET OPERATION INDICATORS

POSITION INDICATOR DESCRIPTION

8

Gen-set failure. Red LED starts flashing when gen-set failure occurs. After FAULT

RESET button is pressed, goes to steady light (if an alarm is still active) or is off (if no

alarm is active).

9

Gen-set voltage OK. Green LED is on if the generator voltage is present and within

limits.

NOTE:

The limits for the generator voltage and frequency are given by setpoints in the Gener

Protect group.

10

GCB ON. Green LED is on, if GCB is closed. It is driven by GCB CLOSE/OPEN

output (MRS 3/4/10/15) or by GCB feedback signal (MRS 11/16).

DISPLAY AND CONTROL BUTTONS

POSITION BUTTON DESCRIPTION

11

PAGE button. Use this button to switch over display pages. See Display

Screens and Pages Structure chapter below this table for more details.

12

UP button. Use this button to move up or increase a value.

13

DOWN button. Use this button to move down or decrease a value.

14

ENTER button. Use this button to finish editing a setpoint or moving right in

the history page.

15 Graphic B/W display, 128x64 pixels

IL-NT Operator Guide

©ComAp – December 2008 5

Page 6

Display Screens and Pages Structure

The displayed information is structured into "pages" and "screens". Use PAGE button to switch over

the pages.

1. The page

Measurement consists of screens which display measured values like voltages,

current, oil pressure etc., computed values like i.e. gen-set power, statistic data and the alarm

list on the last screen.

2. The page

Setpoints contains all setpoints organized to groups and also a special group for

entering password.

3. The page

History log shows the history log in the order that the last record is displayed first.

Measurement Setpoints History log

Generator

L1N 0 L1L2 0V

L1N 0 L1L2 0V

L1N 0 L1L2 0V

Gen freq 0.0Hz

0 0 0 A

OFF MAN AUT TEST !

Not ready

MainsFlt

PF 0.00

RPM 0

No Timer

0 kW 0

ECU AlarmList

>EngOil Press

000225 (000E1h)

FC 100 OC 4 FMI 1

AlarmList 1

Emergency Stop

Password

>Basic Settings

Engine Params

Engine Protect

Gener Protect

AutoMains Fail

Extension I/O

Date/Time

Page

Gen-set Name

>Nominal Power

200 kW

Nomin Current

350 A

CT Ratio

2000 /5A

Gen-set Name

>Nominal Power

250 200 kW

Nomin Current

350 A

CT Ratio

2000 /5A

No. Reason

> 0 Switched On

-1 Fault reset

-2 Emergency Stop

-3 Wrn RA15 Fail

-4 Sprinkler Set

-5 Config Loaded

13:02:17 07/08/2008

Time Date

>13:02:17 07/08/2008

13:00:46 07/08/2008

13:00:46 07/08/2008

13:00:45 07/08/2008

13:00:45 07/08/2008

13:00:43 07/08/2008

0 Switched On

Mode RPM Pwr

> OFF 0 0

OFF 0 0

OFF 0 0

OFF 0 0

OFF 0 0

OFF 0 0

0 Switched On

Page

Page

Page

Page

Page

Page

Page

Enter

Enter

Enter

Enter

Page

Enter

Enter Page

NOTE:

History and Setpoints pages are available only when you choose Engineer interface (not User). See

Controller Information Screen subchapter below.

History Log is not supported in InteliLite MRS 3, 4, 10, 11 and AMF 8, 9, 20.

IL-NT Operator Guide

©ComAp – December 2008 6

Page 7

Alarms

AlarmList 3

*MCB Fail

*Emergency Stop

Sd Override

Inactive unconfirmed alarm

A

ctive unconfirmed alarm

A

ctive confirmed alarm

Browsing ECU Alarms

IL-NT Operator Guide

©ComAp – December 2008 7

Page 8

Setpoint Change

Entering the Password

OFF MAN AUT TEST !

Not ready

MainsFlt

PF 0.00

RPM 0

No Timer

0 kW 0

Password

>Basic Settings

Engine Params

Engine Protect

Gener Protect

AutoMains Fail

Extension I/O

Date/Time

Enter

Page

Enter

Enter Page

Page

Gen-set Name

>Nominal Power

200 kW

*Nomin Current

350 A

CT Ratio

2000 /5A

Gen-set Name

>Nominal Power

250 200 kW

*Nomin Current

350 A

CT Ratio

2000 /5A

NOTE:

Cannot change setpoint?

Setpoints marked with an

asterisk are password

protected. Enter password

as described in the chapter

Entering the Password

below.

IL-NT Operator Guide

©ComAp – December 2008 8

OFF MAN AUT TEST !

Not ready

MainsFlt

PF 0.00

RPM 0

No Timer

0 kW 0

>Password

Basic Settings

Engine Params

Engine Protect

Gener Protect

AutoMains Fail

Extension I/O

Date/Time

>EnterPassword

Changepassword

Enter

Page

Enter

Enter Page

>EnterPassword

0

Changepassword

Page

NOTE:

Lost password? Display the

information screen containing

the serial number and

password decode number as

described in the chapter below

and send them to your local

distributor.

Page 9

Controller Information Screen

OFF MAN AUT TEST !

Not ready

MainsFlt

PF 0.00

RPM 0

No Timer

0 kW 0

InteliLite NT

ComAp 2007-2008

IL-NT-x.y

Serial:12345678

SW ver: x.y, x.y

Appl : AMF25

Branch: Standard

Page

Languages

>English

Chinese

Enter + Page

User interface:

User

>Engineer

Serial: 12345678

Pwd. dec.: 1234567890

Page

Page

Enter

Enter

Display Contrast Adjustment

OFF MAN AUT TEST !

Not ready

MainsFlt

PF 0.00

RPM 0

No Timer

0 kW 0

Enter +

Enter +

OFF MAN AUT TEST !

Not ready

MainsFlt

PF 0.00

RPM 0

No Timer

0 kW 0

OFF MAN AUT TEST !

Not ready

MainsFlt

PF 0.00

RPM 0

No Timer

0 kW 0

IL-NT Operator Guide

©ComAp – December 2008 9

Loading...

Loading...