Page 1

Reference Guide

InteliDrive Lite

®

Modular Engine Controller

SW version 1.9, August 2015

Copyright ©2015 ComAp a.s.

ComAp a.s.

Kundratka 17, 180 00 Praha 8, Czech Republic

Tel: +420 246 012 111, Fax: +420 266 316 647

E-mail:info@comap.cz, www.comap.cz

Page 2

2

Table of contents

1 Document information ................................................................................................................. 11

1.1 Clarification of notation ............................................................................................................. 12

1.2 Text ........................................................................................................................................... 12

1.3 Conformity Declaration ............................................................................................................. 12

2 System overview .......................................................................................................................... 13

2.1 What describes this manual? ................................................................................................... 13

2.2 Warnings .................................................................................................................................. 13

2.3 General description .................................................................................................................. 13

2.4 Configurability and monitoring .................................................................................................. 14

2.4.1 Open connection from LiteEdit ........................................................................................ 14

2.4.2 Open connection from web browser ................................................................................ 16

2.4.3 Open connection from WinScope .................................................................................... 17

2.5 Applications overview ............................................................................................................... 18

2.5.1 Single applications ........................................................................................................... 18

3 Installation .................................................................................................................................... 19

3.1 Mounting ................................................................................................................................... 19

3.2 Package contents ..................................................................................................................... 19

3.2.1 Software package ............................................................................................................ 19

3.2.2 Components..................................................................................................................... 20

3.3 Terminal diagram and dimension ............................................................................................. 20

3.4 Extension plug-in modules ....................................................................................................... 22

3.4.1 Extension plug-in modules installation ............................................................................ 22

3.4.2 IL-NT AOUT8 ................................................................................................................... 22

Examples of default analog output curves: .................................................................................... 22

3.4.3 IL-NT AIO ......................................................................................................................... 24

3.4.4 IL-NT IO1 ......................................................................................................................... 25

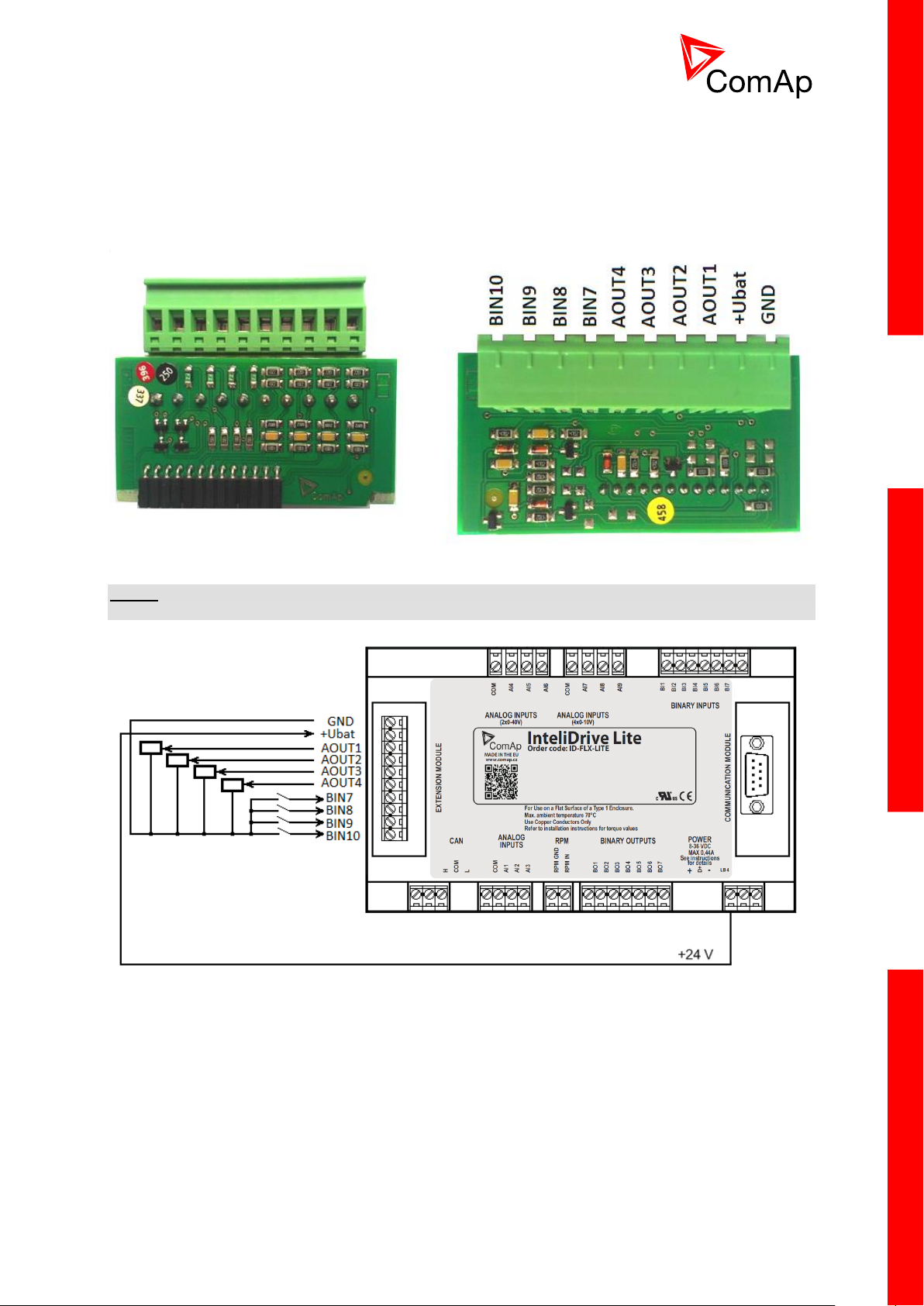

3.4.5 IL-NT BIO8 ....................................................................................................................... 25

3.5 Communication modules .......................................................................................................... 26

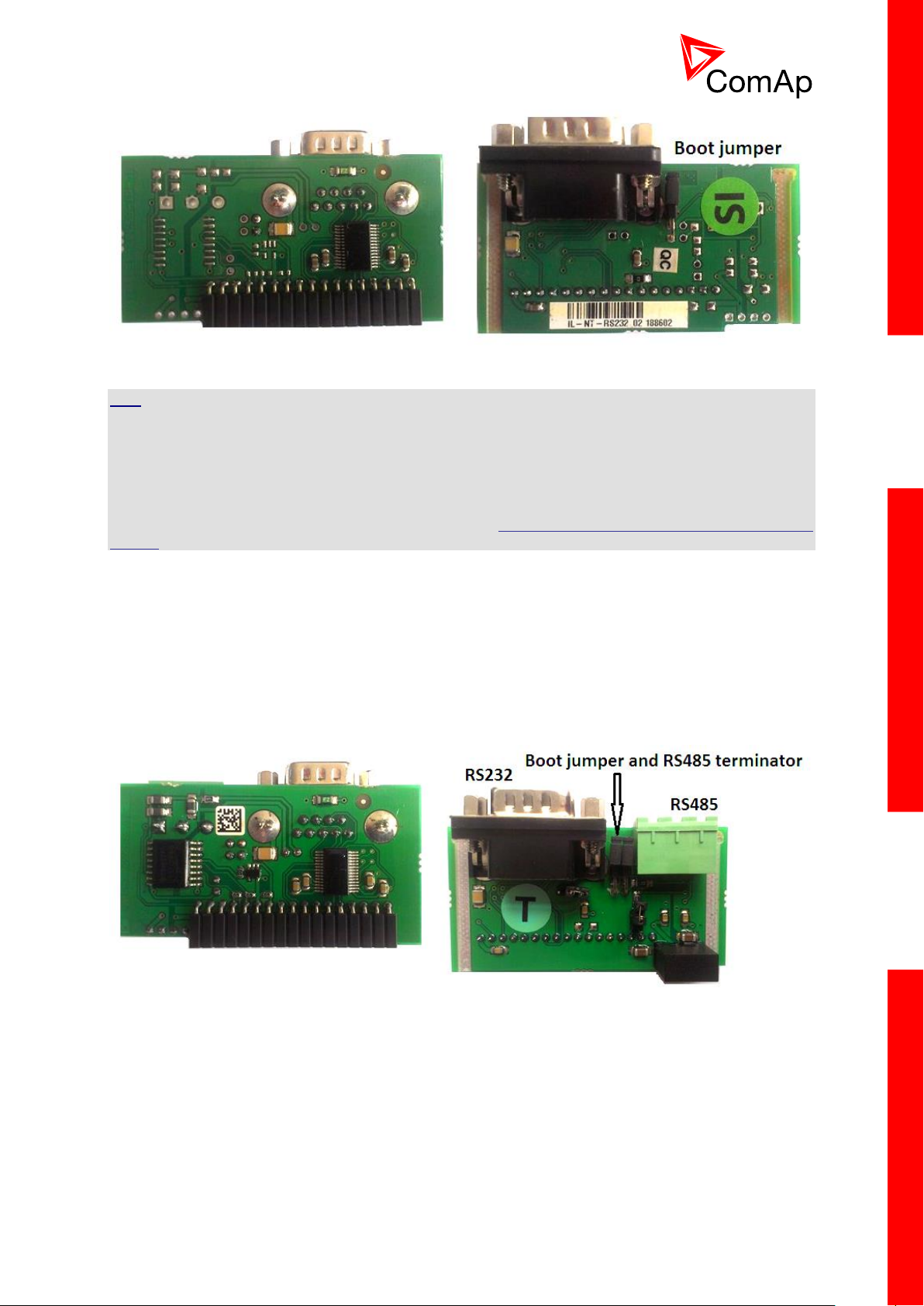

3.5.1 IL-NT RS232 .................................................................................................................... 26

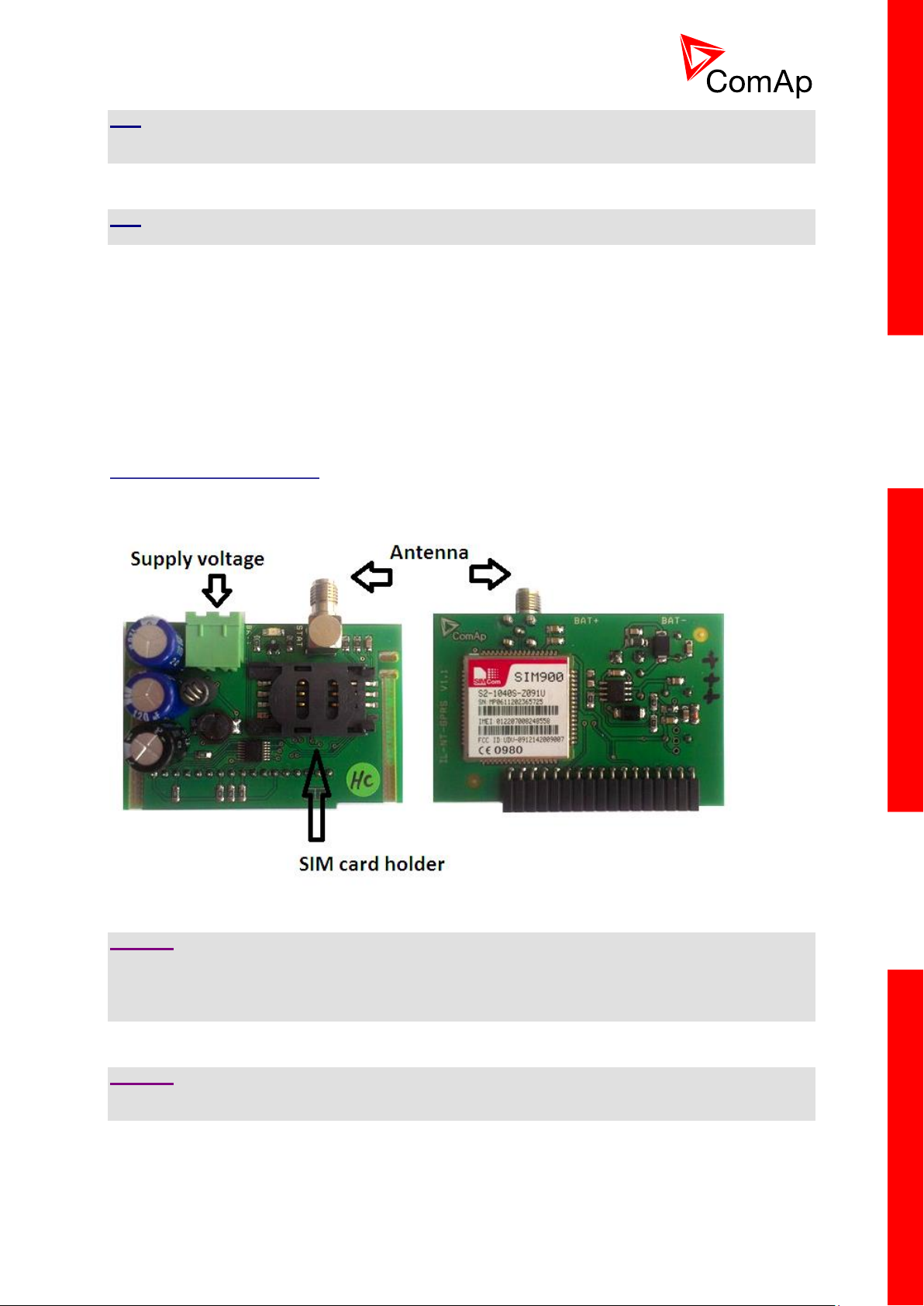

3.5.2 IL-NT RS232-485 ............................................................................................................. 27

3.5.3 IL-NT S-USB .................................................................................................................... 27

3.5.4 IB-Lite ............................................................................................................................... 28

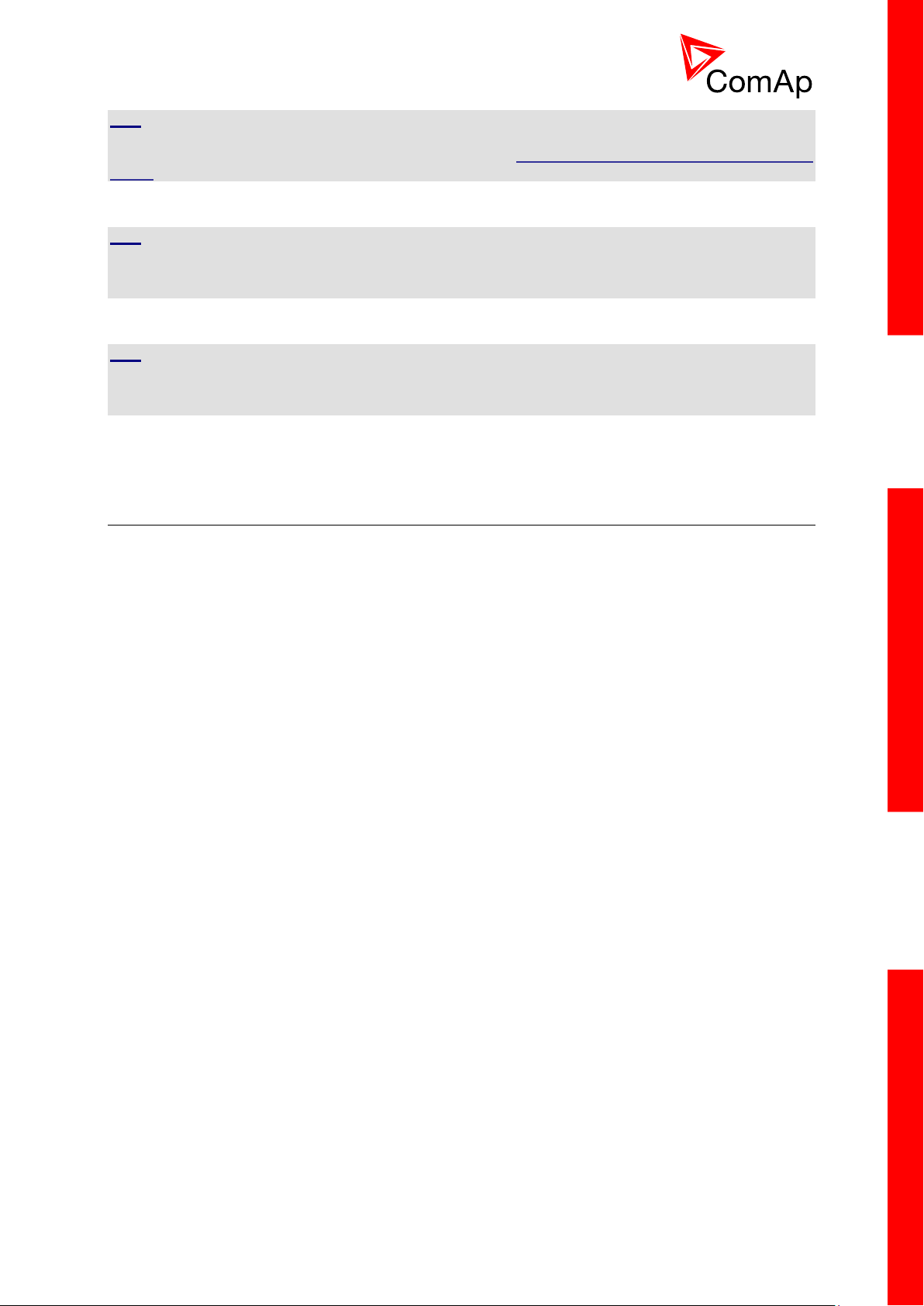

3.5.5 IL-NT GPRS ..................................................................................................................... 29

3.6 Remote modules ...................................................................................................................... 30

3.6.1 IL-NT RD (SW)................................................................................................................. 30

3.6.2 IGL-RA15 ......................................................................................................................... 32

3.6.3 IB-NT ................................................................................................................................ 33

4 Putting it into operation ............................................................................................................... 34

4.1 How to install ............................................................................................................................ 34

4.1.1 Grounding ........................................................................................................................ 34

4.1.2 Wiring ............................................................................................................................... 34

4.1.3 Power supply ................................................................................................................... 34

4.1.4 Power supply fusing ......................................................................................................... 35

4.1.5 Binary output protections ................................................................................................. 36

4.1.6 Magnetic pick-up .............................................................................................................. 36

4.2 Analog inputs ............................................................................................................................ 37

4.2.1 Table of controller analog inputs...................................................................................... 37

4.2.2 Table of analog inputs options ......................................................................................... 38

4.2.3 Connection of InteliDrive Lite analog inputs .................................................................... 40

4.2.4 Current output transducers .............................................................................................. 41

4.2.5 Analog input extension measurement (0 - 70V, 4 - 20mA) ............................................. 41

4.3 Binary inputs and outputs ......................................................................................................... 43

4.4 Analog outputs .......................................................................................................................... 44

4.4.1 Default analog output curves ........................................................................................... 44

InteliDrive Lite, SW version 1.9

ID-FLX-Lite-1.9r1 Reference Guide.pdf, ©ComAp – August 2015

Page 3

3

4.5 Remote modules - CAN bus connection .................................................................................. 45

4.5.1 Connection rules .............................................................................................................. 45

5 Operator guide .............................................................................................................................. 46

5.1 Front panel elements ................................................................................................................ 46

5.2 Init screens ............................................................................................................................... 48

5.2.1 Init screen ........................................................................................................................ 48

5.2.2 Firmware screen .............................................................................................................. 48

5.2.3 Languages screen ........................................................................................................... 48

5.2.4 User Interface screen ...................................................................................................... 48

5.3 Display menus .......................................................................................................................... 49

5.3.1 Switching between User and Engineer menus ................................................................ 49

5.4 How to select the engine mode? .............................................................................................. 49

5.5 How to view measured data? ................................................................................................... 49

5.6 How to view and edit setpoints? ............................................................................................... 49

5.6.1 How to change the display contrast? ............................................................................... 49

5.6.2 How to check software revision? ..................................................................................... 49

5.6.3 How to check the serial number and choose interface? .................................................. 50

5.6.4 How to change language? ............................................................................................... 50

5.7 How to find active alarms? ....................................................................................................... 50

5.8 How to list History records? ...................................................................................................... 51

5.9 MEASUREMENT screens description ..................................................................................... 51

5.9.1 Main measure screen ...................................................................................................... 51

5.9.2 InteliDrive Lite Analog inputs screens ............................................................................. 51

5.9.3 IL-NT-AIO Analog inputs screen ...................................................................................... 52

5.9.4 InteliDrive Lite Binary inputs ............................................................................................ 52

5.9.5 InteliDrive Lite Binary outputs .......................................................................................... 52

5.9.6 IL-NT-BIO8 Binary inputs screen ..................................................................................... 52

5.9.7 IL-NT-IO1 Binary inputs screen ....................................................................................... 52

5.9.8 ECU State ........................................................................................................................ 52

5.9.9 ECU Values ..................................................................................................................... 53

5.9.10 Statistic ............................................................................................................................ 53

5.9.11 ECU AlarmList ................................................................................................................. 53

5.9.12 Alarm list .......................................................................................................................... 54

5.10 Display screens and pages structure ....................................................................................... 55

6 Function description .................................................................................................................... 56

6.1 Engine operation states ............................................................................................................ 56

6.2 OFF mode ................................................................................................................................ 56

6.3 MAN mode ................................................................................................................................ 56

6.3.1 Start-stop sequence (simplified) ...................................................................................... 56

6.4 AUT mode ................................................................................................................................ 58

6.5 Engine without pickup operation .............................................................................................. 58

6.6 Engine timer ............................................................................................................................. 59

6.6.1 MAN mode ....................................................................................................................... 59

6.6.2 AUT mode ........................................................................................................................ 59

6.7 Protections ................................................................................................................................ 59

6.8 Engine RPM control in MAN mode ........................................................................................... 60

6.8.1 Engine RPM Idle - Nominal switching ............................................................................. 61

6.8.2 Engine RPM two/three levels switching ........................................................................... 61

6.8.3 Engine RPM by Up/Down buttons settings ...................................................................... 61

6.8.4 Engine RPM continuous change (using potentiometer) .................................................. 61

6.8.5 Speed request chart ........................................................................................................ 62

6.9 AUT mode: Engine load limitation– overview ........................................................................... 62

6.9.1 Functions 1 and 2 ............................................................................................................ 63

6.9.2 Functions 1 and 2 setpoints ............................................................................................. 64

6.9.3 Functions 1 and 2 examples ............................................................................................ 64

6.10 AUT mode: Engine regulation by RPM control – overview ..................................................... 67

6.10.1 Functions 3 and 4 ............................................................................................................ 68

6.10.2 Functions 3 and 4 setpoints ............................................................................................. 68

6.10.3 Functions 3 and 4 examples ............................................................................................ 69

InteliDrive Lite, SW version 1.9

ID-FLX-Lite-1.9r1 Reference Guide.pdf, ©ComAp – August 2015

Page 4

4

7 Setpoints ....................................................................................................................................... 71

7.1 Password .................................................................................................................................. 71

7.1.1 EnterPassword................................................................................................................. 71

7.1.2 ChangePassword ............................................................................................................ 71

7.2 Basic settings ........................................................................................................................... 71

7.2.1 Engine name .................................................................................................................... 71

7.2.2 Gear teeth [-] ................................................................................................................ 71

7.2.3 RPMbyWterminal [-] ........................................................................................................ 72

7.2.4 Nominal RPM [RPM] ...................................................................................................... 72

7.2.5 GearTeethBI3 [-] ............................................................................................................ 72

7.2.6 RPM source [Pickup, AIO-AIN1, AIO-AIN2, AIO-AIN3, AIO-AIN4] ........................... 72

7.2.7 ControllerMode [OFF, MAN, AUT] ................................................................................. 73

7.2.8 FltResGoToMAN [ENABLED, DISABLED] .................................................................... 73

7.2.9 DispBacklightTO [min] ................................................................................................... 73

7.2.10 Panel Button [Nom/Idle, N/I Init, Conveyor, RegReqst, R RegDis, CloseLoad, Toggle] . 73

7.2.11 RunHoursSource [ECU, INTERNAL, AUTO] .................................................................. 74

7.2.12 Main Screen [SHOW TIMERS, SHOW AIN] ................................................................. 74

7.3 Comms Settings ....................................................................................................................... 74

7.3.1 ControllerAddr [-] ........................................................................................................... 74

7.3.2 COM1 Mode [DIRECT/MODEM/MODBUS/ECU LINK] ................................................ 75

7.3.3 COM2 Mode [DIRECT/MODBUS/ECU LINK] ............................................................... 75

7.3.4 ModemIniString [-] ......................................................................................................... 75

7.3.5 ModbusComSpeed [9600, 19200, 38400, 57600] .......................................................... 75

7.3.6 IBLite IP Addr [-] ............................................................................................................ 75

7.3.7 IBLite NetMask [-] .......................................................................................................... 75

7.3.8 IBLite GateIP [-] ............................................................................................................. 76

7.3.9 IBLite DHCP [DISABLED, ENABLED] ........................................................................... 76

7.3.10 ComAp Port [-] ............................................................................................................... 76

7.3.11 APN Name [-] ................................................................................................................. 76

7.3.12 APN UserName [-] .......................................................................................................... 76

7.3.13 APN UserPass [-] ........................................................................................................... 76

7.3.14 AirGate [DISABLED, ENABLED] .................................................................................. 76

7.3.15 AirGate IP [-] .................................................................................................................. 76

7.3.16 SMTP UserName [-] ....................................................................................................... 77

7.3.17 SMTP UserPass [-] ......................................................................................................... 77

7.3.18 SMTP Server IP [-] .......................................................................................................... 77

7.3.19 Contr MailBox .................................................................................................................. 77

7.3.20 Time Zone ........................................................................................................................ 77

7.3.21 DNS IP Address ............................................................................................................... 77

7.4 Engine params ......................................................................................................................... 77

7.4.1 Starting RPM [RPM] ...................................................................................................... 77

7.4.2 Starting POil [Bar] .......................................................................................................... 78

7.4.3 Prestart time [s] .............................................................................................................. 78

7.4.4 Preglow time [s] ............................................................................................................. 78

7.4.5 MaxCrank time [s] .......................................................................................................... 78

7.4.6 CrnkFail pause [s] .......................................................................................................... 79

7.4.7 Crank attempts [-] .......................................................................................................... 79

7.4.8 Idle time [s]................................................................................................................... 79

7.4.9 Idle speed [RPM] ....................................................................................................... 79

7.4.10 Cooling speed [IDLE, NOMINAL] .................................................................................. 80

7.4.11 Cooling time [s] .............................................................................................................. 80

7.4.12 AfterCool time [s] ........................................................................................................... 80

7.4.13 Stop time [s] ................................................................................................................... 80

7.4.14 Fuel solenoid [DIESEL, GAS] ........................................................................................ 80

7.4.15 FuelSol offset [s] ........................................................................................................... 81

7.4.16 D+ function [ENABLED, CHRGFAIL, DISABLED] ........................................................ 82

7.4.17 ECU Control [ENABLED, DISABLED] ........................................................................... 82

7.4.18 ECU SpeedAdj [RPM] .................................................................................................... 82

7.4.19 RetToSpeedAdj [DISABLED, ENABLED] ................................................................. 82

7.4.20 MinSpeedLim [RPM] ...................................................................................................... 82

InteliDrive Lite, SW version 1.9

ID-FLX-Lite-1.9r1 Reference Guide.pdf, ©ComAp – August 2015

Page 5

5

7.4.21 MaxSpeedLim [RPM] ..................................................................................................... 83

7.4.22 BI Speed Sel 1 [RPM] .................................................................................................... 83

7.4.23 BI Speed Sel 2 [RPM] .................................................................................................... 83

7.4.24 BI Speed Sel 3 [RPM] .................................................................................................... 83

7.4.25 Speed Ramp [RPM/s] ..................................................................................... 83

7.4.26 0%ofSpeedReq [RPM] .................................................................................................. 84

7.4.27 100%ofSpeedReq [RPM] .............................................................................................. 85

7.4.28 Conveyor horn [s] .................................................................................... 85

7.4.29 Running timer [min] ....................................................................................................... 85

7.4.30 FuelTankVolume [L] ....................................................................................................... 85

7.4.31 MaxFuelDrop [%/h] ....................................................................................................... 85

7.5 Regulator .................................................................................................................................. 86

7.5.1 LAI SpdRequest [OFF, CU:AI1, CU:AI2, CU:AI3, CU:AI4, CU:AI5, CU:AI6, CU:AI7,

CU:AI8, CU:AI9, AIO:IA1, AIO:AI2, AIO:AI3, AIO:AI4 ] ................................................................. 86

7.5.2 Reg Input [CU:AI1, CU:AI2, CU:AI3, CU:AI4, CU:AI5, CU:AI6, CU:AI7, CU:AI8, CU:AI9,

AIO:IA1, AIO:AI2, AIO:AI3, AIO:AI4, RPM-BI3 ] ............................................................................ 86

7.5.3 Reg Bias [-] .................................................................................................................... 86

7.5.4 Request 1 [-] .................................................................................................................. 87

7.5.5 Request 2 [-] .................................................................................................................. 87

7.5.6 Reg Gain [%].................................................................................................................. 87

7.5.7 Reg Integral [%] .............................................................................................................. 87

7.5.8 Reg CMP Input [CU:AI1, CU:AI2, CU:AI3, CU:AI4, CU:AI5, CU:AI6, CU:AI7, CU:AI8,

CU:AI9, AIO:IA1, AIO:AI2, AIO:AI3, AIO:AI4, RPM-BI3 ] .............................................................. 88

7.5.9 Reg CMP On [-] .............................................................................................................. 88

7.5.10 Reg CMP Off [-] .............................................................................................................. 89

7.6 Load limit .................................................................................................................................. 89

7.6.1 Load input [ RPM, ECU:Load, CU:AI1, CU:AI2, CU:AI3, CU:AI4, CU:AI5, CU:AI6,

CU:AI7, CU:AI8, CU:AI9, AIO:IA1, AIO:AI2, AIO:AI3, AIO:AI4 ...................................................... 89

7.6.2 Load Bias [-] ................................................................................................................... 89

7.6.3 LoadRequest 1 [-] ........................................................................................................... 90

7.6.4 Load request 2 [-] ............................................................................................................ 90

7.6.5 LoadReq Ramp [1/s] ...................................................................................................... 90

7.6.6 LoadUpLimit [-]................................................................................................................ 90

7.6.7 LoadDnLimit [-]................................................................................................................ 90

7.6.8 Load Gain [%] ................................................................................................................ 90

7.6.9 Load Integral [%] ............................................................................................................. 91

7.6.10 Load CMP Input [RPM, ECU:Load, CU:AI1, CU:AI2, CU:AI3, CU:AI4, CU:AI5, CU:AI6,

CU:AI7, CU:AI8, CU:AI9, AIO:IA1, AIO:AI2, AIO:AI3, AIO:AI4] ..................................................... 91

7.6.11 Load CMP Off .................................................................................................................. 91

7.6.12 Load CMP On .................................................................................................................. 91

7.7 Engine protect .......................................................................................................................... 91

7.7.1 Eng prot del [s] ............................................................................................................... 91

7.7.2 BIN6 delay [s]................................................................................................................ 92

7.7.3 Horn timeout [s] ............................................................................................................. 92

7.7.4 StartOverspeed ................................................................................................................ 92

7.7.5 Overspeed [%] .............................................................................................................. 92

7.7.6 Underspeed [%] ............................................................................................................. 92

7.7.7 Flow SwitchDel [s] ......................................................................................................... 93

7.7.8 UnderspeedSd [DISABLED, ENABLED] ....................................................................... 93

7.7.9 AIN1 Level 1 [Bar] ........................................................................................................... 94

7.7.10 AIN1 Level 2 [Bar] ........................................................................................................... 94

7.7.11 AIN1 Del [s] ..................................................................................................................... 94

7.7.12 AIN2 Level 1 [ ] ............................................................................................................... 95

7.7.13 AIN2 Level 2 [ ] ............................................................................................................... 95

7.7.14 AIN2 Del [s] .................................................................................................................... 95

7.7.15 AIN3 Level 1 [ ] ............................................................................................................... 95

7.7.16 AIN3 Level 2 [ ] ............................................................................................................... 95

7.7.17 AIN3 Del [s] .................................................................................................................... 95

7.7.18 Batt overvolt [V]............................................................................................................... 96

7.7.19 Batt undervolt [V] ............................................................................................................ 96

InteliDrive Lite, SW version 1.9

ID-FLX-Lite-1.9r1 Reference Guide.pdf, ©ComAp – August 2015

Page 6

6

7.7.20 Batt volt del [s] ................................................................................................................ 96

7.7.21 AIN4 Level 1 [ ] ............................................................................................................... 96

7.7.22 AIN4 Level 2 [ ] ............................................................................................................... 96

7.7.23 AIN4 Del [s] .................................................................................................................... 96

7.7.24 AIN4 Eval [NORMAL, CLASS C] .................................................................................... 97

7.7.25 AIN4 LowWrn [ ] .............................................................................................................. 97

7.7.26 AIN4 LowSd [ ] ................................................................................................................ 97

7.7.27 AIN4 LowDel [s] .............................................................................................................. 97

7.7.28 AIN4 HighWrn [ ] ............................................................................................................. 97

7.7.29 AIN4 HighSd [ ] ............................................................................................................... 97

7.7.30 AIN4 HighDel [s] ............................................................................................................. 98

7.7.31 AIN5 Level 1 [ ] ............................................................................................................... 98

7.7.32 AIN5 Level 2 [ ] ............................................................................................................... 98

7.7.33 AIN5 Del [s] .................................................................................................................... 98

7.7.34 AIN5 Eval [NORMAL, CLASS C] .................................................................................... 98

7.7.35 AIN5 LowWrn [ ] .............................................................................................................. 99

7.7.36 AIN5 LowSd [ ] ................................................................................................................ 99

7.7.37 AIN5 LowDel [s] .............................................................................................................. 99

7.7.38 AIN5 HighWrn [ ] ............................................................................................................. 99

7.7.39 AIN5 HighSd [ ] ............................................................................................................... 99

7.7.40 AIN5 HighDel [s] ............................................................................................................. 99

7.7.41 AIN6 Level 1 [ ] ............................................................................................................. 100

7.7.42 AIN6 Level 2 [ ] ............................................................................................................. 100

7.7.43 AIN6 Del [s] .................................................................................................................. 100

7.7.44 AIN6 Eval [NORMAL, CLASS C] .................................................................................. 100

7.7.45 AIN6 LowWrn [ ] ............................................................................................................ 100

7.7.46 AIN6 LowSd [ ] .............................................................................................................. 100

7.7.47 AIN6 LowDel [s] ............................................................................................................ 101

7.7.48 AIN6 HighWrn [ ] ........................................................................................................... 101

7.7.49 AIN6 HighSd [ ] ............................................................................................................. 101

7.7.50 AIN6 HighDel [s] ........................................................................................................... 101

7.7.51 AIN7 Level 1 [ ] ............................................................................................................. 101

7.7.52 AIN7 Level 2 [ ] ............................................................................................................. 101

7.7.53 AIN7 Del [s] .................................................................................................................. 102

7.7.54 AIN7 Eval [NORMAL, CLASS C] .................................................................................. 102

7.7.55 AIN7 LowWrn [ ] ............................................................................................................ 102

7.7.56 AIN7 LowSd [ ] .............................................................................................................. 102

7.7.57 AIN7 LowDel [s] ............................................................................................................ 102

7.7.58 AIN7 HighWrn [ ] ........................................................................................................... 102

7.7.59 AIN7 HighSd [ ] ............................................................................................................. 103

7.7.60 AIN7 HighDel [s] ........................................................................................................... 103

7.7.61 AIN8 Level 1 [ ] ............................................................................................................. 103

7.7.62 AIN8 Level 2 [ ] ............................................................................................................. 103

7.7.63 AIN8 Del [s] .................................................................................................................. 103

7.7.64 AIN9 Level 1 [ ] ............................................................................................................. 104

7.7.65 AIN9 Level 2 [ ] ............................................................................................................. 104

7.7.66 AIN9 Del [s] .................................................................................................................. 104

7.7.67 NextServTime [h] .......................................................................................................... 104

7.7.68 GearBoxRatio [RPM] .................................................................................................... 104

7.7.69 RPMdiff Sd [RPM] ......................................................................................................... 105

7.7.70 RPMdiff Wrn [RPM] ...................................................................................................... 105

7.7.71 RPMdiff delay [s] ........................................................................................................... 105

7.7.72 BIN1 Prot Del…BIN7 Prot Del [s] ................................................................................ 105

7.7.73 DEF Level Min [%] ........................................................................................................ 106

7.7.74 DEF Level Max [%] ....................................................................................................... 106

7.8 Date/Time ............................................................................................................................... 106

7.8.1 Time stamp per [min] ................................................................................................... 106

7.8.2 SummerTimeMod [DISABLED, WINTER, SUMMER, WINTER-S, SUMMER-S] ............... 106

7.8.3 Time [HH:MM:SS] ...................................................................................................... 107

7.8.4 Date [DD:MM:YYYY] ................................................................................................. 107

InteliDrive Lite, SW version 1.9

ID-FLX-Lite-1.9r1 Reference Guide.pdf, ©ComAp – August 2015

Page 7

7

7.8.5 Timer1Function [NoFunc, AutoRun, AutoRegCMP, AutoBatt, AutoStop] ............................ 107

7.8.6 Timer1repeat [NONE, MONDAY, TUESDAY, WEDNESDAY, THURSDAY,

WEDNESDAY, FRIDAY, SATURDAY, SUNDAY, MON-FRI, MON-SAT, MON-SUN, SAT-SUN]

107

7.8.7 Timer1 ON time [HH:MM:SS] ...................................................................................... 107

7.8.8 Timer1Duration [min] .................................................................................................... 107

7.8.9 Timer2Function [NoFunc, AutoRun, AutoRegCMP, AutoBatt, AutoStop] ............................ 108

7.8.10 Timer2repeat [NONE, MONDAY, TUESDAY, WEDNESDAY, THURSDAY,

WEDNESDAY, FRIDAY, SATURDAY, SUNDAY, MON-FRI, MON-SAT, MON-SUN, SAT-SUN]

108

7.8.11 Timer2 ON time [HH:MM:SS] ...................................................................................... 108

7.8.12 Timer2Duration [min] .................................................................................................... 108

7.9 Sensor spec ............................................................................................................................ 109

7.9.1 Calibr AI1, AI2, AI3, AI4, AI5, AI6, AI7, AI8, AI9 […] .................................................... 109

7.9.2 Calibr AIO1, AIO2, AIO3, AIO4 […] ............................................................................ 109

7.9.3 CounterConst 1, CounterConst 2 .................................................................................. 109

7.9.4 Counter mode 1, Counter mode 2 ................................................................................. 110

7.10 AIO module ............................................................................................................................. 110

7.10.1 AnlInAIO1, AIO2, AIO3, AIO4 lev1 [ ] .......................................................................... 110

7.10.2 AnlInAIO1, AIO2, AIO3, AIO4 lev2 [ ] .......................................................................... 110

7.10.3 AnlInAIO1, AIO2, AIO3, AIO4 del [s] .......................................................................... 110

7.11 SMS/E-Mail ............................................................................................................................. 111

7.11.1 Yel Alarm Msg [OFF, ON] ........................................................................................... 111

7.11.2 Red Alarm Msg [OFF, ON] ......................................................................................... 111

7.11.3 TelNo/Addr Ch1, 2 […] ................................................................................................ 111

8 Values .......................................................................................................................................... 113

9 Binary input functions ............................................................................................................... 115

9.1 Binary inputs InteliDrive Lite - default configuration ............................................................... 115

9.2 Configuration of binary inputs ................................................................................................. 115

9.3 Binary inputs list ..................................................................................................................... 116

9.3.1 Not used ......................................................................................................................... 116

9.3.2 Rem start/stop................................................................................................................ 116

9.3.3 Emergency stop ............................................................................................................. 116

9.3.4 Sprinkler ......................................................................................................................... 116

9.3.5 Access lock .................................................................................................................... 116

9.3.6 Remote OFF .................................................................................................................. 116

9.3.7 Remote MAN ................................................................................................................. 116

9.3.8 Remote AUT .................................................................................................................. 117

9.3.9 RemControlLock ............................................................................................................ 117

9.3.10 Emerg. manual............................................................................................................... 117

9.3.11 StartButton ..................................................................................................................... 117

9.3.12 StopButton ..................................................................................................................... 117

9.3.13 FaultResButton .............................................................................................................. 117

9.3.14 HornResButton .............................................................................................................. 117

9.3.15 Nominal/Idle ................................................................................................................... 117

9.3.16 Speed Up ....................................................................................................................... 118

9.3.17 Speed Down .................................................................................................................. 118

9.3.18 Speed Sel1 .................................................................................................................... 118

9.3.19 Speed Sel2 .................................................................................................................... 118

9.3.20 Speed Sel3 .................................................................................................................... 118

9.3.21 Lang selection ................................................................................................................ 118

9.3.22 Conveyor ........................................................................................................................ 119

9.3.23 LoadRequest2................................................................................................................ 119

9.3.24 LoadRegDisable ............................................................................................................ 119

9.3.25 RegRequest2 ................................................................................................................. 119

9.3.26 R Reg Disable ................................................................................................................ 119

9.3.27 Clear DayCons............................................................................................................... 119

9.3.28 Clear TripCons ............................................................................................................... 119

9.3.29 Flow Switch .................................................................................................................... 120

InteliDrive Lite, SW version 1.9

ID-FLX-Lite-1.9r1 Reference Guide.pdf, ©ComAp – August 2015

Page 8

8

9.3.30 Prot Test ........................................................................................................................ 120

10 Binary output functions ....................................................................................................... 121

10.1 Binary outputs InteliDrive Lite - default ................................................................................... 121

10.2 Binary outputs – list ................................................................................................................ 121

10.2.1 Not used ......................................................................................................................... 121

10.2.2 Starter ............................................................................................................................ 121

10.2.3 Fuel solenoid.................................................................................................................. 121

10.2.4 Stop solenoid ................................................................................................................. 122

10.2.5 Stop Pulse ...................................................................................................................... 122

10.2.6 Ignition ........................................................................................................................... 122

10.2.7 Prestart .......................................................................................................................... 122

10.2.8 Preglow .......................................................................................................................... 122

10.2.9 Cooling pump ................................................................................................................. 122

10.2.10 Idle/Nominal ................................................................................................................... 122

10.2.11 Air valves ....................................................................................................................... 123

10.2.12 Alarm .............................................................................................................................. 123

10.2.13 Horn ............................................................................................................................... 123

10.2.14 Ready ............................................................................................................................. 123

10.2.15 Ready to load ................................................................................................................. 123

10.2.16 Running .......................................................................................................................... 123

10.2.17 Cooling ........................................................................................................................... 123

10.2.18 Fault Reset ..................................................................................................................... 123

10.2.19 ChrgAlternFail ................................................................................................................ 124

10.2.20 Stop failed ...................................................................................................................... 124

10.2.21 Overspeed ..................................................................................................................... 124

10.2.22 Underspeed ................................................................................................................... 124

10.2.23 Start failed ...................................................................................................................... 124

10.2.24 Battery flat ...................................................................................................................... 124

10.2.25 V batt failed .................................................................................................................... 125

10.2.26 Common Wrn ................................................................................................................. 125

10.2.27 Common Sd ................................................................................................................... 125

10.2.28 Common Cd ................................................................................................................... 125

10.2.29 Common Fls ................................................................................................................... 125

10.2.30 Sd Oil Press ................................................................................................................... 125

10.2.31 Wrn Oil Press ................................................................................................................. 125

10.2.32 Sd Engine Temp ............................................................................................................ 126

10.2.33 Wrn Engine Temp .......................................................................................................... 126

10.2.34 Sd FuelLevel .................................................................................................................. 126

10.2.35 Wrn FuelLevel ................................................................................................................ 126

10.2.36 OFF mode ...................................................................................................................... 126

10.2.37 MAN mode ..................................................................................................................... 126

10.2.38 AUT mode ...................................................................................................................... 126

10.2.39 ServiceTime ................................................................................................................... 126

10.2.40 DEF Tank Level ............................................................................................................. 127

10.2.41 BI1, BI2, BI3, BI4, BI5, BI6, BI7, BI8, BI9, BI10 - stat.................................................... 127

10.2.42 CtrlHeartBeat ................................................................................................................. 127

10.2.43 BIO8 1, 2, 3, 4, 5, 6, 7, 8 Status .................................................................................... 127

10.2.44 Wrn AIN4, AIN5, AIN6, AIN7, AIN8, AIN9 ..................................................................... 127

10.2.45 Sd AIN4, AIN5, AIN6, AIN7, AIN8, AIN9 ....................................................................... 127

10.2.46 ECU CommOK............................................................................................................... 128

10.2.47 ECU CommError ............................................................................................................ 128

10.2.48 ECU YellowLamp ........................................................................................................... 128

10.2.49 ECU RedLamp ............................................................................................................... 128

10.2.50 ECU PwrRelay ............................................................................................................... 128

10.2.51 Timer1 ............................................................................................................................ 128

10.2.52 Timer2 ............................................................................................................................ 128

10.2.53 Glow plugs ..................................................................................................................... 128

10.2.54 Conveyor ........................................................................................................................ 128

10.2.55 SpeedSwitch .................................................................................................................. 128

10.2.56 LoadSwitch .................................................................................................................... 128

InteliDrive Lite, SW version 1.9

ID-FLX-Lite-1.9r1 Reference Guide.pdf, ©ComAp – August 2015

Page 9

9

10.2.57 Close Load ..................................................................................................................... 129

10.2.58 Toggle ............................................................................................................................ 129

10.2.59 RemoteControl1, 2, 3, 4, 5, 6, 7, 8 ................................................................................ 129

11 Communication .................................................................................................................... 130

11.1 Direct cable connection .......................................................................................................... 130

11.2 Remote connection ................................................................................................................. 131

11.2.1 Internet connection ........................................................................................................ 131

11.2.2 AirGate connection ........................................................................................................ 131

11.2.3 Modem connection ........................................................................................................ 131

11.3 Modbus connection ................................................................................................................ 131

11.3.1 Modbus step by step ...................................................................................................... 131

11.4 ECU engine support ............................................................................................................... 132

11.5 Choosing the ECU to configure .............................................................................................. 133

11.6 ECU Analog inputs ................................................................................................................. 134

11.7 Tier 4 engines support ............................................................................................................ 134

12 Maintenance .......................................................................................................................... 136

13 Troubleshooting ................................................................................................................... 137

13.1 Alarm management ................................................................................................................ 137

13.1.1 Sensor fail (Fls) .............................................................................................................. 137

13.1.2 Warning (Wrn)................................................................................................................ 137

13.1.3 Cooldown (Cd) ............................................................................................................... 137

13.1.4 Shut down (Sd) .............................................................................................................. 137

13.1.5 List of possible alarms ................................................................................................... 138

13.2 History file ............................................................................................................................... 139

13.2.1 Record structure ............................................................................................................ 139

13.3 Diagnostic messages read from ECU .................................................................................... 140

13.4 List of ECU diagnostic codes ................................................................................................. 140

13.5 Tier 4 diagnostic codes........................................................................................................... 141

14 Technical data ....................................................................................................................... 143

14.1 Power supply .......................................................................................................................... 143

14.2 Operating conditions ............................................................................................................... 143

14.3 Low Temperature modification ............................................................................................... 143

14.4 Dimensions and weight .......................................................................................................... 144

14.5 Binary inputs and outputs ....................................................................................................... 144

14.5.1 Binary inputs .................................................................................................................. 144

14.5.2 Binary open collector outputs ........................................................................................ 144

14.6 Analog inputs .......................................................................................................................... 144

14.7 Speed pick-up input ................................................................................................................ 144

14.8 D+ function ............................................................................................................................. 145

14.9 CAN bus interface .................................................................................................................. 145

14.10 IL-NT RS232 (optional card) .................................................................................................. 145

14.11 IL-NT RS232-485 (optional card) ........................................................................................... 146

14.12 IL-NT S-USB (optional card) .................................................................................................. 146

14.13 IB-Lite (optional card) ............................................................................................................. 146

14.14 IL-NT GPRS (optional card) ................................................................................................... 146

14.15 IL-NT AOUT8 (optional card) ................................................................................................. 146

14.16 IL-NT AIO (optional card) ....................................................................................................... 147

14.17 IL-NT IO1 (optional card) ........................................................................................................ 147

14.18 IL-NT BIO8 (optional card) ..................................................................................................... 147

14.19 IGL-RA15 (optional Remote Annunciator).............................................................................. 147

14.19.1 Power supply ................................................................................................................. 147

14.19.2 Operating conditions ...................................................................................................... 147

14.19.3 Dimensions and weight .................................................................................................. 148

14.19.4 Horn output .................................................................................................................... 148

15 Language support ................................................................................................................ 149

16 Appendix ....................................................................................... Error! Bookmark not defined.

16.1 Table of setpoints ....................................................................... Error! Bookmark not defined.

InteliDrive Lite, SW version 1.9

ID-FLX-Lite-1.9r1 Reference Guide.pdf, ©ComAp – August 2015

Page 10

10

16.2 Table of values ........................................................................... Error! Bookmark not defined.

16.3 Table of binary input functions ................................................... Error! Bookmark not defined.

16.4 Table of binary output functions ................................................. Error! Bookmark not defined.

InteliDrive Lite, SW version 1.9

ID-FLX-Lite-1.9r1 Reference Guide.pdf, ©ComAp – August 2015

Page 11

11

1 Document information

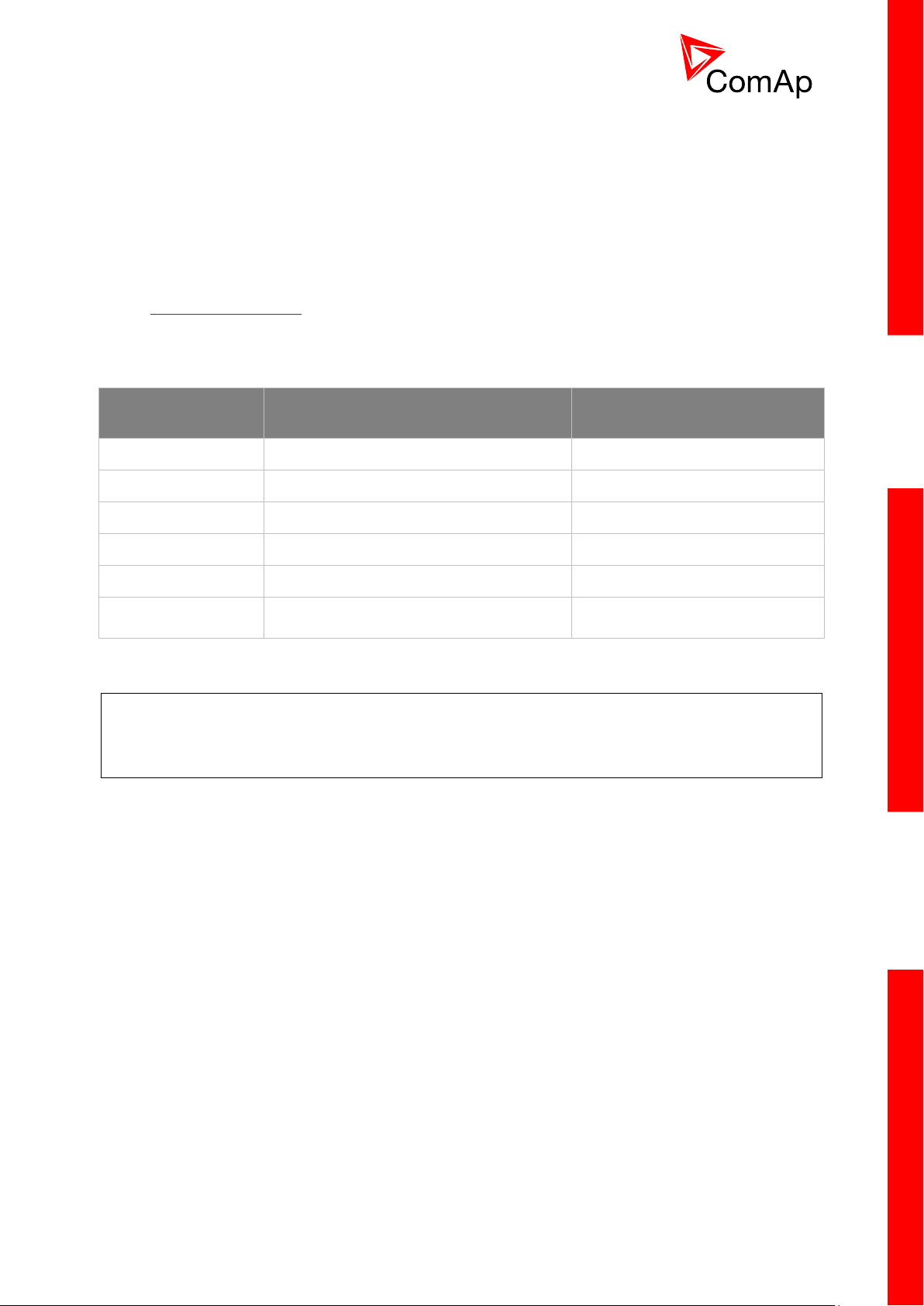

REVISION NUMBER

RELATED SW. VERSION

DATE

1.7

1.7

5.5.2013

1.8

1.8

13.5.2014

1.9

1.9.0

17.12.2014

1.9r1

1.9.0

13.8.2015

InteliDrive Lite® – Reference guide

Written by: JURJ

©2015 ComAp a.s.

Kundratka 17, Praha 8, Czech Republic

Phone: +420 246 012 111, Fax: +420 266 316 647

Web: HTTP://WWW.COMAP.CZ, e-mail: info@comap.cz

DOCUMENT HISTORY

Note:

ComAp believes that all information provided herein is correct and reliable and reserves the right to

update at any time. ComAp does not assume any responsibility for its use unless otherwise expressly

undertaken.

InteliDrive Lite, SW version 1.9

ID-FLX-Lite-1.9r1 Reference Guide.pdf, ©ComAp – August 2015

Page 12

12

The following described machine complies with the appropriate basic safety and health

requirement of the EC Low Voltage Directive No: 73/23 / EEC and EC Electromagnetic

Compatibility Directive 89/336 / EEC based on its design and type, as brought into

circulation by us.

1.1 Clarification of notation

HINT

This type of paragraph points out details to help user installation/configuration.

NOTE:

This type of paragraph calls readers’ attention to a notice or related theme.

CAUTION!

This type of paragraph highlights a procedure, adjustment, etc. which may cause damage or improper

functioning of the equipment if not carried out correctly and may not be clear at first sight.

WARNING!

This type of paragraph indicates things, procedures, adjustments, etc. which demand a high level of

attention, otherwise personal injury or death may occur.

1.2 Text

PAGE (Capital letters in the frame) buttons on the front panel

Gear teeth (Italic) set points

Engine protections (Bold) Set point group

REMOTE START/STOP (Capital letters) binary inputs and outputs

1.3 Conformity Declaration

InteliDrive Lite, SW version 1.9

ID-FLX-Lite-1.9r1 Reference Guide.pdf, ©ComAp – August 2015

Page 13

13

2 System overview

2.1 What describes this manual?

IMPORTANT SAFETY INSTRUCTIONS

This manual contains important instructions for ID-FLX-Lite controllers family that shall be followed

during installation and maintenance of the InteliDrive Lite engine controllers.

This manual describes ID-FLX-Lite application examples for single engine applications.

This manual provides general information how to install and operate InteliDrive Lite controller.

This manual is intended for operators of engines, for engine control panel builders or for everybody

who is concerned with installation, operation and maintenance of the engine applications.

2.2 Warnings

InteliDrive Lite controller can be remotely controlled. In case of the work on the engine check, that

nobody can remotely start the engine.

To be sure:

Disconnect remote control via RS232 line,

Disconnect input REM START/STOP or

Disconnect output STARTER

NOTE:

Because of large variety of InteliDrive Lite parameters setting, it is not possible to describe all

combination. Some of InteliDrive Lite functions are subject of changes depend on SW version.

The data in this manual only describes the product and are not warranty of performance or

characteristic.

NOTE:

SW and HW must be compatible (e.g. ID-FLX-Lite firmware and ID-FLX-Lite hardware) otherwise the

function will be disabled. If wrong software is uploaded the message HARDWARE INCOMPATIBLE

appears on the controller screen.

In the case of using Boot load (jumper) programming – close Boot jumper, follow instruction in

LiteEdite and upload correct software.

2.3 General description

The key feature of InteliDrive Lite is its easy-to-use operation and installation. Predefined

configurations for typical applications are available as well as user-defined configurations for special

applications.

InteliDrive Lite is a comprehensive controller for single engines with extended support of electronic

engines and plug-in modules.

InteliDrive Lite, SW version 1.9

ID-FLX-Lite-1.9r1 Reference Guide.pdf, ©ComAp – August 2015

Page 14

14

InteliDrive Lite controllers are equipped with a powerful graphic display showing icons, symbols and

bar-graphs for intuitive operation, which sets, together with high functionality, new standards in engine

controls.

InteliDrive Lite provides gas engine support without ventilation.

Controller supports WebSupervisor system. This system enables engine fleet and assets

management as well as pure monitoring. Visit www.comap.cz and http://websupervisor.comap.cz/ for

more details about WebSupervisor

The key features are:

ECU support - for singlespeed and allspeed engines e.g. Cummins, Volvo, JohnDeer etc.

Flexibility - with our extension modules e.g. IL-NT-AIO, IL-NT-BIO8 etc.

Communication - via communication modules e.g. IL-NT-GPRS, IB-Lite, IL-NT-S-USB and PC

tools WebServer, WebSupervisor, InteliMonitor etc.

Process logic - active control of engine, history log, configuration-no programming

2.4 Configurability and monitoring

InteliDrive Lite is using as configuration, monitoring and controling tool LiteEdit software. For simple

configuration, monitoring and controlling can be used InteliMonitor.

InteliDrive Lite controller also supports remote monitoring and control via internet, AirGate or cellular

network connection. For this remote control are used web tools WebSupervisor and WebServer.

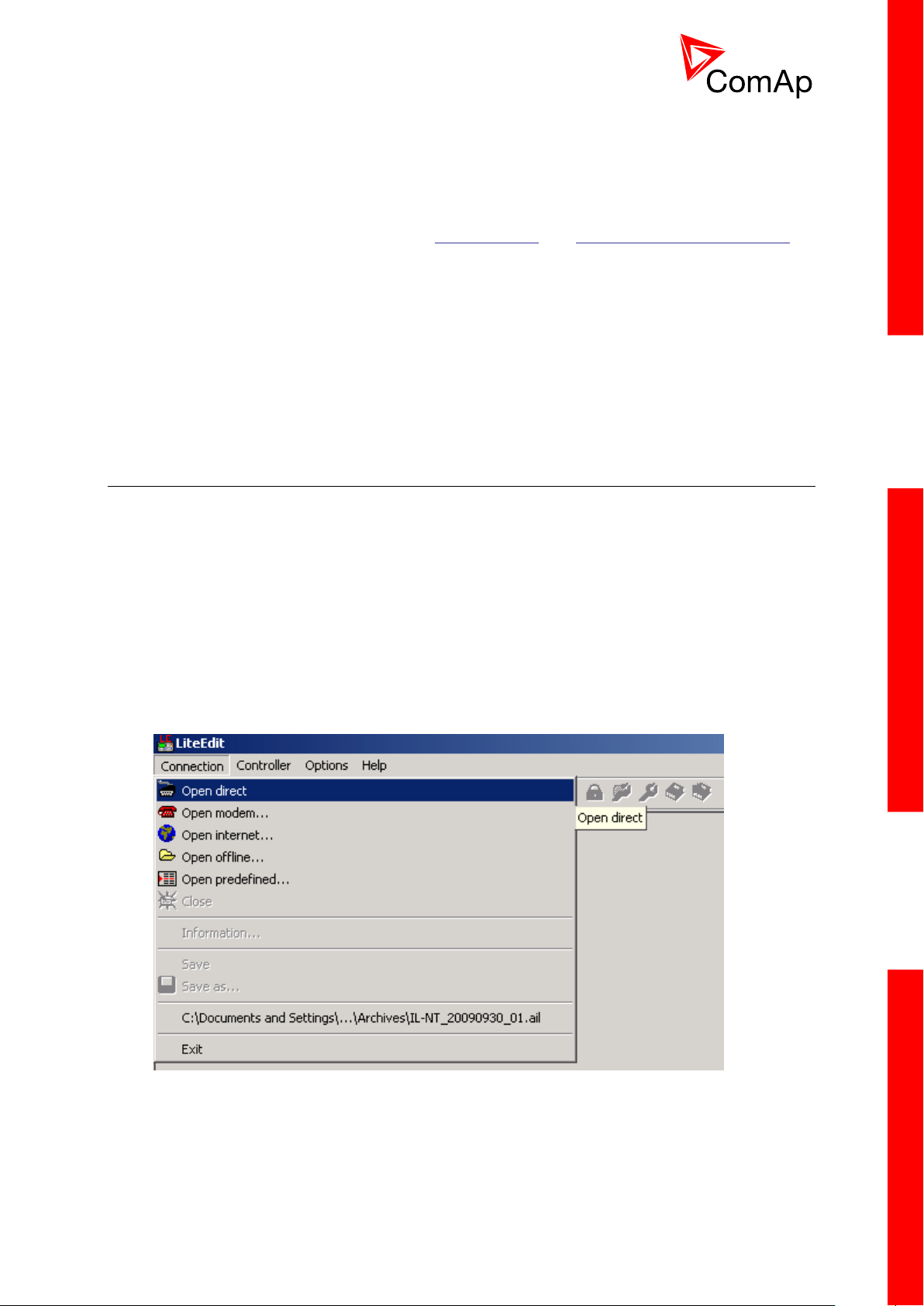

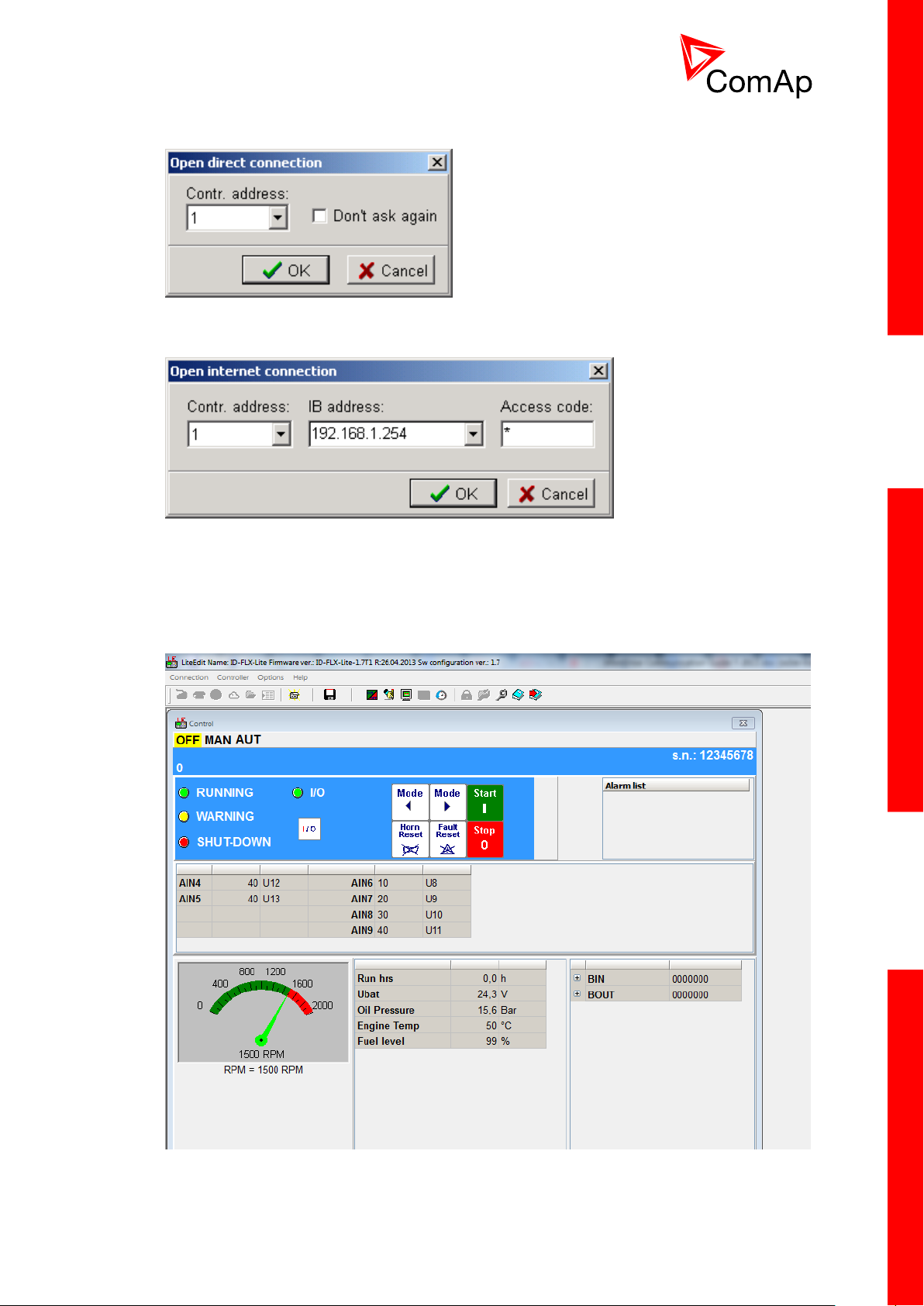

2.4.1 Open connection from LiteEdit

PC tool LiteEdit is used for monitoring, programming and configuration of ID-FLX-Lite controllers.

1. Go to menu Connection and select the type of connection you desire.

LITEEDIT - CONNECTION MENU

InteliDrive Lite, SW version 1.9

ID-FLX-Lite-1.9r1 Reference Guide.pdf, ©ComAp – August 2015

Page 15

15

2. Enter controller address and further information depending on the selected connection type.

FOR DIRECT CONNECTION ENTER CONTROLLER ADDRESS

FOR INTERNET CONNECTION ENTER CONTROLLER ADDRESS, IP ADDRESS OF THE IB-LITE MODULE

FITTED IN THE CONTROLLER YOU WANT TO REACH, ACCESS CODE

3. You will see the Control window and you can continue with configuration of Setpoint, inputs,

outputs etc.

LITEEDIT CONTROL WINDOW

InteliDrive Lite, SW version 1.9

ID-FLX-Lite-1.9r1 Reference Guide.pdf, ©ComAp – August 2015

Page 16

16

NOTE:

For detail description of LiteEdit and InteliMonitor PC tools see the LiteEdit Reference Guide,

InteliMonitor Reference Guide and InteliDrive Communication Guide.

2.4.2 Open connection from web browser

It is possible to connect from a web browser to InteliDrive Lite controllers, mounted with IB-Lite module

(or IB-NT with specific conditions) and connected to internet.

1. Open web browser

2. Enter IP address from controller Comms Settings: IBLite IP Addr

3. Access verification page appears

ACCESS VERIFICATION PAGE

4. Enter access code and Scada page appears

SCADA PAGE

InteliDrive Lite, SW version 1.9

ID-FLX-Lite-1.9r1 Reference Guide.pdf, ©ComAp – August 2015

Page 17

17

NOTE:

You can try the WebServer from ComAp webpage. The access code is 0.

NOTE:

WebSupervisor is possible to use as a control and monitor tool. For access is necessary to be

registered. Connection setting and other information you can find in the WebSupervisor Reference

Guide.

2.4.3 Open connection from WinScope

WinScope is powerful PC tool for observation of controller’s states and measurements.

1. Go to menu Connection -> Open connection... and select the type of connection you desire

in Open connection window (Inteli controllers).

WINSCOPE - OPEN CONNECTION WINDOW

2. Proceed with selection of channels etc. according to WinScope Reference Guide

InteliDrive Lite, SW version 1.9

ID-FLX-Lite-1.9r1 Reference Guide.pdf, ©ComAp – August 2015

Page 18

18

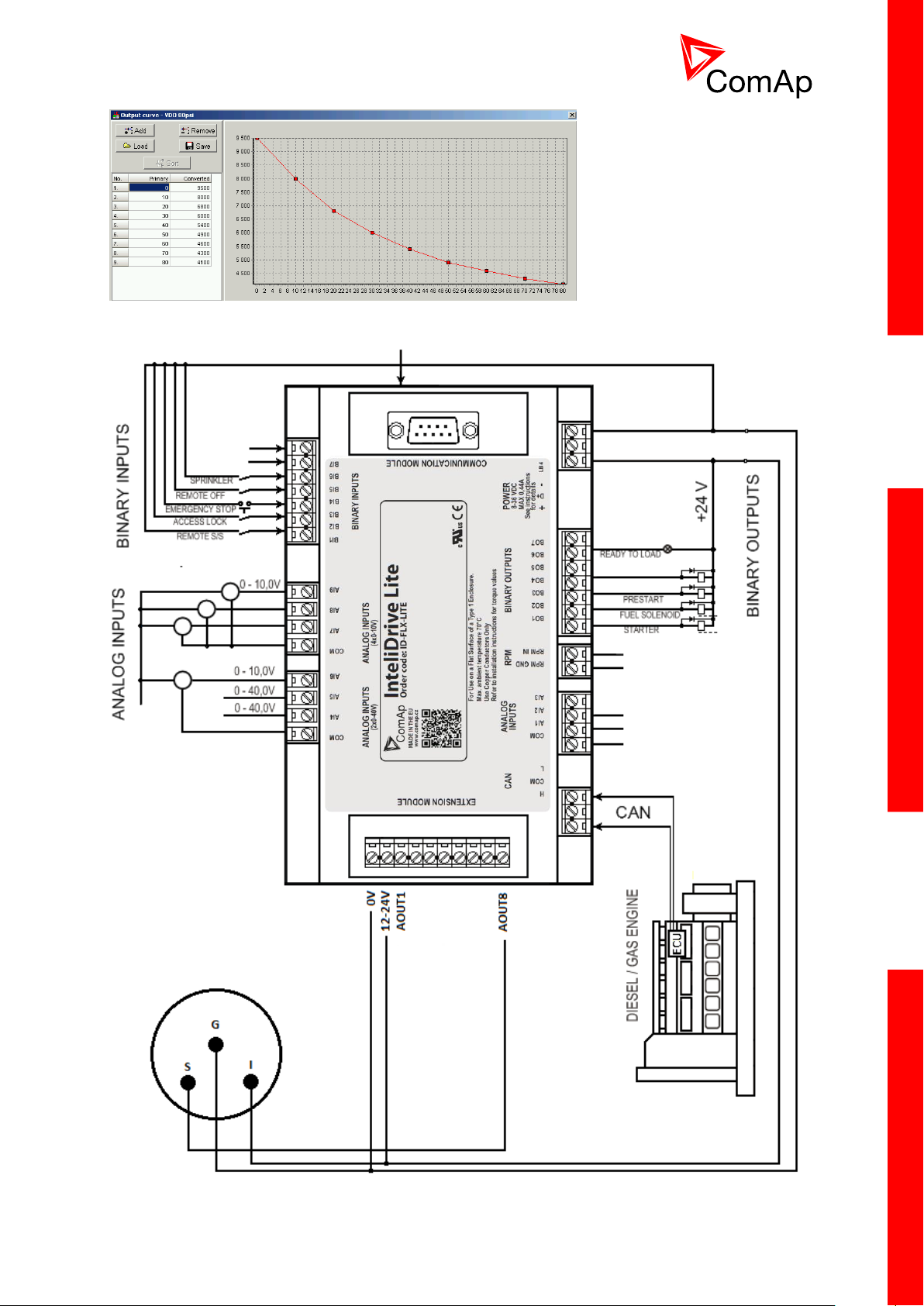

2.5 Applications overview

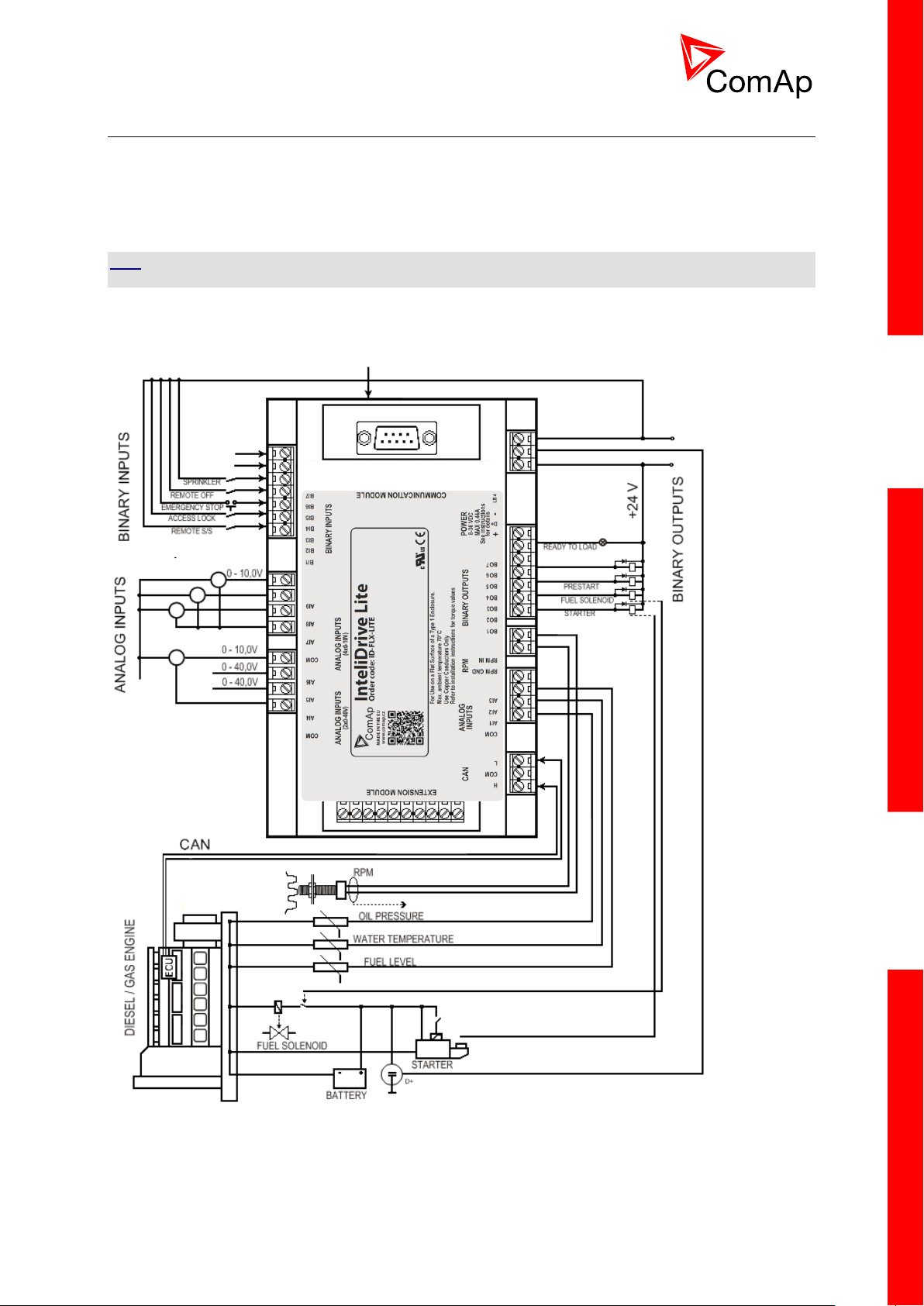

2.5.1 Single applications

Basic wiring scheme for single engine, all engine data are transferred from ECU via CAN J1939

interface in example below.

HINT

The extension IGL-RA15 modules can be connected to CAN bus together with ECU.

APPLICATION DESCRIPTION

InteliDrive Lite, SW version 1.9

ID-FLX-Lite-1.9r1 Reference Guide.pdf, ©ComAp – August 2015

Page 19

19

3 Installation

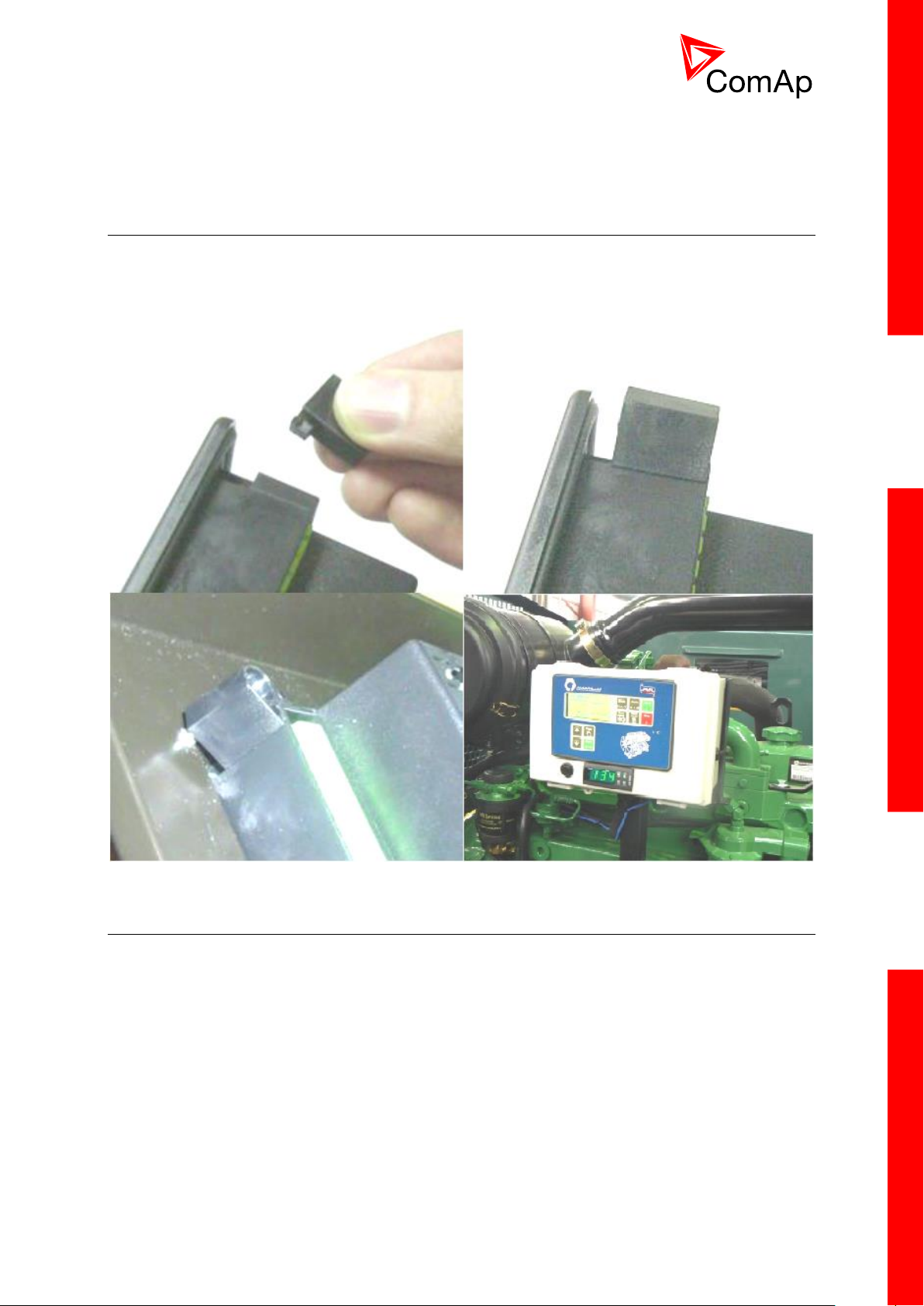

3.1 Mounting

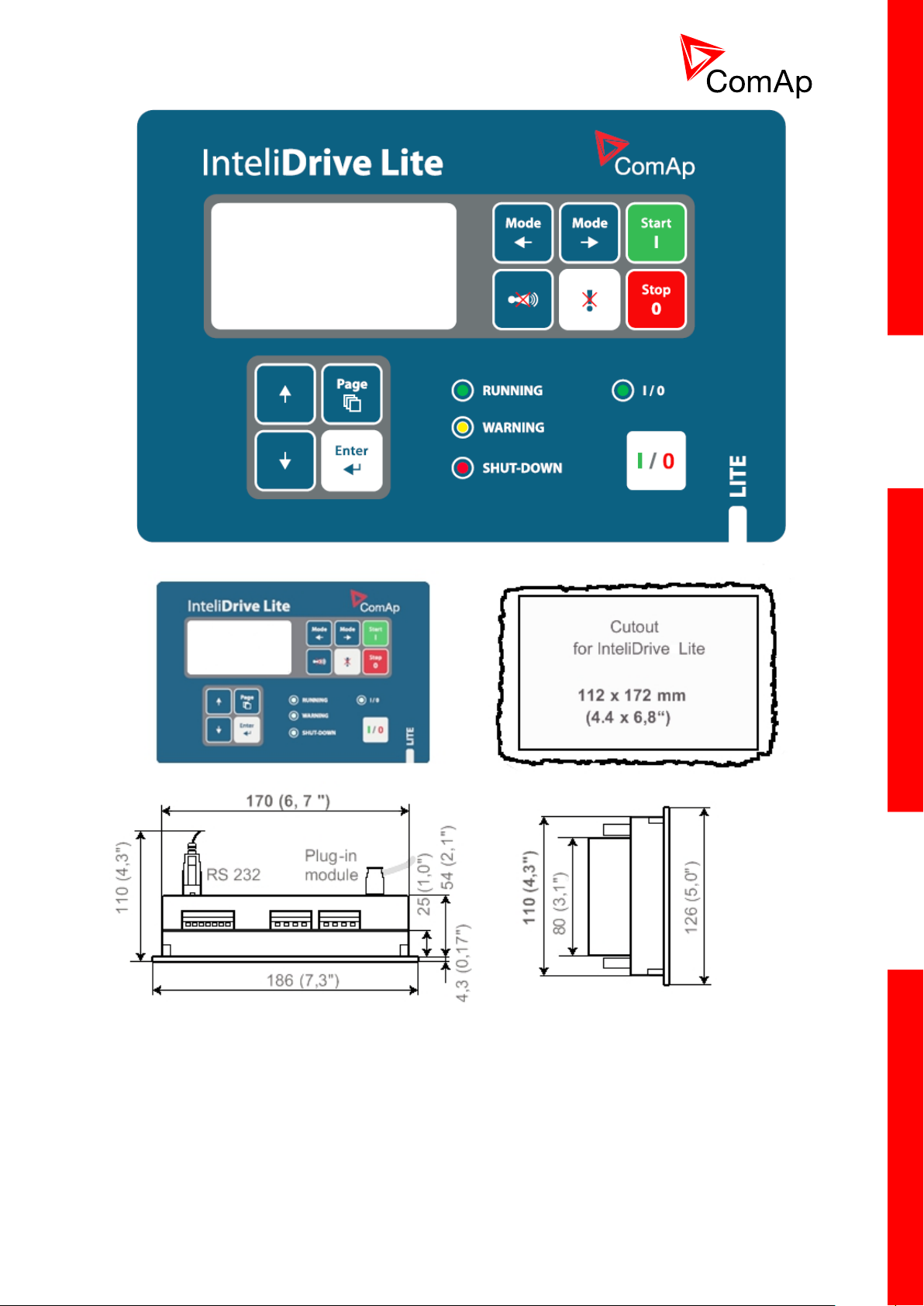

The controller is used to be mounted onto the switchboard door. Requested cutout size is

172x112mm. Use the screw holders delivered with the controller to fix the controller into the door as

described on pictures below.

3.2 Package contents

InteliDrive Lite controller is delivered in the box as one set containing the

ID-FLX-Lite controller programmed with default configuration

4x Fixing clips

Complete connectors (female) set for controller wiring

3.2.1 Software package

ID-FLX-Lite is distributed as ID-FLX-Lite-x.y.iwe package and it is compatible with the PC tool LiteEdit

x.y.z and ECU list-x.y, where x, y, z are numbers of software version. Find installation files on ComAp

web. Version of published files on the webpage are compatible each other.

InteliDrive Lite, SW version 1.9

ID-FLX-Lite-1.9r1 Reference Guide.pdf, ©ComAp – August 2015

Page 20

20

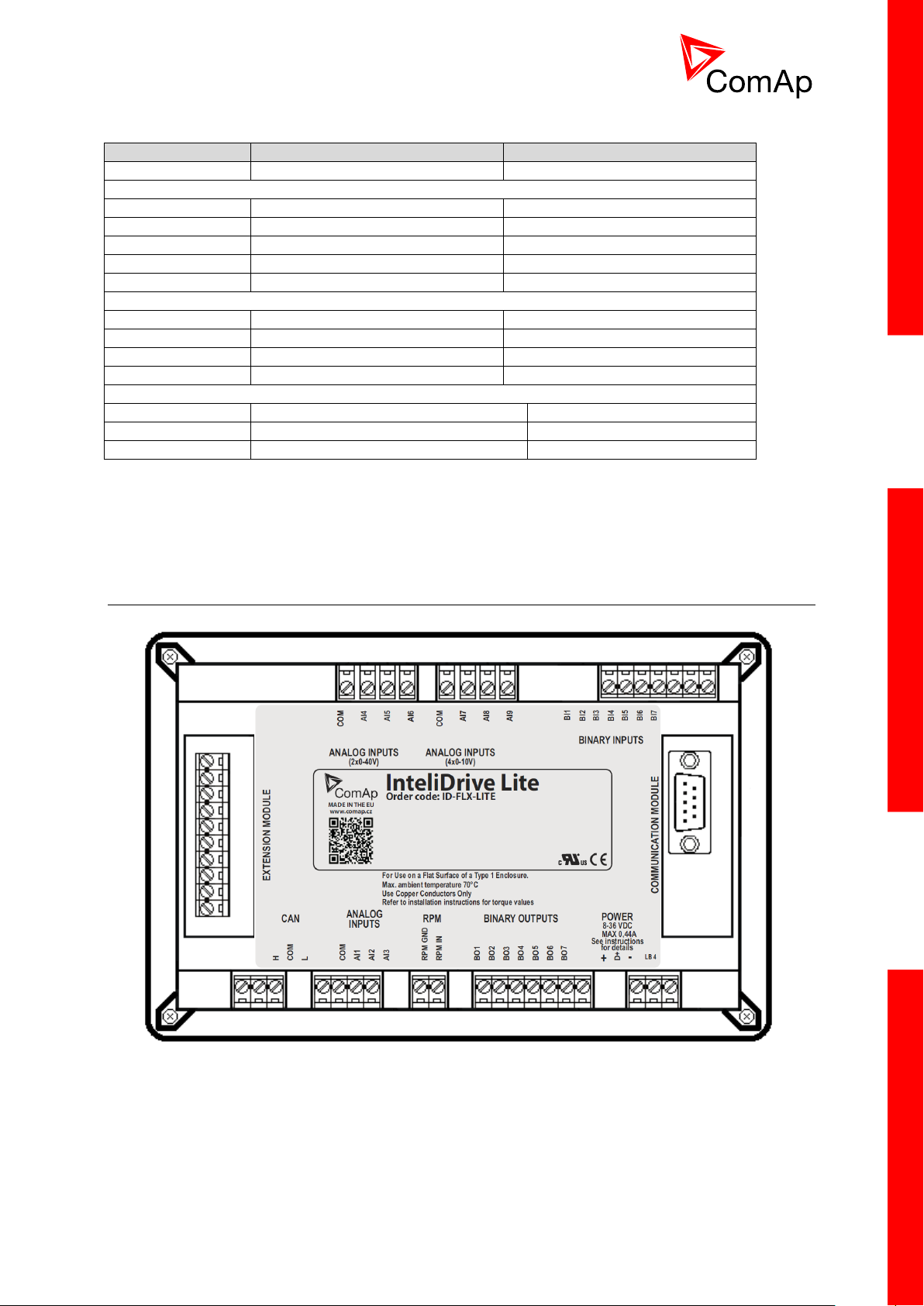

3.2.2 Components

Accessories

Description

Optional / Obligatory

ID-FLX-Lite

InteliDrive-Lite central unit

Obligatory

Communication plug-in

IL-NT RS232

RS232 communication card

Optional plug-in

IL-NT 232/485

Combined communication card

Optional plug-in

IL-NT S-USB

USB communication card

Optional plug-in

IB-Lite

Ethernet/Internet interface

Optional plug-in

IL-NT-GPRS

GSM/GPRS modem

Optional plug-in

Extension plug-in

IL-NT AOUT8

8 AOUT Gauge driver card

Optional plug-in

IL-NT AIO

4xAIN + 1x AOUT

Optional plug-in

IL-NT IO1

4xBIN + 4xAOUT

Optional plug-in

IL-NT BIO8

8x BIN or BOUT

Optional plug-in

External modules

IL-NT RD

Remote display

Optional external

IGL-RA15

Remote annunciator

Optional external

IB-NT

Communication module (3G, Ethernet)

Optional external

3.3 Terminal diagram and dimension

InteliDrive Lite, SW version 1.9

ID-FLX-Lite-1.9r1 Reference Guide.pdf, ©ComAp – August 2015

Page 21

21

InteliDrive Lite, SW version 1.9

ID-FLX-Lite-1.9r1 Reference Guide.pdf, ©ComAp – August 2015

Page 22

22

3.4 Extension plug-in modules

3.4.1 Extension plug-in modules installation

To insert the module, you must open the cover first (use screwdriver to open) and then insert the

module into slot. Once you have inserted it, the module will snap under plastic teeth. It is supposed to

be installed permanently. Should you need to remove it, the safest way is to remove whole back cover

and than remove module manually.

For configuration of extension plug-in modules go to LiteEdit and press button in Modify

configuration window.

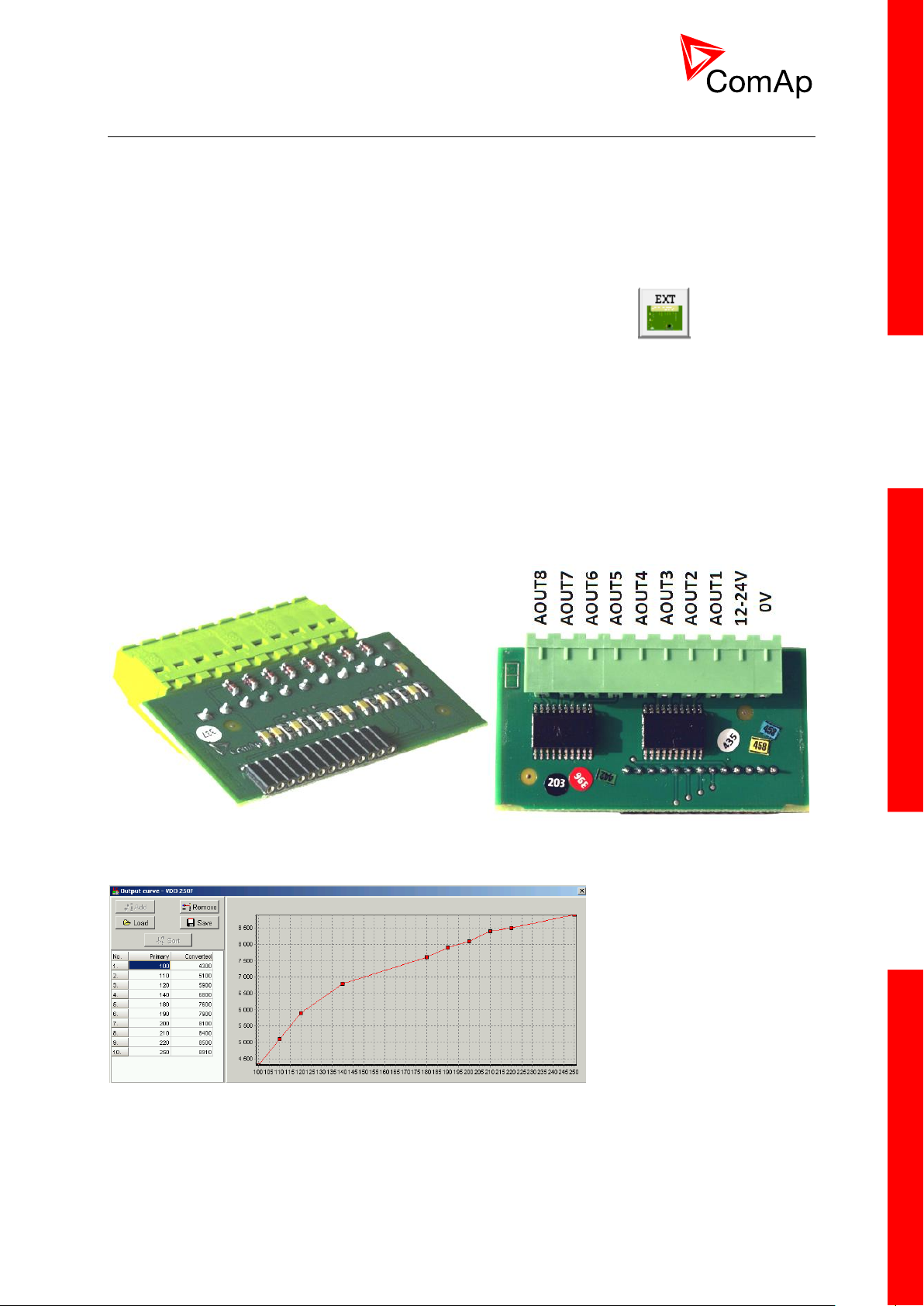

3.4.2 IL-NT AOUT8

IL-NT AOUT8 is optional plug-in card. Through this card can the controller drive up to 8 VDO style

industrial/automotive gauges. This is to provide visual indication of typically ECU values without

installing additional sensors on the engine. PWM signal emulates sensor which would be typically

mounted on the engine. Sensor/gauge curve and value are configured in LiteEdit PC tool. Any analog

value from the controller may be configured to the outputs. All outputs operate as PWM signal at

1200Hz.

Examples of default analog output curves:

InteliDrive Lite, SW version 1.9

ID-FLX-Lite-1.9r1 Reference Guide.pdf, ©ComAp – August 2015

Page 23

23

Example of wiring for Dacon gauges and IL-NT-AOUT8:

InteliDrive Lite, SW version 1.9

ID-FLX-Lite-1.9r1 Reference Guide.pdf, ©ComAp – August 2015

Page 24

24

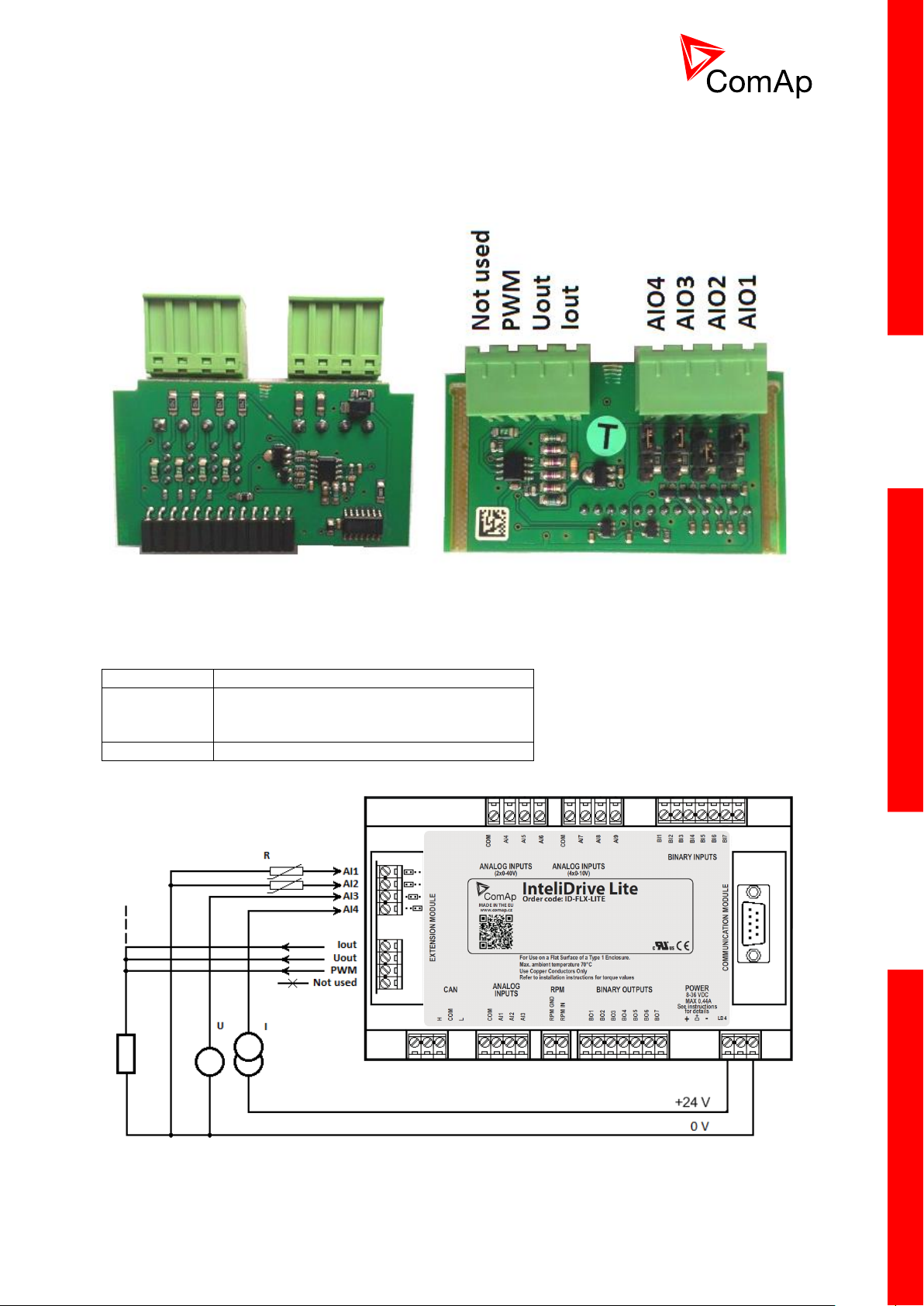

3.4.3 IL-NT AIO

AI1 – AI4

2600 Ohm / 4V / 20 mA

Iout