USE AND MAINTENANCE MANUAL

CS90 B

CS90 D

ED. 10-2012 EN

ORIGINAL

INSTRUCTIONS

Doc. 10037964

Ver. AA

The descriptions contained in this document are not binding.

The company therefore reserves the right to make any modifications at any time to elements,

details, or accessory supply, as considered necessary for reasons of improvement or

manufacturing/commercial requirements.

The reproduction, even partial, of the text and drawings contained in this document is prohibited

by law.

The company reserves the right to make any technical and/or supply modifications. The images

are for reference purposes only, and are not binding in terms of design and supply.

Symbols used in the manual

Open book symbol with an "i"

Indicates the need to consult the instruction manual

Open book symbol

Used to tell the operator to read the manual before using the machine

Warning symbol

Carefully read the sections marked with this symbol and observe the

indications, for the safety of the operator and the machine

Warning symbol

Indicates danger of gas exhalation and leakage of corrosive liquids

Warning symbol

Indicates operator should take safety measures to avoid damage to limbs.

Warning symbol

Indicates the danger of fire.

Do not go near with free flames

Warning symbol

Indicates that the packed product should be handled with suitable lifting

means that comply with the legal requirements

Disposal symbol

Carefully read the sections marked with this symbol for the disposal of

the machine

3

CONTENTS

ON CONSIGNMENT OF THE MACHINE ................................................................................................................................ 5

SERIAL NUMBER PLATE ................................................................................................................................................... 5

INTRODUCTORY COMMENT .............................................................................................................................................. 5

IDENTIFICATION DATA ..................................................................................................................................................... 5

TECHNICAL DESCRIPTION ................................................................................................................................................ 5

INTENDED USE ................................................................................................................................................................ 5

SYMBOLS USED ON THE MACHINE .................................................................................................................................... 7

GENERAL SAFETY REGULATIONS ................................................................................................................................... 12

MACHINE PREPARATION ................................................................................................................................................ 13

1. HANDLING OF THE PACKED MACHINE ........................................................................................................................................ 13

2. HOW TO UNPACK THE MACHINE ................................................................................................................................................ 13

3. HOW TO MOVE THE MACHINE ................................................................................................................................................... 14

4. INSTRUMENT PANEL COMPONENTS (BATTERY VERSION) ............................................................................................................ 15

5. INSTRUMENT PANEL COMPONENTS (DIESEL VERSION) ............................................................................................................... 16

6. CONTROL PANEL COMPONENTS (BATTERY VERSION) ................................................................................................................. 18

7. CONTROL PANEL COMPONENTS (DIESEL VERSION) .................................................................................................................... 18

8. FOOTBOARD FOOTREST COMPONENTS (BATTERY VERSION) ...................................................................................................... 18

9. FOOTBOARD FOOTREST COMPONENTS (DIESEL VERSION) ......................................................................................................... 19

10. REAR COVER COMPONENTS ................................................................................................................................................... 19

11. FRONT COVER COMPONENTS ................................................................................................................................................. 20

12. SIDE COMPONENTS ............................................................................................................................................................... 20

13. TYPE OF BATTERY (BATTERY VERSION) ................................................................................................................................... 20

14. TYPE OF STARTER BATTERY (DIESEL VERSION) ....................................................................................................................... 20

15. BATTERY MAINTENANCE AND DISPOSAL .................................................................................................................................. 21

16. MAINTENANCE AND DISPOSAL OF THE COMBUSTION ENGINE .................................................................................................... 21

17. HANDLING AND INSERTING THE BATTERIES (BATTERY VERSION) ............................................................................................... 21

18. CONNECTING THE BATTERIES AND BATTERY CONNECTOR (BATTERY VERSION) ......................................................................... 22

19. CONNECTING THE BATTERY CHARGER (BATTERY VERSION) ..................................................................................................... 22

20. BATTERY CHARGE LEVEL INDICATOR (BATTERY VERSION) ........................................................................................................ 24

21. FILLING THE FUEL TANK (DIESEL VERSION) .............................................................................................................................. 24

22. FUEL LEVEL INDICATOR (DIESEL VERSION) .............................................................................................................................. 25

23. CHECKING THE OIL LEVEL OF THE COMBUSTION ENGINE .......................................................................................................... 25

24. CHECKING THE COMBUSTION ENGINE'S AIR FILTER .................................................................................................................. 25

25. HOUR METER (BATTERY VERSION) .......................................................................................................................................... 26

26. HOUR METER (DIESEL VERSION) ............................................................................................................................................. 26

27. TURNING LIGHTS ON/OFF ....................................................................................................................................................... 26

28. SERVICE BRAKE – PARKING BRAKE ......................................................................................................................................... 27

29. WORKING FORWARD SPEED ................................................................................................................................................... 27

30. SIDE BRUSH ASSEMBLY ......................................................................................................................................................... 27

31. CHECKING THE HYDRAULIC SYSTEM OIL ................................................................................................................................. 28

32. SAFETY BELT INSERTION (OPTIONAL) ..................................................................................................................................... 29

PREPARING TO WORK ................................................................................................................................................... 30

33. SEAT ADJUSTMENT ............................................................................................................................................................... 30

34. PREPARING THE BATTERY VERSION OF THE MACHINE TO WORK ............................................................................................... 30

35. PREPARING THE DIESEL VERSION OF THE MACHINE TO WORK .................................................................................................. 30

WORK ........................................................................................................................................................................... 32

36. SWITCHING ON THE MACHINE, DIESEL VERSION ....................................................................................................................... 32

37. SWITCHING ON THE MACHINE, BATTERY VERSION .................................................................................................................... 32

38. STARTING TO WORK .............................................................................................................................................................. 33

AT THE END OF THE WORK ............................................................................................................................................ 36

39. AT THE END OF THE WORK ..................................................................................................................................................... 36

DAILY MAINTENANCE .................................................................................................................................................... 39

40. CLEANING THE CENTRAL BRUSH ............................................................................................................................................. 39

41. CLEANING THE SIDE BRUSH ................................................................................................................................................... 40

4

42. CLEANING OF THE DIESEL MOTOR'S CYCLONE PREFILTER ........................................................................................................ 40

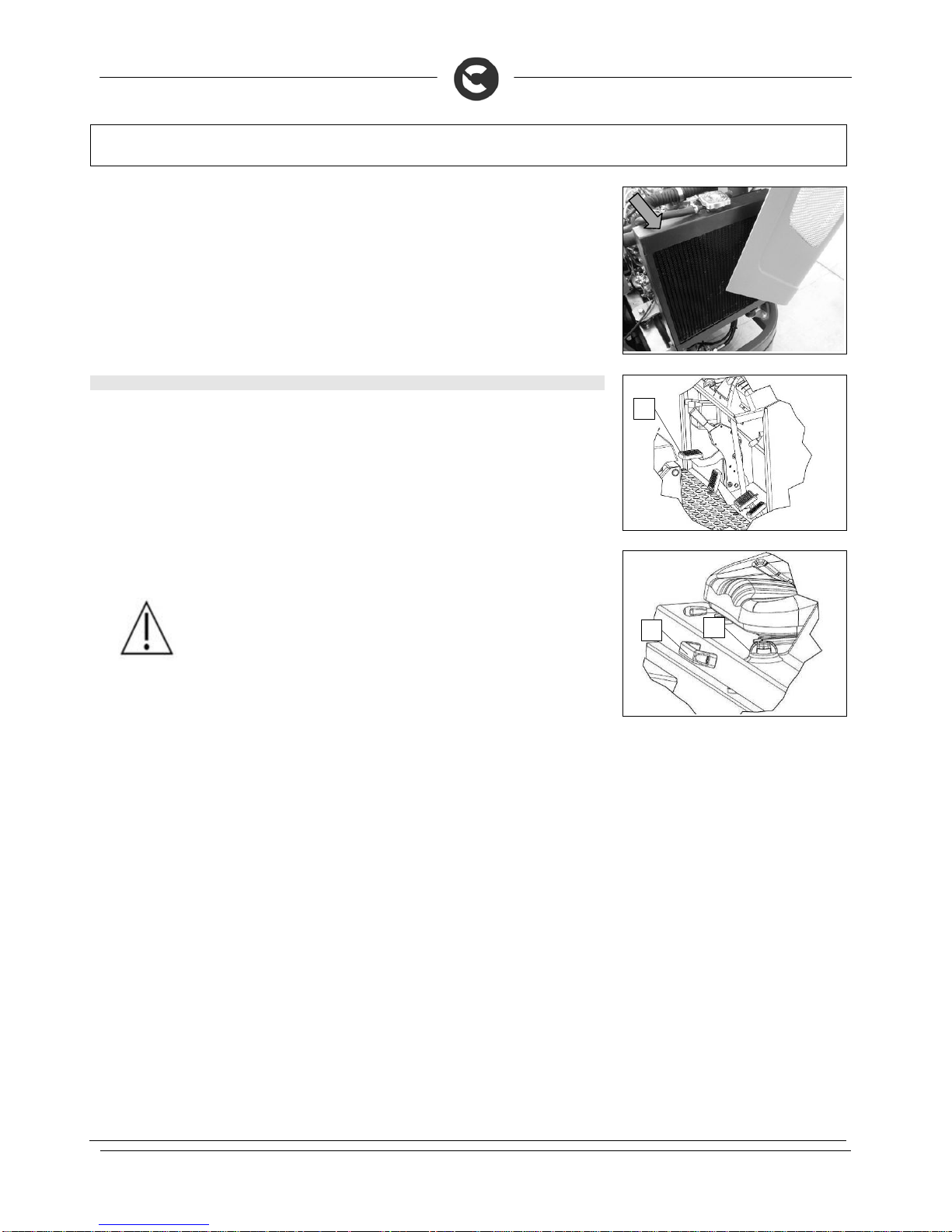

43. CLEANING THE DIESEL MOTOR'S RADIATOR ............................................................................................................................. 41

44. MAINTENANCE OF THE COMBUSTION ENGINE .......................................................................................................................... 42

WEEKLY MAINTENANCE ................................................................................................................................................. 43

45. CLEANING THE VACUUM FILTER .............................................................................................................................................. 43

46. CLEANING THE DEBRIS HOPPER ............................................................................................................................................. 44

47. CENTRAL BRUSH ADJUSTMENT ............................................................................................................................................... 45

48. SIDE BRUSH ADJUSTMENT ..................................................................................................................................................... 46

49. CLEANING THE DIESEL ENGINE'S AIR FILTER ............................................................................................................................ 47

50. CHECKING THE HYDRAULIC SYSTEM OIL LEVEL ........................................................................................................................ 48

51. CHECKING THE LEVEL OF THE DIESEL ENGINE'S COOLANT ....................................................................................................... 49

52. ADJUSTMENT OF THE CENTRAL BRUSH'S REAR FLAP ............................................................................................................... 49

53. ADJUSTMENT OF THE SIDE FLAPS ........................................................................................................................................... 51

54. MAINTENANCE OF THE COMBUSTION ENGINE .......................................................................................................................... 52

EXTRAORDINARY MAINTENANCE ................................................................................................................................... 53

55. CENTRAL BRUSH REPLACEMENT ............................................................................................................................................ 53

56. SIDE BRUSH REPLACEMENT ................................................................................................................................................... 54

57. COOLANT MAINTENANCE (DIESEL VERSION) ............................................................................................................................ 5 4

58. MAINTENANCE OF THE BRAKING SYSTEM FLUID ....................................................................................................................... 55

59. MAINTENANCE OF THE HYDRAULIC FLUID ................................................................................................................................ 56

60. REPLACING THE HYDRAULIC SYSTEM FILTER ........................................................................................................................... 56

61. REPLACING THE STARTER BATTERY (VERSIONS WITH COMBUSTION ENGINES) ........................................................................... 58

62. REPLACEMENT OF THE CENTRAL BRUSH'S REAR FLAP ............................................................................................................. 59

63. SIDE FLAP REPLACEMENT ...................................................................................................................................................... 60

64. REPLACEMENT OF HEADLIGHT BULB ....................................................................................................................................... 61

TROUBLESHOOTING ...................................................................................................................................................... 63

65. THE MACHINE DOES NOT START ............................................................................................................................................. 63

66. THE COMBUSTION ENGINE DOES NOT START ........................................................................................................................... 63

67. THE MACHINE DOES NOT CLEAN WELL .................................................................................................................................... 63

68. THE MACHINE LIFTS DUST DURING OPERATION ........................................................................................................................ 63

69. EXCESSIVE OR ALTERED NOISE OF THE CENTRAL BRUSH ......................................................................................................... 63

70. EXCESSIVE OR ALTERED NOISE OF THE SIDE BRUSH ............................................................................................................... 63

71. FUSES .................................................................................................................................................................................. 63

RECOMMENDED PERIODIC MAINTENANCE OPERATIONS .................................................................................................. 65

DISPOSAL ..................................................................................................................................................................... 66

CHOOSING AND USING THE BRUSHES ............................................................................................................................ 67

EC DECLARATION OF CONFORMITY ................................................................................................................................ 68

EC DECLARATION OF CONFORMITY ................................................................................................................................ 69

5

On consignment of the machine

When the machine is delivered to the customer, an immediate check

must be performed to ensure all the material mentioned in the shipping

documents has been received, in addition to verifying that the machine

has not been damaged during transportation. If this is the case, the

carrier must ascertain the extent of the damage at once, informing our

customer service office. It is only by prompt action of this type that the

missing material can be obtained, and compensation for damage

successfully claimed.

Serial number plate

Introductory comment

Even the best machines will only work well if used correctly and kept in

good working order. We therefore suggest you read this instruction

booklet carefully and read it again whenever difficulties arise while using

the machine. If necessary, remember that our assistance service

(organised in collaboration with our dealers) is always available for advice

or direct intervention.

Identification data

For technical assistance or to request replacement parts, always give the

model, the version and serial number written on the serial number plate.

Technical description

The CS90 are ride-on sweeping machines, powered electrically (with

traction batteries) or with an internal combustion (endothermic) engine,

for the cleaning of both internal and external surfaces with tiled, concrete

or asphalt floors.

The machine must operate on dry surfaces, and if necessary can also

work on wet surfaces making sure the vacuum action is not active.

The machine features a central brush for the collection of brushed up

material, a side brush for cleaning edges and corners, a vacuum system

with filter to avoid raising dust, and a debris hopper that can be manually

removed by means of a mechanical leverage.

Intended use

The sweeping machine is designed to clean both inside and outside

surfaces with tiled, concrete and asphalt floors, for professional use in

industrial, commercial and public places. The machine is only suitable for

use in closed (or at least covered) places. The machine is not suitable for

use in the rain, or under water jets. It is FORBIDDEN to use the machine

for picking up dangerous dusts or inflammable liquids within places with a

potentially explosive atmosphere. In addition, it is not suitable as a means

of transport for people or objects.

6

TECHNICAL DESCRIPTION Unit of measure CS90 B CS90 D

Central brush working width mm

900 900

Working width (central brush + right side) mm

1220 1220

Working width (central brush + right side + left side) mm

1540 1540

Maximum forward speed km/h

8.5 9

Working capacity (central brush + right side brush) m2/h

10370 10980

Central brush No. / (Ø x l) mm

1 / 320x890 1 / 320x890

Central brush rpm rpm

310 350

Central brush motor type -

Orbital hydraulic Orbital hydraulic

Side brush No. / Ø mm

1-2 / 460 1-2 / 460

Side brush rpm rpm

60 70

Side brush motor type -

Orbital hydraulic Orbital hydraulic

Type of traction motor -

Orbital hydraulic Orbital hydraulic

Traction wheel No. / Ø mm

1 / 381 1 / 381

Maximum gradient with full load

%

10 10

Type of vacuum motor -

Gear hydraulic Gear hydraulic

Filter shaker electrical motor V/W

12 / 110 12 / 110

Front wheels No. / Ø mm

2 / 400 2 / 400

Oil capacity of the hydraulic system l

40 40

Turning circle mm

1560 1560

Type of vacuum filter -

With pockets With pockets

Vacuum filter material -

Cloth 15μm Cloth 15μm

Vacuum air flow m3/h

160 160

Filtering surface area m

2

8 8

Debris hopper useful volume (1SL) l

400 400

Max load that can be lifted (without ride-on operator)

kg

200 200

Dumping height mm

1350 1350

Machine width (without side brushes) mm

1240 1240

Machine length mm

2020 2020

Machine height mm

1430 1430

Machine height with optional roof

mm

2210 2210

Battery compartment size (l x w x h) mm

620x420x485 -

Number / Size of battery box (l x w x h) No. / mm

2 / 620x420x450 -

Rated battery voltage V

36 -

Battery weight (max) kg

555 -

Starter battery V/Ah

- 55 / 12

Starter battery weight (max) kg

- 12.5

Combustion engine oil sump capacity l

- 5

Combustion engine fuel -

- Diesel

Combustion engine fuel tank capacity l

- 19

Combustion engine capacity cm

3

- 1100

Combustion engine fuel consumption at rated power

l/h - rpm

- 1.43 - 2800

Combustion engine maximum torque Nm - rpm

- 70.2 - 2300

Combustion engine coolant system capacity l

- 0.85

Combustion engine number of cylinders -

- 3

Maximum power combustion engine kW - rpm

- 21 - 3400

Type of combustion engine -

-

PERKINS 403D-11

Machine weight (empty and without batteries) kg

710 -

Machine weight (empty and without diesel) kg

- 770

Gross weight in running order (machine + batteries + brushes + operator)

kg

1340 -

Gross weight in running order (machine + diesel + brushes + operator)

kg

- 864

Sound pressure level (ISO 11201) -

- -

Hand vibration level (ISO 5349)

-

- -

Body vibration level (ISO 2631)

-

- -

7

SYMBOLS USED ON THE MACHINE

Main switch symbol (battery version)

Used on the instrument panel, to indicate the key switch for machine operation on (I) or off (0)

Main switch symbol (diesel version)

Used on the instrument panel, to indicate the key switch for machine operation on (I) or off (0) or ignition impulse (START) for

running the machine

Symbol denoting horn

Used to indicate the horn button

Debris hopper movement symbol

Used on the instrument panel, to indicate the safety button that controls the movement of the debris hopper

Total - partial work hours symbol

Used on the instrument panel to indicate the button that allows the hours and partial hours that the machine has been working to

be displayed

Total - partial work hours graphic display

Used on the instrument panel to indicate the graphic display that allows the hours and partial hours of work to be displayed

Amperage draw graphic display (battery version)

Used on the instrument panel to indicate the graphic display that allows the machine's amperage draw to be displayed

Graphic display of the charge level of the batteries (battery version)

Used on the instrument panel to indicate the graphic display that allows the charge level of the batteries to be displayed

Filter shaker symbol

Used on the instrument panel to indicate the button that starts the vibrating shaker on the filter unit

8

SYMBOLS USED ON THE MACHINE

Symbol denoting headlights

Used on the instrument panel to indicate the button that switches on or switches off the headlights

Symbol indicating main switch is on (battery version)

It is used on the instrument panel to indicate the green warning light showing that the main key switch is in operation

Symbol for braking system pressure fault

Used on the instrument panel to indicate the red warning light showing the shortage of oil in the braking system

Parking brake symbol

Used on the instrument panel to indicate the red warning light showing that the parking brake is engaged

Symbol indicating headlights are on

Used on the instrument panel to indicate the green warning light showing that the front headlights are on

Hydraulic system critical oil level symbol

Used on the instrument panel to indicate the red warning light showing that the oil level in the hydraulic system has reached a

critical level for the correct functioning of the machine

Hydraulic system clogged filter symbol

Used on the instrument panel to indicate the red warning light showing that the oil filter in the hydraulic system is clogged and is

prejudicing the correct functioning of the machine

Hydraulic system critical oil temperature symbol

Used on the instrument panel to indicate the red warning light showing that the temperature of the oil in the hydraulic system has

reached a level that will prevent the machine from operating correctly

Debris hopper hatch open symbol

Used on the instrument panel to indicate the green warning light showing that the hatch of the hopper is open

9

SYMBOLS USED ON THE MACHINE

Debris hopper hatch closed symbol (diesel version)

Used on the instrument panel to indicate the green warning light showing that the hopper hatch is open

Critical fuel level symbol (diesel version)

Used on the instrument panel to indicate the yellow warning light showing that the fuel level in the tank has reached a critical state

for the correct functioning of the machine

Starter battery recharging fault symbol (diesel version)

Used on the instrument panel to indicate the red warning light showing there is a fault in the electrical system that charges the

starter battery

Critical temperature symbol for the combustion engine's coolant fluid (diesel version)

Used on the instrument panel to indicate the red warning light showing that the temperature of the coolant fluid of the combustion

engine has reached a level that will prevent the machine from operating correctly

Combustion engine glow plugs symbol (diesel version)

Used on the instrument panel to indicate the yellow warning light indicating that the combustion engine's glow plugs are activated

Combustion engine critical oil level symbol (diesel version)

Used on the instrument panel to indicate the red warning light showing that the oil level in the combustion engine has reached a

critical state for the correct functioning of the machine

Combustion engine air filter clogged symbol (diesel version)

Used on the instrument panel to indicate the red warning light showing that the air filter of the combustion engine is clogged and

could compromise the machine from working correctly

Machine general system continuity symbol (diesel version)

Used on the instrument panel to indicate the emergency switch that allows you to cycle the uninterrupted flow of electricity in the

machine's general system

Hydraulic system oil level symbol

Used on the instrument panel to indicate the "maximum" and "minimum" levels of the oil in the machine's hydraulic system

10

SYMBOLS USED ON THE MACHINE

The combustion engine's coolant fluid level symbol (diesel version)

Used on the instrument panel to indicate the "maximum" and "minimum" levels of the fluid in the machine's combustion engine

cooling system

Debris hopper hatch closed symbol

Used on the instrument panel to indicate the direction to push the lever that controls the movement of the hopper hatch, to close it

Debris hopper hatch open symbol

Used on the instrument panel to indicate the direction to push the lever that controls the movement of the hopper hatch, to open it

Debris hopper lifting symbol

Used on the instrument panel to indicate the direction to push the lever that controls the movement of the hopper hatch to bring it to

the height for emptying

Debris hopper lowering symbol

Used on the instrument panel to indicate the direction to push the lever that controls the movement of the hopper to return it to a

work position

Symbol for work speed regulation (diesel version - bifuel version)

Used on the steering column to indicate the manual accelerator

Parking brake symbol

Used on the machine to indicate the pedal for engaging the parking brake

Transport hook symbol

Used on the machine to identify where to screw down the eye bolts for towing the machine safely

Vacuum motor active symbol

Used on the machine to identify the direction the lever that controls the ignition of the vacuum motor has to be turned

11

SYMBOLS USED ON THE MACHINE

Vacuum motor off symbol

Used on the machine to identify the direction to turn the lever that controls the shutting off of the vacuum motor

Central brush in work position symbol

Used on the instrument panel to indicate the direction to push the lever that controls the central brush to return it to a work position

Central brush in idle position symbol

Used on the instrument panel to indicate the direction to push the lever that controls the central brush to put it in an idle position

Right side brush in work position symbol

Used on the instrument panel to indicate the direction to push the lever that controls the right side brush to put it in a work position

Right side brush in idle position symbol

Used on the instrument panel to indicate the direction to push the lever that controls the right side brush to put it in an idle position

Left side brush (optional) in work position symbol

Used on the instrument panel to indicate the direction to push the lever that controls the left side brush to put it in a work position

Left side brush (optional) in an idle position symbol

Used on the instrument panel to indicate the direction to push the lever that controls the left side brush to put it in an idle position

12

GENERAL SAFETY REGULATIONS

The regulations below must be carefully followed in order to avoid harm to the operator and damage to the machine.

WARNING:

Read the labels on the machine carefully. Do not cover them for any reason and replace them immediately if they become damaged.

The machine must be used exclusively by authorised and trained personnel.

The machine is designed for dry use only.

Do not use the machine on surfaces with an inclination greater than the one shown on the plate.

The machine is not suitable for cleaning rough or uneven floors. Do not use the machine on slopes.

In the event of danger immediately use the handle on the battery connector (battery versions), or else turn the battery cut-off switch (Diesel - Bifuel versions).

For all maintenance interventions, switch off the machine and disconnect the battery connector and/or the power supply cable.

Children must be supervised to ensure they do not play with the device.

During the working of the machine, pay attention to other people and especially to children.

Only use the brushes supplied with the machine, or those specified in the "CHOOSING AND USING THE BRUSHES" paragraph of the instruction

manual. The use of other brushes could compromise safety levels.

WARNING:

The machine is not suitable for use by children and persons with reduced physical, mental and sensory capabilities, or people who lack experience and

knowledge.

The machine must not be used or stored outdoors, in damp conditions or directly exposed to rain.

The storage temperature must be between -25C and +55C; do not store outdoors in damp conditions.

Conditions of use: room temperature between 0°C and 40°C with relative humidity between 30 and 95%.

The socket for the battery charger cable must have a prescribed earth connection.

Adapt the speed to the adhesion conditions.

Do not use the machine as a means of transport.

The machine does not cause harmful vibrations.

Do not use the machine in an explosive atmosphere.

Do not use the device to collect dangerous powders.

The machine is not suitable for cleaning carpets.

Do not place any liquid containers on the machine.

Avoid working with the brushes when the machine is standing still, so as not to damage the floor.

In the event of a fire, use a powder extinguisher. Do not use water.

Do not knock against shelving or scaffolding, where there is a danger of falling objects. The operator must always be equipped with the appropriate

safety devices (gloves, shoes, helmet, goggles, etc.).

If the machine does not work properly, check this is not caused by failure to carry out routine maintenance. Otherwise, ask for intervention of the

authorised technical assistance centre.

If you need to replace any components, request the ORIGINAL spare parts from an Authorised dealer and/or Retailer.

Restore all electrical connections after any maintenance interventions.

Before using the machine, check that all the hatches and covers are positioned as shown in this Use and Maintenance Manual.

Do not remove any protection devices which require the use of tools in order to be removed.

Do not wash the machine with direct water jets or with pressurised water, nor with corrosive substances.

Have the machine checked by an authorised technical assistance centre every year.

When disposing of consumable materials, observe the laws and regulations in force.

When your machine has reached the end of its long working life, dispose of the materials it contains (especially oils, batteries and electronic

components) in an appropriate manner, and bearing in mind that the machine itself was constructed using 100% recyclable materials.

The batteries must be removed from the machine before its disposal. The batteries must be disposed of in a safe manner, fully observing the laws and

regulations in force.

Keep children and animals away from the powered motor, as it heats up and may cause burns and injuries (both directly and via the machines which it

moves).

Learn how to switch the combustion engine off quickly, and how to use all the controls. (versions with combustion engine)

When the engine is on, do not bring flammable objects near, for example gasoline, matches, etc. (versions with combustion engine)

Top up the fuel in a well-ventilated area, with the motor switched off; The fuel is highly inflammable and may explode.(versions with combustion engine)

Do not completely fill the fuel tank. Check the cap is firmly closed. (versions with combustion engine)

If any fuel is spilt, clean the area thoroughly and allow the vapours to disperse before switching on the motor. (versions with combustion engine)

Do not smoke or take any unprotected flames in the area where the motor is filled with fuel, or where the gasoline is stored. (versions with combustion engine)

The exhaust gases contain carbon monoxide - an odourless, colourless, but highly poisonous gas. Avoid inhalation. Do not switch the motor on in a

closed garage or in a room without windows (versions with combustion engine)

13

MACHINE PREPARATION

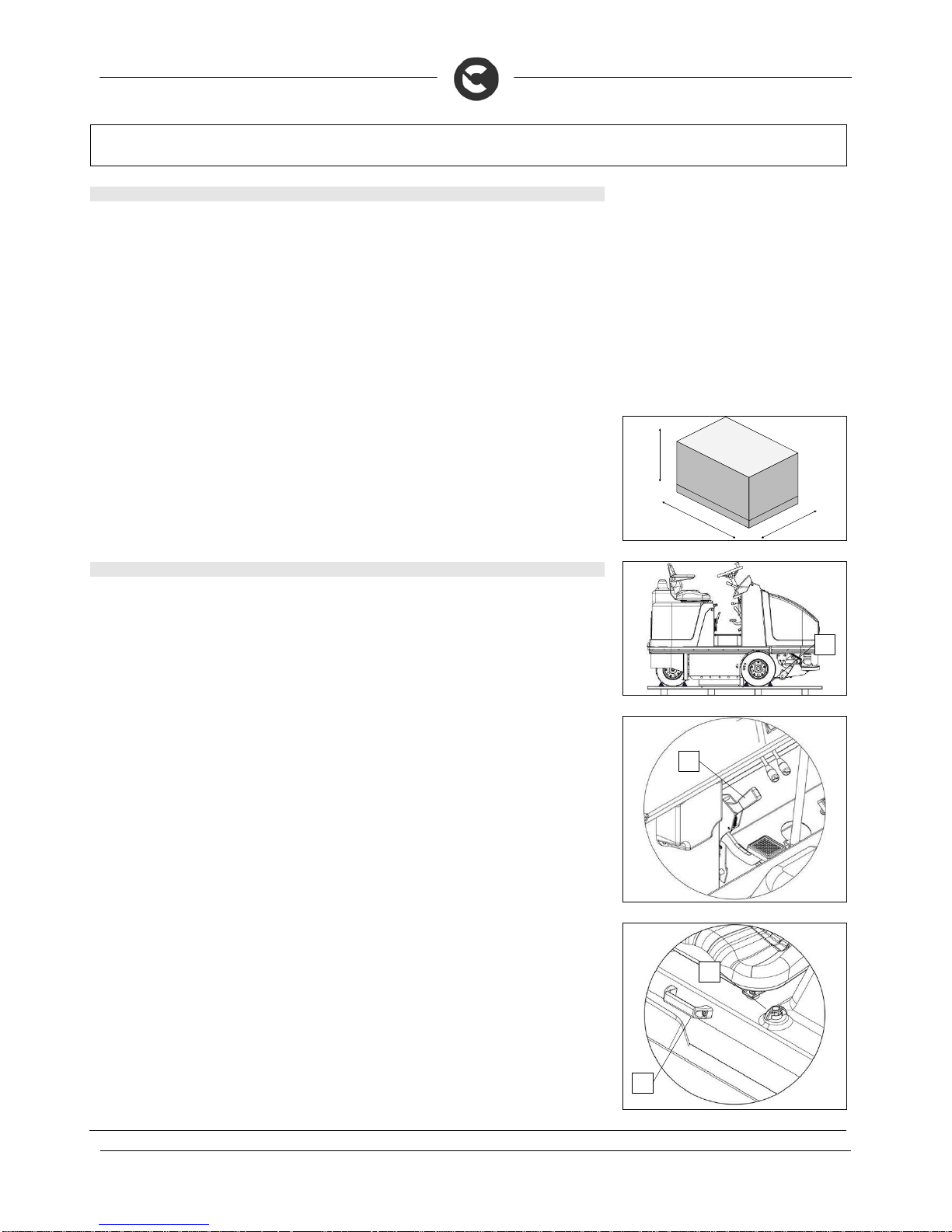

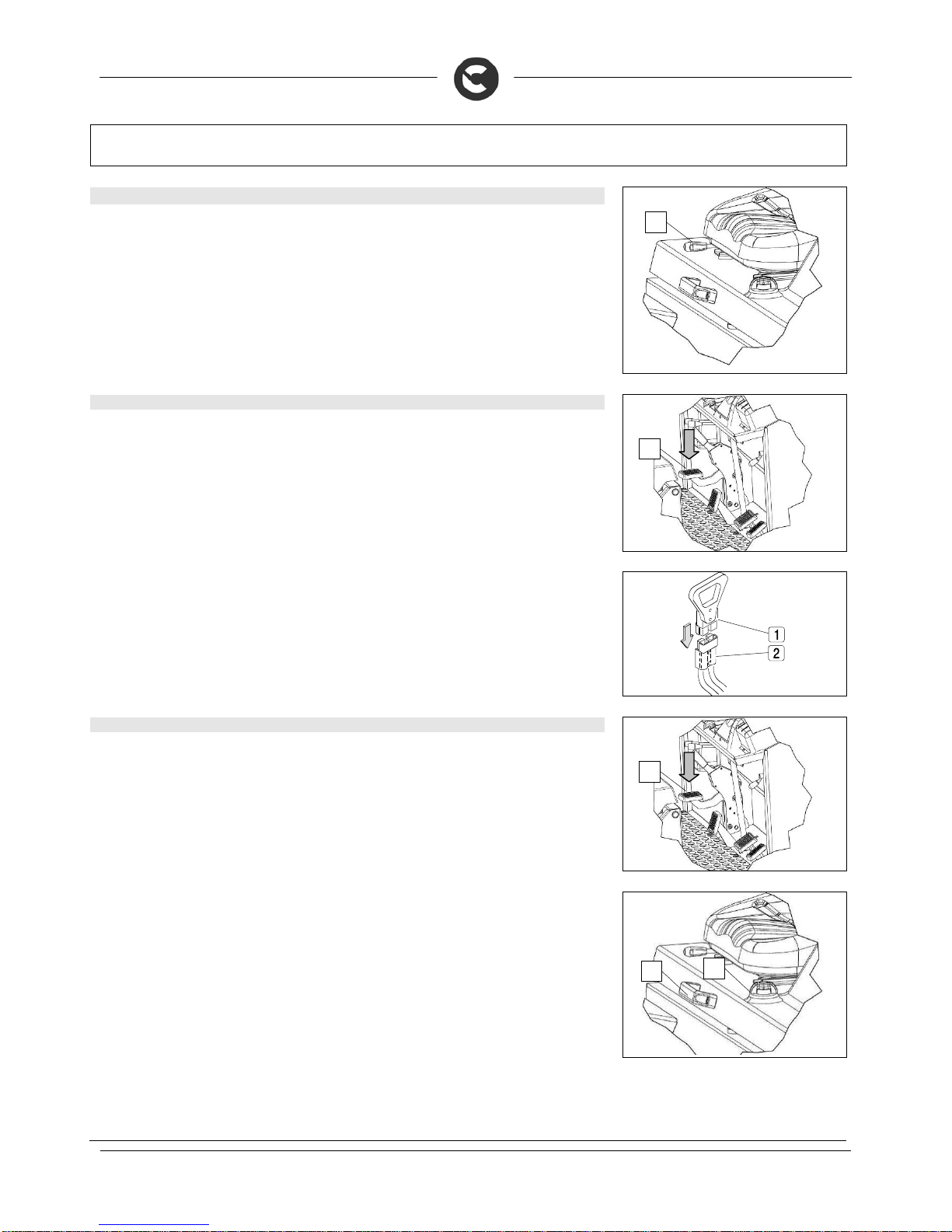

1. HANDLING OF THE PACKED MACHINE

The machine is contained in specific packaging with a pallet for the handling with fork trucks. The

packages cannot be placed on top of each other.

The overall mass of the machine (machine empty and with a side brush) with packaging is:

CS90 B = 810 kg

CS90 D = 870 kg

The dimensions of the packaging is as follows:

CS90

A: 1800 mm

B: 1340 mm

C: 2150 mm

A

C

B

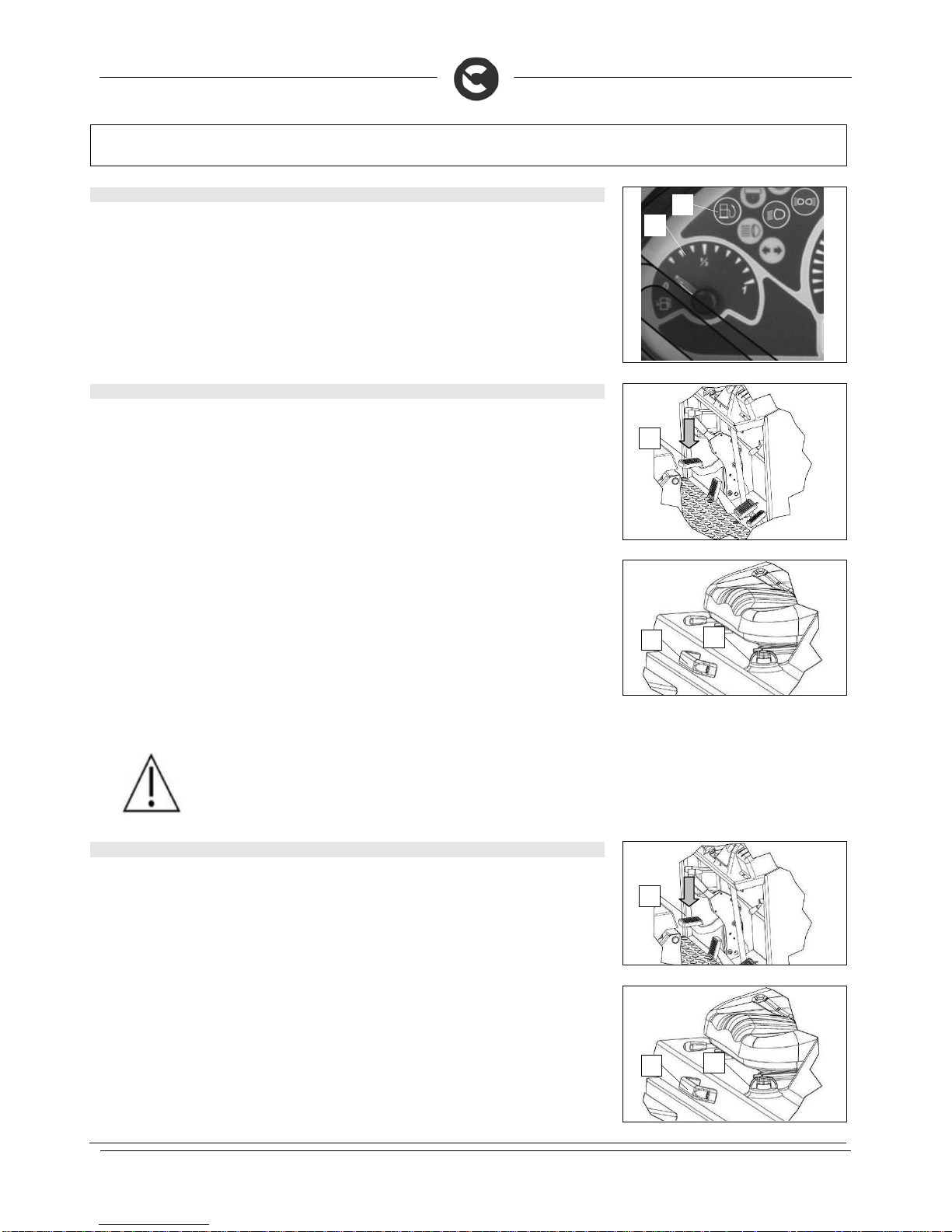

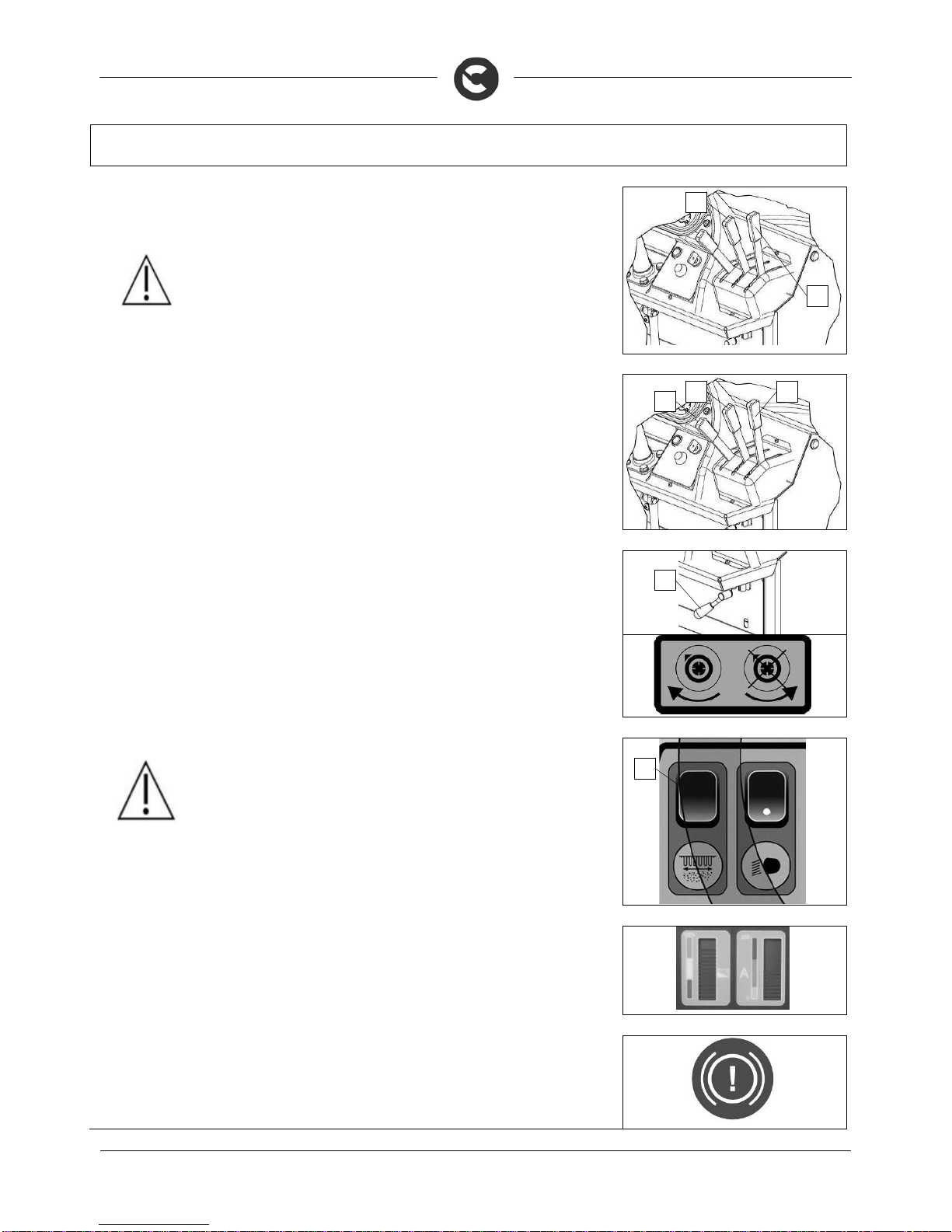

2. HOW TO UNPACK THE MACHINE

1. Remove the outer packaging

2. The machine is secured to the pallet with wedges that lock the wheels, remove these wedges (1)

3. Disengage the parking brake by turning the lever (2) upwards

4. Check the main machine switch is in the “OFF” position, and if this is not the case, turn it by a quarter

rotation to the left.

5. Turn the knob (3) anticlockwise to release the rotation of the rear cover

6. To access the motor compartment, grip the front part of the rear cover (4)

7. Lift up, rotating the rear cover to its maximum rotation

1

2

3

4

14

MACHINE PREPARATION

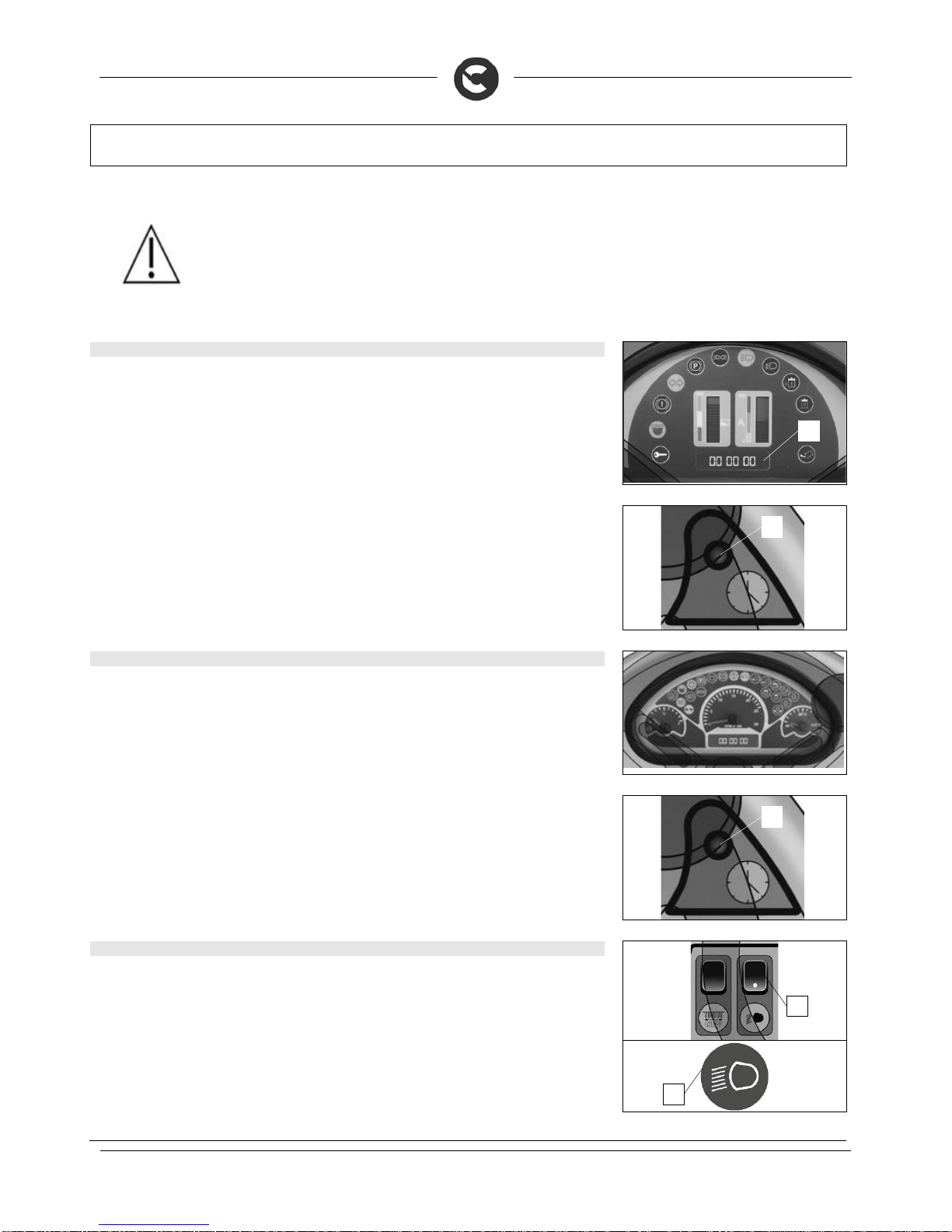

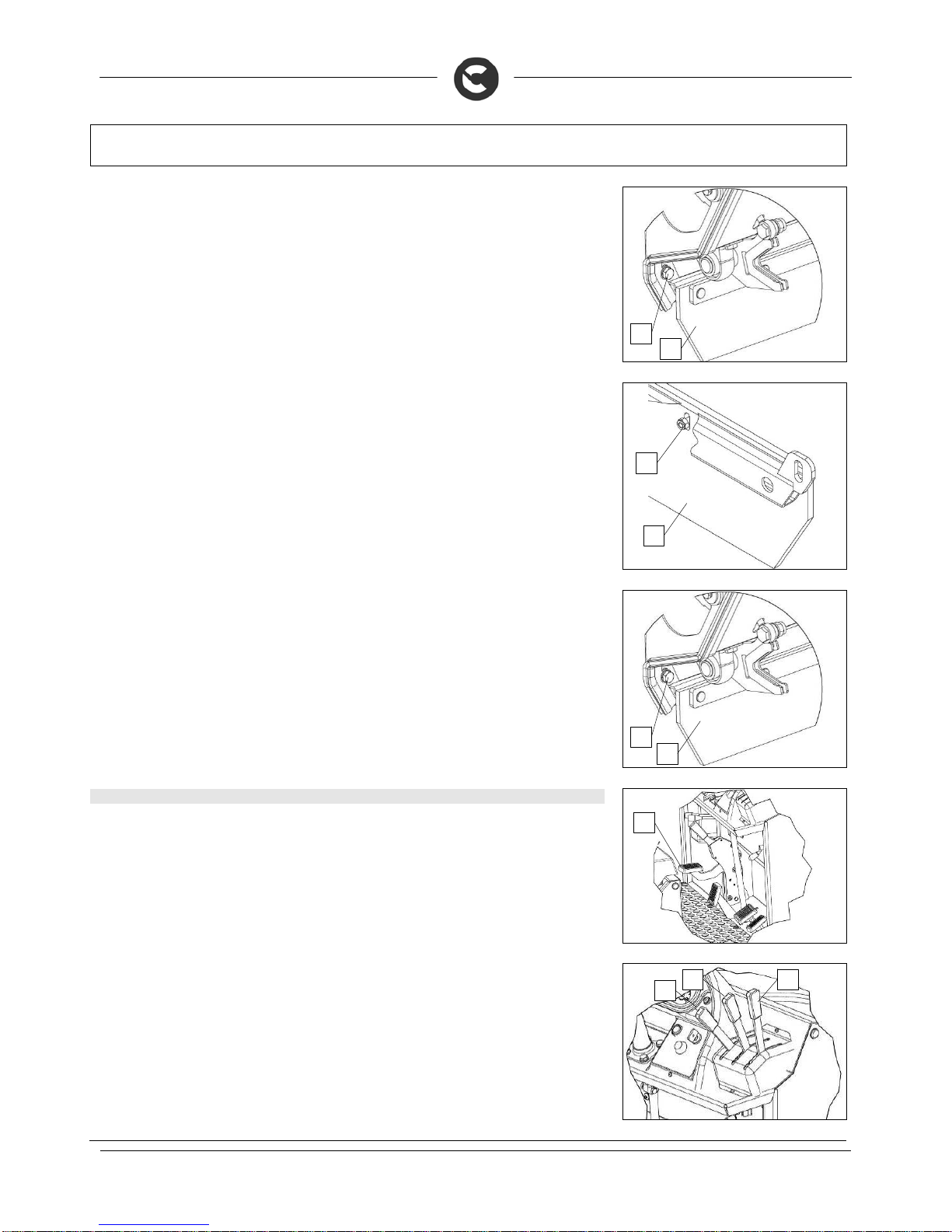

8. Rotate the lever (5) on the b

y

-pass valve until it is vertical; this will put the hydraulic system on standby.

9. Lower the rear cover as far as the working position

10. Turn the knob (3) clockwise to block the rotation of the rear cover

11. Use a chute to get the machine down from the pallet, pushing it backwards

12. Keep the pallet for any future transport needs

13. Turn the knob (3) anticlockwise to release the rotation of the rear cover

14. To access the motor compartment, grip the front part of the rear cover (4)

15. Lift up, rotating the rear cover to its maximum rotation

16. Rotate the lever (5) on the b

y

-pass valve until it is horizontal; this will start the hydraulic system working.

17. Lower the rear cover as far as the working position

18. Turn the knob (3) clockwise to block the rotation of the rear cover

WARNING: if the product is delivered in cardboard containers, handle the packed

product with suitable lifting means that comply with the legal requirements

3. HOW TO MOVE THE MACHINE

1. Make sure the debris hopper is empty, otherwise empty it completely

2. Check the central brush is lifted up off the ground

3. Check the side brush(es) is/are lifted up off the ground

4. Place it on a pallet, using a chute

5. Check the main machine switch is in the “OFF” position, and if this is not the case, turn it by a quarter

rotation to the left

6. Engage the parking brake

7. Secure the machine to the pallet using wooden wedges

3

4

5

5

15

MACHINE PREPARATION

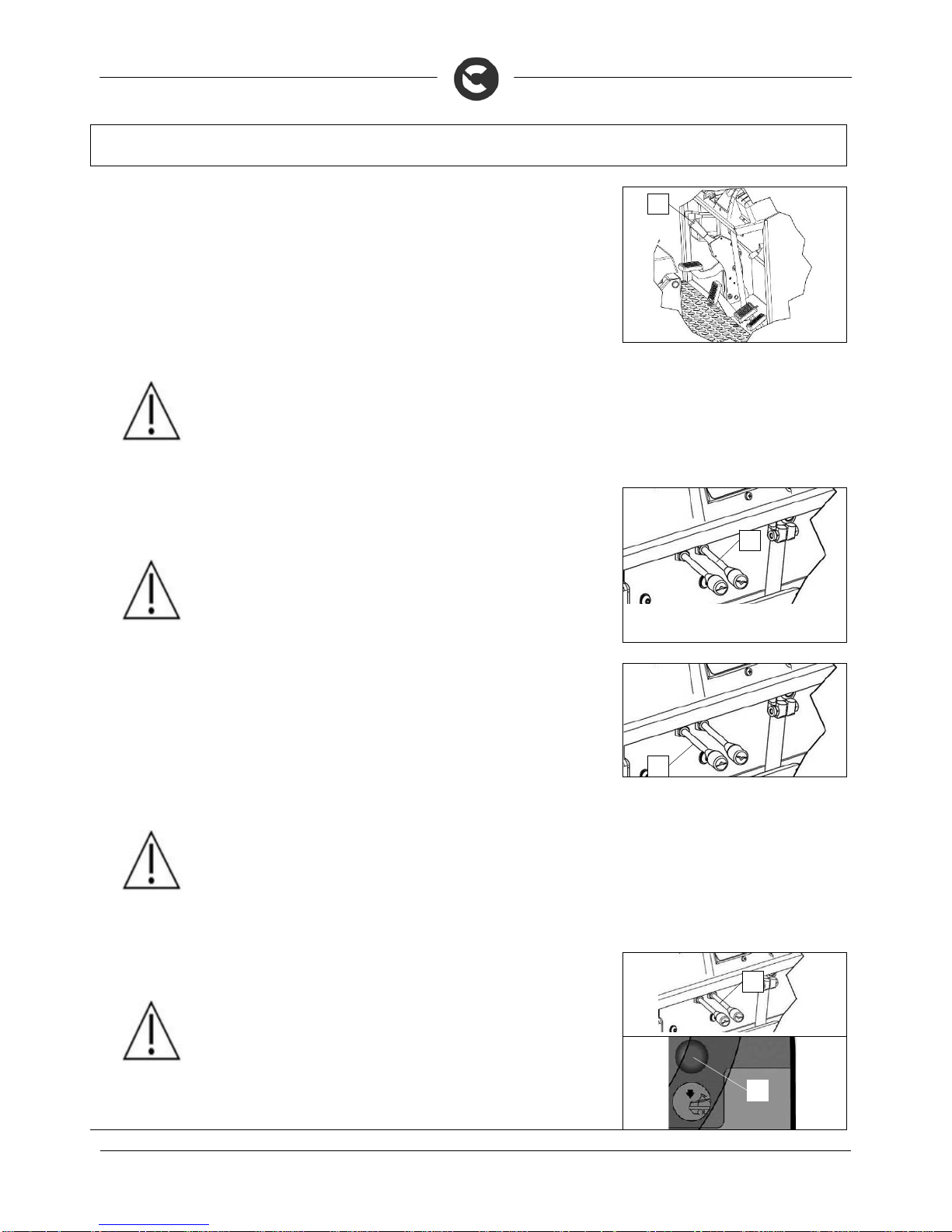

4. INSTRUMENT PANEL COMPONENTS (BATTERY VERSION)

The instrument panel components are identified as follows:

1. Vibrating filter shaker control switch

2. Front headlights control switch

3. Total or partial hour meter selector button

4. Horn button

5. Dead man's safety button for lowering the hopper

6. Main key switch

7. Green warning light indicating that the main switch of the machine is active

8. Red warning light indicating low brake oil level (down to reserve)

9. Red warning light indicating that the parking brake is on

10. Green warning light indicating that the machine headlights are on

11. Indicator light for the charge level of the batteries

12. Hour meter display (absolute or partial)

13. Red warning light indicating the oil level of the hydraulic system is low

14. Red warning light indicating the oil filter of the hydraulic system is clogged

15. Red warning light indicating the oil temperature of the hydraulic system is at a critical level

16. Green indicator light showing that the hopper hatch is open

17. Indicator light for the level of the machine's amperage draw

1

2

3

4

5

6

7

8

11 9

10

16 15 17 14 13 12

16

MACHINE PREPARATION

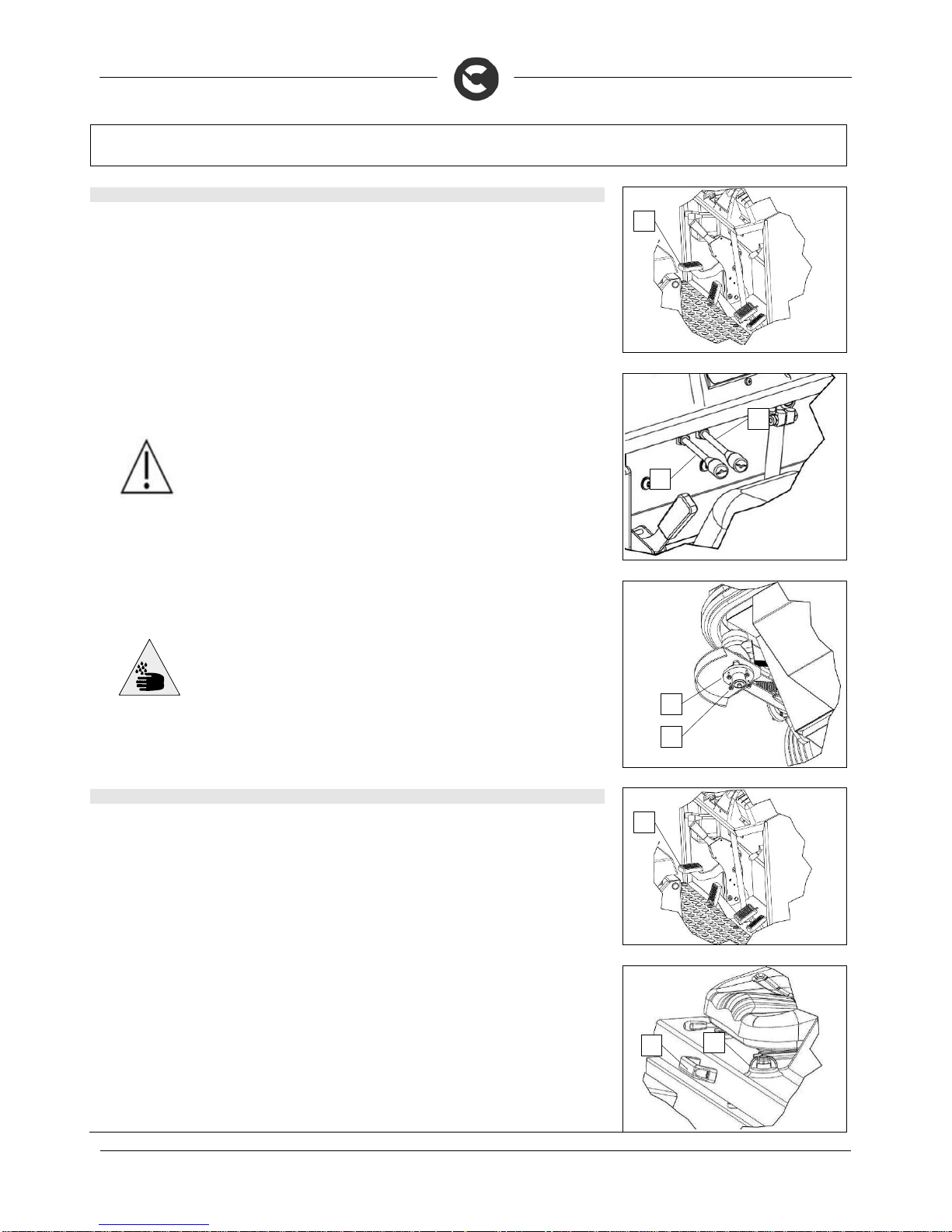

5. INSTRUMENT PANEL COMPONENTS (DIESEL VERSION)

The instrument panel components are identified as follows:

1. Filter shaker control switch

2. Front headlights control switch

3.

A

bsolute or partial hour meter selector button

4. Horn button

5. Dead man's button for lowering the hopper

6. Main key switch

7. Yellow warning light indicating that the fuel level is low

8. Green warning light indicating that the machine headlights are on

9. Red warning light indicating low brake oil level (down to reserve)

10. Red warning light indicating that the parking brake is on

11. Red indicator light indicating that the alternator is not recharging the battery

1

3

4

5

6

2

7

8

10 11

9

17

MACHINE PREPARATION

12. Red warning light indicating the oil level of the hydraulic system is low

13. Red warning light indicating the oil filter of the hydraulic system is clogged

14. Red warning light indicating the oil temperature of the hydraulic system is at a critical level

15. Red indicator light showing that the hopper hatch is closed

16. Green indicator light showing that the hopper hatch is open

17. Yellow indicator light showing that the combustion engine's glow plugs are in the heating phase

18. Red warning light indicating the combustion engine's oil pressure is low

19. Red warning light indicating the air filter of combustion engine is clogged

20. Red warning light indicating the temperature of the combustion engine's coolant is at a critical level

21. Fuel level display

22. Hour meter display (absolute or partial)

23. Rev counter for the combustion engine

24. Combustion engine's coolant temperature display

12

13

14

15

16

17

18

19

20 21

22

24

23

18

MACHINE PREPARATION

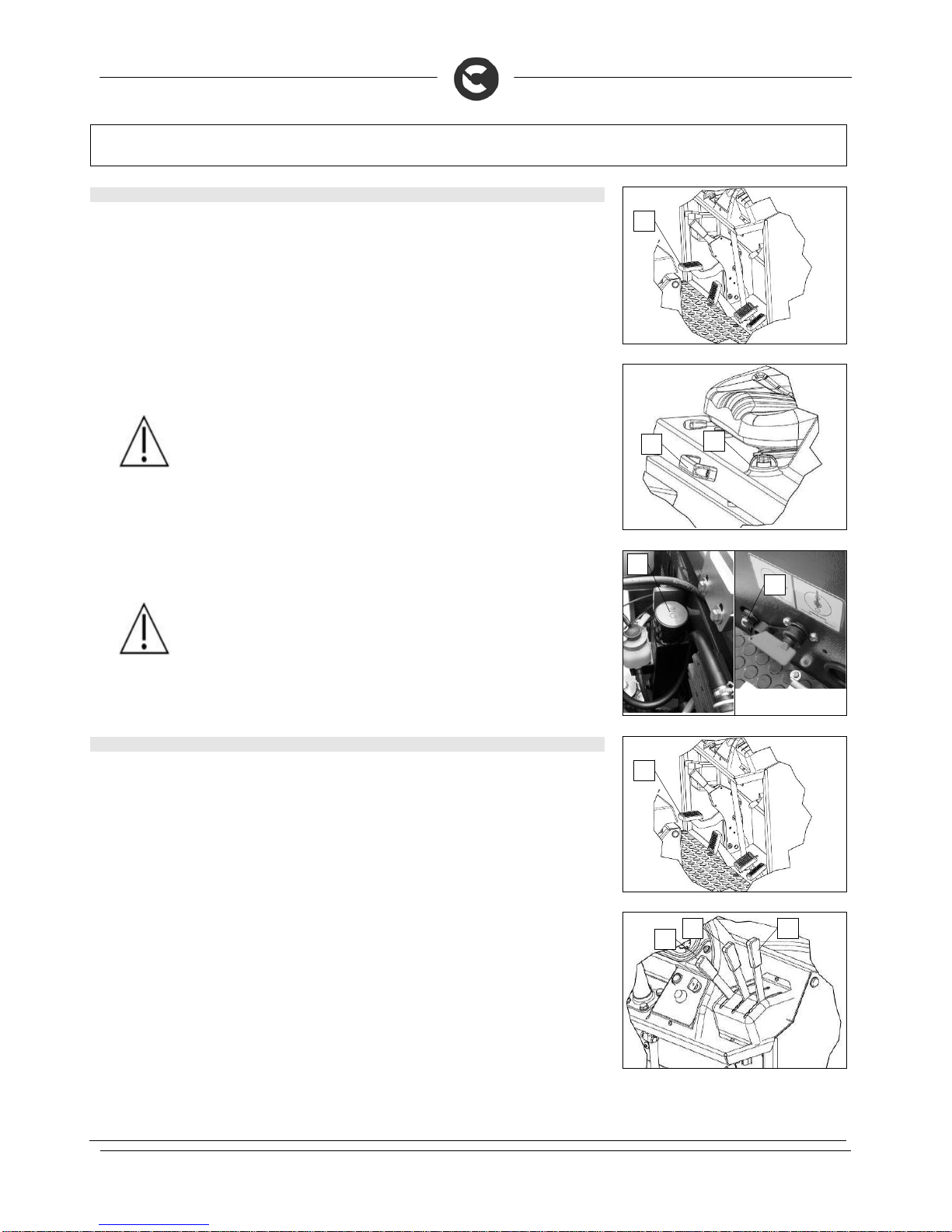

6. CONTROL PANEL COMPONENTS (BATTERY VERSION)

The control panel components in the battery version are identified as follows:

1. Central brush control lever

2. Left side brush control lever (optional)

3. Right side brush control lever

4. Control lever for activating and deactivating the vacuum turbine

7. CONTROL PANEL COMPONENTS (DIESEL VERSION)

The control panel components in the diesel version are identified as follows:

1. Central brush control lever

2. Right side brush control lever

3. Left side brush control lever (optional)

4. Control lever for activating and deactivating the vacuum turbine

5. Lever for adjusting the number of revs of the combustion engine

6. Control lever for the hopper hatch

7. Control lever for raising the hopper

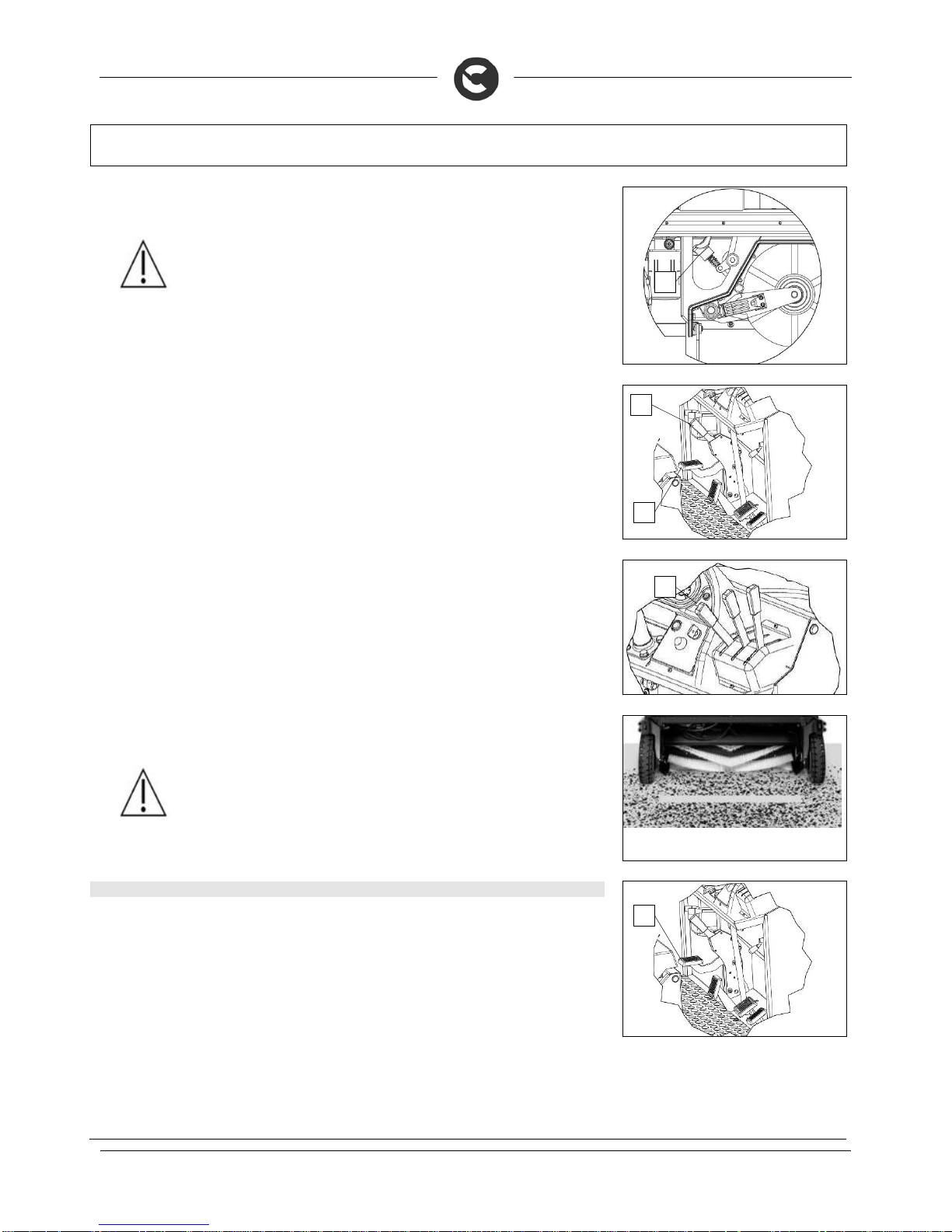

8. FOOTBOARD FOOTREST COMPONENTS (BATTERY VERSION)

The components of the footboard are identified as follows:

1. Forward movement pedal

2. Backward movement pedal

3. Brake pedal

4. Parking brake pedal

5. Lever for releasing the parking brake

1

3

4

2

5

6

7

1

2

4

3

2

1

5

4

3

19

MACHINE PREPARATION

6. Battery connector handle

7. Electrical system connector

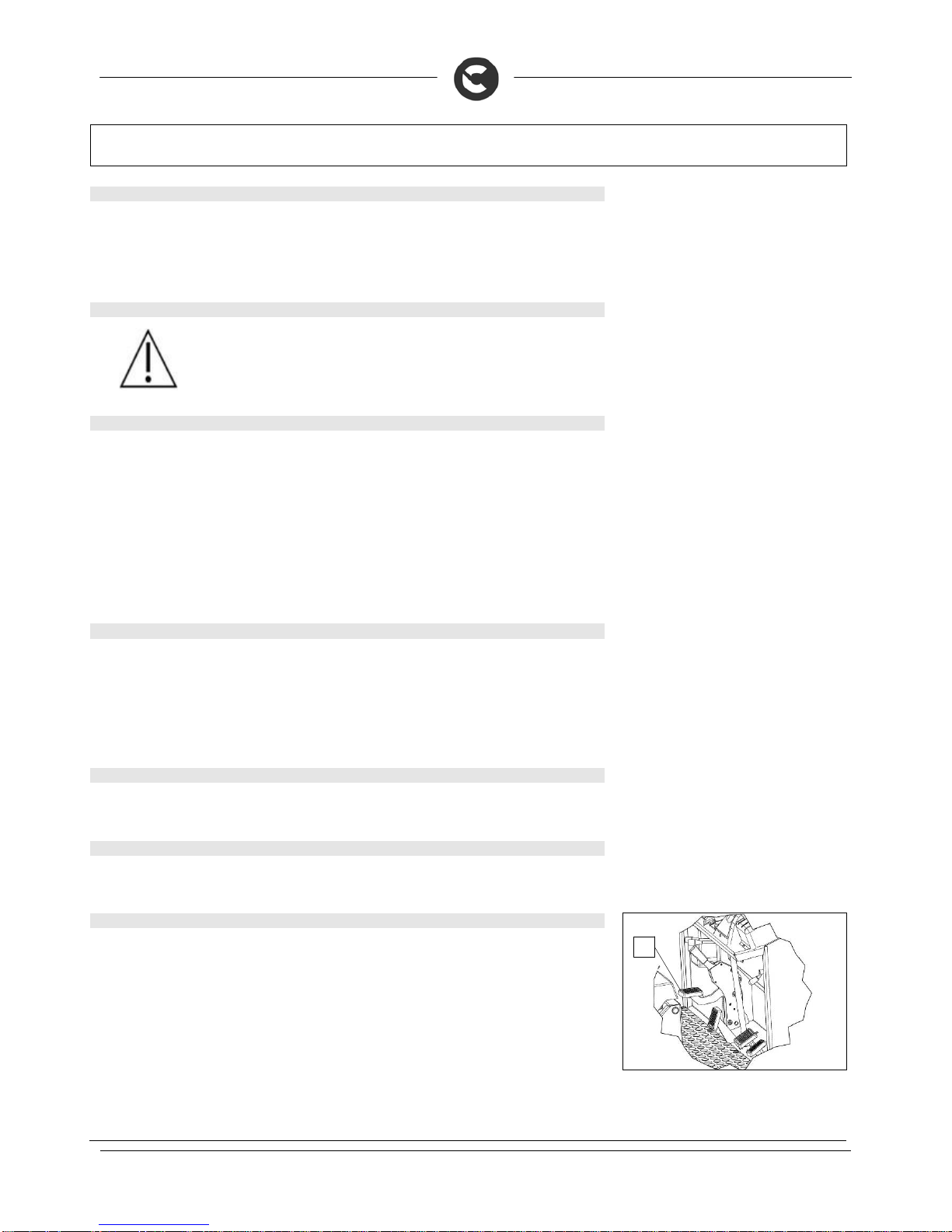

9. FOOTBOARD FOOTREST COMPONENTS (DIESEL VERSION)

The front components of the footboard are identified as follows:

1. Forward movement pedal

2. Backward movement pedal

3. Brake pedal

4. Parking brake pedal

5. Lever for releasing the parking brake

6. Hydraulic system minimum oil level bulb

7. Hydraulic system maximum oil level bulb

8. Emergency button for starter battery cut-off

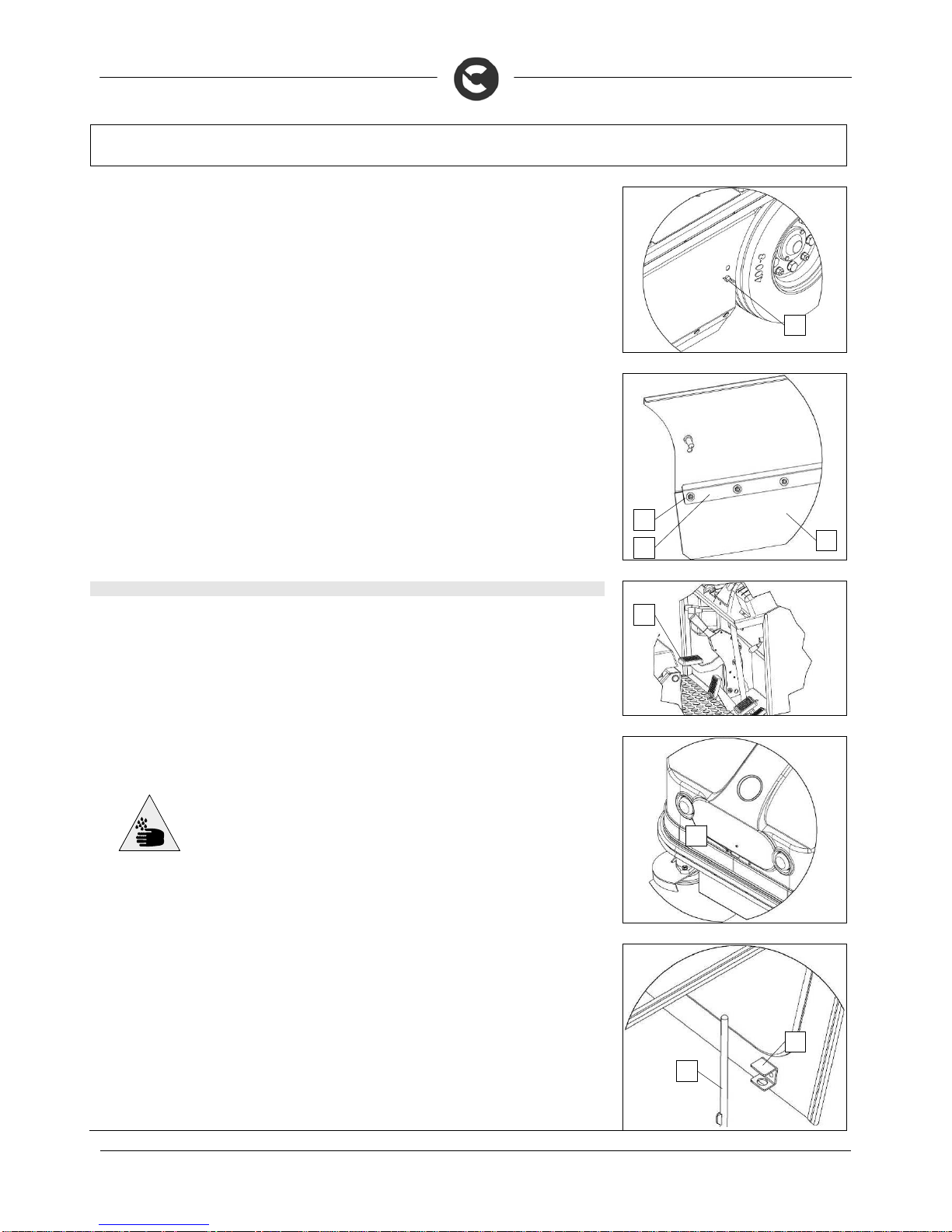

10. REAR COVER COMPONENTS

The rear cover components are identified as follows:

1. Seat adjustment lever

2. Handle for raising the cover

3. Cover rotation catch

2

1

5

4

3

6

7

8

1

2

3

7

6

20

MACHINE PREPARATION

4. Blinking light

11. FRONT COVER COMPONENTS

The front cover components are identified as follows:

1. Headlights

2. Handle for raising the cover

12. SIDE COMPONENTS

The front cover components are identified as follows:

1. Side hatch

2. Step for getting on and off

13. TYPE OF BATTERY (BATTERY VERSION)

To power the machine, two 18V battery boxes with nine 2V 480 Ah/5h liquid electrolyte components are

needed. For optimal work performance, DO NOT USE OTHER TYPES. The batteries must meet the

requirements laid out in the norms: CEI EN 60254-1:2005-12 (CEI 21-5) + CEI EN 60254-2:2008-06 (CEI 21-7)

14. TYPE OF STARTER BATTERY (DIESEL VERSION)

As a starter battery, you are advised to use a 12V/55 Ah C5 battery.

To perform well, OTHER TYPES SHOULD NOT BE USED. The battery must meet the requisites indicated

in standards CEI EN 50342, CEI EN 60095-2 and CEI EN 60095-4

4

1

2

1

1

2

21

MACHINE PREPARATION

15. BATTERY MAINTENANCE AND DISPOSAL

For maintenance and recharging, respect the instructions provided by the battery manufacturer.

Particular attention must be paid when choosing the battery charger, if not supplied, since there are

different kinds according to the type and capacity of the battery.

When the battery reaches the end of its working life, it must be disconnected by expert, trained personnel,

then lifted (using the grips and suitable lifting devices) to remove it from the battery compartment.

EXHAUSTED BATTERIES ARE CLASSIFIED AS DANGEROUS WASTE AND MUST BE CONSIGNED

TO THE AUTHORISED BODIES FOR CORRECT DISPOSAL.

WARNING: You are advised to always wear protective gloves, to avoid the risk of

serious injury to your hands.

WARNING: You are advised to only lift and move the batteries with lifting and

transportation means suitable for the specific weight and size

16. MAINTENANCE AND DISPOSAL OF THE COMBUSTION ENGINE

WARNING: For the maintenance and disposal of the combustion engine, observe

the instructions given by the engine manufacturer (for maintenance) and current

environmental hygiene norms (for disposal).

17. HANDLING AND INSERTING THE BATTERIES (BATTERY VERSION)

The batteries must be housed in the special compartment beneath the rear cover. They should be handled

using lifting equipment that is suitable in terms of both weight and coupling system. They must also satisfy

the requirements of Standard CEI 21-5.

WARNING: For battery maintenance and daily recharging, you must fully respect the

indications provided by the manufacturer or retailer. All installation and maintenance

operations must be carried out by specialised personnel.

To insert batteries proceed as follows:

1. Block the machine by engaging the parking brake, pressing the pedal (1) down

2. Check the main machine switch is in the “OFF” position, and if this is not the case, turn it by a quarter

rotation to the left

WARNING: you are advised to always wear protective gloves, to avoid the risk of

serious injury to your hands.

3. Turn the cover (2) rotation catch

4. Using the handle (3) turn the rear cover as far as it will go

1

2

3

22

MACHINE PREPARATION

5. Using the right tools remove the screw fixing the cable (4) stopping the rear cover rotating

WARNING: Hold the cord stopping the rear cover rotating firmly during this

operation, otherwise it could rotate too much and get damaged.

6. Turn the rear cover until there is space to get at the battery boxes, rest the cover on a structure to

prevent extra-rotation that could damage the machine

7. Place the batteries inside the battery compartment using transport and handling equipment suitable for

the weight and size of the batteries

8. Place the batteries in the battery compartment with the "+" and "-" poles opposite each other

ATTENTION: You are advised to only lift and move the batteries with lifting and

transportation means suitable for the specific weight and size

18. CONNECTING THE BATTERIES AND BATTERY CONNECTOR (BATTERY VERSION)

1. Connect the batteries in series (1) using the jumper cables supplied, to the “+” and “-“ poles

2. Connect the battery connector cable to the “+” and “-“ poles to obtain a voltage of 36V on the terminals (2)

3. Connect the battery connector cable (2) to the machine connector (3)

4. Connect the 14 V line battery connector cable to the “+” (4) pole to obtain a voltage of 14V on the terminals

WARNING: All installation and maintenance operations must be carried out by

expert personnel, trained at the specialised assistance centre

WARNING: It is recommended that the above-mentioned operations be carried out

by personnel trained by the service centre.

WARNING: You are advised to always wear protective gloves, to avoid the risk of

serious injury to your hands.

19. CONNECTING THE BATTERY CHARGER (BATTERY VERSION)

In order not to cause permanent damage to the batteries, it is essential to avoid their complete discharge:

arrange the recharge within a few minutes of the switching on of the "discharged batteries" blinking light.

ATTENTION: never leave the batteries completely discharged, even if the machine

is not being used. Check the battery charger is suitable for the batteries installed, in

terms of both capacity and type.

To connect the battery charger you must:

1. Move the machine near to the battery charger

2

. Block the machine by engaging the parking brake, pressing the pedal (1) down

3. Check the main machine switch is in the “OFF” position, and if this is not the case, turn it by a quarter

rotation to the left

4

1

1

2

4

3

23

MACHINE PREPARATION

4

. Turn the cover rotation catch (2)

5. Using the handle (3) turn the rear cover as far as it will go

WARNING: you are advised to always wear protective gloves, to avoid the risk of

serious injury to your hands.

6. Gripping the handle (4) disconnect the electrical system connector from the battery connector (5)

7. Connect the battery charger cable connector

The coupling connector of the battery charger is consigned inside the bag containing this instruction

booklet, and must be assembled on the cables of the battery charger as indicated in the instructions.

ATTENTION: This process must be carried out by qualified personnel. An incorrect

connection of the connector may cause problems with machine functioning.

8. Connect the recently wired cable to the external battery charger

9. After the charging cycle is complete, the battery connector must be connected to the electrical system connector

WARNING: Make sure that the battery charger that is to be used is suitable for the

batteries in the machine.

WARNING: Carefully read the use and maintenance instructions of the battery

charger that is used for charging.

WARNING: Keep the seat mounting plate raised for the whole duration of the battery

recharging cycle to allow gas fumes to escape

ATTENTION: danger of exhalation of gas and leakage of corrosive liquids.

ATTENTION: danger of fire: do not go near with free flames

2

3

4 5

24

MACHINE PREPARATION

20. BATTERY CHARGE LEVEL INDICATOR (BATTERY VERSION)

On the instrument panel of the machine there is a monitor (1) indicating (amongst other things) the battery

charge status. If the led lights reach a watch level (red colour), the battery charging is critical and an

intermittent buzzer will go off.

21. FILLING THE FUEL TANK (DIESEL VERSION)

The machine is supplied without any fuel in the tank of the combustion engine. To fill the tank, proceed as

follows:

1. Block the machine by engaging the parking brake, pressing the pedal (1) down

2

. Check the main machine switch is in the “OFF” position, and if this is not the case, turn it by a quarter

rotation to the left

3. Turn the cover rotation catch (2)

4

. Using the handle (3) rotate the rear cover as far as it will go

5. Unscrew the cap (4) of the fuel tank and fill it up to the top.

WARNING: Diesel is highly inflammable and can explode.

WARNING: Fill up the fuel tank in a well-ventilated area and with the machine off.

Do not smoke or take any unprotected flames or sparks near the motor while it is

being filled, or in the area where the gasoline is stored.

WARNING: during the filling operation, be careful not to spill the fuel. Spilt fuel or

fuel vapours could ignite. If any fuel is accidentally spilt, remove it thoroughly

before switching on the motor.

1

1

2

3

4

25

MACHINE PREPARATION

22. FUEL LEVEL INDICATOR (DIESEL VERSION)

On the instrument panel of the machine there is a display (1) indicating the level of the fuel tank. If the

yellow led comes on (2) it means that the tank is running extremely low and needs filling up.

23. CHECKING THE OIL LEVEL OF THE COMBUSTION ENGINE

Before checking the level of oil in the combustion engine, do as follows:

1. Block the machine by engaging the parking brake, pressing the pedal (1) down

2

. Check the main machine switch is in the “OFF” position, and if this is not the case, turn it by a quarter

rotation to the left

3. Turn the cover rotation catch (2)

4

. Using the handle (3) rotate the rear cover as far as it will go

5. Follow the procedures set out in the combustion engine's use and

maintenance manual

WARNING: Always check the motor before using it (and read the relevant use and

maintenance manual). In this way, you will avoid any accidents or damage to the motor.

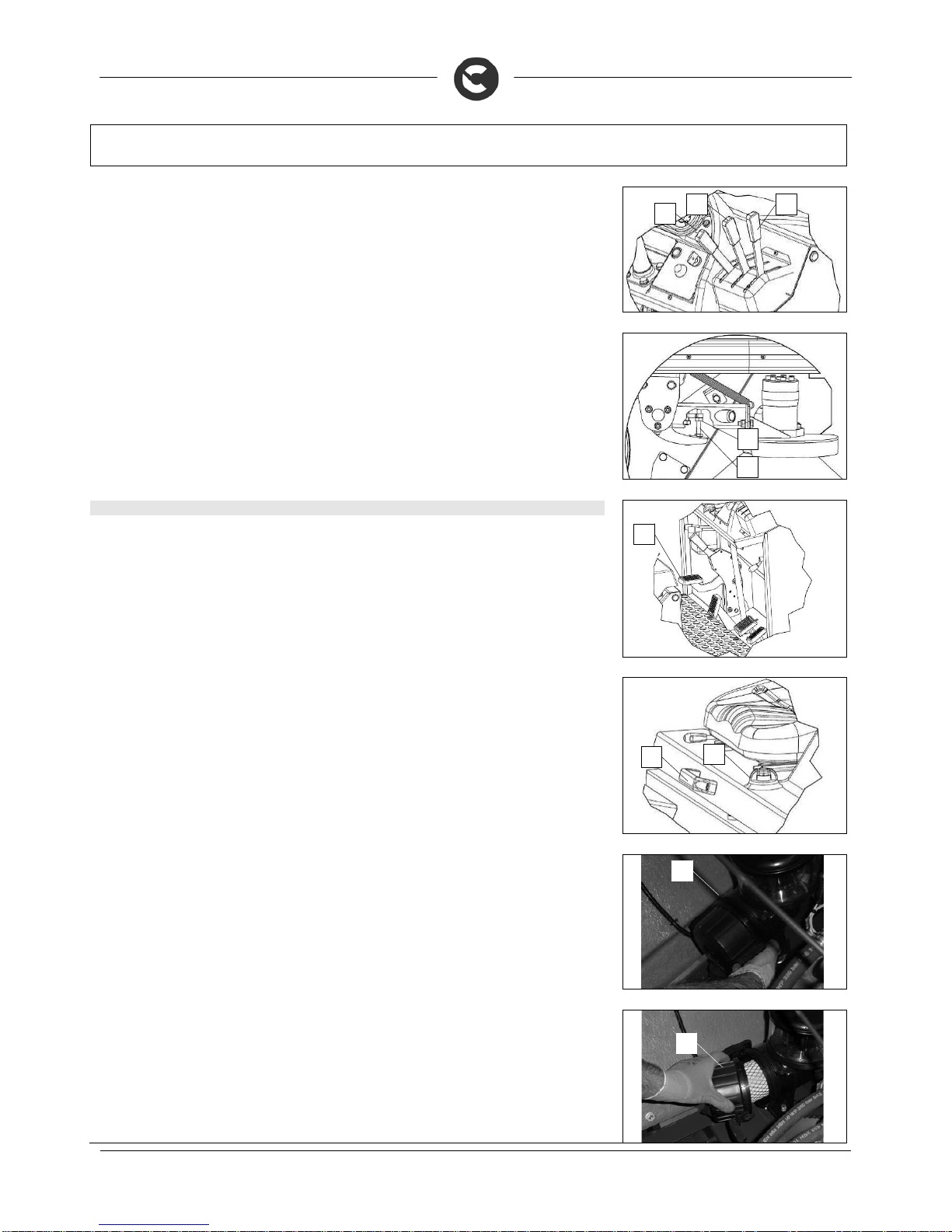

24. CHECKING THE COMBUSTION ENGINE'S AIR FILTER

Before checking the condition of the combustion engine's air filter, do as follows:

1. Block the machine by engaging the parking brake, pressing the pedal (1) down

2

. Check the main machine switch is in the “OFF” position, and if this is not the case, turn it by a quarter

rotation to the left

3. Turn the cover rotation catch (2)

4

. Using the handle (3) rotate the rear cover as far as it will go

1

2

1

2

3

1

2

3

26

MACHINE PREPARATION

5. Follow the procedures set out in the combustion engine's use and maintenance manual

WARNING: Always check the motor before using it (and read the relevant use and

maintenance manual). In this way, you will avoid any accidents or damage to the motor.

25. HOUR METER (BATTERY VERSION)

On the instrument panel of the machine there is a display (1) indicating the total number of working hours,

or by pressing the button (2) the partial hours are displayed. The total number of hours display is divided

into three pairs of numbers that identify the effective work hours that have passed.

The partial number of hours display is divided into three pairs of numbers, the first four identify the hours

that have passed, while the last two numbers identify the tenths of an hour that have passed.

The flashing hourglass symbol indicates that the hour meter is counting the time the machine is operating.

26. HOUR METER (DIESEL VERSION)

On the instrument panel of the machine there is a display (1) indicating the total number of working hours,

or by pressing the button (2) the partial hours are displayed. The total number of hours display is divided

into three pairs of numbers that identify the effective work hours that have passed.

The partial number of hours display is divided into three pairs of numbers, the first four identify the hours

that have passed, while the last two numbers identify the tenths of an hour that have passed.

The flashing hourglass symbol indicates that the hour meter is counting the time the machine is operating.

27. TURNING LIGHTS ON/OFF

The machine is equipped with two front headlights, to help the operator to work in low light. To switch on

the headlights simply turn the switch (1) located on the instrument panel to the "I" position and the green

indicator light (2) on the instrument panel will immediately illuminate; the lights will remain on until you

again operate the switch.

1

2

2

2

1

27

MACHINE PREPARATION

28. SERVICE BRAKE – PARKING BRAKE

The machine has a mechanical braking system, in normal conditions just press the pedal (1) down.

In case of lack of oil in the braking system, the red warning light (2) on the instrument panel will come on;

check the level in the brake oil tank located behind the vehicle nose.

To engage the parking brake press the pedal (3) down, the red warning light (4) on the instrument panel

will come on. To disengage the parking brake, use the lever (5).

29. WORKING FORWARD SPEED

To move the machine in the work direction, turn the key to “ON - I” then press the pedal (1) down, adjusting

the speed by altering the degree of pressure on the pedal. To go in reverse, press the pedal (2) down.

WARNING! The reverse speed is lower than the forward speed to comply with

current health and safety standards.

30. SIDE BRUSH ASSEMBLY

To assemble the side brush, proceed as follows:

1. Check that the side brush is raised off the ground, if not use the lever (1) on the control panel (for the

left side brush), while using the lever (2) on the control panel (for the right side brush)

2. Engage the parking brake located on the left side of the machine

1

4

2

3

5 2 1 2

1

28

MACHINE PREPARATION

3. Make sure that the main switch is in the "ON" position, if not turn it by a quarter rotation to the right

4. Make sure that the hopper hatch is closed, if this is not the case not pull the lever (4) upwards

5. Raise the hopper to its maximum height, pulling the lever (3) up, engage the safety catches supplied

with the machine

ATTENTION! The safety catches, supplied with the machine, should be inserted

into the shafts of the pistons controlling the raising of the hopper.

6. Check the main machine switch is in the “OFF” position, and if this is not the case, turn it by a quarter

rotation to the left

7. With the proper equipment, remove the screws (5) in the side brush hub

8. Insert the side brush into the brush hub (6)

9. With the proper equipment, fix the side brush to the brush hub (6) using the screws (5)

10. Remove the safety catches

11. Make sure that the main switch is in the "ON" position, if not turn it by a quarter rotation to the right

12. Lower the hopper until it is in the work position, pulling the lever (3) downwards, while at the same

time pushing the dead man's button (7) on the instrument panel

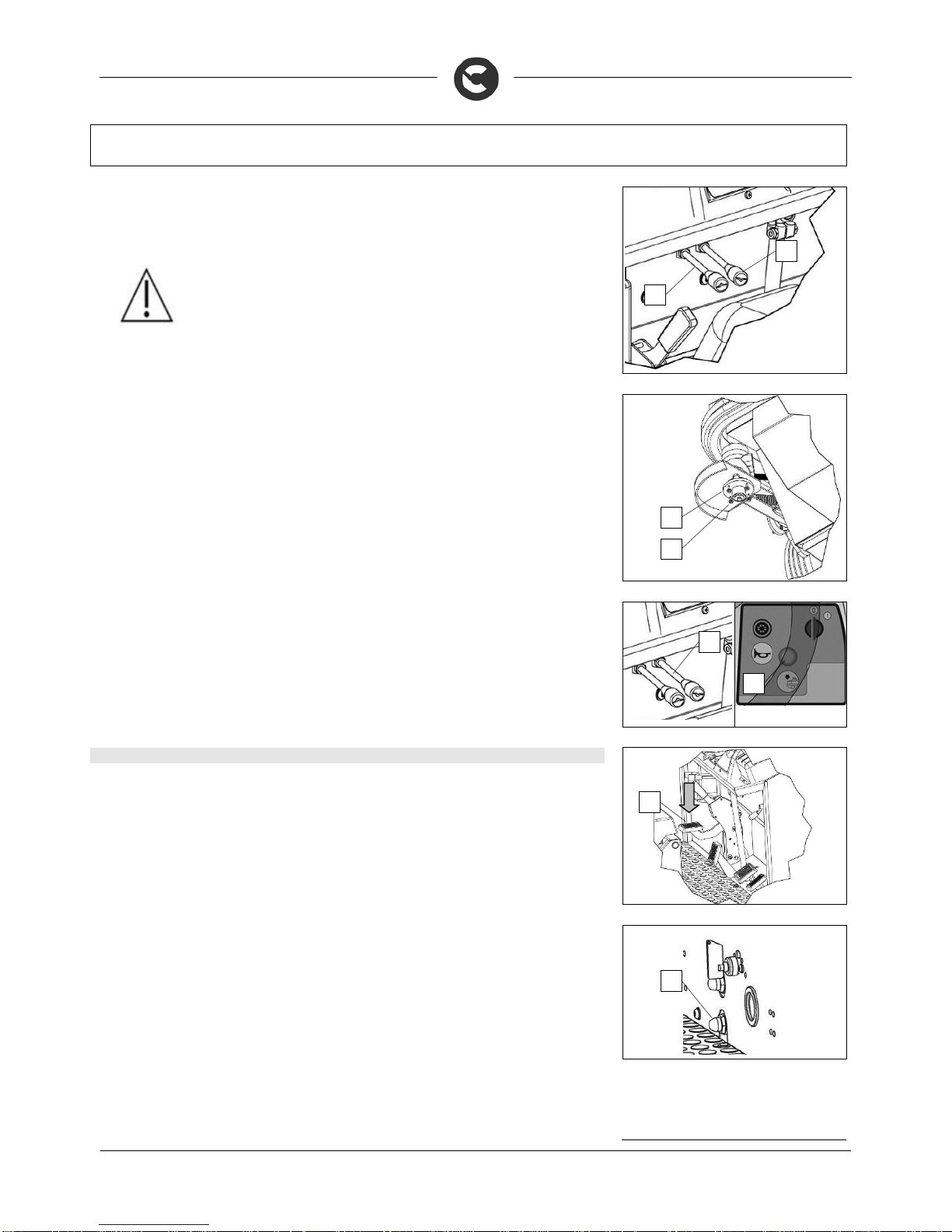

31. CHECKING THE HYDRAULIC SYSTEM OIL

This machine is equipped with a hydraulic system. To ensure optimum machine performance, check the oil

level in the following way:

1. Block the machine by engaging the parking brake, pressing the pedal (1) down

2

. Check the main machine switch is in the “OFF” position, and if this is not the case, turn it by a quarter

rotation to the left

3. Check the oil is not below the minimum level, as seen on the transparent cap (2). If necessary, add

more oil by following the instructions in the “MAINTAINING THE HYDRAULIC OIL LEVEL” chapter.

3

4

1

2

3

7

6

5

29

MACHINE PREPARATION

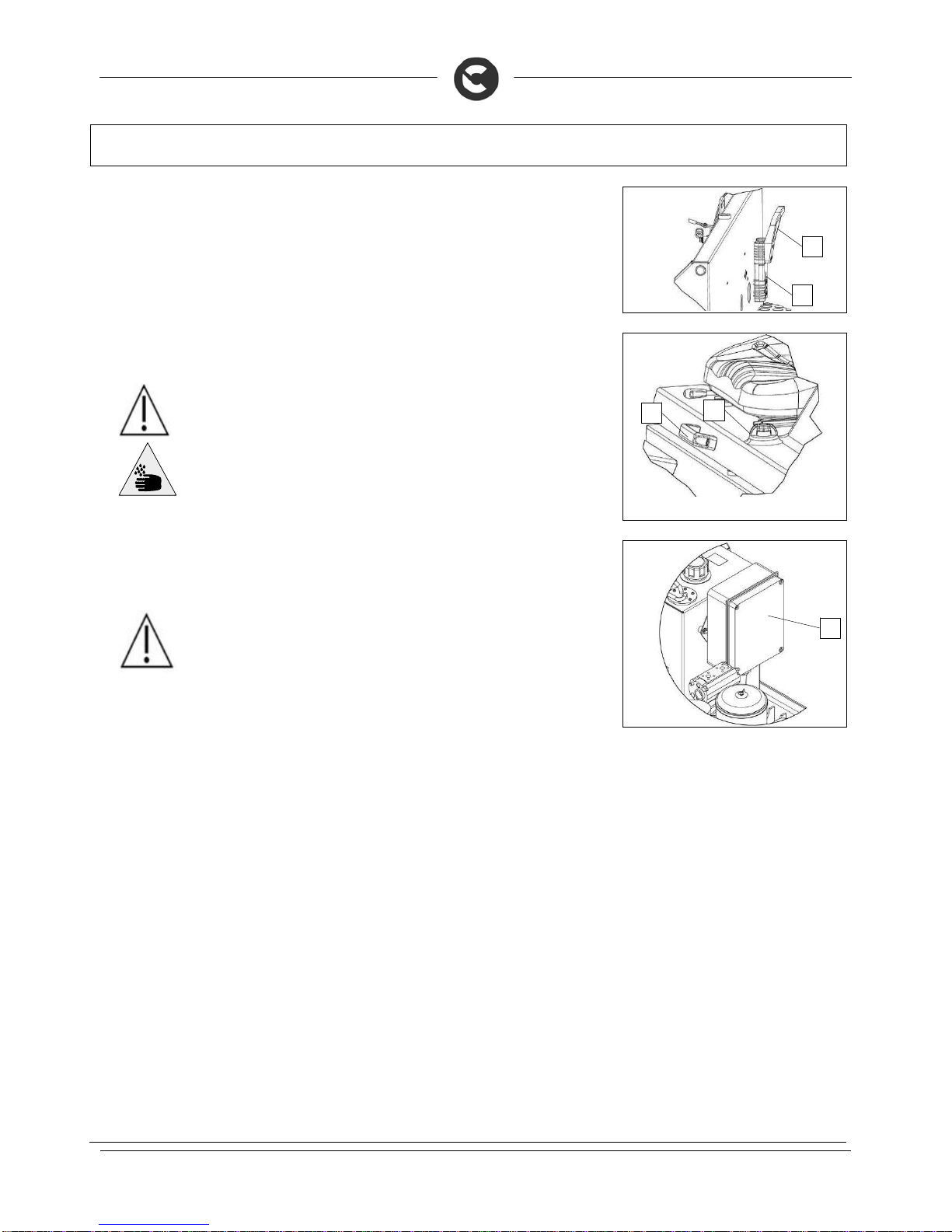

32. SAFETY BELT INSERTION (OPTIONAL)

The machine can be equipped with a lap belt safety device which allows the operator to be anchored to

the driving seat.

To fasten the safety belt proceed as follows:

1. position yourself on the driving seat

2. take hold of the mobile part (1) of the safety belt

3. wrap it around the abdominal area

4. insert the mobile part (1) into the slot on the fixed part (2)

5. release the belt to allow the seatbelt tensioner to roll the belt back up

To uncouple the safety belt press the button (3) and remove the mobile part (1) or push the rapid

uncoupling button (4)

1

3

2

4

30

PREPARING TO WORK

33. SEAT ADJUSTMENT

The adjustment of the driver's seat is very important for ensuring a comfortable position for the operator,

and to do this proceed as follows:

1. sit on the driver’s seat

2

. Use the lever (1), move the seat backwards or forwards until the most suitable position has been found

34. PREPARING THE BATTERY VERSION OF THE MACHINE TO WORK

Before beginning to work, it is necessary to:

1. Block the machine by engaging the parking brake, pressing the pedal (1) down

2

. Check the main machine switch is in the “OFF” position, and if this is not the case, turn it by a quarter

rotation to the left

3. Connect the battery connector (1) to the electric system connector (2)

35. PREPARING THE DIESEL VERSION OF THE MACHINE TO WORK

Before beginning to work, it is necessary to:

1. Block the machine by engaging the parking brake, pressing the pedal (1) down

2

. Check the main machine switch is in the “OFF” position, and if this is not the case, turn it by a quarter

rotation to the left

3. Turn the cover rotation catch (2)

4

. Using the handle (3) rotate the rear cover as far as it will go

1

1

1

2

3

31

PREPARING TO WORK

5. Check that the level of the radiator coolant is between the "MAX" notch and the "MIN" notch, and if

necessary follow the instructions in the section "FILLING THE COMBUSTION ENGINE'S COOLANT

TANK (DIESEL VERSION)"

WARNING: Check the level of the combustion engine's cooling system fluid with the

engine off, with the engine at ambient temperature, with the machine parked on a flat

surface.

6. Check that the cyclone filter is clean, if necessary follow the instructions in the section "CLEANING

THE COMBUSTION ENGINE'S CYCLONE PREFILTER (DIESEL VERSION)"

7. Check that the radiator is clean, if necessary follow the instructions in the section "CLEANING THE

COMBUSTION ENGINE'S RADIATOR (DIESEL VERSION)"

8. Check that the fuel tank is clean, if necessary follow the instructions in the section "FILLING THE

FUEL TANK (DIESEL VERSION)"

32

WORK

36. SWITCHING ON THE MACHINE, DIESEL VERSION

1. sit on the driver’s seat

ATTENTION! The machine is fitted with a dead man's micro-switch beneath the seat;

this prevents the machine from moving if the operator is not correctly seated

2

. Check that the accelerator lever (1) is at the minimum, if not pull it upwards

3. Turn the key of the main switch a quarter of a turn clockwise (to position 1). Immediately, on the

instrument panel, the display (4) will turn on indicating the level of fuel in the diesel tank

4

. Check the parking brake is released, if not use the lever (2), the warning light (3) on the instrument

panel will go out

5. Wait for the yellow led of the glow plugs to go out, then bring the motor ignition switch to the "START"

position (turning the key further to the right), and keep it there until the motor starts. When the engine

starts, release the key

T

o ensure the machine works correctly, a few seconds after the combustion engine starts bringing the lever

(1) to its limit, in this way the accelerator will be at its maximum stroke.

WARNING: Do not use the starter for more than 5 seconds at a time. If the motor does

not start up, release the key and wait for 10 seconds before making a new attempt.

37. SWITCHING ON THE MACHINE, BATTERY VERSION

1. sit on the driver’s seat

ATTENTION! The machine is fitted with a dead man's micro-switch beneath the seat;

this prevents the machine from moving if the operator is not correctly seated

2

. Turn the key of the main switch a quarter of a turn clockwise (to position 1). Immediately, on the

instrument panel, the display (3) will turn on indicating the charge level of the batteries, and also the

display (4), indicating the machine's amperage draw

3. Check the parking brake is released, if not use the lever (1), the warning light (2) on the instrument

panel will go out

1

2

3

4

1

1

2

3

4

33

WORK

The display (3) shows the state of the charge of the batteries, when the batteries supplied with the

machine are full the column composed of luminous notches arrives at the green zone of the scale printed

on the instrument panel. As the batteries gradually run down, the notches go out and, with the batteries

completely run down (red zone), the notches start to flash and an intermittent buzzer starts to sound. The

flashing hourglass symbol indicates that the hour meter is counting the time the machine is operating.

38. STARTING TO WORK

T

o start working, do as follows:

1. Open the hopper hatch, pulling the lever (1) down. As soon as the debris hopper hatch is open, the

indicator light (2) on the instrument panel will come on.

ATTENTION! If along the machine's path there are large pieces of waste, shut the

hatch temporarily to allow the central brush to access and collect it

2. Lower the central brush, using the lever (3) on the control panel

WARNING: The central brush will start to rotate as soon as it reaches its work position.

3. Start the vacuum, turn the lever (4) left

ATTENTION! When working on a wet area or if wet dirt is being collected, the

vacuum motor should be switched off by turning the lever (6) to the right, and once

the critical zone has passed the vacuum motor can be started again.

4. Press the accelerator pedal (5) to start moving the machine

ATTENTION: Adjust the working speed according to the amount of waste and

debris to be collected

To make a reverse manoeuvre, push the accelerator pedal (6) downwards, the machine will begin to

move backwards.

WARNING! The reverse speed is lower than the forward speed to comply with

current health and safety standards.

3

4

1

2

5

6

34

WORK

If the dirt level requires it, lower the right side brush, (1SL versions) using the lever (7) on the control

panel. If you want to lower the optional left brush (2SL versions), use the lever (8)

ATTENTION: Use the side brush or brushes (according to machine version) only

on edges, as it is not assisted by the vacuum action.

WARNING: Both the central brush and the side brush will begin rotating as soon as

they are in their work position.

In order to achieve a correct vacuum action, clean the filter every 10 minutes and always before any

discharge of the debris hopper. To do this, proceed as follows:

1. Stop the machine and engage the parking brake

2. Raise the central brush, using the lever (1) on the control panel

3. Raise the side brush or the side brushes if lowered, using the lever (2) for the right brush and the lever

(3) for the left brush on the control panel

4. Switch off the vacuum, turn the lever (4) to the right

5.

A

ctivate the filter shaker on the filter by pressing the switch (5) on the control panel

Periodically check the filling of the tray and if necessary proceed to empty it. Bear in mind that the weight

of the dirt collected is proportional to the specific weight of the material brushed up. In the case of heavy

material such as sand, soil, gravel, etc. the tray should ideally not be filled more than 70%, otherwise it

may be difficult to empty

ATTENTION! Do not keep the switch (5) pressed longer than ten seconds, repeat

this operation two or three times.

If during the work the amperage draw (only for the battery versions) reaches a critical level, the machine

should be stopped. The machine is fitted with display for diagnosing system anomalies and checking the

electrical motor. Once a critical threshold has been reached, a horn will activate in this case, it is

necessary to stop, park the machine in a suitable place and call for assistance.

If during the work the red warning light shown here on the side on the instrument panel comes on, it

indicates that the level of oil in the braking system is "poor", you need to stop the work you are doing and

take the machine to a suitable place for its maintenance and call for assistance.

8

7

1

3 2

4

5

35

WORK

If during the work the red warning light shown here on the side on the instrument panel comes on, it

indicates that the level of oil in the hydraulic system is "poor", you need to stop the work you are doing

and take the machine to a suitable place for its maintenance and call for assistance.

If during the work the red warning light shown here on the side on the instrument panel comes on, it

indicates that the oil filter of the hydraulic system is clogged, you need to stop the work you are doing and

take the machine to a suitable place for its maintenance and call for assistance.

If during the work the red warning light shown here on the side on the instrument panel comes on, it

indicates that the oil in the hydraulic system reached a critical temperature, you need to stop the work you

are doing and take the machine to a suitable place for its maintenance and call for assistance.

If during the work the red warning light shown here on the side on the instrument panel comes on, it

indicates that there is a fault with the alternator (diesel version), you need to stop the work you are doing

and take the machine to a suitable place for its maintenance and call for assistance.

If during the work the red warning light shown here on the side on the instrument panel comes on, it

indicates that the air filter of the combustion engine is clogged (diesel version), you need to stop the work

you are doing and take the machine to a suitable place for its maintenance and call for assistance.

If during the work the red warning light shown here on the side on the instrument panel comes on, it indicates

that there is a fault with the oil pressure of the combustion engine (diesel version), you need to stop the work

you are doing and take the machine to a suitable place for its maintenance and call for assistance.

If during the work the fuel level displayed on the instrument panel reaches a critical zone the yellow

indicator light comes on, indicating that the diesel fuel is running on reserves (diesel version) you need to

stop the work you are doing and take the machine to a suitable place for its maintenance and fill up the

fuel tank, following the instructions in the chapter "FILLING THE FUEL TANK (DIESEL VERSION)"

36

AT THE END OF THE WORK

39. AT THE END OF THE WORK

A

t the end of the work, do as follows:

1. Stop the machine and engage the parking brake, pressing the pedal (1)

2

. Raise the central brush from the ground, using the lever (2)

3. Raise the right side brush from the ground, using the lever (3)

4

. Raise the left side brush from the ground (if present as an optional), using the lever (4)

5. Close the hopper hatch, pulling the lever (5) upwards. As soon as the debris hopper hatch is closed,

the indicator light (6) on the instrument panel will go out.

6. Switch off the vacuum, turn the lever (7) to the right

7.

A

ctivate the filter shaker on the filter by pressing the switch (8) on the control panel

ATTENTION! Do not keep the switch (5) pressed longer than ten seconds, repeat

this operation two or three times.

2

4 3

1

5

6

8

7

37

AT THE END OF THE WORK

8. Disengage the parking brake by means of the lever (9)

9. Bring the machine close to the waste unloading zone, stop it and engage the parking brake

WARNING! Calculate the distance between the machine and the waste container

correctly, bearing in mind the rotation radius of the debris hopper when moving.

10. Raise the hopper to the desired height, pull the lever (10) upwards.

11. Disengage the parking brake

12. Bring the machine close to the waste container, so that the debris hopper is inside the hopper's refill

opening

WARNING! Reduce the machine's movement speed when the debris hopper is

lifted off the ground.

WARNING! Avoid unloading the debris while the machine is sloped.

WARNING! Do not activate the filter shaker while the debris hopper is lifted off the

ground.

13. Engage the parking brake

14. Slowly open the hopper hatch, pulling the lever (5) upwards. As soon as the debris hopper is open, the

refuse will start to come out.

15. Once the refuse has come out, close the hopper hatch, pulling the lever (5) downwards.

16. Disengage the parking brake

17. Remove the machine from the waste unloading zone, stop the machine and engage the parking brake

WARNING! Reduce the machine's movement speed when the debris hopper is

lifted off the ground.

WARNING! Calculate the distance between the machine and the waste container

correctly, bearing in mind the rotation radius of the debris hopper when moving.

18. Engage the parking brake

19. Lower the hopper, bringing it to a work position, pulling the lever (10) downwards.

ATTENTION! The hopper will not move until the dead man's button (11) on the

instrument panel is pressed

9

10

5

10

11

38

AT THE END OF THE WORK

2

0. Disengage the parking brake

2

1. Take the machine to the designated machine storage place.

2

2. Engage the parking brake.

2

3. Bring the main machine switch to "OFF-0" by turning the key a quarter rotation to the left.

WARNING! Park the machine in a closed place, on a flat and level surface, where

it cannot cause harm to people or damage to other property, but also be protected

from any accidental fall of objects.

ATTENTION! For the diesel and Bifuel versions, avoid parking the machine near

sources of heat.

For the "battery" version, proceed as follows:

1. Disconnect the electrical system connector (1) from the battery connector (2)

For the "diesel" version, proceed as follows:

1. Position the accelerator lever (1) at the minimum, pulling it up

1

39

DAILY MAINTENANCE

PERFORM ALL MAINTENANCE OPERATIONS IN SEQUENCE

40. CLEANING THE CENTRAL BRUSH

Proceed as follows in order to clean the central brush:

1. Engage the parking brake, pressing the pedal (1)

2. Check the main machine switch is in the “OFF-0” position. If this is not the case, turn the key by a

quarter rotation to the left.

3. Turn the knob (2) anticlockwise and open the right hatch (3)

ATTENTION: This operation must be carried out using gloves to protect

against contact with dangerous substances.

4. Release the hinge (4) fixing the articulated arm (5) of the central brush

5. Withdraw the articulated arm (5) of the central brush from the central brush control arm (6)

ATTENTION: This operation must be carried out using gloves to protect

against contact with dangerous substances.

6. Withdraw the articulated arm (5) of the central brush from the central brush (7)

7. Remove the central brush (7) from the machine

8. Clean it under a jet of running water and remove any residue

ATTENTION: This operation must be carried out using gloves to protect

against contact with dangerous substances.

9. Reassemble all the elements.

ATTENTION: The brush is correctly fitted when, seen from above, the cusp

forms an upturned “V” (refer to the picture)

1

2

3

4

5

6

7

40

DAILY MAINTENANCE

41. CLEANING THE SIDE BRUSH

Proceed as follows in order to clean the side brush:

1. Engage the parking brake, pressing the pedal (1)

2

. sit on the driver’s seat

3. Turn the main machine switch to "ON-1" by turning the key a quarter rotation to the right

4

. Make sure that the hopper hatch is closed, if this is not the case not pull the lever (2) upwards

5. Raise the hopper to its maximum height, pulling the lever (3) up, engage the safety catches supplied

with the machine

ATTENTION! The safety catches, supplied with the machine, should be inserted

into the shafts of the pistons controlling the raising of the hopper.

6. Turn the main machine switch to "OFF-0" by turning the key a quarter rotation to the left