Columbia CSFE0365, CSFE4125, CSFE4100, CSFE3100, CSFE4150 Installation, Operation & Maintenance Manual

...

MODEL NUMBERS:

CSFE0365, CSFE3100,

CSFE4100, CSFE4125,

CSFE4150, CSFE5175,

CSFE5200, CSFE6225,

CSFE7275

CSFE STEAM

OIL-FIRED CAST IRON BOILER

INSTALLATION, OPERATION &

MAINTENANCE MANUAL

PATENT 7,823,544

C

OLUMBIA

Main offi ces and Factory: Pottstown, PA

C

OMPANY

P/N 240007513, Rev. G [05/2012]

H

INSTALLATION MANUAL AND OPERATING INSTRUCTIONS

TABLE OF CONTENTS

Ratings, Data, And Dimensions ........................ 3

Installation Procedure ....................................... 4

Ventilation And Combustion Air ........................ 5

Connecting Supply And Return Piping ............. 7

Venting System Inspection & Installation.......... 8

Oil Tank And Piping .......................................... 8

Electrical Wiring ................................................ 9

Thermostat Installation ..................................... 9

Normal Sequence Of Operation ..................... 13

Operating Instructions .................................... 13

Maintenance Procedures................................ 15

Service Checklist ............................................ 17

Replacement Parts ......................................... 18

KEEP THIS MANUAL NEAR BOILER

RETAIN FOR FUTURE REFERENCE

SAFETY SYMBOLS

The following defi ned symbols are used throughout this

manual to notify the reader of potential hazards of varying

risk levels.

IMPORTANT: Read the following instructions

COMPLETELY before installing!!

WARNING

1. Keep boiler area clear and free from

combustible materials, gasoline and

other fl ammable vapors and liquids.

2. DO NOT obstruct air openings to the

boiler room.

3. Modifi cation, substitution or elimination

of factory equipped, supplied or specifi ed

components may result in property

damage, personal injury or the loss of

life.

!

4. TO THE OWNER - Installation and

service of this boiler must be performed

by a qualifi ed installer.

5. TO THE INSTALLER - Leave all

instructions with the boiler for future

reference.

6. When this product is installed in the

Commonwealth of Massachusetts the

installation must be performed by a

Licensed Plumber or Licensed Gas

Fitter.

DANGER

!

Indicates a hazardous situation which, if not

avoided, WILL result in death or serious injury.

WARNING

!

Indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION

Indicates a hazardous situation which, if not

!

avoided, may result in minor or moderate

injury.

NOTICE

Indicates information which should be followed

to ensure proper installation and operation.

WARNING

All installations of boilers and venting

should be done only by qualifi ed expert

and in accordance with this manual.

Installing or venting a boiler or any other

!

gas appliance with improper methods

or materials may result in serious injury

or death due to fi re or to asphyxiation

from poisonous gases such as carbon

monoxide which is odorless and

invisible.

PATENT 7,823,544

Tested For 15 psi.

ASME

Working Pressure

2

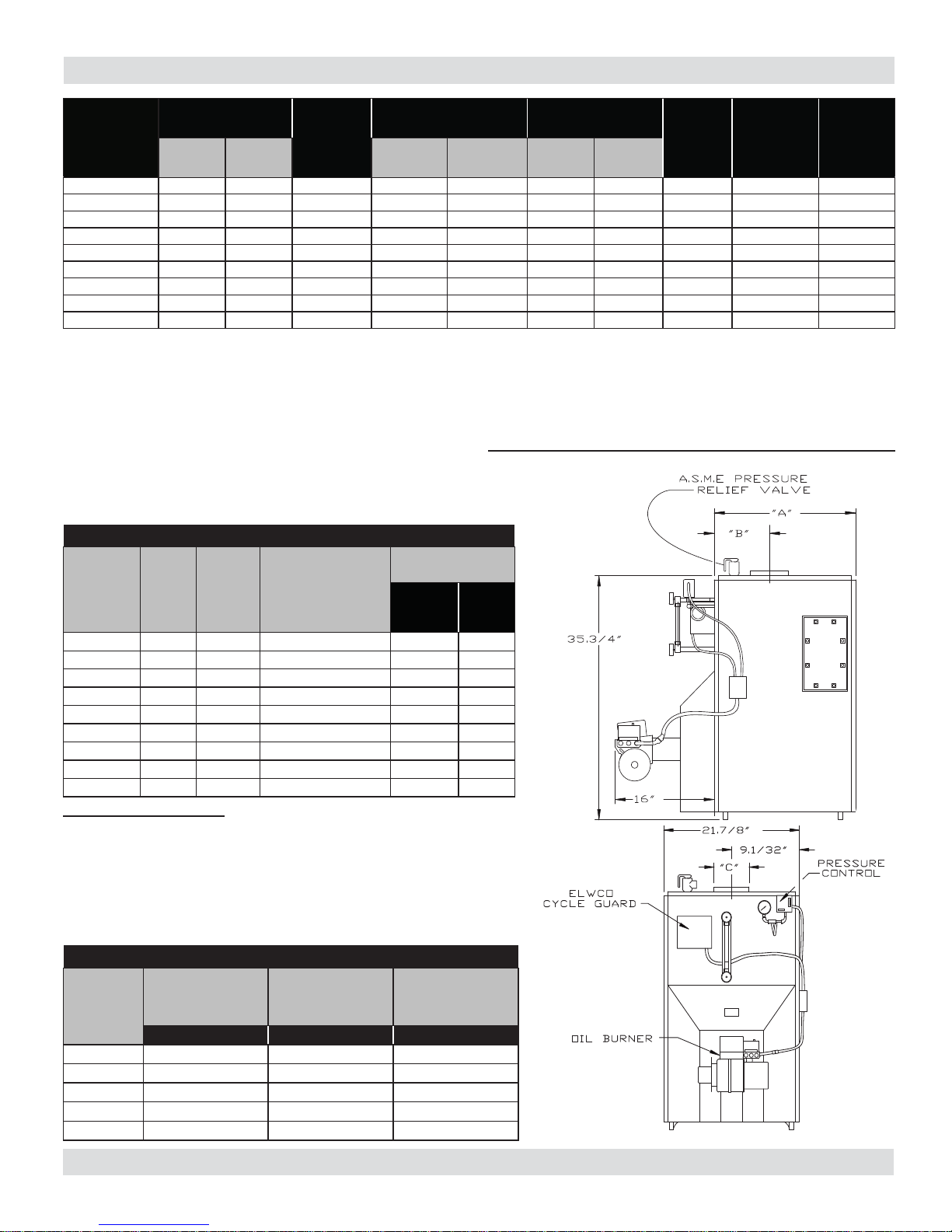

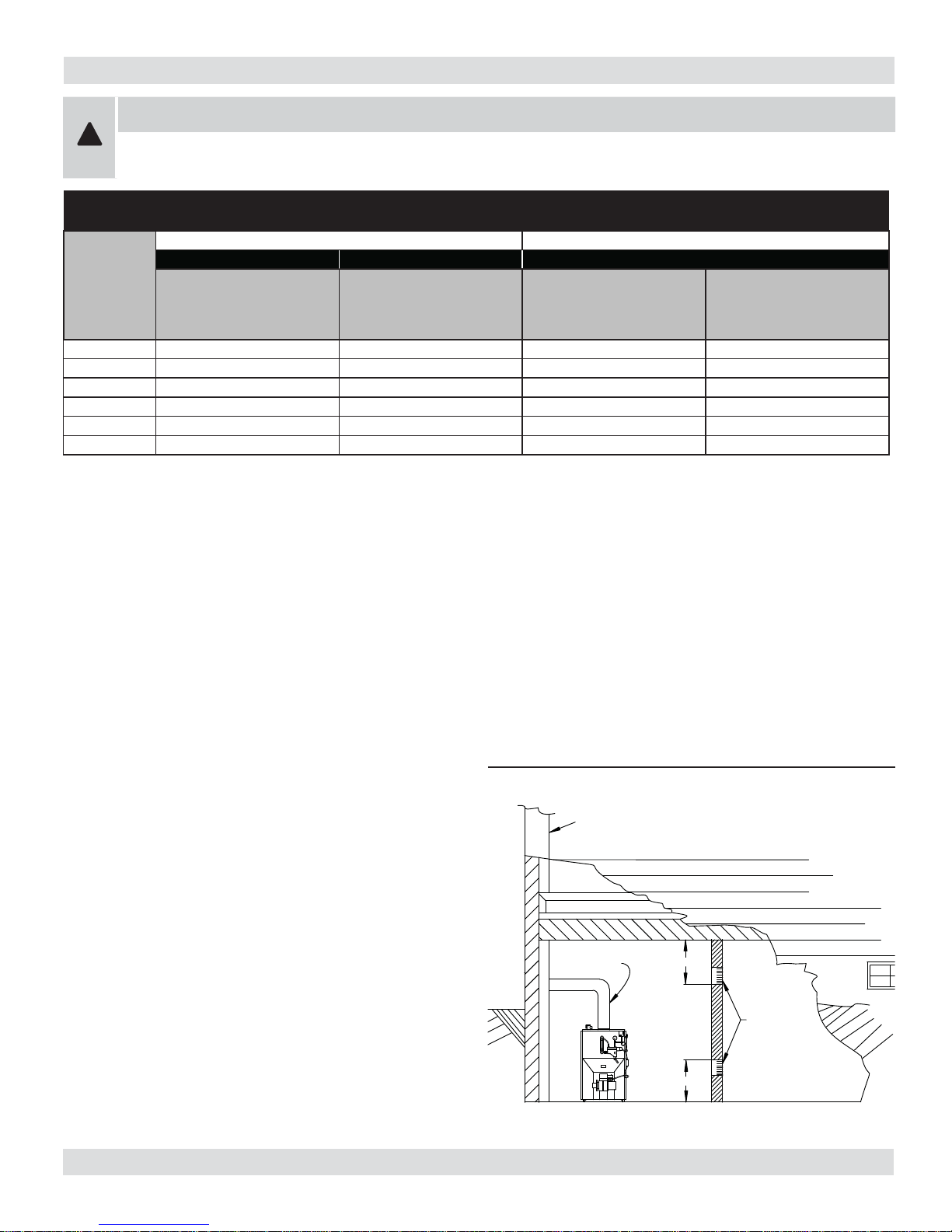

RATINGS, DATA, AND DIMENSIONS

Oil Burner Input

Boiler Model

(1)

Number

365S 0.65 91 79 59 246 6 8x8x15 140 .60 80B 85

3100S 1.00 140 116 87 363 6 8x8x15 140 .85 80B 81.5

4100S

4125S 1.25 175 145 109 454 7 8x8x15 140 1.10 60B 82.5

4150S 1.50 210 170 128 533 7 8x8x15 140 1.25 80B 81

5175S 1.75 245 202 152 633 8 8x8x15 140 1.50 80B H 83

5200S 2.00 280 227 170 708 8 8x8x15 140 1.75 70B H 82

6225S 2.25 315 251 188 783 8 8x12x15 140 2.00 45B 7275S 2.75 385 307 230 958 8 8x12x15 140 2.25 60B -

NOTES:

1. Add suffi x "T" to denote boiler with tankless heater.

2. Burner capacity is based on an oil heating value of 140,000 Btu/gal. and with 13% CO

3. Net Steam Ratings based on piping and pick-up allowance of 1.333. Consult manufacturer for unusual piping and pick-up temperatures.

4. For altitudes above 2,000 ft. ratings maybe reduced at the rate of 4% for every 1,000 ft. above sea level.

5. Nozzle sizes with an H designation are Hago brand, all others are Delavan.

6. Electrical service is 120 Volts, 15 Amps, 60 Hz.

7. MEA number for this boiler series is 182-86E.

8. MEA number for the AFG Beckett Burner used in this boiler series are;

AF/156-77-E, AFG/213-83-E, AFII 85/24-92-E, AFII 150/ 456-90-E.

9. Output is "Heating Capacity," for units with input <300 Mbh and "Gross Output"

for units ≥300 Mbh.

Boiler Model

Number

G.P.H. MBH

1.00 140 120 91 377 7 8x8x15 140 .85 80B 85

TANKLESS WATER HEATER CAPACITIES

Firing

Rate

G.P.H.

Tankless

Heater

Number

(2)

Output

(4)(9)

MBH

(4)

Tankless Heater Capac-

ity Intermittent Draw

G.P.M.

Steam

Net Ratings

MBH

Boiler Water Content

(Gallons)

To Water

Line

(3)(4)

Sq. Ft.

Steam

Figure #1

To LWCO

Line

Min. Natural Draft

Chimney Size

Round

.

2

Square

Pump

Pressure

PSI

Nozzle

Furnished

140PSIG

(5)

A.F.U.E.

Rating

365S 0.65 L-24 Available on request 11 8

3100S 1.00 L-24 4.5 11 8

4100S

4125S 1.25 L-24 4.5 13 9

4150S 1.50 L-24 4.5 13 9

5175S 1.75 L-24 5.0 15 10

5200S 2.00 L-24 5.0 15 10

6225S 2.25 L-24 5.0 17 11

7275S 2.75 L-24 5.0 19 12

1.00 L-24 4.5 13 9

ST ANDARD EQUIPMENT: Crated boiler, fl ush jacket, oil burner, target

wall/liner, ASME relief valve, steam water level gauge, steam pressure

gauge, steam pressure control, mechanical low water cut-off, drain valve,

wiring harness, burner electric disconnect, plastic cover, 2" supply tapping,

1½" return tapping, skim port, and primary control.

(NOTE: For tankless heater units, add tankless hot water coil, and 4006

limit control.)

DIMENSIONS (See Figure A)

Front of Jacket to

Center Line of Flue

Outlet

Boiler No.

Length of Flush

Jacket

-A- -B- -C-

3S 16.375" 6.5" 6.0"

4S 20.25" 8.5" 6.0"

5S 23.875" 10.25" 7.0"

6S 27.5" 8.3125" 8.0"

7S 31.125" 8.3125" 8.0"

Flue Outlet Diam-

eter

3

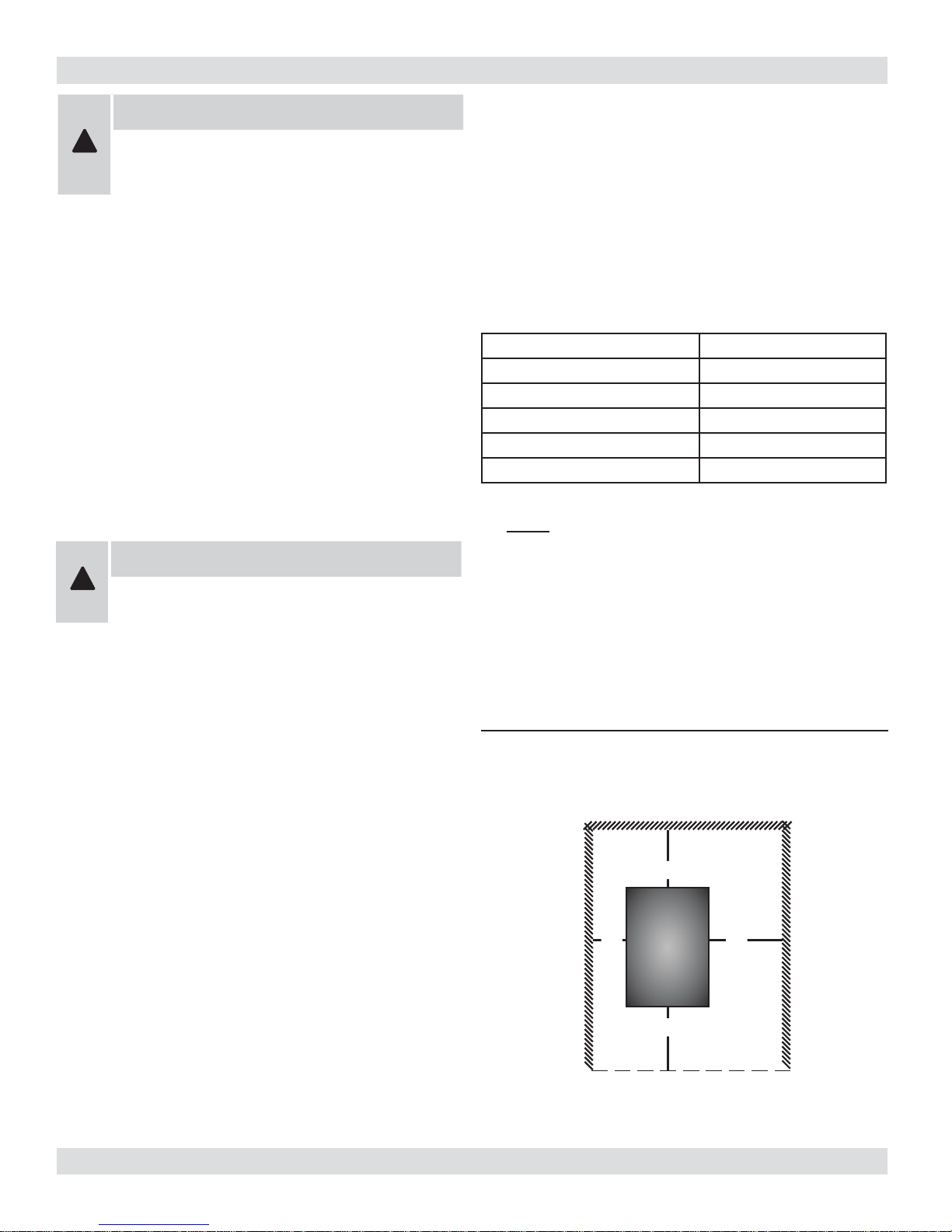

INSTALLATION PROCEDURE

WARNING

replacement of another appliance such as a water heater.

The boiler shall be installed such that the oil ignition system

!

Improper installation, adjustment,

alteration, service or maintenance can

cause injury or property damage.

components are protected from water (dripping, spraying,

rain etc.) during appliance operation and service.

All installations must conform to the requirements of the

authority having jurisdiction. Such applicable requirements

take precedence over the general instructions of this

manual.

FOR INSTALLATION ON NON-COMBUSTIBLE FLOORS

ONLY - The boiler must not be installed on carpeting

or vinyl fl ooring. Minimum clearances to combustible

construction are:

Where required by the authority having jurisdiction, the

installation must conform to the American Society of

Mechanical Engineers Safety Code for Controls and Safety

Devices for Automatically Fired Boilers, ANSI/ASME No.

CSD-1.

Locate boiler in front of fi nal position before removing crate.

Provide a level solid base as near chimney as possible and

centrally located with respect to the heat distribution system

as practical.

WARNING

!

Boiler may not be installed on combustible

fl ooring.

TOP 24 IN.

FRONT 24 IN.

FLUE CONNECTOR 9 IN.

REAR 24 IN.

LEFT SIDE 6 IN.

RIGHT SIDE 24IN.

NOTE: Clearance for access should exceed fire protection

clearance.

Allow 24 inches in the front, top and right hand side for

servicing and cleaning, or removing tankless water heating

coil.

It is recommended that 24 inches be allowed in back of

Figure #2

boiler for convenience when skimming hole is used.

When installed in a utility room, the door should be wide

enough to allow the largest boiler part to enter, or to permit

Minimum clearances to combustible

construction (as seen from above)

24"

6" 24"

BOILER

24"

4

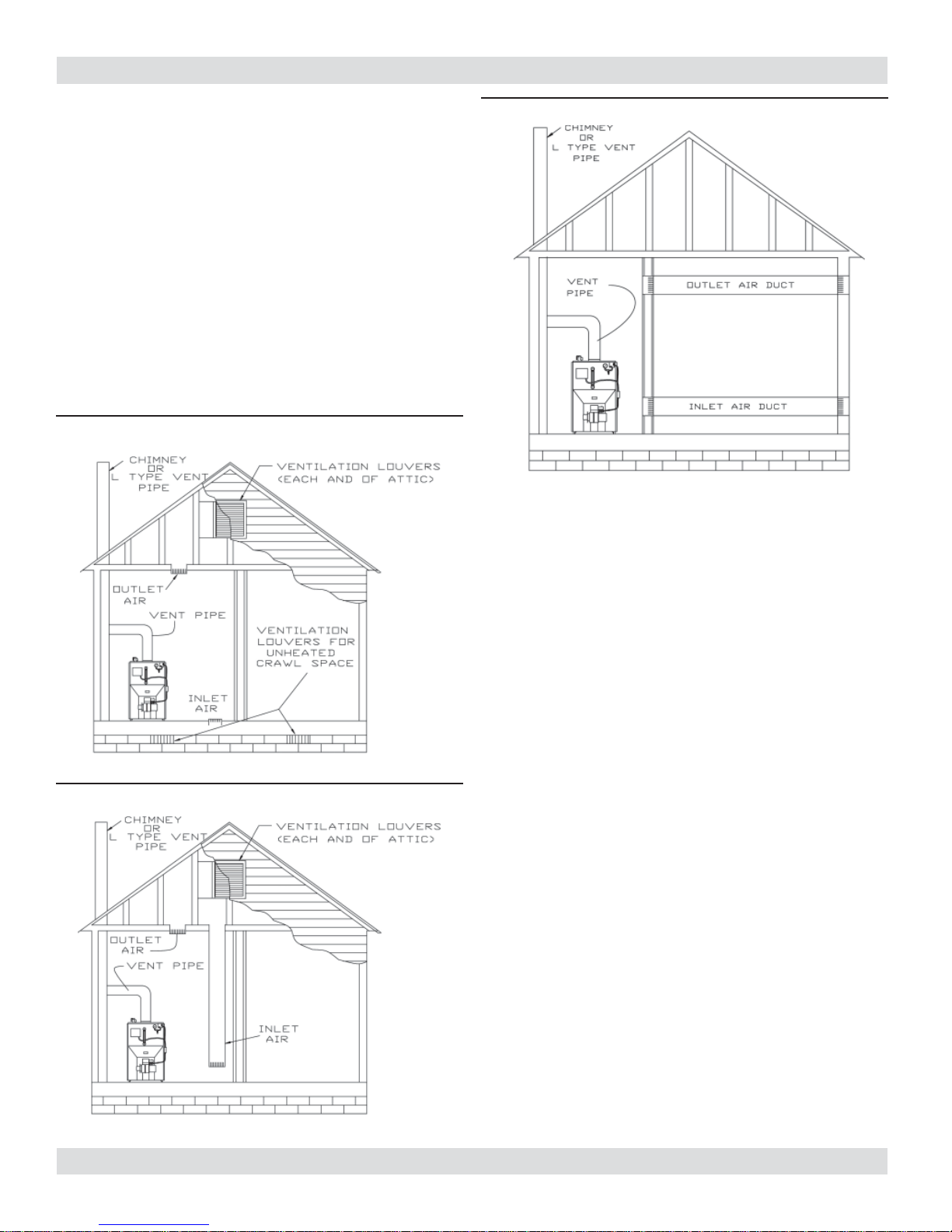

VENTILATION AND COMBUSTION AIR

WARNING

!

Air openings to combustion area must not be obstructed. By following the instructions below,

adequate combustion air can be maintained.

COMBUSTION AIR REQUIREMENTS

(Minimum Opening Requirement)

Unconfi ned Area* Confi ned Area**

Outside Inside Outside Combustion Air

BTU/Hr Input

91,000 19 100 23 46

140,000 28 140 35 70

175,000 35 175 44 88

210,000 42 210 53 106

245,000 49 245 61 122

280,000 56 280 61 140

* A space whose volume is not less than 50 cubic feet per 1000 BTU/Hour of all appliances installed in that space (cubic feet of space = height x width x length)

** A space whose volume is less than 50 cubic feet per 1000 BTU/Hour of all appliances installed in that space (cubic feet of space = height x width x length)

Combustion Air 1 Sq.

In./5000 BTU/Hr

(Step 4)

Combustion Air 1 Sq.

In./1000 BTU/Hr

(Min. 100 Sq. In.) (Figure #1)

Vertical Ducts 1 Sq. In./4000 BTU/

Hr (Figures # 2 & #3)

Horizontal Ducts 1 Sq. In./2000

BTU/Hr (Figure # 4)

1.

Ventilation of boiler room must be adequate enough to

provide suffi cient air to properly support combustion,

venting and maintain safe ambient temperatures under

normal operating conditions.

2.

When the boiler is located in an unconfi ned space in a

building of conventional construction frame, masonry

or metal, infi ltration normally is adequate to provide

air for combustion and ventilation. However, in any

building which has been altered to conserve energy

or to minimize infi ltration, the boiler area should

be considered as a confi ned space. If there is any

doubt, install air supply provisions for combustion

and ventilation in accordance with Chapter 5, Air for

Combustion and Ventilation, of NFPA 31, Standard

for the Installation of Oil Burning Equipment. The

recommendations that follow, or applicable provisions

of the local building codes.

3.

When the boiler is installed in an unconfi ned space,

in a building of unusually tight construction, air for

combustion and room ventilation must be obtained from

outdoors or from spaces freely communicating with the

outdoors. A permanent opening or openings having a

total free area of not less than 1 square inch per 5,000

BTU per hour of total input rating of all appliances shall

be provided. Ducts may be used to convey make-up

air from the outdoors and shall have the same crosssectional area of the openings to which they are

connected.

4.

When air for combustion and room ventilation is from

inside buildings, the confi ned space shall be provided

with two permanent openings, one starting 12 inches

from the top and one 12 inches from the bottom of the

enclosed space. Each opening shall have a minimum

free area of 1 square inch per 1,000 BTU per hour of

the total input rating of all appliances in the enclosed

space, but must not be less than 100 square inches.

These openings must freely communicate with the

interior areas having adequate infi ltration from the

outside. See Figure #3.

Figure #3

CHIMNEY

OR

L TYPE VENT PIPE

BASEBOARD

VENT PIPE

12"

VENTS

12"

5

VENTILATION AND COMBUSTION AIR

5.

When the boiler is installed in a confi ned space and

all air is provided from the outdoors, the confi ned

space shall be provided with two permanent openings,

one commencing within 12 inches from the top and

one commencing 12 inches from the bottom of the

enclosure. The openings shall communicate directly,

or by ducts, with the outdoors or spaces (crawl or attic)

that freely communicate with the outdoors. One of the

following methods must be used to provide adequate

air for ventilation and combustion.

A. When directly communicating with the outdoors, each

opening shall have a minimum free area of 1 square

inch per 4,000 BTU per hour of total input rating of all

equipment in the enclosure. (Figure #4)

Figure #4

Figure #5

Figure #6

B. When communicating with the outdoors by means of

vertical ducts, each opening shall have a minimum

free area 1 square inch per 4,000 BTU per hour of

total input rating of all appliances in the enclosed

space. (Figure #5)

C. If horizontal ducts are used, each opening shall have

a minimum free area 1 square inch per 2,000 BTU per

hour total input rating of all appliances in the enclosed

space. (Figure #6)

D. When ducts are used, they shall be of the same

cross sectional area as the free area of the area of

the openings to which they connect. The minimum

dimension of rectangular air ducts shall not be less

than 3 inches.

6.

In calculating free area using louvers, grills or screens

for the above, consideration shall be given to their

blocking effect. Screens used shall not be smaller than

1/4 inch mesh. If the free area through a design of

louver or grill is known, it should be used in calculating

the size opening required to provide the free area

specifi ed. If the design and free area is not known, it

may be assumed that wood louvers will have 20-25%

free area and metal louvers and grills will have 60-75%

free area. Louvers and grills shall be fi xed in the open

position or interlocked with the boiler so that they are

opened automatically during boiler operation.

6

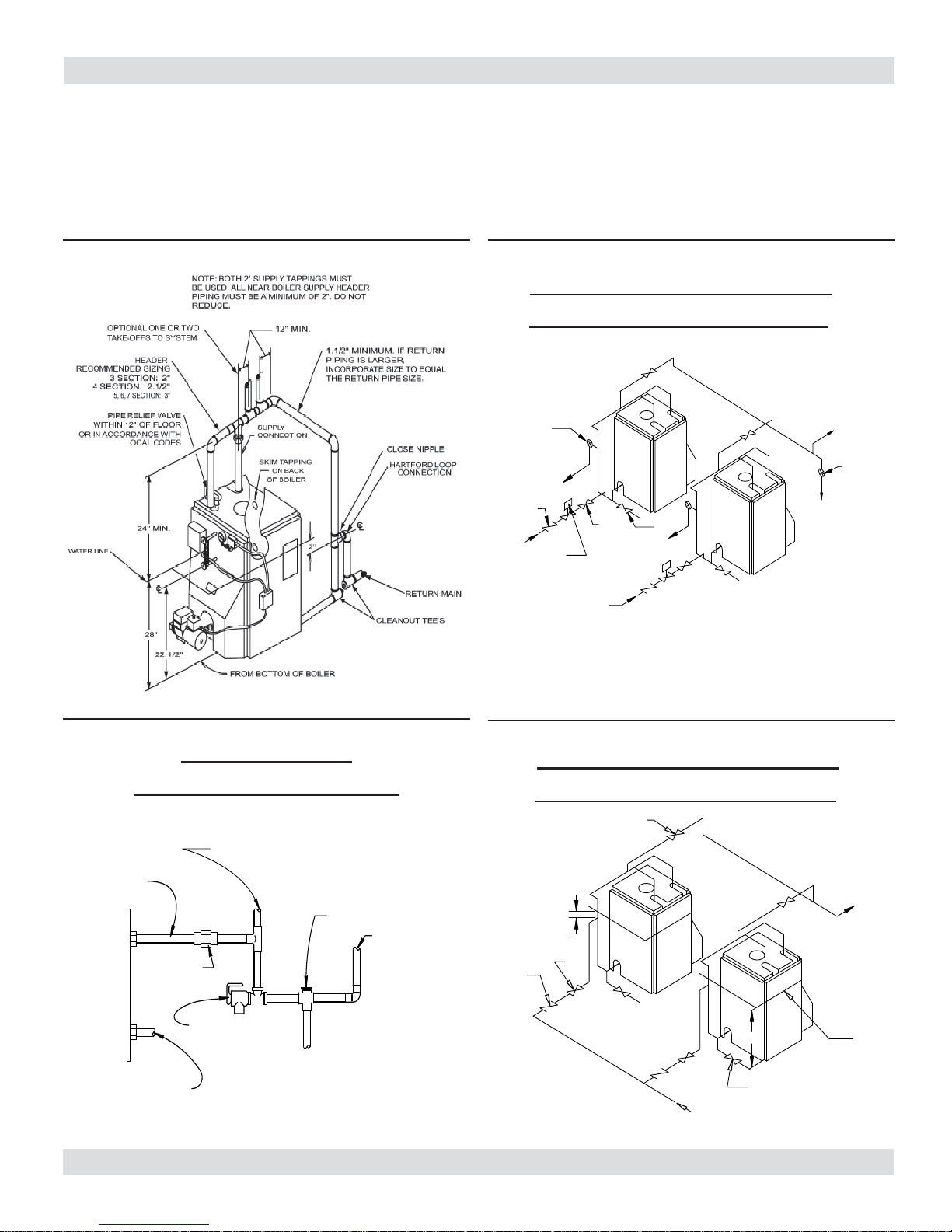

CONNECTING SUPPLY AND RETURN PIPING

CHECK

VALVE

BLOWOFF

VALVE

SOLENOID

VALVE

(OPTIONAL)

F & T TRAP HIGH

LEVEL "SPILL"

(DO NOT USE WITH

CONDENSATE PUMP)

TO

RECEIVER

TANK

STEAM MAIN

TRAP

TO

SYSTEM

FROM

RECEIVER

TANK

FROM

RECEIVER

TANK

STOP

VALVE

TO

RECEIVER

TANK

STOP

VALVE

COLD WATER IN

UNTEMPERED

HOT

FLOW

REGULATOR

TEMPERING VALVE

COLD WATER

DOMESTIC

HOT

WATER

T & P VALVE

UNTEMPERED HOT

WATER TO

AUTOMATIC WASHER

CONTROL

WATER

INSTALLED BELOW CENTER

LINE OF BOILER HOT

CONNECTION

RETURN

2"

TO

SYSTEM

STOP

VALVE

BLOWOFF

VALVE

STOP

VALVE

CHECK

VALVE

(OPTIONAL)

STEAM MAIN

WATER

LINE

28"

1.

Suggested piping for steam heating system can be

seen in Figure #7. Actual piping may vary based on

system design and local conditions.

2.

For further piping information refer to the I=B=R

installation piping guide.

3.

See Figure #8 for typical piping for domestic hot water

heater.

4.

See Figures #9 and #10 for the suggested piping for a

modular steam boiler.

Figure #7

Figure #9

SUGGESTED PIPING FOR MODULAR

STEAM BOILERS - PUMPED RETURN

Figure #8

PIPING FOR BUILT-IN

DOMESTIC HOT WATER HEATER

Figure #10

SUGGESTED PIPING FOR MODULAR

STEAM BOILERS - GRAVITY RETURN

7

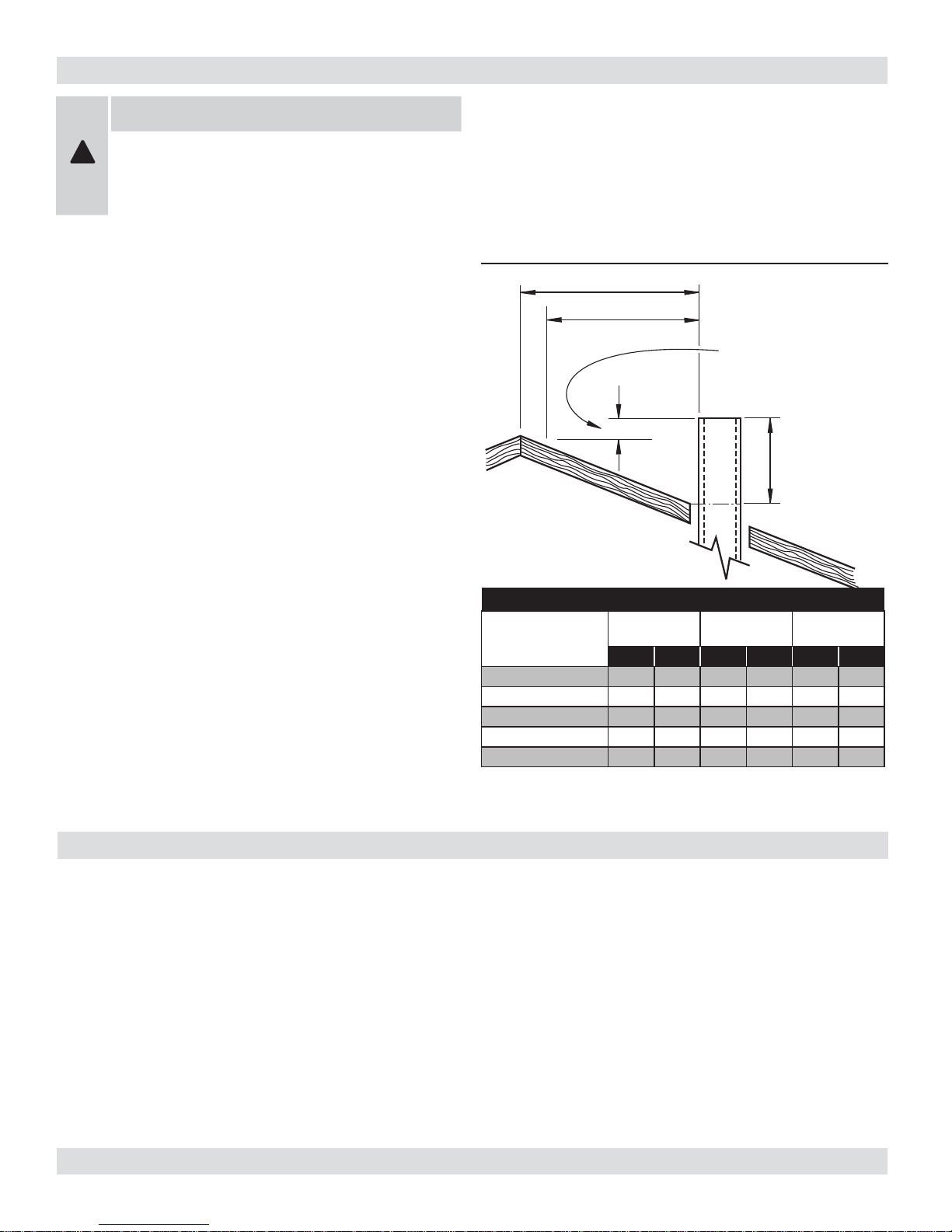

VENTING SYSTEM INSPECTION & INSTALLATION

RIDGE

2’ (.61 M) MIN.

MORE THAN 10’ (3.1 M)

10’ (3.1 M)

HEIGHT ABOVE ANY

ROOF SURFACE WITHIN

10’ (3.1 M)

HORIZONTALLY

CHIMNEY 3’ (.92 M)

GAS VENT OR

TYPE L VENT

2’ (.61 M) MIN.

WARNING

Boiler is to be vented by natural draft and

!

shall not be connected into any portion of

mechanical draft operating system under

positive pressure.

Inspect chimney to make certain it is constructed according

If oil fi red water heater is vented into same fl ue as boiler,

provide separate hole into chimney whenever possible.

When this isn’t possible, use “Y” connection in fl ue pipe,

using separate draft regulator for each unit. When chimney

will not provide adequate draft to handle input from water

heater and boiler simultaneously, wire units so only one will

operate at a time, favoring water heater.

to the latest revision of the NFPA 211. Local regulations

may differ from this code and should be checked. Where

Figure #11

there is a confl ict, the local code will prevail.

The boiler must be installed into a chimney which has a

masonry or metallic chimney liner.

An unlined chimney will have leaks that will cause poor

chimney performance (no draft), and could result in a

positive pressure in the combustion chamber.

Horizontal portions of the venting system should not exceed

10 feet in length. Horizontal lengths over 10 ft. will have a

negative effect on the chimney performance.

The chimney should extend at least 2 ft. above any portion

of the building within 10 ft. (Figure #11) It should produce

a -.02 inch W.C. draft in the combustion chamber. See

"Chimney or Vent Sizes" chart for recommended minimum

and maximum chimney or vent sizes.

Inadequate draft will cause improper combustion, resulting

in dirty fl ue ways and high fuel bills.

Connect fl ue pipe same size as boiler outlet to chimney,

sloping upward continuously toward the chimney

91,000 - 140,000 6 8 8x8 8x8 15 40

175,000 - 210,000 7 8 8x8 8x10 15 40

245,000 - 280,000 8 10 8x8 8x12 15 50

approximately ¼" per foot. Bolt or screw joints together to

avoid sag.

CHIMNEY OR VENT SIZES

ROUND

BTU/HR INPUT

315,000 8 10 8x8 8x12 15 50

385,000 8 10 8x8 8x12 15 50

INCHES

MIN MAX MIN MAX MIN MAX

SQUARE

INCHES

HEIGHT (FT)

Oil tank and piping should be installed in accordance with

National Board of Fire Underwriters and local regulations.

Oil storage tank, vent, fi ll pipe and caps should be as

prescribed by local codes. In no case should vent pipe be

smaller than 1¼" I.P.S. Fill pipe should not be less than 2"

I.P.S.

OIL TANK AND PIPING

Ssuction line from tank to burner should be one continuous

piece of tubing to prevent air entering line. Suction line,

must be ⅜" O.D. copper tubing for runs of 50 feet or less,

and ½" O.D. for longer runs. Oil return line, same size as

suction line, must be used on any installation where bottom

of tank is below fuel unit of burner. Oil lines should be

buried or otherwise protected from mechanical injury. Flare

fi ttings on all oil lines are recommended. Compression

fi ttings on suction line often allow air to be drawn into fuel

pump, making it diffi cult to maintain oil pressure at nozzle.

Do not run overhead fuel lines from tank to oil burner.

8

Loading...

Loading...