Columbia CDVB SERIES Installation, Operation & Maintanance Manual

CDVB SERIES

Gas Fired Boilers For Forced Hot Water

INSTALLATION, OPERATION &

MAINTANANCE MANUAL

Co l u m b i a bo i l e r Co m p a n y

Main ofces and Factory: Pottstown, PA

P/N 37616101, Rev. C [02/09]

GAS FIRED BOILERS FOR FORCED HOT WATER

H

KEEP THIS MANUAL NEAR BOILER AND

RETAIN FOR FUTURE REFERENCE.

TABLE OF CONTENTS

Introduction ..........................................................................................................................................4

Boiler Ratings, Capacities & Dimensions ............................................................................................5

Ventilation & Combustion Air ...............................................................................................................7

Connecting Supply & Return Piping ..................................................................................................10

Applicable Federal Codes ................................................................................................................. 13

Vent System Modication ..................................................................................................................13

Connecting Gas Service ....................................................................................................................14

Electrical Wiring .................................................................................................................................15

Lighting Instructions...........................................................................................................................17

Sequence of Operations ....................................................................................................................18

General Instruction For Seasonal Startup & Maintenance ................................................................ 19

Replacement Parts ............................................................................................................................22

IMPORTANT: Read the following instructions

COMPLETELY before installing!

SAFETY SYMBOLS

The following dened symbols are used throughout this manual to notify the reader of potential hazards of varying

risk levels.

DANGER

!

Indicates an imminently hazardous situation

which, if not avoided, will result in death, serious

injury or substantial property damage.

CAUTION

!

Indicates a potentially hazardous situation which,

if not avoided, could result in minor or moderate

injury or property damage.

Indicates a potentially hazardous situation which,

if not avoided, could result in death, serious

injury or substantial property damage.

Indicates special instructions on installation,

operation or maintenance which are important

but not related to personal injury hazards.

WARNING

!

NOTICE

C.S.A. Certied for

Natural gas or Propane

Tested for 100 lbs.

ASME Working Pressure

2

INTRODUCTION

WARNING

!

1. Keep boiler area clear and free from combustible

materials, gasoline and other ammable vapors

and liquids.

2. DO NOT obstruct air openings to the boiler

room.

3. Modication, substitution or elimination of factory

equipped, supplied or specied components may

result in property damage, personal injury or the

loss of life.

4. TO THE OWNER: Installation and service of

this boiler must be performed by a qualified

installer.

5. TO THE INSTALLER: Leave all instructions with

the boiler for future reference.

6. When this product is installed in the Commonwealth of Massachusetts the installation

must be performed by a Licensed Plumber

or Licensed Gas Fitter.

5.

Allow 24 inches at the front and right side for servicing

and cleaning.

6.

When installed in utility room, the door should be wide

enough to allow the largest boiler part to enter, or to

permit replacement of another appliance such as a water

heater.

7.

The boiler shall be installed such that the gas ignition

system components are protected from water, (dripping,

spraying, rain, etc.), during appliance operation and

service, (circulator replacement, condensate trap, control

replacement, etc.).

8.

FOR INSTALLATION ON NON-COMBUSTIBLE FLOORS

ONLY. *The boiler must not be installed on carpeting.

Minimum clearances to combustible constructions are:

TOP ...................................................... 18 IN.

FRONT .....................................................6 IN.

FLUE CONNECTOR ...............................6 IN.

REAR ........................................................4 IN.

CONTROL SIDE .......................................9 IN.

WARNING

!

Improper installation, adjustment, alteration,

service or maintenance can cause injury or

property damage.

The installation must conform to the requirements of

1.

the authority having jurisdiction or, in absence of such

requirements, to the latest revision of the National Fuel

Gas Code, ANSI Z223-1. (Available from the American

Gas Association, Pleasant Valley Road, Cleveland, Ohio

44134.) Reference should also be made to local gas utility

regulations and other codes in effect in the area in which

the installation is to be made.

2.

Where required by the authority having jurisdiction, the

installation must conform to American Society of Mechanical Engineers Safety Code for Controls and Safety

Devices for Automatically Fired Boilers, ANSI/ASME No.

CSD-1.

3.

This boiler is classied as a Category I and III and vent

installation shall be in accordance with the latest revision

of the National Fuel Gas Code, ANSI Z223.1 or applicable

provisions of the local building codes.

OTHER SIDE ...........................................3 IN.

VENT PIPE ..............................................6 IN.

NOTES:

• Greater clearances for access should supersede re protection clearances.

* For installation on combustible ooring Special Base MUST

BE USED. (See Replacement Parts Section)

4.

LOCATE BOILER on level, solid base as near the outside

wall as possible and centrally located with respect to the

heat distribution system as practicable.

3

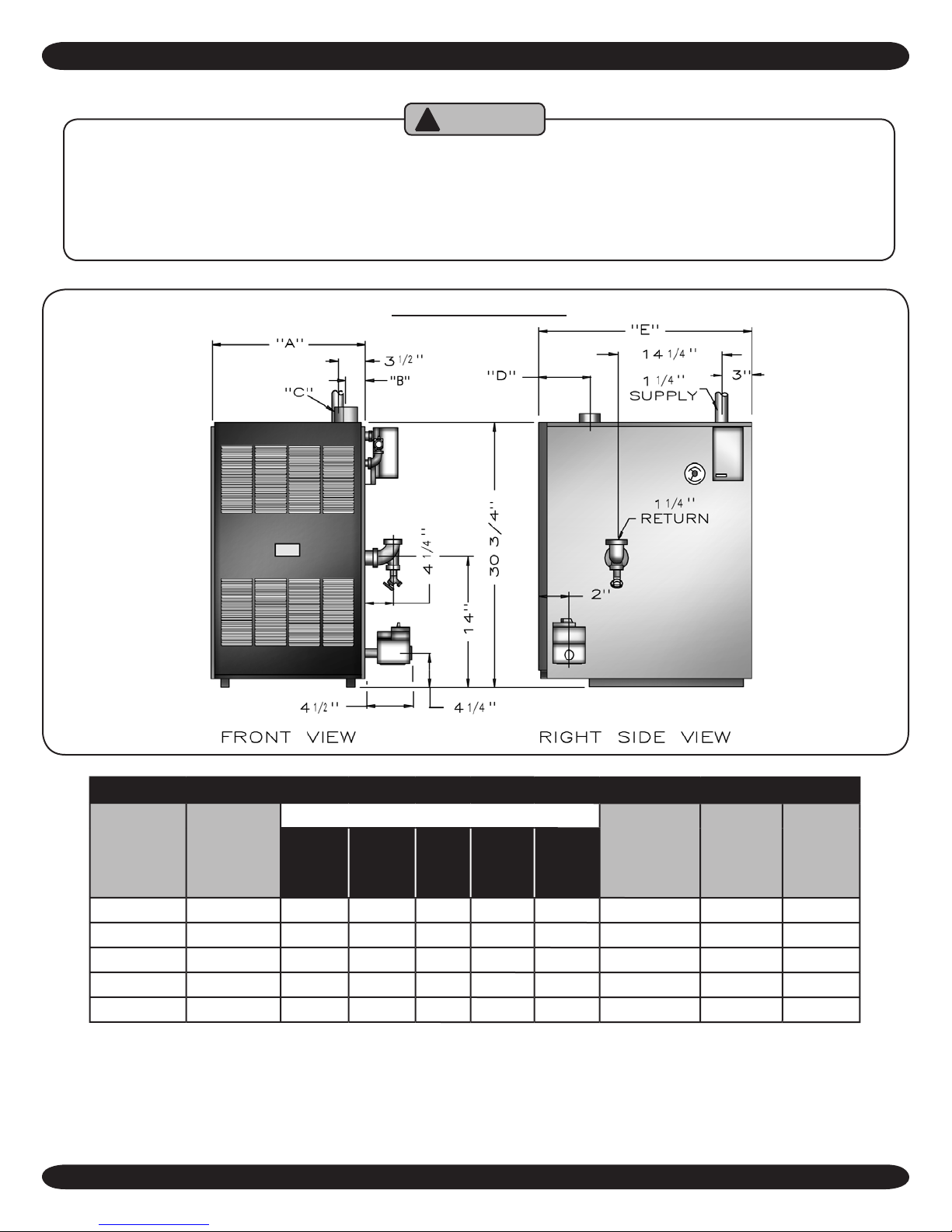

BOILER RATINGS, CAPACITIES & DIMENSIONS

WARNING

!

ALL INSTALLATIONS OF BOILERS AND VENTING SHOULD BE DONE ONLY BY A QUALIFIED

EXPERT AND IN ACCORDANCE WITH THE APPROPRIATE UTICA BOILERS MANUAL. INSTALLING OR VENTING A BOILER OR ANY OTHER GAS APPLIANCE WITH IMPROPER METHODS OR

MATERIALS MAY RESULT IN SERIOUS INJURY OR DEATH DUE TO FIRE OR TO ASPHYXIATION

FROM POISONOUS GASES SUCH AS CARBON MONOXIDE WHICH IS ODORLESS AND INVISIBLE.

BOILER DIMENSIONS

Model #

-50 ½" 11¼ 2⅛ 3 6⅜ 27 1¼" 1 83%

-100 ½" 15⅛ 4⅛ 3 6⅜ 27 1¼" 2 82%

-125 ½" 19 6 3 6⅜ 27 1¼" 3 82%

-150 ½" 19 6 4 6⅜ 27 1¼" 3 80%

-200 ½" 22⅞ 8 4 7 28 1¼" 4 80%

NOTE: For altitudes above 2,000 ft. ratings should be reduced at the rate of 4% for each 1,000 ft. above sea level.

Natural

Gas Inlet

A B C D E

DIMENSIONS FOR NATURAL GAS

Dimensions

4

Pump size

Supply

& Return

Tappings

Number

of

Burners

AFUE

Ratings

BOILER RATINGS, CAPACITIES & DIMENSIONS

A.G.A.

Model #

-50 50,000 42,000 37,000 1 2.4 83%

-100 100,000 82,000 71,000 2 4.0 82%

-125 125,000 103,000 90,000 3 5.6 82%

-150 150,000 122,000 106,000 3 5.6 80%

-200 199,999 160,000 139,000 4 7.2 80%

Input

Btu/Hr.

Heating

Capacity

Btu/Hr.

I=B=R

NetOutput

Btu/Hr

No.

of

Burners

Water

Content

(Gals.)

AFUE

Ratings

STANDARD EQUIPMENT: Boiler Jacket, Cast Iron Boiler Battery, Combination Aquastat Relay, Theraltimeter

Gauge, Circulator, Main Gas Burners, Electric Ignition System, A.S.M.E relief Valve, Drain Valve, Induced Draft

Fan, and Safety Pressure Switch

All boilers are design certied for installation on non-combustible oors. For installation on combustible oors, use

combustible oor kit.

This boiler is a Category III Designed Certied appliance which requires a special horizontal through the wall venting

system. Only HEAT-FAB SAF-T-VENT™, FLEX-L STAR-34™, ProTech™ FasNSeal, and Z-FLEX Z-VENT™ vent

material products shall be used.

Should a chimney installation be required, see venting addendum.

See venting addendum for maximum vent lengths and proper congurations.

MEA number for the boilers is 415-90-E.

Electric service to be 120 Volts, 15 Amps, 60 Hz.

**For equivalent square feet of radiation, divide I=B=R output by 150.

5

VENTILATION & COMBUSTION AIR

WARNING

! !

AIR OPENINGS TO COMBUSTION AREA MUST NOT BE OBSTRUCTED.

BY FOLL O WING T HE I N STRUCTION S BEL O W, A DEQUATE

COMBUSTION AIR CAN BE MAINTAINED.

COMBUSTION AIR REQUIREMENTS

(Minimum Square Inch Openings)

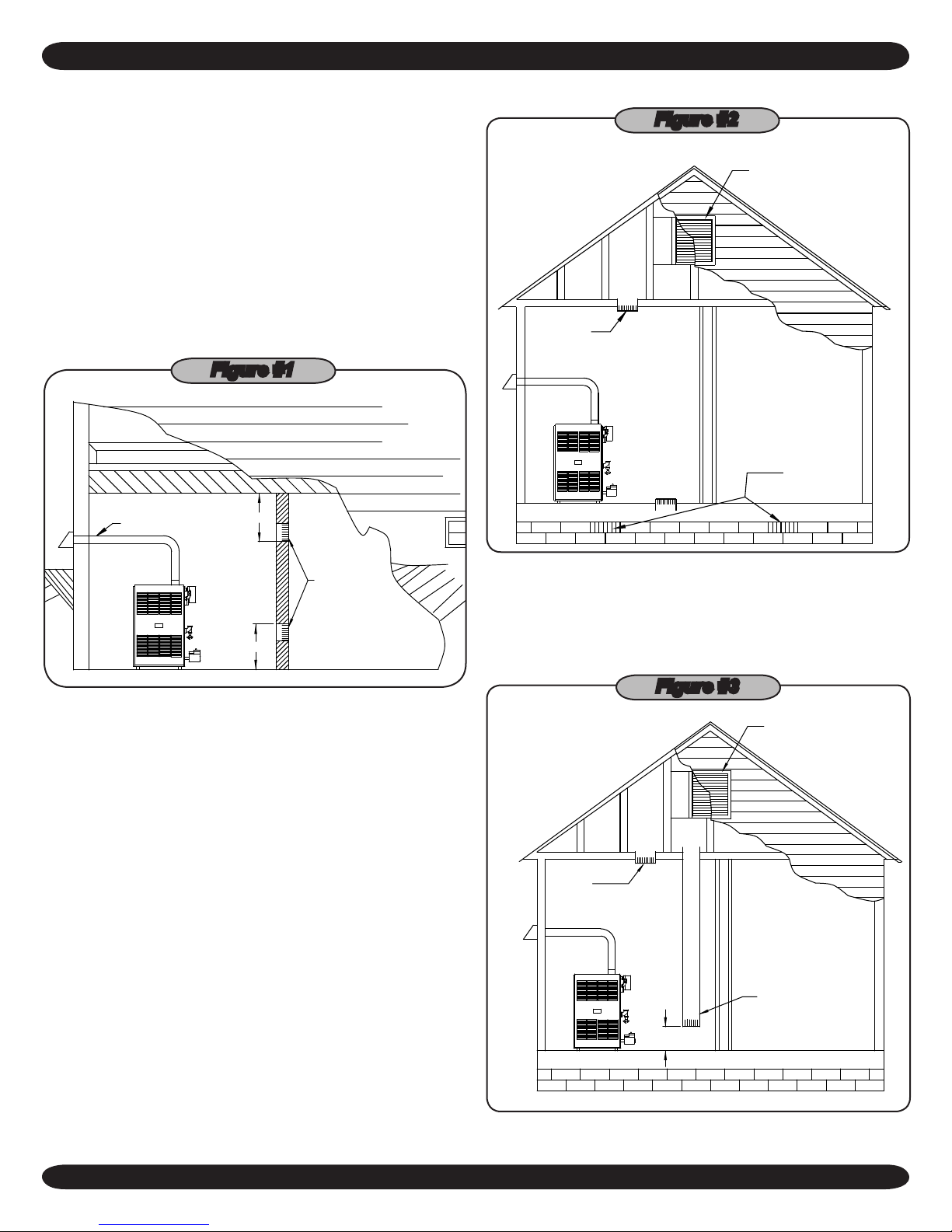

*UNCONFINED AREA **CONFINED AREA

INSIDE

OUTSIDE

MODEL #

-50 10 100 13 25

-100 20 100 25 50

-125 25 125 32 63

-150 30 150 38 75

-200 40 200 50 100

COMBUSTION AIR

1 SQ. IN/5000 BTU/

HR (SEE Figure #2)

COMBUSTION AIR

1 SQ. IN. /1000

BTU/HR

(SEE Figure #1)

* Unconned Area: A space whose

volume is not less than 50 cubic feet

per 1000 BTU per hour of all appliances

installed in that space (cubic feet of space

= height x width x length).

** Conned Area: A space whose volume

is less than 50 cubic feet per 1000 BTU

per hour of all appliances installed in that

space (cubic feet of space = height x width

x length).

Ventilation of the boiler room must be adequate to

1.

provide sufcient air to properly support combustion

per the latest revision of the National Fuel Gas Code,

ANSI Z223.1.

2.

When a boiler is located in an unconned space in a

building or conventional construction frame, masonry

or metal building, inltration normally is adequate to

provide air for combustion and ventilation. However, if

the equipment is located in a building of tight construction

(See the National Fuel Gas Code, ANSI Z223.1 latest

OUTSIDE COMBUSTION AIR

VERTICAL

DUCTS 1 SQ. IN.

/4000 BTU/HR

(SEE Figures #2

& 3)

revision), the boiler area should be considered as a con-

ned space. In this case air for combustion and ventilation

shall be provided according to paragraph #5. If there is

any doubt, install air supply provisions in accordance with

the latest revision of the National Fuel Gas Code.

When a boiler is installed in an unconned space, in a

3.

building of unusually tight construction, air for combustion and ventilation must be obtained from outdoors or

from spaces freely communicating with the outdoors.

A permanent opening or openings having a total free

area of not less than 1 square inch per 5,000 BTU per

hour of total input rating of all appliances shall be pro-

vided. Ducts may be used to convey makeup air from

the outdoors and shall have the same cross-sectional

area of the openings to which they are connected.

4.

When air for combustion and ventilation is from inside

HORIZONTAL

DUCTS 1 SQ. IN.

/2000 BTU/HR

(SEE Figure #4)

6

VENTILATION & COMBUSTION AIR

VENT PIPE

BASEBOARD

VENTS

BOILER

12"

12"

OUTLET

AIR

VENTILATION LOUVERS

(EACH END OF ATTIC)

INLET

AIR

VENTILATION

LOUVRES FOR

UNHEATED

CRAWL SPACE

BOILER

OUTLET

AIR

VENTILATION LOUVERS

(EACH END OF ATTIC)

-- SLAB --

INLET AIR DUCT

12"

buildings, the conned space shall be provided with

two permanent openings, one starting 12 inches from the

top and one 12 inches from the bottom of the enclosed

space. Each opening shall have a minimum free area

of 1 square inch per one thousand (1000) BTU per hour

of the total input rating of all appliances in the enclosed

space, but must not be less than one hundred (100)

square inches. These openings must freely communicate

directly with other spaces of sufcient volume so that the

combined volume of all spaces meets the criteria for an

unconned space. See

Figure #1.

Figure #1

Figure #2

When the boiler is installed in a conned space and all air

5.

is provided from the outdoors the conned space shall be

provided with one or two permanent openings according

to methods A or B. When ducts are used, they shall be

of the same cross sectional area as the free area of the

area of the openings to which they connect. The minimum dimension of rectangular air ducts shall be not less

than 3 x 3 inches or 9 square inches.

When installing two openings, one must commence A.

within 12 inches from the top and the other within 12

inches from the bottom of the enclosure. The open-

ings shall communicate directly, or by ducts, with the

outdoors or spaces (crawl or attic) that freely commu-

nicate with the outdoors. One of the following methods

must be used to provide adequate air for ventilation

and combustion.

When communicating with the outdoors by means of II.

vertical ducts, each opening shall have a minimum

free area 1 square inch per 4,000 BTU per hour of

total input rating of all appliances in the enclosed

space. See

gure #3

.

Figure #3

(DUCT ENDS 1 FT.

ABOVE THE FLOOR)

When directly communicating with the outdoors, each I.

opening shall have a minimum free area of 1 square

inch per 4,000 BTU per hour of total input rating of all

equipment in the enclosure. See

Figure #2

.

7

BOILER

-- SLAB --

INLET AIR DUCT

12"

INLET AIR DUCT

12"

VENTILATION & COMBUSTION AIR

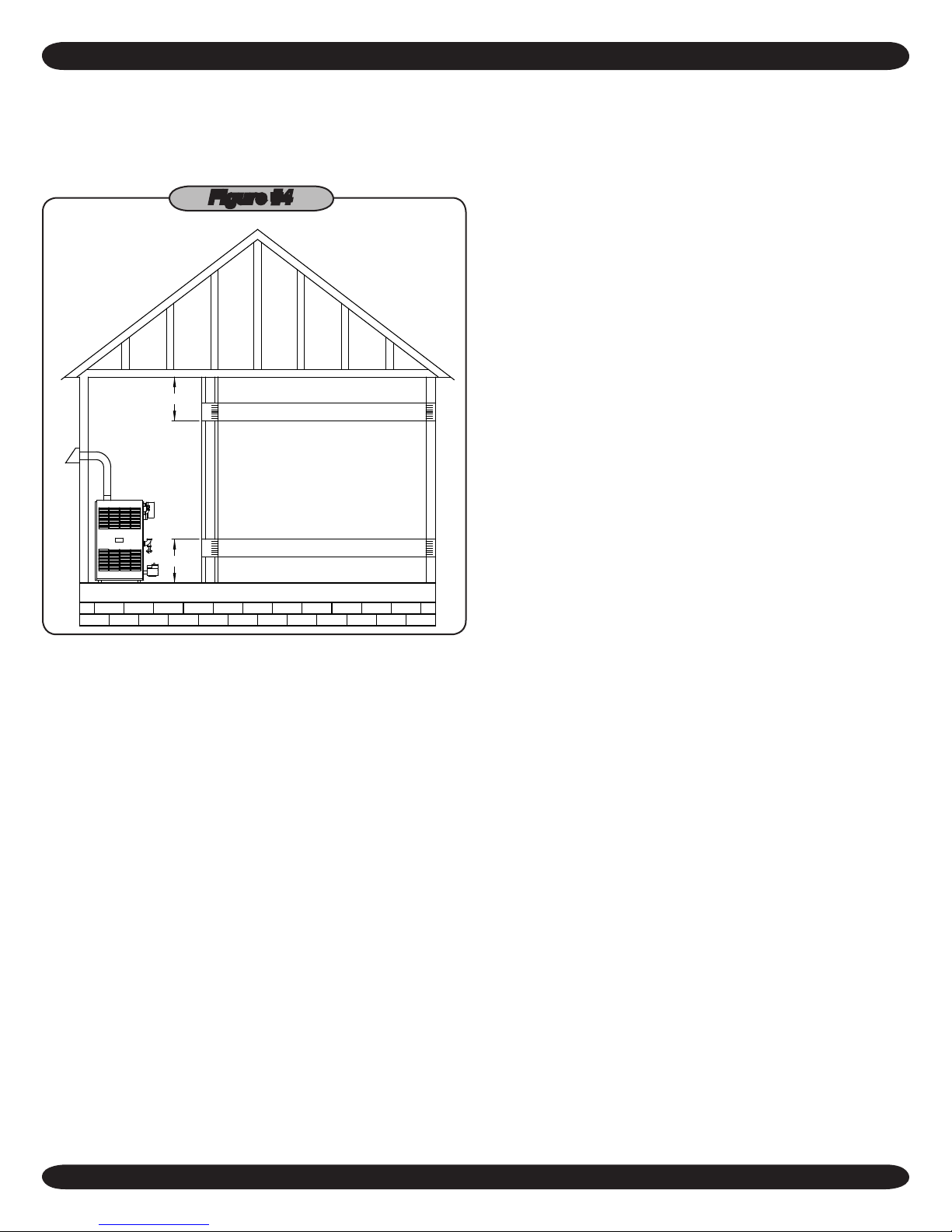

If horizontal ducts are used, each opening and duct III.

shall have a minimum free area 1 square inch per

2,000 BTU per hour of total input rating of all appli-

ances in the enclosed space. See

gure #4

.

Figure #4

In calculating free area using louvers, grilles or screens

6.

for the above, consideration shall be given to their block-

ing effect. Screens used shall not be smaller than 1/4 inch

mesh. If the free area through a design of louver or grill is

known, it should be used in calculating the size opening

required to provide the free area specied. If the design

and free area is not known, it may be assumed that wood

louvers will have 20-25% free area and metal louvers and

grilles will have 60-75% free area. Louvers and grilles

should be xed in the open position or interlocked with the

boiler so they are opened automatically during the boiler

operation.

One permanent opening, commencing within 12 inches B.

of the top of the enclosure, shall be permitted where the

equipment has clearances of at least 1 inch from the

sides, 1 inch from the back, and 6 inches from the front

of the boiler. The opening shall directly communicate

with the outdoors or shall communicate through a vertical or horizontal duct to the outdoors or spaces (crawl

or attic) that freely communicate with the outdoors. The

openings must have a minimum free area of 1 square

inch per 3000 Btu per hour of the total input rating of all

equipment located in the enclosure. The free area must

be no less than the sum of the areas of all vent connectors in the conned space.

8

CONNECTING SUPPLY & RETURN PIPING

CIRCULATOR

VAL VE

EXPANSION

TANK

VAL VE

RETURN

SUPPLY

12"

MAX.

CIRCULATOR

FLOW

VAL VE

SYSTEM

TEMPERATURE

GAUGE

"B"

"A"

SYSTEM

PRIMARY

6"

FEED

WATER

ZONE

CIR.

VAL V E

FLOW

VALVE

EXPANSION

TANK

VAL V E

SYSTEM

TEMPERATURE

GAUGE

RETURN

SUPPLY

"A"

"B"

6"

FEED

WATER

6"

EXPANSION

TANK

TEMPERATURE

SYSTEM

GAUGE

SUPPLY

RETURN

4 WAY MIXING

VALVE

ZONE

CIR.

WATER

FEED

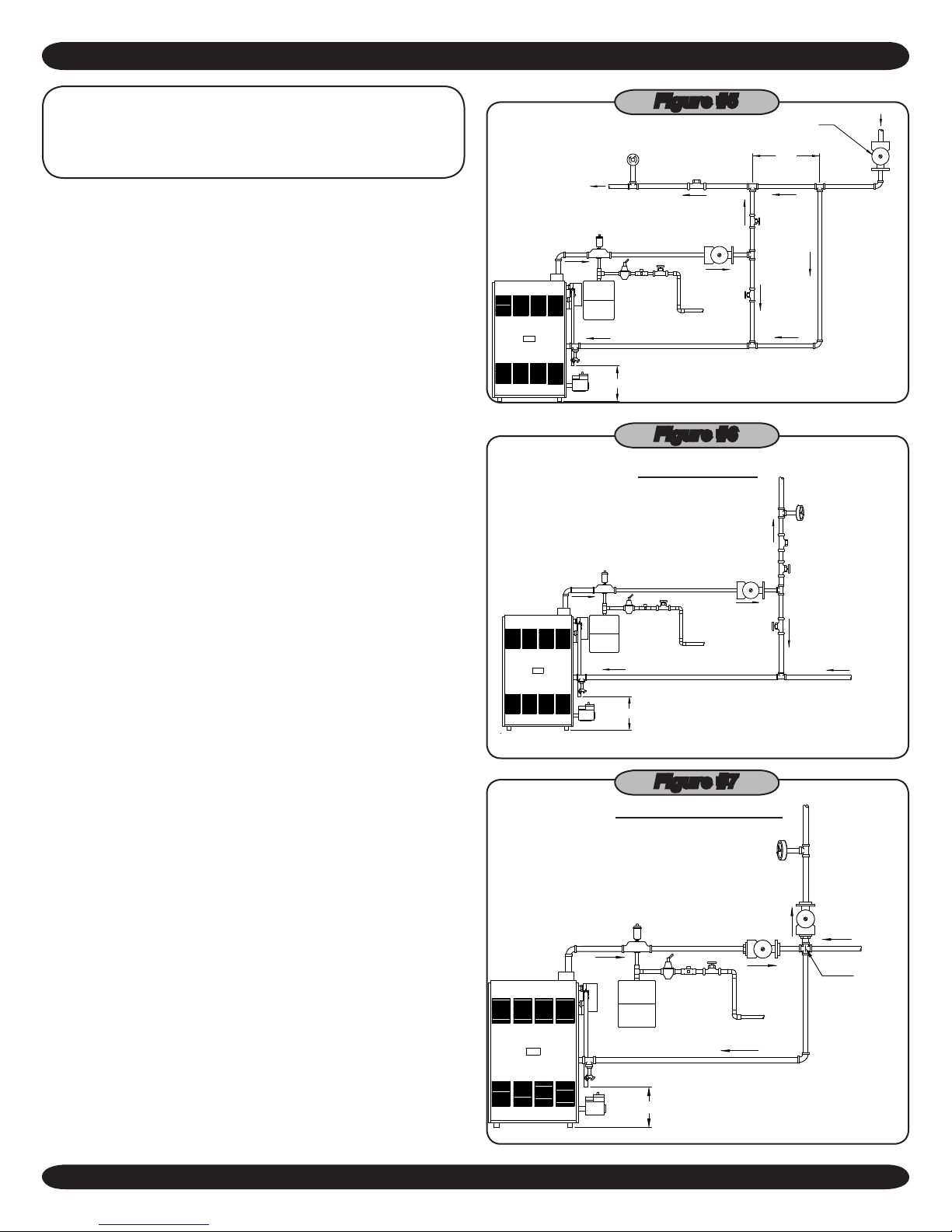

IMPORTANT: Circulators in the following

illustrations are mounted on the system supply

side, but mounting on the system return side is

also acceptable practice.

Connect supply and return piping as suggested in

1. gure

#5

, when the boiler is used in connection with refriger-

ated systems.

The chilled medium MUST BE PIPED IN PARALLEL A.

with the boiler.

Use appropriate valves to prevent the chilled medium B.

from entering the heating boiler.

During heating cycle open valves A and B, close I.

valves C and D.

During cooling cycle, open valves C and D, close II.

valves A and B.

C. Maintain a minimum clearance of one inch to hot C.

water pipes.

2.

When the boiler is connected to heating coils located in

air handling units where they may be exposed to refrigerated air circulation, the boiler piping system MUST

BE supplied with ow control valves or other automatic

means to prevent gravity circulation of the boiler water

during the cooling cycle.

Figure #5

Figure #6

BYPASS PIPING

3.

Hot water boilers installed above radiation level must be

provided with a low water cut-off device.

4.

When a boiler is connected to a heating system that

utilizes multiple zoned circulators, each circulator must

be supplied with a ow control valve to prevent gravity

circulation.

5.

Hot water boilers and system must be lled with water

and maintained to a minimum pressure of 12 pounds per

square inch.

6.

Bypass piping is an option which gives the ability to adjust

the supply boiler water temperature to t the system or

the condition of the installation. This method of piping,

however, is not typically required for baseboard heating systems. Typical installations where bypass piping is

used are as follows:

This method is used to protect boilers from conden-A.

sation forming due to low temperature return water.

Generally noticed in large converted gravity systems or

other large water volume systems. See

This method is used to protect systems using radiant B.

gure #6

.

panels and the material they are encased in from high

temperature supply water from the boiler. And protect

the boiler from condensate. See

gure #7

and

#8

.

Figure #7

MIXING VALVE PIPING

9

Loading...

Loading...