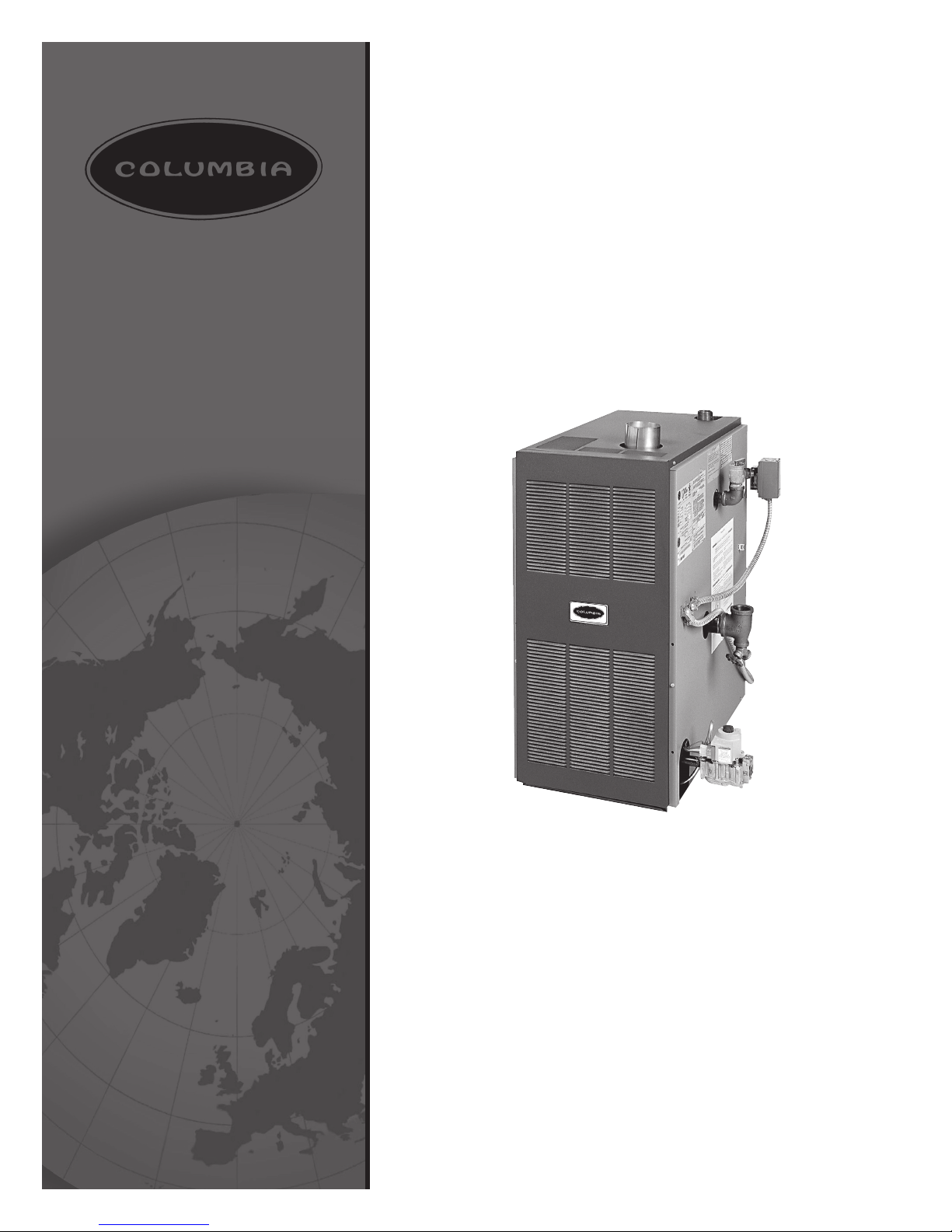

Columbia CDVB-50, CDVB-150, CDVB-125, CDVB-100, CDVB-200 Installation, Operation & Maintenance Manual

CDVB SERIES

Gas Fired Boilers

For Forced Hot Water

INSTALL ATION, OPER ATION &

MAINTENANCE MANUAL

Columbia Company

Main ofces and Factory: Pottstown, PA

P/N 37616101, Rev. F [05/2012]

H

GAS FIRED BOILERS FOR FORCED HOT WATER

Introduction ................................................................................................................................ 3

Boiler Ratings, Capacities & Dimensions .......................................................................................... 4

Ventilation & Combustion Air ......................................................................................................... 6

Connecting Supply & Return Piping ................................................................................................ 7

Applicable Federal Codes .............................................................................................................11

Vent System Modication .............................................................................................................11

Horizontal Vent Pipe Installation Instructions ..................................................................................12

Vertical Vent Pipe Installation Instructions ......................................................................................22

Connecting Gas Service ...............................................................................................................28

Electrical Wiring .........................................................................................................................29

Lighting Instructions ...................................................................................................................31

Sequence Of Operation................................................................................................................32

General Instruction For Seasonal Startup & Maintenance ..................................................................33

Replacement Parts ......................................................................................................................37

KEEP THIS MANUAL NEAR BOILER AND

RETAIN FOR FUTURE REFERENCE.

IMPORTANT: Read the following instructions

COMPLETELY before installing!

SAFETY SYMBOLS

The following dened symbols are used throughout this manual to notify the reader of potential hazards of

varying risk levels.

DANGER

Indicates a hazardous situation which, if

!

not avoided, WILL result in death or serious

injury.

WARNING

Indicates a hazardous situation which, if

!

not avoided, could result in death or serious

injury.

Indicates a hazardous situation which, if not

!

avoided, may result in minor or moderate

injury.

Indicates information which should be

followed to ensure proper installation and

operation.

CAUTION

NOTICE

C.S.A. Certied for

Natural gas or Propane

Tested for 100 psi. ASME

Working Pressure

2

WARNING

1. Keep boiler area clear and free from

combustible materials, gasoline and other

ammable vapors and liquids.

2. DO NOT obstruct air openings to boiler

room.

3. Modication, substitution or elimination

of factory equipped, supplied or specied

components may result in property damage,

personal injury or loss of life.

!

4. To owner: Installation and service of this

boiler must be performed by qualied installer.

5. To installer: Leave all instructions with

boiler for future reference.

6. Boiler installation must conform to

Commonwealth of Massachusetts code 248

CMR when installed in Commonwealth of

Massachusettes. This includes, but is not

limited to, installation by licensed plumber or

gas tter.

INTRODUCTION

7.

Install boiler such that gas ignition system components

are protected from water, (dripping, spraying,

rain, etc.), during appliance operation and service,

(circulator replacement, condensate trap, control

replacement, etc.).

8.

Requirements for Commonwealth of

Mas sachusetts: Boiler installation must conform to

Commonwealth of Massachusetts code 248 CMR which

includes but is not limited to installation by licensed

plumber or gas tter.

9.

FOR INSTALLATION ON NON-COMBUSTIBLE

FLOORS ONLY. *Boiler must NOT be installed on

carpeting.

10.

Minimum clearances to combustible constructions are:

TOP ...........................................18 in.

FRONT ........................................6 in

FLUE CONNECTOR .........................6 in

REAR............................................4 in.

CONTROL SIDE..............................9 in.

OTHER SIDE .................................3 in.

VENT PIPE ....................................6 in.

(457mm)

(152mm)

(152mm)

(102mm)

(229mm)

(76mm)

(152mm)

NOTICE

WARNING

Improper installation, adjustment, alteration,

!

service or maintenance can cause injury or

property damage.

1.

Installation must conform to requirements of authority

having jurisdiction or, in absence of such requirements,

to the National Fuel Gas Code, ANSI Z223.1/NFPA 54

and/or Natural Gas and Propane Installation Code,

CAN/BS149.1

2.

Where required by the authority having jurisdiction,

installation must conform to Standard for Controls and

Safety Devices for Automatically Fired Boilers, ANSI/

ASME No. CSD-1.

3.

This boiler is classied as Category I and III and vent

installation shall be in accordance with latest revision of

the National Fuel Gas Code, ANSI Z223.1 or applicable

provisions of the local building codes.

4.

LOCATE BOILER on level, solid base as near outside

wall as possible and centrally located with respect to

heat distribution system as practicable.

5.

Allow 24 inches at front and right side for servicing and

cleaning.

6.

When installed in utility room, door should be wide

enough to allow largest boiler part to enter, or to

permit replacement of another appliance such as a

water heater.

• Greater clearances for access should

supersede re protection clearances.

* For installation on combustible ooring

Special Base MUST BE USED. (See

Replacement Parts Section)

3

All installations of boilers and venting should be done only by a qualied expert and in accordance with

!

the appropriate utica boilers manual. Installing or venting a boiler or any other gas appliance with

improper methods or materials may result in serious injury or death due to re or to asphyxiation from

poisonous gases such as carbon monoxide which is odorless and invisible.

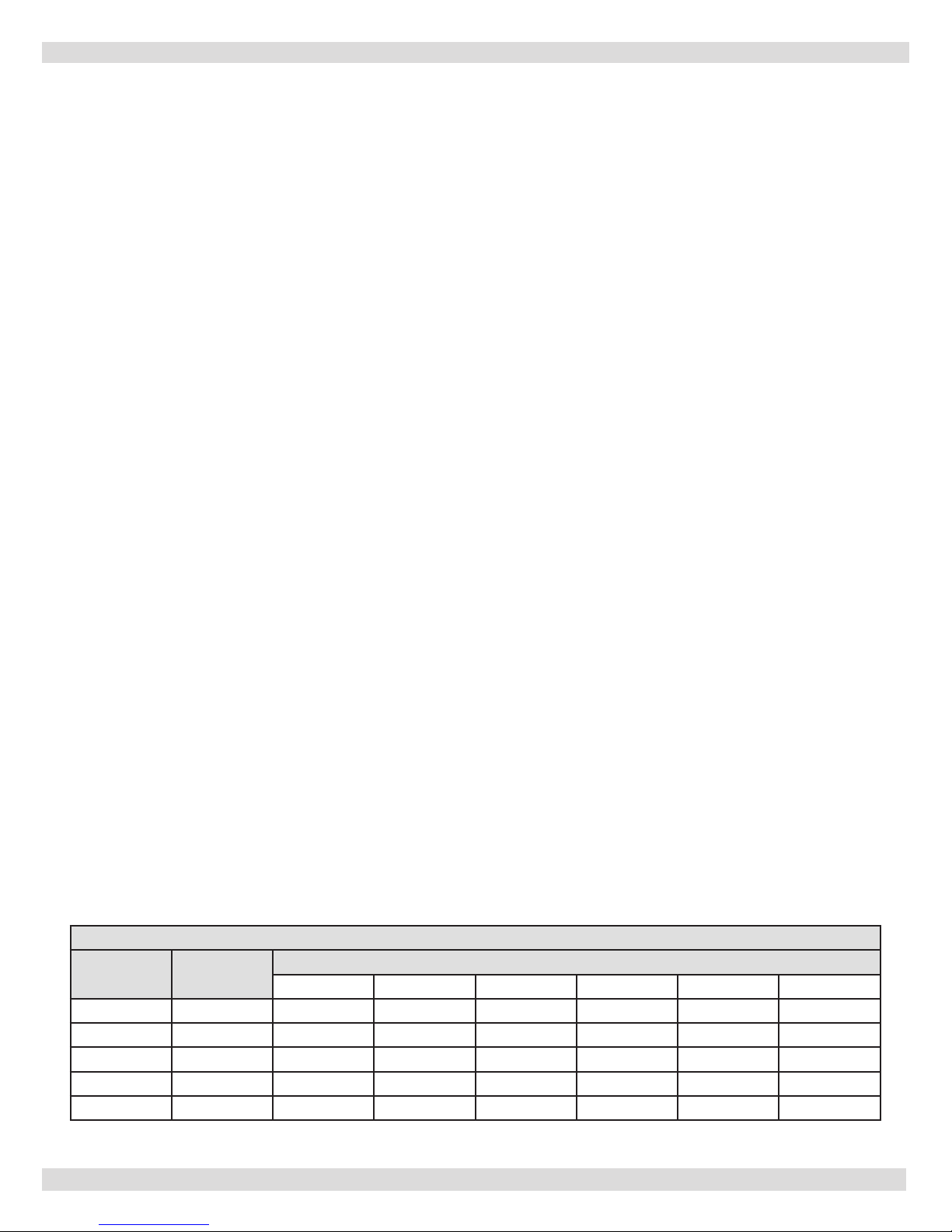

Figure 1 -Boiler Dimensions

BOILER RATINGS, CAPACITIES & DIMENSIONS

WARNING

Table 1- DIMENSIONS FOR NATURAL GAS

Model #

-50

-100

-125

-150

-200

NOTE:

each 1,000 ft. above sea level.

For altitudes above 2,000 ft. ratings should be reduced at the rate of 4% for

Natural

Gas Inlet

½"

½"

½"

½"

½"

Dimensions

A B C D

11¼

15⅛

19

19

22⅞

2⅛

4⅛

6

6

8

3

3

3

4

4

4

6⅜

6⅜

6⅜

6⅜

7

E

27

27

27

27

28

Pump

size

Supply &

Return

Tappings

1¼"

1¼"

1¼"

1¼"

1¼"

BOILER RATINGS, CAPACITIES & DIMENSION

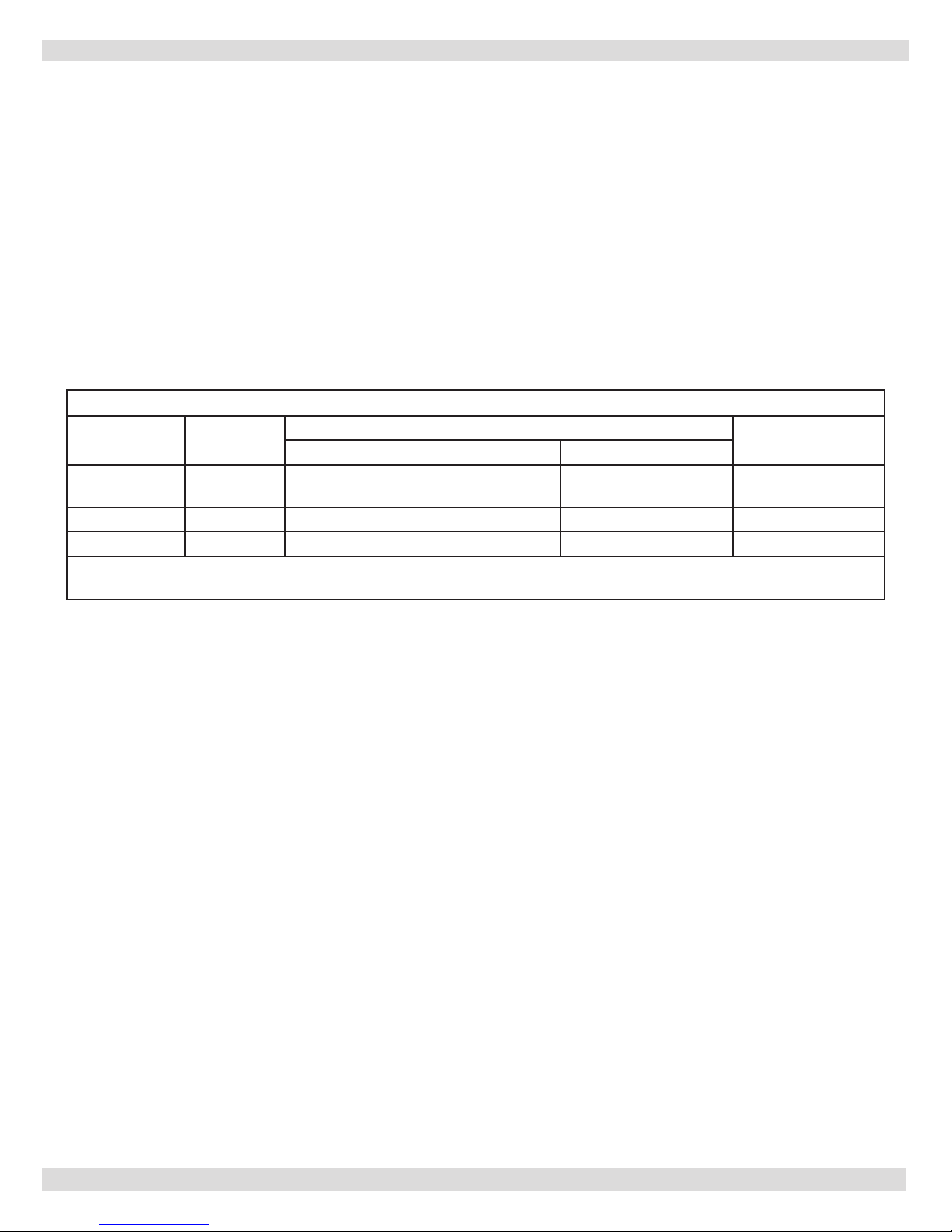

Table 2 - RATINGS AND CAPACITIES

Model #

-50

-100

-125

-150

-200

(1)

Mbh = 1000 Btu per hour

(2)

Net Water Ratings shown based on piping and pickup allowance of 1.15.

Input

Btu/hr

50,000

100,000

125,000

150,000

199,999

Heating

Capacity

(1)

Mbh

42

82

103

122

160

Net

Rating

Water,

Mbh

37

71

90

1060

139

AFUE

(1)

(2)

83.0%

82.0%

82.0%

80.0%

80.0%

No.

of

Burners

1

2

3

3

4

Water

Content

(Gals.)

2.4

4.0

5.6

5.6

7.2

Contact manufacturer before selecting boiler for installations having unusual

piping and pickup requirements, such as intermittent system operation,

extensive piping systems, etc.

STANDARD EQUIPMENT: Boiler Jacket, Cast Iron Boiler Battery, Combination Aquastat Relay, Theraltimeter Gauge,

Circulator, Main Gas Burners, Electric Ignition System, A.S.M.E relief Valve, Drain Valve, Induced Draft Fan, and Safety

Pressure Switch

All boilers are design certied for installation on non-combustible oors. For installation on combustible oors, use

combustible oor kit.

Boiler is Category III Designed Certied appliance which requires a special horizontal through the wall venting system.

Only HEAT-FAB SAF-T-VENT™, FLEX-L STAR-34™, ProTech™ FasNSeal, and Z-FLEX Z-VENT™ vent material products

shall be used.

Electric service to be 120 Volts, 15 Amps, 60 Hz.

5

VENTILATION & COMBUSTION AIR

Provide combustion air and ventilation air in accordance

with the section “Air for Combustion and Ventilation,” of the

National Fuel Gas Code, ANSI Z223.1/NFPA 54, or Sections

8.2, 8.3 or 8.4 of Natural Gas and Propane Installation

Code, CAN/CSA B149.1, or applicable provisions of local

building codes.

Provide make-up air where exhaust fans, clothes dryers,

and kitchen ventilation equipment interfere with proper

operation.

National Fuel Gas Code recognizes several methods

of obtaining adequate ventilation and combustion air.

Requirements of the authority having jurisdiction may

override these methods.

• Engineered Installations. Must be approved by

authority having jurisdictions.

• Mechanical Air Supply. Provide minimum of 0.35

cfm per Mbh for all appliances located within space.

Additional requirements where exhaust fans installed.

Interlock each appliance to mechanical air supply

system to prevent main burner operation when

mechanical air supply system not operating.

• All Indoor Air. Calculate minimum volume for all

appliances in space. Use a different method if

minimum volume not available.

о Standard Method. Cannot be used if known air

inltration rate is less than 0.40 air changes per

hour. See Table 3 for space with boiler only. Use

equation for multiple appliances.

Volume ≥ 50 ft3 x Total Input [Mbh]

о Known Air Inltration Rate. See Table 3 for

space with boiler only. Use equation for multiple

appliances. Do not use an air inltration rate

(ACH) greater than 0.60.

Volume ≥ 15 ft3/ACH x Total Input [Mbh]

о Refer to National Fuel Gas Code for opening

requirements between connection indoor spaces.

National Gas and Propane Installation Code Requires

providing air supply in accordance with:

• All Outdoor Air. Provide permanent opening(s)

communicating directly or by ducts with outdoors.

о Two Permanent Opening Method. Provide opening

commencing within 12 inches of top and second

opening commencing within 12 inches of bottom

enclosure.

Direct communication with outdoors or

communicating through vertical ducts. Provide

minimum free area of 1 in2 per 4 Mbh of total

input rating of all appliances in enclosure.

Communicating through horizontal ducts.

Provide minimum free area of 1 in2 per 2

Mbh of total input rating of all appliances in

enclosure.

о One Permanent Opening Method. Provide opening

commencing within 12 inches of top of enclosure.

Provide minimum clearance of 1 inch on sides

and back and 6 inches on front of boiler (does not

supersede clearance to combustible materials).

о Combination Indoor and Outdoor Air. Refer to

National Fuel Gas Code for additional requirements

for louvers, grilles, screens and air ducts.

• Combination Indoor and Outdoor Air. Refer to

National Fuel Gas Code for application information.

• Section 8.2 and 8.3 when combination of appliances

has a total input of up to and including 400 Mbh (120

kW).

о Does not have draft control device.

• Section 8.4 when combination of appliances has total

input exceeding 400 Mbh (120 kW).

• Refer to Natural Gas and Propane Installation Code

for specic air supply requirements for enclosure

or structure where boiler is installed, including air

supply openings and ducts.

Table 3

Input Mbh

50 2500 7500 3750 2500 1875 1500 1250

100 5000 15000 7500 5000 3750 3000 2500

125 6250 18750 9375 6250 4688 3750 3125

150 7500 22500 11250 7500 5625 4500 3750

200 10000 30000 15000 10000 7500 6000 5000

Standard

Method

0.1 0.2 0.3 0.4 0.5 0.6

Known Air Inltration Rate Method (Air Changes Per Hour)

6

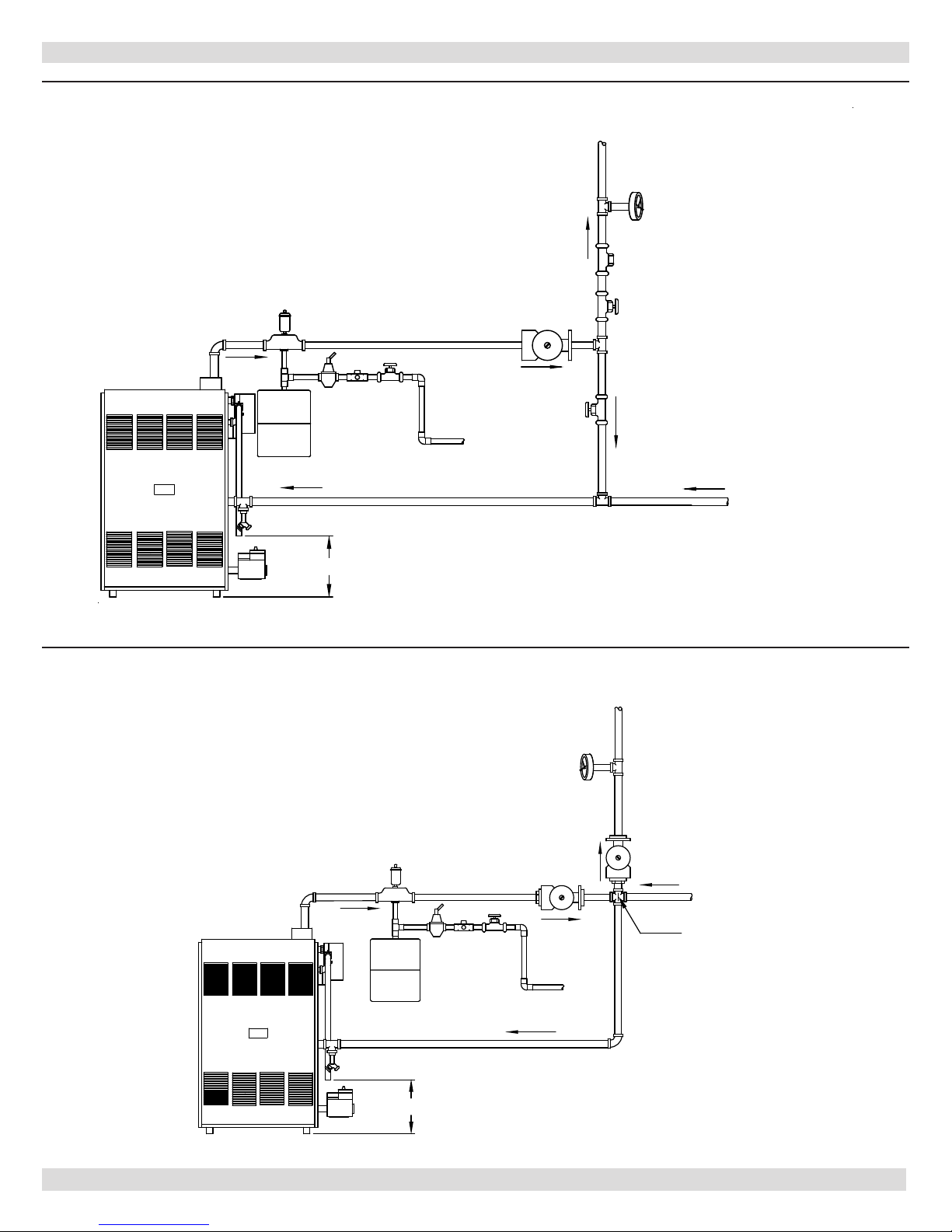

CONNECTING SUPPLY & RETURN PIPING

IMPORTANT: Circulators in following illustrations

are mounted on system supply side, but mounting on

system return side is also acceptable practice.

1.

Maintain minimum clearance of one inch (25mm) to hot

water pipes.

2.

Boiler, when used in connection with refrigeration

system, must be installed so chilled medium is piped in

parallel with boiler with appropriate valves to prevent

chilled medium from entering boiler.

3.

Boiler piping system of hot water boiler connected to

heating coils located in air handling units where they

may be exposed to refrigerated air circulation must be

equipped with ow control valves or other automatic

means to prevent gravity circulation of boiler water

during cooling cycle.

4.

Hot water boiler installed above radiation level or as

required by the Authority having jurisdiction, must be

provided with low water cutoff device either as part of

boiler or at time of boiler installation.

5.

When boiler is connected to heating system that utilizes

multiple zoned circulators, each circulator must be

supplied with ow control valve to prevent gravity

circulation.

6.

Hot water boilers and system must be lled with water

and maintained to minimum pressure of 12 psi.

7.

Bypass piping is option which gives ability to adjust

supply boiler water temperature to t system or

condition of installation. This method of piping,

however, is not typically required for baseboard heating

systems. Typical installations where bypass piping is

used are as follows:

A. This method is used to protect boilers from

condensation forming due to low temperature

return water. Generally noticed in large converted

gravity systems or other large water volume

systems. See

B. This method is used to protect systems using

radiant panels and the material they are encased

in from high temperature supply water from boiler,

and protect boiler from condensate. See

and 4.

C. This method is used to protect boilers from

condensate forming as well as protecting heating

system from high water temperatures, see

4

.

gure 2

.

gure 3

gure

7

Figure 2 - BYPASS PIPING

CONNECTING SUPPLY & RETURN PIPING

SUPPLY

SYSTEM

TEMPERATURE

GAUGE

FLOW

VALVE

EXPANSION

TANK

Figure 3 - MIXING VALVE PIPING

FEED

WATER

ZONE

CIR.

"B"

VALV E

"A"

VALV E

RETURN

6"

SUPPLY

EXPANSION

TANK

SYSTEM

TEMPERATURE

GAUGE

ZONE

CIR.

RETURN

4 WAY MIXING

VALV E

FEED

WATER

6"

8

CIRCULATOR

VALV E

EXPANSION

TANK

VALV E

RETURN

SUPPLY

12"

MAX.

CIRCULATOR

FLOW

VALV E

SYSTEM

TEMPERATURE

GAUGE

"B"

"A"

SYSTEM

PRIMARY

6"

FEED

WATER

CONNECTING SUPPLY & RETURN PIPING

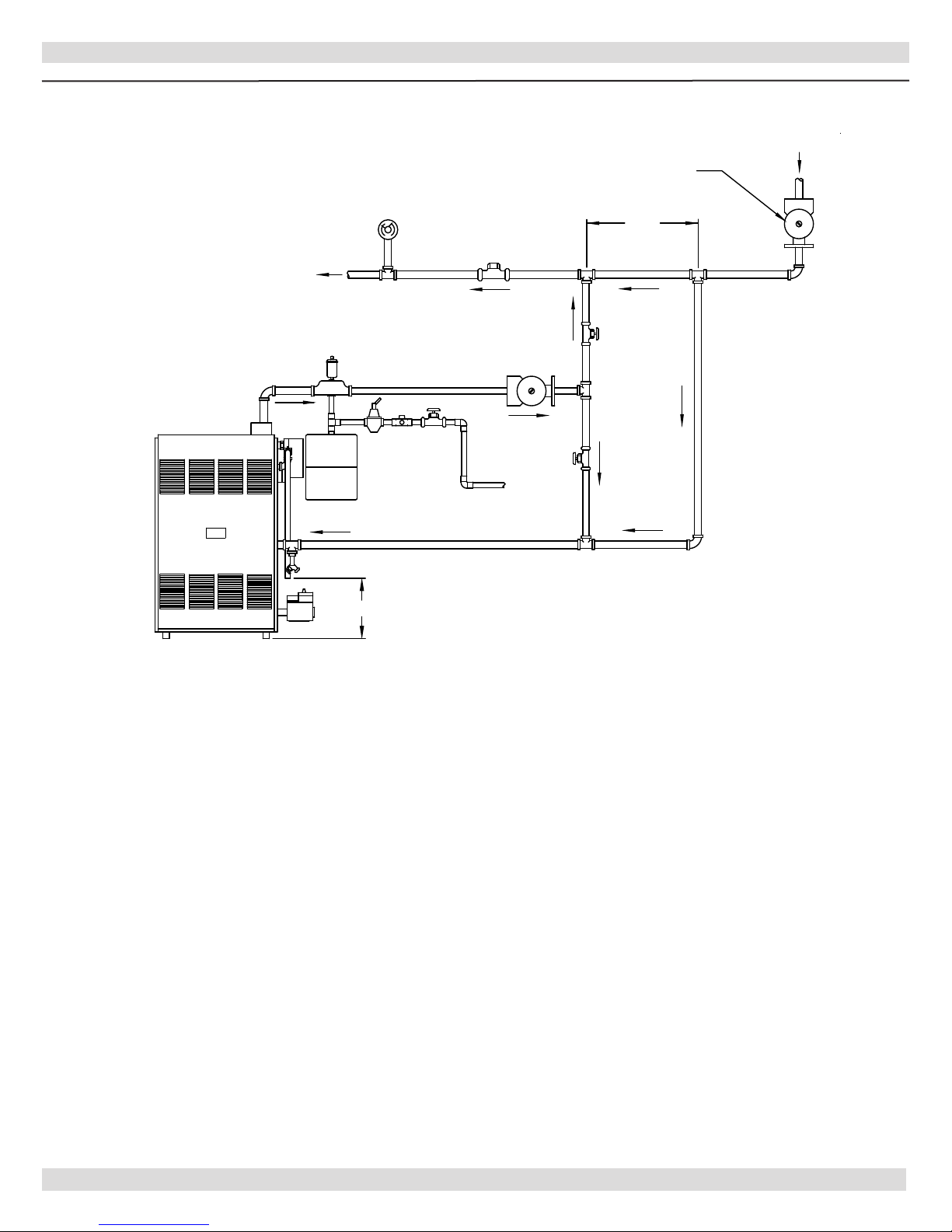

Figure 4 - PRIMARY SECONDARY PIPING WITH BYPASS

NOTE #1: When using bypass piping, adjust

valves A and B until desired system temperature is

obtained.

NOTE #2: Bypass loop must be same size piping as

the supply and return piping.

8.

Installation using circulators is shown in

9.

Installation using zone valves is shown in

10.

For further piping information refer to the I=B=R

Installation and Piping Guide.

gure 5

gure 6

.

.

9

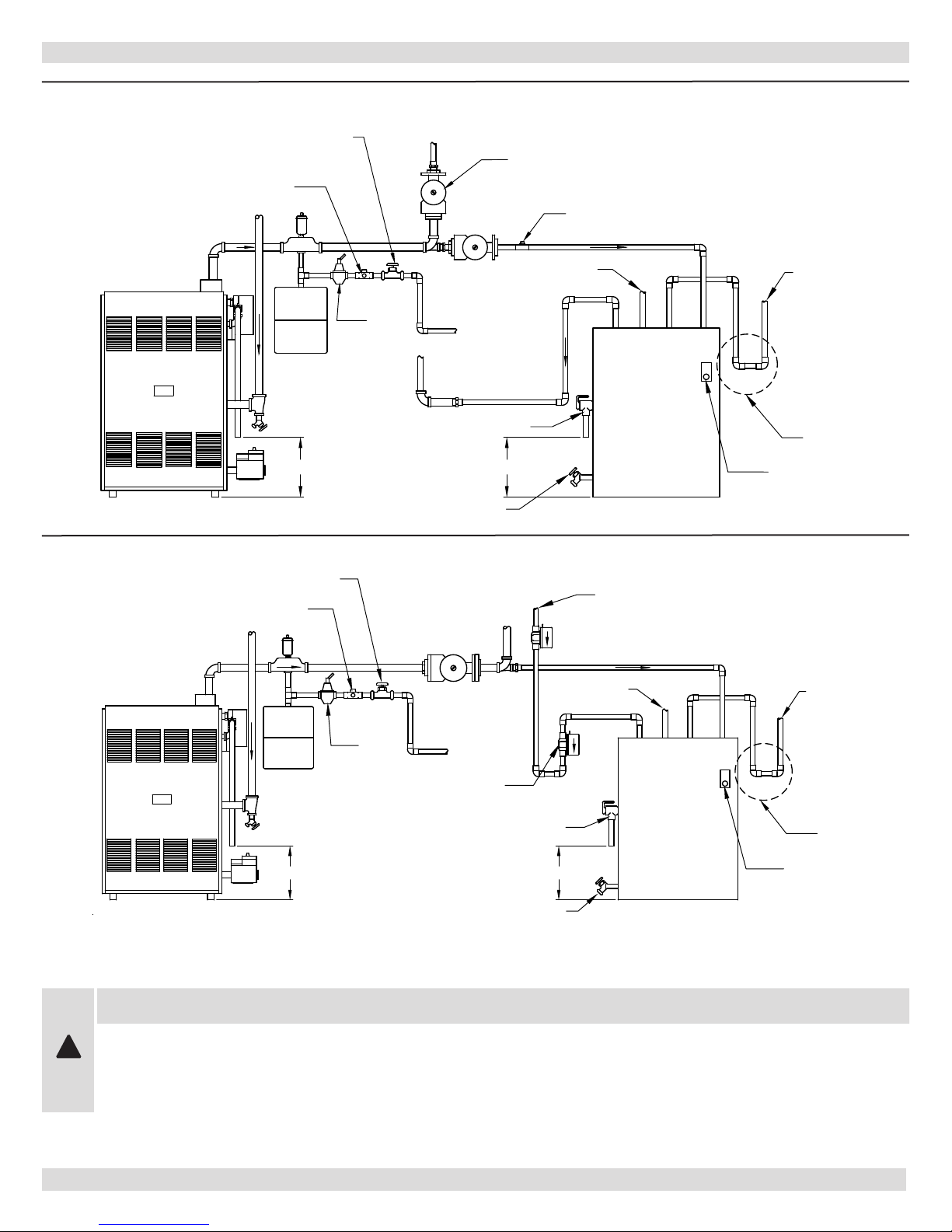

CONNECTING SUPPLY & RETURN PIPING

WARNING

To avoid burns, scalding, or water damage due to discharge of steam and/or hot water during operation, a

discharge line shall be installed to relief valve outlet connection.

Discharge line shall:

• connect to relief valve outlet and piped down to safe point of disposal. Check local codes for

maximum distance from oor or allowable safe point of discharge.

• be of pipe size equal to or greater than that of the relief valve outlet over the entire length of

discharge line;

• have no intervening shutoff valve between safety relief valve and discharge to atmosphere (do not

plug or place any obstruction in discharge line.

• terminate freely to atmosphere where any discharge will be clearly visible and at no risk of freezing;

• allow complete drainage of the valve and the discharge line;

• be independently supported and securely anchored to avoid applied stress on the relief valve;

• be as short and straight as possible;

• terminate with plain end (not threaded);

• be constructed of material suitable for exposure to temperatures of 375° F; or greater.

Refer to local codes and appropriate ASME Boiler and Pressure Vessel Code for additional installation

requirements.

WARNING

Burn and scald hazard. Safety relief valve

!

could discharge steam or hot water during

operation. Install discharge piping per these

instructions.

11.

Install discharge piping from safety relief valve.

• Use ¾" or larger pipe.

• Use pipe suitable for temperatures of 375°F (191°C)

or greater.

• Individual boiler discharge piping shall be independent

of other discharge piping.

• Size and arrange discharge piping to avoid reducing

safety relief valve relieving capacity below minimum

relief valve capacity stated on rating plate.

• Run pipe as short and straight as possible to location

protecting user from scalding and properly drain

piping.

• Install union, if used, close to safety relief valve outlet.

• Install elbow(s), if used, close to safety relief valve

outlet and downstream of union (if used).

• Terminate pipe with plain end (not threaded).

10

CIRCULATOR

DRAIN COCK

RELIEF VALVE

HOT WATER

OUTLET

THERMAL

TRAP

PUMP CONTROL

WIRING FOR

THERMOSTAT/

SYSTEM RETURN

PIPING

INLET

COLD WATER

VALV E

TANK ZONE

6"

6"

PRESSURE

REDUCING

VALV E

BACKFLOW PREVENTER

REDUCED PRESSURE

GATE VALVE

Figure 5 - Piping with Circulator

REDUCED PRESSURE

BACKFLOW PREVENTER

CONNECTING SUPPLY & RETURN PIPING

GATE

VALV E

SYSTEM

CIRCULATOR

FLOW CONTROL

OR CHECK VALVE

6"

Figure 6 - Piping with Zone Valves

PRESSURE

REDUCING

VALV E

TANK

CIRCULATOR

FEED

WATER

RELIEF VALVE

DRAIN COCK

COLD WATER

INLET

6"

HOT WATER

OUTLET

THERMAL

TRAP

WIRING FOR

THERMOSTAT/

PUMP CONTROL

All installations of boilers and venting should be done only by a qualied expert and in accordance

!

with the appropriate installation manual. Installing or venting a boiler or any other gas appliance with

improper methods or materials may result in serious injury or death due to re or to asphyxiation from

poisonous gases such as carbon monoxide which is odorless and invisible.

WARNING

11

APPLICABLE FEDERAL CODES

NFPA 54/ANSI Z223.1, National Fuel Gas Code and NFPA/

ANSI 211, Chimneys, Fireplaces, Vents and Solid Fuel

Burning Appliances. These codes contain information on

special gas vents for Category II, III and IV appliances,

vent sizing, location, air space clearances to combustibles

and safe installation practices. The gas vent installer

should be familiar with these Federal Codes as well as

Local Codes and Regulations.

General Information Gas Vents And Appliances:

By Federal Codes, gas appliances are categorized by

the pressure and temperature of the ue gas vented

from the appliance. Category I and II appliances are

natural draft (draft hood) vented, with high ue gas

temperatures (Category I), and low ue gas temperatures

(Category II). Category III and IV appliances are fan

forced vents with high temperature (Category III) and

low temperature (Category IV) ue gasses. Appliance

efciency is directly related to ue gas temperature.

Higher efciency appliances remove more heat from the

gas, so they will have lower temperature ue products.

VENT SYSTEM MODIFICATION

When ue gas temperatures are lowered, corrosive

condensates may form in the gas vent or in the appliance.

Condensates may form in Category II, III, IV appliance

vents, so special, corrosive resistant venting systems are

required for higher efciency appliances.

WARNING

Vents for Category I appliances may not be

!

suitable for use with Category II, III, or IV

appliances because condensate may corrode

the vent.

WARNING

Vents for Category III appliances may not be

!

suitable for use with Category I appliances

because ue gas temperatures may be too

high.

When an existing boiler is removed from a common venting

system, the common venting system is likely to be too

large for the proper venting of the appliances remained

connected to it. If this situation occurs, the following test

procedure must be followed:

REMOVAL OF BOILER FROM VENTING SYSTEM

At the time of removal of an existing boiler, the following

steps shall be followed with each appliance remaining

connected to the common venting system placed in

operation, while the other appliances remaining connected

to the common venting system are not in operation.

1.

Seal an unused opening in the common venting

system.

2.

Visually inspect the venting system for proper size and

horizontal pitch and determine there is no blockage or

restriction, leakage, corrosion and other deciencies

which could cause an unsafe condition.

3.

Insofar as is practical, close all building doors and

windows and all doors between the space in which the

appliances remaining connected to the common venting

system are located and other spaces of the building.

Turn on clothes dryers and any other appliance not

connected to the common venting system. Turn on

any exhaust fans, such as range hoods and bathroom

exhausts, so they operate at maximum speed. Do

not operate a summer exhaust fan. Close replace

dampers.

4.

5.

6.

7.

Place in operation the appliance being inspected. Follow

the lighting instructions. Adjust thermostat so appliance

will operate continuously.

Test for spillage at the draft hood relief opening after

5 minutes of main burner operation. Use the ame of

a match or candle, or smoke from a cigarette, cigar or

pipe.

After it has been determined that each appliance

remaining connected to a common venting system

properly vents when tested as outlined above, return

doors, windows, exhaust fans, replace dampers and

any other gas burning appliances to their previous

condition of use.

Any improper operation if the common venting system

should be corrected so the installation conforms with

the National Fuel Gas Code, ANSI Z223.1/NFPA 54,

and/or the Natural Gas and Propane Installation Code,

CAN/CSA B149.1. When resizing any portion of the

common venting system, the common venting system

should be resized to approach the minimum size as

determined using the appropriate tables in Chapter 13

of the National Fuel Gas Code, ANSI Z223.1/NFPA 54,

and/or the Natural Gas and Propane Installation Code,

CAN/CSA B149.1.

12

HORIZONTAL VENT PIPE INSTALLATION INSTRUCTIONS

Horizontal Vent Pipe Installation Instructions

(Through the wall)

This boiler is design certied for use with the following venting systems

Company HEAT-FAB

Product SAF-T-VENT™ STAR-34™ Z-VENT™ FasNSeal™

®

FLEX-L

CAUTION

The above vent pipe and ttings are used

for venting gas burning category III and

!

IV appliances. Do not use this vent pipe or

ttings for venting appliances burning fuels

such as wood, oil, kerosene or coal.

CAUTION

!

Do not use this vent pipe and ttings for

venting incinerators of any kind.

®

Z-FLEX

®

ProTech

®

WARNING

All installations of boilers and venting

should be done only by a qualied expert

and in accordance with the appropriate

manufacturers manual. Installing or venting

!

a boiler or any other gas appliance with

improper methods or materials may result

in serious injury or death due to re or to

asphyxiation from poisonous gases such

as carbon monoxide which is odorless and

invisible.

!

WARNING

1.

For correct installation of vent system,

read all of these instructions and refer to

the vent pipe manufacturer's instructions.

2.

Failure to use this venting system will void

the manufacturer’s warranty and may

result in rapid deterioration of the venting

system, a potential health hazard.

3.

Faulty vent installation can allow toxic

fumes to be released into living areas.

This may cause serious bodily injury or

property damage. Vent performance may

also be affected by improper assembly.

4.

Install separate vents for forced exhaust

appliances and natural draft appliances.

A common vent between natural draft

and forced exhaust appliances may cause

toxic gases to exhaust through the natural

draft appliance rather than to outside air.

Breathing exhaust gases will cause serious

personal injury or death.

13

HORIZONTAL VENT INSTALLATION INSTRUCTIONS

A. Boilers covered in this section are design-certied as

CATEGORY III for venting, only when installed with

manufacturer specied vent system components and

installation practices.

B. Install vent pipe beginning at the vent connector and

work toward the vent cap.

C. Vent pipe and ttings MUST NOT be routed into,

through, or within any other vent, such as an

existing masonry chimney or factory built chimney.

(Recommended installation is shown in gure 7a & 7b

page 14, unacceptable installation is shown in gure 8

page 14).

D. Vent pipe lengths. The maximum length is the

combined length of straight horizontal and vertical

runs, and the equivalent straight length of ttings. The

required lengths for each boiler are as follows:

Vent Pipe Lenghts

Model

DV50/DV100 3" (7.6cm)

DV125 3" (7.6cm) 25 ft (7.6m) w/1 elbow 2 ft (0.6m) w/1 elbow 5 ft (1.5m)

DV150/200 4" (10.2cm) 30 ft (9.1m) w/1 elbow 2 ft (0.6m) w/1 elbow 5 ft (1.5m)

Example: 20 feet (6m) of vent pipe w/1 elbow is equivalent to 15 feet (4.6m) of vent pipe w/2 elbows.

Note: condensate trap is not required on models DV150 thru 200.

Vent Pipe

Diameter

Maximum Minimum

30 ft (9.1m) w/condensate Tee & 2

elbows

Vent Lengths

Equivalent Feet

Per Fitting

2 ft (0.6m) w/1 elbow 5 ft (1.5m)

E. Slope horizontal runs upwards not less than 1/4 inch/

foot (21mm/m) from boiler to vent terminal.

F. No portion of the vent pipe should have dips or sags

where condensate could collect, see gure 9 on page

14 for a typical vent system.

G. Rigidly support vent pipe every 5 feet and at the

elbows. Plumbers straps may be used.

H. Clearances and enclosures. ALL vent pipe and ttings

must be installed with appropriate air space clearances

to combustibles. These air space clearances apply

to indoor or outdoor vents, whether they are open,

enclosed, horizontal or vertical or pass through oors,

walls, roofs, or framed spaces. The appropriate air

space clearances should be observed to joists, studs,

suboors, plywood, drywall, or plaster enclosures,

insulated sheathing, rafters, roong, and any other

combustible material. The minimum air space clearance

also applies to electrical wires and any kind of building

insulation.

I. Do not insulate or otherwise wrap vent pipe or ttings.

J. For Horizontal runs maintain minimum clearance of

6 inches from vent pipe to any combustible material,

electric wires, and building materials.

14

Loading...

Loading...