Columbia 300 User Manual

1

INSTRUCTION

AND

PARTS

CLASS

BLINDSTITCH

300-5

300-5

300-10 300-20

300-11

300-12 300-30

D

CATALOG

FOR

MODELS

300

MF

BOOK

300

MACHINES

300-14

300-15

300-20

R

D

New

April,

York

1974

Office

Rights

INDUSTRIAl

for

Columbia

Edition

by

in

Union

Reserved

Second

Copyright

Special

CORPORATION

SEWING

CHICAGO

Machines-

Printed

in

U.S.A.

1959

Corporation

All

370

Countries

MACHINES

7th

Avenue.

N.Y

••

N.Y.

10001

2

GENERAL

GENERAL

structions

ADDITIONAL

tions

INDEX

HOW

For

your

its

various

group).

are

listed

of

the

All

the

for

each

The

CROSS-REFERENCE

models

INDEX

INSTRUCTIONS

cover

cover

TO

the

(Page

ORDER

convenience

component

Pictures

in

the

machines

groups

model).

in

which

3)

INSTRUCTIONS

to

ALL

subjects

applying

adjustments,

INSTRUCTIONS

special

for

PARTS

Index

in

used

each

features

each

model.

in

finding

groups

of

these

(Pages 4 and

which

in

group

these

each

groups

model

CHART

is

appears

to

threading,

for

EACH

of

each

parts

(such

as

are

5)

groups

are

on

used.

for

USING

on

Pages 3 to

ALL

MODELS

needle

MODEL

model

and

part

main

shown

with a description

are

used.

also

Pages

which

numbers,

shaft

in

PLATES

listed

33, 34,

sizes,

appear

group,

under

this

appear

do

and

BOOK

6.

on

etc.

covering

on

Pages

not

apply

we

have

presser

numbered

of

the

the

Model

35

show

Pages 7 to

all

17

to

to

other

broken

foot

group,

from A to

Group

heading

the

Groups

and

16.

models.

31.

models.

down

the

(See

and

These

These

the

needle

33.

model

Index

the

in-

instruc-

See

machine

drive

The

Plates

numbers

Page

various

I

into

I

3

To

find

top

cover

this

group,

opposite

If

the

part

Plates

ORDER

SERIAL

any

of

each

number

of

Groups

by

PART

number

part

each

and

Plate.

number,

machine.

locate

of

the

is

known,

where

NUMBER,

the

first

Determine

part

refer

the

part

giving

machine.

refer

and

to

the

the

its

number.

to

the

is

used.

DESCRIPTION,

Model

group

Numerical

in

The

number

which

Index

QUANTITY,

and

each

descriptions

(Pages

Serial

part

of

105-108)

MODEL

number

belongs,

the

parts

number

stamped

find

are

to

locate

the

on

and

into

Plate

the

all

page

of

the

for

the

I

I

I

I

I

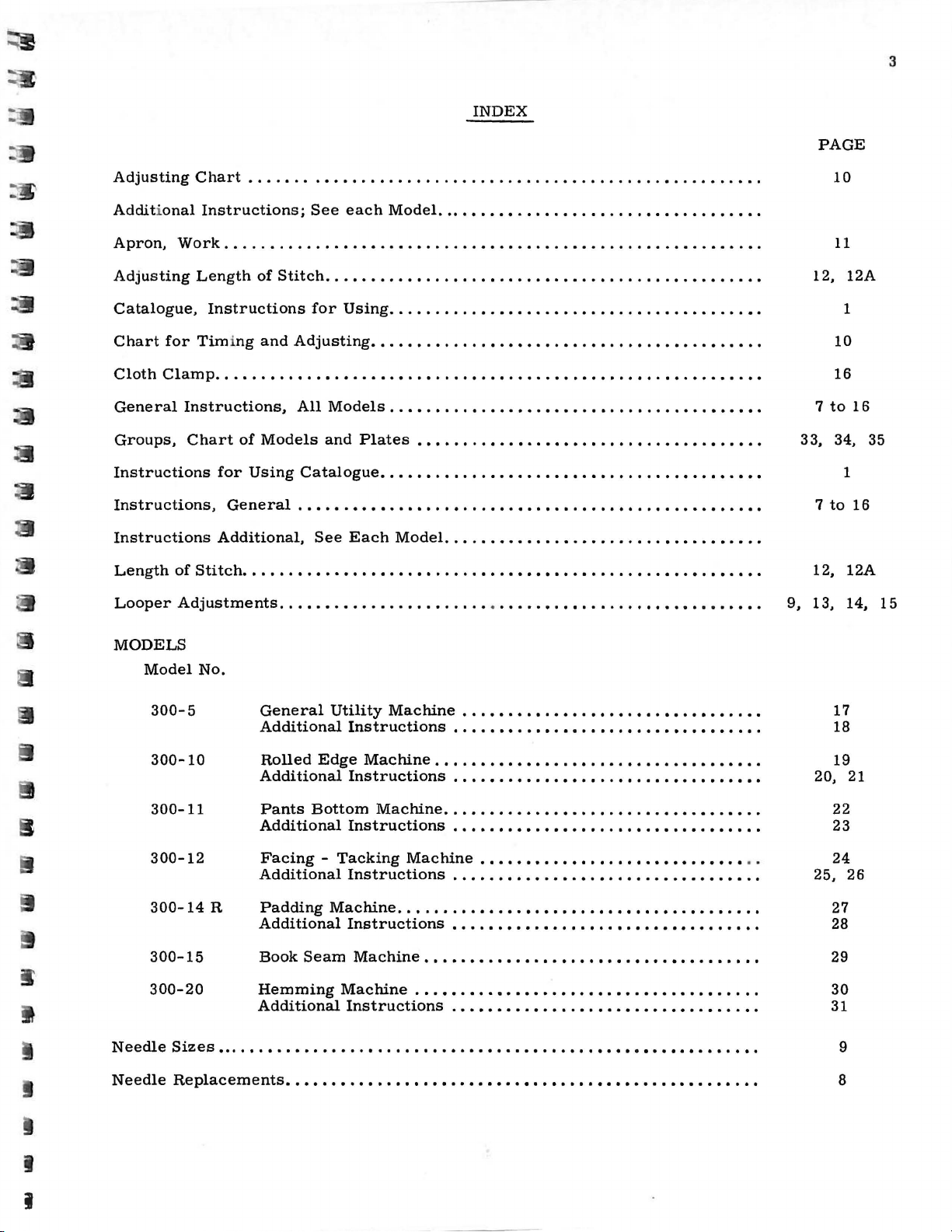

INDEX

3

PAGE

Adjusting

Additional

Apron,

Adjusting

Catalogue,

Chart

Cloth

General

Groups,

Instructions

Instructions,

Instructions

Length

Looper

Work

for

Clamp

Instructions,

Chart

of

Adjustments .......................

Chart

Length

Timing

Stitch ........................................................

..........••......•.....

Instructions;

............

of

Instructions

and

......••••..•.•...•.•..•.

of

Models

for

Using

General

Additional,

See

Stitch

for

Adjusting.

All

Catalogue

.•..•.••••..•••.••.

each

.

..

Using.

Models

and

See

Plates

Each

Model.

.....••

.•••••

•...••.••.•

Model.

.•

.

............................

10

11

12, 12A

1

10

16

to

16

7

33,

34,

35

1

7

to

16

12,

.

9,

.

12A

13, 14,

15

MODELS

Model

300-5

300-10

300-11

300-12

300-14

300-15

300-20

Needle

Needle

Sizes

Replacements

No.

R

•..••.•..•..

General

Additional

Rolled

Additional

Pants

Additional

Facing-

Additional

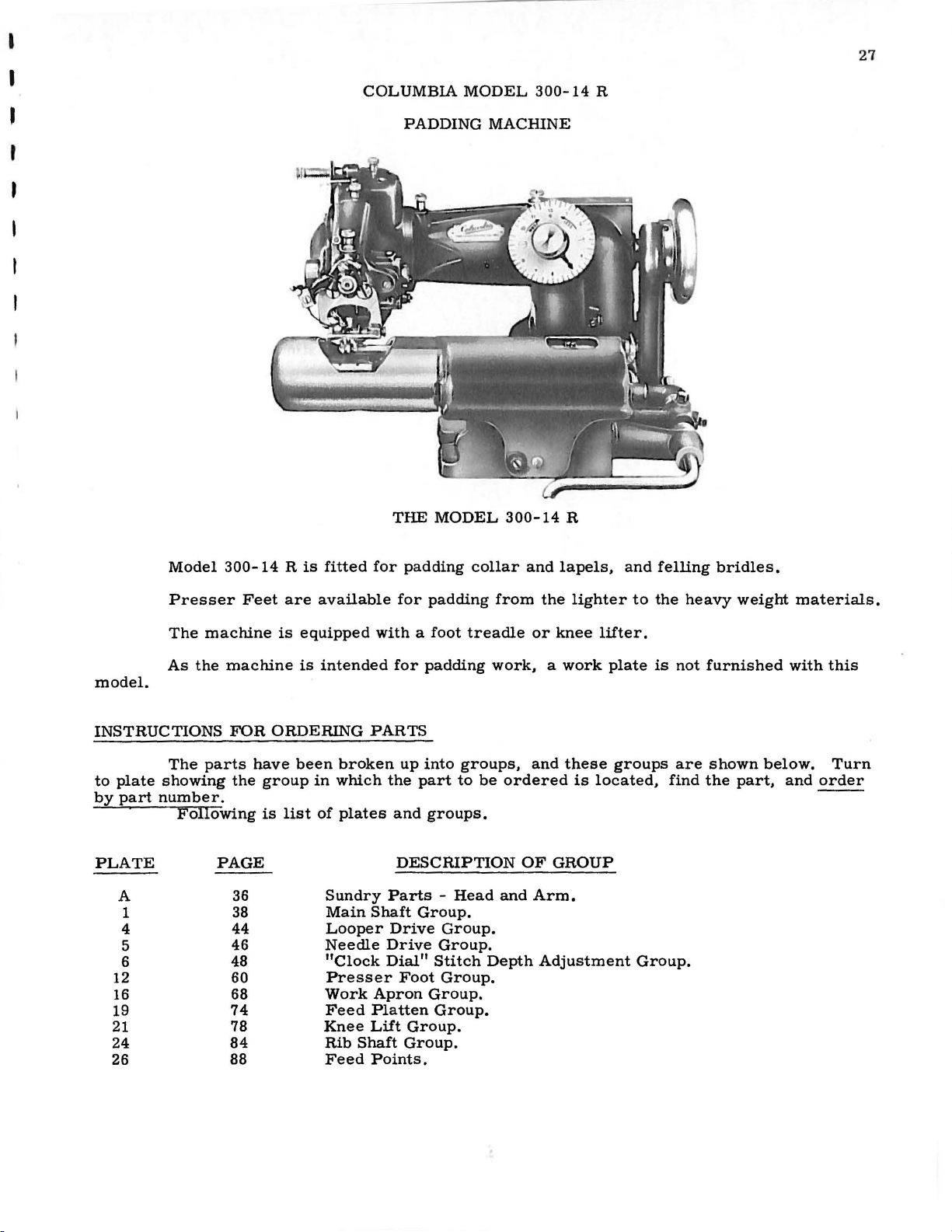

Padding

Additional

Book

Edge

Bottom

Machine

Seam

Hemming

Additional

..••

Utility

Tacking

Machine

Instructions

Machine

Instructions

Machine ................................

Instructions

Machine

Instructions

..•.•.

Instructions

Machine

Machlne

Instructions

.....................................

...••••

•.•.

...................................

..•.•.•••.••••••..•••.•••.••••••••

.•••.••••.•••••••.•••.•••••.••••

••

.................................

17

18

.

.

.

.

19

20, 21

22

23

24

25,

26

27

28

29

30

31

9

8

I

i

4

INDEX

PAGE

Needle,

Numerical

Oi

ling

Machlne .........................................................

Operating

PLATES

Plate

Adjusting

Index

Machlne

No's

A

1

2

3

4

5

6

Stroke

of

Part

.....................................................

Sundry

Main

300-15

Main

Main

Looper

Needle

"Clock

..•...••..••.•••••••.•.•..••.....•.....•..•.••••

Numbers

Parts -Head

Shaft

..............................................

Shaft

Shaft

Drive

Drive

Dial"

....•.•...•.......•..•.••....••.•.•..•••

and

Arm,

Group -300-5,

Group -300-20

Group -300

Group,

Group,

Stitch

- 12

All

All

Depth

Models

Models

Adjustment

All

Models

300-10, 300-11,

..••..•..•.••.••.

300-14

.•.••.•••••.•...••..•.••.•••••.

.•..•.•

,

••••••••

, ,

•.•••••••.•••

..•••••.•••••.•••..•.•

.•••••.•••••••.•••••••

Group,

All

R,

Models

. 7

.

.

,

••

,

••

.•..

11

105,

108

7, 8, 9

36,

37

38,

39

40,

41

42,

43

44,

45

46,

47

48,

49

10

11

12

13

14

15

16

17

18

19

20

7

8

9

~

.r..lp

Stitch

Skip

Stitch

Presser

Presser

Presser

Presser

Presser

Presser

Work

Work

300-15

Feed

Feed

Feed

Feed

Group -300-20

Mechanism -300-20

Foot

Foot

Foot

Foot

Foot

Foot

Table

Apron

Platten

Platten

Platten

Platten

and

Group-

..

300-20

Group -300-5,

Group -300-10

GroupGroup -300-15

...•.•.•.•.••..•.•

,

.••••.....•.

•..•..•.•..••..••.•••.•.•.

Group -300-5,

Group -300-12

Group -300-11

300-20

.•••....•••.•••.•.••..

..•.•.•.•••••••••.•...•.•••.

..•.••.••••.••••.••••.••.•

Group -300-14 R •..••••••••••••••..•••.••.

Group -300-10

Group -300-15

Knee

Lift

300-5,

.......................................

•.•••••••••.•.••.••.•.••.•••

•••.•.••.••••.•..••.•••..••.

Group -300-5,

300-10,

300-11,

300-11,

300-20

300-15,

300-14

.••••••••••••••

..••.•••••••.••••••••..•..•.•

300-14 R ••.••••••••••.••.••.••••.•.

••••.••.•.••••••••.•••.••.•••

300-20

R,

, .

•••

.

50,

52,

54,

56,

58,

60,

62,

64,

66,

68,

70,

72,

74,

76,

51

53

55

57

59

61

63

65

67

69

71

73

75

77

INDEX

5

PAGE

Plate

21

22

23

24

25

26

27

28

29

30

31

32

33

No's

Knee

Lift

Group -300-10, 300-11, 300-12,

Folder

Folder

Rib

Rib

Feed

Right

Feed

Left

Left

Work

Work.Support

Work

Group -300-10

Group -300-15

Shaft

Shaft

GroupGroup -300-15,

Points,

Hand

Platten

Hand

Hand

Rib

Rib

Apron

Support

300-5,

All

Models

Rib

Drive

Group -300-12

Drive

Adjusting

Group,

GroupBracket

Group -300-12

Group -300-12

Two

300-12.

Group -300-12

300-10,

300-20

•.

Group -300-12.

Rib

300-11,

...•••••••.•••.••.•••••••

..••.

••••••.••••••

••••

Machine,

300-14 R .•..•..

300-14 R ...•••..

300-12

...•.•.•.••..•••.••.

•...•..••••••

78,

80,

82,

84,

86,

88,

90,

92,

94,

96,

98,

100,

102,

79

81

83

85

87

89

91

93

95

97

99

101

103

Penetration

'Presser

Retainer

Rib

Adjustment

Speed

Threading

Threading

Timing

Work

of

Chart

Apron

of

Needle

Foot,

or

Machine

Mounting

Cloth

...

Machine.

Chart

.

..

..........................................................

.••.••••••••••••

Clamp

.•

on

Machine

.•••••

9,

12,

8,

8,

10,

15

12B

12B

10

11

9

11

13

7

7

UNPACKING

1.

breaking

destroying

the

project

looper.

machine

the

machine

beyond

l,

3,

should

4.

hole

for

the

the

two

machine

5.

the

machine

used

to

the

AND

To

remove

machine.

it,

so

out

the

Set

up

Place

Mark

belt;

The

machine

first

machine,

that

of

the

the

be

the

place

bolts

be

the

head

set

INSTRUCTIONS

SETTING

the

machine

Be

sure

all

the

box

very

of

the

machine;

machine

on

the

two

holes

the

in

the

may

operated

and

then

ADJUSTING

COLUMBIA

UP

OF

from

to

look

parts

felt

and

carefully

machine.

clean

on

the

table

for

pad

package

be

run

at

about

step

bench

so

the

under

3000

up

FOR

AND

CLASS

MACHINE

the

carefully

equipment

to

Small

away

accumulated

with

that

the

machine

the

of

parts

revolutions

2500

the

machine

THE

INSTALLATION,

OPERATION

300

box,

take

through

that

avoid

breaking

parts

the

pulley

knee

lever

screws

machine

shipped

revolutions

to

will

OF

ALL

MACHINES.

off

the

cover.

the

material

go

with

the

the

be

found

lint

and

lined

is

1/2"

and

bore

and

fasten

with

the

per

minute;

per

minute

increase

Use a nail

machine

tension

wrapped

dust,

up

with

from

for

the

the

machine.

it

is

until

the

speed.

used

for

will

studs,

in a package.

especially

the

transmitter.

the

edge

screw

machine

suggested,

the

puller

packing

be

found.

as

these

from

of

holes;

to

the

however,

operator

to

parts

the

the

bore

table,

becomes

avoid

before

Lift

The

table.

the

using

that

curring

HAND

OILING

with

red

the

plate

SPEED

2500

revolutions

6.

We

the

obligation

WHEEL

7.

The

8.

Before

paint,

to

one

9.

Check

reserve

hand

starting

are

filled

side,

the

per

the

to

install

wheel

with

oil

all

speed

minute,

right

turns

the

the

of

the

and

to

change

such

away

OPERATING

machine

oil.

Should

openings,

machine.

should

specifications

changes

from

make

your

reset

not

on

the

operator

THE

certain

machine

and

The

machine

exceed

machines

MACHINE

that

lock

3000

or

designs

previously

in

clockwise

all

oil

have a Top

the

plate.

should

revolutions

run

at

any

manufactured.

direction.

cups,

and

Plate

stamped

at a minimum

per

minute.

time,

all

without

openings

"OIL"

speed

in-

m~rked

push

of

10.

To

be

knee-lifter

to

the

certain

right,

that

turn

there

pulley

are

by

no

obstructions

hand

in

the

direction

in

and

of

around

the

the

arrow a complete

machine,

press

turn.

the

8

THREADING

11,

h i

ghest

mercerized

INSERTING

Apron,)

small

fold

machine,

ADJUSTING

fabric

"LESS",

possible

12.

Then

curved

should

13.

as

just

desired,

following

To

thread

position,

thread.

WORK

To

insert

place

slot

be

held

watch

NEEDLE

Run

off a few

the

work

the

folded

in

the

gauge

against

this

guide

PENETRATION

test

adjust

the

the

instructions

machine

Proceed

in

the

edge

on

the

guide

(not

inches

penetration

GENERAL

turn

the

as

shown

machine,

or

sewed

top

of

the

extending

the

needle).

and

below:

INSTRUCTIONS

belt

pulley

in

Threading

press

presser

inspect

by

turning

edge

in

the

front

the

of

foot.

work.

the

by

knee

the

of

dial

hand

until

Chart

lifter

garment

Once

the

presser

If

the

indicator

the

Page

to

the

DIRECTLY

this

is

needle

marked

needle

llB.

right.

done,

foot.

does

arm

We

suggest

(This

UNDER

the

In

operating

not

"MORE"

rest

catch

is

in

lowers

of

the

or

its

/#00

the

the

the

the

more

to

graduations

likely,

from

this

NEEDLE

or

soon

tighten

needle

does

slight

penetration,

the

left,

will

penetrating

feather-edge.

plunger,

as

tp.e

in

not, take

tension.

14.

Turn

this

15.

Usually

to

obtain

and

get

have

been

the

REPLACEMENT

16.

Before

remains

the

machine

17.

When

screw.

back

of

the

replacing

the

needle

dial

until

the

it

is

the

desired

no

results,

turned

fabric

If

it

does,

inserting

clear

is

started.

Then

eye,

indicator

needle

sufficient

up

properly.

discard

the

of

the

the

turn

the

rides

out

and

either

catches

to

stitch,

then

look

to a feather-edge,

new

needle,

needle,

needle,

belt

on

the

curve

move

however,

for

Pass

the

needle.

or

make

pulley

needle

it

just

to

the

the

your

else

slowly

the

right

bottom

dial

should

trouble

finger

turn

the

the

sure

guide

eno-ugh

for

less

layer

indicator a few

at

causing a dull

dial

needle

that

and

before

to

you

the

over

it

is

look

make

of

move

point

to

the

will

pushed

to

the

the

needle

it

penetration,

the

garment

graduations

the

dial

of

the

needle,

point

edge

right,

get a defective

see

rest

up

that

enters

on

that

to

see

("LESS")

as

far

the

the

or

to

the

left

properly.

(NOT

indicator a few

which,

prevents

if

the

point

as

it

full

bend

the

work.

guide,

needle

until

will

under

turns)

very

the

the

again

go,

of

the

If

for

needle

has

rib,

as

and

it

a

STARTING

right;

machine

insert

18.

pulls

TO

You

the

it

SEW

are

work

from

now

as

you.

ready

explained

to

proceed

above,

with

release

the

production.

the

knee-lifter,

Press

and

the

knee-lifter

guide

the

work

to

as

the

the

...

9

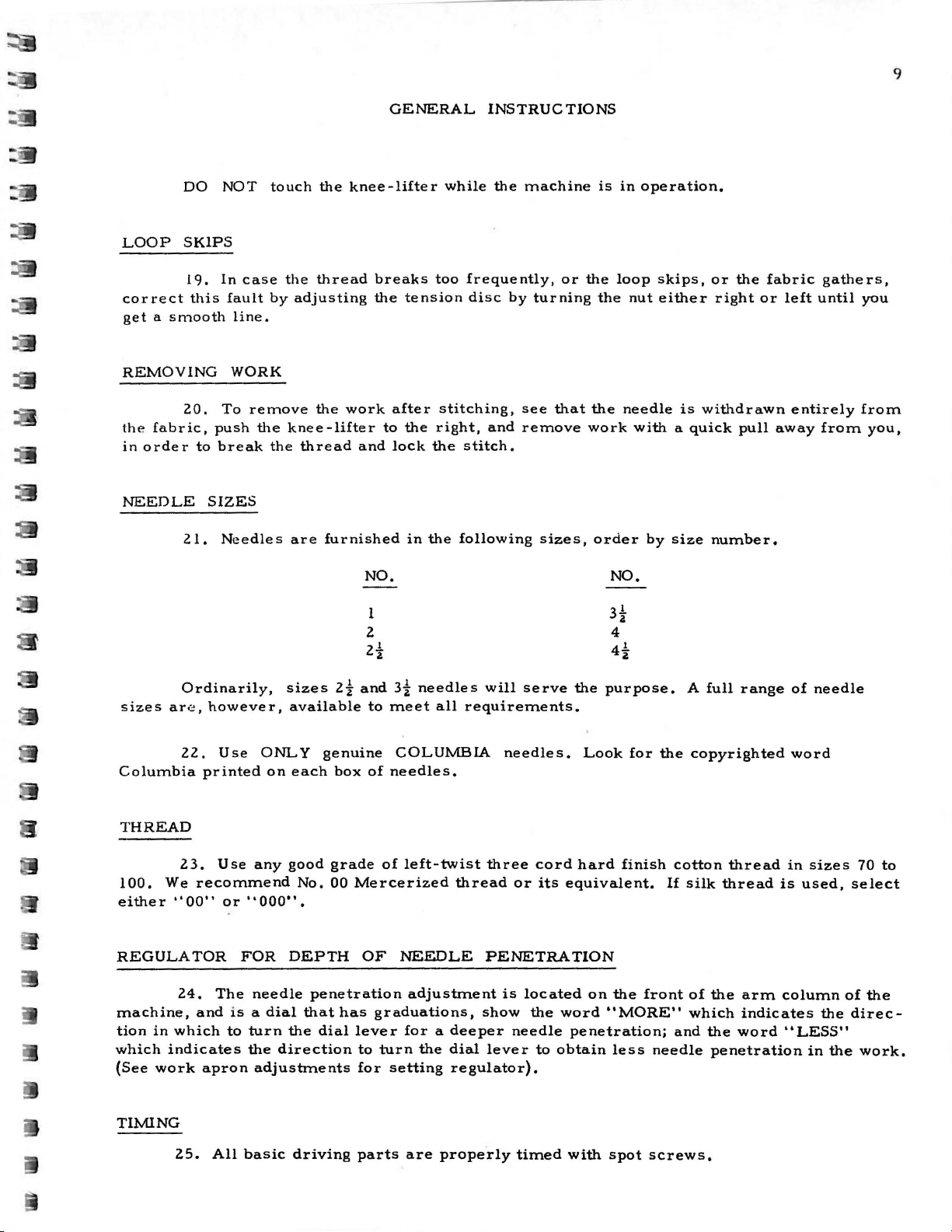

DO

LOOP

correct

get a smooth

REMOVING

SKIPS

19.

this

20.

th e

fabric,

in

order

NEEDLE

to

21.

NOT

In

case

fault

line.

WORK

To

push

break

SIZES

Needles

touch

the

by

remove

the

knee-lifter

the

the

thread

adjusting

the

thread

are

furnished

GENERAL

knee-lifter

breaks

the

work

after

to

and

lock

too

tension

stitching,

the

right,

the

in

the

INSTRUCTIONS

while

the

frequently,

disc

and

stitch.

following

machine

by

turning

see

remove

or

that

sizes,

is

the

the

the

work

order

in

loop

needle

operation.

skips,

nut

either

is

withdrawn

with a quick

by

size

or

the

right

pull

number.

fabric

or

away

left

until

entirely

gathers,

from

from

you

you,

Ordinarily,

sizes

are,

22.

Columbia

THREAD

23.

100.

We

recommend

either

REGULATOR

machine,

tion

which

(See

••

00"

24.

in

which

indicates

work

and

however,

Use

printed

Use

or

"000".

FOR

The

is a dial

to

apron

sizes

available

ONLY

on

each

any

good

No.

DEPTH

needle

turn

the

adjustments

penetration

that

the

direction

NO. NO.

2-i

and

3-k

genuine

box

grade

00

Mercerized

has

dial

lever

to

meet

COLUMBIA

of

needles,

of

left-twist

OF

NEEDLE

adjustment

graduations,

for a deeper

to

turn

for

setting

needles

all

the

will

requirements.

needles.

three

thread

PENETRATION

is

show

needle

dial

lever

regulator).

serve

cord

or

located

the

to

the

hard

its

equivalent.

word

penetration;

obtain

purpose.

Look

on

"MORE"

for

finish

the

less

the

If

front

needle

A

full

copyrighted

cotton

silk

thread

of

the

which

and

the

penetration

range

thread

arm

indicates

word

of

needle

word

in

sizes

is

used,

column

"LESS"

in

the

the

70

select

of

direc-

work.

to

the

TIMING

25.

All

basic

driving

parts

are

properly

timed

with

spot

screws.

.....

0

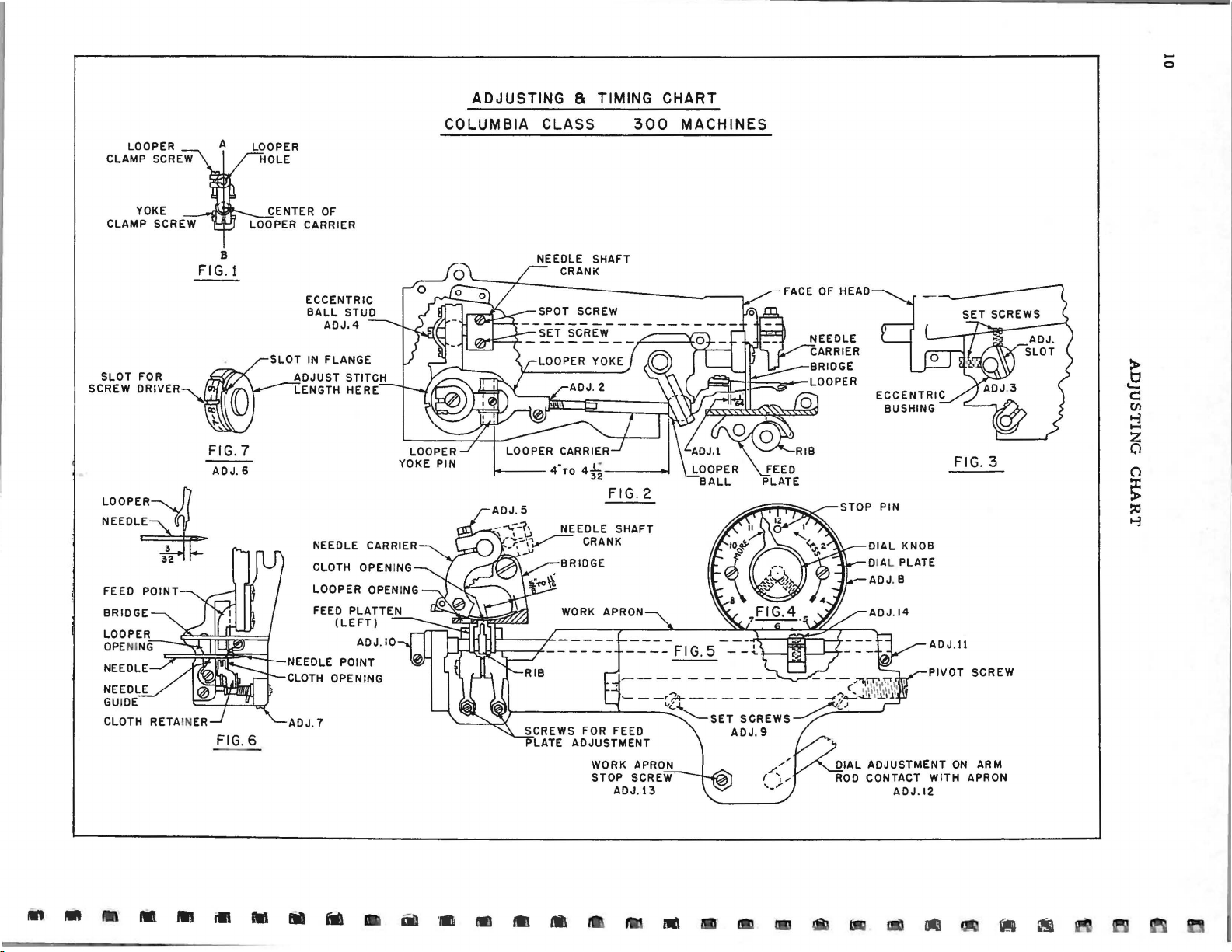

LOOPER

CLAMP

SCREW

A

B

LOOPER

HOLE

FIG.l

FIG. 7

ADJ

. 6

LOOPER~.

n

NEEOL~

··~

ECCENTRIC

BALL

STUD

AOJ.4

ADJUSTING

COLUMBIA

-~-?

,

-~::..'?..

_r~Jt'

CLASS

,

__.---

a TIMING CHART

NEEDLE

CRANK

300

FIG. 2

SHAFT

MACHINES

FACE OF HEAD

ECCENTRIC

BUSHING

FIG. 3

FEED

POINT

BRIDGE

NEEDLE

NEEDLE

GUIDE

NEEDLE POINT

CLOTH OPENING

ADJ.

7

FIG. 6

WORK APRON

STOP

SCREW

AOJ.I3

DIAL

ROO

CONTACT

ADJ.

PIVOT

ADJUSTMENT

WITH

AOJ.I2

II

ON

SCREW

ARM

APRON

11

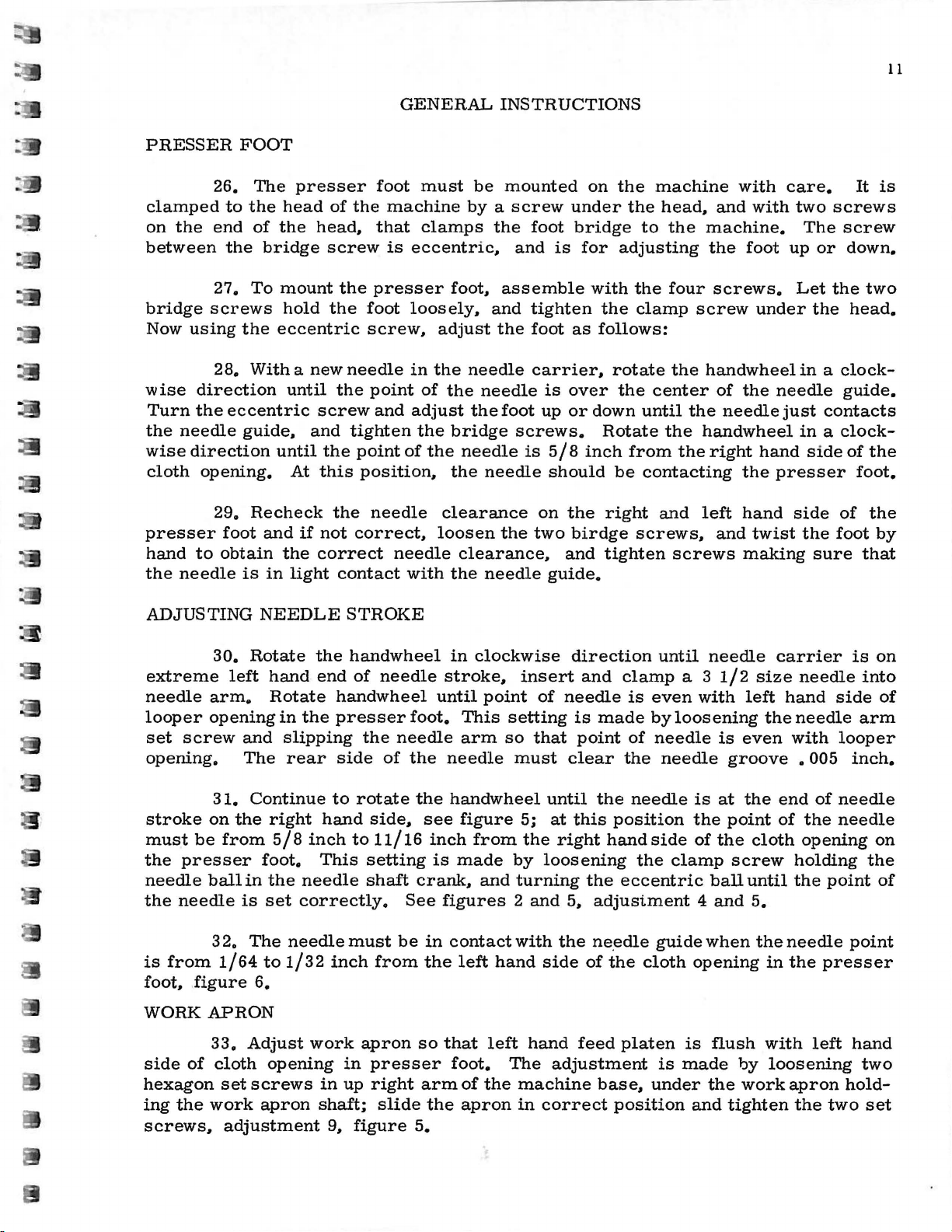

PRESSER

26.

clamped

on

the

end

between

27.

bridge

Now

screws

using

28.

wise

Turn

the

wise

cloth

direction

the

needle

direction

opening.

29.

presser

hand

the

to

needle

FOOT

The

to

the

of

the

the

bridge

To

the

eccentric

With a new

eccentric

guide,

until

Recheck

foot

and

obtain

is

in

presser

head

head,

mount

hold

until

screw

and

the

At

this

if

not

the

correct

light

of

the

screw

the

the

foot

screw,

needle

the

tighten

point

position,

the

correct,

contact

GENERAL

foot

machine

that

is

eccentric,

presser

loosely,

in

point

and

adjust

the

of

needle

needle

with

must

by a screw

clamps

foot,

adjust

the

needle

of

the

bridge

the

needle

the

clearance

loosen

clearance,

the

INSTRUCTIONS

be

mounted

under

the

foot

bridge

and

is

assemble

and

tighten

the

foot

as

carrier,

needle

the

foot

is

up

over

or

screws.

is

5/8

needle

the

should

on

two

the

birdge

and

needle

guide.

on

the

for

adjusting

with

the

follows:

rotate

the

down

Rotate

inch

be

right

tighten

machine

the

head,

to

the

the

four

clamp

the

center

until

the

from

the

contacting

and

screws,

screws

with

and

with

machine.

the

foot

screws.

screw

handwheel

of

the

the

needle

handwheel

right

the

left

hand

and

twist

making

care.

up

under

needle

just

hand

presser

It

two

screws

The

screw

or

down.

Let

the

two

the

head.

in a clock-

guide.

contacts

in a clock-

side

of

foot.

side

of

the

foot

sure

that

is

the

the

by

ADJUSTING

30.

extreme

needle

looper

set

left

arm.

opening

screw

opening.

31.

stroke

must

the

needle

the

on

be

from

presser

ball

needle

the

is

3 2.

is

from

foot,

WORK

1/64

figure

APRON

33.

side

of

cloth

hexagon

ing

screws,

the

set

work

adjustment

NEEDLE

Rotate

hand

Rotate

in

and

slipping

The

rear

Continue

right

5/8

foot.

in

the

set

correctly.

The

needle

to

1/32

6.

Adjust

opening

screws

apron

STROKE

the

end

handwheel

the

presser

side

to

hand

inch

This

needle

inch

work

in

in

up

shaft;

9,

handwheel

of

needle

foot.

the

needle

of

the

rotate

to

side,

11/16

the

see

setting

shaft

crank,

See

must

be

from

apron

the

so

presser

right

arm

slide

figure

5.

in

clockwise

stroke,

until

point

This

setting

arm

so

needle

must

handwheel

figure

inch

from

is

made

and

by

turning

figures 2 and

in

contact

that

foot.

the

left

of

apron

hand

left

The

the

with

machine

in

insert

of

needle

that

clear

until

5;

at

the

right

loosening

5,

the ne.

side

hand

adjustment

correct

direction

and

is

made

point

the

this

hand

the

until

clamp

is

even

by

of

needle

the

needle

needle

position

side

the

clamp

eccentric

a 3

loosening

adjusiment 4 and

edle

guide

of

the

cloth

feed

platen

base,

is

is

made

under

position

needle

1/2

with

left

is

even

groove

is

at

the

the

point

of

the

screw

ball

when

opening

flush

by

the

work

and

tighten

carrier

size

hand

the

needle

with

end

of

cloth

holding

until

the

5.

the

needle

in

the

with

loosening

apron

the

is

needle

side

looper

• 005

the

of

inch.

needle

needle

opening

point

point

presser

left

hand

hold-

two

on

into

of

arm

on

the

of

two

set

12

needle

Figure

apron

against

and

turn

screw.

raised

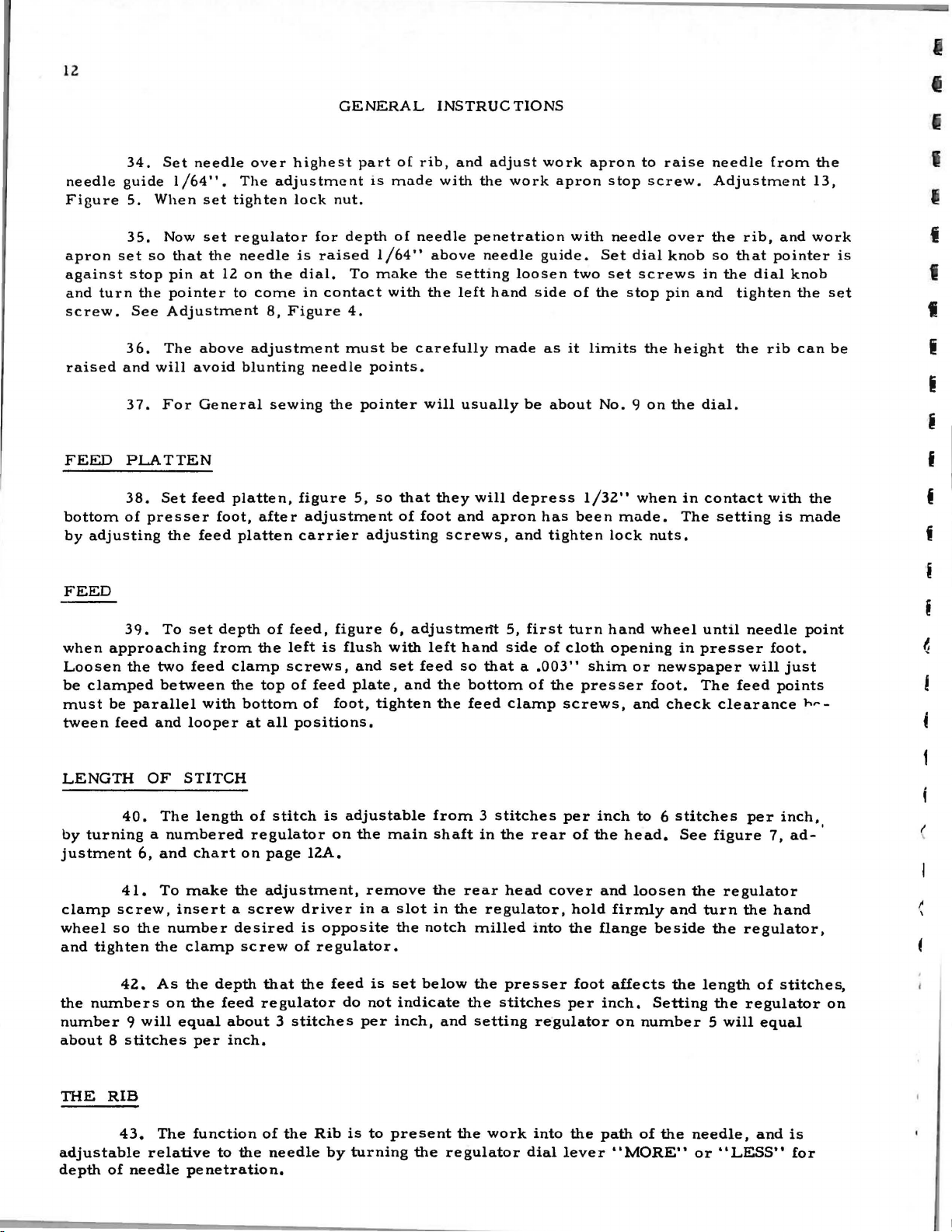

34.

guide

5.

35.

set

stop

See

36.

and

37.

Set

1/64".

When

Now

so

that

pin

the

pointer

Adjustment

The

will

For

needle

set

tighten

set

the

at

12

above

avoid

General

over

The

adjustment

regulator

needle

on

the

to

come

8,

adjustment

blunting

sewing

highest

lock

for

is

raised

dial,

in

Figure

needle

GENERAL

part

is

nut.

depth

To

contact

4.

must

points.

the

pointer

of

made

of

l/64"

make

with

be

INSTRUCTIONS

rib,

and

adjust

with

the

needle

the

carefully

will

above

the

penetration

needle

setting

left

hand

made

usually

work

loosen

side

be

work

apron

with

guide.

two

of

as

it

about

apron

stop

needle

Set

set

the

limits

No.9

to

screw.

dial

screws

stop

the

on

raise

over

knob

pin

height

the

needle

Adjustment

the

rib,

so

that

in

the

and

tighten

the

dial.

from

dial

rib

13,

and

work

pointer

knob

the

can

the

is

set

be

I

I

i

I

I

I

I

I

t

i

i

FEED

bottom

by

FEED

when

Loosen

be

must

tween

LENGTH

by

justment

clamp

wheel

and

PLATTEN

38.

Set

of

presser

adjusting

approaching

clamped

be

feed

turning a numbered

41.

screw,

so

tighten

39.

the

parallel

OF

40.

6,

the

the

To

two

between

and

The

and

To

number

the

feed

platten,

foot,

after

feed

platten

set

depth

from

feed

with

looper

STITCH

length

chart

make

insert a screw

clamp

the

clamp

the

top

bottom

at

of

regulator

on

page

the

adjustment,

desired

screw

of

all

stitch

figure

adjustment

carrier

feed,

figure

left

is

screws,

of

feed

of

foot,

positions,

is

on

12A.

driver

is

opposite

of

regulator.

5,

so

that

of

adjusting

6,

flush

with

and

set

plate,

tighten

adjustable

the

main

remove

in a slot

the

they

will

foot

and

screws,

adjustmertt

left

hand

feed

so

and

the

bottom

the

feed

from 3 stitches

shaft

in

the

rear

in

the

notch

milled

depress

apron

that a .003"

regulator,

and

5,

side

clamp

the

head

has

first

of

of

rear

into

tighten

the

screws,

per

cover

1/32"

been

turn

cloth

shim

presser

of

hold

the

made.

lock

hand

opening

inch

the

head,

and

firmly

flange

or

and

loosen

when

in

contact

The

setting

nuts,

wheel

foot.

to 6 stitches

beside

until

in

presser

newspaper

The

check

and

See

the

clearance

figure

turn

the

with

needle

foot.

will

feed

per

7,

regulator

the

hand

regulator,

the

is

made

point

just

points

h---

inch,

ad-'

(

t'

\

42.

As

the

the

numbers

number 9 will

about 8 stitches

THE

adjustable

depth

RIB

43.

of

The

relative

needle

depth

on

the

equal

per

function

penetration,

that

the

feed

regulator

about 3 stitches

inch.

of

the

to

the

needle

Rib

by

feed

do

is

turning

is

not

per

to

set

below

indicate

inch,

pre

sent

the

the

the

and

setting

the

work

regulator

presser

stitches

regulator

into

dial

lever

foot

per

the

affects

inch.

path

Setting

on

number 5 will

of

"MORE"

the

the

length

the

needle,

or

"LESS"

of

stitches,

regulator

equal

and

is

for

on

I

I

I

12A

I

t

I

t

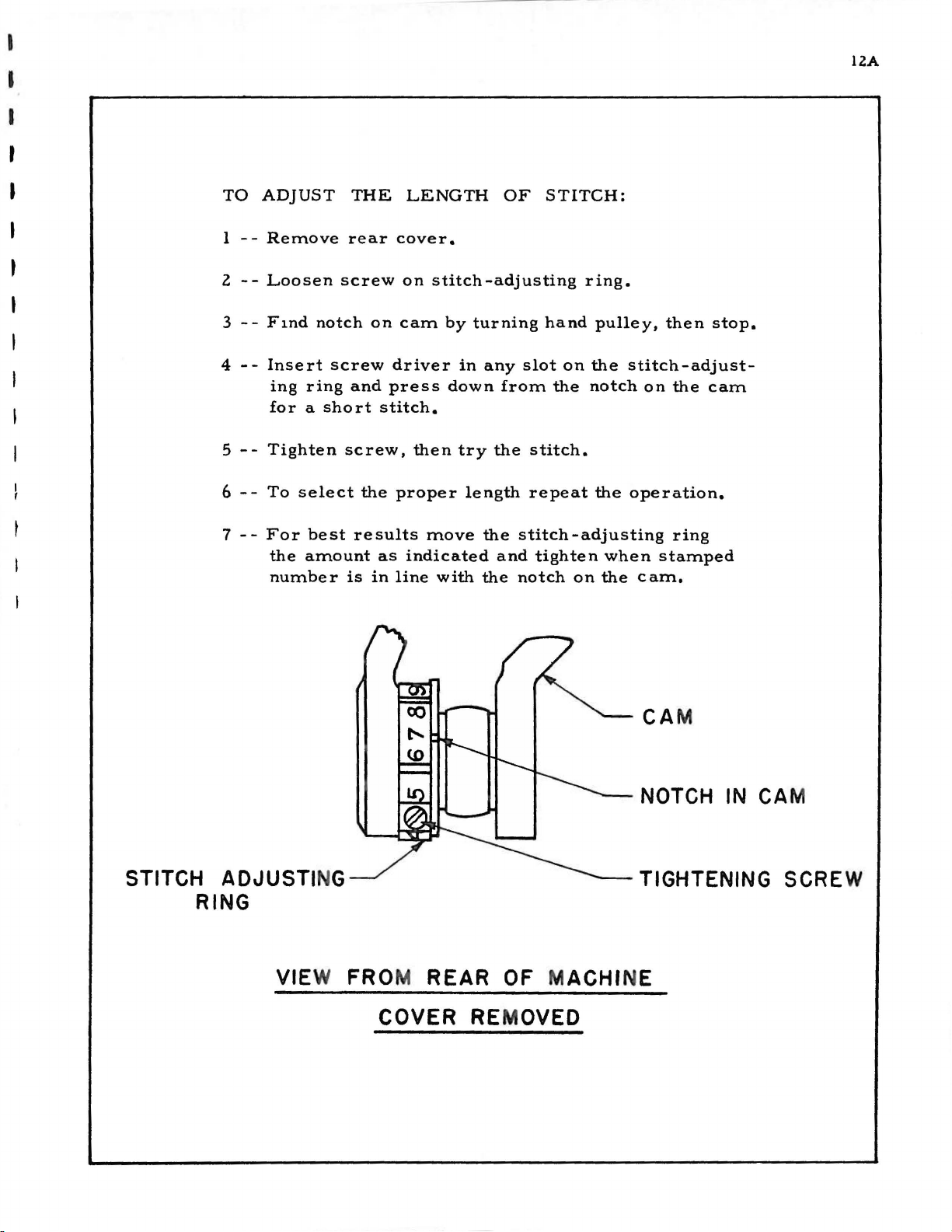

TO

ADJUST

1 --Remove

2

--Loosen

3

--

Fmd

4

--

Insert

ing

ring

for a short

5

--

Tighten

6

--

To

select

7 --For

best

the

amount

number

rear

screw

notch

screw

screw,

is

THE

on

and

press

stitch.

the

results

as

in

LENGTH

cover.

on

stitch-adjusting

cam

by

driver

proper

indicated

line

then

move

with

in

down

try

OF

turning

any

from

the

length

the

and

the

STITCH:

hand

slot

stitch.

repeat

stitch

tighten

notch

ring.

pulley,

on

the

the

notch

the

-adjusting

on

stitch-adjust-

on

operation.

when

the

stamped

cam.

then

the

ring

stop.

cam

STITCH

RING

ADJUSTI

VIE W

NG

FRO

COVER

M

REAR

REMOVED

OF M

ACHI

CA

M

NOTCH IN CAM

TIGHTENING SCREW

NE

-N

Ill

I

.-

I

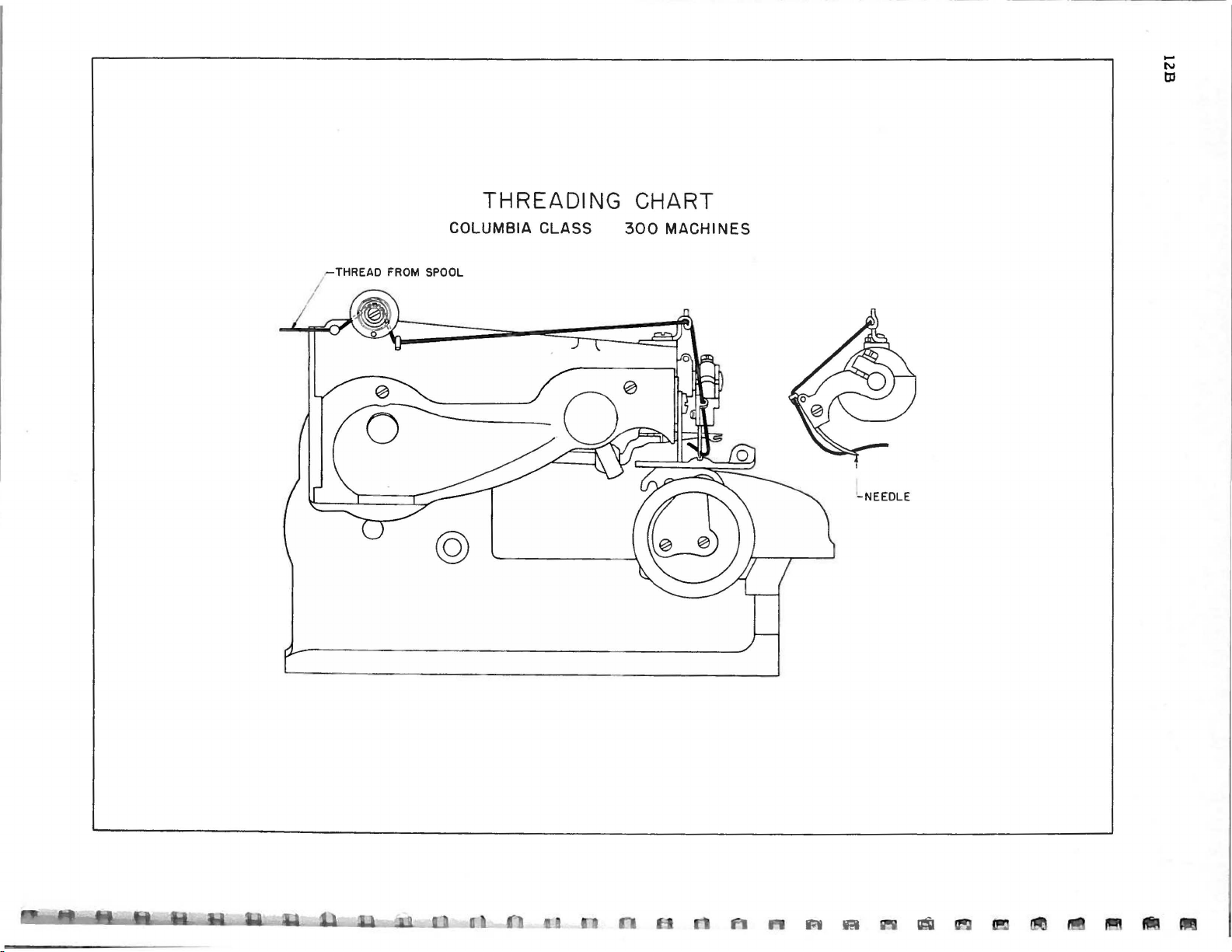

THREAD

FROM

THREADING

COLUMBIA CLASS

SPOOL

@

CHART

300

MACHINES

LNEEDLE

13

presser

end

of

ing

and

the

garment

ter

of

as

follows:

with

nose

set

rib

screw.

LOOPER

and

Timing

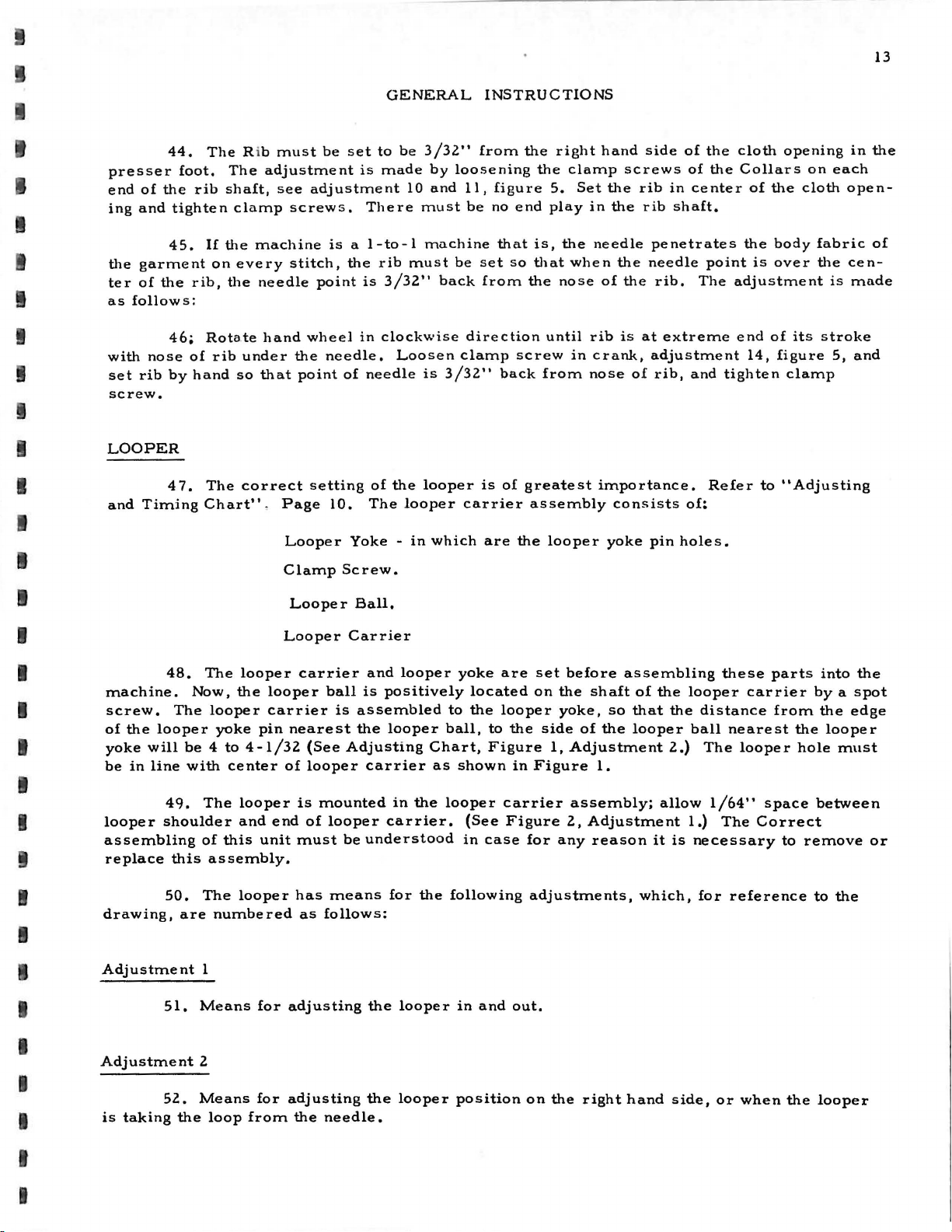

44.

foot,

the

tighten

45.

the

46;

by

4

7.

The

rib

If

on

rib,

Rotate

of

rib

hand

The

Chart".

R ib

The

shaft,

clamp

the

every

the

under

so

correct

must

adjustment

see

screws.

machine

stitch,

needle

hand

wheel

the

that

point

Page

Looper

be

set

is

adjustment

There

is a 1-to-1

the

point

setting

is

in

needle.

of

needle

10.

Yoke -in

of

The

GENERAL

to

be

3/32"

made

rib

clockwise

10

must

3/32"

Loosen

the

looper

by

and

must

machine

is

looper

which

INSTRUCTIONS

from

loosening

11,

figure

be

no

that

be

set

back

from

direction

clamp

3/32"

back

is

carrier

are

end

so

screw

of

the

the

greatest

right

the

clamp

5.

Set

play

is,

the

that

when

the

nose

until

in

from

assembly

looper

hand

side

screws

the

rib

in

the

rib

needle

the

needle

of

the

rib

is

at

crank,

nose

of

importance.

consists

yoke

pin

of

the

of

the

in

center

shaft,

penetrates

point

rib,

The

extreme

adjustment

rib,

and

Refer

of:

holes.

cloth

Collars

of

the

the

body

is

over

adjustment

end

of

14,

figure

tighten

to

opening

on

each

cloth

fabric

the

is

its

stroke

5,

clamp

"Adjusting

in

open-

cen-

made

and

the

of

I

I

I

48.

machine.

screw.

of

the

looper

yoke

will

be

in

line

49.

looper

assembling

replace

drawing,

Adjustment

shoulder

50,

51.

Now,

The

be 4 to

with

this

are

Means

The

looper

the

looper

yoke

4-1/32

center

The

looper

and

of

this

assembly.

The

looper

numbered

1

Clamp

looper

carrier

pin

end

unit

for

Looper

Looper

carrier

ball

nearest

(See

of

looper

is

mounted

of

looper

must

has

means

as

follows:

adjusting

Screw.

Ball.

Carrier

and

is

is

assembled

the

Adjusting

carrier

be

understood

the

looper

positively

looper

Chart,

as

in

the

carrier.

for

the

looper

yoke

located

to

the

ball,

to

Figure

shown

looper

(See

in

case

following

in

and

are

set

on

looper

the

side

in

Figure

carrier

Figure

for

adjustments,

out.

before

the

shaft

yoke,

of

1,

Adjustment

1.

assembly;

2,

Adjustment

any

reason

assembling

of

so

that

the

looper

which,

the

the

2.)

allow

it

is

these

looper

distance

ball

nearest

The

1/64"

1.)

The

necessary

for

reference

parts

carrier

looper

space

Correct

from

the

hole

to

into

by a spot

the

looper

must

between

remove

to

the

the

edge

or

I

I

I

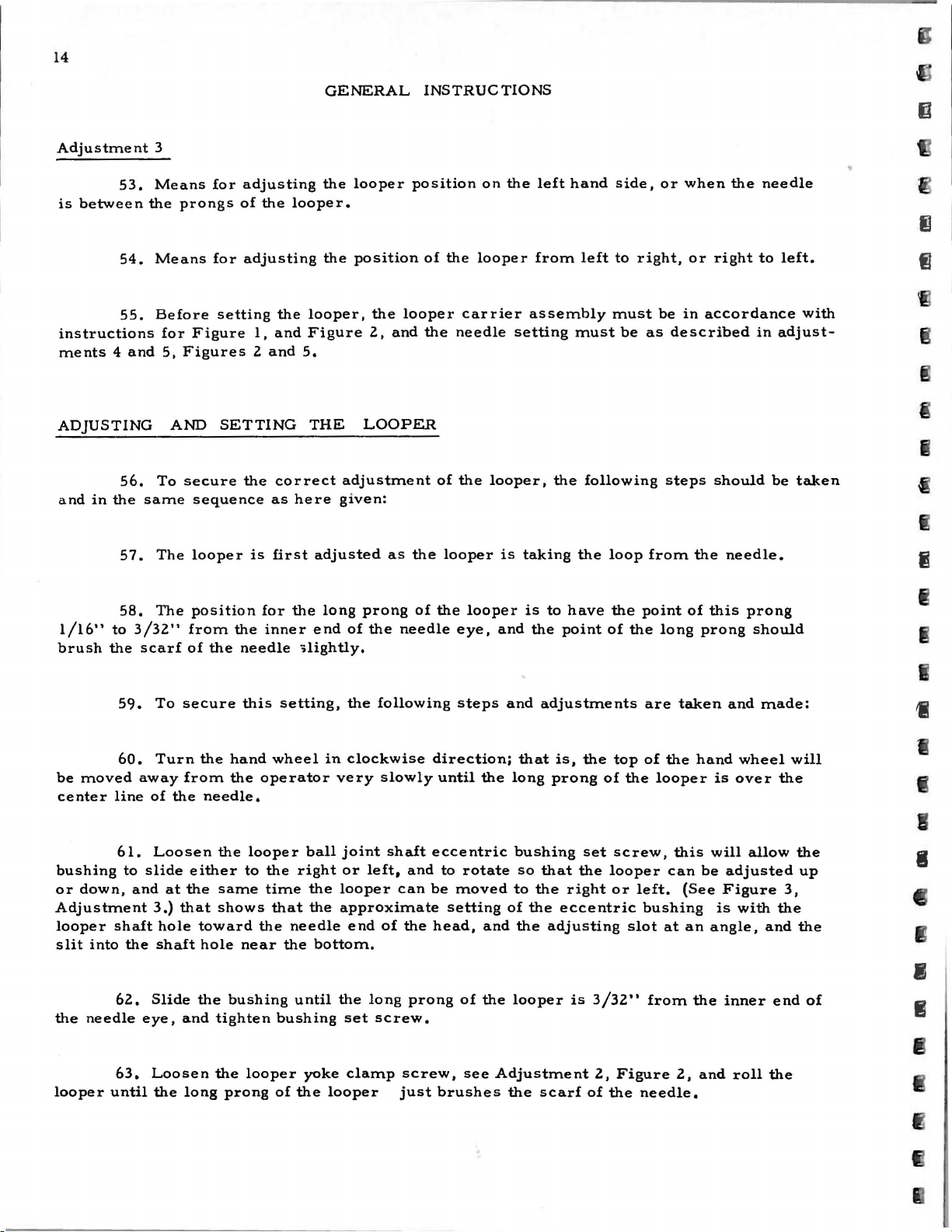

Adjustment

52.

is

taking

the

2

Means

loop

for

from

adjusting

the

needle.

the

looper

position

on

the

I

I

right

hand

side,

or

when

the

looper

14

Adjustment

53.

is

between

54.

55.

instructions

ments 4 and

ADJUSTING

56.

and

in

the

3

Means

the

Means

Before

for

5,

AND

To

same

for

prongs

for

setting

Figure

Figures

SETTING

secure

sequence

adjusting

of

the

adjusting

the

1,

and

2

and

the

correct

as

GENERAL

the

looper.

the

looper,

Figure

5.

THE

here

looper

position

the

2,

and

LOOPER

adjustment

given:

INSTRUCTIONS

position

of

looper

the

the

of

on

looper

carrier

needle

the

looper,

the

left

from

assembly

setting

hand

must

the

side,

left

to

must

be

following

or

right,

be

as

when

or

right

in

accordance

described

steps

should

the

needle

to

left.

in

adjust-

be

with

taken

I

I

I

57.

58.

1/16"

brush

be

center

bushing

or

Adjustment

looper

slit

the

to

the

59.

60.

moved

line

61.

to

down,

shaft

into

62.

needle

3/32"

scarf

away

slide

and

the

eye,

The

The

from

of

To

secure

Turn

from

of

the

Loosen

at

the

3.)

that

hole

shaft

Slide

and

looper

position

the

the

the

hand

the

needle.

the

either

same

shows

toward

hole

the

bushing

tighten

is

first

for

inner

needle

this

wheel

operator

looper

to

the

time

that

the

near

adjusted

the

end

;lightly.

setting,

ball

right

the

the

needle

the

bottom.

until

bushing

long

prong

of

the

the

following

in

clockwise

very

slowly

joint

or

left,

looper

approximate

end

of

the

long

set

screw.

as

needle

shaft

and

can

the

prong

the

looper

of

the

direction;

until

eccentric

to

be

setting

head,

looper

eye,

steps

the

rotate

moved

and

of

the

is

taking

is

and

and

that

long

bushing

so

to

of

the

looper

the

to

have

the

point

adjustments

is,

the

prong

set

that

the

the

right

the

eccentric

adjusting

is

loop

the

of

top

of

screw,

looper

or

3/32"

from

point

the

are

of

the

left.

bushing

slot

from

of

long

taken

the

looper

this

can

(See

at

an

the

this

prong

hand

is

will

be

is

angle,

the

needle.

prong

should

and

made:

wheel

over

allow

adjusted

Figure

with

and

inner

the

3,

the

end

I

will

I

the

up

the

I

of

I

63.

looper

until

Loosen

the

long

the

prong

looper

of

yoke

the

clamp

looper

screw,

just

see

brushes

Adjustment

the

scarf

of

2,

Figure

the

2,

needle.

and

roll

the

15

needle,

looper

If

the

then

looper

not

enter

looper

Move

looper

needle

short

the

has

the

64.

and

65.

is

at

previous

66.

passed

the

slot

in

bushing

slot.

6

7.

should

Check

is

3/32"

Continue

nearest

prong

adjustments

Continue

looper

the

foot

the

Care

must

be

entering

to

point

does

the

slot

see

from

to

not

to

rotate

edge

by

least

be

that poi

the

rotate

when

clear

of

in

the

moving

amount

taken

between

nt

inner

hand

passing

the

have

the

the

foot,

the

now

GENERAL

of

the

end

of

wheel

chaining

chaining

not

been

hand

wheel

looper

possible

the

slot

adjust

eccentric

as

the

prongs

INSTRUCTIONS

long

prong

the

needle

in

clockwise

finger,

finger,

correctly

in

clockwise

in

the

so

that

bushing

so

that

needle

of

the

foot.

the

the

may

looper,

of

the

eye.

direction,

not

or

if

made,

short

for

short

strike

looper

See

exceeding

the

clearance

and

direction

If

the

prong

the

looper,

prong

the

just

Figure

until

these

short

will

clears

crotch

brushes

5,

the

short

1/32"

is

should

until

the

prong

clear

Adjustment

the

of

the

the

-See

greater

be

short

of

the

the

edge

looper

scarf

prong

Figure

than

re-made,

prong

looper

edge

3,

Figure

of

of

of

1/32",

of

the

the

when

the

the

6,

of

does

the

the

3,

should

following

about

loosen

Adjustment

When

long

the

the

not

clusive

the

Different

ments,

more

the

by

enter

an

the

this

prong

long

point

exist,

looper

72.

however,

heavy

point

re-adjusting

68.

Continue

corrective

69.

The

equal

70.

In

eccentric

3,

setting

71.

Continue

of

prong

of

the

the

under

-Adjustment

The

materials

materials.

of

the

between

needle

amount.

case

Figure

has

the

looper

of

the

long

eye

must

the

heading

machine,

there

needle

the

to

turn

the

the

prongs,

steps

the

bushing

to

looper

prong

or

needle

are

must

needle

3,

until

been

made,

rotate

is

over

is

just

be

corrected

"ADJUSTING

2,

Figure

as

far

different

adjustments

When

1/16" -Figure

ball

hand

but

required:

enter

should

clamp

the

prongs

tighten

the

hand

the

1/16"

brushes

2,

as

threads

hemming

stud,

wheel

instead

between

not

enter

screw,

of

the

wheel

center

to

3/32"

the

--

this

AND

Do

not

the

looper

may

will

give

silks

6,

instead

Adjustment

in

clockwise

of

doing

the

prongs

about

Figure

the

looper

bushing

in a clockwise

line

of

from

scarf

is

done

SETTING

turn

and

cause a slightly

the

and

3,

the

of

the

as

the

needle

best

cotton,

of

3/32",

4,

Figure

midway

and

set

the

looper

results

direction

so,

strikes

of

the

turn

are

about

screw.

needle,

inner

needle.

described

THE

are

however,

without

2.

the

looper,

of

the

the

looper

equal

See

direction

Check

end

of

In

in

LOOPER".

eccentric

concerned

variation

when

it

until

the

crotch

clearing

two

prongs

distance

Figure

until

to

see

eye

case

the

the

56

bushing,

is

from

padding

may

changing

point

of

the

the

eccentric

3,

the

that

of

the

above

to

65

Be

now

the

or

hemming

be

advisable

the

of

the

looper.

two

prongs

to

correct

bushing

from

the

point

of

the

point

needle,

conditions

paragraphs

sure

to

ready

looper

to

above

needle

The

this,

in

needle,

the

of

and

that

roll

sew.

adjust-

the

to

set

position

do

in-

16

RETAINER

73,

be

adjusted

firmly

carried

Adjustment

eccentric

left

for

hold

along

setting

OR

The

as

close

the

work

with

7,

bushing

CL01H

cloth

onto

the

To

adjust

and

retainer

retainer

to

the

the

needle,

turn

to

CLAMP

needles

disc

the

retainer

bushing

the

GENERAL

located

as

while

no

loop

for

rib,

and

INSTRUCTIONS

in

the

possible,

the

needle

will

for.m,

loosen

setting

tighten

cloth

and

set

screw

retainer

set

opening

set

is

penetrating

resulting

in

to

screw

of

relative

in

foot

the

in

the

the

presser

to

the

missed

and

needle,

presser

the

ridge

material.

stitches,

turn

and

foot

the

slide

foot,

must

forming

If

cloth

the

See

retainer

to

the

at

all

disc

work

Figure

right

times

to

is

6,

or

c

17

and

for

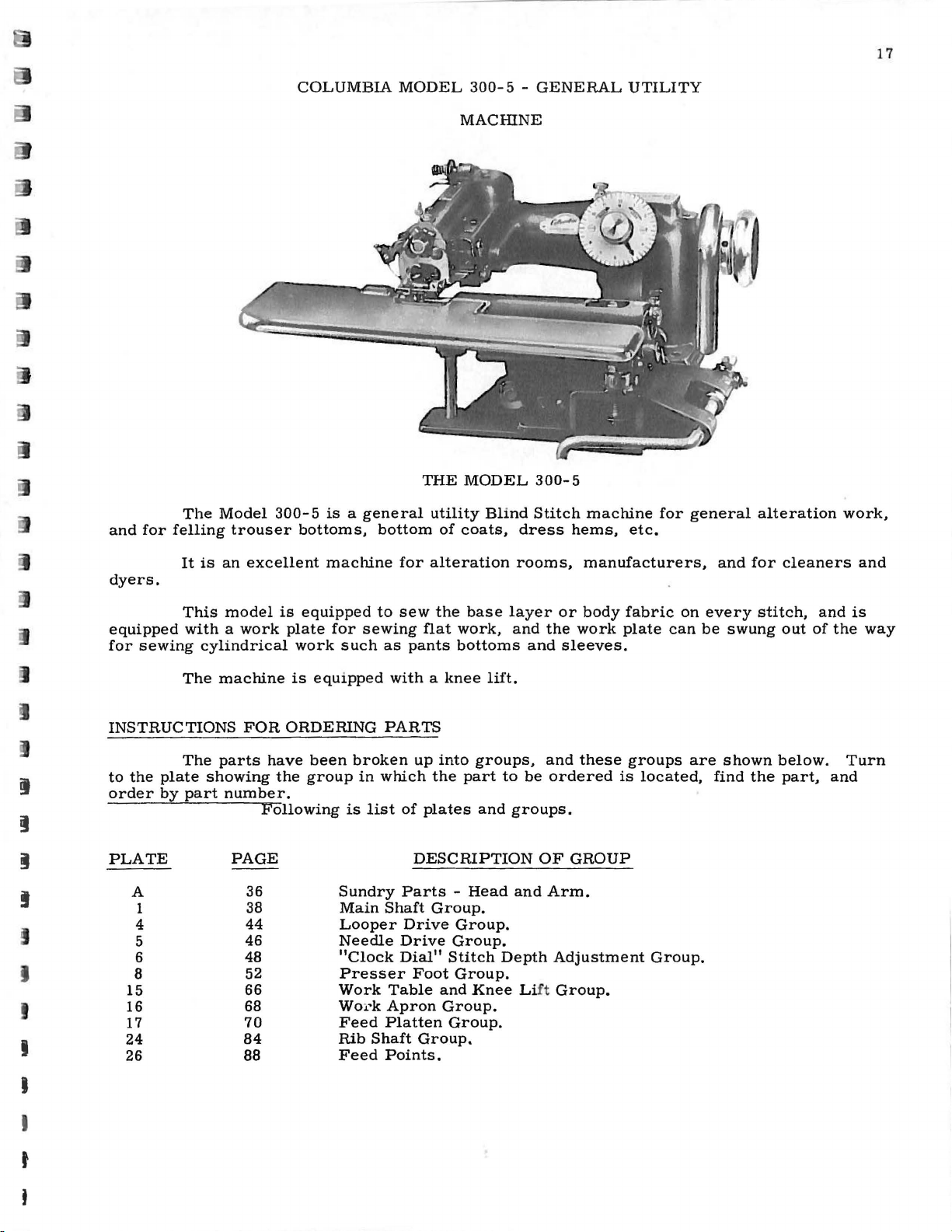

The

felling

Model

trouser

COLUMBIA

300-5

is a general

bottoms,

MODEL

bottom

THE

utility

of

300-5 -GENERAL

MACIDNE

MODEL

Blind

coats,

300-5

Stitch

dress

hems,

UTILITY

machine

etc.

for

general

alteration

work,

J

I

I

It

is

an

dyers.

This

equipped

for

INSTRUCTIONS

to

the

order

PLATE

A

1

sewing

plate

by

with a work

cylindrical

The

machine

The

parts

showing

part

4

5

6

8

15

16

17

24

26

excellent

model

FOR

have

number.

Following

PAGE

36

38

44

46

48

52

66

68

70

84

88

machine

is

equipped

plate

for

work

such

is

equipped

ORDERING

been

the

group

Sundry

Main

Looper

Needle

"Clock

Presser

Work

Wo:ck

Feed

Rib

Feed

to

sewing

broken

in

is

list

Shaft

which

for

alteration

sew

the

flat

work,

as

pants

with a knee

PARTS

of

Parts -Head

Shaft

Drive

Drive

Dial"

Table

Apron

Platten

Points.

bottoms

up

into

the

part

plates

DESCRIPTION

Group.

Group.

Group.

Stitch

Foot

Group.

and

Group.

Group.

Group.

rooms,

base

layer

and

and

lift.

groups,

to

be

and

groups.

and

Depth

Knee Lift

manufacturers,

or

body

the

work

sleeves.

and

these

ordered

OF

GROUP

Arm.

Adjustment

Group.

fabric

plate

groups

is

located,

on

can

are

Group.

and

every

be

swung

shown

find

for

stitch,

below.

the

cleaners

and

out

of

part,

the

Turn

and

and

is

way

J

I

t

t

18

ADDITIONAL

Refer

STITCH

RIB

CLOTH

needle.

rib.

the

LENGTH

Generally

Set

RETAINER

Rotate

Adjust

To

check

retainer

ADJUSTMENTS

to

timing

set 3 stitches

rib

in

center

hand

wheel

the

cloth

this

setting,

must

clamp

both

FOR

chart,

of

retainer

page

per inch,

cloth

clockwise

insert a strip

strips

COLUMBIA

MODEL

10.

#9

opening

to

of

unt

just

the

in

il

the

clear

of

paper.

MODEL

300-5

on

the

rib

the

paper

stitch

presser

is

at

needle,

on

See

300-5

regulator,

foot,

the

end

and

each

side

Adjustment

Adjustment

Adjustment

of

its

oscillation,

center

of

the

7,

the

rib,

Figure

9,

cloth

under

6.

6,

Figure

Figure

and

retainer

the

7.

5.

under

to

the

retainer;

e

c

the

19

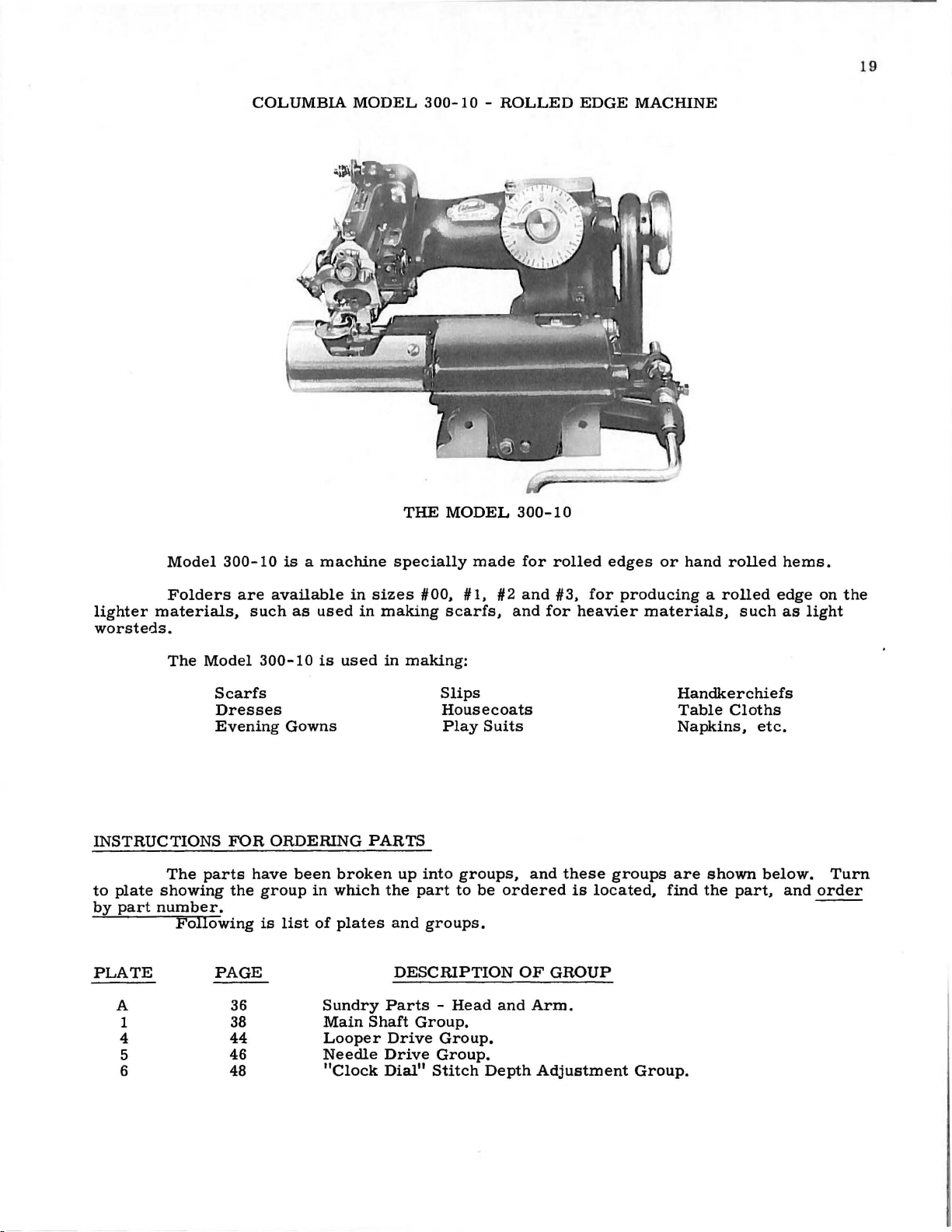

COLUMBIA

MODEL

THE

300-10-

MODEL

ROLLED

300-10

EDGE

MACHINE

Model

Folders

lighter

materials,

worsteds.

The

Model

INSTRUCTIONS

The

parts

to

plate

showing

by

part

number.

Following

PLATE

A

1

4

5

6

300-10

are

such

300-10

Scarfs

Dresses

Evening

FOR

have

the

group

is

PAGE

36

38

44

46

48

is a machine

available

as

used

is

used

in

Gowns

ORDERING

been

broken

in

which

list

of

plates

Sundry

Main

Looper

Needle

"Clock

specially

sizes

in

#00,

making

in

making:

PARTS

up

into

the

part

and

groups.

DESCRIPTION

Parts-

Shaft

Group.

Drive

Drive

11

Dial

made

#1,

#2

scarfs,

Slips

Housecoats

Play

Suits

groups,

to

be

Head

Group.

Group.

Stitch

Depth

for

and

and

and

ordered

OF

and

Arm.

Adjustment

rolled

#3,

for

for

heavier

these

is

GROUP

edges

or

hand

producing a rolled

materials,

Handkerchiefs

Table

Napkins,

groups

located,

are

find

Group.

rolled

Cloths

shown

the

part,

such

etc.

below.

hems.

edge

as

and

on

light

Turn

order

the

20

PLATE

13

16 68

18 72

21

22

24

26

ADDITIONAL

Refer

STITCH

RIB

10

and

LENGTH

Set

Set

11,

Figure

PAGE

---

62

78

80

84

88

ADJUSTMENTS

to

timing

for 6 stitches

rib . 093

(3/32

5.

Presser

Work

Feed

Knee

Folders.

Rib

Feed

chart,

per

11

)

COLUMBIA

DESCRIPTION

Foot

Apron

Platten

Lift

Group.

Shaft

FOR

page

inch,

from

Group.

Points.

MODEL

10.

#5

right

on

Group.

Group.

Group.

300-10

feed

hand

MODEL

regulator,

side

of

300-10

cloth

Adjustment

opening

in

6,

Figure

presser

7.

foot,

·c

c

Adjustment

c

CLOTH

retainer

FEED

Set

end

FEED

in

the

presser

NEEDLE

hand

stroke,

arm,

foot,

and

and

RETAINER

Set

cloth

even

with

Rotate

of

feed

Set

depth

PLATTEN

Set

left

foot.

STROKE

Rotate

insert

set

the

tighten

hand

3/64

hand

hand

point

clamp

spring

right

side

wheel

11

from

of

feed

sidE.

Adjustment

wheel

needle

of

screw.

retainer

of

in

clockwise

back

11

1/32

of

slot

in

clockwise

in

the

needle

as

close

rib,

side

of

needle.

below,

in

9,

needle

even

Adjustment

and

feed

Figure

direction

arm,

with

to

the

direction

parallel

platten

5.

and

the

left

5,

Figure

needle

until

1/

64"

until

clamp.

hand

with

from

the

5.

as

end

bottom

needle

Loosen

side

possible

of

feed

of

the

left

of

looper

with

is

the

hand

arm

clamp

right

nearest

foot.

side

is

at

screw

opening

the

hand

to

of

in

the

cloth

end

of

the

side

needle.

opening

of

its

needle

presser

of

left

a

a

21

right

11/16

not

HOO

side

Continue

hand

11

to

3/4

correct,

FOLDER

When

of

the

Set

end

11

reset

cloth

stitch

to

of

its

from

roll

opening

rotate

stroke.

the

by

using

edging

length

COLUMBIA

hand

wheel

The

point

right

hand

eccentric

with

#00

in

the

presse'r

for 8 stitches

in

of

side

of

ball

folders,

foot.

per

MODEL

clockwise

the

needle

the

cloth

stud.

the

rib

inch,

300-10

direction

when

opening

Adjustment

must

be

H4

on

feed

so

in

this

in

the

4.

Figure

set

.

regulator.

that

needle

position

presser

047

(3/64

is

at

should

foot,

2.

11

)

from

Adjustment

the

extreme

be

from

check,

the

6,

and

right

Figure

if

hand

7.

22

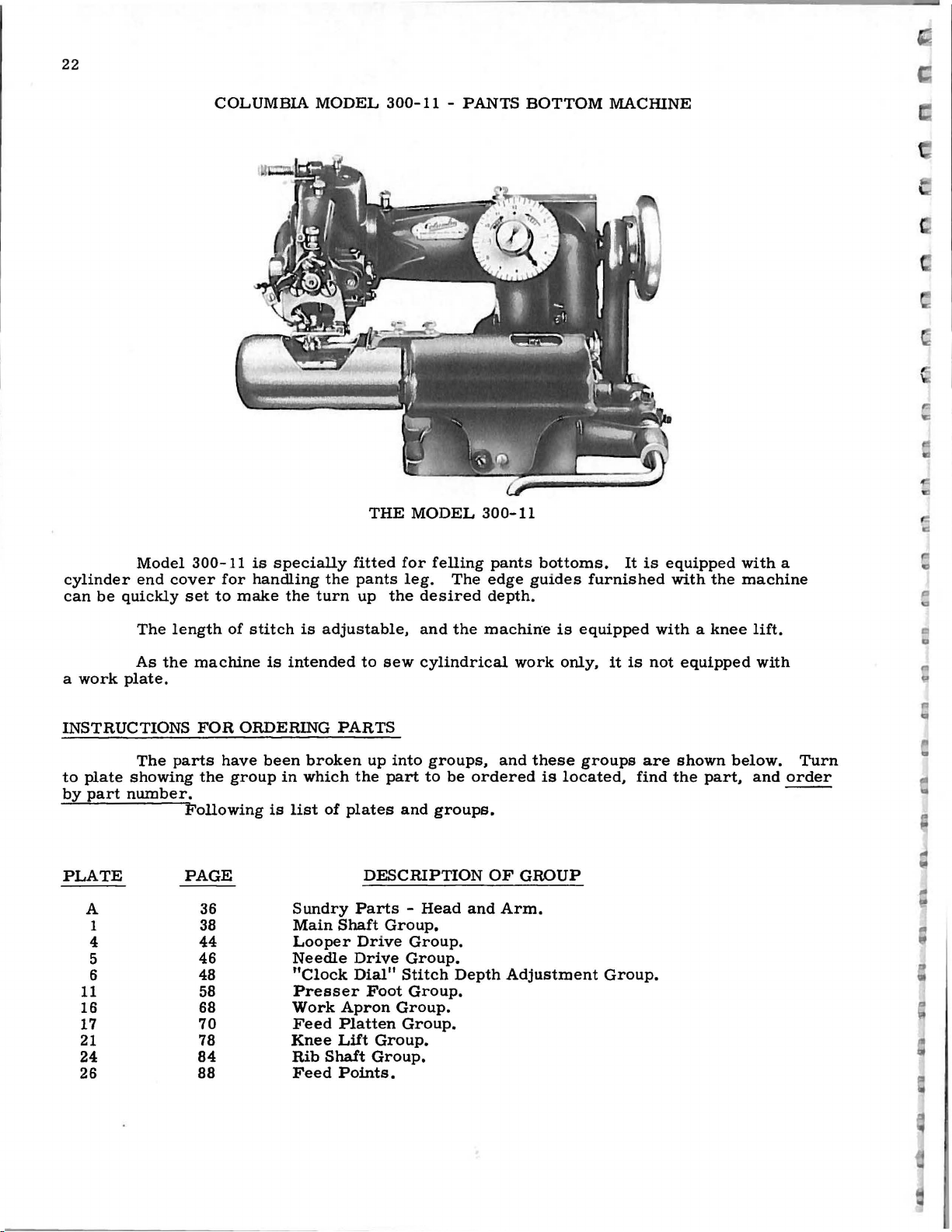

COLUMBIA

MODEL

THE

300-11 -PANTS

MODEL

300-11

BOTTOM

MACHINE

Model

cylinder

can

a

work

be

end

quickly

The

As

the

plate.

cover

length

INSTRUCTIONS

The

parts

to

plate

showing

by

part

number.

PLATE

A

1

4

5

6

11

16

17

21

24

26

300-11

for

set

to

make

of

stitch

machine

FOR

ORDERING

have

the

group

Following

PAGE

36

38

44

46

48

58

68

70

78

84

88

is

specially

handling

the

is

is

intended

been

broken

in

which

is

list

Sundry

Main

Looper

Needle

"Clock

Presser

Work

Feed

Knee

Rib

Feed

fitted

the

pants

turn

up

adjustable,

to

PARTS

up

the

of

plates

DESCRIPTION

Parts -Head

Shaft

Drive

Drive

Dial"

Foot

Apron

Platten

Lift

Group.

Shaft

Group.

Points.

for

leg.

the

desired

and

sew

cylindrical

into

part

and

Group.

Group.

Group.

Stitch

Group.

Group.

Group.

felling

The

the

groups,

to

be

groups.

Depth

pants

edge

depth.

machine

and

ordered

OF

and

Arm.

Adjustment

bottoms.

guides

is

work

these

is

GROUP

furnished

equipped

only,

it

groups

located,

Group.

It

is

equipped

with

with a knee

is

not

are

find

the

the

equipped

shown

part,

with

machine

lift.

with

below.

and

a

Turn

order

23

ADDITIONAL

Refer

STITCH

LENGTH

Set

Figure

7.

RIB

Set

presser

foot,

ADJUSTMENTS

to

timing

machine

rib

to

. 045 ( 3 I

sew 6 stitches

64

Adjustment

chart,

11

)

10

COLUMBIA

FOR

page

from

and

11,

MODEL

10.

per

right

hand

Figure

MODEL

300-11

inch.

side

5.

300-11

(No. 5 on

of

rib

to

feed

left

regulator).

hand

side

Adjustment

of

cloth

opening

6,

in

the

24

COLUMBIA

MODEL

300-12 -FACING-

THE

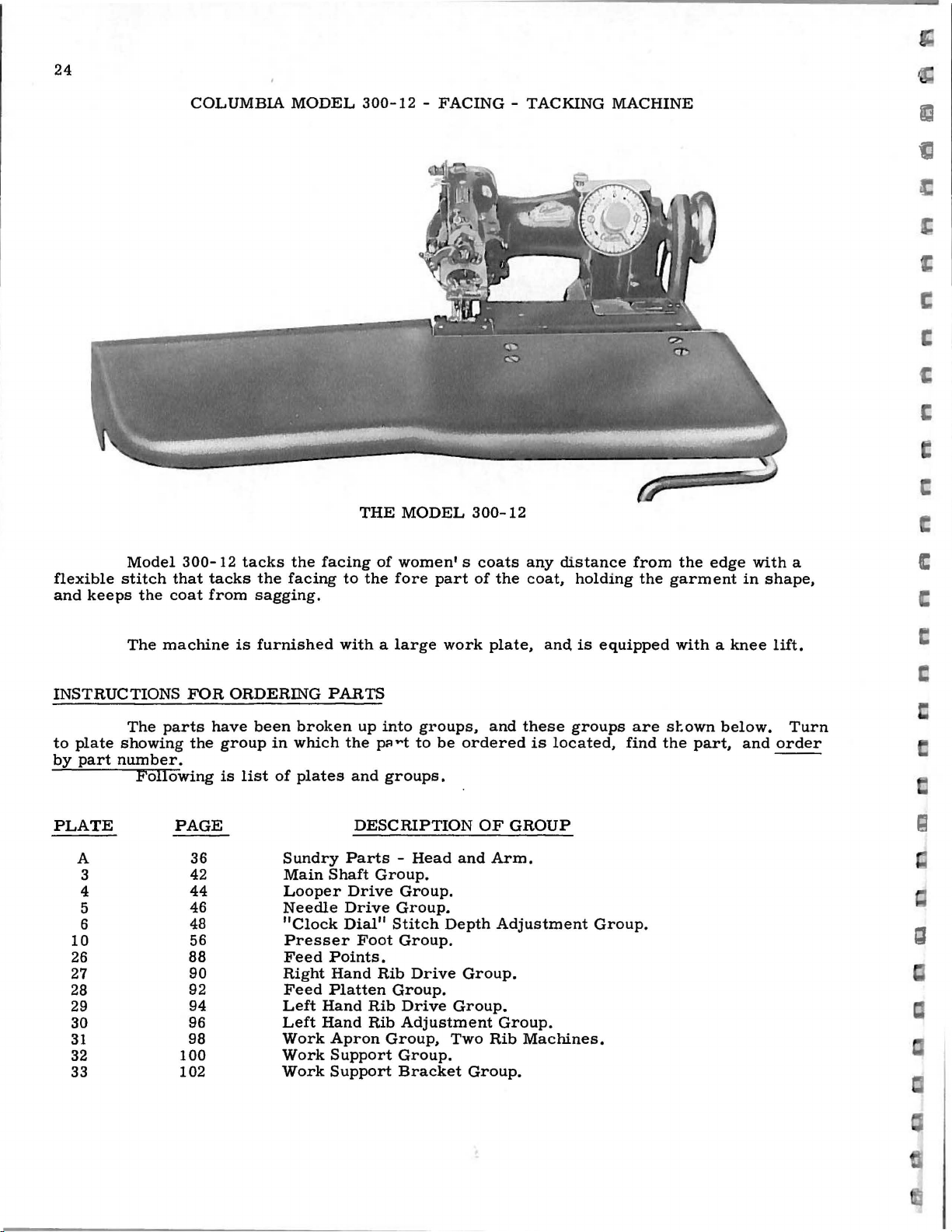

MODEL 3 00-12

TACKING

MACHINE

Model

flexible

and

INSTRUCTIONS

to

by

PLATE

10

keeps

plate

part

A

3

4

5

6

stitch

the

The

machine

The

parts

showing

number.

Following

coat

26

27

28

29

30

31

32

33

300-12

that

FOR

the

PAGE

36

42

44

46

48

56

88

90

92

94

96

98

100

102

tacks

tacks

from

the

sagging.

is

furnished

ORDERING

have

been

group

is

list

the

facing

broken

in

which

of

plates

Sundry

Main

Looper

Needle

"Clock

Presser

Feed

Right

Feed

Left

Left

Work

Work

Work

facing

PARTS

Shaft

Points.

Hand

Platten

Hand

Hand

Apron

Support

Support

of

to

the

with a large

up

into

the

p;P·t

and

groups.

DESCRIPTION

Parts -Head

Group.

Drive

Drive

Dial"

Stitch

Foot

Rib

Group.

Rib

Rib

Group,

women's

fore

part

work

groups,

to

be

ordered

and

Group.

Group.

Depth

Group.

Drive

Drive

Adjustment

Group.

Bracket

Group.

Group.

Two

coats

of

the

plate,

and

OF

GROUP

Arm.

Adjustment

Group.

Rib

Group.

any

distance

coat,

these

Machines.

and

is

located,

holding

is

groups

from

the

equipped

are

find

Group.

the

edge

garment

with a knee

sl:own

the

below.

part,

with

in

and

a

shape,

lift.

Turn

order

c

c

c

25

ADDITIONAL

Refer

STITCH

LENGTH

Set

PRESSER

FOOT

See

NEEDLE

STROKE

Set

side

of

cloth

for

all

Models.

LOOPER

ADJUSTMENT

Looper

ADJUSTMENTS

to

timing

machine

General

point

opening

to

sew 3 stitches

Instructions

of

needle

to

the

Adjustment

adjustments

chart,

when

point

COLUMBIA

FOR

page

for

at

of

5,

Figure

are

the

MODEL

10.

per

all

Models.

right

hand

the

needle,

5.

same

MODEL

300-12

inch,

as

in

119

on

end

of

stroke,

otherwise

General

300-12

feed

regulator.

the

Instructions

5/8

same

Adjustment

11

to

as

21/32

in

for

11

from

General

all

Models.

6,

Figure

right

hand

Instructions

7.

RIBS

fabric

apron.

to

the

SET

RIGHT

side

of

shafts

correct

arm,

set

screw.

pin.

Figure

directly

rod

clamp

There

to

the

needle,

The

right

needle,

HAND

Set

position

cloth

opening

set

s~rews.

position.

Set

height

Adjustment

The

Turn

the

5,

leaves

over

the

screw,

are

two

hand

and

penetration

RIB

Adjustment

of

8,

Figure

knob with

dial

contact

right

Adjustment

ribs

and

penetration

rib

of

right

in

the

right

knob

with

hand

in

the

raises

is

hand

presser

hand

4.

Set

pointer

in

"LESS"

the

rib,

14,

Model

is

the

regulated

rib . 089

foot.

9,

Figure

rib

as

pointer,

can

apron.

remove

Figure

300-12

regulated

folded

by

11

(3/32

The

5,

follows:

or

now

be

direction

Turn

cover

5,

and

machine.

by

facing,

dial

11

setting

and

sliding

First.

hand

turned

until

the

on

rotate

the

including

knob

)

from

is

on

without

the

hand

top

of

The

dial

knob

on

the

right

made

the

work

loosen

top

of

the

the

adjustment

wheel

the

apron

right

hand

left

on

the

body

arm.

hand

by

loosening

apron

two

stop

pointer

until

rib

hand

side

set

rod,

the

and

the

fabric

until

screws

pin,

striking

needle

loosen

so

lower

that

rib

raises

part

(3

ply

of

rib,

to

the

two

the

rib

in

dial

and

tighten

the

Adjustment

point

rib

connecting

the

point

the

of

of

right

work

is

knob

stop

12,

is

body

the

material)

hand

apron

in

on

one

of

the

26

needle

needle