colorFabb FL6000 data sheet

Technical Data Sheet

Eastman Amphora™ Flex 3D Polymer FL6000

Application/Uses

Production of 3D Printing filaments

Key Attributes

Dimensional stability

Enhanced aesthetics

Excellent Temperature Resistance

Excellent toughness

Extended Processing Window

Low odor

Property retention in 3D applications

Steam Sterilizable

Styrene-free

Workability

Product Description

Eastman Amphora™ Flex 3D polymer FL6000, a flexible material uniquely engineered for

extrusion-based additive manufacturing processes. Amphora Flex FL6000 is a polymer that can

be used with standard 3D printers—e liminating the need to sw itch to specialized flex

extruders. Thanks to exceptional layer-to-layer adhesion and melt strength, it prints at a

faster speed than other elastomeric materials, saving you time. Amphora Flex FL6000 is an

engineering-grade material that demonstrates superior durability and toughness, enabling

designers to quickly create truly functional parts that can withstand the rigors of everyday

use. Amphora Flex FL6000 is highly useful for applications that demand both the durability of

an engineering-grade polymer and the comfort and utility of a flexible material. With a Shore A

hardne ss level of 95, outstanding chemical resistance, and a temperature resistance that

allows steam sterilization, users may find it to be the ideal polymer for additive manufacturing

of prosthetics, orthotics, automotive parts, apparel, tooling, or a variety of consumer products.

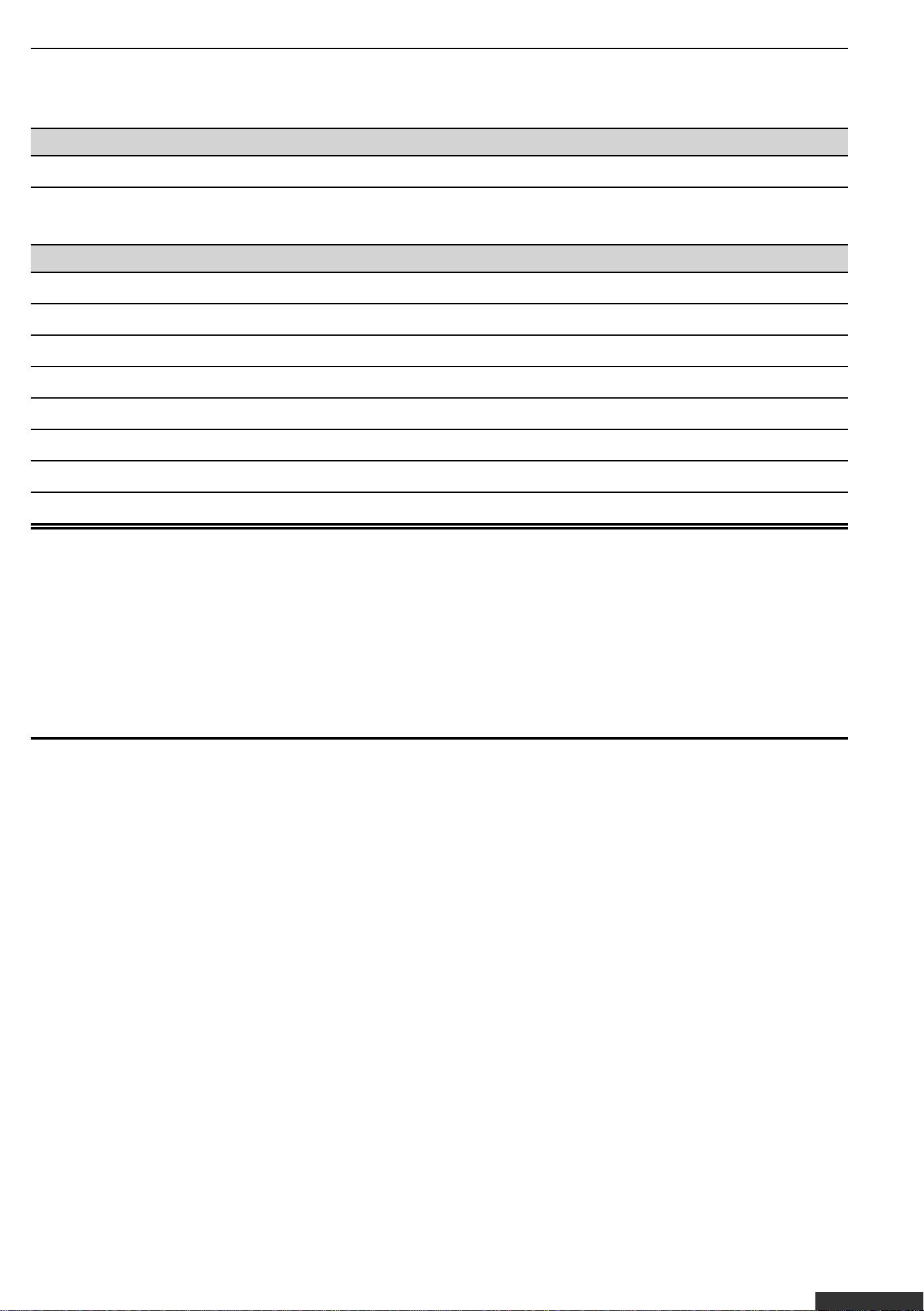

Typical Properties

Property

a

Test

b

Method

Typical Value, Units

c

General Properties

Specific Gravity

D 792

1.13 g/cm

3

Mechanical Properties

Tensile Stress @ Yield

D 638 14 MPa (2030 psi)

Tensile Stress @ Break

D 638 22 MPa (3200 psi)

Elongation @ Yield

D 638 38%

Elongation @ Break

D 638 400%

Flexural Modulus

D 790 150 MPa (21750 psi)

Tear Strength

D 1004 350 N (79 lbf)

Durometer Hardness

Shore D Sc ale

D 2240 55

pdfcrowd.com

Shore A Scale

D 2240 95

Izod Impact Strength, Notc hed

@ -40°C (-

40°F)

D 256 40 J/m (0.75 ft·lbf/in.)

Thermal Properties

Brittleness Temperature

D 746 <-70°C (<-103°F)

Vicat Softening Temperature

@ 1 kg load

D 1525 170°C (338°F)

Typical Processing Conditions

Processing Melt Temperature

240-260°C

Heated Bed Temperature

d

80°C

Cooling

0 to 50%

Layer Height

0.1 or 0.2 mm

Speed

30 to 50 mm/s

Infill

As needed up to 100%

Perimeter

Around 1 mm

Minimal Layer Time

5 sec

a

Unless noted otherwise, all tests are run at 23°C (73°F) and 50% relative humidity.

b

Unless noted otherwise, the test method is ASTM.

c

Units are in SI or US customary units.

d

Will most of the time require BuildTak(TM) support to promote the best adhesion.

Comments

Properties reported here are typical of average lots. Eastman makes no representation that

the material in any particular shipment will conform exactly to the values given.

Eastman and its marketing affiliates shall not be responsible for the use of this information, or of any

product, method, or apparatus mentioned, and you must make your own determination of its suitability and

completeness for your own use, for the protection of the environment, and for the health and safety of your

employees and purchasers of your products. No warranty is made of the merchantability of fitness of any

product, and nothing herein waives any of the Seller's conditions of sale.

12-Sep-2016 7:30:52 AM

pdfcrowd.com

Loading...

Loading...