l

t

Collins Government

Telecommunications

Group

Revision, 1

3rd

523-0556933-302831

April

10

August

1969

1977

,F

Rockwell

lnternational

Collins

Rotatable

Collins Government

(\

_j

--:

\_-

:_.

-

4'l

/4Ta

'\

.z t

\- ri

\

\-

&,5^

instruction book

2378,-3

Directional

HF Antenna

Telecommunications

Rockwell I nternationa!

Printed in

!.

,

Dallas,

, :

Texas

United States of America

Group

25207

"

;P,,

E't

t

,s'-'

nn,

,

Ziqarfi:3iqq

3A

f-t,

{t'ltii

>T

2,1

o'r'v,€

1c"'i.:3c7i

tt;

Q

Eefl''

Q

(?

c;u/(

';

W*

i,^,

b

i

\

'..

[ltr-c-

Qttl

\)),'qY'

r,fry

'-

,R\)lgvrl

h\

c

lt

BE

e

-Jct-3

.,{,J.-\r-

))i ::

r-

fl

"14

ls'Y

*,-\.,'.

-.,fX,

tahle of

eontents

Page

Section

1.1

1.2

1. 3

1.4

1.

1.6 Optional

1.7 Items

1. 8

1. I Service

Section 2 lnstallation ... .

2.1

2.2

7 General Descnption

Purpose of This

Purpose

Equipment Description

SpecificationSummary

Equipment Supplied

5

Packing Dimensions and

General

Site Selection. .

Equipment . . .

of

Equipment

Required

Information

2.3 Foundation and

Construction....

2.4

2.5

2.6

2.7

2.8

Assembly

Installation of

Transmission

Antenna

Erection

Stowing of

2.9 143A-3

2.10 Radio

of the Tower

Array Installation

the Tower

of

Antenna

Rotator Control Unit

Frequency Interference

Book .

But Not Furnished

Shipping Data.

.

Assembly Anchor

Guy

Rotator

Line Kit . .

Kit. Control

.

Kit

Installation

Kit

Point

and

1-1

1-1

1-1

1-1

1-1

l-4

l-4

l-4

l-4

l-4

2-l

2-l

2-t

2-l

2-2

Rf

2-14

2-25

2-26

2-30

2-30

2-30

Section

3.1

3.2

3.3

3.4

3.5

Section

Operating Instructions

3

General

Operation

LocaI

Remote

Control

143A-3

Stowing of

Theory

4

Operation From

Antenna Rotator Control Calibration

Antenna

oJ Operation

4.1 General

4.2 Local Rotator

4.2.1

4.2,2

4.3

4.3.

General

Operation

Remote

Control

1 General

4.3.2 Operation

the t43A-3

Controt Circuit

Circuit

Antenna Rotator

(Tower

Base) .

3-1

3-1

3-1

3-1

3-1

3-52l3-6

4-l

4-l

4-l

4-l

4-2

4-2

4-2

4-2

table of

eontents (cont)

Sectionslilaintenance....

5.1

5.2

5.2.1

5.2.2

5.3

5.3.1

5.3.2

5.3.3

5.3.4

5.3.5

5.4

5.4.1

5.4.2

5.4.3

5.4.4

General

Lubrication

Rotator

Erecting

Winch and

Inspection

Antenna Tower

and Guy Cables

Rotator

Antenna

The 143A-3

Obstruction

Antenna Tower

Array

Antenna Rotator

Light

Coating/Painting

SurfacePreparation....

Pre-Primer Coat

Primer Coat

Top Coat

(CPN

(CPN

005-1494-xxx)

Pulley Block

Control

.

Control

(CPN

005-1494-010)

. 5-3

'

005-1494-070)

..

Page

5-1

5-1

5-1

5-1

5-1

5-1

5-1

5-2

5-2

5-3

5-3

5-3

5-5

5-5

5-6

list of

Figure

1-1

l-2

2-l

2-2

2-3

2-4 Rotator

2-5 Rotator

2-6

2-7 Instal}ation of

2-8 Installation of

2-9 Installation of

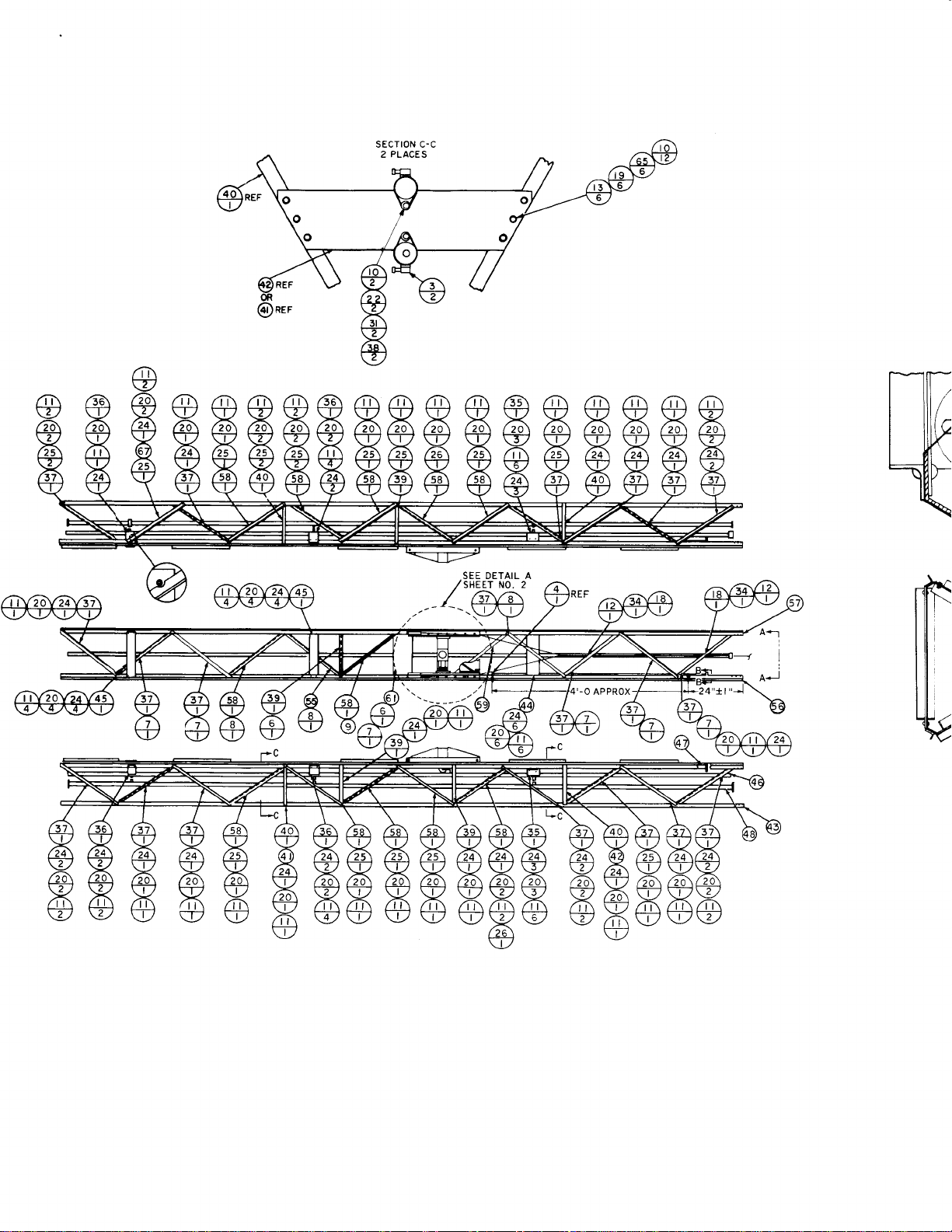

2-10 Boom

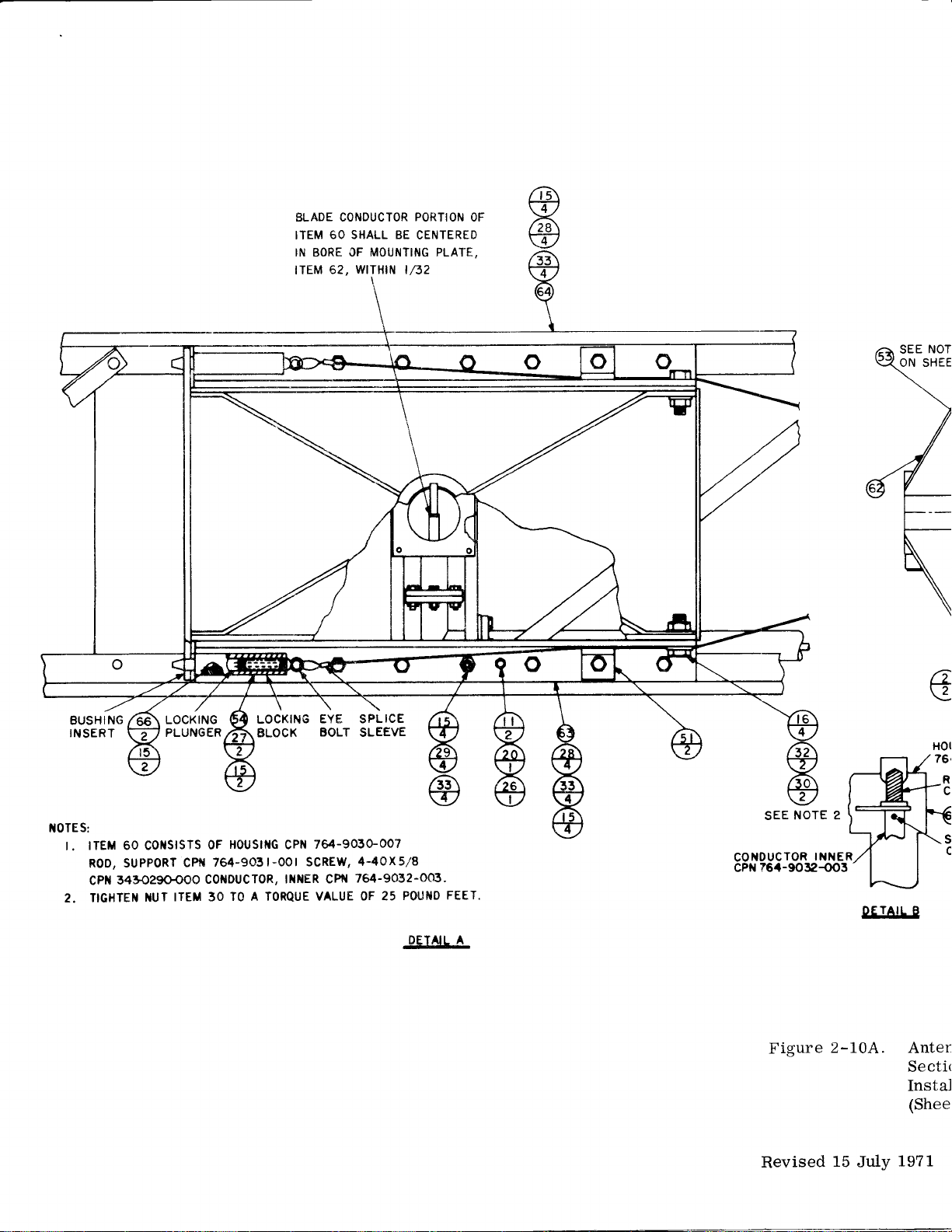

2-10A Antenna Array Center Boom

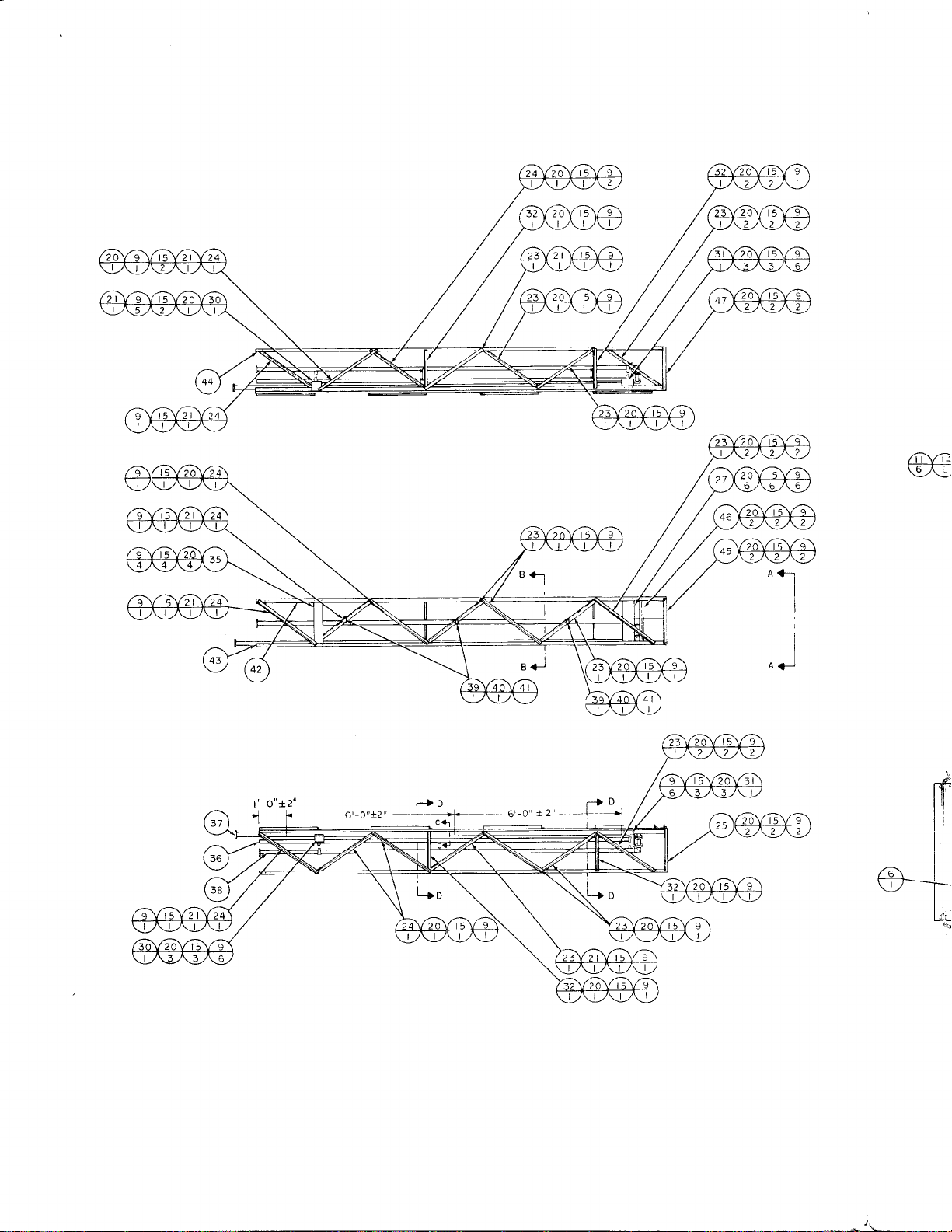

2-ll Boom Assembly,

2-12 Boom

2-l2A

2-13

illustrations

2378-3 Rotatable

143A-3

Anchor

Anchor and Foundation

Installation

Antenna Rotator

and

Assembly

Heater Kit Instaltation

Installation of

Assembly,

Latching Assembly,

Assembly, Rear.

Antenna Array,

Balun Components .

Installation of

Directional

Foundation

Erection Kit

of

Rotator

Rotator Control

Obstruction

RF Transmission

Center

Installation

Front

Transmission

..

Antenna Array

Control

Details

Details

Kit . .

.

Antenna

HF

(3000-PSF

(1000-PSF

..

Kit. . .

Lighting Kit .

Kit ..

Line

Section

and

Details

and

Soil)

Soit)

.

.

.....

.. .

Page

1-0

l-2

2-3/2-4

2-7/2-8

2-9/2-10

2-15/2-16

2-17/2-18

2-19/2-20

2-21/2-22

2-23/2-24

2-25

2-27/2-28

2-30A/2-308

2-31/2-32

2-33/2-34

2-34A/2-348

2-35/2-36

ii

Revised 15 JuIy

19?1

list of

illustrations

(cont)

Figure

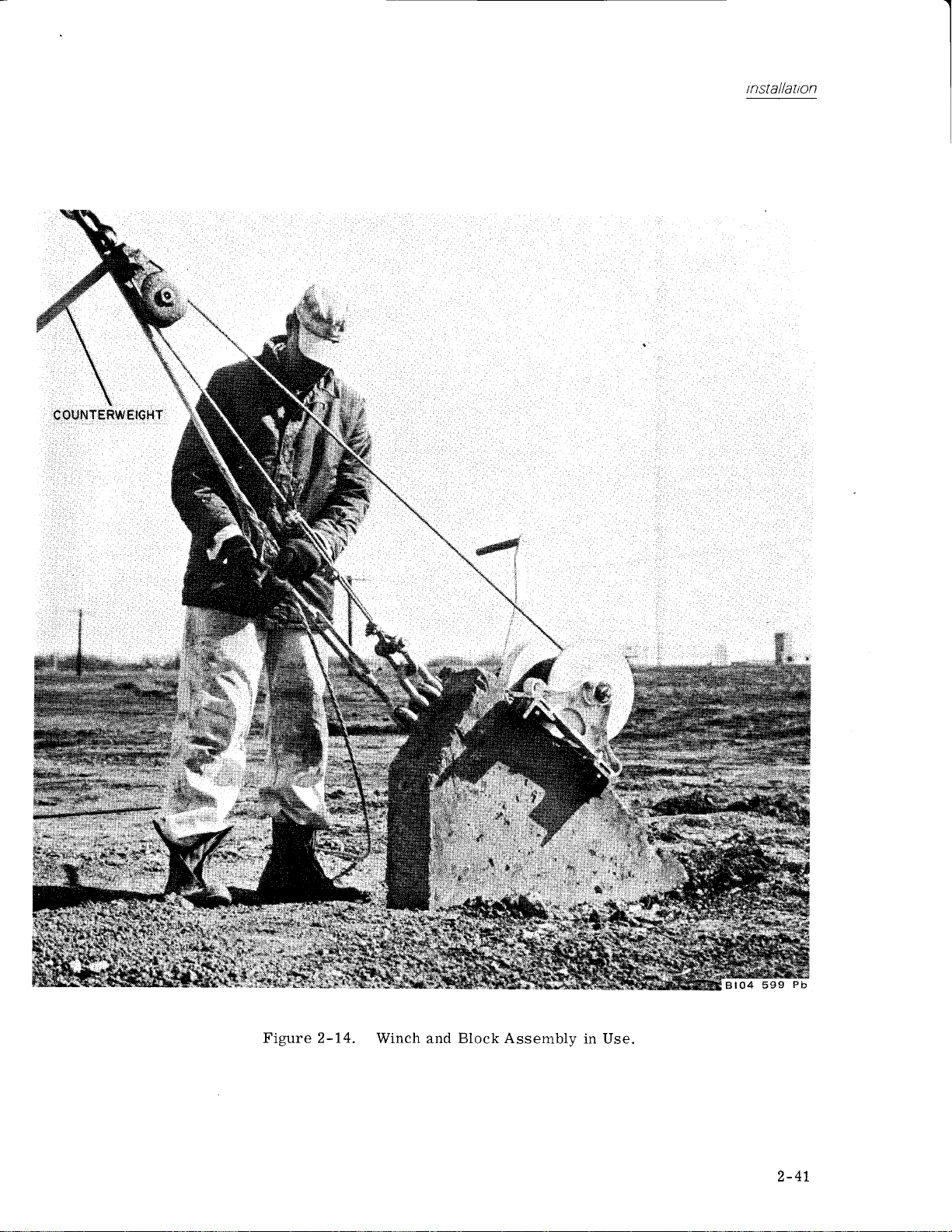

2-14

2-15

2-16

2-17

2-18

Winch and

Antenna

InstaIled

Antenna

Antenna

Antenna Raising

2-19 Radio

3-1

3-2

4-l

4-2

4-3

4-4

4-5

4-6

4-7

4-8

4-9

5-1

Local Control

143A-3

Indicators

237B-3

6.5-MHz

10-MHz

20-MHz

30-MHz

40-MHz Elevation

Azimuth

Plot of Vertical

143A-3

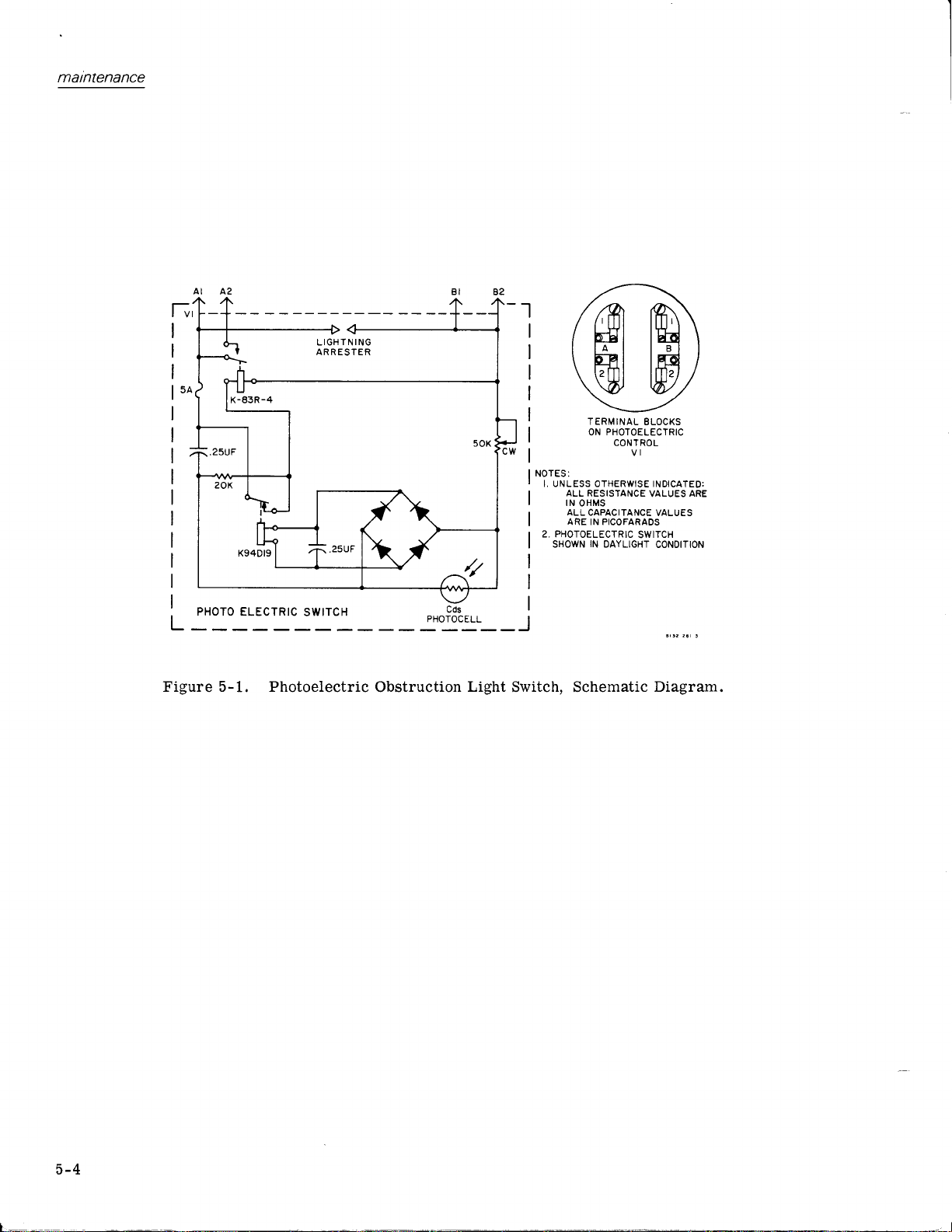

Photoelectric

Diagram

Block Assembly

Lowered

in

During

During

Frequency

Erection

Erectlon

and

Unit,

Antenna

Directional

Elevation

Elevation

Elevation

Elevation

Plane

Antenna

Rotator

Patterns,

Angle Versus

Rotator

Obstruction

in Use

Position With

With Array

With

Lowering

Interference

Controls

Control,

HF Antenna,

Plane

Plane

Plane

Plane

Plane

Patterns,

Patterns,

Patterns,

Patterns,

Patterns,

237B'-S Antenna

Control,

Light Switch,

Erecting

Hinging

Array

Checklist

Locked

Placard

Kit Installation

and Indicators

Controls and

Design

Frequency

Schematic

Parameters

237B-3

237B-3

237B-3

2378-3

2378-3

Schematic

Mast

Detail

Antenna

Antenna

Antenna

Antenna

Antenna

. . . ..

...

. . . .

. .

. .

Diagram . ..

.. . .

. . . .

. . .

. . .

Page

2-4t

2-42

2-43

2-44

2-45

46

2-

3-2

3-4

4-2

4-3

4-7

4-3

4-4

4-4

4_5

4_5

4-6

/4-8

'.

.

5-4

Table

1-t

l-2

1-3

3-1

3-2

5-1

5-2

5-3

Equipment

Optional

Packing

Loca1

143A-3

Supplied

Equipment

Dimensions

(Tower

Antenna

Indicators

Recommended

Spraying

and

Spraying

Equipment,

Carboline

Equipment,

Base)

Rotator

Tower

1294

Shipping

and

Controls,

Control,

Coatings

Carboline

Coat

ToP

Rustbond

Data

Fuses and

Controls

WP

1037

Primer

6C . . .

list of

Indicators

and

Primer

Wash

...

tahles

Page

r-5/t-6

'

5-7

/5-8

5-7

/5-8

l-4

l-4

3-3

3-3

5-6

1r1

general

descrrptton

1-0

Figure

si-)

ts*

k\

t$

ti

ti

I t;i

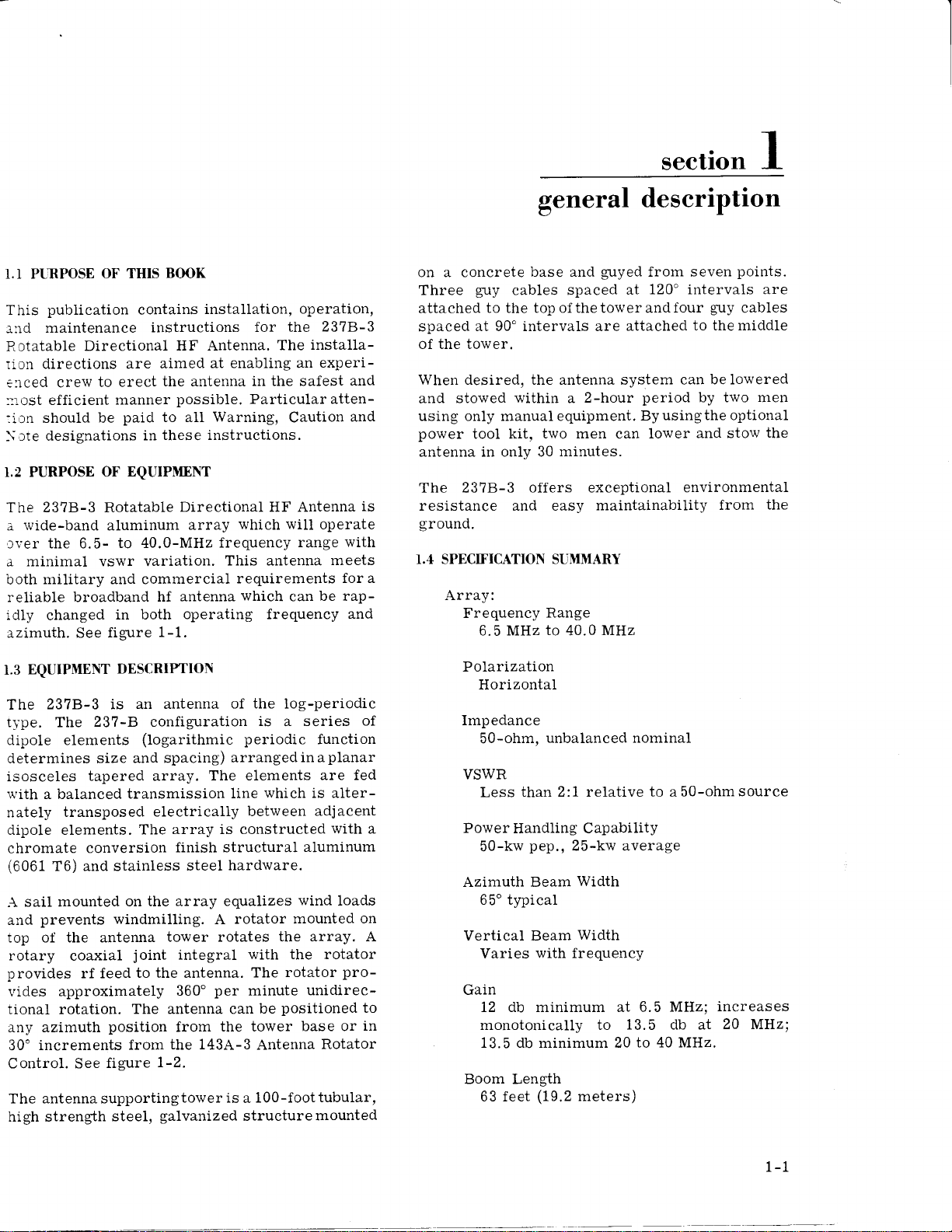

1-L. 237B-3 Rotatable Directional HF

Antenna.

seetion

I

BOOK

1.1 PLIRPOSE OF

publication

This

maintenance

a:rd

Rotatable

directions are

rion

elced crew

::.:.ost efficient

:1on should be

designations

\,:te

1.2 PURPOSE OF

THIS

contains

instructions

Directional

aimed

to erect

manner

paid

in

EQUTPMENT

the antenna

to all

these instructions.

The 23?B-3 Rotatable

wide-band

a

:ver the 6.5-

minimal vswr variation.

a

military and commercial

both

reliable broadband

idly

changed

azimuth. See

aluminum

to 40.0-MHz

hf

in both

figure

1-1.

installation,

HF Antenna.

at enabling an

in the safest

possible.

Directional HF Antenna

array

Particularatten-

Warning,

which

frequency

This antenna

requirements

antenna

which

operation,

the 2378-3

for

installa-

The

Caution

will

range

can

experi-

operate

meets

be rap-

operating frequency

and

and

is

with

for a

and

general

on a concrete

Three

attached to the

spaced

of the tower.

When desired, the antenna system can

and

using only manualequipment.

power

antenna in only 30

guy

at 90' intervals are

stowed

tool kit,

The 2378-3 offers exceptional

resistance and easy

ground.

base and

cables spaced

topofthetowerandfour

within

2-hour

a

two men

minutes.

deseription

guyed

maintainability

frotn seven

120" intervals are

at

attached

period

Byusingtheoptional

lower

can

environmental

f.4 SPECIFICATION SUMMARY

Array:

Frequency

6.5 MHz

Range

to

40.0

MHz

points.

guy

cables

to the middle

be lowered

by two men

from

the

the

and stow

EQUIPMENT

1.3

2378-3 is an

The

tl'pe. The

dipole elements

determines size

isosceles

rvith

a balanced

nately

transposed

dipole elements.

chromate

(6061

T6) and stainless

sail mounted

A

prevents

and

top of the antenna

rotary

provides

vides

tional rotation.

any azimuth

30o

Control. See

The antenna supportingtower

high strength

approximately

increments

DESCRII"IION

antenna

237-8 configuration

(logarithmic periodic

and spacing)

tapered array.

transmission

electrically

array is constructed

The

conversion

on the array

windmilling. A

coaxial

rf feed

position

figure

steel,

finish structural

steel

tower rotates

joint

integral

to the antenna.

360'

The antenna can

from

the 143A-3

from

1-2.

galvanized

of the

arrangedinaplanar

log-periodic

is

series

a

The elements

which

line

between

is alter-

aluminum

hardware.

equalizes

rotator

with the rotator

per

minute

the tower

is

a

structure

wind

mounted on

the array. A

rotator

The

unidirec-

positioned

be

base or

Antenna

100-foottubular,

of

function

are fed

adjacent

with

a

loads

pro-

to

in

Rotator

mounted

Polarization

Horizontal

Impedance

50-ohm,

VSWR

Less

PowerHandling

50-kw

Azimuth Beam

unbalanced nominal

than 2:1 relative

Capability

pep.,

25-kw average

Width

65'typical

Vertical Beam

Varies

Gain

Width

with frequency

72 db minimum at 6.5

monotonically to

13.5 db minimum 20

Boom Length

(19.2

63 feet

meters)

to

a50-ohmsource

MHz;

13.5 db at

to 40 MHz.

increases

20 MHz;

1-1

general

descnPtlon

F

:f

9o

JC

FJ

z()o

oqe

-JF

*"*;5

H

ai

-E5u

x

(}

cm

o

Edt

UF

&7

o

o

6

a

a

>U

63

ro

or

z

x

(D

*<)

iitr

v=

<{

t

E

(B

)

x

o

fi

T

E

td

:a

(r,

I!

g0

=

z*.

()o

F

Ir<

()

trt

35

o2

{L-

ldy

tLLL

(\lNN

3=

o=

a-a

)

(J

rr- E

L l"rl

o

oa

J

&, tf)

)a

()

1

z

Lrl

o

z.

o

l,

F

:E

&

6

m

t-2

()

*8

Z

(/)I]J

\2

e2

98

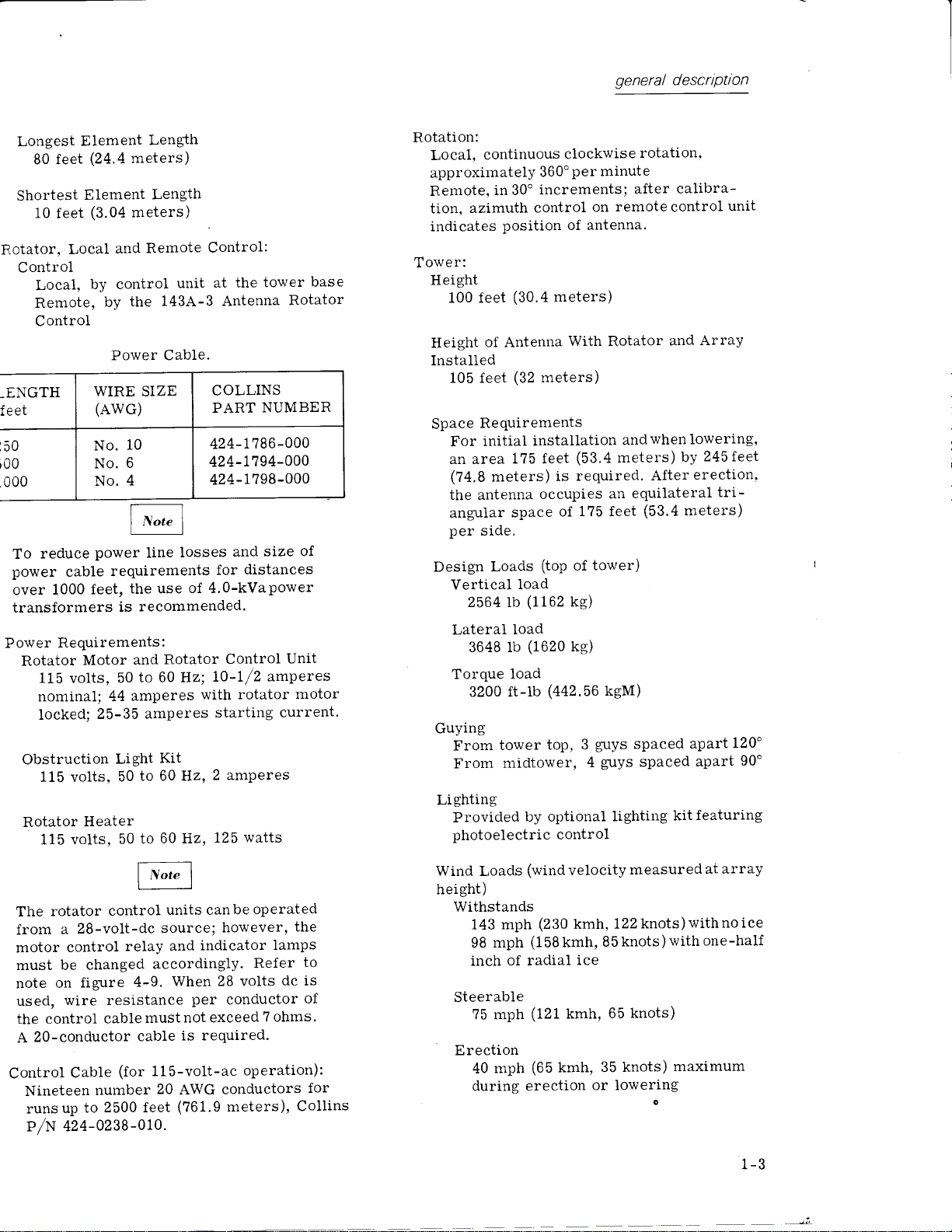

Figure

1-2.

143A-3 Antenna

Rotator Control.

general

descrlptlon

Longest

80 feet

Shortest

10

feet

Rotator,

Local

Control

Local,

Remote,

Control

ENGTH

eet

t50

r00

.000

reduce

To

power

over

cable

1000

transformers

Power

Requirements:

Rotator

115

volts,

nominal;

locked;

Obstruction

115 volts,

Rotator

115 voIts,

Element

(24.4

meters)

Element

(3.04

meters)

and

by control

the

by

Power Cab1e.

WIRE SIZE

(Awc)

10

No.

6

No.

4

No.

power

requirements

the use

feet,

recommended.

is

Motor

and

to 60 Hz;

50

amperes

44

25-35

Lighi

to 60 Hz,

50

Heater

to

50

Length

Length

unit

Control:

at the

Remote

143A-3 Antenna

COLLINS

PART

424-t786-000

424-7794-000

424-1798-000

line

losses

and size

for

of 4,0-kVapower

Rotator

Control

lO'lf2

rotator

with

amperes

Kit

60 Hz,

starting

2 amPeres

125

tower

Rotator

NUMBER

distances

Unit

amperes

motor

current'

watts

of

base

Rotation:

Local,

continuous

approximately

Remote,

azimuth

tion,

indicates

Tower:

Height

100 feet

Height

of Antenna

Installed

105 feet

Space

Requirements

initial

For

an area

(?4,8

the antenna

angular

per

sj.de.

Design

Vertical

2564 rb

Lateral

3648 lb

Torque load

3200 ft-lb

Guying

From

From

Lighting

Provided

photoelectric

clockwise

Per

minute

on

in 30o

360"

increments;

control

position of antenna.

(30.4

meters)

With Rotator

(32

meters)

installation

1?5 feet

meters)

space

Loads

load

(1162

load

(1620

tower

midtower,

by optional

(53.4

required.

is

occupies

1?5 feet

of

(top

of

ke)

kg)

(a42.56

3

top,

tower)

guys

4

kgM)

guys

control

rotation.

after calibra-

remote

andwhen

control

and

meters)

After

equilateral

an

(53.4

spaced

spaced

lighting

kit

Array

lowering,

245feet

by

erection.

tri-

meters)

apart

apart

featuring

unit

120"

90'

rotator

The

a

from

motor

must be

on

note

used,

the control

20-conductor

A

Control

Nineteen

up

runs

control

28-vo1t-dc

control

changed

figure

wire resistance

cable

Cable

number

2500 feet

to

P/N 424-0238-010.

units canbe

source;

relay

accordingly.

4-9.

must

cable

(for

115-volt-ac

20

operated

however,

indicator

and

Refer

28 volts

When

per

conductor

not exceed

7 ohms.

is required'

operation):

AWG conductors

(?61.9

meters),

the

lamps

dc is

Collins

to

of

for

Wind Loads

height)

Withstands

mph

143

mph

98

of radial

inch

Steerable

?5 mph

Erection

mph

40

during

(wind

veloci.ty

(230

kmh,

(158

kmh,

ice

(121

kmh,

(65

kmh, 35

erection

measured

122knots)withnoice

knots)with

85

knots)

65

knots)

one-half

maximum

or lowering

at array

1.)

t-u

-i,

general

descrrptrcn

r.5 EQUIPMENT

The equipment supplied consists

in table

r.6

The optional equipment available consists

1-1.

OPTIONAL

items listed

SUPPLIED

EQUIPMENT

in table 1-2.

the items

of

For operation of the rotator intempera-

tures below +10'F

mended that the rotator

changed

to a

Molub-Alloy or

Imperial Oil and

Wilshlre

The

optional Rotator

8605

t.7

ITEMS

a.

Site

BIvd, Los

alternative

-002.

REQUIRED

for antenna

(-12.2"C)

lighter

Artic

grade,

Gear

Grease

Angeles

would

be

Heater

BLIT

NOT FURNISHED

it is recom-

gear

oil be

such as

Oil.

Contact

Co.,

California.

to install the

Kit,

CPN 515-

Tabte

6505

1-1.

listed

of the

Equipment

b.

Concrete and

and anchor

C.

Coaxial

transmitter

Andrews He1iax recommended)

d.

Control

control

if remote

dc operation)

Coaxial cable flange,

EIA

Power

f .

r.B PACKING

Packing

nished in table

r.9

SERYICE INFORMATION

Inquiries

be

directed to: HF Antenna Product Line Pro-

gram

International, Dallas,

2

14-690-5029.

-

t,

+:_.2

a,A

Ert:-

iil-

..:

Supplied.

cable

dimensions and shipping data

concerning the

Manager,

.i,o

.z

tl

'.:

reinforcing

assembly encasement

rf transmission

and

antenna base

cable, 18-conductor,

unit

and antenna

steel for tower base

line cable between

(1-5/8-inch,

between remote

(20-conductor

base

control unit is modified for 28-volt-

1-578-inch

to antenna.

DIMENSIONS

1-3.

Collins

*_:

i

;

',

:

l- u

\Lu-.

AND

SHIPPING DATA

237B-3

Radio

Texas

l/,.l.-'l.r;i-

;

Group, Rockwell

,

Antenna

75207. Phone

standard.

fur-

are

should

COLLINS

758-

758

-

515-8012-001

515-8551-001

515-85?6-001

5

15- 8600-00

COLLINS

51 5-8453-001

515-8601-001

51 5-8524-001

51 5-8605-002

51

5

-8606

PART NUMBER NAME

5346-002

5346- 00 1

PART

-001

1

NUMBER

2378-3 Antenna

Antenna array

Tower,

Rotator

Rotator

Rf transmission

Table 1-2.

NAME

Lighting

Power tool kit

Erection kit

Rotator heater

Rfi kit

kit

guy,

md anchor

kit

control kit

line kit

Optional Equipment.

kit

kit

(to

meet MIL I 26-6)

kit

PARTS BREAIOOWN

KIT

REFER TO FIGURE

2-13

,

2-L0

2- 10A, 2- 11,

,

2-12,2-L2A

2-l

2-6

2-7, 4-9

2-9

KIT PARTS

REFER TO FIGURE

2-8

2-3,

sheet

2-3, sheet 1

OR

2-t9

BREAKDOWN

2

1-4

I

Revised

1 December

1975

general

descrrptton

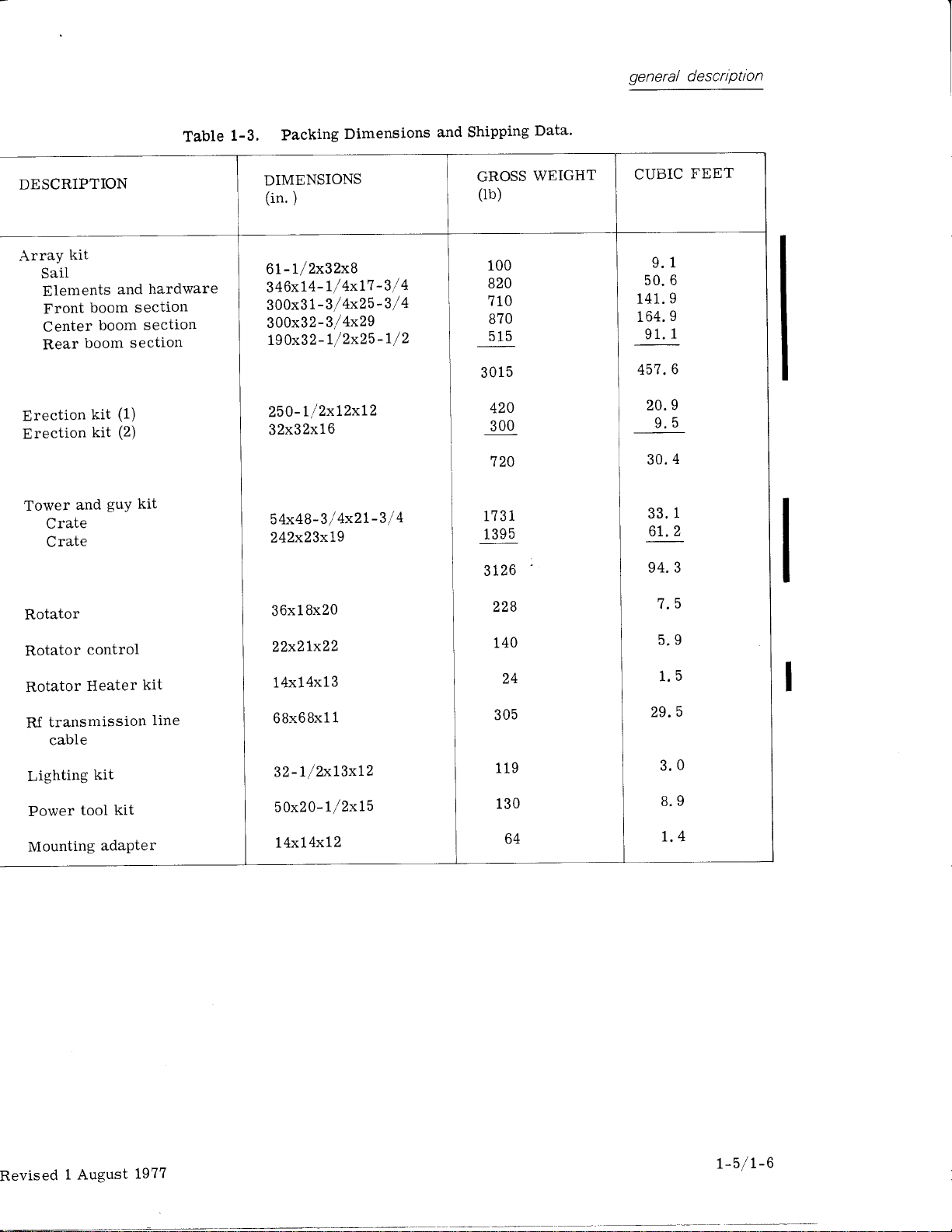

DESCRIPTION

Array

kit

SaiI

Elements

Front

Center

Rear

Erection

rection

E

Tower

boom

boom section

boom

kit

kit

guY

and

Crate

Crate

and

section

section

(1)

(2)

kit

Table

hardware

1-3.

Packing

DIMENSIONS

(in.)

6l-l/2x32x9

346x14-

300x31-3/4x25-3/

3gg1tl-t

190x32-

250-l/2xl2xl2

32x32x16

54x48-3/

242x23x19

Dimensions

t/ 4xl7

i

4x29

-3/

t/2x25-t/2

4x2l-3/

and Shipping

4

4

4

GROSS

(rb)

100

820

710

870

515

5

301

420

300

720

1

173

5

139

3126

Data'

WEIGHT

CUBIC

1

9.

50.6

9

141.

164.9

91.1

6

457.

20.9

9.5

4

30.

33.1

6t.2

94. 3

FEET

Rotator

Rotator

Rotator

R.f transmission

control

Heater

cable

Lighting

Power

Mounting

kit

tool

adaPter

kit

kit

line

Bx20

36x1

22x21x22

14x14x13

68x68x11

32-l/2xl3xl2

50x20-l/2x15

l4xl4xl2

228

140

24

305

119

130

64

7.5

5.9

1.5

29.5

3.0

8.9

1.4

Revised

1

August

1977

r-5

/t-6

seetion

2

installation

ZT GEMRAL

This section

the 2378-3

selection and

Site

should be

contains

Rotatable

performed

installation. Installation

form of

ings

possible,

procedures

ment. In making the

written, step-by-step

pictures.

and

in

are

are

drawings and emphasis

procedure

the

steps. Refer

identification, and

optional

22

Site

factors; only

will

a.

equipment.

SITE SELECTION

selection

be

covered

for

those

Physi.cally, the antenna requires a clear

area,

meters) for

operations.

pies

175

feet

a space

triangle 1?5

installation instructions for

Directional HF Antenna.

training of installation crews

prior

to starting antenna

instructions are in the

procedures,

procedures,

The

chronological

as nearly as

order. Installation

also listed for optional equip-

installation, refer to the

notes

which

to table 1-1 for kit

table 1-2 for a

the

antenna

directly

in this section.

(53.4

meters)by 245 feet

initiai installation and lowering

When

erected,

in the form

(53.4

feet

depends

relating tothe237B-3

the

antenna occu-

of

an equilateral

meters) on

To facilitate accurate vertical

guy

of

should be 1evel

anchor

tower base and

2-L,

sheet

tion in

plans

tion in

2-2,

It is

1,

3000-psf

and construction

1000psf

desirable to

site in order

Other

are ease

of

compllance

tions

airfield

agency.

in

considerations

of

the

antenna

covering

zoning of

possible,

If

locations

access

on or near anairfieldrequires

with

lateral airfield

where

loops,

within

to

guy

anchor

were designed

soil; however,

soil are

to maintain this firmness.

and

civil

the airfield operating

avoid

wind ducting

ground

the

percent.

t2

plans

for

details for installa-

furnished in figure

well drained

choose

in

a

selecting

routing. Siting

cable

or military regula-

clearance

siting

the antenna

may

dralv-

line

accompany

listing

on

placement

selected

of

many

(74.8

side.

a

Antenna

in figure

installa-

alternate

the site

and

occur.

Wind ducting

and./or

antenna structure. Typically,

multipty the

occurs near

can cause severe

wind

effect

cliffs, canyons,

turbulence

on

an exposed

wind

built up

ducting

areas

or rugged terrain.

b. For

the

best site selection electrically, avoid

obj ects in the immediate vicinity

antenna

flect radiated energy such as large

woods,

The balanced

minimizes

good ground

vertical angle of

conductivity in

for the antenna, its transmission

as sociat ed

ure to

base for lightning

the lightning stroke seeking

where

quate

which would tend to

absorb

trees or

other antennas and steel buildings.

design

the radiating

of

the dependance of the antenna on

conductivity

radiation.

providing

for

control

Consider

lightning

protection

line and

r e

ceiver

provide

in the

lightning

and/ or transmitter.

good ground

a

protection

communication system. Ade-

protection

can

the

at

could

ground

a

be

result in

gained

of

or de-

array

of its

ground

Fail-

antenna

attaching one of the tower legs to a

ground,

portions

at the same

length and

transmission

rf

minimum.

115-vo1t

winch

far

base.

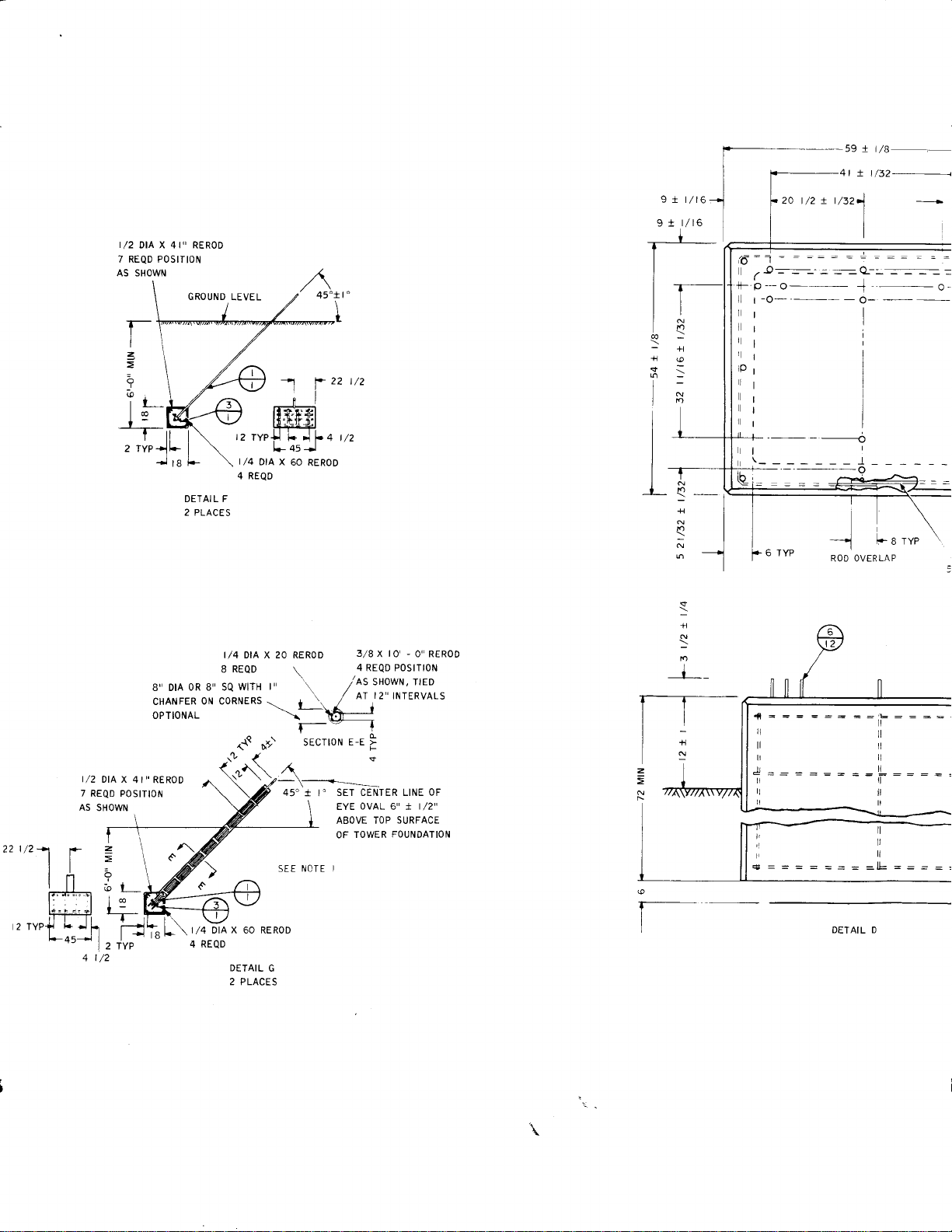

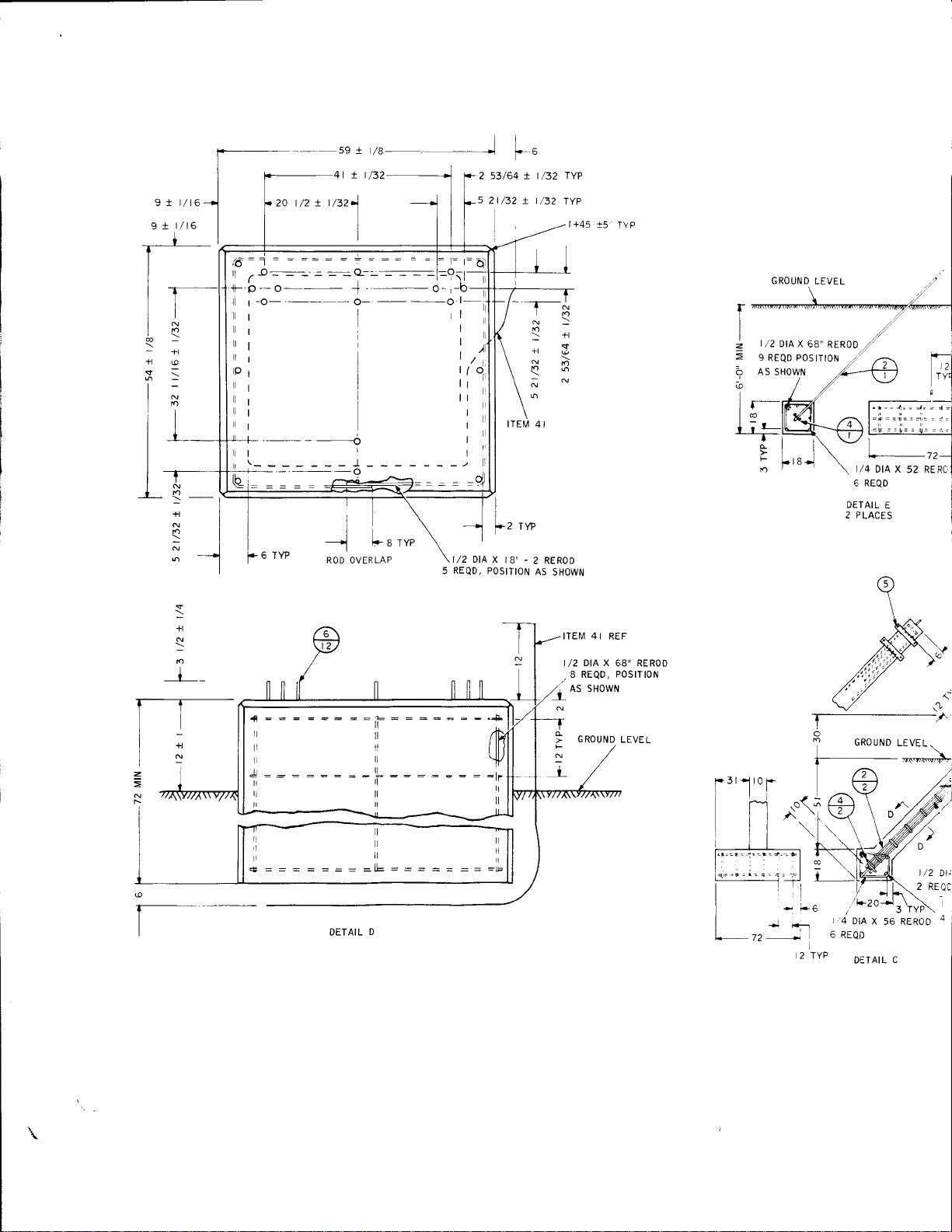

2.3 FOUNDATION AND

POINT CONSTRUCIION

The tower foundation and

first items installed

requirements

figures

mended

these items.

through a large

the

of

antenna

potential.

dc

routing

of

line cables

power

losses

and

For added convenience,

convenience outlet near the erecting

foundation

to unswitched

end

for

GUY ASSEMBLY ANCHOR

at

these

for

2-1 and 2-2.

configuration and layout information

(Reinforcing

The figures

conductor, as all

tower structure

Carefully

power,

control, and

to reduce

to keep

power

power

guy

the

cable cost at a

install

tool use.

cable

anchors are

Connect

at tower

site. Installation

items are shown in

provide

steel and concrete

recom-

ac and

the construction of these assemblies are

supplied

with the

antenna kits.)

the

any-

by

good

are

plan

a

the

for

for

not

2-7

tnstallatlon

It is imperative that

bolt locations be

with

and

guy

the

ment

guys

ing

anchors.

will

anci/or

and lowering

In constructing

the foundation

well

as absorb horizontal loads

erection

28-day

or

stowage

concrete

around foundations

In acid, alkaline

with

anchor

The

rods

concrete

blies should

erection

of the tower assembly.

guy

the

cause excessive

tower during antenna

the tower

can support

strength

or salty

bituminous

the

in

foundation

be aged at least

the tower base

in

Even a smallmisalign-

with

line

attachment

strain

each other

points

on the

rais-

operations.

foundation,

the tower

process.

is 3000-psi,

should be

installations,

soil

wrap,

The recommended

well

andanchor assem-

make sure

weight

due to the tower

Back

compacted.

14 days before

on

cover

as

fill

zontally and

loops

sheet

b.

A

be

foundation. This support shouldbe ofwoodwith

to within

1, detail

support for the bottomtower

placed

a large surface area. The

support

pivot

to form

should be above the leve1 of the base

shaft.

this

Assemble

position.

Attach

and right

It

tower

i.s

necessary to install the bottom

vertically with side anchor

+1/2 inch.

G.

about

(Wooden

support.)

15

crossties

See

sectionshould

from the tower

feet

top

surface of

may be stacked

figure

the tower in a horizontal

members to

pivot

vertical

assemblies.

horizontal brace on the inside of the

tower

vi.ew B-8.

as shown in figure 2-1,

sheet

the

2-1,

the

leftc.

2,

The side anchor

in the

be

planes

equidistant from

See

remaining five anchor

located

shown in figure

locate anchor

Iy can

and

lowering

ASSEMBLY

2.4

In

assembly

torque

limits:

3/8-inch bolts

1/2-inch bolts

3/4-inch bolts

a. Install the

of items

sheet

the nuts

level

14

same

as

figure

2-1,

at the

cause

buckle

the tower

operations.

OF THE TOWER

of the tower,

tower

10,

2) on the

on

tower

the

(figure

the tower

2-1,

Centerline of

terminating loops

vertical

and horizontal

pivot

the foundation

sheet

1, detail

points

distances

2-1, sheet

terminating loops

guy

cables

to overtighten

during raising and

use the following

pound-foot

25

pound-foot

90

pound-foot

320

pivot

assembly

11, 12,13,14,

and19;

concrete

the

foundation

pivot

assembly,

sheet 2) as a

pivot,

item 14,

MUST

shaft and

center.

The

G.

should be

and angles

1.

Failure

proper-

(consisting

figure 2-1,

foundation.

anchor

bolts to

using item

reference.

up hori-

Iines

to

Use

Place the

d.

support. Attach the lattice

two members

Place the third tower vertical member atop

e.

the

completed tower side.

f,

At either end of

erect lattice bracing

tower vertical members on the

bracingto

cross

the

completed

(four

in figure 2-1,

tower

braces) for the

as shown

third member.

o

h.

i.

j.

k.

I.

m.

and bolt the third

Lift

position.

Attach lattice bracing

to either

Lift third member into

place.

into

Attach

Attach tower

view B-B,) to tower.

Check

quately greased

greases:

aco

or

To

sheet

sheet

nut from cable

the center of

large

cable

tached, through

remaining

that

lattice bracing.

(item

1eg

winch

and

with

ANG-25; CPN

Unitemp; Beacon 325;

Super

attach hoisting cable

Mi1 ?2832

1) to

cable

winch,

2. Remove setscrew and

dog.

the

cable

hole in the

dog

setscrew,

hollow

with

the hollow axle of

vertical

member

end of

position

15, figure 2-1,

tackle block is

any of the following

005-0423-000;

Air

Shell

(American

(item

3, figure

see figure 2-3,

its

Insert

cable dog into

winch reel through

reel

core.

securing nut at-

the

sheet

side,

into

tower.

and bolt it

sheet2,

ade-

Tex-

No. ?A

Oit

Co.).

2-3,

securing

Insert

the winch

2.

I

2-2

Revised 15 JuIy 1971

4t

! t/32+

t/2+1

22

,r"r{

I/zDIAX4I"REROD

7 REQD POSITION

AS

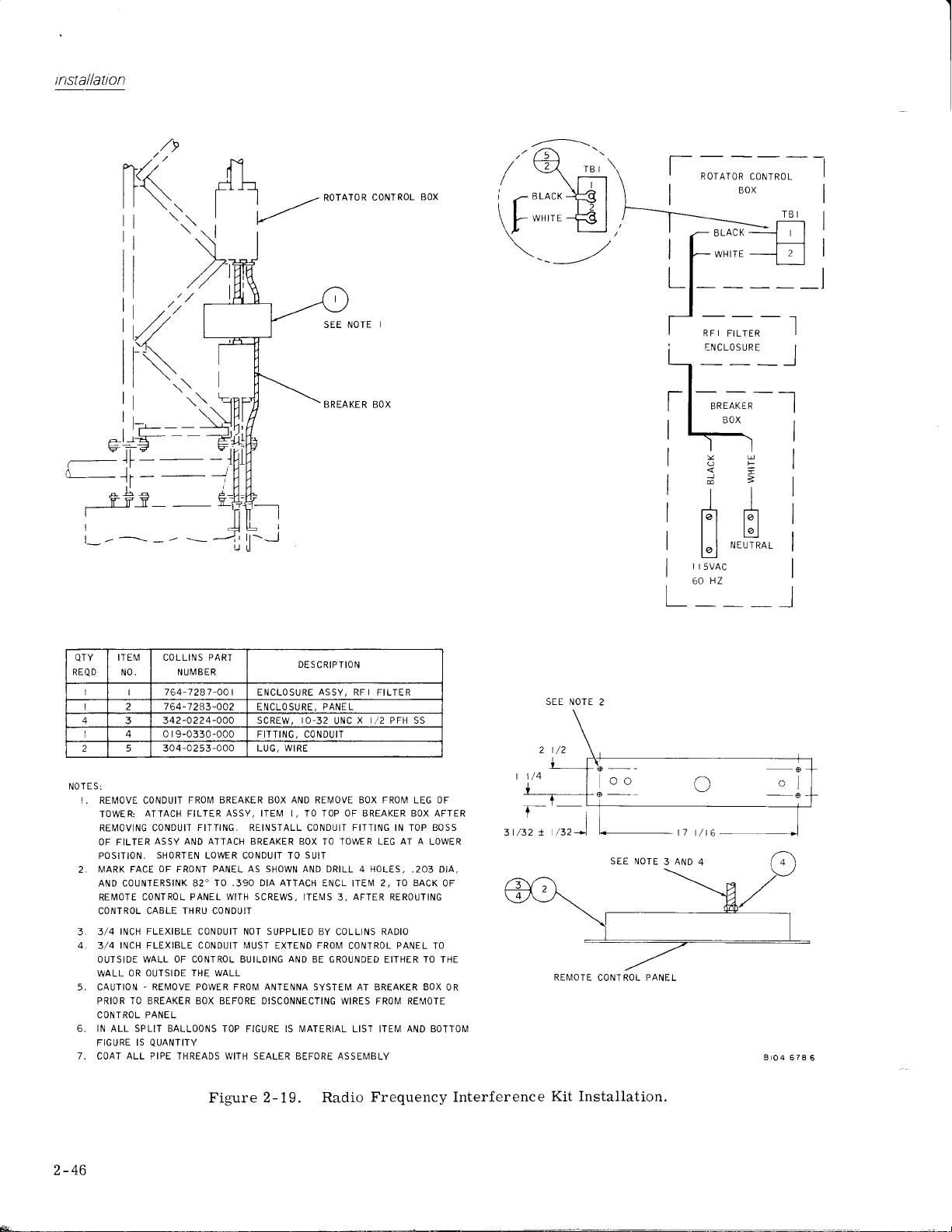

[

t-L

*

1.,.

i, *l

L-lL

Lo.--,1 l

'-l

t/2

4

t/2

otA x 4r,, RERoD

7 REQD POSITION

AS SHOWN

z

=

o

b

SHOWN

z

=

o

bi

lo

t___

+

--1

I

2 TYP

GROUND

LEVEL

)M

,z

t/4

4 REQD

DETAI L F

2 PLACES

t

/4

REQD

I

oR 8" 5Q

B" DtA

cHANFER 0N C0RNERS

oPnoNAL

I t\

I,/4 DIA X 60 REROD

t*

re

4

wlrH

REQD

DETAIL

2 PLACES

A

'

45"

-l

4

rvelfL

DtA x

DIA X 20 RERoD

t'

-

!f

60

RERoD

\

r /

+ ,n

\-\&j

I-t

SECTION

45'

t I'

SEE NCTE

G

22

t/2

3/8

to'

x

0" RER00

4 REQD PoSlTloN

/'es

Ar

E-E >

SET CENTER LINE OF

EYE OVAL 6' t I /2"

ABOVE TOP

TOWER

OF

I

-

sxowN' ttEo

12"

INTERVALS

d

F

$

SURFACE

FOUNDATION

9 t r/16

r/16

91

N

S

+t

+1

I

:

I

N

l

n

l

I

I

I

I

I

NI

I

_1

*l

-l

nl

-l

N

6 --l

+l

N

l

t_

1--T---

tt

t-

i+

N

z

=

N

;--

I

,,6:1

I

l

I

s

+t

i

l

I

I

I

9 t t/16

r/16

9 t

N

n

+t

I

:

n

>-i

+l

-t

nl

>t

ol

'l

zo trz t

trczl

+_b_o___J,_6-,

lll'

I

-!

I

I x t/32

1

r*,

,,,

t/2 )tAx

REQD,

5

2 53/64

I

l*,

lB' -

POSITION

!

-1---

n

,*

t

/32

+l

2 RERoD

AS

SHOWN

TYP

N

n

+t

@

o

l+45

t5

TYP

I

|

/2

z

9

o

@

lr-

lo

t_

L+

c

F

n

GROUND

)tA x

REQD POS

LEVEL

68,'

ITION

RER0D

t/4

DtA X

REQD

6

DETAIL

2 PLACES

52 RERC:

E

z

=

N

N

I

=-

I

+l

N

D

I

t_

ITE[,4 4I REF

I /2 DIA X 68" REROD

.8

REQD,

P0StTt0N

(-

3

++6

T-^

I

I

2 TYP

lq

6

GROUND

1.,' r\

/

't

-ln-J

otn

REQD

DETAIL

LEVEL

;JI

D]

l+\\

\ \

3 TYP\

x

56 REnoO

C

|

/2

2 REoc

Dt;

a

rlll

1l!l

lrll

J:::::=:--[

tlll

rr,ll

DETAIL D

F

N

I

GROUND

LEVEL

a,-l

r

r

L_

l*

'o

3rl

L-

r0

___r

72

li

JI

QTY

R EQD

SEE

DETAIL

F

\

d

n

{

q

a

\

\/"I

\

-,.

\,/

SEE DEIAIL D

6 REQD

DETAIL

E

2

PLACES

T

o

GROUND

?

LEVEL

SEE

j

z

@

NOTE

SEE DETAIL F,-

l\

__a_\/

a4',

ta

i-

_ i ,___)--

\

\

'*

,'-r\

.,. I

sEE DETATL E

325-O

A

PLAN

U..-

VIEW

-sEE

oETnrL

DETAILS

c

25.a

35.0

t/2

BENT

L

t/4

9 REQD

DtA x t4'-a

AS

SHOWN

/2

TYP+rP I

DtA

x

20 RERoD

SECTION

ROTATED

+

[sl

[a-----

45'

l+ r0 REF

i

N

i

D-D

CW

ANCHOR AND FOUNDATION

2 TYP

)/2

DtA

X t0'-0

RERoD

2 REQD

t

/4

I

DIA

X

6 REQD

l

t2

TYP

56 REROD

DETAIL C

/2 ltA x 68' RERoD

4 REQD P0StTt0N

ITEM

N0.

4

4

4

4

I

t2

3

I

I

2

I

I

I

I

I

6

t8

6

t2

I

I

2

I

9

I

I

I

2

2

I

8

4

4

B

3

3

3

3

I

2

I

2

3

4

6

7

I

9

t0

il

t2

t3

t4

t5

t6

t7

t8

t9

2A

2l

22

24

25

26

27

28

29

3t

32

33

34

35

36

37

38

39

40

4t

42

44

45

QTY

R EQD

4

4

4

I

t?

325.O

3

5

I

I

2

I

I

I

I

I

6

t8

6

t2

I

2

9

2

2

8

4

4

8

3

3

3

3

25.4

35.0

installation

PART

I

2

3

4

5

6

1

I

9

t0

il

t2

t3

t4

t6

t7

t8

t9

20

2l

22

23

24

25

26

27

2A

29

30

3l

32

33

34

35

36

37

39

40

4l

42

43

44

45

COLLINS

MBE R

NU

r

0

5-0856-000

0r5-t064-000

JIU-U)ZI-UUU

r

3

0-0523-000

766-2356-004

0r3-r324-040

432-r09r-000

766-2364-00

0t3-1891-040

766-2352-Aa3

1 66-2352-004

766-2362

766-236

-003

l -003

766-2366-00

-

2365

766-

766-2

003

367- 005

766-2354-O04

326-r53r-000

r 282-000

334766-23ss-00

t271 -AOa

334-

0r9-r313-000

766-2377

0

0r9-l3t

-Oa3

I 9-0279-000

t-000

0t9-0129-000

t 222-A2a

oa5-

I 5-2702-000

0

766-2369-00

I 2-000

332-07

338-0096-000

0t9-1314-000

r s-2352-000

0

0t5-4136-000

0r5-4t97-000

r

0

5-4235-000

I 5-2354-000

0

0t5-4r39-000

0t5-4r98-000

r

5-4237-000

0

-2448-000

t

42

788-6275-00

42r-r020-000

774-633r-001

-0994-OO3

3

or

DESCRIPTION

ROD,ANCHOR-34XIOFT.

ROD,ANCHOR-IXIOFT.

WASHER-4X4Xl/2THK.

WASHER.6X6X3,/8THK.

BRACKET,

BOLT,

WINCH

ANCHOR

STRAND,GUY-38(FT)

I

I

UPPER

GUY,

SECTION,

LEFT

PIVOT,

RIGHT

PIVOT,

BRACKET,

BRACKET,

PIVOT

SHAFT,

LEG. TOWER

ROTATOR

PLATE,

BRACKET,

scREW,

TOWER

BASE

CENTER

LOWER

CAP

NUT.HEX.-34.I0

U -BO

LT

r

NUT.HEX.-3E-16

JUNCTIOIT

BOX,

CONDUIT-NIPPLE

ARM,

NUT,

BREATHER,

LOCK

-

CONDUIT

CONDUIT.34X

COMPOUND,

KIT, STRAPPING

-

CONDUIT

I

3

PLUG,PIPE-34

COTTER

PIN,

JUNCTION

BOX,

STRAND

GUY,

TURNBIJCKLE-58X12

SHACKLE

THIMBLE

GLY,

TURNBUCKuE-34XlB

SHACKLE

THIMBLE

WIRE, ELEC

I

5TRAP,

WIRE

INSTRUCCLAMP,

-

-

STRAND

.

- I 2

GROLi\i]INC

{FT)

O\

HOSE

3 t

5 3

-

4 - l0 X2

3

3.1

IOFT.

SEALING

4

.

DEAD

2

.

DEAD

IFT'

;.ATE

(TUBE)

ENO

END -

NOTES:

LOWER SIDE

I.

2. IN

3. EARTH

4. IN

5.

l.tz

6. SAFETY

WITHIN

SHAFT

HORIZONTALLY

AND

ACID,

ANCHOR

SHOWN

ALL SPLIT

AND

ITEM

LEVEL

TOWER

I/2 INCH

HOLES

FORMED

ARE

ITEM

USING

7. ANCHORS

TOLERANCE

8.

9.

IO.

I I. END

FIE O

CI

SPE

OVERALL

OTHERWISE

LACING

VIEW

MAIN

LOWER

OF

WITH TUBE

OF CABLE

I INCH

I2. COAI

.

3.8

I3.

ALL

4I

ITEM

ROD FOR

SUITABILIW

STORMS

I4. GROUT

I 2

AFTER

ANCHOR

GUY

OF

IN BASE

ALKALINE

WITH BITUMINOUS

RODS

ANCHORS

PREFERRED

BALLOONS

BOTTOM

I4

BEFORE

ALL TURNBUCKLES

WIRE

ITEM

FOUNDATION

AND

ON FRACTIONS

OIMENSIONS

SPECIFIED

TOWER

OF

AND VIEW

GUY BRACKET,

SECTION

SHOULD

EXPOSED

CONDUIT

REF, TO

LIGHTNING

DEPENDS

AND GROUND

UNDER

SPACE

LEVELING

LINE

BRACKETS

OR SALTY

FIGURE

43

ON CONCRETE

MUST BE

B-B

AS SHOWN

THREADS

BE CONNECTED

AND STATIC

ON FREQUENCY

CONDUCTIVITY

BRACKETS,

MUST

LOOPS

PASSING

SOIL

WRAP

TO MINIMUM

TOP FIGURE

IS

QUANTITY

RAISING

DESIGIIED

I,/4 UNLESS

t

ASSEMBLED

INSURE

TO

I7. ORIENT

ITEM

IN SECTION

VISIBLE

BE

WITH SEALER,

BE

THROUGH

ITEM

COVER

DIMENSIONS

IS MATERIAL

TOWER

AFTER

FOR 3OOO

ARE

PROPER

WiTH

SUITABLE

TO

DRAIN

OF

ITEMS

LOCATED

PIVOT

I2, VERTICALLY

EXPOSED

LIST

PLUMBING

PSF

OTHERWISE

OPERATION

ITEM

A-A

27

ITEM

GROUI'ID

ELECTRICA'L

I3

8104

UNLESS

IN

I7

564

MINIMUM

AS SHOWN

A MINIMUM

PROTECTION.

I2 AND

SOIL

OF

6

IT EM

N0.

I

I

I

I

I

I

I

I

z

Figure

Revised 1

2-1"

Anchor and

(3000-PSF

December 1975

Foundation

(Sheet 1 of

Soil)

Details

2).

2-3/2-4

I

D

\ta/ lo

IIX|.J

-

_l

THIS ANCHOR

PLACE ONLY

I

ROD

\^

/'_\ 4

A )o) v-

\::Y-r*-JL.S

\\

rl

LIGHTING

PART OF

(OPTIONAL

N0. 515-8453-001

PART

\f\

EQUI

\.cV

\:\

-/

\.:\

_.t\

DETAIL

PLACES

3

P)

(

6iK--

-

A

KIT

COLLINS

sEcTtotr A-A

rF

II

le

ITEM 4I

IIOTE

SEE

REF

I3

t/2

20

B.B

VIEW

SEE NOTE I O

.E NOTE 12

DETAIL A

SEE

(2

ANCHOR RODS)

DETAIL E

SEE

t/2

t

_/

SEE DETAIL

inst

allation

i-

I

\

)

!1E!t-9:9.

ROD

ANCHOR

THIS

I PLACE ONLY

DETAIL

PLACES

3

PART OF LIGHTING

(OPTIONAL

PART N0.5r5-8453-001

SEE NOTE

SEE DETAIL A

(2

ANCHOR

KIT

EQUIP) COLLINS

12

RODS)

SEE NOTE

A

DETAIL B

PLACES

4

DETAIL B

SEE

I I

€

,EE

i

't

-j

,

NOTE

4 I

ITEM

sEE iloTE

REF

13

20 t/2

vtEt/Y B_B

SEE tiOTE

tt/2

IO

DETAIL B

SEE

SEE DETAIL

ELEVATION

?

PLAN VIEW

\;-

Figure 2-1.

sEE DETAIL A

Anchor and Foundation

(3000-PSF

Soil)

(Sheet 2 of.

Details

2).

2-5/2-6

I

N

n

+l

@

:

n

4'-lrJl.8

tl

4l

@

>

+1

o

-

n

+l

o

o

PT-A.

/^ I

\

"o,-.

c \ t.

l.)o)*:,

I

,?o

,O

ur".

>-_

''ti'-=t{*f

-ci

,.\

*o\

d-q') I

'i'--f--(o

/32'

J

o

OF

F<

o

I

-,,

\

-,+)

tu"__{-,uV

,"ykJ*

|

I

/".,

"

-n

\"

--

-,'-<

..6-

P.

50'r3"

EYE

/42

OVAL

I\

Ai F.2

1-

(TYP,)

2 53/64!l

_5

2t/32tt,j?_ l\P.

o

''-

V

n

rl

@

+l

N

m

3

N

ll

NOTES

Dta

3/4"

ANCHOR

n

o

j

BOLTS

CHAM

N

a

n

N

n

_\

N

FER

-..

;

I

L__

3'. Ct.

I

I TYP.

l_._L4

o<

FJ

llo

bu

o>

I

N

n

t]'I

_

4L

WiRE

REF

NO.2T

25 ELEC

ITEM

u

I

THRU

,

DIA

---,1

;

!lOLES

ANCHORS

I

(2E.W.

IN

/.r'

r0

N0.

WINCH

BRAC KE T S

)

{+

/

t'"( I

I

4 E.W.

L,.

4-N0.4-6"X36

POSITION

N0.3

BR ACKE T

AT 24',1

f--

].--

r-"

xxi

- N0.

4

4n E.W.

FINISH

GRADE

N0.

3UAr 24"1

N0.

3 AT

I

16 NO.

SIDE BARS ACROSS ENDS

NO. 3L.J AT 24"1

25,

24"1

4 - BSND

ELEC W]RE

TE[/ 4i REF

ALT.

E LEVATION

FOUNDATION F-

DETAIL D

6'X6"X3l8"

WA

SHERS

I

2',-C"

X t0'-0,,

ELEVATIOI\

FOUNDATIC

DETAIL C

\

f\ P

I

53/64+

/32

2t

/32].t,82

I

I

I

LJ

-T----

f^

J_\

l{1

rp

!n-

16

!N

1

:5 ELEC

TEIVl

-

,4

FINISH

r-l"yx-ge'--

-

lto. s nt

I6 NO. 4

SIDE BARS ACROSS

'N0.

25

\

I-TEM 4] REF

'

so'tr

gyal

6yg

W RE

4I REF

N0.

4n E.W.

GRADE

NO. 3U AT 24,,1

24,t

.

BEND ALT.

ltl Ar 21't

ELEC WLRE

, AT

,

F-2

ENDS

x 6"

6'

WA SHERS

(TYP,)

x

3/

I

o

9

lT-

I]

i

t-

lZ)

I'

l+

lt

il

+i

li

l.__

4 - N0. 4 - 6"

POSITION

BR ACKE T

N0.3Ar24t

I

o

i

3'

cr.

I

tl*o'

i

L

2'_0"

THRU I]OLE5 IN

I

r-

I

I

L-

t-

I

L=3

2',-0"

x t0,-0,

__.1

X 36"

.

DIA

-T

)

,l

I'DIA

(2

ANCHORS

I

I

/r"

)

a

t0 N0.4

WINCH BRACKEIS

ANCHOR

WINCH

BR

E.!v.

/:,,.

;rLl

E.w.

NOTES

ALL

IN

t.

AI\D

IlEfuI

iTE\4

AiL

?.

TIGURE 2-I SHEET

Tc

NO. 2

TIES

2

ACKE-T S

r.

l,

.3JAi

_-

8'-0 x 2,-0

E LE

VAT ION

FOUNDATION F-3

C

OETAIL

t]ALI-OONS

SPLIT

BOTTOI\1

NI]I,'lBERS

AT IB 1

4

N0.

.1

)

<,/"'(\

'

/.>l

\$l

zal

.ldl

'\.i

l

l1'llr

r

--]-

tl

lrl

i--

1--

aaa

24

TOP FIGURE

IS

FIGURE

AND DEiAIL REFERENCES

I

AI

IOO T3"TO CENTER

le.

9., >

,

-YJ

---J

't

I

-

--l

-

l-

IS

QUANiIT\

2 PAGE'., 2--7/2

T

riz

B

-

-|

r---+

!

I,IAiERIAL

REFER

1

LINE F-I

J

I

-T

L',<i

-_I

a

N

I

l

FINISH GRADE

/

FINISH

GRAD

4" \4' X

WASHE R

6'X6

WASHER

X3l8'

E

4 NO. 3

,*to-rri.

',

N0.3AT24t

/2'

EXTEND

\[--1

*, + N--l

-L[q!J

CHAMFER

8"7

\_

NO,2

H AIV]FE R

C

\

TIES

T-

f-

I

,,'

I

L

I

I

I

3'-o'

l-

ELEVAT

ON

FOUNDAT

ON

DEIAILF_2PLAC:

DETALG_ZPLAC

I

DIA

4',-0

ELEVAT

FOUNDAT

DETAIL E-2

-_

x 6'-0'

F_2

ANCHOq

x 6

ON

ON

-0

F- 4

PL:

Figure

2-2.

Revised 15

July

Ar

(1

19

4NO.3EX

I

2

lNTo F'

TEND

TG.

tr

C H AIVIFE R

T0 REF.

50 13'

PT. A AT F.I

3/4,,DIA ANCHOR

rnstallatt;on

I

L

o

I

INISH

_/

GRADE

FIN IS H

cnnog\

t'vAS:ER

\

N0.

N0,3

b

3

CHAI\,4

AT

AT

24',r

NO.2

24

t

FE

R

i-

t-

L,'

l-J

r.J

i*-.

ELEVAT

FOL,NDATIoN

DETAiLF-2PLACES

DETAILG_2PLACES

f-

TIES

/_

. ,.-o

ON

F-2

CHAM FER

t7

---]'

q,

NOTE

IO

NO.

SIDE

BARS

N0,

3UAT

3'CL. TYP._

IOOIt3'

q.

16 NO.4 -

SIDE BARS

N0.

SET CENTER LINE

OVAL61I,/2 ABOVE

TOP SURFACE OF

FOUNDATION

CASE

ANCHORS

DETAIL

G ONIY

-

4

BEND

ACROSS

24"1

TO CENTER LINE F-I

1r

o

{

[

---/

3L_l

AT

AT

CENTER

ENDS

rrrursn

caaor

BEND ALT,

ACROSS

24"1

TOWER

ENDS

OF EYE

X6

6

WASHER

X3l8

t_

Figure

Revised

t

ELEVAT]ON

FOUNDATION

DETAL

4

-0"

E-2 PLACES

2-2"

15

JuIy 1971

x 6'-0"

F-

4

Anchor

(1000-PSF

_l

n

I

and

Soil).

Foundation

B

04

Details

2-7

/2-8

705

6

QIY

REQD

4

2

4

2

2

4

M

ITE

N0.

I

334-

0r5-2r28-000

I

I

I

I

I

I

I

I

I

2

4

5

6

7

9

t0

I

t2

r3

t4

l5

r6

t7

764-7259

0 |

0r5-4r98-000

ot5-086t-oo0

ot

at5-42a7-OOO

766-235

326-124t-OOO

76A-244s-OO

766-2446-OO3

764

333-0444-000

326-2293-OOO

3

PART

COLLINS

NUMBER D ES CRi PTI ON

r 279-000

-40 t

5-2364-000

5-2354-OAO

I

-O05

-7262-OOt

NUT, SELF.LKG-

WINCH,

CABLE

HOISTING

CABLE-

TACKLE

BLOCK,

SHACKLE-

wlRE

cltP,

DEAD-END.

THIMBLE.

MAST, ERECTION FIXTURE

scREW,

t

CAP

BRACKE T

COUNTER

HANDLE, EXTENSIOiI

NUT, HEX -

scREw 5/t6

ro-0762-Or0

WASHER, I/2

SEE

I,/2-I3

5/8

-t/2

ROPE

GUY.STRAND.

I/2

- t/2-t3X2

WEIGHT

5/t6

-

- rSxr

DETAIL

B

t8

3/8.

I/2

SEE

NOTE

4

NOTES:

I.

IN ALL SE

2.

GREASE

5 .2.2.

3. TO ATTAC

CABLE DC

HOLL0Yr

H0t.L0\,,

T HE LIF-i

HOLE IN:

T HR 0

CABLE DC

(200

WARIIINC:

4.

REFI.]SE]

CAIJSI\G

5, DRIVE EX'

E. LOCATE

(ASSUT'lrI

BLOCK, I-

CLIPS, IT

WARNIN

WITHOU

cAUTl0l\:

8.

ri

6r-r

PcL'

,'

!

I

i

G,

i

IT SHOUL:

El\'4ERG Er'

ITEM 3

'e@

EXISTING

CABLE

TOWER

SEE WARNING NOTE

CETAIL

SEE

q+-

DETAIL A

@

DETAIL

AFTER ERECTION

VIEW

A

GREASE

FITTING

Rev,

t'nstallatlon

NOTES:

I. IN ALL SPL.IT BALLOONS,

2. CREASE

3. T0

4.

WINCH AND

ATTACH

CABLE

CABLE DOG

HOLLOW

HOI.LOW AXLE OF THE

THE

HOLE IN THE

THROUGH CABLE DOG.

CABLE DOG

(2OO

WARNING: ONCE THE DEAD-END, ITEM 7, HAS

REFUSED. REUSE

CAUSING DEATH OR INJURY TO PERSONNEL AND DAMAGE

INTO THE CENTER

REEL

CORE

LIFTING CABLE THROUGH THE SMALL

CABLE DOG,

(I5O

POUND FEET).

5, DRIVE EXTENSION

6. LOCATE DEAD-END, ITEI\,4

(ASSUMING

BLOCK, ITEM 4, AND

CLIPS, ITEM 6.

WARNING: D0 N0T ATTEMPT

WITHOUT

CAl.lTl0N: THE

8.

IT SHOULD

EI\.4ERGENCY

LEVEL

COUNTERWEIGHT.

WINCH BRAKE lS

NOT BE USED IN

BRAKE, APPLY FORCE SLOWLY

TOP FIGURE

PULLEY, ITEMS

T0WINCH,

INSERT CABLE DOG

WINCH REEL AXLE

ALLOWING APPROXII\,'lATELY SIX INCHES

TIGHTEN SET SCREW

POUND FEEI). TIGHTEN

IO 2OO

A DEAD-END

OF

HANDLE, ITEM

7, SO THAT TYE IS

GROUND).

PULL

UP

NORMAL LOWERING OF THE ANTENNA. IF USED AS AN

IS ITEI,l

2 AND 4 USING GREASE CALLED

SEE SHEE'r

OF THE CABLE

SET SCREW

AND

RESULT

CAN

I4, ONTO SHORT BRAKE

EXTEND CABLE,

TENSION BEFORE

T0 RAISE ANTENNA

AN E[IERGENCY BRAKE 0R STATIC H0LDING DEVICE.

NO. AND

BOTTOM

FIGURE IS

QUANTITY,

OUT IN PARAGRAPH

2, RElrovE SCREW FR0t\,1 CABLE D0G, INSERT

TVINCH REEL THROUGH LARGE HOLE IN THE

WITH

SECURING

LOOSELY INTO CABLE DOG. INSERT

SCREW

HOLE

THE REEL CORE AND THROUGH THE

IN

UNTIL CABLE IS TIGHTLY SECURED IN

CABLE DOG

BEEN INSTALLED

IN SLIPPAGE

TO

HANDLE

NUT THROUGH THE

OF

CABLE

SECURING

IT

SHALL

THE

OF

EQUIPMENT,

OF ITEIVl

TO EXTENT)

NUT TIGHTLY

NOT BE

DEAD-END

2.

I34 FEET FROM UPPER END OF GUY

ITEM 3, FROM WINCH, ROUTE THROUGH

ATTACHING TO ANCHOR WITH ROPE

WITH U/INCH/BLOCK AND TACKLE

TO PREVENT SUDDEN STOPS.

@

SEE DETAIL

A

SEE NOTE 6

lfne'e"'

ELEVATION VIEW

Figure

2-3,

Revised 1 December

NOTE 6

Installation

(Sheet 1 of 2).

1975

.i/

Blo4

of Erection Kit

2-e/2-L0

668

4

inst

alla

f---

o

I

ADAPTER

SEE DETAIL

errurolr

@

A

sHowN

paRTrALLy

INSERTED

DETAIL

CAELE

II{SIDE

A

ENO L

WINCH

DRUT

SECURING NUT

QIY

REQD

CABLE DOG

OT

N

I. REMOVE ANCHOR ADAPTER

REEL

3.

Figure 2-3.

SET SCREW

ITEM

COLLINS PART

N0.

NUMBER

I

I

I

I

ES:

CAUTION: CHECK CONDITION OF I/4 20 X 3 SCREW,

ITEM

DRI

CAUTI0N:

POSITION ONLY

PINION BY A SPRING

CAPTIVATED

758-529 r

2

or5-3049-0r0

4

326-2274-OAa

5

333-O428-000

AND

ITEM 2

CABLE WINCH,

4 AND NUT,

VE R.

-00 I

REPLACE WITH ITEMS

ITEM 5 BEFORE EACH

POWER

USE

(PINION

LOADEO DEIENT). PINION

IN LOW RATIO

Installation

(Sheet

2

of.2).

NOI'ENCLATURE

DESCRIPTION

ANCHOR ORIVER

P INION

scREw-

t/4-20x.

NUT,SELF.LKG-I4

FROIlI ANCHOR

3,4,

USE

TOOL lN HIGH RATI0

IS CAPTIVATED IN

POSITION.

of Erection

DRIVER

AND

PlNl0N

HIGH RATII

OR

ASSY

AS

5 TO

OF ANC

IS NC

Kit

z-LL/2

installation

I

--___!

I

)

,

ANCHOR

6)

6',

SEE

PrNloN

DEIAIL

O

A

sHowN

PARTtaLLY

INSERTEo

l.IIGH

RATIO

PINION POSITION

(

SECURING

I\IUT

@

CABLE DOG

Figure 2-3.

5ET SCREW

!TEM

QTY

REQD

NOT

ES:

I.

REI\,IOVE ANCHOR

ITEIil 2 AND

CABLE

2.

CAUTION:

ITEM 4

DRIVE R.

3. CAUTI0N:

P05tTt0N

PINION

CAPTIVATED IN

COLLINS

N0.

2

3

4

5

WINCH.

AND

0NLy

BY A SPRING

PART

NUMBER

7

t -OO I

58-529

015-3049-Ot0

326-2274-OOa

-0428-000

333

ADAPTER

REPLACE

CHECK

CONDIIION OF

NUT,

ITEM

POWER

USE

(ptNt0N

LOW RATIO

Installation

(Sheet

2 of.2l.

ANCHOR

P

scREW- t/4-20X3

NUT, SELF-LKG

FROIU ANCHOR

WITH

ITEMS

5 BEFORE

T00L

lN HtcH

ts cApTtvATED

LOADED

DETENT).

POSITION.

of

Erection

NOMENCLATURE OR

DESCRIPTION

DRIVER

INION

DRIVER

3,4, AND

I/4

20 X

SCREW,

3

EACH

RATTO

tN HtcH

PINION

UsE

ptNtON

OF ANCHOR

Kit

ASSY

-

-

I'4

?A

ASSY,

5 TO POWER

RATIO

IS NOT

2-1L/2-L2

rnstallatlon

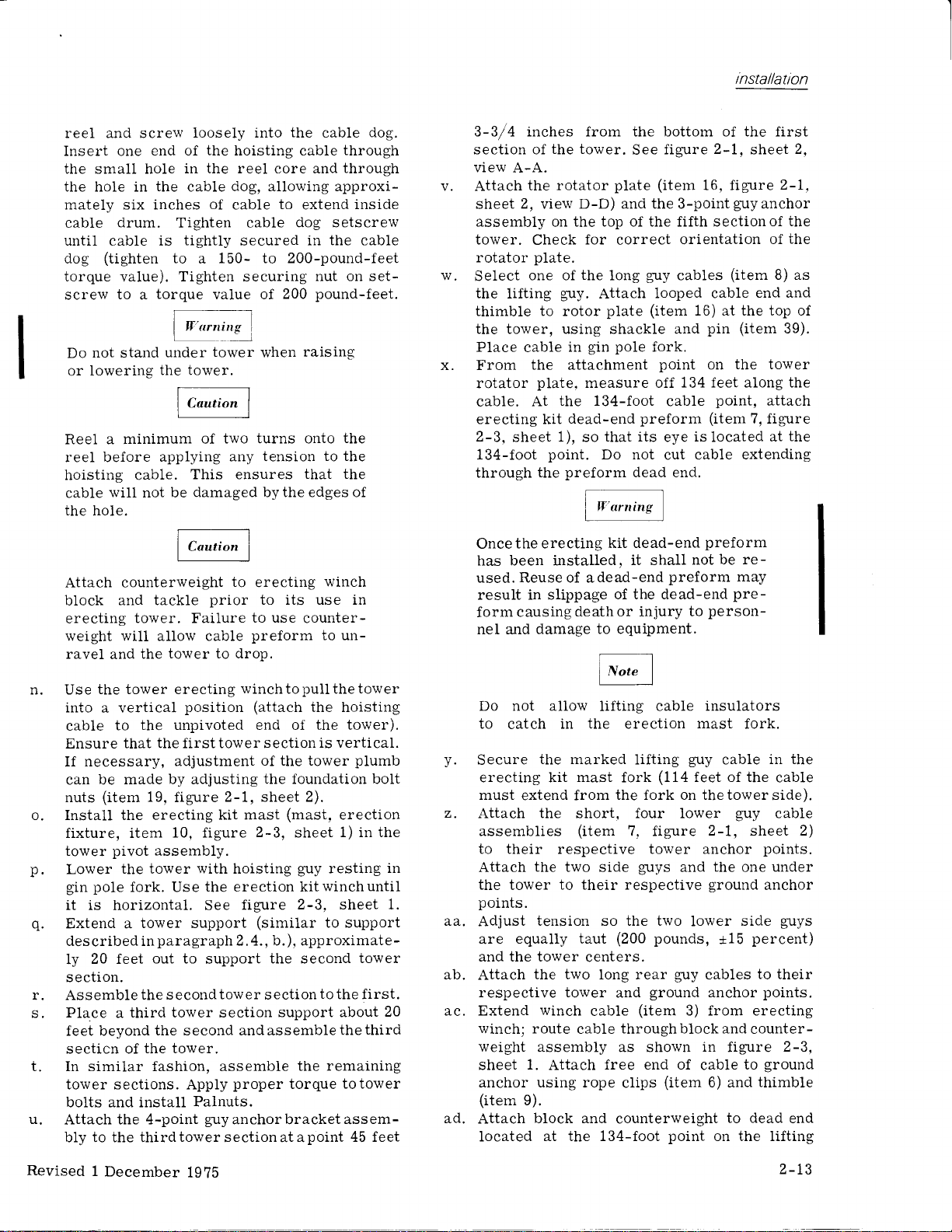

reel and screw

Insert one

the small hole

the hole in

mately six inches

cable

drum.

until cable i.s

(tighten

dog

torque

screw

Do

or

ReeI a minimum

reel before

hoisting cable.

cable

the

Attach counterweight

block

erecting

weight will allow cable

ravel

value).

to

a

not stand

lowering

will

not be

hole.

and tackle

tower. Failure

the

and

loosely into

end of the hoisting cable

in the reel core and

the

Tighten cable

tightly

to

Tighten securing

torque

under

the tower.

applying

dog, allowing approxi-

cable

of

cable

150- to 200-pound-feet

a

value of

torver

two turns onto

of

any tension

This ensures

damaged by the edges of

to

prior

tower to drop.

the

to

extend

dog setscrew

200

when

in the cable

rarsrn€l

secured

that the

erecting

to its use in

to use

preform

counter-

cable

dog.

through

through

inside

nut on set-

pound-feet.

the

to the

winch

to un-

3-3/4 inches from the bottom of the first

section of

view

Attach

v.

sheet

assembly

tower.

rotator

w.

Select

the

thimble to rotor

the tower.

A-A.

the rotator

2,

view

on

Check

plate.

one of

lifting

plate

D-D) and the 3-point

the top of the fifth secti.onof

for

correct

the

long

guy.

Attach

plate

the tower, using shackle and

pole

gin

in

measure off

the 134-foot

dead-end

that its

point.

Do not

preform

kit dead-end

of the dead-end

death or injury

to equipment.

x.

Place

From

rotator

cable

the attachment

plate,

cable. At

erecting kit

2-3,

sheet 1), so

134-foot

through

Once

has been installed,

used. Reuse of adead-end

the

the erecting

result in slippage

causing

form

nel and damage

figure

See

(item

guy

looped cable

(item

fork.

point

cable

preform

eye

cut cable

dead end.

it shall

2-1,

16, figure

orientation

cables

16) at the top of

pin

on

134 feet along the

point,

(item

islocated at

preform

be re-

not

preform

person-

to

sheet

2-1,

guy

anchor

the

the

of

(item

8) as

end and

(item

39).

the tower

attach

7, figure

the

extending

may

pre-

2,

n. Use

the tower erecting

into a vertical

cable

Ensure that the first tower section

If

can be

nuts

to

necessary,

made by adjusting

(item

position

the unpivoted end of

adjustment

19.

figure

o. Install the erecting

fixture, item

pivot

tower

p.

q.

Lower

gin

it is

Extend a

des

ly

section.

the tower

pole

horizontal.

cribed

20 feet

r. Assemble

Place

s.

feet bevond

secticn of

a

10, figure

assembly.

fork. Use

tower support

paragraph

in

out to

the s

econd

third tower section

the second andassemblethethird

the tower.

winchtopullthetower

(attach

of the tower

the foundation bolt

2-1, sheet 2).

kit mast

2-3,

with

hoisting

the erection kitwinchuntil

figure

See

(similar

2. 4., b.), approximate-

support

tow er

the second

ection

s

support about

t. In similar fashion, assemble

tower sections. Apply

bolts and install

u.

Attach

bly to the thirdtowersectionatapoint

the 4-point

proper

Palnuts.

guyanchorbracketassem-

the hoisting

the tower).

is vertical.

plumb

(mast,

sheet

guy

erection

1) in the

resting

2-3. sheet 1.

to support

tower

to

the first.

remaining

the

torque

totower

45 feet

20

in

Do not a1low

to

catch

Secure

v.

erecting kit

must

z.

Attach the short, four lower

assemblies

the marked

extend from

lifting cable

in the erection

lifting

mast

(item

(114

fork

the fork on thetowerside).

7, figure

to their respective tower anchor

Attach

the

points.

aa,

Adjust

are

and the tower

ab.

Attach

respective tower

Extend

ac.

winch; route

weight

sheet

anchor using rope

(item

ad.

Attach

the

tower

tension so the two

equally taut

the two long rear

assembly as shown

1.

9).

block and

located

two side

to their respective

centers.

winch

cabie

cable

Attach

at the 134-foot

guys

and

(200

pounds,

guy

ground

and

(item

throughblockand

free end of

(item

clips

counterweight

point

insulators

mast

guy

feet of the

fork.

cable

Cuy

in the

cable

cable

2-1, sheet 2)

points.

the

ground

lower

+15

cables

anchor

3) from erecting

in

cable

6) and

on the lifting

under

one

anchor

side

percent)

to their

points.

counter-

figure

ground

to

thimble

to dead

guys

2-3,

end

Revised

1

December

1g?5

2-13

tnstallatron

guy.

Pull

up slack in the winch

guy

cable.

winch

The

two wraps

taining

to the

will

cable

of

the

hole.

Do not stand

or lowering

must

of

cable

hole

before tension is applied

cable. This

not

be

under tower

the tower.

ae. The builder should

and

installation by erecting and

tower

prior

to installation of the rotator,

array and accessories. To

1. Ensure that all

to the upper

attached to the

2.

Be sure

two

side

shaft) and the tower

guys,

side

that

the tension is

guys (in

and

have a mi.nimum

past

the

cable

ensures

damaged

the towerassembly

check

except

of the

lowered tower, are

correct anchor

line

that

by the

raising

when

lowering

erect

thoseattached

equal on the

with

edges

the tower:

facilities.

is centered.

re-

the

the

lifting

of

the

pivot

Meropa

Check

greased

to

ANG-25; CPN

No. 7A; or

Oil

Co.). See

1

No.

see

with

or

that the

of the

any

005-0423-000;

Super

Ml1. 72832

section 5 foralternateoils.

005-1269-020.

CPN

rotator has been

following

The rotator heater kit is recommended

for operation

below +10'F

where

(-12.2"C).

temperatures fall

See

figure 2-5.

If the rotator heater kit is not used and

temperatures

+10oF,

drain

are

rotator

Motub-Alloy Artic Gear

Oiland Grease Co.,

Los Ange1es, California).

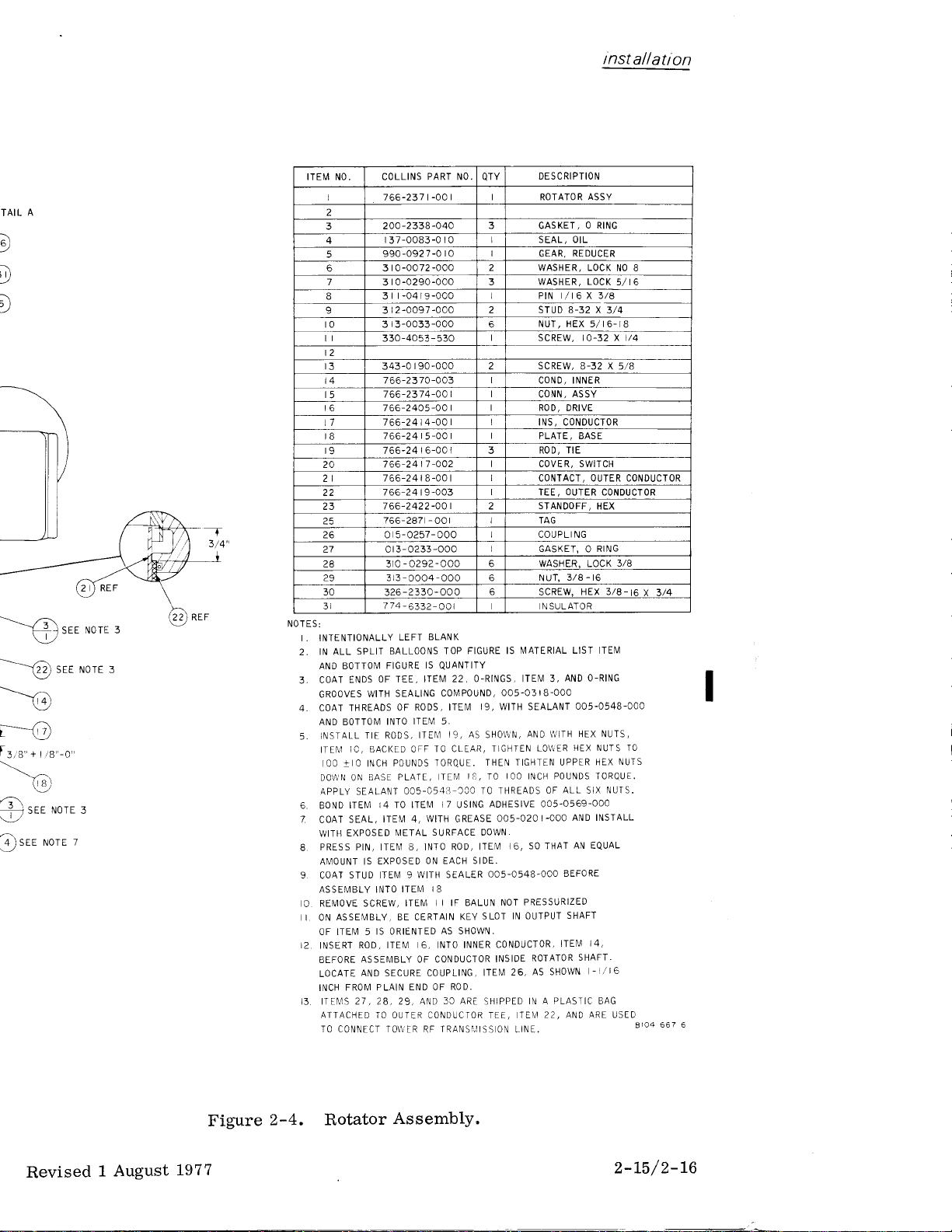

a.

b.

Install the

figures

InstaII

on the

2-7 and

rotator to the rotator

2-4

and

the

rotator

gear

case. See

read

expected

oi1

6505

2-6.

motor

pertinent

to falI below

replacewith

and

OiI

Wilshire

andswitch assembly

figures

emphasis notes.

greases:

Air

She1l

(American

(Imperial

Blvd.,

platform.

2-4,2-6, and

See

Vvvl

The back

come

3.

Use the

fork of the

pull

4.

Check

vertical

adjust

5. Adjust

percent,

200

assemblies.

6.

Lower

procedure.

the

array and

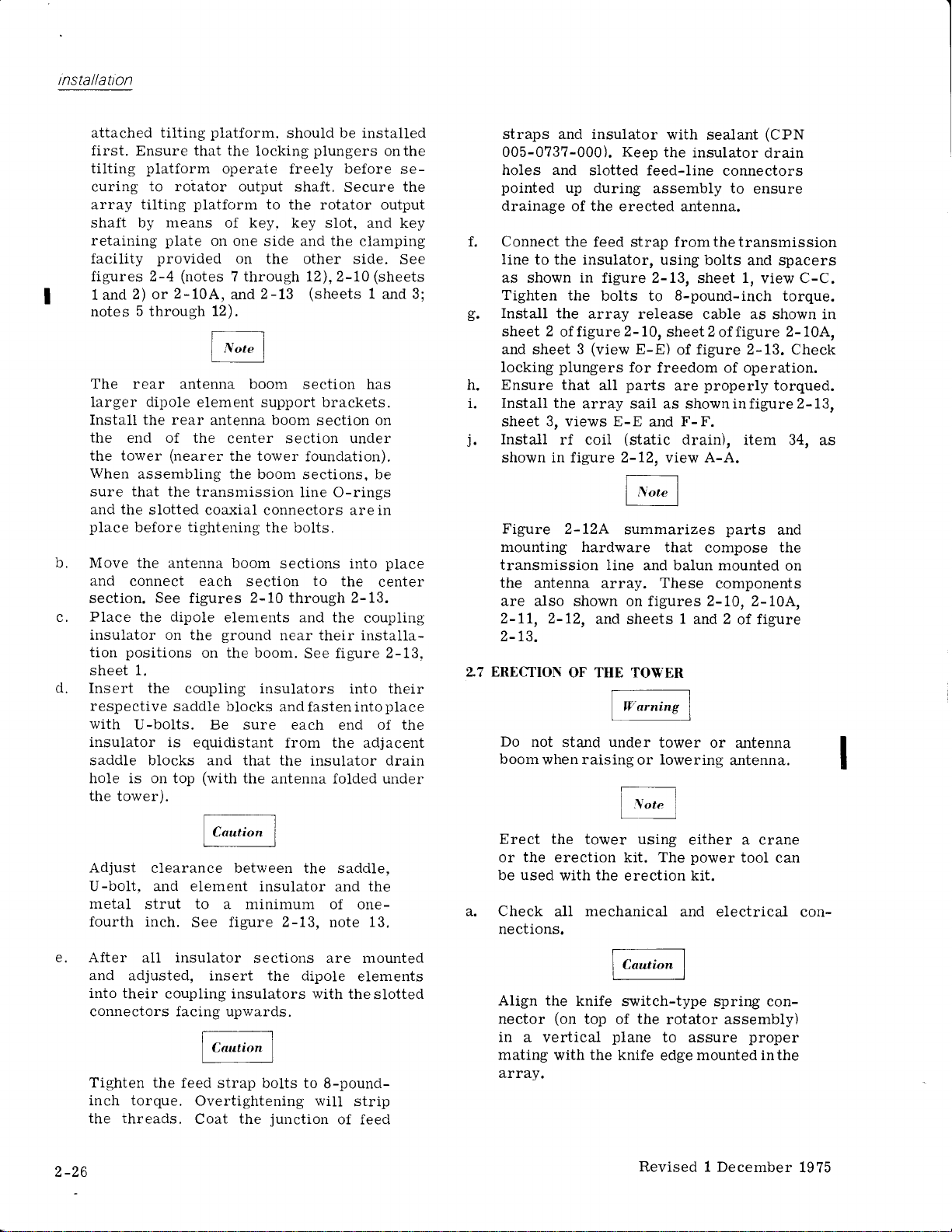

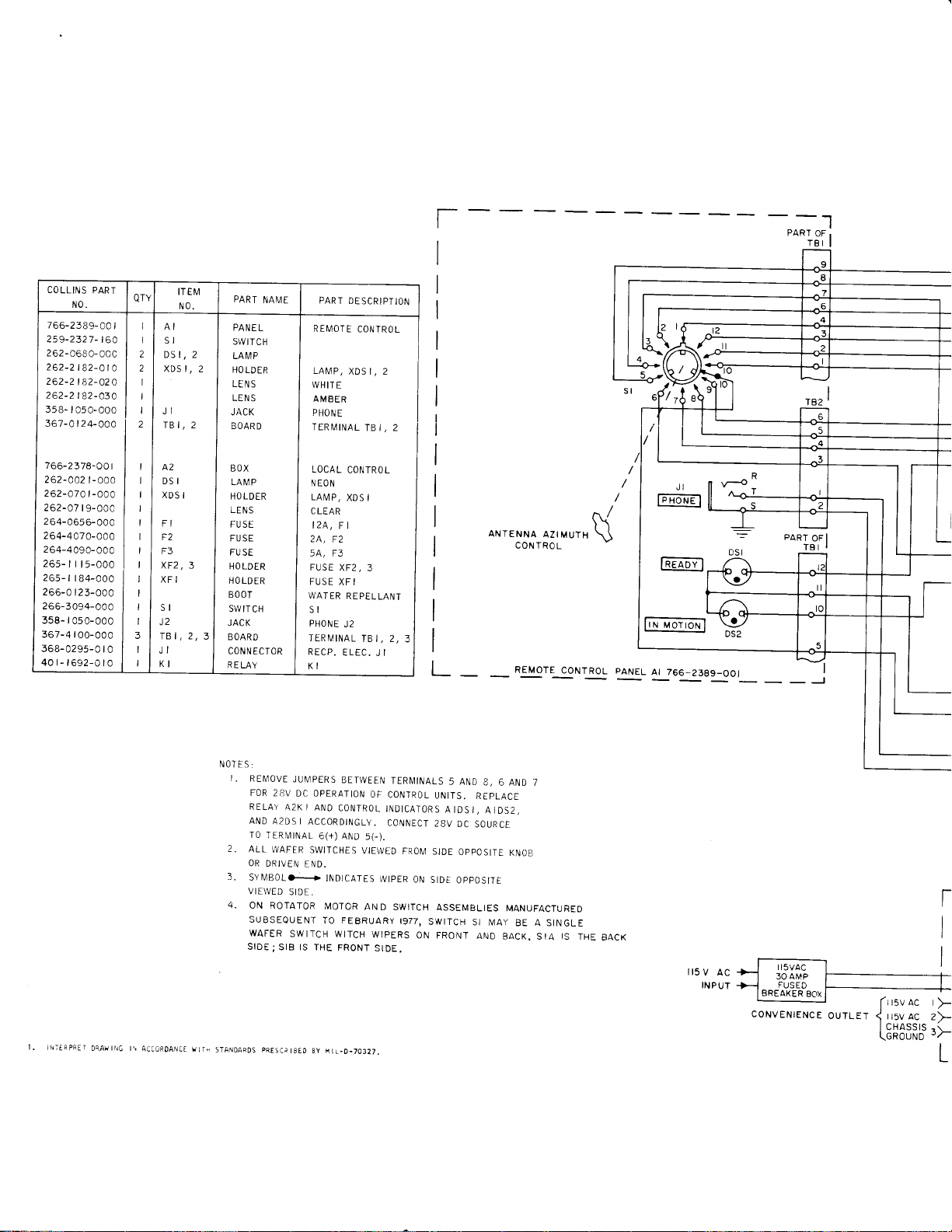

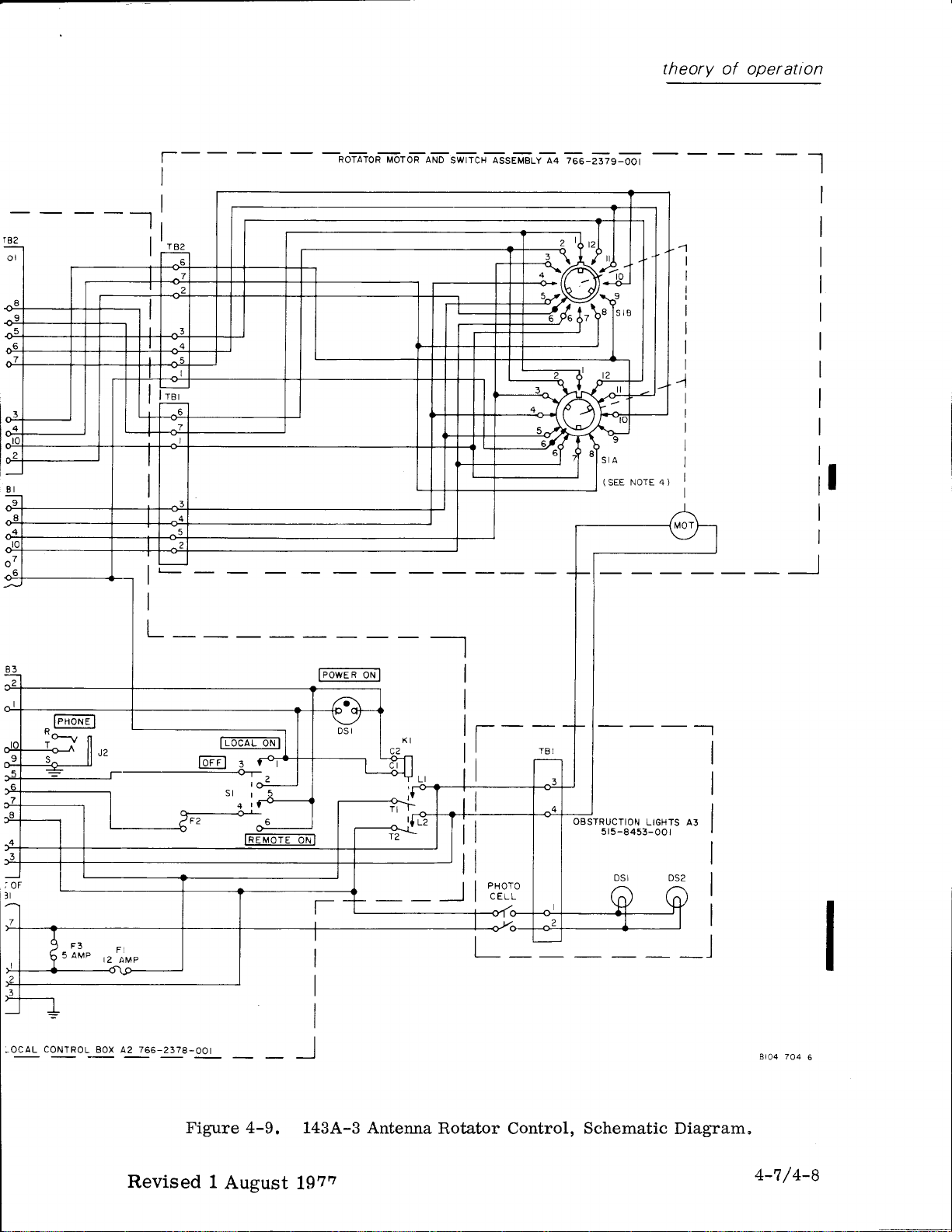

INSTALLATION OF ROTATOR KIT, CON'TROL

25

KIT AND RF

Before installing

gearcase

plug (approximately

gallon).

a

guy

assembly

taut

before tower is

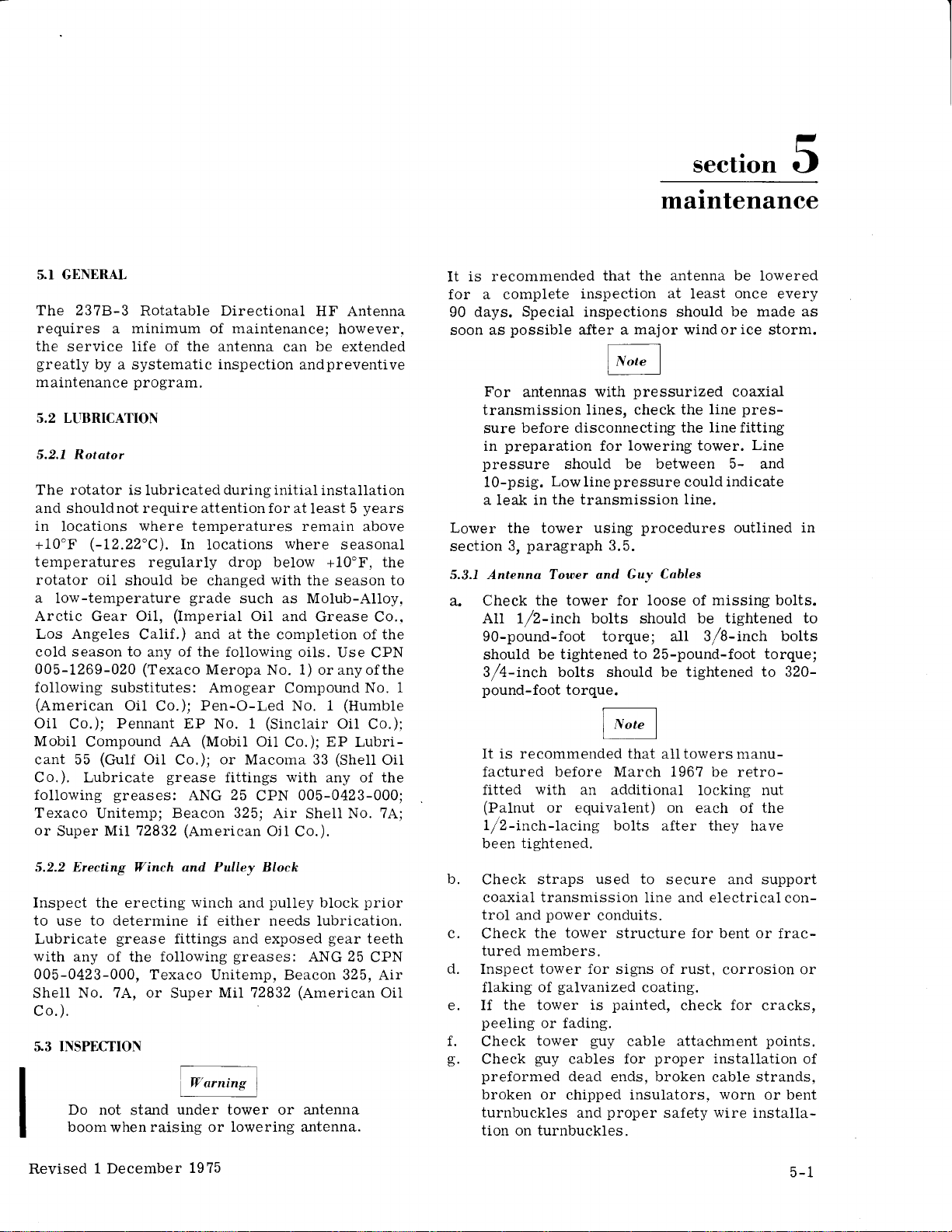

upper

g".ry

must not be-

fully erect.

cable assembly

tower erecting

the tower

the tower

(x1/2

the

guy

on

pounds,

the tower

base of the tower in order

up to

inch).

guy

turnbuckles.

tension to

the

upper

percent,

*15

by reversing the

Place

a support 60 feet

an erect

to be

sure

If out of tolerance,

1300

guy

assemblies,

on the

support the lowered tower.

TRANSMISSION

the

with

oil up to the

LINE

rotator

seven-eighths

figure 2-4. lJse

See

ki,t mast), to

KIT

oil ievel

(in

position.

that it

pounds,

lower

erection

to

clear

filI the

of

Texaco

the

115

and

guy

from

the

motor drive key slides

If

wedging results. Motor must fit freely

rotator

into

with thread

recess. Coat

lubricant

toward

mounting bolts

and insert and

motor,

tighten to 25-pound-foot torque value.

Install the

the tower.

of

is

facility J-box at each end and

place

in

conduit

with

figure 2-1, sheet

on the hinged, lower side

The conduit has

a

is

the steel straps

2)

furnished

with the tower

clamping

fastened

(item

28,

kit.

(45),

d.

Attach

the breaker box

rotator control box, item

figure

See

Use a

cable

2-7.

fish tape

assembly through

at both ends using the

the

f.

Connect

electrical

in the J-boxes and

switch assembly.

o

h.

the obstruction

If

stalled,

Apply

see figure

power

and operate

facility on the rotator

that the rotator functions

rotator with the key

person

a

and

standing

facing the rotator.

pull

to

the rotator

the

cable

wires

to the rotator motor and

figure 2-7.

See

lighting

2-8.

controlJ-boxtoensure

slot located

at the top end of

item 20, and

2, tothetowerlegs.

control

conduit.

clamping

to theterminals

kit is

the

properly.

C1amp

J-box.

be in-

to

local control

the

Stop

to the left of

the tower

it

2-14

Revised 1

December

1975

rnstallation

i.

Attach

input

the rf transmission

the rotator.

of

inch reducer

1

506-000 and 01 3-1

transmission

2 and 3.

Strap transmission

straps

(item

Use a 3-l/8- to 7-Sf8-

and a

coaxial elbow

30 1-020) furnished

line kit.

See

line to the

figure 2-9, items

coaxial

(CPN

with

013-

the

Use O-ring supplied with reducer.

line to tower with steel

28, figure 2-1).

Revised

1 December 1975

2-L4A/2-t4B

POSITION

OPTIONAL

SLOT

,,.

-

(*-

,lb-t

'-r-

OF

qljAlll

i O"

SECTION

:

REF

A-A

I

(.]

/

s) ner

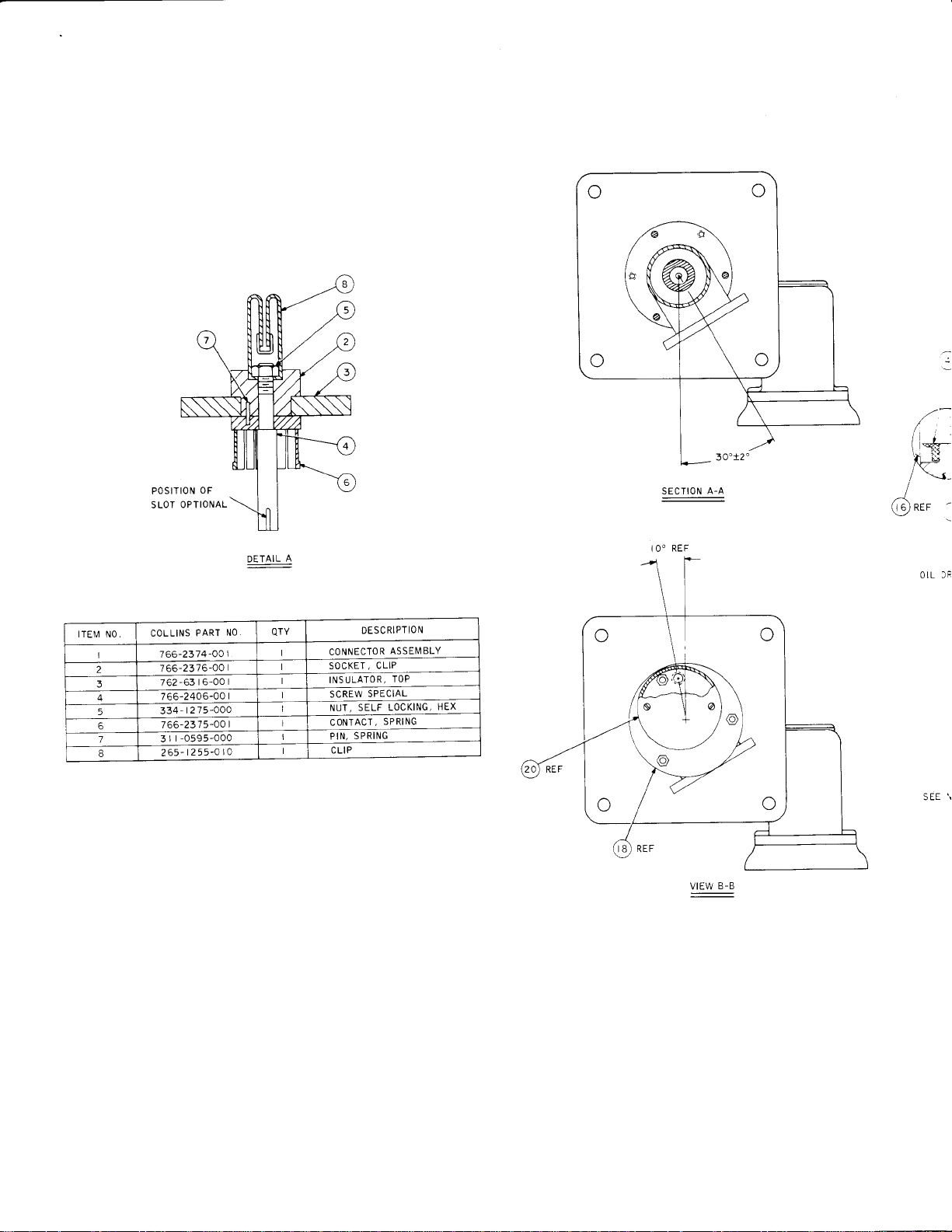

tTEl\,1 N0 .

I

2

3

4

5

6

7

B

PART

COLLINS

7 66-2374-OO

756-2376-00

-63 I 6-00

762

7

406-00

66-2

334-r275-000

766-2375-00

-O595-O00

r

I

3

t255-O

265-

NO QTY

I

I

I

la

DESCRIPTION

SPECIAL