Manufactured by ISO 9001/

14001 certified plant.

Index

Chapter 1 Safety and Compliance 03

Chapter 2 Specification 04

Chapter 3 Print Principle 05

Chapter 4 Accessory Checklist 06

Chapter 5 Electrical Connection 07

Chapter 6 Install and Setup Repetier-Host

6.1

Install Repetier-Host

6.2

Setup Repetier-Host 09

08

Chapter 7 DIY 3D Printer Calibration and Print

7.1

Calibration

7.2

Filament Test

7.3

Print with Repetier-Host

10 -13

Chapter 8 Troubleshoot

14 -15

16 - 18

19

This User Manual is designed to start your journey with the DIY 3D

Printer.

Welcome to the world of DIY 3D Printing!

Following this manual will help you make amazing products.

2

Chapter 1 Safety and Compliance

In this manual, Safety Alert Symbols will be marked at the start of all safety messages. The Safety Alert Symbol means potential safety hazards, which may possibly harm you or others and potentially cause product or property loss.

Safety Alert Symbol

WARNING: HOT SURFACE - DO NOT TOUCH

Desktop 3D Printers reach high temperatures when printing.

Make sure the Desktop 3D Printer is given time to cool down before

touching printer parts.

WARNING: HAZARDOUS MOVING PARTS - KEEP FINGERS AND

OTHER BODY PARTS AWAY

The moving parts of the Desktop 3D Printer will po ssibly cause harm. Do

not touch the Desktop 3D Printer when the printer is r unni ng.

WARNING: Make sure you do not stand too close to the Desktop 3D

Printer when it is running.

CAUTION: Be careful when using unapproved m at erials, these may

damage your Printer and significantly impact on the print quality.

CAUTION: In an emergency, disconnect the power plug from the power

socket.

CAUTION: Ensure that the power socket is located n ear the Printer and

within reach in case of an emergency.

CAUTION: Place the Desktop 3D Printer in a well-ventilated area as the

melted plastic may emit plastic odor when printing.

3

Chapter 2 Specification

Printing Mechanical

Print Technology: Fused Deposition Modeling

Construction Dimension: 200 x 200 x 170mm

Layer Resolution Setting: 0.1 - 0.4mm

Positional Accuracy: XY: 0.011mm

Z: 0.00 25mm

Filament: PLA only

Filament Diameter: 1.75mm

Nozzle Diameter: 0.4mm

Frame: Steel + Engineering Plastic

Platform: Engineering Plastic

XYZ Bearing: Steel

Stepper Motors:

1.8° step angle,

1/16 micro-stepping

Electrical

Storage Temperature: 0

Operating Temperature: 15

Power: 60W

Input Voltage: 110V - 240V 50/60HZ

o

C - 32 oC [32 oF - 90 oF]

o

C - 32 oC [60 oF - 90 oF]

Dimension

Printer Size: 502 x 536 x 382MM

Package Size: 565 x 290 x 285MM

Software

Software package: REPETIER-HOST 0.95F

File Type: .STL,.GCO

Operating System: WINDOWS 7, MAC OS,

LINUX Connection: USB

4

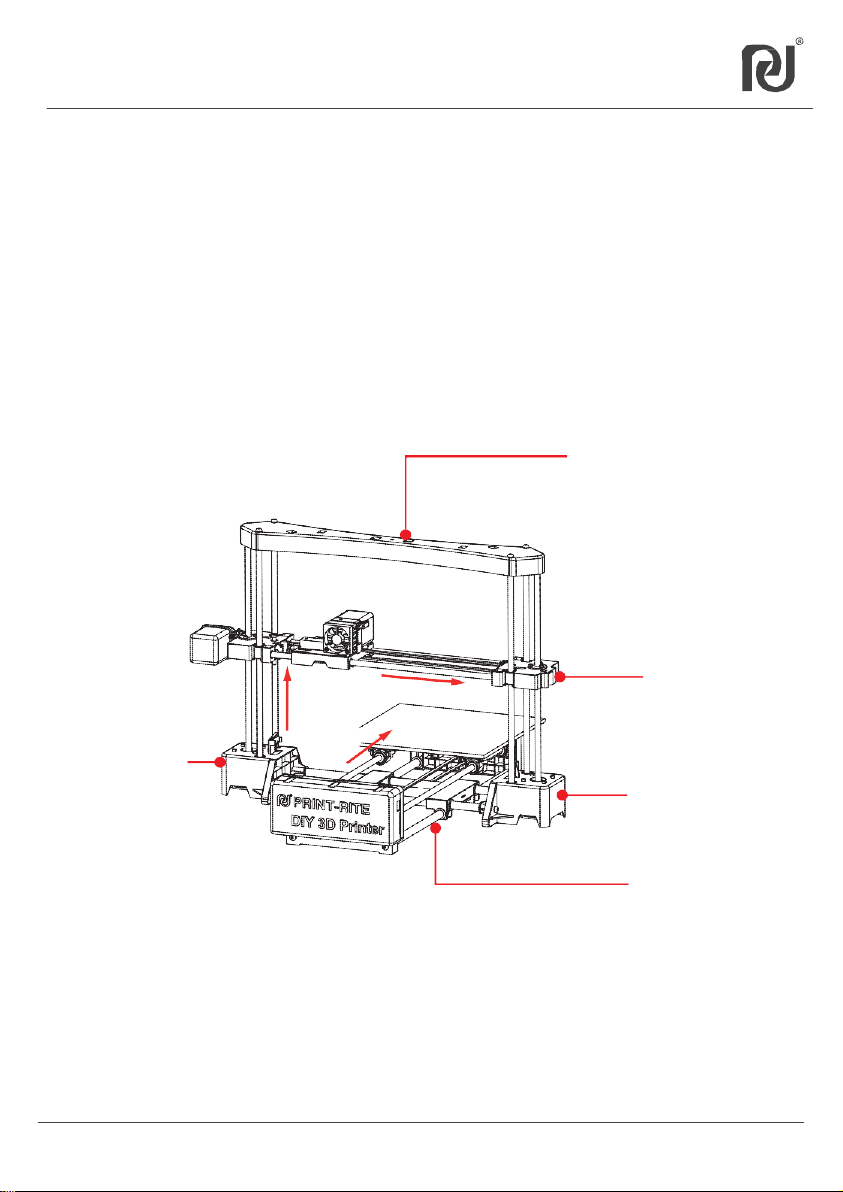

Chapter 3 Print Principle

The DIY 3D Printer makes solid, three-dimensional objects by melting PRINT-RITE PLA filament. The designed 3D files are converted into DIY 3D Printer command through computer software called “Repetier-Host” this is then sent to the printer via a USB Cable. Then, the printer will heat up and melt PRINT-RITE PLA filament and extrude it from the nozzle to make a solid object layer by layer. This method is called Fused Deposition Modeling or FDM.

Filament Insertion

Hole

Left Z Module

Z

Y

X

Back

Y Module

Left

Right Z Module

Right

Front

5

X Module

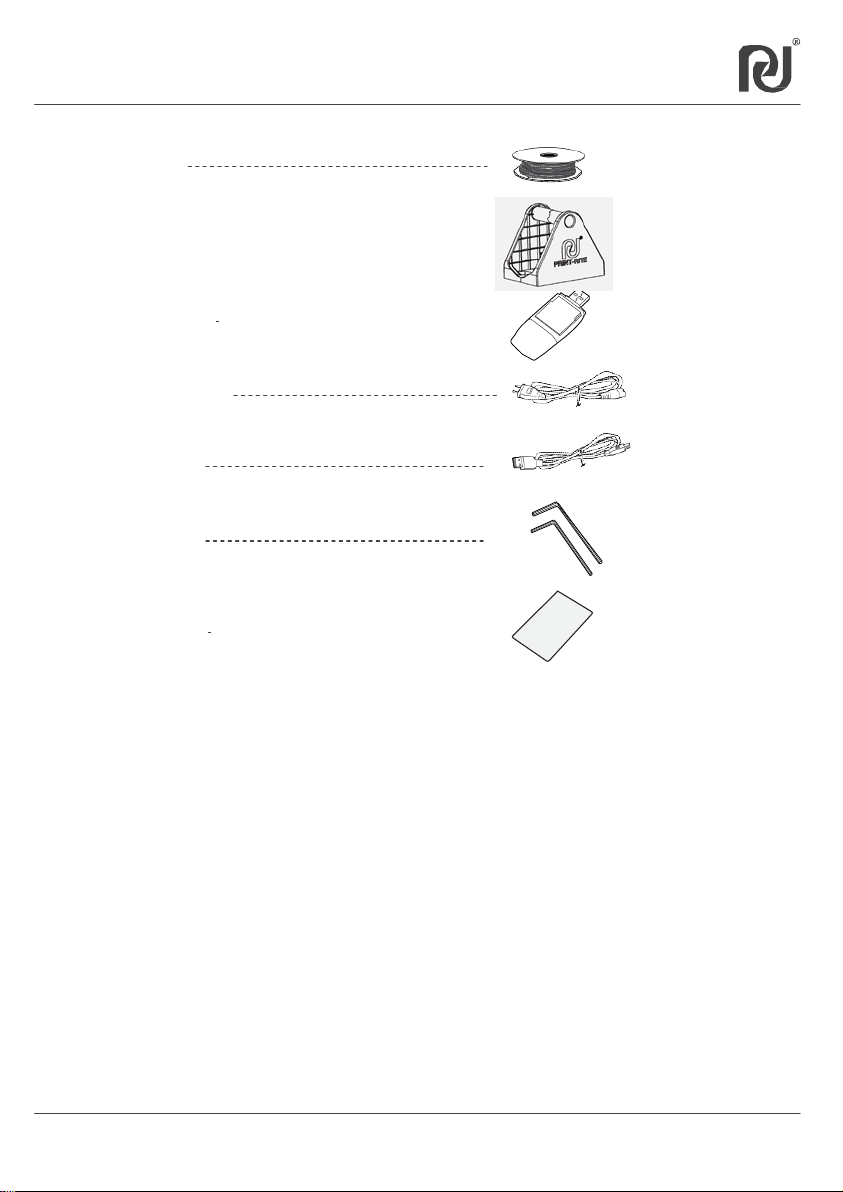

Chapter 4 Accessory Checklist

1 x 0.5kg PLA Filament

Spool Holder

Flash Drive

Power Cable

USB Cable

Screw Drivers

Test Sheet

6

using the USB cable.

Power

Connection

USB

Connection

Chapter 5 Electrical Connection

5.1 Connect the wires to the Mainboard as show below.

(Each wire is uniquely labelled)

3 4 5 6 7 8

2

1

1. X-MOTOR

2. Y-MOTOR

3.

Z-MOTOR

4. E-MOTOR

3R. connect to Z-Motor

3L. connect to Z-Motor

2A connect to Y-Motor

5.2

DIY Printer is now ready.

Connect the printer using the power cable. Connect the printer to the computer

5.

6.

7.

8.

12

FAN

XSTOP

YSTOP

ZSTOP

9.

10.

11.

12.

NOTE: Make sure the

USB Cable Port

ETEMP

HOTEND

POWER INPUT

Z Limit Switch

Z Limit Switch on

the Left Z Module

is assembled.

7

11 10

2A

3L

Reminder during Electrical Connection

1. Connect the wire to the mainboard base

using the label on each wire.

2. Do not connect to the power supply

during electrical set up.

3. Harness the wire cable after connection.

Avoid wire entangelement as this can

cause a connection problem.

9

3R

1 2

3

4

Chapter 6 Install and Setup REPETIER-HOST Software

6.1 Install REPETIER-HOST

REPETIER-HOST is a software which is used to slice the 3D

models (.GCO .STL) and commands the DIY Printer to print.

Computer Operation System:WINDOWS 7, MAC OS, LINUX

Find“setup-RepetierHost_0_95F.exe”in t he Fl ash Drive provided and double click

to start the set-up. You can also download the software from below link.

http://3dclub.przhfanling.com/file/setupPrint-Rite-RepetierHost_0_95F.zip

Start to install the software. (The computer will a sk “Do you want to allow the

following program to make changes to this compute r?”,please click “Yes” to continue

with the software installation.

Repetier-Host is now installed on the computer. See below. Tick “Install driver”

and “Launch Print-Rite Repetier-Host” and then click “Finish” to continue.

The driver is now installed on the computer, click “Fi nish”.

8

-20

200

170

20

15

Printer Settings

4

1

2

3

6.2 Setup REPETIER-HOST

Double click ,to go into "Repetier-Host”software

”

Click "Printer Settings

Set printer settings as below, select the corresponding port (COMx),

Baud rate:115200. Click “Refresh the port” and then select the correct COMx.

NOTE: COMx depends on the

computer or 3D printer you are using.

Also, the COMx can be seen and

matched with COMx in Device

Manager as below when the computer

connects to the printer.

Click “Printer Shape” and set the parameters as shown below. Click “Apply” and then “OK”. Repetier-Host Setup is now complete.

-15

200

200

200

9

Test S

heet

Test S

heet

Chapter 7 DIY 3D Printer Calibration and Print

7.1 Calibration

The printer head and the platform calibration is very important. Incorrect calibration will

severely impact on the printing qua l ity.

7.1.1 “Manual Control”introduction

The DIY Printer calibration and pr inting is controlled by the “Manual Control” menu.

X/Y/Z moving direction

X/Y/Z Home

Printer Head moving rate

Filament flowing rate

Z Home

Returns to initial

position.

Lock/Unlock Motor

Filament flow rate

Filament Retract

7.1.2 Turn off the printer. Rotate the two Z screw rods at the same time until the distance

between the Y Module and Z Module is equal to the test sheet width. This is to ensure the Y

module is level.

Left Y Base

Right Y Base

Nozzle, Platform and Fan

status

Cancel print queue

10

7.1

Calibration

7.1.3 Move the platform away from the nozzle tip before calibration. This is to avoid a ny nozzle

and platform damage.

7.1.4 Turn ON the printer. Click “Connect” to have DIY 3D printer connect to the computer.

7.1.5 Click “Z HOME”in “Manual Control” m enu to go to Z Home position.

11

Z Limit

Switch

Z Limit

Screw

7.1 Calibration

7.1.6 Use the test sheet to check the gap between the nozzle tip and the platform. They

must meet the “Calibration Standard Conditions” as shown below.

Calibration Standard Condition:

The test sheet must be laying

completely flat on the platform,

and the test sheet must be just

touching the nozzle tip.

If the calibration standard condition is not met, the platform level must be adjusted

by adjusting the Z Limit Screw.

Condition 1: There is a gap between the noz zle tip and the test sheet

Adjustment 1: Rotate the Z Limit Screw anti-clockwise by using a screw driver

to move the Z Limit Screw a little closer to the Z Limit Switch as shown

below. Click “Z HOME” to check the calibration condition until the nozzle tip

touches the test sheet.

Test Sheet

Platform

c

Nozzle Tip

12

.

Z Limit

Switch

Z Limit

Screw

7.1 Calibration

Condition 2: The test sheet is over the nozzle tip.

Adjustment 2: Click “+Z” to move up th e nozzle approximately 5mm, rotate the Z Limit

Screw in a clockwise direction using the screwdriver to move the Z Limit Screw

closer to the Z Limit Switch as sho wn bel ow.

Click “Z HOME” to check the calibration condition until the nozzle tip just touches

the test sheet.

555

13

7.2

Filament Test

7.2.1 Load Filament

7.2.1.1 Cut the filament tip using sc issors, Ensure that the end of the filament is flat.

7.2.1.2 Push down the Printer Hea d arm. Insert the filament into the hole located on the top

of the the Printer Head. Push the fil am ent until the tip of the filament is inserted into the

nozzle receiving port. Then release the Printer Head arm.

Printer Head arm

Receiving Port

7.2.2 Filament Test

7.2.2.1 Click “Heat Extrude” to heat up the nozzle to the setting temperature. Once the actual

temperature reaches the setting temperature, click “

”

to extrude the melted filament.

Note: Setup the nozzle setting temperature

base on the filament material you

are using (190 - 210 ℃ for PLA) .

Nozzle Actual Temp

Nozzle Setting Temp

14

Good

Bad

7.2 Filament Test

7.2.2.2 Check the melted filament condition flowing out from t he nozzle.

Good condition:

The melted filament flows out smoothly and continuously from the nozzle.

Bad condition:

The melted filament does not flow out smoothly and continuously from the nozzle.

Note: If the flow of filament is not constant,

check the following.

a. Nozzle Temperature - must be equal to the setting

temperature and according to the filament

material melting temperature.

b. Nozzle Cleanliness - No Clogging

c. Filament Insertion on the receiving port

7.3 Print with Repetier-Host

7.3.1 Click “Load” to select the fi le that you want to print.

Note: The load file should be .STL format. If want to load .GCO file, the .GCO file should be converted from .STL file firstly through following steps, then refer to 7.3.6 to print.

15

“

Click "

" of Bed Temperature “First layer” and “Other layer” and change to “0”.

0 0

c. Click “

”

to save the file and amend the settings name if desired.

0

0

DIY PLA

7.3 Print with Repetier-Host

7.3.2 Setup the platform temperature to “0”.

a.

Click “Configure” to go into “Slic3r” menu.

b.

Click “Filament Settings”, select “printrite PLA”and “Filament”.

7.3.3 Setup the platfom printing size.

Click “Printer Settings” and “General”, revise the “Size”and “Printer Center”as below.

Click " ”to save and name the printer setting.

16

7.3 Print with Repetier-Host

7.3.4 Select “Print Setting”base on the model/effect you want to print, Select “Printer

Settings”and “Filament settings”, then select “Slice with Slic3r” to generate the G-code file.

Print Settings: Select the model that you want to print

Printer Settings: Select “printrite PLA DIY”

Filament settings: Select “DIY PLA”

7.3.5 Click “Run Job”, to start the pr int.

NOTE: Once the nozzle actual temperature reaches the setting temperature, the

printer will start to print.

Slice to generate G-code

Estimated filament usage

17

Estimated filament usage

Estimated printing time

7.3 Print with Repetier-Host

7.3.6 If want to save the file directly after slicing and generating the G-code file (7.3.4), click

“Save Job” to save the G-code file on to the computer. Then refer to 6.3.1 to load the GCO

file and directly click “Run Job” to print .

7.3.7

Additional Information

1. Printed objects must be closed drawings based on the FDM process.

After loading the STL file in Repetier software. It can be moving, scaled down/up, rotated or duplicated.

By clicking “Put Down”, you can place the model on the platform by cl icking “Put In Center”. The m odel

will be placed in the middle of the printing area as shown below. Then slice the revised STL file to print.

2. For 3D printing with the FDM process, we suggest printing the model with OA structure. If

printing the model with OB or OC structure (called Suspended Printing), the parallel or downward layers

will fall down on the model or on the platform due to the lack of supporting layers. You will need to add

support where needed.

18

Remark:

OA– the structure is upward to stretch

OB– the structure is parallel to stretch

OC– the structure is downward to stretch

1.

2.

3.

1.

2.

Chapter 8 Troubleshoot

Question

The filament does not flow

out smoothly or continuously?

What to do when the nozzle

is clogged?

The printed object does not

stick on the platform?

The filament cannot be

pulled out from the printer

head?

The printer does not work after

sending a file to the printer?

The computer cannot

connect to the printer

although Repetier software is

installed?

Need stop during printing ,

what to do?

How long and how much

filament will it take to

print one sample?

The printed sample stick to

the platform and cannot be

removed?

Check if the filament is loaded into the print head properly.

Check if the filament roll can rotate continuously

Check if the nozzle temperature is reaching the correct setting temperature.

1. Heating up the nozzle to the higher temperature (over 20

2. Push down the printer head arm and gently push the thinnest Alan Key into the print

head. This should remove any blockage. Try to re-load filament.

1. Re-calibrate the printer.

2. Check if the temperature setting is correct and matches the filament material you are

using.

3. Check if there is any dust or oil on the heat table. If so, remove with a soft cloth. DO

NOT wash the table.

Check if the nozzle temperature reaches the setting temperature;

When the nozzle temperature reaches the setting temperature, push down the

printer head arm and push a bit filament into the nozzle, then pull the filament out.

.

1. Check the connection between the printer and the computer.

2. Check if there are files in the print queue. Click “OK” in the manual control menu to

cancel the print queue.

3. Power OFF the printer and Power ON to re-start.

1. Check if the printer is connected to the computer with the USB cable and turned on.

2. Check if the selection of COM port in the printer setting is right by referring to 6.2

3. Un-install the Repetier software and re-install.

1. If you need to pause printing temporarily, click “Pause Job” in the Repetier software

2. If need stop printing, click “Kill Job”in the Repetier software.

The filament usage and printing time is based on the sample size and simple/complex

shape, the filling density (the higher the filling density, the more filament usage and lower

printing time), the printing setting (Best, Standard, Draft in Print Rite Repetier).

Refer to 7.3.5, after selected the printing setting to slice, the software will show the estimated

filament usage and printing time.

Using a thin metal sheet to remove the printed sample from the platform carefully.

If you need more assistance, please feel free to contact us:

Email: 3Dsupport@utec.com.mo

DIY

Printer

19

Solution

℃

than setting temperature).

Loading...

Loading...