Page 1

WARRANTY

COLE-PARMER INSTRUMENT CO. , for itself does hereby offer a warranty for products from the date of receipt by the user, under normal

and proper usage, against defects in workmanship and materials for 12

months, and will repair or replace any defective part ( s) without charge

when same is shipped Prepaid to COLE_PARMER INSTRUMENTS

from which the product was originally

purchased.

Should the nature of any defect require that the product , or any constituent portion thereof , be returned to Cole-Parmer Instrument Co.,

Vernon Hill, Illinois, prepaid for service, a condition precedent to any

return shall be the procurement of authorization from Cole-Parmer Instrument Co. assigning a Return Goods Number to the product or part

requiring service.

Parts and accessories manufactured by others are warranted only to

the extent of the regular warranty of the manufacturer or supplier of

such materials and only insofar as Cole-Parmer Instrument Co. is able

to transfer the benefits of warranty coverage, if any , to the user. Any

adequately warranted defective part or accessory manufactured or supplied by others may be exchanged through Cole-Parmer Instrument Co.

for a replacement part is shipped prepaid and received at Cole-Parmer

Instrument Co. within 30 days from the date any replacement part is

obtained by the user.

This warranty supersedes and is given in lieu of all implied warranties,

and is void if the user causes damages from improper usage of product

under normal operating conditions.

12 MONTHS LIMITED WARRANTY ON ALL PARTS AND LABOR IS

GIVEN BY COLE-PARMER INSTRUMENT COMPANY

CATALOG NUMBER 28680-30

SERIAL NUMBER _________

DATE OF PURCHASE _______________

page 8

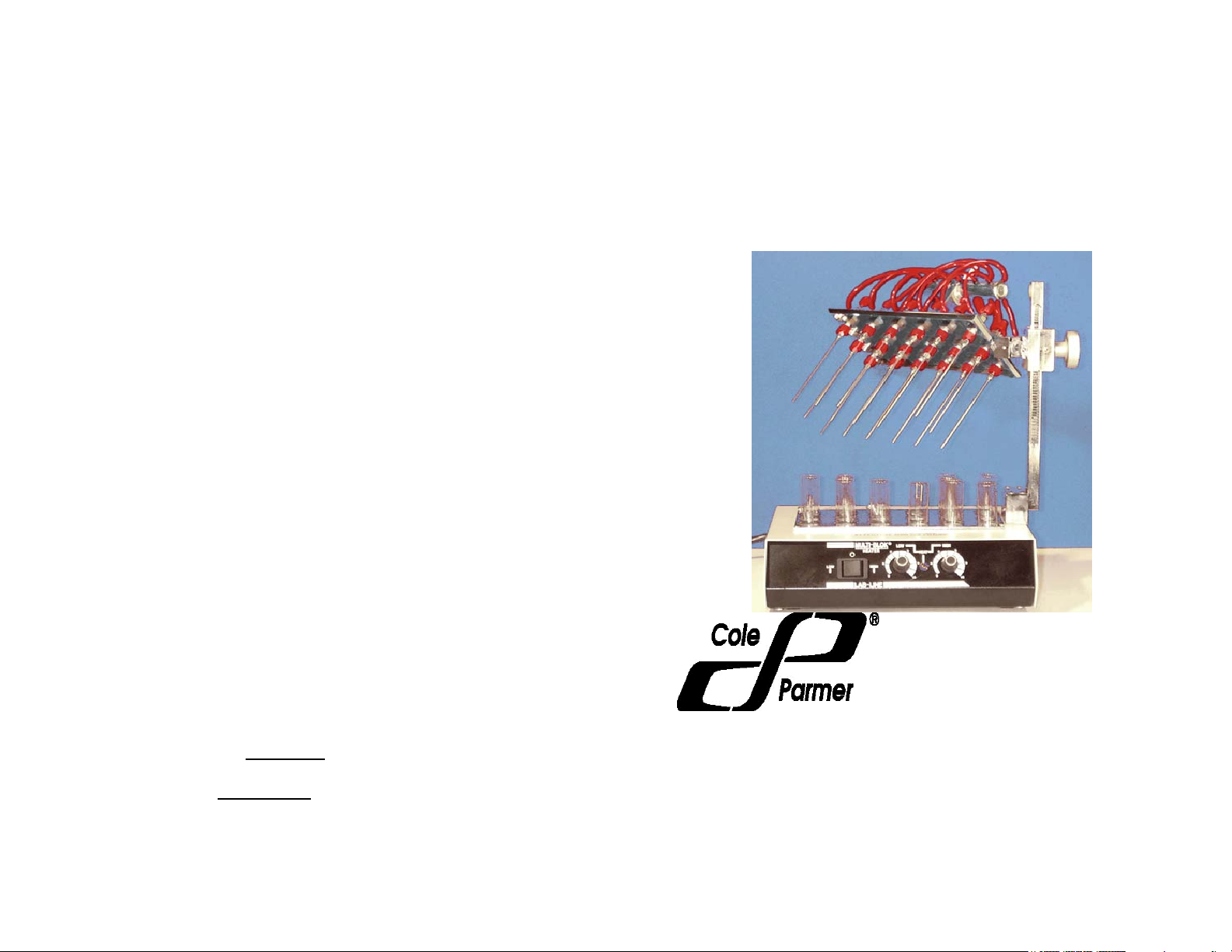

Operation Manual

Cole-Parmer Model Z1800

Catalog No. 28680-30

18 position ZipVap

Cole-Parmer Instrument Company

625 East Bunker Court, MS 18

Vernon Hills, Illinois 60061-1844, U.S.A

Phone: 847-549-7600 Fax: 847-549-7676

( 800) 323-4340

Page 2

INTRODUCTION

Cole-Parmer Instruments Z1800 Cat# 28680-30 Evaporator and Con-

centrator is designed to provide rapid evaporation of solvents or water

for 18 samples, test tubes or containers. It is supplied with a triple

block heater. It includes 18 individual needle valves for controlling the

flow to each positions containers. It is designed to be easily accessible

with the geared height adjustment and a manifold swing away platform.

1 to 18 samples can be utilized for evaporation at any time.

Materials of Construction

Cole-Parmer Model Z1800 evaporator is fabricated with aluminum,

brass, and plastic. All brass pats are nickel plated for corrosion resistance.

Features

► compact size to take minimal space

► rectangular manifold plate that pivots 90˚ forward and backward, and

it will rotate 360° horizontally for easy access to needles and valves.

► a rack to be able to insert different tubes and easily align the needles

for evaporation

► accomadates tubes or containers from 8 mm to 25 mm diameter with

volumes from 1 ml to 50 ml.

► 18 individual fine needle control valves

► 18 stainless steel needles 4 inch x 16-gauge

Contents

Page 1- Title Page

Page 2– Introduction and Table of Contents

Page 3- System Specifications

Page 4- User Instructions

Page 5- Drawing

Page 6- Parts List

Page 7- Maintenance

Page 8- Warranty

Page 2

Maintenance

BE ADVISED:

NOTE: MAKE NO ATTEMPT TO SERVICE OR REPAIR A COLEPARMER PRODUCT UNDER WARRANTY BEFORE CONSULTING

COLE-PARMER.

AFTER THE WARRANTY PERIOD, SUCH CONSULTATION IS STILL

AD-VISED, ESPECIALLY WHEN THE REPAIR MAY BE TECHNICALLY SOPHISTICATED OR DIFFICULT.

IF ASSISTANCE IS NEEDED, PLEASE CALL COLE-PARMER

AT 847- 549-7600OR FAX US AT 847-.549-7676

NO MERCHANDISE, HOWEVER, SHOULD BE RETURNED DIRECTLY TO COLE-PARMER WITHOUT PRIOR APPROVAL FROM

COLE_PARMER

CAUTION: IF UNIT IS SUPPLIED WITH HEATER DISCONNECT

PLUG FROM ELECTRICAL OUTLET BEFORE ATTEMPTING ANY

MAINTENANCE OR REPAIR.

PARTS REPLACEMENT:

Unplug heater from outlet. Remove it from evaporator. Identify and

replace defective parts by referring to drawing on page 6 and parts

list page 7.

If replacement parts are needed please contact COLE-PARMER.

GENERAL MAINTENANCE:

Unplug heater after use. Clean the inside. This will insure proper

operation for an extended period of time.

Page 7

Page 3

Parts List

Part Number

1. 10-- 00011—00 Manifold Plate

2. 12—00012—00 Top Clamping device for manifold

3. 12 – 00013—00 Bottom clamping device for manifold

4. 10 – 00014—00 Manifold cylinder

5. 10 – 00015—00

6. 18 – 00016—00 Support Post

7. 12 – 00017—00 Inner Part for gear assembly

8. 14 – 00018—00 Height positioning knob

9. 18 – 00019—00 Gear holding rack

10. 12 – 00110—00 Inner Part for gear assembly

11. 14 – 00111—00 (4) ½” 10-32 LPSC

12. 12 – 00112—00 Inner Part for gear assembly

13. 12 – 00113—00 Inner Part for gear assembly

14. 12—00114—00 Inner Part for gear assembly

15. 12 – 00115—00 Inner Part for gear assembly

16. 14 – 00116—00 Inside support bar

17. 24 – 00117—00 4” SS luer Needle

18. 28 – 00118—00 Male Luers 10-32

19. 10 – 00119—00 Needle valve/ 10-32 * .062 Black fitting

20. 26 – 00120—00 Red handle

21. 10 – 00121—00 (18 ) Polyurethane Tube 1/8 x 1/16

22. 10 – 00122—00 ½” 10-32 Low profile socket screws

23. 10 – 00123—00 (18 pcs.)10-32 Black Nylon fitting for

1/16” tube

24. 18 – 00124—00 (3) ¼” 10-32 Low profile socket screw

25. 18 – 00125—00 Base post holder

26. 30 – 00126—00 Lab-Line triple block heater

27. 30 – 00127—00 Test tube rack

28. 30—00128—00 Zirconia beads for heater (500cc)

NEED A PEPLACEMENT PART? CALL COLE-PARMER

Phone: 847-549-7600 Fax: 847-549-7676

Cole-Parmer Instruments reserves the right to make changes to

specifications without prior notice.

page 6

Description

¼” tube inlet

System Specifications

Z-1800 System Specifications

Number of samples 18

Bench space 16.5 x 11 x 15 in.

(w x d x h) 18 x 33 x 46 cm

Test tube size range 8 to 25 mm

Type of Gas Nitrogen or Air

Gas Flow 0 to 10 Liters/min.

The instrument consists of a base and stand assembly, a sample holder, and a gas

distribution system. Test tubes (or other containers) can be held in position by the

Zirconia beads. Each position is numbered. Gas passes through a constant pressure

manifold assuring an equal access to each valve to the amount of gas needed. Gas is

supplied by a flexible 1/4” od. x 1/8” id silicone tube to the manifold, inert red

polyurethane tubing supplies each needle valve with gas from the manifold. The depth

can be lowered to any desired height. The height depends on the container, bath

temperature , the solvent to be evaporated, and flow rate of the evaporating gas.

Evaporation rate depends on both temperature and flow rate of the gas. Flow can be

adjusted with the individual needle valves. Gas pressures up to a maximum of 40 psig

can be utilized. Most applications require only 10 to 25 psig.

All materials used are laboratory quality and can be used with all standards organic

solvents and water including mild acid and bases.

Typical Evaporation Rates

boiling heater time to flow

Solvent point temp dryness rate

Name

Hexane 69°C 22°C 10 min 100 cc/min

Methylene

Chloride 40°C 37°C 12 min 300 cc/

Methanol 65°C 63°C 20 min 300 cc/min

page 3

min

Page 4

User Instructions

1. Place unit in required area to be used with an exhaust apparatus

such as a hood.

Evaporation of water does not need an exhaust.

2. Attach the 1/4 inch inlet of the round distribution manifold located on

top of the unit to Nitrogen or air source

Refer to drawing diagram page 5 part no. 5.

3. Raise needle holder plate to desired height by using knob

part no. 8 .

Refer to drawing diagram page 5, part no. 8.

4. A light push or twist on manifold plate will unlock the plate and it will

rotate for easy access to all tubes.

Refer to page 5, no. 1

5. Twist lightly on the left side of the manifold plate for up to 90° de-

grees of pivot forward, and/or backwards for easy access to needles

and valves.

Refer page 5, no. 1

6. Insert test tubes in one or more of the 18 position test tube holder

provided. Sizes 8 mm diameter to 25 mm diameter can be used.

7. Lower the needle holder plate by using gear knob part no. 8 in the

figure on page 5 to desired height.

Refer to figure page 5, no. 8.

8. Adjust test tubes so that the needle will be centered in the tube and

lower needles to desired height.

9. Adjust gas flow by using the individual needle valves. We suggest

you set gas flows by first fully opening the valves (counter clock

wise), then setting desired flows. It is suggested to start flow

adjustment with the fine needle valve fully open (counterclockwise)

then reduce flow to desired amount.

10. Set heater to desired temperature.

11. Caution: Do not over tighten needle valves. Over tightening can

causebreakage. To shut off a port use the supplied plugs, not the

valve.

If you have any questions please contact Cole-Parmer on the use

of this product. Phone: 847-549-7600 Fax: 847-549-7676

page 4

Model Z1800

No. of samples 18

Model No. Z1800

Bench space 16.5 x11 x 15 in

( w x d x h ) ( 42 x 28 x 38 cm )

page 5

Loading...

Loading...