Page 1

TN100 PortableTurbidity Meter

Instruction Manual.

Page 2

Table of Contents

1. Overview --------------------------------------------------------------------------------------

2. Technical Specifications --------------------------------------------------------------

3. Instrument Description ----------------------------------------------------------------

3.1 Instrument Overview ---------------------------------------------------------------------

3.2 Meter and Accessories --------------------------------------------------------------

3.3 Display-----------------------------------------------------------------------------------

3.4 Keypad ----------------------------------------------------------------------------------

3.5 Battery Installation----------------------------------------------------------------------

4. Meter Calibration -----------------------------------------------------------------------

4.1 Calibration Standards--------------------------------------------------------------

1

2

3

3

4

5

5

6

6

6

4.2 Calibration Procedure------------------------------------------------------------------

4.3 Calibration Notes --------------------------------------------------------------------------

5. Turbidity Measurement---------------------------------------------------------------------

5.1 Sample Vial Handling------------------------------------------------------------------

5.2 Measurement Preparation ----------------------------------------------------------

5.3 For Single-Shot Measurement---------------------------------------------------------

5.4 For Continuous Measurement----------------------------------------------------------

5.5 Measurement Notes----------------------------------------------------------------------

6. Warranty--------------------------------------------------------------------------------------

7

8

8

8

8

9

9

9

10

Page 3

1. Overview:

Thank you for selecting our portable TN100 turbidity meter.

This meter is perfect combination of the most advanced electronic technology and software

design, and is the most cost-effective handheld turbidity meter. This meter operates on the

nephelometric principle of turbidity measurement and is designed to meet the criteria

specified in ISO7027 and DIN 27027 standards. TN100 allows you to measure turbidity of

an aqueous sample both in laboratory and in the field.

With built-in microprocessor chips, beautiful appearance, easy to use, the meter has the

following marked characteristics:

z Intelligent functions, such as automatic calibration, operation directive, automatic

power-off and low voltage display etc.

z Large TFT color screen, showing blue background in measuring mode, green

background in calibration mode and text and graphics in operation directive.

z With advanced digital processing technology, the accuracy of the meter is greatly

improved.

z The meter structure design meets the requirements of IP67sealing level and is suitable

for use in field and on-site.

z With customized carrying case, containing calibration standards, sample vials and other

necessary accessories which are more convenient to use and carry.

- 1 -

Page 4

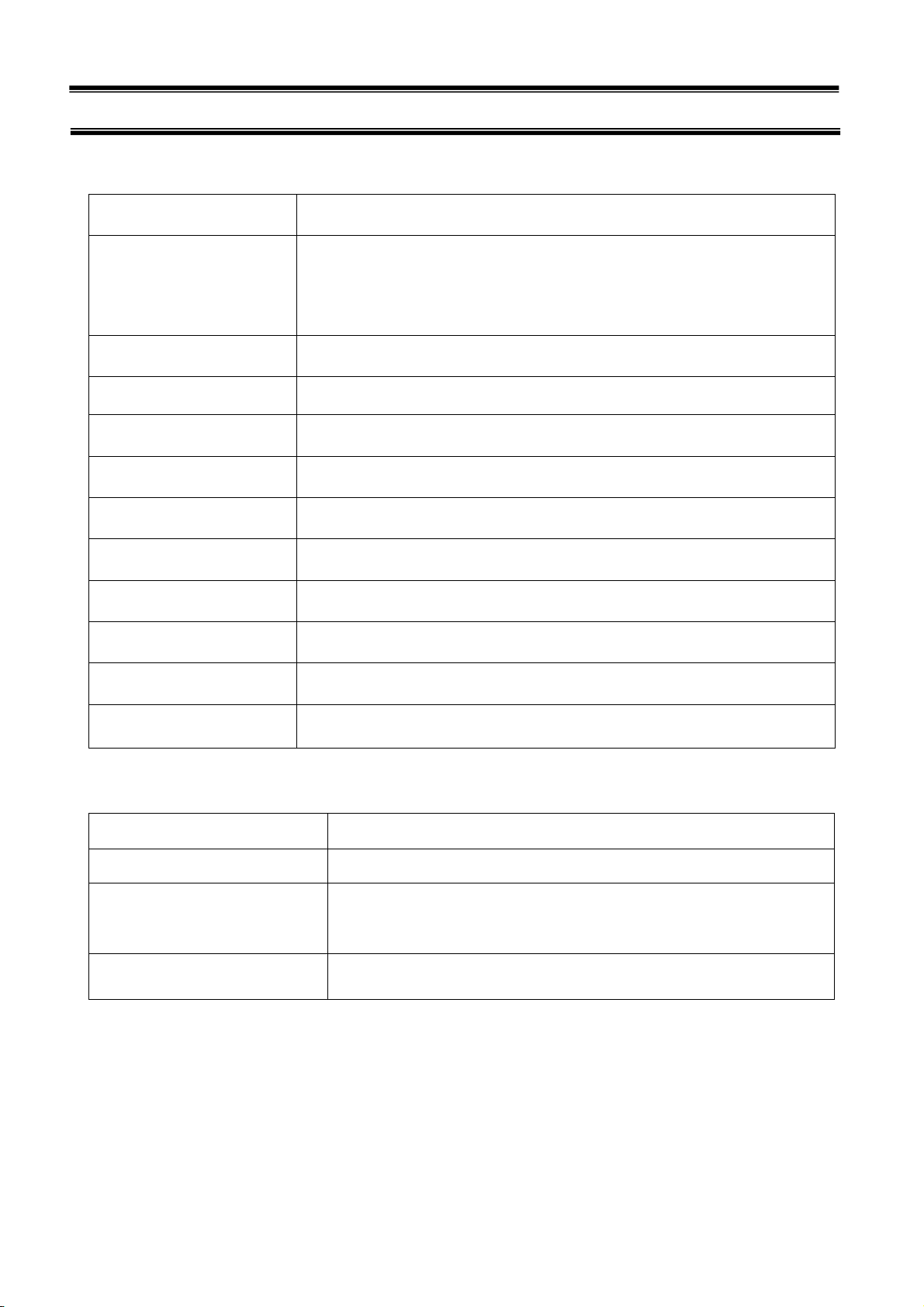

2. Technical Specifications

2.1 Technical Parameters

Measuring Method

ISO 7027 compliant nephelometric Method(90°)

0 ~ 1000 NTU, automatic range selection:

Measuring Range

0.01~19.99 NTU

20.0~99.9 NTU

100~1000 NTU

Resolution 0.01 / 0.1 / 1 NTU

Indication Error ≤ ±2 % of reading±stray light

Repeatability ≤ ± 1% of reading or 0.02 NTU, subject to whichever is greater

Calibration Standards 0.02 NTU, 20.0 NTU , 100 NTU, 800 NTU(Polymer)

Light Source

Infrared-emitting diode(850nm wavelength)

Detector Silicon photovoltaic

Display TFT Color screen

Sample Vials Φ25×60 mm, high borosilicate glass with screw cap

Sample Volume 18 ml

Operating Temp.

Range

0~50℃(32 ~122℉℉)

2.2 Others

Power Supply 4x “AA” Alkaline Batteries

IP Rating IP67

Meter:(90×203×80)mm / 385 g

Dimension/Weight

Quality and Safety

Certificate

Carrying case:(310×295×110)mm / 1.5 kg

ISO9001:2008 & CE

- 2 -

Page 5

3. Instrument Description

3.1 Instrument Overview

① Housing ⑥ Sample well

Flip cover of the sample well(Close the

②

cover when measuring)

③ Display ⑧

④ Keypad ⑨ Battery cover

Diagram-1

⑦ Calibration vials or sample vials

Positioning mark (Align the mark with

the mark on the calibration vial or the

sample vial)

Dust proof plug(Take off the plug when

⑤

measuring)

- 3 -

Page 6

3.2 Meter and Accessories

Standard solution: 0.02NTU, 20.0NTU,

①

100NTU, 800 NTU

② Carrying case ⑦ Sample vial×3

③ TN100 Meter ⑧

④ Soft cloth ⑨ Instruction manual

⑤ “AA” Alkaline battery×4

Diagram-2

⑥ Silicon oil(10 ml)

Screwdriver(to remove battery

cover)

- 4 -

Page 7

3.3 Display

Measuring Mode

① — Measuring indication icon

② — Measured value/Unit

③ — Progress bar

④ — Operation directive

⑤ — Low battery indicator

Calibration Mode

① — Calibration indication icon

② — Measured value/Unit

③ — Progress bar

④ — Operation directive

Calibration Menu Mode

3.4 Keypad

① — Calibration indication Icon

② — Standard solution value

③ — Operation directive

- 5 -

Diagram- 3

Page 8

Key Functions

z Power on/off

z The meter will automatically shut off 10 mins after last key press

z Initiate /Exit the calibration mode

z In measuring mode:Short press the key to perform single-shot

measurement; long press the key to perform continuous measurement.

In calibration mode: press the key to confirm the calibration.

z In calibration mode, press the key to select standard solution.

3.5 Battery Installation

1. Use the screwdriver to remove the four screws on the battery cover and open the

battery cover.

2. Insert 4 pieces of “AA” alkaline battery. Please make sure the polarity is correct.

3. Put on the battery cover and screw tightly.

4. Meter Calibration

TN100 turbidity meter needs to be calibrated with the provided standard solution when

used for the first time. For normal use, it is suggested to calibrate the meter monthly or

weekly; or user can perform verification test, which is to test the standard solution that is

close to the value of the test sample. If the error is big, it is necessary to calibrate the meter.

To ensure the accuracy, 4 polymer standards included in the meter kit should be selected to

calibrate the meter.

4.1 Calibration Standards

TN100 turbidity meter adopts US EPA certified Reagecon high-molecular polymer turbidity

standard solution. Compared with traditional Formazin standard solution, Reagecon

standard solution has a lot of advantages, such as non-toxicity, high accuracy, long

shelf-life, traceable to NIST and so on. The standard solution supplied in the TN 100

turbidity meter kit has a shelf-life of 12 months (from the date of manufacture). Please

check the date on the bottom of the vials before using.

- 6 -

Page 9

4.2 Calibration Procedure

1)Apply a little silicone oil on the

calibration vial and wipe with the soft

cloth to obtain an even distribution.

Turn the vial of 20.0, 100, 800 NTU

upside down several times and set it

still for 2 mins.(0.02 NTU doesn’t

need to be overturned)

4) Press key to enter into

calibration menu, and press

key to perform calibration when

cursor indicates on 0.02NTU.

7) After calibration with 20.0 NTU

standard, press key to

enter into calibration menu.

2)Press key to turn on the

meter. The meter indicates

measuring mode.

After calibration with 0.02NTU

5)

standard, press key to

enter into calibration menu.

8) When cursor indicates on

100NTU, put the calibration vial of

100NTU into the sample well and

press key to calibrate.

3) Open the flip cover and put in

0.02NTU calibration vial. Align the

mark on the vial with the mark on

the sample well and then close the

cover.

6) When cursor indicates on

20.0NTU, put the calibration vial of

20.0 NTU into the sample well and

press key to calibrate

9) After calibration with 100 NTU

standard, press key to

enter into calibration menu.

10) When cursor indicates on

800NTU, put the calibration vial of

800 NTU into the sample well and

press key to calibrate.

11) After calibration with 800 NTU

standard, press key to

confirm.

- 7 -

12) The meter enters into

measuring mode.

Page 10

4.3 Calibration Notes

1) Place turbidimeter on a flat and level surface,

please don’t hold the instrument in hand.

2) When place calibration vial into measuring well, the arrow

mark on vial cap must be aligned with the arrow mark on

the measuring well. See diagram-4

3) Apply 1-2 drops of silicone oil on the calibration vial and

wipe even with soft cloth to cover up the scratches and

flaws on the glass surface. It’s helpful for light scattering. After wiping and cleaning, set

the calibration vial still on the table for at least 2 minutes to eliminate micro bubble in

solution. For 0.02 NTU calibration vial, the standing time should be at least 5 minutes.

4) Please perform 4 points calibration for first time use according to clause 4.3. 2~4 points

calibration can be selected for subsequent use according to requirement. Measuring

value is better to be between two calibration values. When calibrating, press

or to select calibration standard. After calibrating, press button to quit

and enter into measurement mode.

5) If use Formazin standard to calibrate, please note the diluents Formazin standard is not

stable. Please make sure to use new prepared Formazin standard to ensure calibration

precision.

6) Please don’t open cap of calibration vial. Inspect the expiration of calibration standard.

Make sure the calibration vial free from dust, dirt, fingerprint and scratch.

7) Please use same method to calibrate every time, and establish standard operating

procedure.

Diagram- 4

5. Turbidity Measurement

5.1 Sample Vial Handling

1) There are 3 sample vials contained with the instrument, marked 1#, 2# and 3# on the

vial cap. There is also same number in the bottom of sample vial. Please note the

number of sample vial should be same with that of vial cap, don’t mix up.

2) Sample vial has been meticulously cleaned and disinfected. It can be used directly for

the first time. When subsequent using sample vial should be strictly cleaned: wash the

interior and exterior of the vial in a detergent solution repeatedly rinse with clean

distilled water or deionized water rinse sample vial with sample solution twice

fill sample vial with sample solution

screw the vial cap tightly.

5.2 Measurement Preparation

1) Collect sample solution in clean vessel, fill sample solution to the

four fifth position of sample vial(approx 18ml), see diagram-5,

screw the vial cap tightly.

2) Before measuring, please make sure sample solution is uniform.

- 8 -

Diagram- 5

Page 11

Slowly roll over the sample vial to make sample solution uniform, and wait air bubble to

eliminate completely.

3) Wipe the sample vial surface with the soft cloth. Ensure that the outside of the vial is

dry, clean and free from smudges.

4) Apply 1~2 drops of silicone oil on the vial surface. Wipe with a soft cloth to obtain an

even distribution over the entire vial’s surface, in order to fill small scratches and mask

the imperfection on vial surface.

5) Place turbidimeter on a flat and level surface, please don’t handheld the instrument.

6) Hold vial cap, aligning the arrow mark on vial cap with the arrow mark on the calibration

well, insert sample vial into the measuring well and close the cover

5.3 For Single-shot Measurement

Press button, the display shows progress

bar(see diagram-6). It will display measured value

after 8 seconds. Please press button again for

repeated measurement.

5.4 For Continuous Measurement

Diagram-6

1) Press and hold button, release it until the display

shows wire frame of process bar(see diagram-7). The

instrument enters into continuous measurement mode, the

display is updated every 8 seconds, continuous measurement

and display. If to quit, press button again, the

instrument will enter into single-shot measurement.

Diagram-7

2) Continuous measurement mode can be used to observe the process of turbidity

changes to stable. It’s also suitable for sample solution which precipitates faster, record

every measuring value and calculate the average value.

5.5 Measurement Notes

Turbidity is a very complex analytical measurement which can be affected by many

factors. Some are inherent in the instrument’s design. However, there are also other

factors such as stray light, air bubbles, care of vial and operating technique etc.

1) Sample Vial

Sample vial must be meticulously clean and free from spot and scratches. Its surface

should be applied some silicone oil and wiped by soft cloth to treat on the outside with

a uniform thin coat of silicone oil. This is to mask minor imperfections and scratches

that may contribute to stray light. Do not apply large quantity of oil as this may collect

dirt and dust. When wiping sample vial, it should be handled only by the top to avoid

fingerprints left on the surface of glass vial.

2) Silicone Oil

The refractive index of silicone oil should be same with that of glass vial. It is

recommended to use silicone oil supplied with the instrument.

3) Match Sample Vials

Instrument is supplied with 3 sample vials which were optically matched when leaving

- 9 -

Page 12

factory, they have good consistency. If user need to purchase more sample vials,

please use separately according to a set of 3 pieces. Or user can operate optical

match by himself, the method as below: clean the sample vial, fill about 0.5 NTU pure

water or distilled water into vial. After cleaning the surface of vial, more than 5 minutes

stewing time to eliminate bubble. For each vial, rotate and measure the data of 8

angles and record it. Find the closest position of these vials measuring value and mark

it.

4) Mix and Degassing

Samples should not be violently shaken or agitated. It is recommended to slowly roll

over sample vial to make solution evenly; Air bubble in solution will cause big error to

turbidity measurement. So air bubble must be eliminated before measuring. But

obviously mix and degassing is a process of contradiction, especially for solution with

precipitate, it’s much more difficult to handle. Need some operating experience or

stipulate some measurement condition. For example, stipulate same mix condition and

stewing time for degassing, then compare measuring value.

5) Low Turbidity Measurement

To measure sample with very low turbidity, it’s better to use same sample vial. This can

offer best accuracy and repeatability.

6) Other Requirement

a) On the premise of ensuring uniform sample, sample should be measured immediately

to prevent temperature changing and precipitate from effecting measuring value.

b) As far as possible to avoid the sample dilution for measurement.

c) Avoid operating under direct sunlight.

d) Don’t pour solution into measuring well, sample vial must be used for measurement.

e) Please don’t try to wash measuring well, this may damage the optical structure of

measuring well.

6. Warranty

6.1 Since the purchasing date, the meter is supplied with a 2-year guarantee period and

calibration standards for 6 months.

Within the guarantee period, repair, component or product replacement will be made

without charge due to unable work caused by manufacturing defects.

6.2 The above warranty shall not inadequate maintenance by customer, or damage caused

by opening to apply to defects resulting from improper use, repair by oneself.

Cole-Parmer Instruments

625 E Bunker Court

Vernon Hills, IL 60061

www.coleparmer.com

- 10 -

Loading...

Loading...