Page 1

Thermo Scientific

STD5000 & STD6000

Current-to-Pressure (I/P) Transducers

Based on superior E-Pi technology,

Thermo Scientific STD5000 and

TD6000 current-to-pressure (I/P)

S

transducers set the standard in the

industry for reliable electronic input

signal conversion. An innovative,

field-proven design and superior

technology ensure accuracy,

reliability and ease-of-use to facilitate

operations and increase productivity.

Product Specifications

Features and Benefits

• Accuracies of ±0.15% to ±0.25% of span

• Advanced E-Pi technology that is unaffected

by vibration, shock or mounting position

• High supply pressure ranges of 35 PSIG to

100 PSIG available with select output ranges

• Intrinsically safe or explosion-proof

models available

• Operating temperature range of

-40°C to +66°C (-40°F to +150°F)

• Rugged NEMA 4X and IP65 enclosure

• Field-selectable direct and reverse modes

Accurate & Reliable

The rugged, compact Thermo Scientific

STD5000 and STD6000 current-to-pressure

(I/P) transducers provide reliable electronic

input signal conversion in the most

demanding industrial environments.

Backed by our field-proven E-Pi technology,

these transducers ensure accurate,

repeatable performance that is unaffected

by shock, vibration or mounting position,

minimizing maintenance and increasing

process optimization.

Field-Proven & Stable

Field-proven Thermo Scientific E-Pi transducer

technology is recognized as a revolutionary

breakthrough that provided the industry

with its first “solid state” I/P transducer.

This advanced E-Pi technology uses a

minimal amount of electrical energy and

air consumption to convert a 4-20 mA input

signal to a proportional pneumatic output

signal (3-15 PSIG, 0.2-1 BAR, etc.). This

pneumatic (backpressure) output is precisely

modulated by a virtually weightless, low mass

membrane that is held in a continuously

balanced position. The output of the E-Pi is

fed into an integral volume booster to

deliver a pneumatic output signal with

an output capacity of 4.0 SCFM. Overall

performance, accuracy and repeatability

are further enhanced via an internal

feedback network that allows the

transducer to quickly respond to input

changes. These balanced supply and

exhaust dynamics enhance stability while

delivering accuracies of ±0.15% to ±0.25%

of span for superior process control.

Easy to Install & Maintain

When the installation area is limited,

the compact size of the transducer enables

it to be situated on the valve as needed,

including at an angle or upside down,

with no effect on functionality. In addition,

the rugged NEMA 4X housing ensures

durability and long life for maximum

return on investment.

Page 2

Specifications

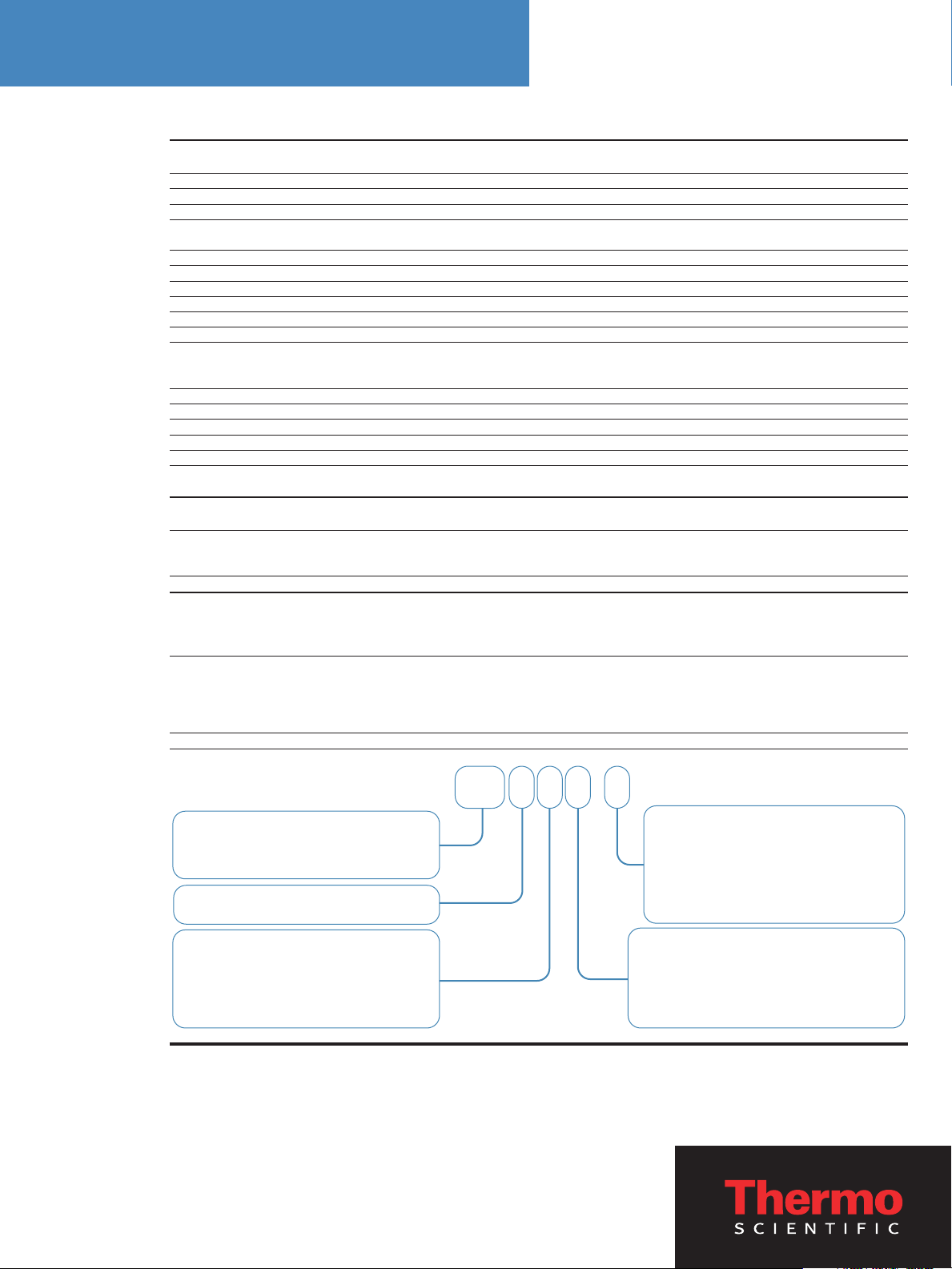

STD A B C D

MODEL NUMBER

STD5: STD5000 I/P (current-to-pressure), NEMA 4X

STD6: STD6000 I/P (current-to-pressure),

explosion proof, dust ignition proof, NEMA 4X

A. INPUT

1: 4-20 mA, intrinsically safe

B. OUTPUT

1: 6-30 PSIG; split range not available

2: 3-27 PSIG; split range not available

3: 3-15 PSIG (standard or high supply pressure)

4: 1-17 PSIG

6: 0.2-1.0 BAR (standard or high supply pressure)

C. SUPPLY PRESSURE

1: Standard supply pressure

(20 PSIG for 3-15 PSIG & 0.2-1.0 BAR outputs;

35 PSIG for 1-17, 6-30 & 3-27 PSIG outputs)

H: High supply pressure

(35-100 PSIG for 3-15 PSIG / 0.2-1.0 BAR outputs only)

D. OPTIONS

1: Pipe mount; includes mounting bracket

and U bolt for 2.5-inch pipe

2: Jack plug for I/P (not ATEX approved)

3: Direct only; reverse mode has been disabled

5: Valve mount kit; includes bolts and washers

for mounting to valve yoke

-

MODEL NUMBER

INPUT

OUTPUT

SUPPLY PRESSURE

OPTIONS

Thermo Scientific STD5000 & STD6000 Current-to-Pressure (I/P) Transducers

Functional Specifications

Accuracy ±0.15% of span (3-15 and 1-17 PSIG output); ±0.25% of span (3-27 and 6-30 PSIG output)

Repeatability 0.05% of span

Deadband 0.02% of span

Stability/Reproducibility 0.5% of span/6 months

Output Capacity Standard: 4.0 SCFM (supply and exhaust characteristics are balanced to within ±10%)

Air Consumption 0.04 SCFM steady state average (0.06 SCFM maximum)

Position Effect Not measurable

Vibration Effect <0.25% from 1-200 Hz/1g

Frequency Response -3 db at 5 Hz (per ISA-S26.4.3.1 Configuration A)

Loop Load 3.8 VDC + 5 ohm (195 ohm load at 20 mA)

Operating Current 3.7 mA min; 200 mA max; continuous at 120°F half cycle 70 amp 1/120 second at 68°F

Supply Pressure Standard: minimum of 3 PSIG and maximum of 10 PSIG above the maximum calibrated output

Air Supply Clean, dry and oil-free instrument air

Operating Temperature -40°C to +66°C (-40°F to +150°F)

Temperature Effect Range of +18°C to +66°C (0°F to +150°F): ±0.02% / °F of span; Range -40°C to +66°C (-40°F to +150°F): ±0.04% / °F of span

RFI-EMI Effect Less than ±1% effect on zero/span (26-1000 mHz @ 30V/m) when installed per product installation guidelines

Operational Modes Field selectable direct, reverse and/or split range; see notes in model number description

Failure Mode Mechanically direct (i.e., if the input current drops below 3.7 mA DC, the output will drop to 1 to 2 PSIG regardless

Physical Specifications

Enclosure Internally purged NEMA 4X/IP65; cast/machined aluminum with powder-coated epoxy

Connections Supply port; 1⁄4-in NPTF (1X)

Weight 1.13 kg (2.5 lbs)

Certifications

ATEX STD5000: intrinsically safe, 4-20 mA models only; II 1G Ga Ex ia IIC T4 [Tamb -20°C to +60°C (-4°F to +140°F)];

CSA/US STD5000: intrinsically safe, 4-20 mA models only; Class I, Div 2, Groups A, B, C & D; Class I, Div 1, Groups A & B; Class II,

CE Compliant

High Pressure: 4-8 SCFM possible (dependent on air supply and tubing size)

High Pressure: for outputs of 3-15 PSIG and 0.2 to 1.0 BAR, supply range is 35 to 100 PSIG or 2.4 to 6.9 BAR;

Pressures below 35 may affect the output of the unit; Other output ranges may be possible (consult Thermo Fisher Scientific)

of direct or reverse mode selection)

Pneumatic Output Port: 1⁄4-in NPTF (2X)

Electrical: 1⁄2-in NPTF conduit (2X); terminals 12-22 AWG wire

II 1D Da Ex iaD 20 T+62°C (+144°F)

STD6000: flameproof; II 2 G Ex d IIC T5 [Tamb -20°C to +50°C (-4°F to +122°F)];II 2 D Ex tD A21 IP6X T+100°C (+212°F)

Div 1, Groups E, F & G; Class III, Div 1 when connected to CSA certified barriers rated 31.5V max, 463 ohms min, T3C;

Class I, Div 1, Groups C & D; Class II, Div 1, Groups E, F & G; Class III, Div 1 when connected to CSA certified

barriers rated 28V max, 120 ohms min, T3C; STD6000: Class I, Div 2, Groups A, B, C & D; Class I, Div 1, Groups B, C & D;

Class II, Div 1, Groups E, F & G; Class III, Div 1

Ordering Information

Process Instruments www.thermoscientific.com

© 2010 Thermo Fisher Scientific Inc. All rights reserved. Results may vary under different operating conditions. Specifications, terms and pricing are subject to change.

Not all products are available in all countries. Please consult your local sales representatives for details. Literature Code PI.2063.1210

Unit 702-715, 7/F Tower West

Yonghe Plaza No. 28, Andingmen East Street

Beijing 100007 CHINA

A-101, ICC Trade Tower, Senapati Bapat Road

Pune 411016 Maharashtra INDIA

Ion Path, Road Three,

Winsford, Cheshire CW7 3GA UK

1410 Gillingham Lane

Sugar Land, TX 77478 USA

+86 (10) 8419-3588

+86 (10) 8419-3580 fax

+91 (20) 6626 7000

+91 (20) 6626 7001 fax

+44 (0) 1606 548700

+44 (0) 1606 548711 fax

+1 (800) 437-7979

+1 (713) 272-0404

+1 (713) 272-4573 fax

Loading...

Loading...