Page 1

Refrigerated Circulators

User’s Manual

Manual P/N U00971

Rev. 02/14/08

Page 2

PolyStat® Refrigerated Circulator

Preface

Safety

General Information

Installation

Instruction and Operation Manual

Compliance............................................................3

Unpacking..............................................................3

Warranty ................................................................3

Warnings................................................................4

Description............................................................. 5

Specifications........................................................ 5

Site........................................................................ 6

Electrical Requirements......................................... 7

Plumbing Requirements ........................................8

Fluids .....................................................................9

Filling Requirements ............................................. 9

Operation

Digital Controller

Advanced Digital

Controller

Controllers ........................................................... 10

Start Up................................................................ 10

Main Display ........................................................ 11

Key Button Definition ........................................... 11

Viewing Setpoint ..................................................11

Changing Setpoint ............................................... 11

Setup Loop ..........................................................12

Calibration Loop................................................... 13

Main Display ........................................................ 14

Key Button Definition ........................................... 14

Changing Setpoint ............................................... 14

Viewing Setpoint ..................................................14

Setup Loop ..........................................................15

Calibration Loop................................................... 16

- 1 -

Page 3

Programmable

Controller

Additional Features

Maintenance &

Troubleshooting

Main Display ........................................................ 17

Key Button Definition ........................................... 17

Changing Setpoint ............................................... 18

Programming Loop .............................................. 18

Setup Loop ..........................................................19

Calibration Loop................................................... 21

Sample Program.................................................. 22

DB9 Connector Pinouts ....................................... 23

RS-232 Serial Communications Protocol............. 24

High Temperature/Low Liquid Safety................... 25

Cleaning............................................................... 26

Algae....................................................................26

Checklist ..............................................................26

PID Values........................................................... 27

Appendix

Water Quality Standards and Recommendations

- 2 -

Page 4

Compliance

Unpacking

Warranty

Preface

Products tested and found to be in compliance with the requirements defined

in the EMC standards defined by 89/336/EEC as well as Low Voltage

Directive (LVD) 73/23/EEC can be identified by the CE Mark on the rear of

the unit. The testing has demonstrated compliance with the following directives:

LVD, 73/23/EEC Complies with IEC/EN61010-1

EMC, 89/336/EEC IEC/EN61326-1

For any additional information, refer to the Declaration of Conformity that

shipped with the unit.

Retain all cartons and packing material until the unit is operated and found to

be in good condition. If the unit shows external or internal damage contact

the transportation company and file a damage claim. Under ICC regulations,

this is your responsibility.

The Cole-Parmer circulators distributed by Cole-Parmer, Cole-Parmer

warrants to the direct purchaser that the product will be free from defects in

material or workmanship for a period of two years from the date of delivery.

Cole-Parmer will repair or replace the product or provide credit, as its sole

option, upon prompt notification and compliance with its instructions.

The Distributor warrants to Customer that upon prompt notification and

compliance with Distributor's instructions, that the Distributor will repair or

replace, at Distributor's sole option, any Product which is defective in material or workmanship.

Distributor expressly disclaims all other warranties, whether expressed,

implied or statutory, including the warranties of merchantability, and fitness

for a particular purpose. Distributor's sole responsibility and the Customer's

exclusive remedy for any claim arising out of the purchase of any Product is

repair or replacement, as described above. In no event shall Distributor's

liability exceed the purchase price pain therefor; nor shall Distributor be liable

for any claims, losses or damage of any third party or for lost profits or any

special, indirect, incidental, consequential, or exemplary damages, howsoever arising, even if Distributor has been advised of the possibility of such

damages.

- 3 -

Page 5

Warnings

Safety

In addition to the safety warnings listed below, warnings are posted throughout

the manual. These warnings are designated by an exclamation mark inside an

equilateral triangle with text highlighted in bold print. Read and follow these

important instructions. Failure to observe these instructions can result in

permanent damage to the unit, significant property damage, personal injury or

death.

The lightning flash with arrow symbol, within an equilateral triangle, is

intended to alert the user to the presence of non-insulated "dangerous

voltage" within the unit's enclosure. The voltage may be of significant magnitude to constitute a risk of electrical shock.

This label, engraved into the front of the tank lip, indicates the presence of

hot surfaces.

Make sure you read and understand all instructions and safety precautions

listed in this manual before installing or operating your unit. If you have any

questions concerning the operation of your unit or the information in this

manual, contact our Sales Department.

Performance of installation, operation, or maintenance procedures

other than those described in this manual may result in a hazardous

situation and may void the manufacturer's warranty.

Transport the unit with care. Sudden jolts or drops can damage the

unit's components.

Observe all warning labels.

Never remove warning labels.

Never operate damaged or leaking equipment.

Never operate the unit without fluid in the circulator.

Use water unless operating above 80°C or below 7°C. Above 80°C use

Dow 200 silicon oil. For operation below 7°C, a 50/50 mixture, by volume, of filtered tap water and laboratory grade ethylene glycol is

suggested.

Always turn off the unit and disconnect the line cord from the power

source before performing any service or maintenance procedures, or

before moving the unit.

Always empty the circulator before moving the unit.

Never operate equipment with damaged line cords.

Refer service and repairs to a qualified technician.

- 4 -

Page 6

Description

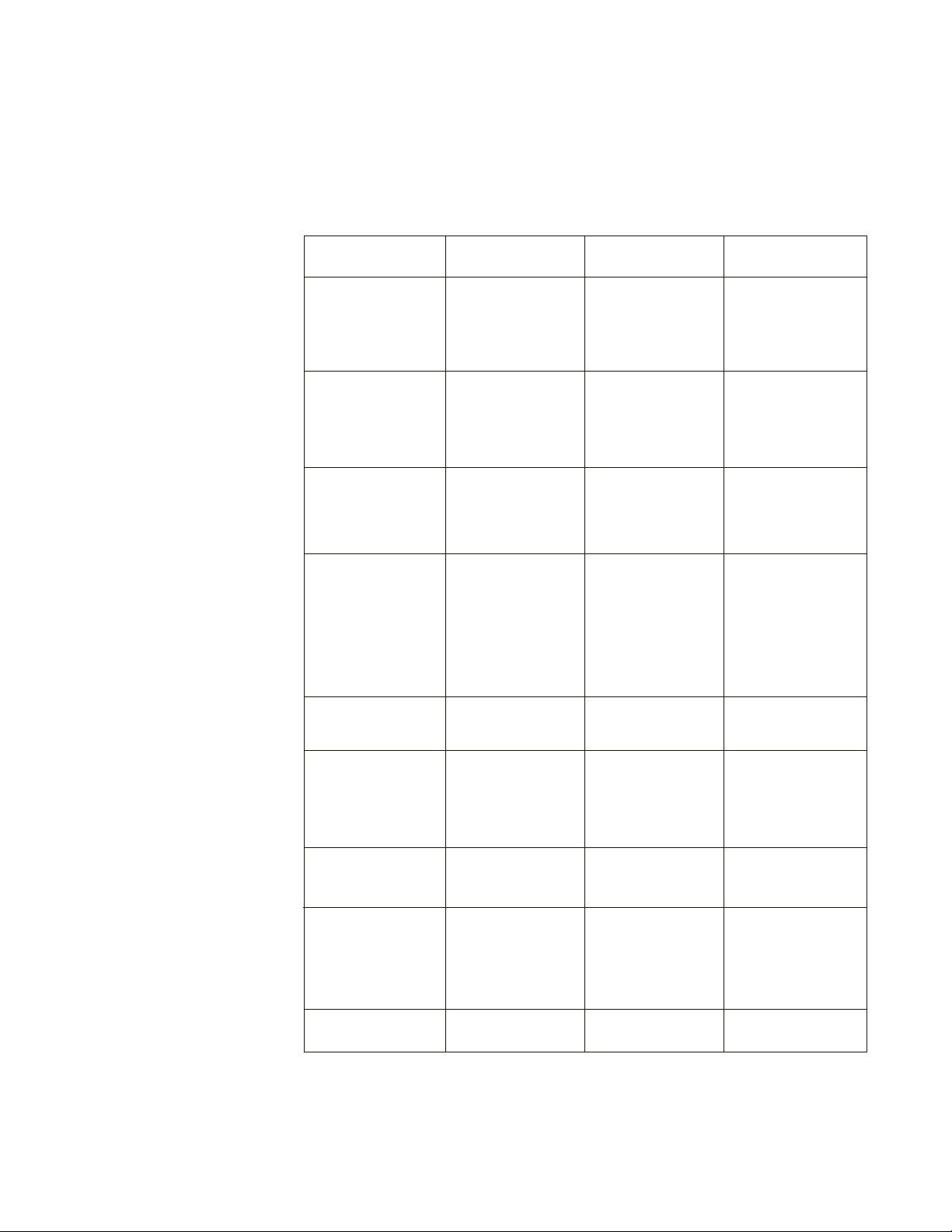

Specifications

Temperature Range °C

Digital -20 to +150 -20 to +150 -30 to +150 -25 to +100

Advanced Digital -20 to +200 -20 to +200 -30 to +200 -25 to +100

Programmable -20 to +200 -20 to +200 -30 to +200 -25 to +100

General Information

The PolyStat® Refrigerated Circulators are designed to provide temperature control for

applications requiring a fluid work area or pumping to an external system.

The units consist of a circulation pump, stainless steel reservoir, a work area

cover, and a temperature controller.

R6L R6LP R13L R28L

1

Temperature Stability

Digital ±0.05 ±0.05 ±0.05 ±0.05

Advanced Digital ±0.01 ±0.01 ±0.01 ±0.01

Programmable ±0.01 ±0.01 ±0.01 ±0.01

Pumping Capacity

60Hz 15 lpm at 0 psig 15 lpm at 0 psig 15 lpm at 0 psig 15 lpm at 0 psig

50Hz 12 lpm at 0 psig 12 lpm at 0 psig 12 lpm at 0 psig 12 lpm at 0 psig

Cooling Capacity Watts

(60Hz/50Hz)

@+20°C 350 / 290 350 / 290 6604 / 545

@ 0°C 120 / 100 190 / 175 480 / 400 450 / 370

@ -10°C 90 / 75 90 / 85 - -

@-20°C - - 200 / 165 175 / 145

Heater Watts

60/50Hz 800 / 1000 800 / 1000 800 / 1000 800 / 1000

Circulator Work Area

(L x W x D)

Inches 5¼ x 8 x 6 5¼ x 8 x 6 5¼ x 9 x 8 11½ x 11¼ x 8

Centimeters 13.3 x 20.3 x 15.2 13.3 x 20.3 x 15.2 13.3 x 22.9 x 20.3 29.2 x 28.6 x 20.3

2

3

1

4

7004 / 580

4

Reservoir Volume

Gallons/Liters 1½ / 6 1½ / 6 37/16 / 13 73/8 / 28

Dimensions

(L x W x H)

Inches 15¾ x 10 x 21½ 15¾ x 18¾ x 155/8 175/8 x 15 x 261/8 22 x 27½ x 185/8

Centimeters 40.0 x 25.4 x 54.6 40.0 x 47.6 x 39.7 44.8 x 38.1 x 66.4 55.9 x 69.9 x 47.4

Shipping Weight

Pounds/Kilograms 79 / 36 70 / 32 112 / 51 162 / 73

1. Low-end temperatures and cooling capacities achieved using a fluid with a specific gravity of 0.5.

2. Stability is measured at fluid temperature of 20°C, ambient of 20°C, with water as the fluid and not

in maximum cooling mode.

3. Pumping capacity for units operating at fluid temperature of 20°C, ambient of 21°C, using water.

4. 20°C heat load data taken in maximum cooling mode.

5. R28L shipping weight includes a 23 pound (10 Kilograms) skid.

- 5 -

Page 7

Site

Installation

Never place the unit in a location where excessive heat, moisture, or

corrosive materials are present.

Locate the unit on a sturdy table or bench top.

Ambient Temperature Range +50°F to +89.6°F (+10°C to +32°C)

Relative Humidity Range 10% to 80% (non-condensing)

Operating Altitiude Sea L evel t o 200 0 meters ( 6 562 feet)

Overvoltage Category II

Pollution Degree 2

The unit has an air-cooled refrigeration system. Air is drawn through the front

panel and discharged through the rear panel. The unit must be positioned so

the air intake and discharge are not impeded. A minimum clearance of

12 inches (30 centimeters) at the front and rear of the unit is necessary for

adequate ventilation. Inadequate ventilation will reduce cooling capacity and,

in extreme cases, can cause compressor failure.

Excessively dusty areas should be avoided and a periodic cleaning schedule

should be instituted, see Cleaning on page 26.

- 6 -

Page 8

Electrical

Requirements

Line voltage may be easily accessible inside the pump/control box.

Always unplug the unit prior to removing the pump/control box cover.

The unit construction provides protection against the risk of electric

shock by grounding appropriate metal parts. The protection may not

function unless the power cord is connected to a properly grounded

outlet. It is the user's responsibility to assure a proper ground connection is provided.

Refer to the serial number label on the rear of the unit to identify the specific

electrical requirements of your unit.

En sure the voltage of the power source meets the specified voltage, ±10%.

Electrical Service Required:

R6L/R6LP

Voltage Frequency Phase Branch Circuit Line Cord

Requirements Plug

115 VAC 60 Hz 1 15 A N5 - 15P

230 VAC 50 Hz 1 10 A CEE7

R13L/R28L

Voltage Frequency Phase Branch Circuit Line Cord

Requirements Plug

115 VAC 60 Hz 1 20 A N5 - 20P

230 VAC 50 Hz 1 16 A CEE7

- 7 -

Page 9

Plumbing

Requirements

Ensure the unit is off before connecting tubing to the unit.

To prevent damage to the plumbing lines, always support the ¾"

fittings while installing/removing the pumping caps and lines.

Hose Connections

The pump connections are located at the rear of the pump box and are

labelled

(pump outlet) and (pump inlet). The connections are

capped with stainless steel serrated plugs.

The pump lines have ¼ inch male pipe threads for mating with standard

plumbing fittings. For your convenience two stainless steel adapters, ¼ inch

female pipe thread to 3/8 inch O.D. serrated fitting, are provided. (To ensure

proper fit, they should be installed using Teflon

®

tape around the threads.)

Flexible tubing, if used, should be of heavy wall or reinforced construction.

Make sure all tubing connections are securely clamped. Avoid running

tubing near radiators, hot water pipes, etc. If substantial lengths of tubing

are necessary, insulation may be required to prevent loss of cooling capacity.

It is important to keep the distance between the unit and the external system

as short as possible, and to use the largest diameter tubing practical. Tubing

should be straight and without bends. If diameter reductions must be made,

make them at the inlet and outlet of the external system, not at the unit.

If substantial lengths of cooling lines are required, they should be pre-filled

with bath fluid before connecting them to the unit. This will ensure that a

adequate amount of fluid will be in the circulator once it is in operation.

Pumping

The pump is designed to deliver a flow of 15 liters/minute (4 gallons per

minute) at 0 feet head. To prevent external circulation, the INLET and

OUTLET lines are capped. The caps must be removed when external

circulation is required.

To properly secure the external hose connections to the unit, wrap Teflon

®

tape around the pipe line threads before installation. Once the hose connections are made, the pump must be properly plumbed to an external system. It

is important the circulator is not in operation until all plumbing is complete.

If the circulator is not used for external circulation, make sure the stainless

steel caps are in place prior to operating the circulator.

- 8 -

Page 10

Fluids

Filling

Requirements

Never use flammable or corrosive fluids with this unit.

Water is the recommended fluid for operation from +7°C to +80°C, see the

Appendix.

Dow 200 silicon oil is recommended for operation above +80°C.

Due to potential fire hazard, do not use any other fluid above +80°C.

For operation below +7°C, a 50/50 mixture, by volume, of laboratory grade

ethylene glycol and filtered tap water is suggested.

Never use pure ethylene glycol as a fluid. A maximum 80/20 mixture of

ethylene glycol and filtered tap water is allowed.

The circulator work area has a high and low level marker to guide filling. The

markers are 1 inch horizontal slits located in the center of the stainless steel

baffle separating the work area and the pump assembly. The correct fluid

level falls between these two markers. The heating and cooling coils will be

exposed and may become damaged if the correct fluid level is not provided.

When pumping to an external system, keep extra fluid on hand to maintain

the proper level in both the circulating lines and external system.

Never run the unit when the work area is empty.

When using Dow 200-50, ensure the work area contains no water

before filling the unit.

Dow 200-50 fluid will expand when heated.

- 9 -

Page 11

Controllers

Start Up

Operation

Three temperature controllers are available with the unit: Digital, Advanced

Digital and Programmable. This section explains these three controllers.

Before starting the unit, check all electrical and plumbing connections and

make sure the work area has been properly filled with fluid.

To start any unit place the I/O switch on the side of the controller to the

I (power on) position. The pump will start and the controller display will light.

For units with the Digital Controller the refrigeration is manually controlled by

the ON/OFF switch on the side of the control box.

For units with standard controllers, the refrigeration is manually controlled by

the ON/OFF switch on the side of the control box. In addition, units R13L and

R28L have HI/LO refrigeration control. For optimal cooling, use HI when

operating at 20°C or below, otherwise use LO.

The refrigeration system is not designed to operate above 35°C. When

operating above 35°C ensure that the refrigeration is turned off.

If the FAULT light is illuminated see page 25.

NOTE: When the unit is shut off, wait approximately five minutes before

restarting. This allows time for the refrigeration pressures to equalize. If the

pressures are not allowed to equalize, the compressor will short-cycle

(clicking sound) and no cooling will occur.

- 10 -

Page 12

Main Display

Digital Controller

The Digital Controller consists of a seven-segment LCD, unit-temperature

status indicators, a three-button keypad and a user-adjustable Proportional,

Integral and Derivative (PID) control.

The LCD Main Display normally indicates the fluid temperature.

°C

°F

Key Button Definition

Viewing Setpoint

Changing Setpoint

SET ENTER is used to change the current value or status of a function within

the software, and then to "accept" the new value or function.

NEXT is used as a means to quickly scroll through the software loops and

settings.

The up and down arrow keys are used to change a numeric value.

The setpoint is the desired fluid temperature. To view the setpoint, press

SET ENTER. The current setpoint will flash. Press SET ENTER again to

return to the temperature display.

To change the setpoint, press SET. The current setpoint will flash. Use the

arrow keys to change the setpoint. Scrolling includes three speed acceleration. Press ENTER to accept the new setpoint. NOTE: If you do not press

ENTER, a time out will occur 30 seconds after the last key is pressed and

the old setpoint will be used.

- 11 -

Page 13

Setup Loop

Pxx.x

I x.xx

Dx.xx

unit

The setup loop is used to adjust the PID control and change the temperature scale. (Preset PID values are P = 1.2, I = 0.20, D = 0.05.) To enter the

setup loop, from the main display press and hold NEXT for three seconds.

The display will indicate Pxx.x. NOTE: If a key is not depressed within 60

seconds, a "time out" will occur and the main display will revert to the fluid

NEXT key

temperature.

Press SET and the number will start flashing. Use the arrow keys to change

the value. Press ENTER to accept the new value. Press NEXT to display

the I parameter Ix.xx.

Press SET and the number will start flashing. Use the arrow keys to change

the value. Press ENTER to accept the new value. Press NEXT to display

the D parameter Dx.xx.

Press SET and the number will start flashing. Use the arrow keys to change

the value. Press ENTER to accept the new value. Press NEXT to display unit.

Press SET and the currently selected temperature scale lamp flashes. Use

either arrow key to change the scale. Press ENTER to accept the new

scale. Press NEXT to display the temperature.

MAIN DISPLAY

- 12 -

Page 14

Calibration Loop

Lo

xxx.x

hi

Use the calibration loop to recalibrate the unit's temperature display. The

wider the temperature spread used, the more accurate the calibration.

NOTE: Changing the factory set calibration will affect the accuracy of the

controller. A time out is not used in this loop.

To enter the calibration loop, from the main display press and hold the

up arrow key while pressing ENTER - NEXT - ENTER. The display

will indicate Lo (low calibration temperature).

NEXT key

SET key

Press SET and the low calibration temperature will flash indicating it

can be changed. NOTE: Pressing NEXT instead of SET scrolls to the

high temperature calibration.

Use the arrow keys to change the displayed value to the actual fluid

temperature. Press ENTER to accept and the numbers will stop

flashing. NOTE: The calibration will adjust to the temperature value

read at the moment ENTER is pressed. Press NEXT to display hi

(high calibration temperature).

xxx.x

MAIN DISPLAY

Press SET and the high calibration temperature will flash indicating it

can be changed. NOTE: Pressing NEXT instead of SET scrolls to Lo,

the cold temperature calibration.

Use the arrow keys to change the displayed value to the actual fluid

temperature. Press ENTER to accept and the numbers will stop

flashing. NOTE: The calibration will adjust to the temperature value

read at the moment ENTER is pressed. Press NEXT to calibrate.

The calibration constants are calculated and GOOD or BAD is briefly displayed to indicate whether the calibration was accepted. The display will then

indicate the fluid temperature.

- 13 -

Page 15

Main Display

Advanced Digital Controller

The Advanced Digital controller consists of a seven-segment LCD Display

with contrast control, heating/cooling status indicators, a four-button keypad

and user adjustable 0.1° or 0.01° display resolution. It also features on/off

refrigeration control, automatic min/max refrigeration control, audio/visual

alarm messages, user selected high/low temperature limits, RS232 communication, and a user-adjustable Proportional, Integral and Derivative (PID)

control.

The LCD Main Display indicates the fluid temperature as well as the current

setpoint temperature.

Key Button

Definition

Viewing Setpoint

Changing Setpoint

SET ENTER is used to change the current value or status of a function within

the software, and then to "accept" the new value or function.

The up and down arrow keys are used to change a numeric value and to

confirm, change or reject a question asked within the software.

The up and down arrow keys are used to change a numeric value.

The setpoint is the desired fluid temperature. To view the setpoint, press

SET ENTER. The current setpoint will flash. Press SET ENTER again to

return to the temperature display.

To change the setpoint, press SET. The current setpoint will flash. Use the

arrow keys to change the setpoint. Scrolling includes three speed acceleration. Press ENTER to accept the new setpoint. NOTE: If you do not press

ENTER, a time out will occur 30 seconds after the last key is pressed and

the old setpoint will be used.

- 14 -

Page 16

Setup Loop

SETUP LOOP?

MAIN DISPLAY

The setup loop is used to enable cooling, change the display

resolution, change the temperature scale, change temperature limits, adjust the PID values, enable/disable max cooling, and enable/disable RS232 communications.

COOLING ENABLED

PRESS NO TO CHANGE

RESOLUTION = 0.01

PRESS NO TO CHANGE

UNITS ARE C

PRESS NO TO CHANGE

U=K1(C+K2)+K3

Kn=xxx.x

HIGH T LIMIT xxx.xxC

LOW T LIMIT xxx.xxC

ENTER PID

CONSTRAINTS?

PROPORTIONAL

TERM

P=xx.x% OF SPAN

INTEGRAL TERM

I=x.xx REPEATS/MIN

DERIVATIVE TERM

D=x.xx MINUTES

To enter the setup loop, press and hold NEXT for three

NEXT key

Up arrow key

Down arrow

seconds. The display will indicate

SETUP LOOP?

NOTE: Pressing NO displays the software version and then the Main Display.

Also, the display times out 60 seconds after any key is pressed and reverts to

the Main Display.

Press NEXT or YES to display

COOLING ENABLED PRESS NO TO CHANGE. Press

NO to toggle between cooling enabled and cooling disabled.

Press NEXT to display RESOLUTION = 0.01 PRESS NO TO CHANGE. Press NO to

toggle the resolution between 0.1° and 0.01°.

Press NEXT to display UNITS ARE C PRESS NO TO CHANGE. Press NO to toggle the

scale between Fahrenheit (F), Celsius (C) or a user (U) scale.

NOTE: The following is needed only if a user (U) scale was selected. Press

NEXT to display U = K1(C + K2) + K3 Kn=xxx.x. Press SET and then use the

arrow keys to change the K values.

Press NEXT to display HIGH T LIMIT xxx.xxC LOW T LIMIT xxx.xxC. Press SET to

be able to use the arrow keys to change the high temperature limit. Press

ENTER to accept the new value. Press SET again to be able to change the

low temperature limit. Press ENTER to accept the new value. NOTE: To

bypass changing the high temperature value press SET twice when HIGH T

LIMIT xxx.xxC LOW T LIMIT xxx.xxC

is initially display.

Press NEXT to display ENTER PID CONSTANTS? (Preset PID values are P =

1.2, I = 0.20, D = 0.05.) Press NO to bypass changing the constants and

display SAVE SETUP? Press YES or NEXT to display PROPORTIONAL TERM P =

xx.x% OF SPAN

. Press SET and then use the arrow keys to change the value.

Press NEXT to display INTEGRAL TERM I = x.xx REPEATS/MIN. Press SET and

then use the arrow keys to change the value. Press NEXT to display DERIVA-

TIVE TERM D = x.xx MINUTES

. Press SET and then use the arrow keys to

change the value.

MAX COOLING DISABLED

PRESS NO TO CHANGE

RS232 DISABLED

PRESS NO TO CHANGE

SAVE SETUP?

PRESS YES OR NO

Press NEXT to display MAX COOLING DISABLED PRESS NO TO CHANGE. Press NO

to toggle between cooling modes.

Press NEXT to display RS232 IS DISABLED PRESS NO TO CHANGE. Press NO to

toggle between disabled and enabled, or press ENTER to use the displayed

mode.

Press NEXT to display SAVE SETUP? PRESS YES OR

NO.

Press YES to accept all the changes. Press NO

MAIN DISPLAY

to ignore all of them. With either choice the unit will

return to the Main Display.

- 15 -

Page 17

Calibration Loop

CALIBRATE RTD?

NOTE: The Calibration Loop is not accessible if RS232 communications is

enabled.

Use the calibration loop to calibrate the RTD temperature probe. The wider

the temperature spread used, the more accurate the calibration. NOTE:

Changing the factory set calibration will affect the accuracy of the controller.

A time out is not used in this loop.

Run the temperature to a suitable low-end

MAIN DISPLAY

value. Once stabilized enter the calibration

loop. From the main display press and hold

NEXT while pressing, within three seconds,

ENTER - NO - ENTER. The display will

indicate

CALIBRATE RTD?

CALIBRATE LOW TEMP?

CAL RTD

LOW TEMP xxx.xxC

CALIBRATE HIGH TEMP?

CAL RTD

HIGH TEMP xxx.xxC

SAVE CALIBRATION?

PRESS YES OR NO

NEXT key

Up arrow key

MAIN DISPLAY

Down arrow

Press NEXT and the display indicates

CALIBRATE LOW TEMP? To perform a low

temperature calibration press YES or NEXT

and the display will indicate

CAL RTD LOW TEMP xxx.xxC. Press SET and

then use the arrow keys to change the

displayed value to the actual fluid temperature (as measured with a calibrated reference

thermometer). Press NEXT until the display

indicates SAVE CALIBRATION PRESS YES OR

NO.

Press YES to save the change. The

display will momentarily indicate BOTH HIGH

AND LOW CAL MUST BE DONE

then return to

the main display.

Run the temperature to a suitable high-end

value. Once stabilized reenter the calibration

loop. Press YES or NEXT until the display

indicates CALIBRATE HIGH TEMP? To perform

a high temperature calibration press NEXT

and the display will indicate CAL RTD HIGH

TEMP xxx.xxC.

Press SET and then use the

arrow keys to change the displayed value to

the actual fluid temperature (as measured

with a calibrated reference thermometer).

- 16 -

Press NEXT and the display will indicate SAVE

CALIBRATION PRESS YES OR NO.

Press YES to

save the change. The unit will return to the

main display.

Page 18

Main Display

Programmable Controller

The Programmable Controller consists of a seven-segment LCD with contrast control, heating/cooling status indicators, a 12-button keypad and user

adjustable 0.1° or 0.01° temperature display resolution, external sensor input

with automatic switching in the event of external sensor failure. It also

features automatic on/off refrigeration control, automatic min/max refrigeration control, audio/visual alarm messages, automatic fixed temperature limit,

user selected high/low temperature limits, programmable temperature profile,

RS-232 communication and a user-adjustable Proportional, Integral and

Derivative (PID) control.

The LCD normally indicates the fluid temperature as well as the current

setpoint temperature, or the external temperature and setpoint.

Key Button Definition

SET ENTER is used to change the current value or status of a function within

the software, and then to "accept" the new value or function.

YES is used to confirm a question asked within the software.

NO is used to reject or change a function within the software.

NEXT is used as a means to quickly scroll through the software loops and

settings.

± is used to change the current numeric value from positive to negative, or

negative to positive.

SETUP is used to enter the controller's setup loop.

PROG is used to enter the controller's program loop.

ESC is used to backtrack to the previous screen within a software loop.

1 - 9 keys are used to enter a number.

- 17 -

Page 19

Changing Setpoint

Program Loop

RUN PROGRAM A?

RUN PROGRAM B?

EDIT PROGRAM A?

A SET xxx.xxC

STEP n TIME hhh:mmm

A REPETITIONS nnn

FINAL SETPT xxx.xxC

To change the setpoint, press SET ENTER. The current setpoint will flash. If

the number to be entered is negative, press the +/- key. Otherwise, enter the

most significant digit of the number. The digit will appear in the least significant decimal position. As each digit is entered the previously entered digits

will shift up in significance. Enter trailing zeros as needed to obtain the

desired order of magnitude. Press SET ENTER to accept the new setpoint.

NOTE: If you do not press SET ENTER, a time out will occur 30 seconds

after the last key is pressed and the old setpoint will be used.

NOTE: The program loop is not accessible if the RS-232 communications is

enabled, see Setup Loop. The program loop is used to program the controller.

The controller can store up to two

programs, each with as many as ten

steps. (Refer to the Setup Loop on the

next page for other options.) A sample

NEXT key

Up arrow key

ESC key

Down arrow

MAIN DISPLAY

program is shown on page 22.

To enter the program loop, press and

hold PROG for three seconds. The

display will indicate RUN PROGRAM A? NOTE: A time out will occur 60

seconds after the last key is pressed and the program will revert to old

values and the display will revert to the fluid temperature.

The unit's are not shipped with stored programs. Before a program can

be run, it has to be edited and stored. Therefore, for initial programming or program editing press NEXT to display RUN PROGRAM B? and

then press NEXT again to display EDIT PROGRAM A?

Press YES or NEXT to display the temperature, step number and time

duration. Steps start at 0. Press SET ENTER and using the keypad

enter the setpoint temperature. Press SET ENTER. Press SET ENTER

and enter the number of hours. Press SET ENTER. Press SET ENTER

and enter the number of minutes. Press SET ENTER.

EDIT PROGRAM B?

B SET xxx.xxC

STEP n TIME hhh:mmm

B REPETITIONS nnn

FINAL SETPT xxx.xxC

SAVE PROGRAMS?

MAIN DISPLAY

The display will increment to step 1. Repeat the procedure for the total

number of desired steps. To skip a number press SET ENTER twice.

To end a program with fewer than ten steps, enter 0 hours and 0

minutes.

Press NEXT to display the number of program repetitions. Press SET

ENTER and enter the number of reps. Press SET ENTER. Press SET

ENTER and enter the final setpoint for the program. Press SET ENTER.

Press NEXT to display EDIT PROGRAM B? Use the same procedures.

Press NEXT to display SAVE PROGRAMS? Press YES to save or NO

to ignore. The unit returns to the main display.

With program(s) saved, when the display reads RUN PRO-

pressing YES will start the program, pressing NO will

GRAM

stop it. With either choice the unit returns to the main display.

- 18 -

Page 20

Setup Loop

SETUP LOOP?

REFRIGERATION OFF

WHEN SETPOINT >xxC

RESOLUTION = 0.01

PRESS NO TO CHANGE

UNITS ARE C

PRESS NO TO CHANGE

NOTE: The setup loop is not accessible if a program is running. If RS-232

communications is enabled, only the RS-232 portion of the setup loop is active.

The setup loop is used to enable refrigeration, change the display resolution,

change the temperature scale, change temperature limits, adjust the PID

control (preset PID values are P = 1.2,

MAIN DISPLAY

I = 0.20, D = 0.05.), selects internal or

external probe, enter the maximum

internal and external temperature differ-

ence and enable RS-232.

NEXT key

Up arrow key

Down arrow

ESC key

To enter the setup loop from the main

display, press and hold SETUP for three

seconds. The display will indicate SETUP LOOP? NOTE: A time

out will occur 60 seconds after the last key is pressed and the

display will revert to the fluid temperature.

U=K1(C+K2)+K3

Kn=xxx.x

HIGH T LIMIT xxx.xxC

LOW T LIMIT xxx.xxC

ENTER PID

CONSTRAINTS?

PROPORTIONAL TERM

P=xx.x% OF SPAN

INTEGRAL TERM

I=x.xx REPEATS/MIN

DERIVATIVE TERM

D=x.xx MINUTES

PROBE IS INTERNAL

PRESS NO TO CHANGE

MAX INTERN EXTERN

TEMP DIFFERENCE xxC

RS232 DISABLED

PRESS NO TO CHANGE

MAX COOLING DISABLED

PRESS NO TO CHANGE

Press YES or NEXT to display

SETPOINT>xxC.

Use the keypad to display the desired temperature.

REFRIGERATION OFF WHEN

The refrigeration system is not designed to

operate above 35°C.

Press NEXT to display RESOLUTION = 0.01 PRESS NO TO CHANGE.

Press NO to toggle between 0.1°C and 0.01°C display resolution,

press YES or NEXT to maintain the displayed resolution.

Press NEXT to display UNITS ARE C PRESS NO TO CHANGE. Press

NO to toggle between temperature scales Celsius (C), Fahrenheit

(F) and a user defined (U) scale. Press YES or NEXT to maintain

the displayed scale.

NOTE: The following is used only if a user (U) scale was selected.

Press NEXT to display U = K1(C + K2) + K3 Kn=xxx.x. Press SET ENTER

and use the keypad to change the values.

Press NEXT to display HIGH T LIMIT xxx.xxC LOW T LIMIT xxx.xxC.

Press SET ENTER and enter the high temperature limit. Press SET

ENTER to accept the new value. Press SET ENTER again to be

able to change the low temperature limit. Press SET ENTER to

accept the new value. NOTE: To bypass changing the high temperature value press SET ENTER twice when HIGH T LIMIT xxx.xxC

LOW T LIMIT xxx.xxC

is initially display.

SAVE SETUP?

PRESS YES OR NO

MAIN DISPLAY

- 19 -

Press NEXT to display ENTER

PID CONSTANTS?

Press NO to

Page 21

bypass changing the constants and display PROBE IS INTERNAL PRESS NO TO

CHANGE

or press NEXT to display PROPORTIONAL TERM P = xx.x% OF SPAN.

Press SET ENTER and use the keypad to enter the desired value.

Press NEXT to display INTEGRAL TERM I = x.xx REPEATS/MIN. Press SET

ENTER and use the keypad to enter the desired value.

Press NEXT to display DERIVATIVE TERM D = x.xx MINUTES. Press

SET ENTER and use the keypad to enter the desired value.

Press NEXT to display PROBE IS INTERNAL PRESS NO TO CHANGE. Press NO

to toggle between internal or external probe or press YES or SET ENTER to

use the displayed probe.

Press NEXT to display MAX INTERN EXTERN TEMP DIFFERENCE xxC. Press

SET ENTER and use the keypad to enter the desired value.

Press NEXT to display RS232 IS DISABLED PRESS NO TO CHANGE. Press NO

to toggle between disabled and enabled or press YES or SET ENTER to use

the displayed mode.

Press NEXT to display MAX COOLING DISABLED PRESS NO TO CHANGE. Press

NO to toggle between disabled and enabled or press YES or SET ENTER to

use the displayed mode.

Press NEXT to display SAVE SETUP? PRESS YES OR NO. Press YES to accept

the changes. Press NO to ignore them. The unit will return to the main

display.

- 20 -

Page 22

Calibration Loop

CALIBRATE?

CAL INTERNAL RTD?

NOTE: The calibration loop is not accessible if a program is running or if

RS-232 communications is enabled.

Use the calibration loop to calibrate the internal and external RTD temperatures. NOTE: Changing the factory set calibration will affect the accuracy of

the controller. A time out is not used in this

loop.

MASTER DISPLAY

Run the temperature to a suitable low-end

value. Once stabilized enter the calibration

loop. From the main display press and hold

NEXT while pressing ESC - ENTER - ESC. The

NEXT key

Up arrow key

ESC key

Down arrow

display will indicate

CALIBRATE?

CALIBRATE LOW TEMP?

INTERNAL

LOW TEMP xxx.xxC

CALIBRATE HIGH TEMP?

INTERNAL

HIGH TEMP xxx.xxC

CAL EXTERNAL RTD?

CALIBRATE LOW TEMP?

Press YES or NEXT and the display indicates CAL INTERNAL

Press YES or NEXT and the display indicates CALIBRATE

RTD?

LOW TEMP?

LOW TEMP xxx.xxC

Press NEXT and the display indicates INTERNAL

. Press SET and use the keypad to change

the displayed value to the actual fluid temperature (as measured

with a calibrated reference thermometer). Press NEXT until the

display indicates CAL EXTERNAL RTD? Use the same procedure

to calibrate the external probe (if desired). Press NEXT until the

display indicates SAVE CALIBRATION PRESS YES OR NO. Press YES

to save the changes. The display will momentarily indicate BOTH

HIGH AND LOW CAL MUST BE DONE

then return to the main display.

Run the temperature to a suitable high-end value. Once stabilized reenter the calibration loop. Repeat the same procedure for

the high temperature calibration. Press NEXT and the display will

indicate SAVE CALIBRATION? PRESS YES OR NO. Press YES to

save the changes. The unit will return to the main display.

EXTERNAL

LOW TEMP xxx.xxC

CALIBRATE HIGH TEMP?

EXTERNAL

HIGH TEMP xxx.xxC

SAVE CALIBRATION?

PRESS YES OR NO

MASTER DISPLAY

- 21 -

Page 23

Sample Program

This sample program A has three steps and two repetitions. The final

setpoint is 35.0°C. Enter these values as described on page 18.

Stepn SETxxx.xxC TIME hhh mmm

0 25.0 0 2

1 20.0 0 3

2 30.0 0 1

3 NA* 0 0

REPETITIONS nnnn FINAL SETPT xxx.xC

2 35.0

* Any value can be entered.

Pressing YES to RUN PROG A? returns to the MAIN DISPLAY which now

has a lower line reading:

PGM A 0 w 25.0C

A is the current program, 0 is the current step, w indicates a waiting phase

(described in the next paragraph) and 25.0 is the current setpoint.

A w is displayed when the program is waiting for the bath to heat or cool

from the previous setpoint to the current setpoint. When the bath temperature gets to within 0.5° of the current setpoint, the display changes to PGM A

0 r 25.0, the r indicating the running phase for that step. Actual step time

starts when the display turns to r.

The following graph displays this program and indicates the lower half of the

MAIN DISPLAY.

35°C

30°C

25°C

20°C

PGM A 0 w 25.0C

PGM A 1 w 20.0C

PGM A 0 r 25.0C

PGM A 1 r 20.0C

PGM A 2 w 30.0C

PGM A 0 w 25.0C

PGM A 2 r 30.0C

PGM A 1 w 20.0C

PGM A 0 r 25.0C

PGM A 1 r 20.0C

PGM A 2 w 30.0C

PGM A 2 r 30.0C

SETPOINT 35.0C

STEP 0

STEP 1

REPETITION 1 REPETITION 2

STEP 2

STEP 0

STEP 1

STEP 2

NOTE: There is no indication on the display as to which repetition the

program is in.

- 22 -

Page 24

DB9 Connector

Pinouts

Additional Features

RS232 Connections DB9 Female (J3)

5 Common

3 Receive (RxD) (Data from computer)

2 Transmit (TxD) (Data to Computer)

External RTD DB9 Male (P2)

3 RTD2A

4 RTD2A

8 RTD2B

- 23 -

Page 25

RS232 Serial

Communications

Protocol

Commands Description Response

(UPPERCASE only)

?[CR] Help Protocol Examples

A1[CR] Reports “OK” to indicate that RS232 is enabled [CR]OK[CR][CR]

S?[CR] Report temperature setpoint n[CR]OK[CR][CR]

Sn[CR] Change temperature setpoint to n [CR]OK[CR][CR]

F?[CR] Report bath temperature n[CR]OK[CR][CR]

U?[CR] Report bath temperature units (x = C, F or U) x[CR]OK[CR][CR]

C[CR] Change temperature units to °C [CR]OK[CR][CR]

F[CR] Change temperature units to °F [CR]OK[CR][CR]

U[CR] Change temperature units to °U (user defined units) [CR]OK[CR][CR]

&LH?[CR] Report high temperature limit n[CR]OK[CR][CR]

&LL?[CR] Report low temperature limit n[CR]OK[CR][CR]

&LHn[CR] Change high temperature limit to n [CR]OK[CR][CR]

&LLn[CR] Change low temperature limit to n [CR]OK[CR][CR]

&P?[CR] Report temperature resolution n[CR]OK[CR][CR]

&Pn[CR] Change temperature resolution (n = 1 or 2) [CR]OK[CR][CR]

Baud rate: 9600 Stop bits: 1

Parity: none Flow control: none

Data bits: 8

(number of decimal places)

[CR] = carriage return

n = numeric data

Error Messages Description

INPUT OR RANGE ERROR[CR][CR] Controller received a setpoint that was out of range.

REQUEST DENIED[CR][CR] Setpoint can be changed only while:

Displaying temperature

A value is not currently being entered

Not in program mode.

- 24 -

Page 26

High Temperature/

Low Liquid

Level Safety

To protect your application, the adjustable High Temperature/Low Liquid

Level Safety (HIGH TEMP/LOW LEVEL) ensures the heater will not exceed

temperatures which can cause serious damage to your unit. A single temperature sensor, located on the heater coils in the circulator, monitors both

conditions. A High Temperature/Low Liquid Level fault occurs when the

temperature of the sensor exceeds the set temperature limit.

In the event of a fault, the unit will shut down and a FAULT LED will illuminate. The cause of the fault must be identified and corrected before the unit

can be restarted.

To set the safety, locate the HIGH TEMP/LOW LEVEL SAFETY adjustment

dial in back of the pump box. Turn the dial fully clockwise.

Start the unit. Adjust the setpoint for a few degrees higher than the highest

desired fluid temperature and allow the circulator to stabilize at the temperature setpoint. Turn the HIGH TEMP/LOW LEVEL SAFETY dial counterclockwise until you hear a click and the unit shuts down. The red FAULT LED on

the temperature controller will light to indicate a fault has occurred.

Cool the circulator and then, without moving the adjustment dial, turn the unit

off then back on.

-

+

HTC

- 25 -

Page 27

Cleaning

Maintenance & Troubleshooting

Allow sufficient for the fluid to cool to room temperature before handling.

Turn the unit off before cleaning.

Routine cleaning can be achieved by simply sponging down the seamless

stainless steel tank with a mild soapy solution.

Do not use steel wool; its abrasiveness will lead to rusting.

Dry the circulator using a soft cloth.

For proper operation, the unit needs to pull substantial amounts of air

through a condenser. A build up of dust or debris on the fins of the condenser will lead to a loss of cooling capacity.

Periodic vacuuming of the condenser is necessary. The frequency of cleaning depends on the operating environment. After initial installation we recommend the wrapper be removed and a monthly visual inspection of the

condenser be made. After several months the frequency of cleaning will be

established.

Algae

Checklist

To restrict the growth of algae in the circulator, we recommend the circulator

cover be kept in place and that all circulation lines be opaque. This will

eliminate the entrance of light required for the growth of most common algae.

We recommend the use of Chloramine-T, 1 gram per 3.5 liters.

Unit will not start

Make sure the voltage of the power source meets the specified voltage,

±10%. Refer to the serial number label on the rear of the unit to identify the

specific electrical requirements of your unit.

Check the High Temperature/Low Liquid Level Safety. If the FAULT light is

on, make sure the fluid level in the circulator is between the marks in the

baffle and the HIGH TEMP/LOW LEVEL SAFETY setting is greater than the

fluid temperature. Turn the unit's I/O switch off then back on to reset the

safety.

- 26 -

Page 28

Loss of cooling capacity

Be sure the cooling capacity of the unit has not been exceeded if circulating

to an external system.

When the unit is shut off, wait approximately five minutes before restarting.

This allows time for the refrigeration pressures to equalize. If the pressures

are not allowed to equalize, the compressor will short-cycle (clicking sound)

and no cooling will occur.

Proper ventilation is required for heat removal. Make sure ventilation

through the front and rear panels is not impeded and the panels are free of

dust and debris.

Ice build up on the cooling coils can act as insulation and lower the cooling

capacity. Raise the temperature of the circulator to de-ice the cooling coil

and increase the concentration of non-freezing fluid.

Check controller PID values, see below.

No external circulation

Make sure the stainless steel plugs on the PUMP INLET and PUMP

OUTLET have been removed.

PID Values

Check for obstructions, kinks, or leaks in the circulation tubing.

Circulation will cease when the pump head has been exceeded.

The PID values can be verified in the controller's Setup Loop. The factory

preset PID values are:

Digital P = 1.2 I = 0.20 D = 0.05

Advanced Digital P = 1.2 I = 0.20 D = 0.05

Programmable P = 1.2 I = 0.20 D = 0.05

- 27 -

Page 29

Appendix Fluids

Water Quality Standards and Recommendations

Microbiologicals

(algae, bacteria, fungi) 0 0

Inorganic Chemicals

Calcium <25 <0.6

Chloride <25 <10

Magnesium <12 <0.1

Sulfate <25 <1

Total Hardness <17 <0.05

Unfavorably high total ionized solids (TIS) can accelerate the rate of galvanic

corrosion. These contaminants can function as electrolytes which increase

the potential for galvanic cell corrosion and lead to localized corrosion such

as pitting which can be observed at the studs and on the outside surface of

cooling coils. Eventually, the pitting will become so extensive that the coil will

leak refrigerant into the water reservoir.

Permissible (PPM) Desirable (PPM)

For example, tap water in the U.S. averages 171 ppm (of NaCl). The recommended level for use in a water system is between 0.5 to 5.0 ppm (of NaCl).

Recommendation: Initially fill the tank with distilled/deionized water. Do not

use untreated tap water as the total ionized solids level may be too high.

Maintain this water quality at a resistivity of between 1 to 10 MOhmcm

(compensated to 25°C) by using a purification system. Although the initial fill

may be as high as 18 MOhmcm (compensated to 25°C), the desired level for

long time usage is 1 to 3 MOhmcm (compensated to 25°C).

The above two recommendations will reduce the electrolytic potential of the

water and prevent or reduce the galvanic corrosion observed.

- 28 -

Loading...

Loading...