Page 1

FoodTech

Source™

PORTABLE FOOD ANALYZER

with AutoBIAS™

USER'S MANUAL

Version 2.1

COLE PARMER INSTRUMENT CO.

625 East Bunker Court

Vernon Hills, IL USA 60061

Phone: 847-549-7600

Fax: 847-247-2983

E-mail: info@coleparmer.com

Website: http:/www.coleparmer.com

© Zeltex, Inc. 2001

This manual provides you with all the information needed to operate the

Cole-Parmer FOODTECH™

Page 2

2

TABLE OF CONTENTS

WARNING: 4

ABOUT THE FOODTECH™ 5

FEATURES OF THE FOODTECH™ 5

UNPACKING THE FOODTECH™ 5

PREPARATION 7

ELECTRICAL REQUIREMENTS 7

OPTIONAL PRINTER 7

PRINTER PAPER INSTALLATION FOR OPTIONAL PRINTER 7

SAMPLE CUP 8

CLAM-SHELL CUP 9

VARIABLE PATHLENGTH SAMPLE CUP 12

KEYPAD DESCRIPTION 13

TURNING THE FOODTECH™ ON FOR THE FIRST TIME 14

AUTOMATIC BIAS INITIALIZATION AND STANDARDIZATION 15

ANALYZED SAMPLE FORM 17

SELECT PRODUCT 18

MENU SELECTIONS 18

MEASURING A SAMPLE 19

ADJUSTING THE CALIBRATION 21

ADJUSTING THE BIAS 22

AUTOBIAS 22

ADJUSTING THE TIME 23

ADJUSTING THE DATE 23

ADJUSTING THE NUMBER OF READ CYCLES 23

STORE SAMPLES 24

DATA LINK 24

PRINTING 25

PAPER FEED 25

RESET ID # 26

WARNINGS AND ERROR CODES 27

Page 3

3

GENERAL SPECIFICATIONS 31

A NOTE ON THE TEXT

Throughout this manual, keystrokes are represented in bold type; references to

messages on the computer screen or the FOODTECH™ display screen are in

“quotations.”

GLOSSARY 32

APPENDIX I 34

COMBINATION LOCK 34

INDEX 35

Page 4

4

WARNING:

THE FOODTECH™ PORTABLE NEAR-IR

ANALYZERS ARE NOT EXPLOSION

PROOF: REASONABLE CARE MUST BE

USED IN HANDLING THESE

INSTRUMENTS.

THE FOODTECH™ IS SUPPLIED WITH A

SPECIAL STATIC-FREE CLEANING

BRUSH. FAILURE TO USE THIS BRUSH

BETWEEN SAMPLES MAY CAUSE

BAD READINGS.

Page 5

5

ABOUT THE FOODTECH™

FEATURES OF THE FOODTECH™

Easy sampling: no grinding, no preparation

Analyzes whole grain products such as wheat (spring and winter), barley,

soybean and corn

Analysis in 60 seconds or less

Stores calibrations for 3 constituents each of up to 10 products

Accurate up to 95% of moisture, protein, oil, etc.

Able to analyze samples at temperatures from -20ºC to +50ºC.

Direct readout in percentage form for both AS-IS and CM

Totally solid state optics (no moving parts)

Automatic Bias Initialization and Standardization

UNPACKING THE FOODTECH™

Check that all items 1 through 6 are in the box. If any items are missing,

please contact Cole-Parmer immediately.

1. FOODTECH™ Portable Food Analyzer (PFA)

2. User's Manual

3. Quick Start Manual

4. AA Batteries

5. 16 mm Sample Cups

6. Static Brush

Optional:

1. Carrying Case

2. Software Disk and Calibration Manual

3. A/C Adapter

4. RS232 Cable

5. Printer

6. Printer Paper

7. 25 mm Sample Cup (corn, soybean)

8. Variable Pathlength Sample Cup 5 mm-16 mm (small grains)

9. AutoBIAS perma-sample

The optional carrying case has the combination set at the factory to open at

000. You may leave it at this setting or you can set your own combination.

(See Appendix 1 in this manual for instructions on how to set your own

combination.)

Page 6

6

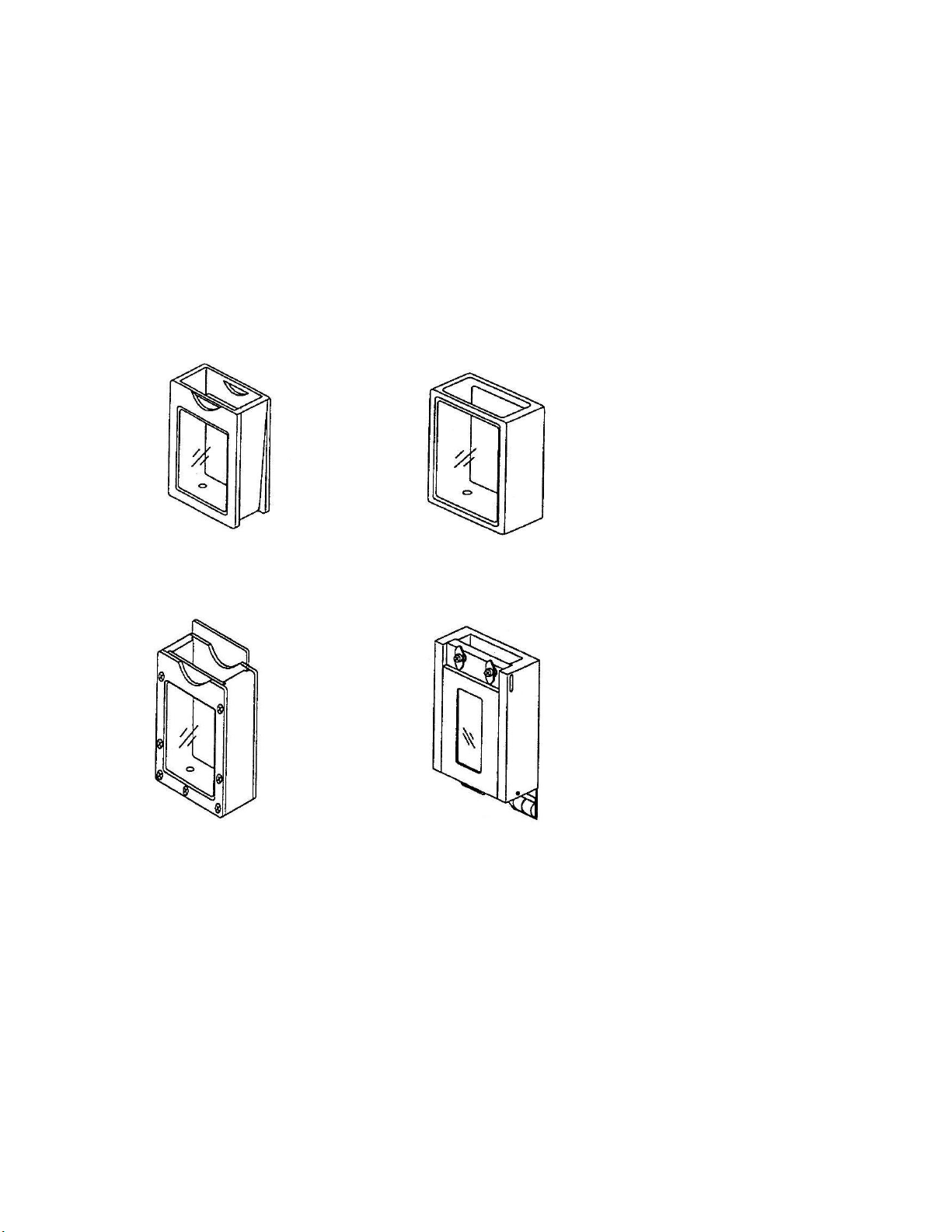

APPEARANCE AND PART NAMES

Page 7

7

PREPARATION

ELECTRICAL REQUIREMENTS

After you have opened the carton, take a moment to consider where to

place the FOODTECH™ The instrument has been designed to work

flawlessly in the manufacturing environment, but please take into account

the following requirements before setting up the instrument.

The FOODTECH™ operates from six AA cells or 9v DC from an A/C

adapter. For the best operation and the most reliable analysis, the

FOODTECH™ should have a clean, independent electrical line with the A/C

adapter. Depending on the A/C voltage at the customer’s site, the

appropriate adapter (nominal 115 or 230 VAC) is shipped with the

instrument. Connect the A/C adapter cable to the jack closest to the top on

the right-hand side of the instrument. Also, insert six 1.5v AA size alkaline

batteries into the battery compartment located on the rear of the main body.

Be sure the batteries are oriented as indicated in the compartment.

OPTIONAL PRINTER

The optional printer can be attached directly to the FOODTECH™

PRINTER PAPER INSTALLATION FOR OPTIONAL PRINTER

1. Remove the clear plastic cover from the printer.

2. Cut the end of the roll at an angle to form a point in the center.

3. Feed the paper into the slit inside the Paper Roll Compartment and press

the PAPER FEED key.

Page 8

8

SAMPLE CUP

Molded 16mm Cup

Stock #2670

24mm Cup

Stock #A-572

Variable Path-Length Cup

Stock #2672

Clam-Shell Cup

Stock #A0636

The FOODTECH™ is shipped with 2 standard 16mm (approx. 3/4”) sample

cups to be used with wheat and barley. A 24mm (approx. 1”) cup and a

variable pathlength cup are also available.

Do not place objects on the sample cup. It should not be placed in direct heat

or cleaned with harsh chemicals such as scouring powder.

Page 9

9

CLAM-SHELL CUP

The A0636 Clam-shell Cup allows the analysis of pastes and slurries in clear

“whirl-pak”–type bags. The Clam-shell Cup includes an internal A0633

Thermistor Module (a), contact strips (b), windows in the body and door (c), and

an assortment of different thickness windows (d).

Because the Clam-shell cup has its own thermistor, the thermistor probe in the

instrument must be removed. First, locate the thermistor cover (e). It is the

smaller of the two covers on the bottom of the instrument.

Remove the thermistor cover by pressing down with the thumbs, and sliding

the cover upward.

Page 10

10

Inside the thermistor recess, you’ll note the Thermistor Probe assembly

(f) (held in with two 6-32 screws), and the Black Spacer (g).

Remove the Black Spacer (held in with tape), and the Thermistor Probe,

exposing the Contact Board (h). Note the red and green wires which are

connected to the Contact board.

This is a close-up of the A0516 Thermistor Probe. Note that one end of the

probe is painted green. If the Thermistor Probe is re-installed later, the green end

should be closest to the green wire on the contact board.

Page 11

11

To plug the holes in the sample chamber, make a Spacer

Assembly from the Gray Stop Plate, the Black Spacer,

and two 6-32 screws.

Install the Spacer Assembly as shown. Storing the

Thermistor Probe as shown will keep it from getting

lost. Re-install the Thermistor Cover, and you’re

done. To convert back, reverse the procedure.

Page 12

12

VARIABLE PATHLENGTH SAMPLE CUP

The Variable Pathlength Sample Cups uses windows of different thicknesses slide in and out of slots

Page 13

13

KEYPAD DESCRIPTION

The Cole-Parmer keypad is designed to be easy to use.

ENTER This key is used after a selection has been made on the menu.

PRODUCT This key is used to make a product selection.

SELECT This key is used before entering any adjustable programming

ESC within the instrument. It can also be used to cancel a current

entry in the instrument.

MEASURE This key is used to make measurements.

CM * This key toggles the displayed result between Protein on a

AS-IS Constant Moisture basis or on an AS-IS basis.

▲ ▼ These arrow keys cycle through menu selections.

Page 14

14

TURNING THE FOODTECH™ ON FOR THE FIRST TIME

1) If you are using batteries, simply turn on the FOODTECH™ by the

switch on

the right side and go to step 3).

If you are running the FOODTECH™ on batteries, please make sure the

instrument is shut off when not in use. The batteries will last much longer if

the instrument is off when sitting idle.

2) Plug the adapter into the right side of the FOODTECH™ Turn on the

power

switch. The FOODTECH™ begins a test sequence: “TEST EPROM, TEST

RAM, TEST IREDS, TEST ADC, TEST THERM.” When “Measure Standard”

is displayed, the test sequence has been completed.

3) Run the AutoBIAS sample (if option is installed), following the

directions on page 15.

4) Measure ten samples of the product that the instrument has been

calibrated for. (These samples must have already been analyzed by your lab.)

Write the analysis in the chart provided on page 17 and fax the form or call

Cole-Parmer at:

FAX: 1-847-247-2983

PHONE in the USA: 1-888-409-3663

outside the USA: 1- 847-549-7600

Cole-Parmer will give you any necessary adjustments.

Page 15

15

AUTOMATIC BIAS INITIALIZATION AND STANDARDIZATION

You can elect to run an AutoBIAS at any time, in

addition to the daily AutoBIAS prompt. Make sure

you are in the product whose bias you want to

adjust. Press SELECT ESC. Use the arrow keys

(▲▼) to scroll through the menu until “Auto Bias”

appears on the screen. Press ENTER.

(Optional)

When you turn the instrument on each day, it will require you to run

an AutoBIAS sample in each product you use.* The AutoBIAS feature uses

the latest NIR technology to prevent the FOODTECH™ from drifting out of

calibration.

The instrument will prompt, “BIAS ADJUST [product].” Press

ENTER. The instrument will read the empty chamber, then prompt, “Insert

Sample.” Do so; then press MEASURE. The screen will prompt, “Remove &

Turn.” DO NOT TURN THE CUP: the perma-sample can only be inserted

one way. Just press MEASURE. Remove and replace the sample when

prompted; press MEASURE. Remove the sample when prompted and press

MEASURE. The instrument will read the empty chamber again.

The instrument will decide how many times it needs to read the

sample. At this point, it may prompt, “READ AGAIN.” If it does so, DO NOT

INSERT THE SAMPLE. Press MEASURE. After it reads the empty

chamber again, it will tell you to “Insert Sample.” Repeat the process. It may

ask you to read the sample several times. Do not be alarmed. Simply follow

the directions until the screen gives the constituent name and a value. This

value is the amount of the bias adjustment for that constituent: Write it on

the attached Daily AutoBIAS Adjustment Record. Press ENTER. The

instrument will automatically adjust the bias by the amount shown. The

second constituent bias amount will appear. Record it and press ENTER

again. Continue until all the constituents have been adjusted.

You are now ready to begin reading samples in the adjusted product!

* If you are unable to run the AutoBIAS sample for some reason, you can escape the daily

AutoBIAS prompt by pressing the arrow keys in the following order: up, down, up (▲▼▲). Do

not make a habit of ignoring the AutoBIAS prompt. If you have lost the AutoBIAS sample,

contact Cole-Parmer for a replacement.

Page 16

16

PRODUCT # AutoBIAS AMOUNT FOR

and NAME

DATE

CON 1

CON 2

CON 3

CON 4

___/___/___

___/___/___

___/___/___

___/___/___

___/___/___

___/___/___

___/___/___

___/___/___

___/___/___

___/___/___

___/___/___

___/___/___

___/___/___

___/___/___

___/___/___

___/___/___

___/___/___

___/___/___

DAILY AutoBIAS™ ADJUSTMENT RECORD

Keep a blank copy of this sheet.

Page 17

17

ANALYZED SAMPLE FORM

Sample

Number

Analyzed

Sample

Lab

Protein

AS-IS

FOODTECH

™ Protein

AS-IS

Analyzed

Sample

Lab

Moisture

FOODTECH

™

Moisture

Analyzed

Sample

Lab

_________

FOODTECH

™

_________

1

2

3

4

5

6

7

8

9

10

SEND TO: Cole-Parmer Instrument Co., USA, FAX NO.: 1-847-247-2983

FROM: Company name, Country ___________________________________________

CONTACT PERSON: (please print) _________________________________________

PHONE: Country code ________ Number __________________________________

FAX: _____________________________________________________________________

Enter in the Analyzed Sample columns ten (10) samples that have been

analyzed by your lab. In the corresponding columns, enter the FOODTECH™

readings for the same samples. Fax to Cole-Parmer for advice concerning any

needed adjustments.

Page 18

18

SELECT PRODUCT

1. Press Product.

Press the arrow keys (▲ ▼) to cycle through the products. The different products

will be listed. (The Portable Food Analyzer is able to store ten products,

numbered as 0-9.)

2. Press ENTER when the product to be tested is on the display. Only one

product can be selected at a time.

MENU SELECTIONS

1. Turn on analyzer.

2. After test sequence is complete, press Select Esc. “Enter Bias” will

appear on the FOODTECH™ screen.

3. Press the arrow keys to cycle through the selections:

Enter Bias - adjust the calibration

Data Link - to communicate with the computer

Store Sample - saves samples in internal memory to be downloaded

to the computer

Paper Feed - for the optional printer

Reset ID # - resets the sample ID number to 1

Auto Bias - maintains calibration accuracy

Set Date

Set Time

Printing - for the optional printer

Set Readings - number of times that each sample is read—Cole-

Parmer recommends 4

4. Press ENTER to select the option on the screen.

Page 19

19

MEASURING A SAMPLE

1. Turn power switch ON. “FOODTECH™ PFA” will be displayed. The display

will show a version number and then will begin a test sequence. “Measure

Standard” will be displayed when the test sequence has been completed.

2. Select the product according to the sample type to be measured. (See “Select

A Product”)

3. Fill the sample cup with sample and tap the cup twice on a hard surface.

4. Make sure there is nothing in the sample chamber and close the lid over the

sample chamber.

5. Press MEASURE. The display will show “Reading . . .,” then “Insert

Sample.” This indicates that the instrument has been standardized. The

PFA must be standardized prior to making any measurement.

6. Lift the lid from the sample chamber and place the cup containing the sample

in the chamber.

7. Replace the lid over the sample in the chamber. This shield must always be

used when measuring a sample or a standard; otherwise, the results will be

incorrect.

8. Press MEASURE. The display will show “Reading . . .,” then “Remove &

Turn.” Remove the sample, rotate the sample cup 180 degrees and replace it

in the FOODTECH™ PFA. Close the lid.

9. Press MEASURE. The display will show “Reading . . .,” then “Remove &

Reload.” Remove the sample cup, pour out the sample, and refill the cup with

the same sample.

10. Tap the sample cup twice on a hard surface, replace it in the sample

chamber, and close the lid.

11. Press MEASURE. The display will show “Reading . . .,” then “Remove &

Turn.” Remove the sample cup, rotate the cup 180 degrees, and replace it in

the FOODTECH™ PFA. Close the lid.

12. Press MEASURE. The display will show “Reading . . .,” then “Remove &

Press M.” Remove the sample.

Page 20

20

13. Close the lid over the empty chamber and press MEASURE.

14. The results will be displayed. Use the down arrow key to list the results of

each constituent.

15. To measure another sample of the same product, press SELECT ESC to

clear the results. The instrument will return to “Measure Standard.” Repeat

steps 3-14.

Remember:

At any prompt where you have to either enter a sample or remove a sample and

press MEASURE, the instrument will allow you only 50 seconds to do so. If

after the elapse of 50 seconds you have not completed the task required, the

FOODTECH™ will flash “Time Out!” and automatically return to “Measure

Standard.” This feature is designed to prevent readings from becoming “stale.”

Page 21

21

ADJUSTING THE CALIBRATION

Sample Number

FOODTECH™ Protein

As-Is

Lab Protein As-Is

1

10.0

10.2

2

11.1

11.3

3

12.3

12.6

4

10.4

10.5

5

9.1

9.3

6

10.8

11.0

7

12.0

12.1

8

11.2

11.4

9

8.8

9.0

10

9.6

9.8

Column Average =

10.5

10.7

The FOODTECH™ has been carefully calibrated at the factory or at your

location; however, sometimes it is necessary to adjust the calibration for a bias.

A bias adjustment fine tunes the FOODTECH™ by shifting all readings up or

down by the same amount.

A. Obtain ten laboratory-analyzed samples.

B. Measure the samples in the FOODTECH™

C. Compare the instrument readings with the laboratory analysis or fax the

data to Cole-Parmer at 847-247-2983 and Cole-Parmer will provide any

necessary adjustments. See the following example of data requiring a

bias adjustment.

Example: Determine the average FOODTECH™ value and the average

laboratory value. The difference between the two will be the bias adjustment.

In the above example, the FOODTECH™ is reading Protein As-Is 0.2% too low

(determined by the difference between the averages of the two columns). The

bias adjustment will be +0.2 for Protein As-Is.

Page 22

22

ADJUSTING THE BIAS

1. Turn on the instrument.

2. Make sure you are in the product that requires the bias adjustment. (See

“Select a Product”)

3. When “Measure Standard” is displayed, press SELECT ESC.

4. “Enter Bias” will appear on the display. Press ENTER.

5. The product and constituent appear:

Example: PØ WHT C1 PRO

6. Use the arrow keys to cycle through the constituents. Press ENTER after the

constituent for which you are adjusting the bias appears.

7. “Bias: Ø.Ø” will appear. Use the arrow keys to cycle through the numbers.

Press ENTER when the correct bias is displayed. Make sure the decimal

point is in the right place. “Complete” will appear.

8. If for any reason you must abort, press SELECT ESC to abort the bias

adjustment.

AUTOBIAS

1. To run the optional AutoBIAS, select “Auto Bias” on the FOODTECH™ menu

and press ENTER. (See also the AutoBIAS instructions on page 15.)

2. Follow the instructions on the screen, using the AutoBIAS perma-sample

provided by Cole-Parmer or your own sealed AutoBIAS sample. (See the

FOODTECH™ Calibration Manual for instructions on creating an AutoBIAS

sample and setting the instrument to read a different AutoBIAS sample.)

3. Run the sample as many times as the instrument requests.

4. Record the date and the amount of the bias adjustment on a copy of the

AutoBIAS Adjustment Record on page 16.

Page 23

23

ADJUSTING THE TIME

1. Turn PFA on.

2. At the “Measure Standard” prompt, press SELECT ESC.

3. When “Enter Bias” is displayed, use the arrow keys ((▲ ▼) to cycle through

the menu until “Set Time” appears.

4. Press ENTER.

The up arrow key (▲) cycles through the hours.

The down arrow key (▼) cycles through the minutes.

The CM* AS-IS key zeroes the seconds.

5. Press ENTER after the time has been adjusted.

ADJUSTING THE DATE

1. Turn on the PFA.

2. After the test sequence is completed, “Measure Standard” is displayed.

3. Press SELECT ESC. “Enter Bias” will appear.

4. Use the arrow keys to cycle through the menu to find “Set Date.” Press

ENTER.

The up arrow key (▲) cycles through the months.

The down arrow key (▼) cycles through the days.

The CM*/AS-IS key cycles through the years.

5. Press ENTER after the date has been adjusted.

ADJUSTING THE NUMBER OF READ CYCLES

The FOODTECH™ is designed to allow you to use between 1 and 9

repetitions to get the maximum accuracy needed for your samples in a minimum

of time.

Cole-Parmer recommends using four (4) repetitions.

1. Turn on PFA.

Page 24

24

2. At the “Measure Standard” prompt, press SELECT ESC.

3. When “Enter Bias” is displayed, use the arrow keys (▲ ▼) to cycle through

the menu to find “Set Readings.” Press ENTER.

4. “# Reads: 4” is displayed. Use the arrow keys to cycle through the numbers.

Press ENTER at the number of your choice.

STORE SAMPLES

(Optional)

The PFA is able to store the OD’s and sample ID’s for up to 25 samples in

battery-backed RAM. The samples are stored in the same memory as the K

values. This means that the sample readings are preserved even when the

FOODTECH™ is turned off. The samples that are saved in the FOODTECH™'s

memory can be downloaded to a PC.

To save the last sample that was read:

1. Press SELECT ESC. “Enter Bias” will be displayed.

2. Use the arrow keys ((▲ ▼) to cycle through the menu until “Store Samples”

appears. Press ENTER.

3. “Saved #______“ indicates the number (1-25) of the saved sample in the

FOODTECH™’s memory.

After saving 25 samples, the instrument will wrap around and begin to

save again in position 1. This will overwrite the previous sample(s).

The samples can be downloaded to the PC using the optional software by

connecting the FOODTECH™ to the computer with an RS232 cable and

selecting “Download Saved Samples” from the Utility Menu of the calibration

program. See “Download Saved Samples” in the Calibration Manual.

DATA LINK

The FOODTECH™ must be in Data Link mode for it to communicate with

the PC. The FOODTECH™ is connected to the PC with an RS232 cable.

1. Turn on PFA.

Page 25

25

2. At the “Measure Standard” prompt, press SELECT ESC.

3. When “Enter Bias” is displayed, use the arrow keys ((▲ ▼) to cycle through

the selections to find “Data Link.”

4. Press ENTER. “DATA LINK” will be displayed in capital letters.

PRINTING

This selection is used with the optional printer.

To enable the printer:

1. Turn on the PFA.

2. At the “Measure Standard” prompt, press SELECT ESC.

3. “Enter Bias” will appear. Use the arrow keys (▲ ▼) to cycle through the

menu to find “Printing.” Press ENTER.

4. “PRN ENABLED” will be displayed. Press ENTER.

NOTE: Each time the FOODTECH™ is turned on, the printer must be enabled.

To disable the printer:

1. Turn on the PFA.

2. At the “Measure Standard” prompt, press SELECT ESC.

3. “Enter Bias” will appear. Use the arrow keys (▲ ▼) to cycle through the

menu to find “Printing.” Press ENTER.

4. “PRN DISABLED” will be displayed. Press ENTER.

PAPER FEED

This selection is used with the optional printer. The printer must be enabled

(See above). To advance the paper on the optional printer:

Page 26

26

1. Press SELECT ESC. “Enter Bias” will appear.

2. Use the arrow keys to cycle through the menu until “Paper Feed” is

displayed.

3. Press ENTER. The paper will advance one line each time ENTER is

pressed.

4. Press SELECT ESC to return to “Measure Standard.”

RESET ID #

This selection is used to reset the automatic sampling number to #1.

1. Turn on the PFA. Wait for “Measure Standard” to be displayed.

2. Press SELECT ESC. “Enter Bias” will appear on the display.

3. Use the arrow keys to cycle through the menu until “Reset ID #” appears.

Press ENTER.

4. “ID # Reset” will be displayed. The next sample run will be labeled sample

#1.

Page 27

27

WARNINGS AND ERROR CODES

Error: TOO DARK

Error: TOO LITE

****** WARNING ******

Error

AMB. TEMP TOO LOW

********************

The FOODTECH™ has a number of warnings and error codes built into it.

Some are overridden automatically on the analyzer; others require you to start

the reading again.

The range for the warnings can be set by using the Instrument Edit Utility

program on the Calibration Software.

1) This error occurs if the energy reaching the detector is less than the

acceptable level.

2) This will be displayed if the detector is in saturation. This normally is

caused by not placing the light shield on correctly while the instrument is

reading a sample or measuring the standard.

3) The FOODTECH™ was set up with a temperature check for itself. If the

instrument temperature is too cold, a warning, “AMB. TEMP TOO LOW” will

appear on the display. This can be overridden by pressing ENTER.

Page 28

28

****** WARNING ******

Error

AMB. TEMP TOO HIGH

*********************

****** WARNING ******

Error

SMP. TEMP TOO LOW

*********************

****** WARNING ******

Error

SMP. TEMP TOO HIGH

*********************

****** WARNING ******

* BAD CURVE *

********************

4) This indicates that the instrument is above the recommended

temperature range.

5) The FOODTECH™ was also set up with a temperature check for the

sample. If the sample temperature is too cold, a warning, “SMP. TEMP LOW,”

will appear on the screen. This can be overridden by pressing ENTER.

6) This indicates that the sample temperature is above the recommended

temperature range.

7) This will be displayed only if A, B, and C have been activated using the

Instrument Edit Utility program in the Calibration Software.

Page 29

29

Note: When entering Curve Checking on the Constituent Menu you should

****** WARNING ******

Error

HIGH VAR

***********************

****** ERROR ******

VALUE TOO LOW

**********************

always look at the curve on a typical sample on the computer. On the

bottom of the computer screen the filter numbers are displayed. You

should choose A as the highest peak of the sample, B as the second

highest peak on the sample, and C as the low point of the sample. This

allows you to verify that the curve is a reasonable shape for the curve you

calibrated for.

8) This is displayed if the variance among the four readings is more than

normal variance in the sample. This tells you that the repeatability within the

sample is not as reasonable as we would expect. This could be caused by light

leaks, an improperly aligned sample, or just variations in the samples.

9) This occurs when the reading for a particular constituent is outside the

range that was set up on the range of data on the Instrument Edit Utility

program.

10) At any prompt where you have to either enter a sample or remove a

sample and press MEASURE, the instrument will allow you only 50 seconds to

do so. If after the elapse of 50 seconds you have not completed the task required,

the FOODTECH™ will flash “Time Out!” and return to “Measure Standard.”

This feature is designed to not allow readings to become “stale.”

Page 30

30

****** ******

NO CONS NAME

**********************

****** ******

LOW BATTERIES

**********************

11) This is displayed after a sample reading to warn the user that the product

selected to run the sample does not have constituents named for that product.

12) This is displayed when the batteries need to be replaced.

Page 31

31

GENERAL SPECIFICATIONS

Carrying case

AutoBIAS perma-sample

Calibration software

Calibration manual

RS232 cable

AC adapter

Variable pathlength sample cup

24mm sample cup

Printer

Printer paper

1. MEASUREMENT

Measuring Principle: Near-Infrared Transmittance based on technology from the United

States Department of Agriculture

2. PRINTER OUTPUT (optional)

Product and Constituent name and analysis with time, date, and identification number

(manual or automatic)

3. DISPLAY

Product and Constituent name and analysis

4. POWER SOURCE

Six AA 1.5V alkaline batteries

9V A/C adapter (included)

5. DIMENSIONS

Main Body - 4.7 x 13.5 x 2.2 inches

6. WEIGHT

3 lbs

7. ACCESSORIES

Part Number

2 sample cups

1 Static Brush

6 AA alkaline batteries ZXP 103

1 User's Manual ZXP 111

1 Quick Start Manual

8. OPTICAL MEASUREMENT TECHNIQUE TRANSMITTANCE OF NEAR-INFRARED

USING: 14 wavelengths covering the range from 893 nanometers to 1045 nanometers

9. OPTIONS:

Page 32

32

GLOSSARY

application - the type of product the user is analyzing for a certain

constituent(s)

AutoBIAS - Automatic Bias Initialization and Standardization. Maintains the

accuracy of the calibration by daily adjustment.

bias - the average overall shift of the regression curve from the ideal laboratory

regression curve

constants - numbers that relate to the influence of each wavelength use in the

statistical calibration of the customers product

constituent - organic compound that is found in the sample being tested

diffuse transmittance - light energy is transmitted and distributed evenly

through the sample being tested

diodes - near-infrared red light sources

IR - abbreviation of infrared

K’s or K values - same as constants

lab analysis - the chemical or physical analysis of constituent(s) in a product

light absorption - the amount of light energy absorbed by various constituents

in the product being measured

linear regression - a graphical representation of a statistical analysis of the

relationship between two or more measured variables

nanometer or nm - one billionth of a meter

near-infrared - the range of light energy near the visible spectrum

near-IR - See near-infrared

OD - optical data expressed in terms of voltage values for each wavelength used

in a Cole-Parmer analyzer

Page 33

33

regression - the statistical liner, quadrant, or cubic means of comparing two or

more variables (ex: OD versus percentage of moisture)

sample - a measured amount of product to be tested

sensor - a device used in Cole-Parmer analyzers that converts light energy to

electrical signals for processing optical data

spectrum - the range of OD energy measured in wavelength increments

transmittance - the ease with which light or other forms of energy can pass

through a sample being tested

wavelengths - specific band widths of light energy, usually expressed in

nanometers in near-infrared instrumentation

HRS - Hard Red Spring Wheat

HRW - Hard Red Winter Wheat

SWW - Soft White Wheat

SRW - Soft Red Winter Wheat

BLY - Barley

CRN - Corn

SOY - Soybean

SML - Soymeal

Page 34

34

APPENDIX I

COMBINATION LOCK

Your combination lock is set at the factory to open at 000. You may leave

it at this setting or you can set your own secret combination in the following

manner:

1. Open the case. At the back of the lock you will see the change lever extending

from the body of the lock.

2. Move the change lever toward the dials of the combination lock and down.

3. Now turn the dials to your own secret number and write it down in a safe

place.

4. Without disturbing the setting of the dials, move the change lever back to its

original (normal) position. Make sure you have done this before closing the

case and using the lock.

Your case will now open only at your secret combination. If you want to

change the combination again, simply repeat these steps.

Page 35

35

INDEX

A/C adapter 7, 31

absorption 32

AutoBIAS 1, 5, 14, 15, 16, 22, 32

BAD CURVE 28

Batteries 5

bias 21, 22, 32

Bias 18, 22, 23, 24, 25

BIAS 22

bias adjustment 21, 22

BLY 33

BRUSH 4

calibration 18, 21, 24, 32

Calibration Software 27, 28

combination 5, 34

constituent 20, 22, 29, 32

CRN 33

curve 29, 32

Curve 29

CURVE 28

DARK 27

DATA LINK 24, 25

DATE 23

disable 25

ELECTRICAL REQUIREMENTS 7

enable 25

ERROR 27, 29

HRS 33

HRW 33

Instrument Edit Utility 27, 28, 29

KEYPAD 13

lab 14, 17, 32

light shield 27

LITE 27

main body 7

Measure Standard 14, 19, 20, 22, 23, 24, 25, 29

PATHLENGTH 12

printer 7, 18, 25

PRN DISABLED 25

PRN ENABLED 25

PRODUCT 13, 18

range 27, 28, 29, 31, 32, 33

READ CYCLES 23

regression 32, 33

repetitions 18, 23

RS232 cable 24

sample 5

Sample Cup 5

SML 33

SOY 33

SRW 33

standard 8, 19, 27

Standard 14, 19, 20, 22, 23, 24, 25, 29

SWW 33

temperature 27, 28

TIME 14, 23

Time Out! 20, 29

Transmittance 31

United States Department of Agriculture 31

variance 29

WARNING 4, 27, 28, 29

Page 36

36

Addendum

CM DISPLAY

When displaying measurement results, the instrument displays the AS-IS

calculation first by default. Pressing the CM/AS-IS Button will toggle back and

forth between CM and AS-IS.

If you should wish to display the CM results first, simply press the CM/AS-IS

button while the display says "Measure Standard". When pressed, the display

will say "CM DEFAULT". Any readings taken afterwards will show the CM

results first. To view the AS-IS results first, press the CM/AS-IS button again

while the display says "Measure Standard" and the display will say "AS-IS

DEFAULT".

Loading...

Loading...