Page 1

User Manual

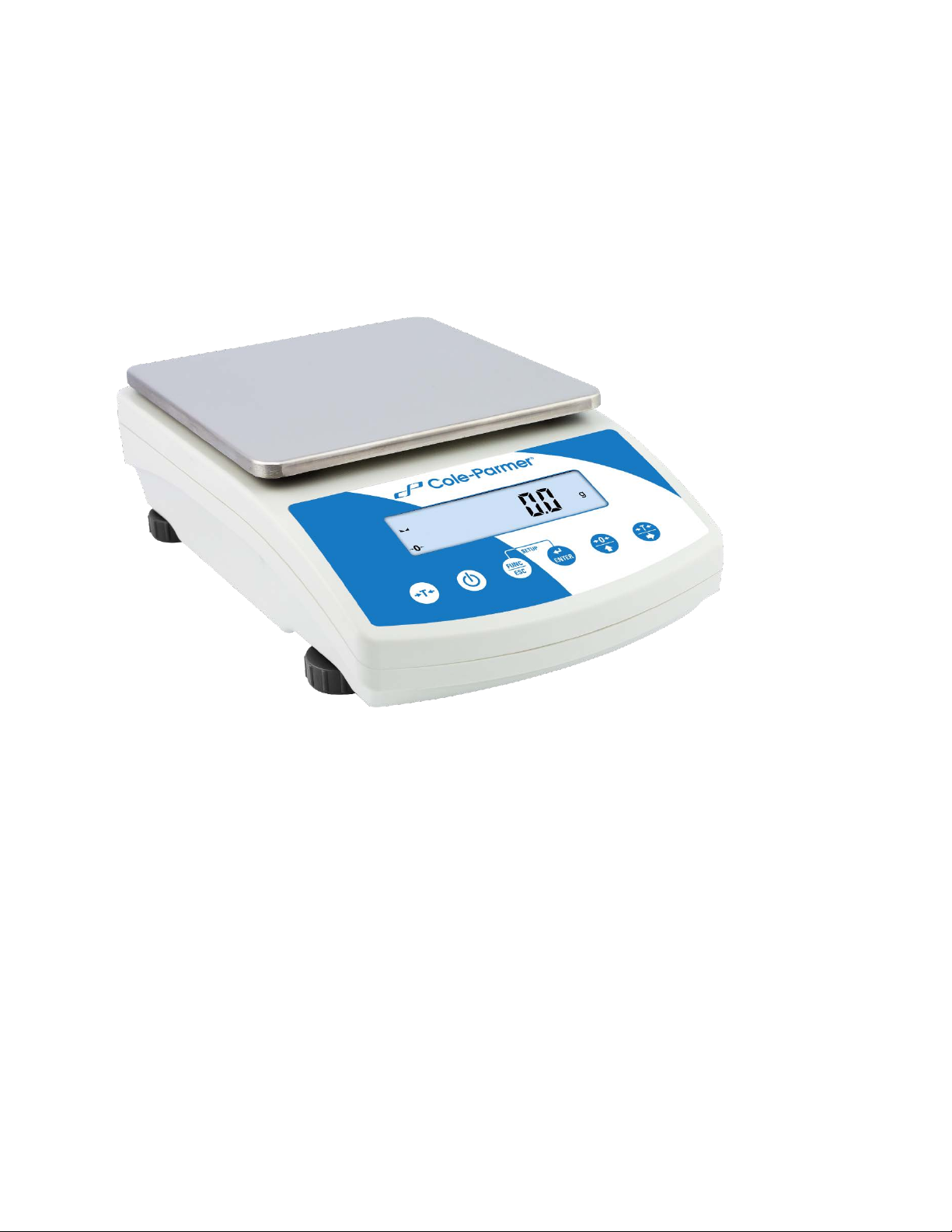

Cole-Parmer Symmetry Balances

Portable High Capacity Balances: PBH Series

5-18-18

Page 2

GENERAL INFORMATION .................................................................................................................................1

1.1. INTENDED USE ............................................................................................................................................1

1.2. PRECAUTIO NS .............................................................................................................................................1

1.3. BATTERY ......................................................................................................................................................1

1.4. WARRANTY CONDITIONS ............................................................................................................................2

UNPACKING AND INSTALLATION ....................................................................................................................2

2.

1. PLACE OF USE AND ASSEMBLING ...........................................................................................................2

2.2. STANDARD DELIVERY COMPONENTS LIST ............................................................................................2

2.3. UNPACKING .................................................................................................................................................3

2.4. BALANCE ASS EM BL Y .................................................................................................................................3

2.5. BALANCE LEVELING ...................................................................................................................................4

2.6. POWERING THE DEVICE ............................................................................................................................4

2.7. BATTERY STATUS .......................................................................................................................................5

2.8. BATTERY POWER .......................................................................................................................................5

BALANCE CONTROL .........................................................................................................................................5

3.

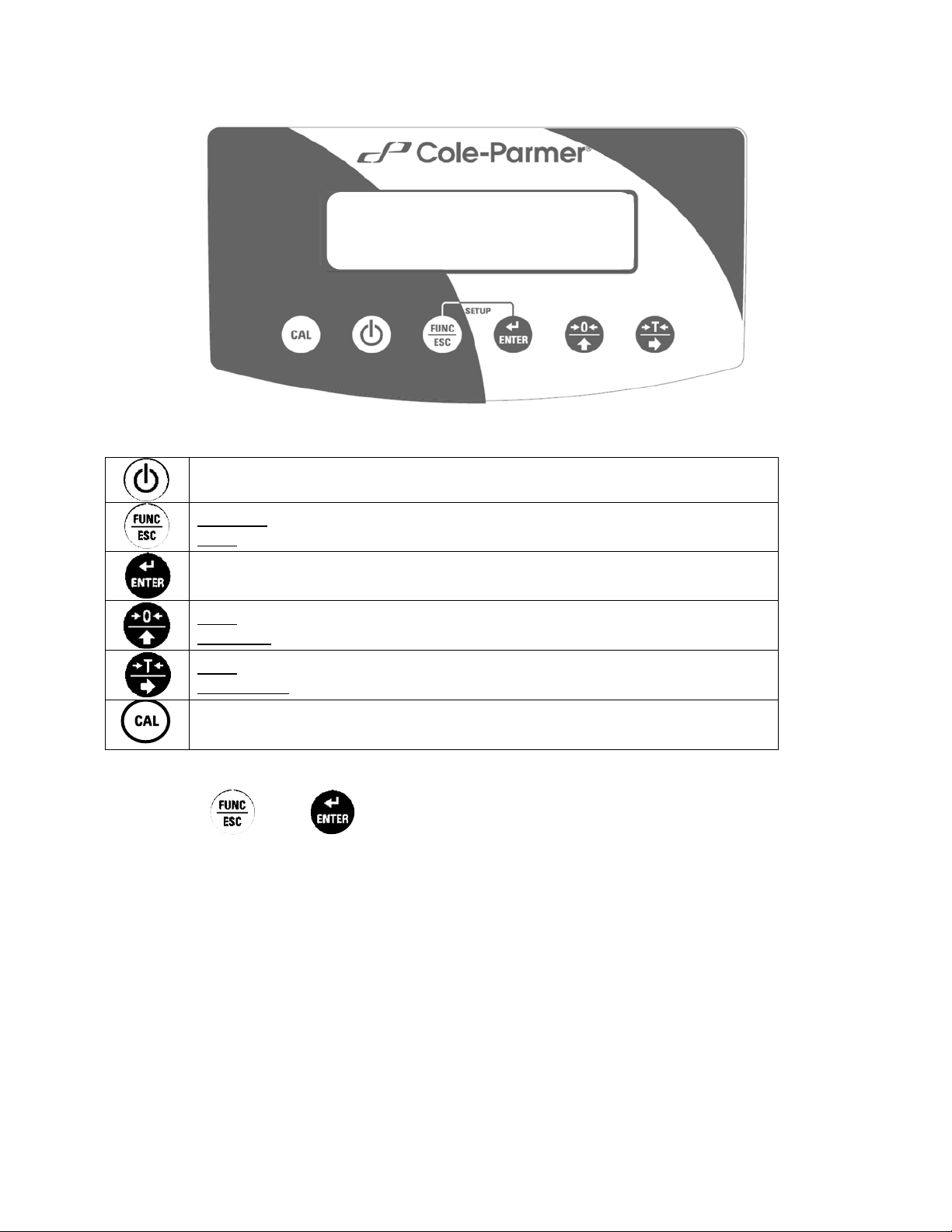

1. BALANCE KEYBO ARD .................................................................................................................................5

3.2. ENTERING BAL ANCE MENU .......................................................................................................................7

3.3. INSCRIPTIONS ON THE DISPLAY ..............................................................................................................8

3.4. BALANCE MENU ..........................................................................................................................................9

WEIGHING MODE ............................................................................................................................................ 10

4.1

. UNITS ......................................................................................................................................................... 11

4.2. START UNIT .............................................................................................................................................. 11

4.3. TEMPORARY UNIT ................................................................................................................................... 12

4.4. TARING ...................................................................................................................................................... 12

4.5. MANUAL TARE ENTERING ...................................................................................................................... 13

4.6. ZEROING ................................................................................................................................................... 13

4.7. UNDER-PAN WEIGHING........................................................................................................................... 14

BALANCE PARAMETERS ............................................................................................................................... 15

5.1.

FILTER LEVEL ........................................................................................................................................... 15

5.2. AUTOZERO ................................................................................................................................................ 15

5.3. TARE FUNCTION ...................................................................................................................................... 16

5.4. MEDIAN FILTER ....................................................................................................................................... 17

ADJUSTMENT (PBH.C SERIES) ..................................................................................................................... 18

6.

1. INTERNAL ADJUSTMENT ........................................................................................................................ 18

6.1.1 MANUAL INTERNAL CALIBRATION ................................................................................................. 18

6.1.2 AUTOMATIC INTERNAL CALIBRATION .......................................................................................... 19

6.2. EXTERNAL CALIBRATION ....................................................................................................................... 20

6.3. CALIBRATION REPORT............................................................................................................................ 22

ADJUSTMENT (PBH SERIES) ........................................................................................................................ 23

7.

1. EXTERNAL CALIBRATION ....................................................................................................................... 23

7.2. START MASS ADJUSTMENT ................................................................................................................... 25

WORKING MODES ........................................................................................................................................... 26

8.

1. RUNNING WORKING MODE .................................................................................................................... 26

8.2. ACCESSIBILITY OF WORKING MODES .................................................................................................. 26

8.3. COUNTING PIECES .................................................................................................................................. 27

8.4. +/- CONTROL ............................................................................................................................................. 29

8.4.1 DECLARING CHECKWEIGHING THRESHOLDS ............................................................................. 29

8.5. PERCENT WEIGHING ............................................................................................................................... 30

8.5.1 REFERENCE MASS DETERMINED BY WEIGHING ........................................................................ 31

8.5.2 REFERENC E M AS S DETERMINED BY ENTERIN G ........................................................................ 31

8.6. PEAK HOLD ............................................................................................................................................... 32

8.7. TOTALIZING .............................................................................................................................................. 33

8.7.1 MEMORY OF LAST VALUE............................................................................................................... 34

8.7.2 RETURN TO WEIGHING ................................................................................................................... 34

Page 3

8.8. ANIMAL WEIGHING ................................................................................................................................... 35

8.9 AUTOMATIC TARE ..................................................................................................................................... 36

8.10 TARE MEMORY ........................................................................................................................................ 37

8.10.1 SELECT TARE VALUE FROM THE MEMORY ............................................................................... 38

RS232 INTERFACE .......................................................................................................................................... 38

9.1. RS232 SETTINGS ...................................................................................................................................... 38

9.2. PRINTOUTS ............................................................................................................................................... 39

9.3 MINIMAL MASS THRESHOLD ................................................................................................................... 39

9.4 BAUD RATE .............................................................................................................................................. 40

9.5 SERIAL TRANSMISSION PARAMTER ..................................................................................................... 41

PERIPHERALS ........................................................................................................................................... 41

10.

1. COMPUTER ............................................................................................................................................. 41

10.2 PRINTER ............................................................................................................................................ 42

BALANCE SETTINGS ................................................................................................................................ 42

11.

1. BACKLIGHT ............................................................................................................................................. 42

11.2. 'BEEP' SOUND ......................................................................................................................................... 43

11.3. AUTOMATIC SHUTDOWN ...................................................................................................................... 44

11.4. ACCUMULATOR CHARGING OPTION .................................................................................................. 45

ACCESSORIES .......................................................................................................................................... 45

APPENDIX .................................................................................................................................................. 46

1

3.1. BALANCE SPECIFICATIONS .................................................................................................................. 46

13.2. MAINTENANCE ....................................................................................................................................... 47

13.2.1 CLEANING ABS COMPONETS ....................................................................................................... 47

13.2.2 CLEANING STAINLESS STEEL COMPONETS ............................................................................. 47

13.3. DIMENSIONS ........................................................................................................................................... 47

13.4. TROUBLESHOOTING ............................................................................................................................. 48

13.5. ERROR MESSAGES ................................................................................................................................ 48

13.6. WARRANTY CARD .................................................................................................................................. 48

Page 4

GENERAL INFORMATION

1.1. INTENDED USE

PBH-series balances are designed for fast and precise measurements of weighed loads masses and

direct commercial settlements. Taring in full weighing range enables to determine net mass of

weighed loads.

1.2. PRECAUTIONS

• Prior to first use, it is highly recommended to carefully read this User Manual, and

oper

ate the balance as intended.

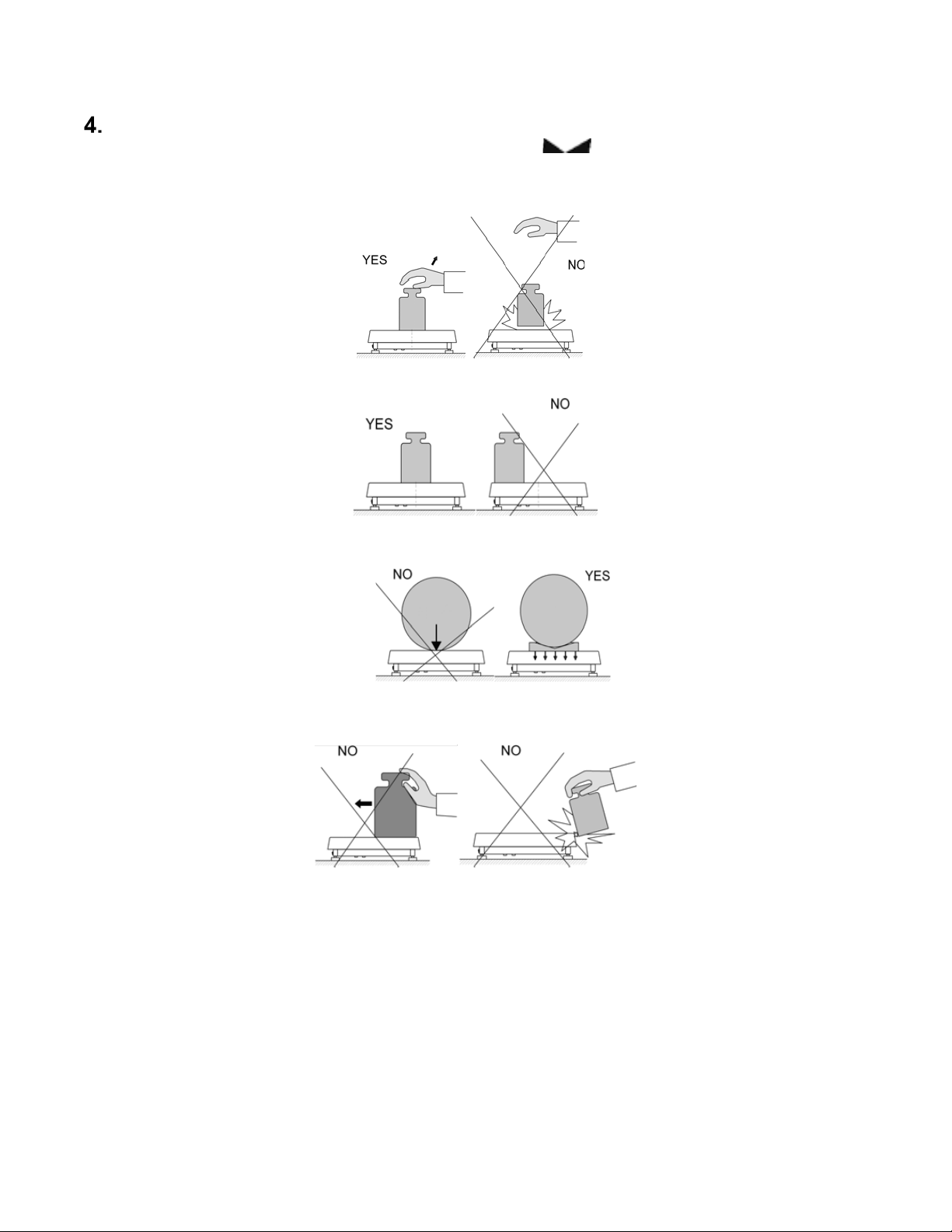

• Do not use the balance for a dynamic weighing. Even if small quantities of weig

aterial are added or removed from the weighing pan of the instrument, the reading

m

should be taken only after stabilization of the measurement results.

• While loading the balance make sure that load is placed in the very center of the

weighing pan.

• Make sure the load does not exceed instrument’s measuring range (maximum capacity).

• Do not leave heavy loads on the weighing pan for a long period of time.

• In case of failure, immediately unplug the instrument.

• Balances to be decommissioned, should be decommissioned in accordance with vali

gal regulations.

le

• Do not use the balance is areas endangered with explosion. The balance is not

designed to operate in EX zones.

hed

d

1.3. BATTERY

The device connected to mains power monitors the battery state and charges it if possible. After

sudden lack of power supply from the mains the device automatically switches to accumulator

without breaking operation.

PBH scales are devices designed to be supplied from SLA accumulators (Sealed lead acid type) 6V

and capacity 3 to 4Ah charged while connected to mains without stopping operation.

In case of an elongated storage period in low temperatures, it is not allowed the full

discharge of the accompanied batteries.

he equipment including accumulators does not belong

T

to your regular household waste. The European legislation requires that electric and

electronic equipment be collected and disposed separately from other communal waste

with the aim of being recycled.

C

aution:

Some symbols on accumulators identify harmful elements/compounds: Pb = lead,

Cd = cadmium, Hg = mercury.

1

Page 5

1.4. WARRANTY CONDITIONS

Cole-Parmer will exchange, replace or repair the existing balance for any damage that appears to be

faulty by production or by construction within the 5-year warranty period.

arranty is voided if:

W

A. Cole Parmer will exchange, replace or repair the existing balance for any damage that

appears to be faulty by production or by construction within the 5-year warranty period.

B. Warranty is voided if:

• mechanical defects caused by inappropriate use:

• defects of thermal and chemical origin,

• defects caused by lightning, overvoltage in the power network

• defects caused by water damage

• or other random event

• overloading the mechanical measuring system

• installing another version of the operating system

• utilizing the balance contrary to its intended use

• repairs carried out by non-authorized service centers

• removing or destroying protective stickers which secure the balance’s housing against

unauthorized access

C. Warranty card must be filled out for warranty to be valid.

UNPACKING AND INSTALLATION

2.1. PLACE OF USE AND ASSEMBLING

• The balance should be stored and used in locations free of vibrations and shakes, free of

air movement and dust.

• Ambient air temperature should not exceed the range of: +15 °C ÷ +30 °C.

• Ambient relative humidity should not exceed 80%.

• During balance operation, ambient temperature in the weighing room should not chan

r

apidly.

• The balance should be located on a stable wall console desk or a stable working table

w

hich is not affected by vibrations and distant from heat sources.

• Keep all package element should your device be transported in the future. Remember that

only original packaging can be used for shipping purposes. Prior to packing, uncouple any

cables, remove any separable components (weighing pan, shields, inserts). Pack the

device components into an original packaging. The original packaging protects th

eq

uipment against potential damage during transportation.

2.2. STANDARD DELIVERY COMPONENTS LIST

• Balance and components shown in Section 2.4 depending on balance

model

• Warranty Card

• USB

o User Manual

o RLAB Software

ge

e

2

Page 6

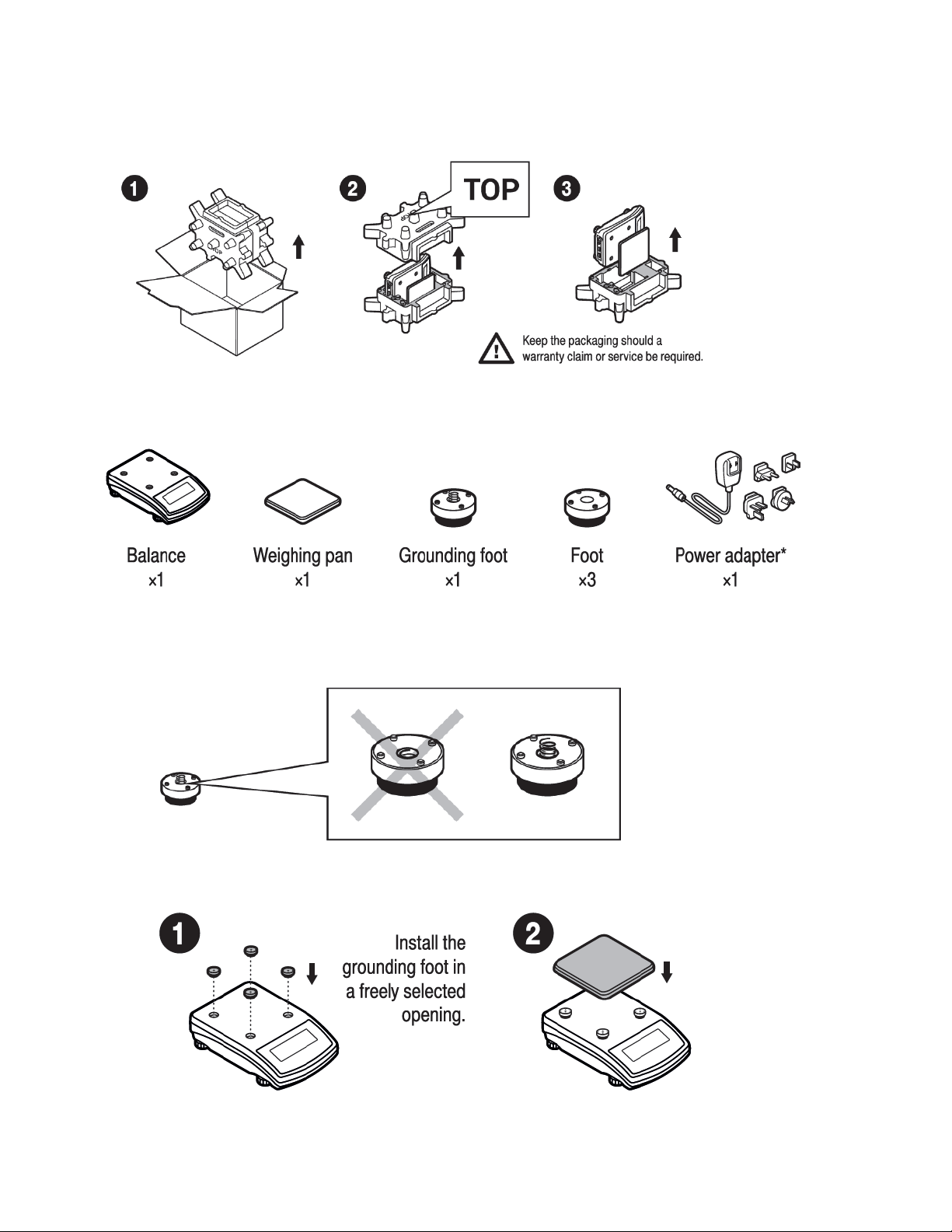

2.3. UNPACKING

To unpack the system, follow the diagram below-

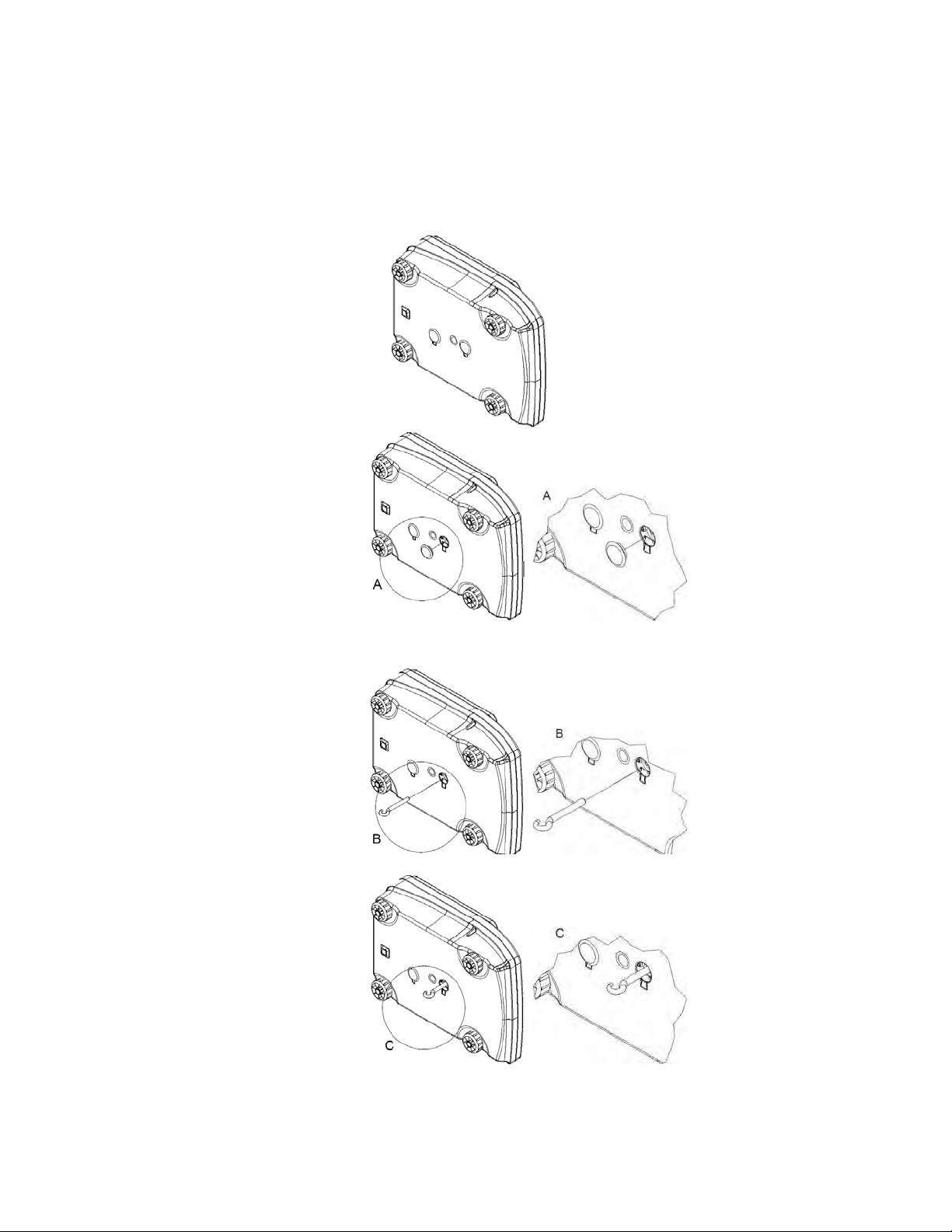

2.4. BALANCE ASSEMBLY

C

omponents:

In

stallation:

• Check grounding spring to insure it is in the appropriate location. Make sure that the

grounding spring juts slightly out of the hole.

• Install components following diagram below:

• Grounding Foot and 3 x Feet

• Weighing Pan

3

Page 7

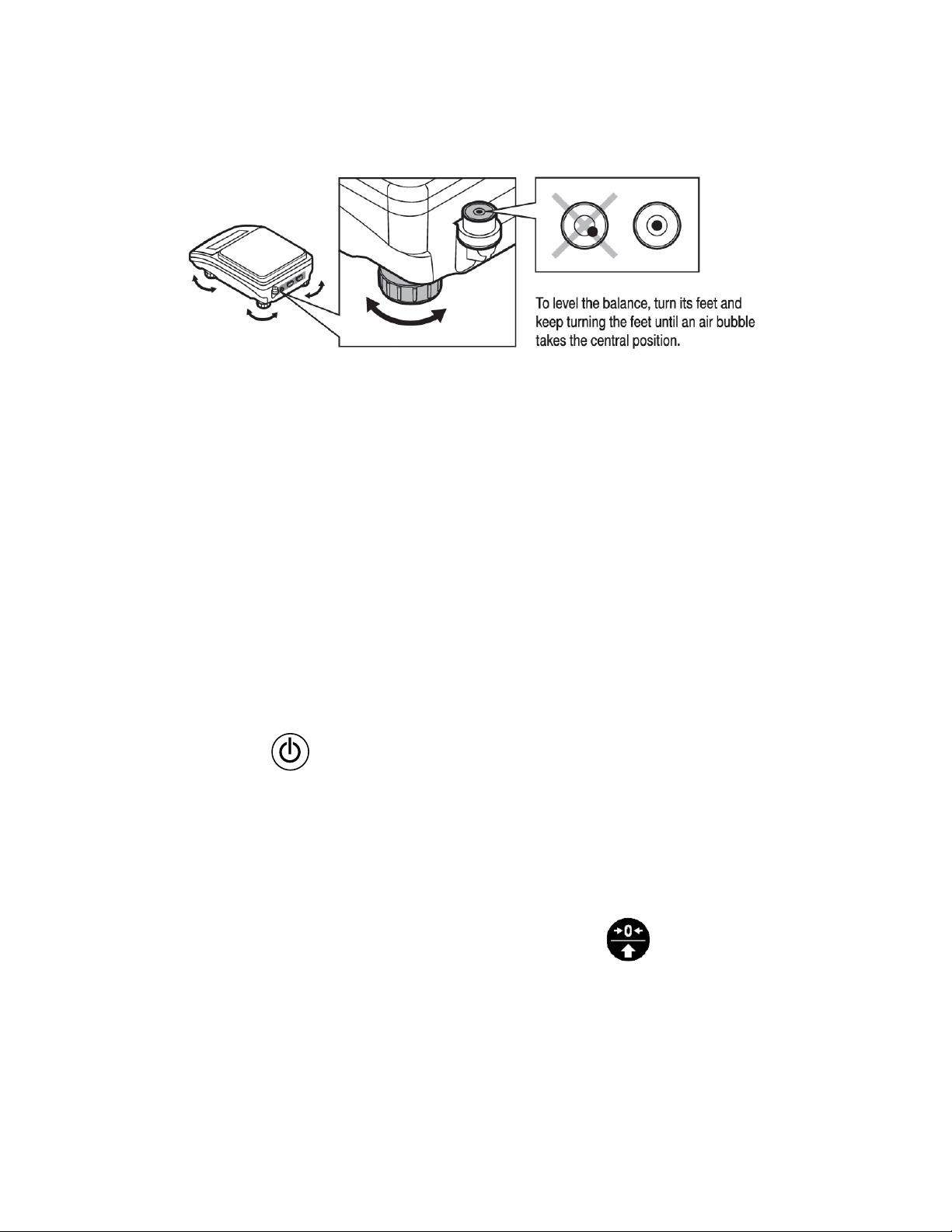

2.5. BALANCE LEVELING

It is necessary to level the balance prior to plugging it in. To level the balance, turn its feet until the

air bubble is in the center position.

The balance should firmly rest on a surface, each of the feet must be supported.

2.6. POWERING THE DEVICE

Before plugging in your balance, it is imperative to wait until the balance reaches thermal

stabilization (estimated 1-8 hours). On switching on, the balance requires 30 minutes of temperature

stabilization time. During temperature stabilization displayed information may change. Adjustment

should be carried out after temperature stabilization.

r correct operation of the balance the temperature range is +15˚C ± +30˚C; Any changes of

Fo

temperature and humidity during operation can cause indication errors. Errors can be corrected by

carrying out user adjustment.

For

balances that were stored in much lower temperatures (e.g. during winter period), thermal

stabilization period may be extended.

• Balance should be plugged in only with the power adapter that comes standard wit

he model. Nominal power supply of the power adapter (specified on the power

t

adapter data plate) should be compatible to the power supply.

• Plug the balance in – connect the power adapter to the socket, next connect its

connector to port located at the back of the balance housing.

• Press button on the key pad.

! Remember to start the balance with no load on the weighing pan

• Test of the display unit takes place right after connecting the balance to the power, all

the elements and pictograms are backlit for a short time.

• Next, the name and the program number appears

• the indication gets to ZERO (displayed reading unit depends on the balance). During

the balance start, the test of an internal mass adjustment mechanism occurs (single

location and elevation of the internal mass adjustment).

• If the indication is different than zero, please press button

h

4

Page 8

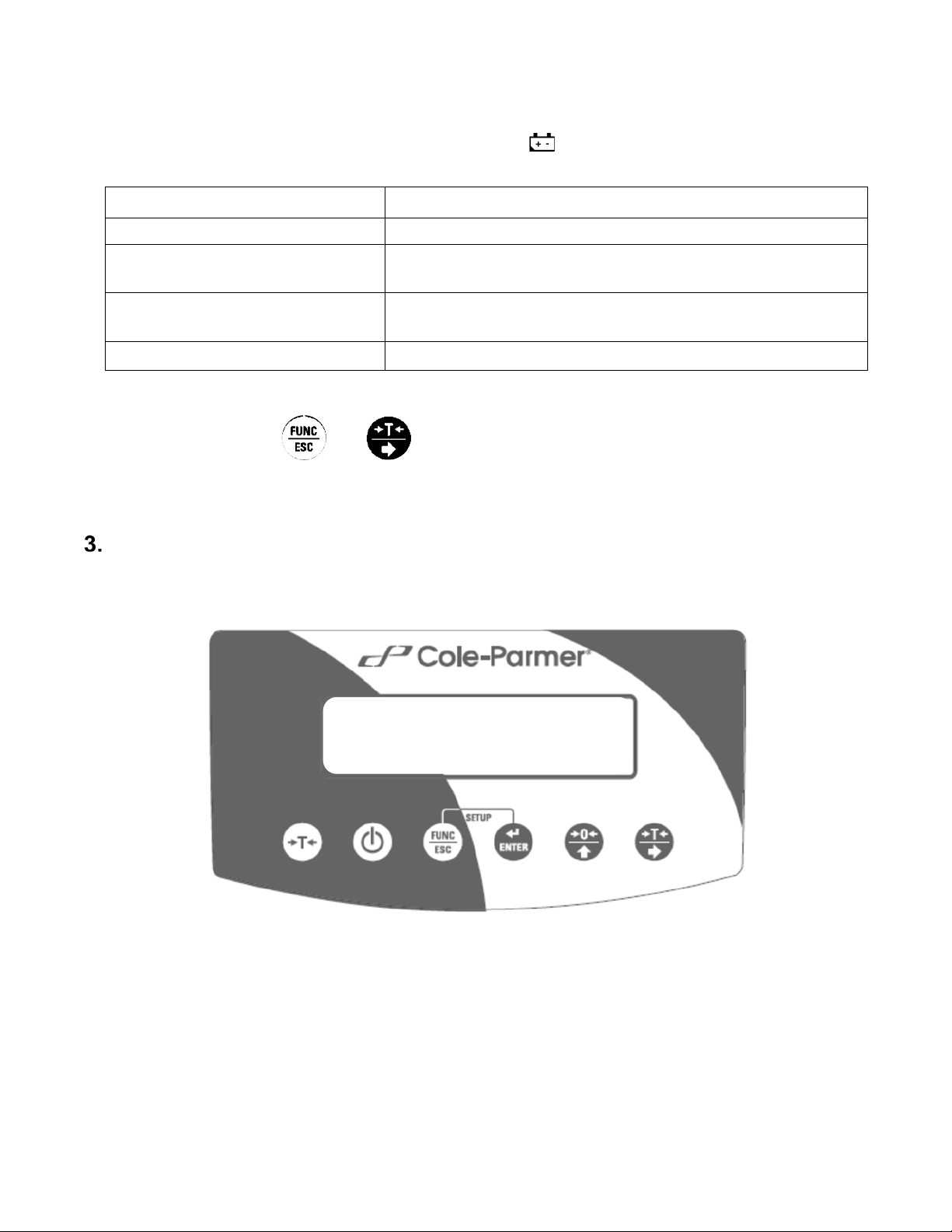

2.7. BATTERY STATUS

No pictogram

Battery full. Standard balance operation.

Pictogram blinks every 1 s.

Pictogram blinks every 0.5 s.

Battery error. Battery is damaged

An internal battery comes standard with the balance. pictogram, displayed at the top of the

display, signals battery status.

Pictogram operation Overview

Pictogram displayed continuously Battery status low. The balance will shut down. Immediately

charge the battery.

Battery charge in progress. The device is connected to the

power supply charging the battery.

2.8. BATTERY POWER

•

Simultaneously

• Battery power given in % is displayed for 2s.

• Wait for the home screen to be displayed.

and

keys.

BALANCE CONTROL

3.1. BALANCE KEYBOARD

PBH Overlay

5

Page 9

C

aution:

PBH.C Overlay

Press to switch the balance on/off

Function: press to select working mode.

ESC: Exit out of menus/submenus

Press to send the weighing result to a printer or a computer.

Zero: press to zero the balance.

Up arrow: move up the menu or submenu

Tare: press to tare the balance.

Right arrow: enter into menu or submenu or select parameter to modify

Triggers internal calibration (only available on PBH.C models)

On pressing

detailed overview of keys' functions go further down this user manual.

and

keys balance menu is displayed and keys' functions change. For

6

Page 10

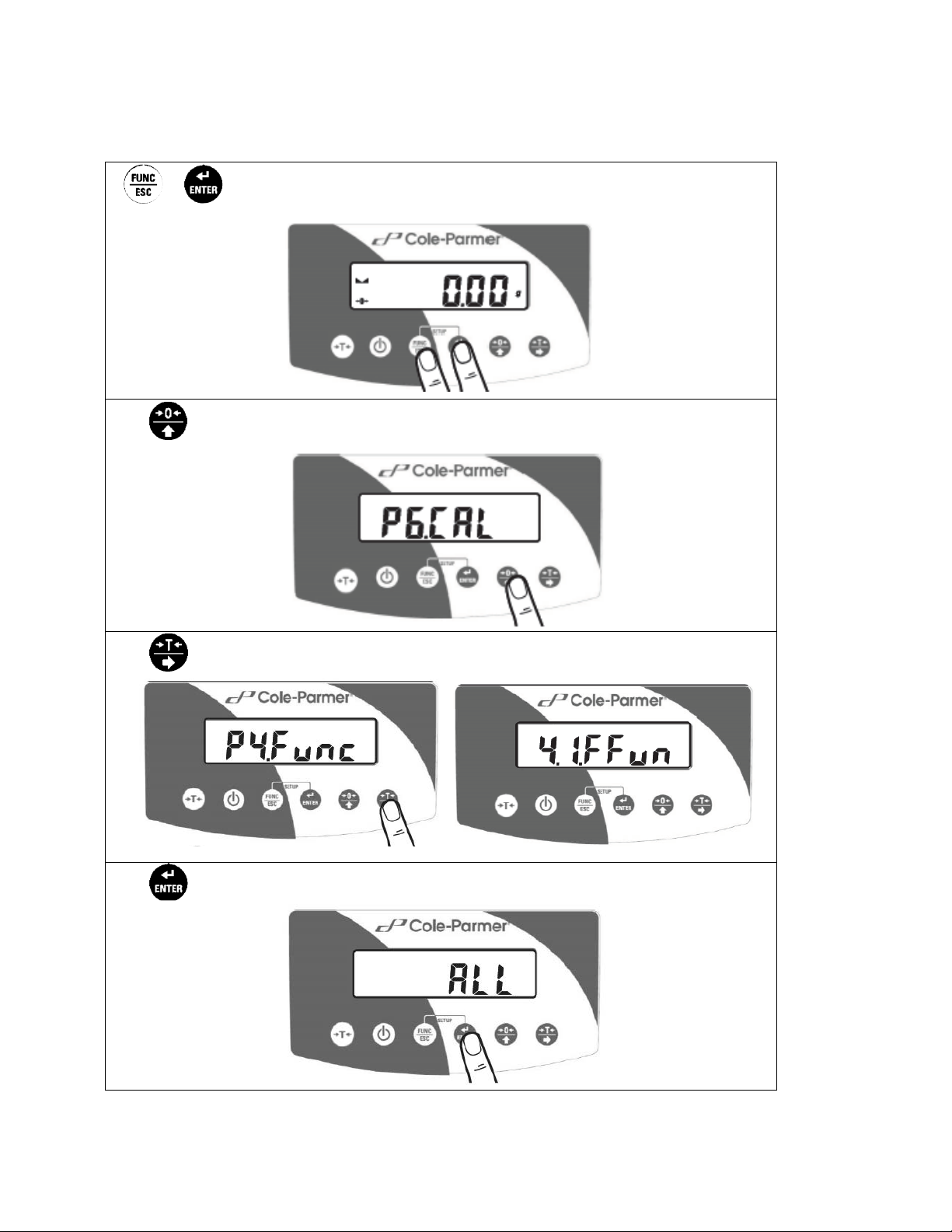

3.2. ENTERING BALANCE MENU

+

Use keypad to navigate in the balances menus and submenus.

Simultaneously press to enter 'Main Menu'

Press to move upwards within balance menus and submenus

Press to enter submenu

Press to confirm introduced modifications

7

Page 11

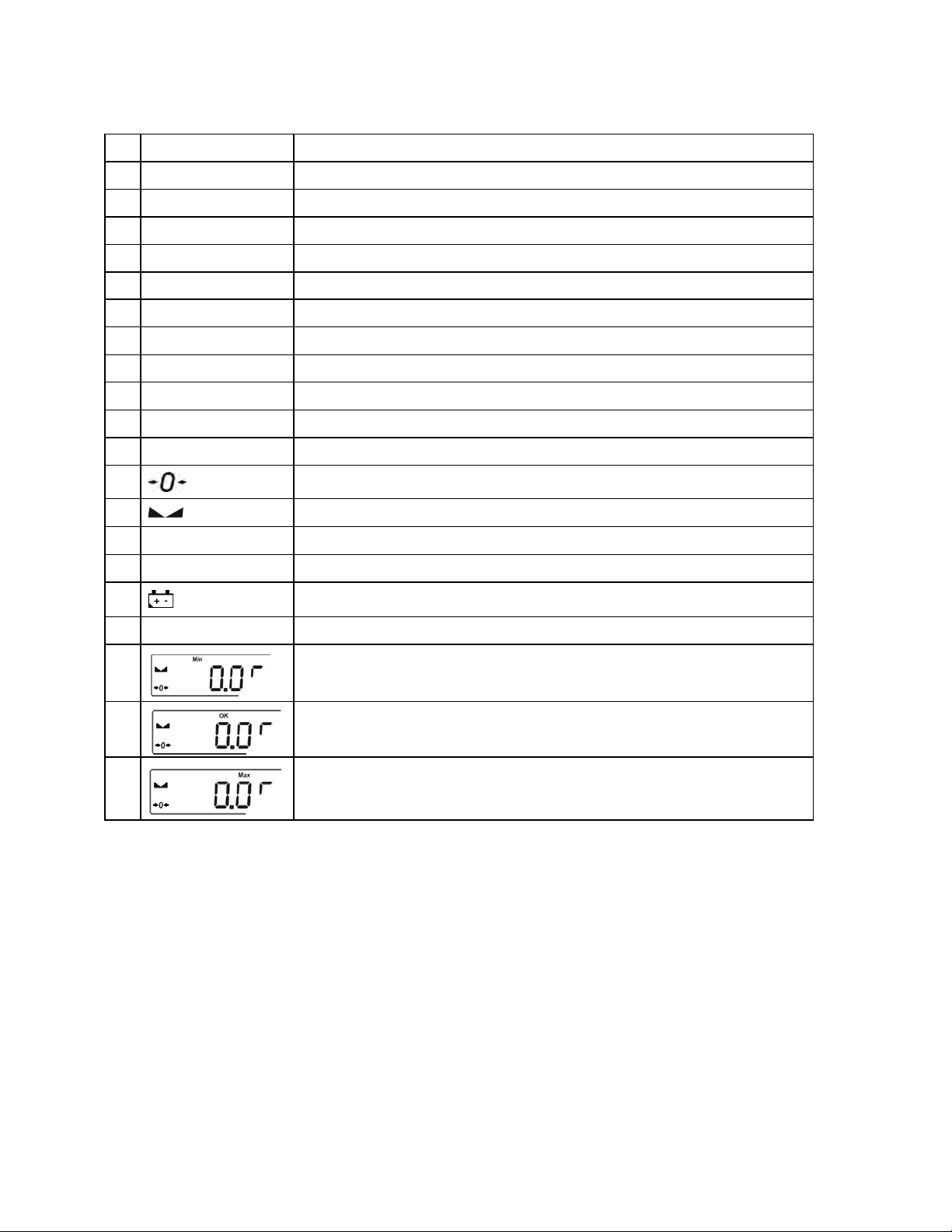

3.3. INSCRIPTIONS ON THE DISPLAY

No

Text string

Description

1

FIL

Filter level

2

bAud

Transmission baud rate

3

PCS

Piece counting

4

HiLo

+/- control according to a standard mass

5

rEPL

Automatic printout

6

StAb

The condition of printing data

7

Auto

Autozero correction

8

t1

Power save – time to switch off while no operation

9

toP

Latch of the max measurement

10

Add

Totalizing

11

AnLS

Weighing animals

13

Stable result (ready to read)

14

PCS

Operation mode - counting pieces

15

kg (g)

Operation mode - weighing

17

Net

Tare function has been used

ndication in autozero zone (indication = exact zero)

12

I

16

18

19

20

echargeable battery pack or battery discharged (BAT-LO)

R

+/- control with reference to the standard mass : setting the lower

threshold or mass below the first threshold.

+/- control with reference to the standard mass: load masa

between the thresholds

+/- control with reference to the standard mass: setting the upper

threshold or mass over the second threshold.

8

Page 12

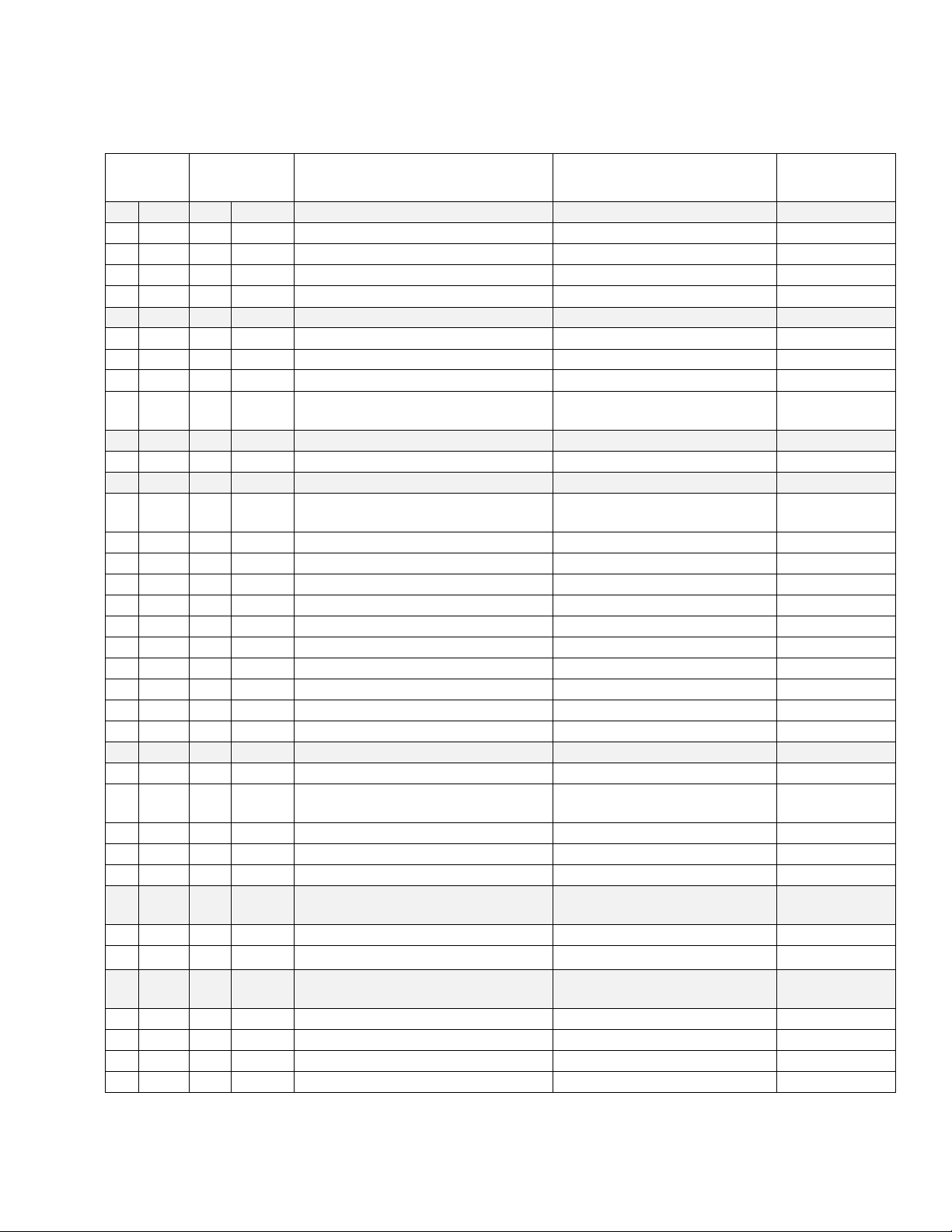

3.4. BALANCE MENU

P1.

rEAd

Balance parameters

1.1.

FIL

1, 2, 3, 4

Filter

Section 5.1

1.2.

Aut

YES, no

Autozero

Section 5.2

1.3.

tare

no, tArF, AtAr

Tare

Section 5.3

1.4

Fnnd

YES, no

Median Filter

Section 5.4

P2.

Prnt

Printouts

2.1.

Pr_n

noStab, StAb, rEPL, CntA, Cntb

Printout Type

Section 9.2

2.2.

S_Lo

Minimal Mass Threshold

Section 9.3

2.3.

bAud

2400, 4800,9600,19200,38400

Baud Rate

Section 9.4

8d1SnP, 8d2SnP, 8d1SEP, 8d1SoP

P3. Unit

Units

3.1.

StUn

g, ct, lb

Start unit

Section 4.2

P4.

Func

Working Modes

AtAr, toP, Add AnLS, tArE

4.2

Funi

YES, no

Weighing

Section 4

4.3

PcS

YES, no

Counting Pieces

Section 8.3

4.4

HiLo

YES, no

+/- Control

Section 8.4

4.5

PrcA

YES, no

% Weighing

Section 8.5.1

4.6

Prcb

YES, no

% Weighing

Section 8.5.2

4.7

AtAr

YES, no

Automatic Tare

Section 8.9

4.8

toP

YES, no

Peak Hold

Section 8.6

4.9

Add

YES, no

Totalizing

Section 8.7

4.A

AnLS

YES, no

Animal Weighing

Section 8.8

4.b

tArE

YES, no

Memory of 9 tare values

Section 8.10

P5.

Othr

Other Parameters

5.1

bL

Auto, no, YES

Backlight- mains

Section 11.1

100

5.3

bEEP

YES, no

“beep” sound

Section 11.2

5.4

t1

Auto, no, YES

Automatic switch off

Section 11.3

5.5

CHr6

YES, no

Accumulator charging option

Section 11.4

P6.

CAL

Calibration Models

6.1

St_u

Start Mass Adjustment

Section 7.2

uCal

P6.

Calibration Models

6.1

iCal

-

Internal Calibration

Section 6.1

6.2

uCal

User Calibration

Section 6.2

6.3

CA-C

Calibration Triggered by Timer

Section 6.1.2

6.4

CA-r

YES, no

Calibration Report

Section 6.3

Main menu is divided into function groups. Function group is a group of interrelated parameters.

Main

Menus

Submenus Options Overview Additional Info

2.4.

S_rS

4.1 FFun

5.2 bLbt

7d2SnP, 7d1SoP, 7d1SEP,

All, Funi, PcS, HiLo, Pr c A, Pr c b,

no, 20, 30, 40, 50, 60, 70, 80, 90,

Serial Transmission Parameter Section 9.5

Working Mode Availability Section 8.2

Backlight- battery pack Section 11.1

6.2

CAL Calibration for Internal

Calibration for External

User Calibration Section 7.1

9

Page 13

WEIGHING MODE

Load the weighing pan. You can read weighing result when , pictogram is displayed. To assure

long-term operation and correct mass measurements follow the rules presented below:

•

Load the weighing pan steadily avoiding shocks:

•

Place weighed loads centrally on the weighing pan (eccentricity errors are specified by PN-EN

45501 s

•

Do not load the pan with concentrated force:

tandard, points 3.5 and 3.6.2.):

•

Avoid side loading, in particular side shocks:

10

Page 14

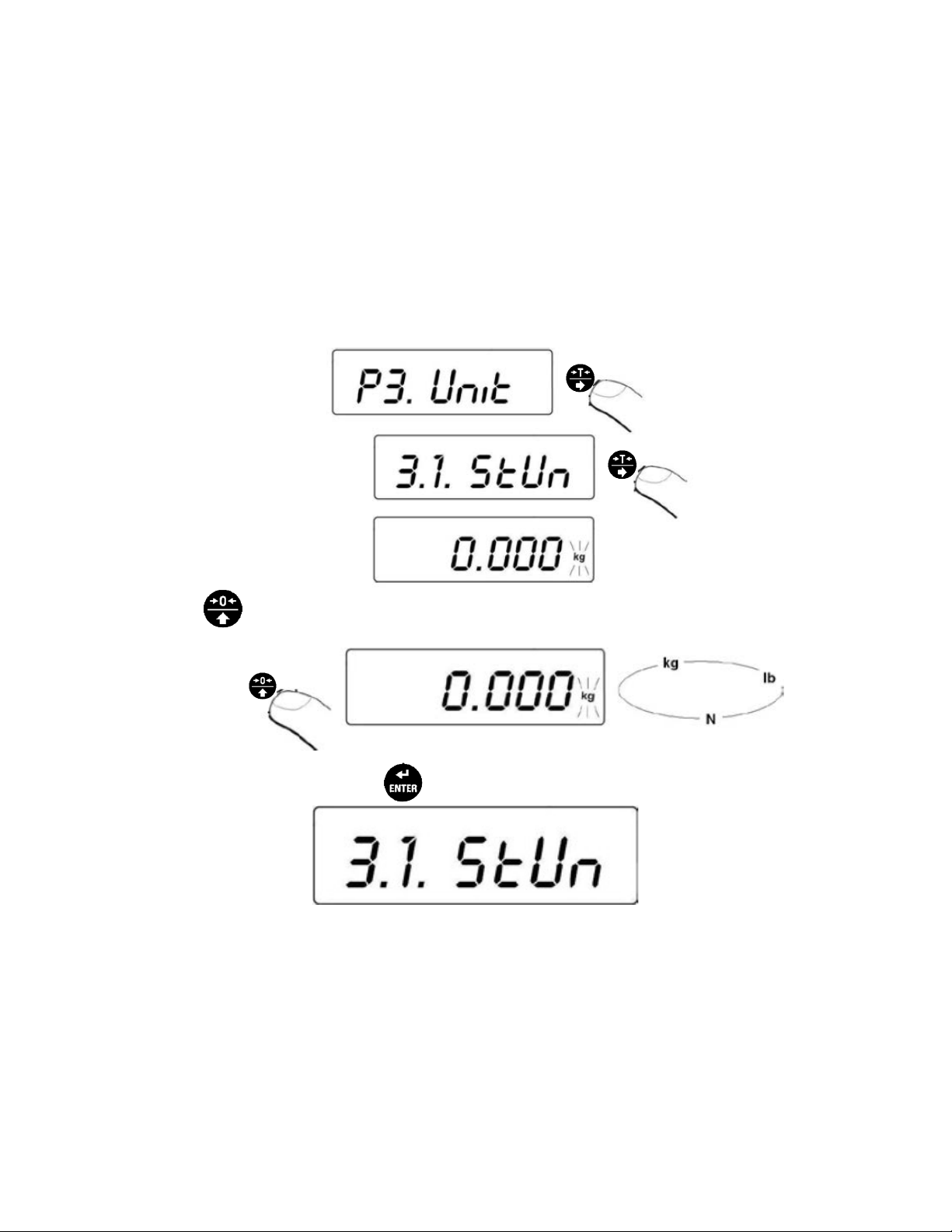

4.1. UNITS

<P3.Unit> parameters group enables selecting start and temporary unit. Selecting unit other than [g]

is possible during weighing or during other modes operation. 'Parts counting' and 'Percent weighing'

modes are exceptions for which the unit cannot be changed.

4.2. START UNIT

This function is used to set weight unit the scale will start with.

Pr

ocedure:

• To enter menu navigation, follow process found in Section 3.2. Enter the submenu <P3.Unit>

and then:

• Pre

• Afte

Not

After turning on the scale, it always starts with the start unit.

ss , until the expected unit appears on the display:

r you select the unit press the scale returns to:

ice:

11

Page 15

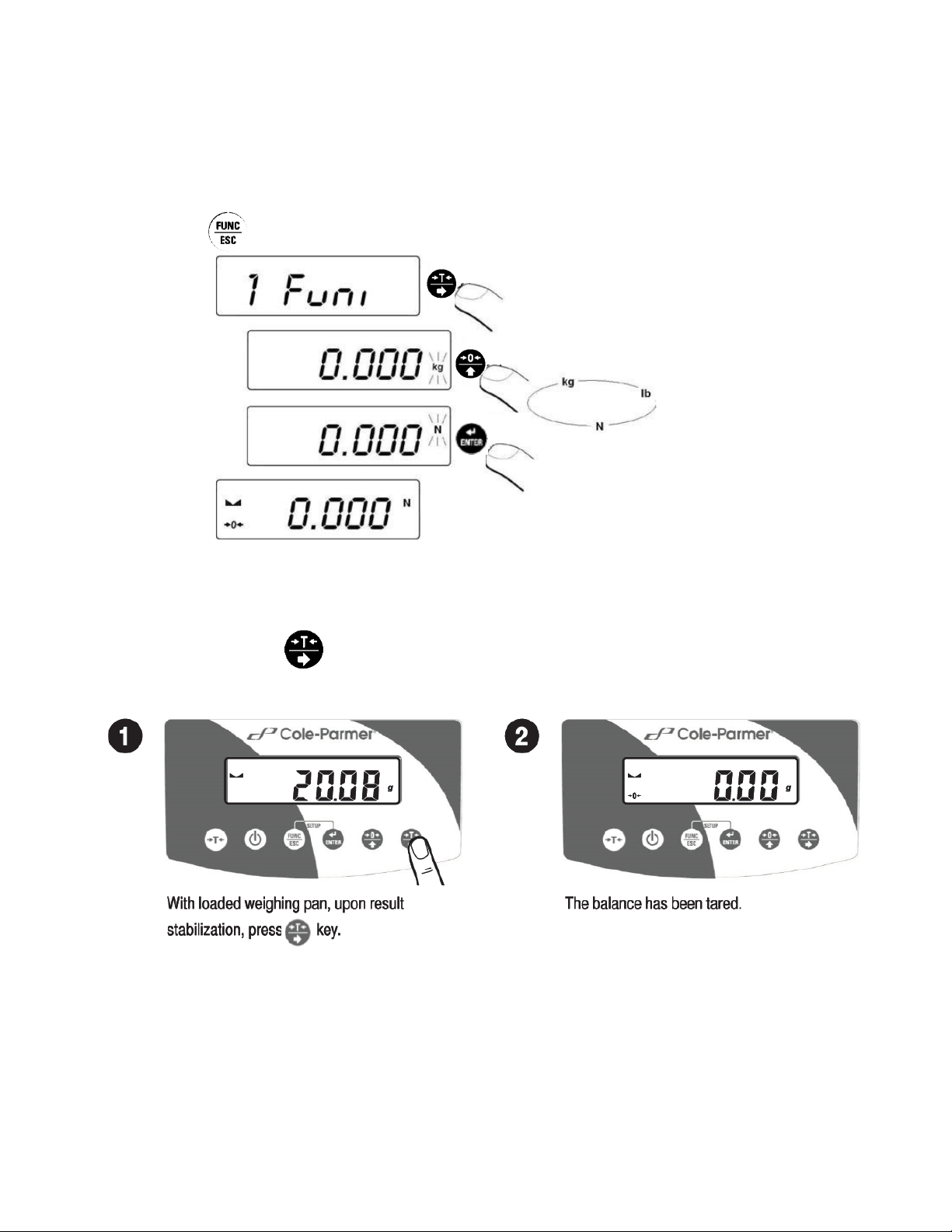

4.3. TEMPORARY UNIT

This function is used to set weight unit the scale will use temporarily until the next power off or

next selection.

rocedure:

P

•

Press

• After you select the unit you want come back to weighing procedure.

and then:

4.4. TARING

In order to determine the net mass put the packaging on the pan.

After stabilizing press - (Net pictogram will be displayed in the left upper corner and zero will be

indicated).

After placing a load on the weight pan net mass will be shown.

Taring is possible within the whole range of the scale. After unloading the pan the display shows the

tarred value with minus sign.

Notice:

Taring cannot be performer when a negative or zero value is being displayed. In such case

Err3 appears on the display and short audible signal will be emitted.

12

Page 16

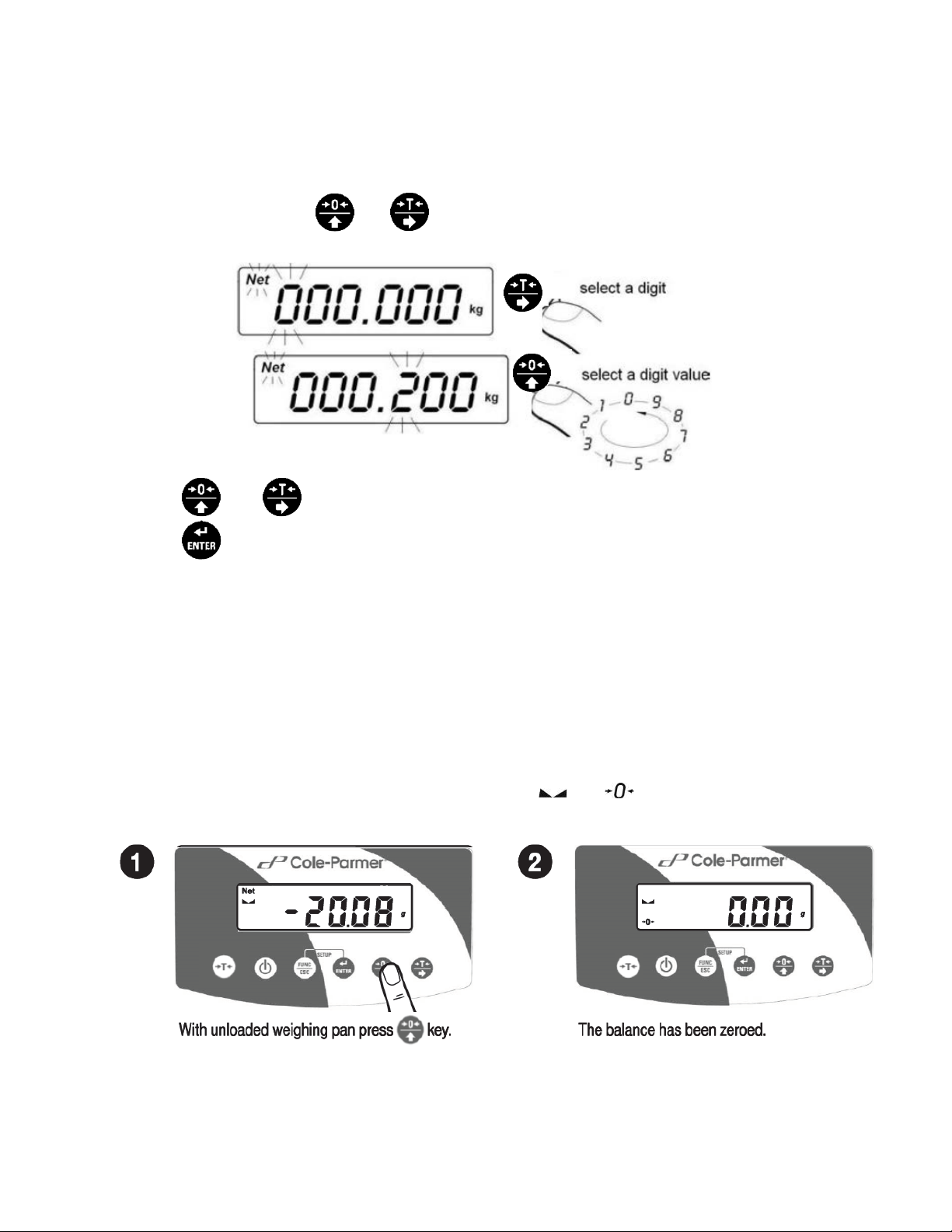

4.5. MANUAL TARE ENTERING

You can also inscribe a tare value.

Pr

ocedure:

•

Press simultaneously

•

You will see :

•

Using and set the tare value,

•

Press ,

•

Program returns to weighing’s mode. The inscribed tare value can be seen on the display with "–"

sign,

•

Tare can be inscribed anytime in weighing’s mode.

and

Not

ice:

1.

You cannot inscribe a new tare value when the tare value in memory is greater than zero. In the

case of trying this the <Err3> message will be displayed and short audible signal will be emitted.

2.

Users can also enter up to 9 tare values to the scale memory.

4.6. ZEROING

The scale will display zero and following pictograms: and .

ice:

Not

Zeroing is possible only within the ±2% interval of the maximal range. If zeroing is performed

beyond this range the <Err2> message and short audible signal will be emitted.

13

Page 17

4.7. UNDER-PAN WEIGHING

1. Unpack the scale,

2. Remove the hole plug.

4. Turn the scale bottom side down.

PBH scales offer under-pan weighing option wherein the load is weighed when hanged under the

device. This is especially useful when there is a need to weigh load of non-standard dimension,

shape or load that generates electromagnetic field.

P

reparing the scale for under-pan weighing:

assemble the unit and

turn the scale one si

dow

n.

de

x the hook.

3. Fi

14

Page 18

BALANCE PARAMETERS

You can adjust the balance to ambient conditions (filter level) or to your own needs (autozero, tare

value). The parameters are to be found in <P1.rEAd> submenu.

5.1. FILTER LEVEL

Procedur

•

•

e:

To enter menu navigation, follow process found in Section 3.2. Enter the submenu <P1.rEAd>

and then:

1 - 4 -

By pressing select the filtering level you need

level of filtering

Notice:

Filtering level influences the time of stabilization. The higher the filtering level, the longer stabilization

time is needed.

5.2. AUTOZERO

The autozero function has been implemented in order to assure precise indications. This function

controls and corrects "0" indication. While the function is active it compares the results continuously

with constant frequency. If two sequential results differ less than the declared value of autozero

range, so the scale will be automatically zeroed and the pictograms and will be displayed.

n AUTOZERO is disabled zero is not corrected automatically. However, in particular cases, this

Whe

function can disrupt the measurement process e.g. slow pouring of liquid or powder on the weighing

pan.

In t

his case, it is advisable to disable the autozero function.

15

Page 19

Procedure:

• To enter menu navigation, follow process found in Section 3.2. Enter the submenu

<P1.rEAd> and then:

Auto no - auto zero disabled

Auto YES - auto zero enabled

5.3. TARE FUNCTION

This parameter enables users to configure a tare function.

Procedur

•

e:

To enter menu navigation, follow process found in Section 3.2. Enter the submenu <P1.rEAd>

and then:

16

Page 20

tArA

AtAr

-

automatic tare function on and is stored in balance memory after unplugging it

from mains (Description of function operating point 16.6 automatic tare)

-

tArA

tArA

no

tArF

automatic tare function off (user can turn on operating of automatic tare F6

AtAr – till unplugging the balance from mains)

-

tare memory function – stores last value of tare in balance memory. It is

automatically displayed after starting the balance. Value of tare is displayed with

minus sign, and there is Net symbol indicated on the display. (user can turn on

operating of automatic tare F6 AtAr – till unplugging the balance from mains)

5.4. MEDIAN FILTER

This filter eliminates short changes (impulses) of measure signal (e.g. shocks).

Pr

ocedure:

• To enter menu navigation, follow process found in Section 3.2. Enter the submenu

<P1.rEAd> and then:

Fnnd no

Fnnd YES - filter enabled

- filter disabled

17

Page 21

ADJUSTMENT (PBH.C SERIES)

In precise scales changes of gravitational acceleration have noticeable influence. The gravitational

acceleration changes with altitude and latitude. Every scale has to be adjusted to the place of use

especially when the place changes. Frequent calibration also prevents weighing process from the

influence of humidity and temperature.

assuring the maximal accuracy of weighing a periodical user calibration is required.

For

C

alibration should be performed:

• Before weighing process,

• After a long break between series of measurements,

• After the ambient temperature change.

Conditions of triggering off calibration:

• Automatic internal calibration:

o Started after adjusted time period

o Started after powering up the device

• Manual internal calibration started from the keyboard,

• Calibration with an external weight.

6.1. INTERNAL ADJUSTMENT

The internal calibration process can be initiated manually or automatically. Press to initiate it

manually. Automatic calibration system performs internal calibration and informs a user on the

display about the course of the process.

6.1.1 MANUAL INTERNAL CALIBRATION

P

rocedure:

•

While in weighing mode press ,

•

The scale program starts to check stability conditions for the calibration process and displays

the following message:

•

Then the program automatically goes to the internal calibration procedure which is signaled

by the following message:

•

After completion of the calibration process program returns to the weighing mode,

18

Page 22

•

Calibration process can be terminated anytime by pressing which is signaled by the

following message on the display:

Notice:

1.

It should be remembered that internal calibration should be performed with unloaded pan with

k

eeping possibly constant ambient conditions.

2.

If the calibration process lasts longer than 15 seconds scale software will react with <Err8>

displayed and a short sound and then the calibration procedure will start again.

6.1.2 AUTOMATIC INTERNAL CALIBRATION

The automatic calibration process can be triggered off by 2 different factors:

C

alibration after powering up

−

After performing the start procedure, the scale program starts to check stability conditions for

the calibration process and displays the following message:

−

Then the program automatically goes to the internal calibration procedure which is signaled by

the following message:

−

After completion of the calibration process program returns to weighing mode.

C

alibration triggered off by timer

−

The time condition for subsequent automatic calibration is 3 hours. It means that, when no

other triggering factor appear, the calibration will appear every 3 hours;

−

The calibration procedure triggered off by the time change starts with checking which is

signaled by the following message:

−

Then the program automatically goes to the internal calibration procedure which is signaled by

the following message:

19

Page 23

Procedure:

−

To enter menu navigation, follow process found in Section 3.2. Enter the submenu

<P6.CAL> and then:

−

After completion of the calibration process program returns to weighing mode.

−

Calibration process can be terminated anytime by pressing which is signaled by the

following message on the display:

Notice:

1.

It should be remembered that internal calibration should be performed with unloaded pan

with keeping possibly constant ambient conditions.

2.

If the calibration process lasts longer than 15 seconds scale software will react with <Err8>

displayed and a short sound and then the calibration procedure will start again.

6.2. EXTERNAL CALIBRATION

External calibration is carried out by means of an external mass standard of specified accuracy class

and weight. Both, accuracy class and mass standard weight depend on balance type and max

capacity and the correct value is saved within the balances factory settings. The process takes semiautomatic form; successive stages are signaled with prompts.

20

Page 24

Procedure:

•

To enter menu navigation, follow process found in Section 3.2. Enter submenu <P6.CAL>

and then:

•

Following messages will be displayed:

•

During this time start mass is adjusted, and after completing the procedure calibration weight

mass is displayed (e.g. 3.000kg),

•

Place the required weight on the pan,

•

Calibration process starts automatically after placing the adequate weight that is signaled by

the following message:

•

The completion of the calibration procedure is signaled by the following message:

21

Page 25

•

Take off the weight from the pan, the message <donE> is displayed for 1s and the program

returns to the calibration submenu:

•

Calibration process can be terminated anytime by pressing which is signaled by the

following message on the display:

•

Return to weighing with saving changes that have been made.

Caution:

If the calibration process (span adjustment) lasts longer than 15 the <Err8> message will be

displayed and short audible signal will be emitted. Press to perform calibration again with more

stable ambient conditions!

6.3. CALIBRATION REPORT

Users, in parameter <P6.4.CA-r>, can enable a function of automatic printout of report form

calibration process on a connected printer.

Procedure:

• To enter menu navigation, follow process found in Section 3.2. Enter the submenu <P6.CAL>

and then:

22

Page 26

The

example printout of report from calibration:

ADJUSTMENT (PBH SERIES)

In precise scales changes of gravitational acceleration have noticeable influence. The gravitational

acceleration changes with altitude and latitude. Every scale has to be adjusted to the place of use

especially when the place changes. Frequent calibration also prevents weighing process from the

influence of humidity and temperature.

For as

Cal

Conditions of triggering calibration:

suring the maximal accuracy of weighing a periodical user calibration is required.

ibration should be performed:

• Before weighing process,

• After a long break between series of measurements,

• After the ambient temperature change.

• Calibration with an external weight.

7.1. EXTERNAL CALIBRATION

External calibration is carried out by means of an external mass standard of specified accuracy class

and weight. Both, accuracy class and mass standard weight depend on balance type and max

capacity and the correct value is saved within the balances factory settings. The process takes semiautomatic form; successive stages are signaled with prompts.

Procedure:

•

To enter menu navigation, follow process found in Section 3.2. Enter submenu <P6.CAL> and

then:

23

Page 27

•

Following messages will be displayed:

•

During this time start mass is adjusted, and after completing the procedure calibration weight

mass is displayed (e.g. 3.000kg),

•

Place the required weight on the pan,

•

Calibration process starts automatically after placing the adequate weight that is signaled by the

following message:

•

The completion of the calibration procedure is signaled by the following message:

•

Take off the weight from the pan, the message <donE> is displayed for 1s and the program

returns to the calibration submenu:

•

Calibration process can be terminated anytime by pressing which is signaled by the

following message on the display:

•

Return to weighing with saving changes that have been made.

24

Page 28

Caution:

If the calibration process (span adjustment) lasts longer than 15 the <Err8> message will be

displayed and short audible signal will be emitted. Press to perform calibration again with more

stable ambient conditions!

7.2. START MASS ADJUSTMENT

The scale can require only adjusting new start mass. In this scale adjusting start mass can be

excluded from the process of calibration and performed separately.

ocedure:

Pr

•

To enter menu navigation, follow process found in Section 3.2. Enter submenu <P6.CAL> and

then:

•

The following messages are displayed:

•

The new start mass is adjusted and returns to the submenu:

•

The process of start mass adjustment can be terminated by pressing , which is signaled on

the display:

•

Return to weighing with saving changes that have been made.

ion:

Caut

If the start mass adjustment lasts longer than 15 the <Err8> message will be displayed and short

audible signal will be emitted. Press to perform calibration again with more stable ambient

conditions!

25

Page 29

WORKING MODES

The balance features the following working modes:

•

Weighing

•

Parts counting

•

+/- control

•

Percent weighing

•

Peak hold

•

Totalizing

•

Animal Weighing

8.1. RUNNING WORKING MODE

• I n home screen press key. Name of first available working mode is displayed.

• Press key to view available working modes.

• Press key to e nter a working mode.

Caution:

The balance is restarted with the last working mode activated.

8.2. ACCESSIBILITY OF WORKING MODES

In this parameter group users can disable/enable accessibility of functions after pressing key.

Procedure:

26

Page 30

8.3. COUNTING PIECES

Parts of the same mass are counted based on determined and reference mass of a single part.

S

tandard solution is equipped with option of counting small pieces of the same mass. It is possible to

execute a tare function in this operating mode in order to tare a container value.

tice:

No

•

Counting pieces does not work together with other scale functions,

•

The counting pieces function is not saved as a default start function so it is not remembered after

restarting.

27

Page 31

Procedure:

• Enter to <PcS> function:

• You will see a blinking value of sample quantity.

• Press key to start setting quantity of sample, you have a few options to choose from:

• If option <LASt> is chosen in the scale program displays estimated unit mass of t he last

piece (about 3 seconds) and then goes to Counting pieces automatically setting the

previously displayed value as valid for the procedure.

• If the <FrEE> option is selected you will see:

• Using

• Confirm the value by pressing ,

and

- selection of digit position

- setting the digit

enter the required sample quantity, where:

28

Page 32

• You will see <LoAd> on the display and then:

• If weighing is performed in a container put the container on the pan first and then tare it. Then

put the declared quantity of pieces on the pan and confirm it when stable (signaled by ):

• The program will automatically calculate the mass of a single piece and go on to the Piece

Counting mode (pcs). You will see the following display:

Notice:

1.

If a user presses the key when load is not present on the pan, the message -Lo- will be

indicated for a few seconds and the scale will automatically return to weighing.

2.

In order to comply with the rules of appropriate counting pieces put as many pieces as possible

during unit mass adjustment. Single piece mass should not be less than 5 divisions.

3.

If a single piece mass is lower than a reading interval d the display will show the <Err5> message

and short audible signal will be emitted than the scale returns to weighing.

8.4. +/- CONTROL

+/- control working mode enables entering checkweighing thresholds values (Min, Max).

8.4.1 DECLARING CHECKWEIGHING THRESHOLDS

Procedur

• Enter to <HiLo> function:

e:

29

Page 33

• The program enters the window of setting the lower threshold of weighing (Min):

• The inscribed value confirm by pressing , the program will automatically go to the higher

threshold of weighing (Max):

• The inscribed value confirm by pressing , the program will automatically go to the m ain

window.

• During setting threshold values following cases take place:

Notice:

If a user erroneously enters a value of the lower threshold higher than the upper one, the scale will

indicate an error message and will return to weighing.

8.5. PERCENT WEIGHING

Scale software enables control of deviation (in %) of weighed loads mass referring to the

inscribed standard mass. Mass of standard can be determined by its weighing (PrcA function) or

entered to the scale memory by an user (PrcB function).

30

Page 34

8.5.1 REFERENCE MASS DETERMINED BY WEIGHING

•

Enter to <PrcA> function:

•

You will see <LoAd> on the display and then:

•

Place an load on the pan which mass will be accepted as standard

•

Press to confirm this operating mode

•

After few seconds the indication 100.00% will be displayed

•

From this moment display will not indicate mass of weighed load but deviation of load mass

placed on the pan referring to the mass of standard (in %).

8.5.2 REFERENCE MASS DETERMINED BY ENTERI NG

•

Enter to <PrcB> function:

•

The program goes to the weight display window:

31

Page 35

•

Using

and

set standard mass, where:

- digit selection

- digit setting

•

Confirm the entered value by pressing ,

•

You will see the indication equal to 0,000%,

•

From this moment display will not indicate the mass of weighed load but deviation of the load

ass placed on the pan referring mass of standard (in %).

m

8.6. PEAK HOLD

<toP> function enables snapping value of maximum force applied to the weighing pan during one

loading.

rocedure:

P

•

Enter to <toP> function:

•

Confirmation of choice of <toP> function is indication of the Max pictogram:

•

Apply a force to the weighing pan,

•

The display of scale will latch the maximum value of the force,

•

Remove loads from the pan,

•

Before the next measurement press the key.

32

Page 36

8.7. TOTALIZING

Working mode enables mass totalizing of weighed ingredients and printing totalizing report on a

printer connected to the balance.

ocedure:

Pr

• Enter to <Add> function:

• A letter “P” in the left side of the display is a confirmation that <Add> function have been

selected:

• Put the first load on the pan. If the weighing procedure is performe d in a container put the

container on the pan first and tare it. Then put the first load on the pan and confirm it by

pressing when stable (signaled by ),

• You will see a sum of weighings on the display, the „▲” pictogram in the upper right corner

will be displayed and the weighing result will be printed on the printer connected to the

indicator.

• Take off the load from the pan, indication returns to ZERO and the letter “P” in the left part of

the display appears,

• Put the next load on the pan,

• After stabilizing press , the sum of first and second weighing will appear on the display,

the “▲” pictogram in the upper right corner will be displayed and the second weighing result

will be printed on the printer connected to the indicator:

33

Page 37

• Press to complete the procedure (with the loaded or unloaded pan), a sum of all

weighings will be printed:

(1) 1.912 kg

(2) 1.912 kg

------------------------ TOTAL: 3.824 kg

• In case of pressing one more time with loaded pan, you will see the <unLoAd>

message. Unload the pan, the scale will return to ZERO and the letter “P” in the left part of

the display will appear. The scale is ready for the next procedure.

• In case of pressing one more time with loaded pan, you will see the letter “P” in the left

part of the display will appear. The scale is ready for the next procedure.

8.7.1 MEMORY OF LAST VALUE

After interrupting (e.g. switching off) the totalizing procedure, it is possible to restart the

procedure without losing data.

Procedure:

• Enter <Add> function

• You will see the last memorized sum of weighings on the display

n order to continue the procedure press , the indication

• I

“P” appears in the left part of the display. The scale is ready for weighing,

• In order to terminate the previous totalizing procedure press

will see the letter “P” in the left part of the display. The scale is ready for weighing.

returns to ZERO and the letter

key,

8.7.2 RETURN TO WEIGHING

P

rocedure:

• Pre

• B

ss k

efore leaving the <Add> function it is possible to print out subsequent weighings and t

ey, you will see:

, or . You

he

um of weighings on the connected printer (press to print, press to cancel).

s

34

Page 38

• The following message will appear on the display:

• Pr

ess key to return to weighing,

• Press to return to totalizing.

No

tice:

In case of overflow of the range of the display in totalizing you will see

<5-FULL> message in the display. In that case unload the pan and press to complete the

procedure with a printout of sum of all weighings or put a lower mass on the pan which does not

cause the overflow error.

8.8. ANIMAL WEIGHING

Animal weighing is a working mode allowing reliable determination of mass of weighed objects in

motion.

rocedure:

P

• Enter to <AnLS> function:

• The <tinnE> message appears on the display for 1s, and then the program goes to the

window of setting the duration time (in seconds) of the animal weighing process:

35

Page 39

• Confirm the selected value by pressing ,

• You will see the following window

• Load an anim

al to the platform,

• After exceeding the -LO- value, program starts the weighings process. The appearance of

subsequent hyphens < - - - - - - - > showing the progress,

• After completing the process of weighings the result is latched on the display and additionally

the OK pictogram is shown in the upper part of the display:

• You c

an start the procedure of weighing animals again by pressing ,

• After removing the animal from the platform program returns to the window:

8.9 AUTOMAT IC TARE

This function is useful for fast net mass determina tion o f w ei ghed load in case when tare val ue of

is different for each load. In case when the function is active the cycle of scales operating looks

as follows:

Pr

ocedure:

• Enter to <AtAr> function:

•

Proceed pressing zeroing key when the pan is empty,

•

Place the container for pieces,

36

Page 40

•

When indication is stable automatic taring of the container mass will be performed (Net

marker will appear in the upper part of the display),

•

Place a sample into the package,

•

Display will indicate net mass of sample,

•

Remove the sample together with the container,

•

Display will indicate tare mass with minus sign,

•

Place a container for the next sample. When indication is stable automatic tarring will take

ace (Net marker will appear in the upper part of the display),

pl

•

Place next sample into the package.

8.10 TARE MEMORY

Users are allowed to enter up to 9 tare values to the memory.

P

rocedure:

• Enter to <tArE> function:

• The program goes to displaying the first value from the selection of tare values <tArE 0>

(press to chose different values):

• After selecting the right position press and you will see an editing field:

• Enter the selected tare value to the scale memory ,

• The program returns to the following window:

37

Page 41

8.10.1 SELECT TARE VALUE FROM THE MEMORY

Pr

ocedure:

• Enter <tArE> function

• The program goes to displaying the first value from the selection of tare values <tArE 0>

(press to chose different values):

• To use an entered tare value press , you will see the tare value on the display preceded

by the “-“ sign and the Net pictogram:

Caution:

A tare value from the memory is not remembered after powering off and on the scale.

RS232 INTERFACE

External devices connected to RS 232C have to be supplied from the same mains and common electric

shock protection. It prevents from appearing a potential difference between zero leads of the two

devices. This notice does not apply to the devices that do not use zero leads.

9.1. RS232 SETTINGS

Transmission parameters:

•

Baud rate - 2400 – 38400 bit / s

•

Data bits - 7,8

•

Stop bits - 1,2

•

Parity control - no, even, odd

There are four ways of sending data via RS232 interface:

•

Manually – after pressing

•

Automatically – after stabilizing the indication over -LO- threshold

•

Continuously – after it is activated in parameter or by a command sent via RS232

•

On external request

The indication can be sent as:

•

stable – the indication is sent after the scale stabilizes.

•

any – the indication is sent immediately after pressing the key, this state is assign with

<?> in the printout.

38

Page 42

9.2. PRINTOUTS

immediate printout

(not accessible in verified scales)

Pr_n

rEPL

Pr_n

CntA

<P2.Prnt> m enu enables sending of results to a printer or computer.

Procedure:

• To enter menu navigation, follow process found in Section 3.2. Enter the submenu

<P2.Prnt> and then:

Pr_n noStAb

Pr_n StAb

Pr_n Cntb

-

-

sending stable results

-

automatic operation

-

continuous transmission in basic unit

-

continuous transmission in present unit

9.3 M INIM AL MAS S THRESHOLD

This function is necessary while working with automatic tare or automatic operation or weighing

animals.

Automatic tarring will not be applied until the indication (gross) is lower than the value

inscribed in S_Lo parameter.

In automatic operation measurements (net) are sent via RS232 when the indication is equal or

greater than the value inscribed

in S_Lo parameter.

Weighings animals is performed when the indication is equal or greater than the value

inscribed in S_Lo parameter.

39

Page 43

Procedure:

• To enter menu navigation, follow process found in Section 3.2. Enter the submenu

<P2.Prnt> and then:

9.4 BAUD RATE

Allows for setting the baud rate for printing of data.

Procedure:

• To enter menu navigation, follow process found in Section 3.2. Enter the submenu

<P2.Prnt> and then:

40

Page 44

9.5 SERIAL TRANSMISSION PA RA MTER

Allows for setting the tran smission parameter for printing of data.

Procedur

• Enter the submenu <P2.Prnt> and then:

e:

7d2SnP - 7 data bits; 2 stop bits, no parity control

7d1SEP - 7 data bits; 1 stop bit, EVEN parity control

7d1SoP - 7 data bits; 1 stop bit, ODD parity control

8d1SnP - 8 data bits; 1 stop bit, no parity control

8d2SnP - 8 data bits; 2 stop bits, no parity control

8d1SEP - 8 data bits; 1 stop bit, EVEN parity control

8d1SoP - 8 data bits; 1 stop bit, ODD parity control

PERIPHERALS

10.1. COMPUTER

Each time the key is pressed a current mass value together with mass units is sent to

RS 232 interface.

Depending

Depending on setting of REPL parameter, printout will be automatic or manual.

on setting of STAB parameter it can be printed out with temporary or stable value.

41

Page 45

10.2 PRINTER

- manually

after pressing key,

- automatically

bL no

-

backlight switched off

bL YES

- backlight switched on

bL Auto

- backlight switched off automatically if indication becomes stable for about 10s

Sending weighing results to the computer can be done:

-

- in continuous way

- on the request from the computer

-

after function activating or sending an appropriate command,

-

After stabilizing the indication

-

After sending a control command

BALANCE SETTINGS

The user can set parameters which influence the scale operation. They are gathered in the

submenu <P5.othr> e.g. backlight and beep signal.

11.1. BACKLIGHT

Program recognizes the way the scale is supplied (mains, battery) and automatically selects

the way of operating on the backlight:

bl – for mains,

blbt – for batteries or rechargeable battery pack.

BACKLIGHT FOR SUPPLYING FROM MAINS

P

rocedure:

• To enter menu navigation, follow process found in Section 3.2. Enter the submenu

<

P5.othr> and then:

42

Page 46

Notice:

When bl=Auto, and the indication has not changed for 10s, the backlight is automatically

switched off. The backlight is switched on again automatically after the result changes.

BACKLIGHT FOR SUPPLYING FROM BATTERIES

The user can change the intensity of backlight from 0% to 100%. The lower the intensity is the

longer the scale operates without recharging or exchanging batteries. When the intensity is

set this function works as AUTO (described above).

P

rocedure:

• To enter menu navigation, follow process found in Section 3.2. Enter the submenu

<

P5.othr> and then:

11.2. 'BEEP' SOUND

The parameter enables switching on/off a ‘beep’ sound responsible for informing a user about

pressing any key.

rocedure:

P

• To enter menu navigation, follow process found in Section 3.2. Menu <P5.othr> and then:

bEEP no - switched off

bEEP YES - switched on

43

Page 47

11.3. AUTOMATIC SHUTDOWN

Operation

Mains

Batteries / accumulator

Parameter enables automatic shutdown of the balance.

T

his function is essential to save the battery power. The scale is switched off automatically when

(function t1 = YES) no weighing appears in 5 minutes. (no changes on the display). In case when

this function disrupts the operation (e.g. long time weighing procedures) or while working with

connection to mains, switch off this function.

Operation according to the power supply:

Setting

t1 = 0 disabled disabled

t1 = YES enabled enabled

t1 = Auto * disabled enabled

*automatic enabling/disabling according to the source of power.

Procedure:

• To enter menu navigation, follow process found in Section 3.2. Enter the subm

<

P5.othr> and then:

enu

44

Page 48

11.4. ACCUMULATOR CHARGING OPTION

This function allows to switch on charging algorithm for gel cell SLA accumulator:

a)

Parameter <CHr6> set to <no>:

•

Pictogram

•

During software initializing, after turning on <bAtt>.

b)

Parameter <CHr6> set to <YES>:

•

Pictogram

•

Message <nImh> appears on the display <SLA>,

•

In case of damaging accumulators or lack of it the

quickly (period about 0.5 sec).

Procedure:

•

To enter menu navigation, follow process found in Section 3.2. Enter the submenu <P5.othr>

and then:

does not appear, charging disabled,

blinks slowly (period about 2 seconds), charging is enabled,

pictogram

blinks

CHr6 YES - enabled

CHr6 no - disabled

ACCESSORIES

Available Accessories:

• 10100-83 PO108 Cable- RS232 Cable to USB

• 10100-84 PO151 Cable- RS232 Cable to Epson Printer

• 10100-85 EPSON TM-U220D Printer

• 10100-86 Printer Paper

45

Page 49

APPENDIX

Scale type:

PBH-1002

PBH-2002

PBH-6001(.N)

PBH-10001

PBH-20001

Max capacity

1kg

2kg

6kg

10kg

20kg

Reading division [d]

0.01g

0.01g

0.1g

0.1g

0.1g

Range of tare

-1kg

-2kg

-6kg

-10kg

-20kg

Repeatability

0.03g

0.03g

0.1g

0.3g

0.3g

Linearity

±0.03g

±0.03g

±0.1g

±0.3g

±0.3g

Pan size

195×195mm

Stabilization time

3 sec

Operation temperature

+15°C to +30°C

Atmospheric humidity

10÷85% RH no condensation

Ingress protection rating

IP43

Power supply

11V AC, 10,5÷15V DC, Imax=600mA and battery

Display

LCD (with backlight)

Supplied from batteries

45h (average time)

Net / Gross weight

2.8/4.3kg

Package dimensions

470x380x336mm

PBH-1002.C(N)

PBH-2002.C(N)

PBH-6001.C(N)

Max capacity

1kg

2kg

6kg

Reading division [d]

0.01g

0.01g

0.1g

Range of tare

-1kg

-2kg

-6kg

Repeatability

0.03g

0.03g

0.2g

Linearity

±0.03g

±0.03g

±0.2g

Pan size

195x195mm

Stabilization time

3 sec

Operation temperature

+15°C to +30°C

Atmospheric humidity

10÷85% RH no condensation

Ingress protection rating

IP43

Power supply

11V AC, 10,5÷15V DC, Imax=600mA and battery

Adjustment/Calibration

internal (automatic)

Display

LCD (with backlight)

Supplied from batteries

45h (average time)

Net / Gross weight

3.6/5.6kg

Package dimensions

470x380x336mm

13.1. BALANCE SPECIFICATIONS

Scale type:

46

Page 50

13.2. MAINTENANCE

Disassembly of weighing pan and other detachable components (the components differ depending

on a balance type – see: UNPACKING AND INSTALLATION sectio n ).

aution:

C

Cleaning anti-draft chamber while still installed may cause damage to the measuring system.

13.2.1 CLEANING ABS COMPONETS

To clean dry surfaces and avoid smudging, use clean non-coloring cloths made of cellulose or

cotton. You can use a solution of water and detergent (soap, dishwashing detergent, glass

cleaner). Gently rub the cleaned surface and let it dry. Repeat cleaning process if needed.

In the case when contamination is hard to remove, e.g. adhesive, rubbe r, resin, polyurethane foam

residues etc., you can use a special cleaning agents based on a mixture of al iphatic hydrocarbons

that do not dissolve plastics. Before using the cleanser for all surfaces, we recommend carrying

out tests. Do not use products containing abrasive substances.

13.2.2 CLEANING STAINLESS STEEL COMPONETS

Avoid using cleansers containing any corrosive chemicals, e.g. bleach (containing chlorine). Do

not use products containing abrasive substances. Always remove the dirt using microfiber cloth to

avoid damage of protective coating.

In case of a daily maintenance:

1.

Remove the dirt using cloth dipped in warm water.

2.

For best results, add a little dishwashing detergent.

13.3. DIMENSIONS

47

Page 51

13.4. TROUBLESHOOTING

Problem

Cause

Solution

Err2

- Value beyond the zero range

Err3

-

Value beyond the tare range

weight, ±10 for start mass)

Err5

-

Mass of a single piece lower than the scale division

adjustment

NULL

- Zero value from the AD converter

FULL2

- Measurement range overflow

acceptable range (-5% to +15% of start mass)

5-FULL

- Display range overflow in totalizing

Discharged batteries.

T

urning on does not

work

The scale turns off

automatically

After turning on “LH”

message on the display

No batteries (not installed or

improperly installed)

“t1” set to “YES” (P o wer

save)

Loaded weight pan during

powering up

13.5. ERROR MESSAGES

Calibration mass or start mass beyond the acceptable range (±1% for

Err4

Err8

Err9

-

Exceeded the time for tarring, zeroing, start mass adjustment or span

-

-

Time for internal weight lifting/dropping down exceeded (PBH.C series)

Connect to mains or change

batteries

Check the correctness of installation

(polarization)

In “othr” submenu change

“5.4 t1” to “no”

Unload the pan. Then the scale will

indicator zero.

Start mass error, the mass on the weighing platform is beyond the

LH

Notice:

1.

Errors: Err2, Err3, Err4, Err5, Err8, Err9, null, that appear on the display are also signaled by a

short beep sound (about 1 sec.);

2.

Error FULL2 that appears on the display is also signaled by a continuous sound until the cause of

error disappears.

-

13.6. WARRANTY CARD

Below you will find an additional Warranty Card for the balance.

48

Page 52

Five-Year Limited Warranty

Cole-Parmer will exchange, replace or repair the existing balance for any damage that

appears to be faulty by production or by construction within the 5-year warranty period.

Warranty is voided if:

A. Cole Parmer will exchange, replace or repair the existing balance for any damage that

ap

pears to be faulty by production or by construction within the 5-year warranty period.

B. Warranty is voided if:

• mechanical defects caused by inappropriate use:

• defects of thermal and chemical origin,

• defects caused by lightning, overvoltage in the power networ

• defects caused by water damage

• or other random event

• overloading the mechanical measuring system

• installing another version of the operating system

• utilizing the balance contrary to its intended use

• repairs carried out by non-authorized service centers

• removing or destroying protective stickers which secure the balance’s housing against

authorized access

un

C. Warranty card must be filled out for warranty to be valid.

k

Cut Here_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Warranty Registration Card

(Please Return Within 30 Days)

Company or Institution Department

Contact Name Title

Street Address

City State Zip

Telephone Date Purchased

Purchased From

Model Number Serial Number

Industry Application_

What influenced you to purchase this product?

49

Page 53

Model Number

Serial Number

Purchase Date

For your reference and records:

Cole-Parmer

Warranty Registration

625 East Bunker Ct

Vernon Hills, IL 60061

Place Stamp Here

50

Page 54

It is

recommended that Cole-Parmer products are calibrated annually to ensure proper

function and accurate measurements; however, your quality system or regulatory body

may require more frequent calibrations. To schedule your recalibration, please contact

InnoCal, an ISO 17025 calibration laboratory accredited by A2LA.

Phone: 1-866-INNOCAL (1-866-466-6225)

Fax: 1-847-327-2993

E-mail: sales@innocalsolutions.com

Web: InnoCalSolutions.com

For Product and Ordering Inf orm a ti on, Contact:

7ROO)UHH1-800-323-4340

3KRQH1-847-549-7600

)D[ 1-847-247-2929

51

Loading...

Loading...