Page 1

Start up Guide

MB-T

Moisture analyzers

Page 2

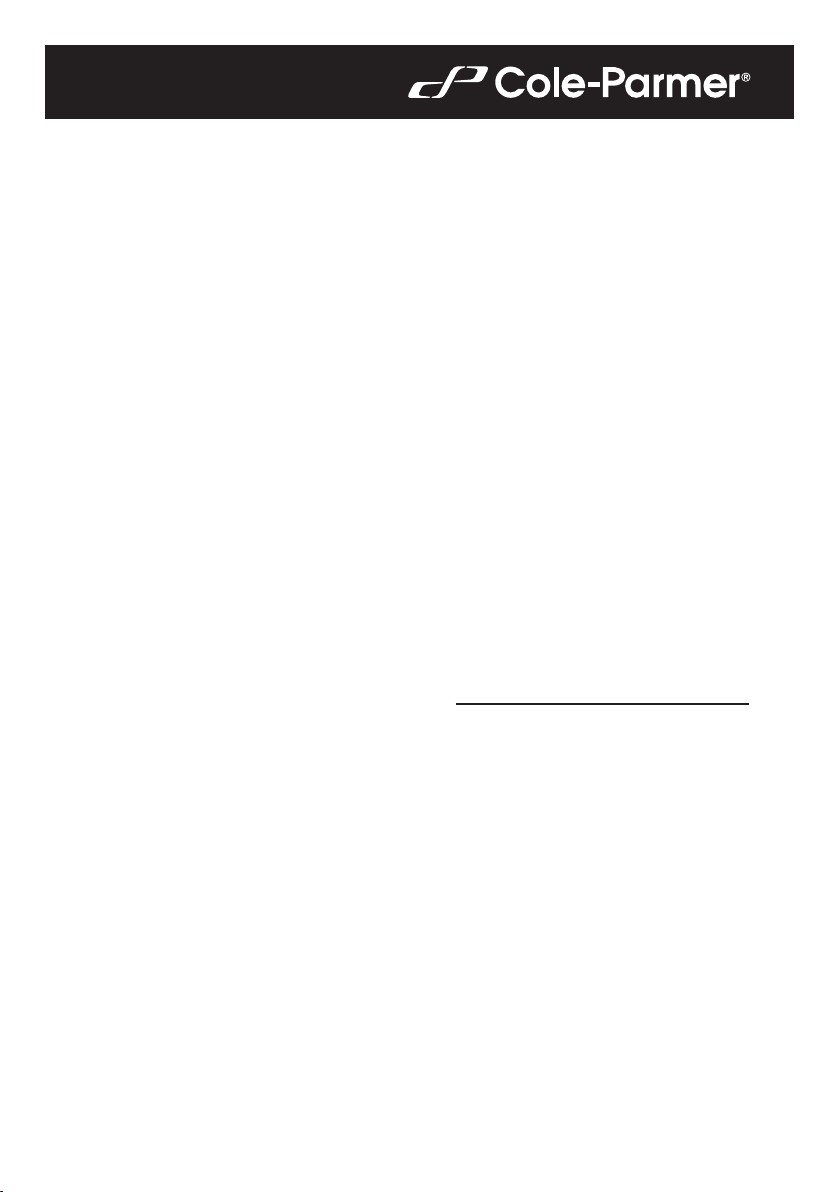

1. CONTENT

To view a complete user manual

scan QR code.

Moisture Analyzer

x 1

Disposable pan

x 10

Cross-shaped

holder

x 1

Drying pan

handle

x 1

2. UNPACKING

TOP

1 2 3

Keep the packaging should a warranty

claim or service be required.

Drying pan

shield

x 1

Power cord

x 1

Page 3

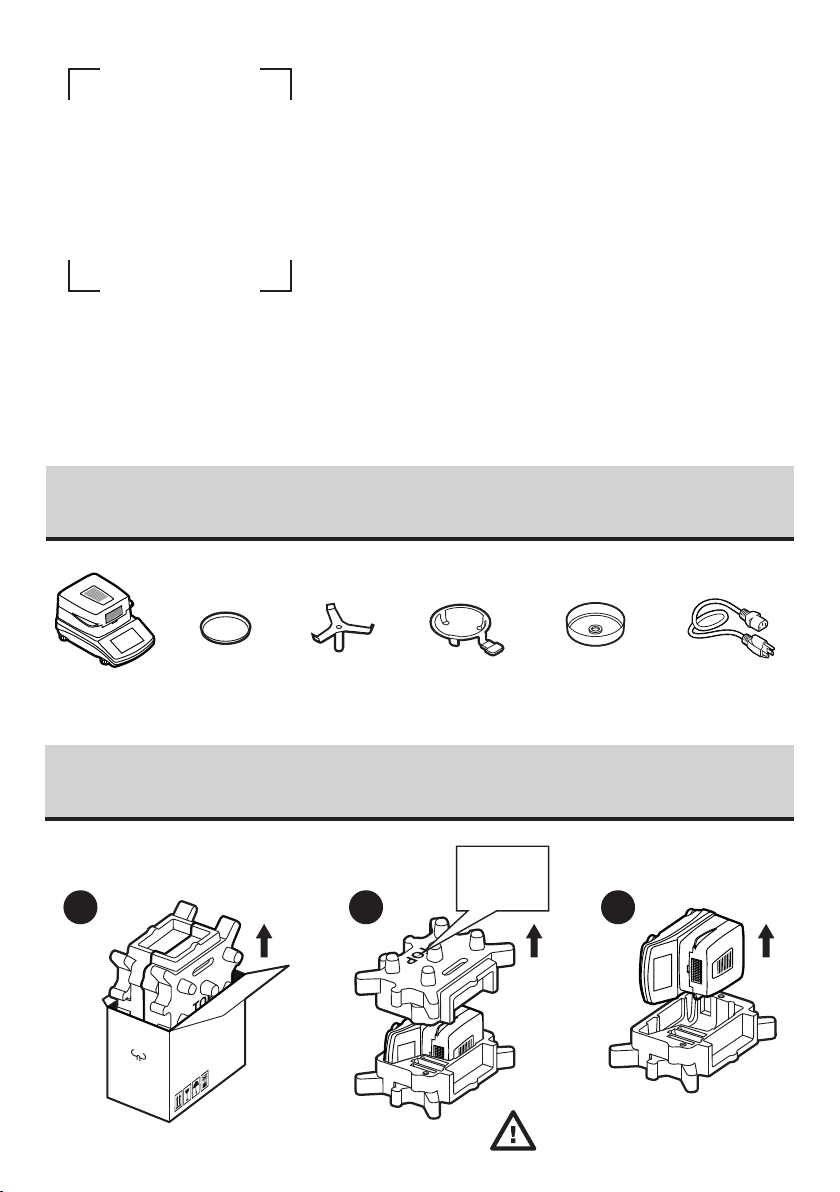

3. WORKROOM AND BASIC OPERATION GUIDELINES

Operate the device in a room where the temperature ranges between 10–40 °C

o

(50–104 °F) and where the relative humidity is below 80%.

C

o

F

Place the balance on a solid surface to ensure stability. To obtain stable and

repeatable weighing results, an anti-vibration table is recommended.

o

F

h

+40

+104

+10oC

+50

h ≥ 100 cm (39”)

w ≥ 20 cm (8”)

ww

Keep space free around the device:

h = min. 100 cm (39 in.),

w = min. 20 cm (8 in.).

Avoid air drafts and air movements

at the workstation.

Not intended for usage within EX

zones. Not intended for weighing

explosive or flammable substances.

Place the balance away from heat

sources. Avoid exposing the balance

to the sunlight.

Make sure that the balance is placed

on an even surface.

Not to be opened in the course of

operation since the heating components reach very high temperature.

Avoid exposing the balance to a

magnetic field. Do not weigh magnetic

substances.

Do not place the balance on an unstable

surface exposed to shocks and

vibrations.

Be extremely careful while taking the

sample out. The sample and the

moisture analyzer elements may be hot.

Page 4

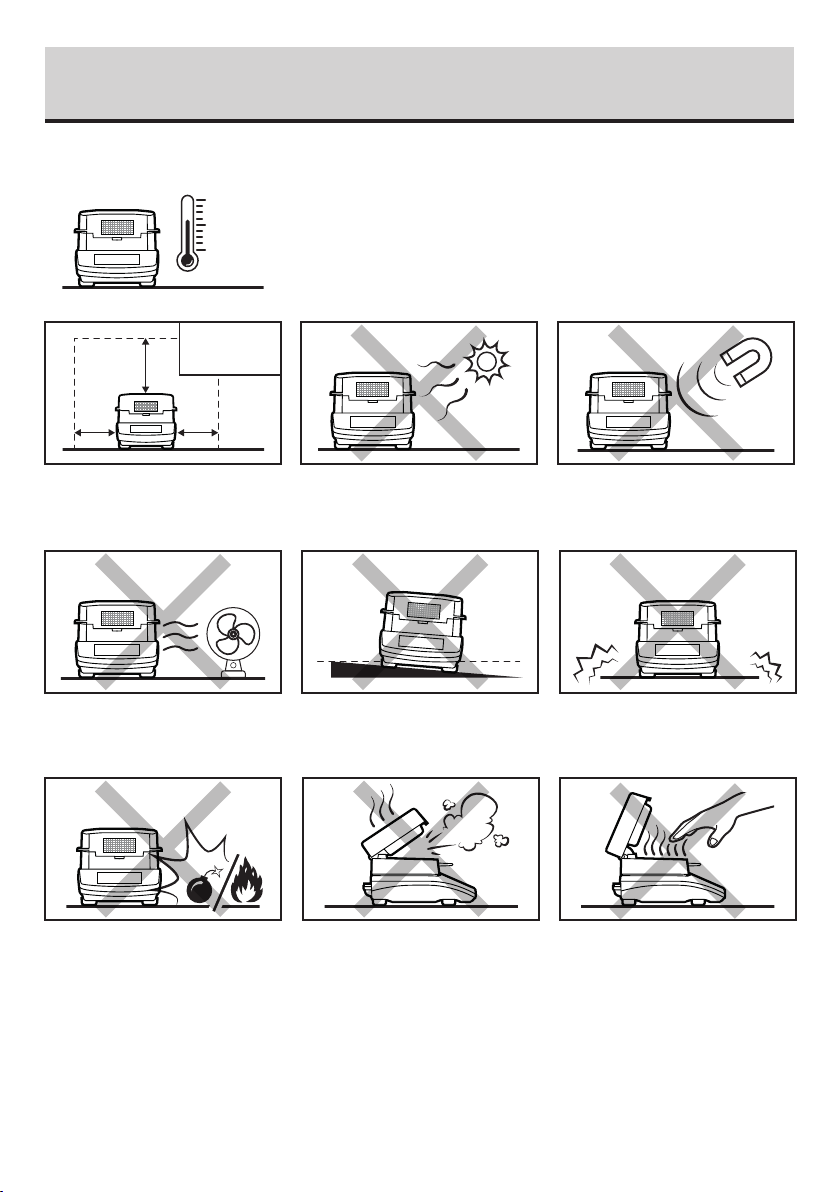

4. ACTIVITIES TO BE DONE PRIOR TO OPERATION

Grounding spring check

1 2 3

Check the grounding

spring.

Make sure that the grounding

spring juts slightly out of the hole.

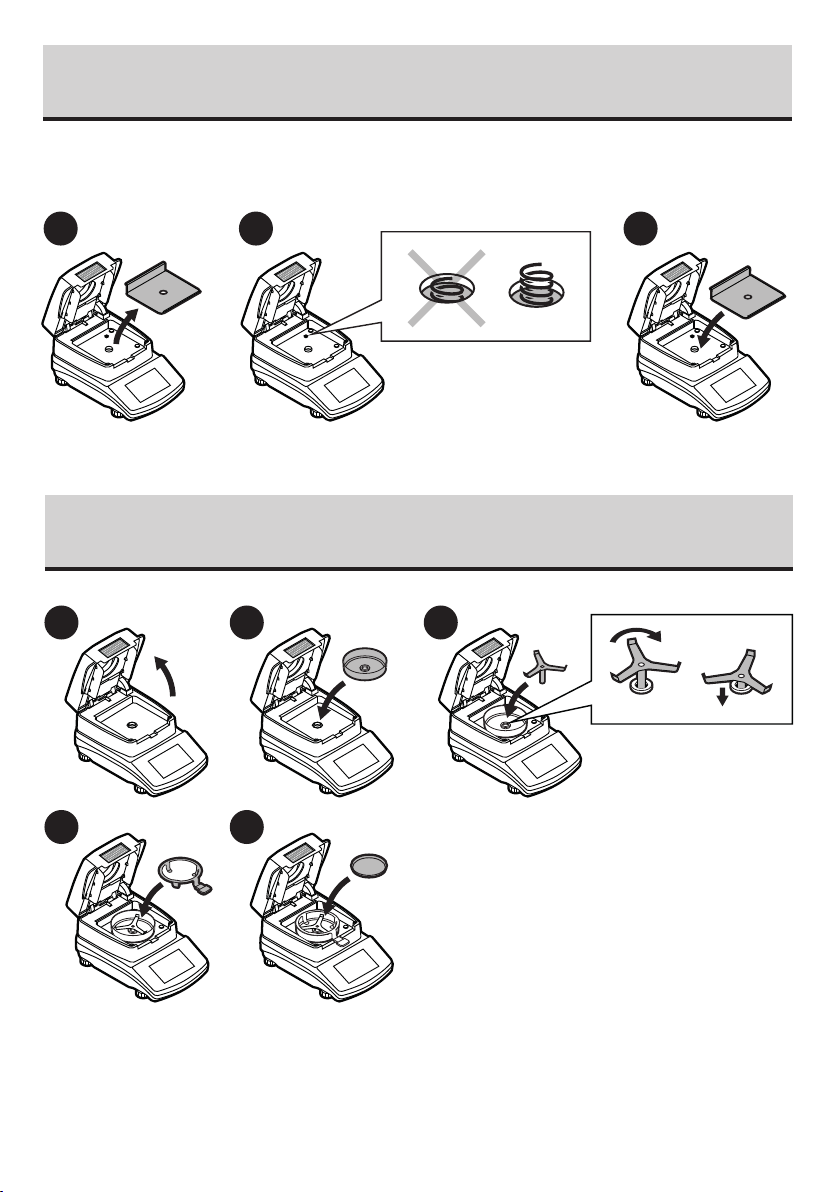

5. COMPONENTS ASSEMBLY

Install the base insert.Remove the base insert.

1

4 5

2 3

Slowly rotate the cross-shaped

holder, keep rotating until the

holder sinks deeper.

Page 5

6. PREPARING FOR WORK

USB 1

USB 2 Ethernet

COM

USB 1

USB 2

AC 120V/405W

60Hz

Ethernet

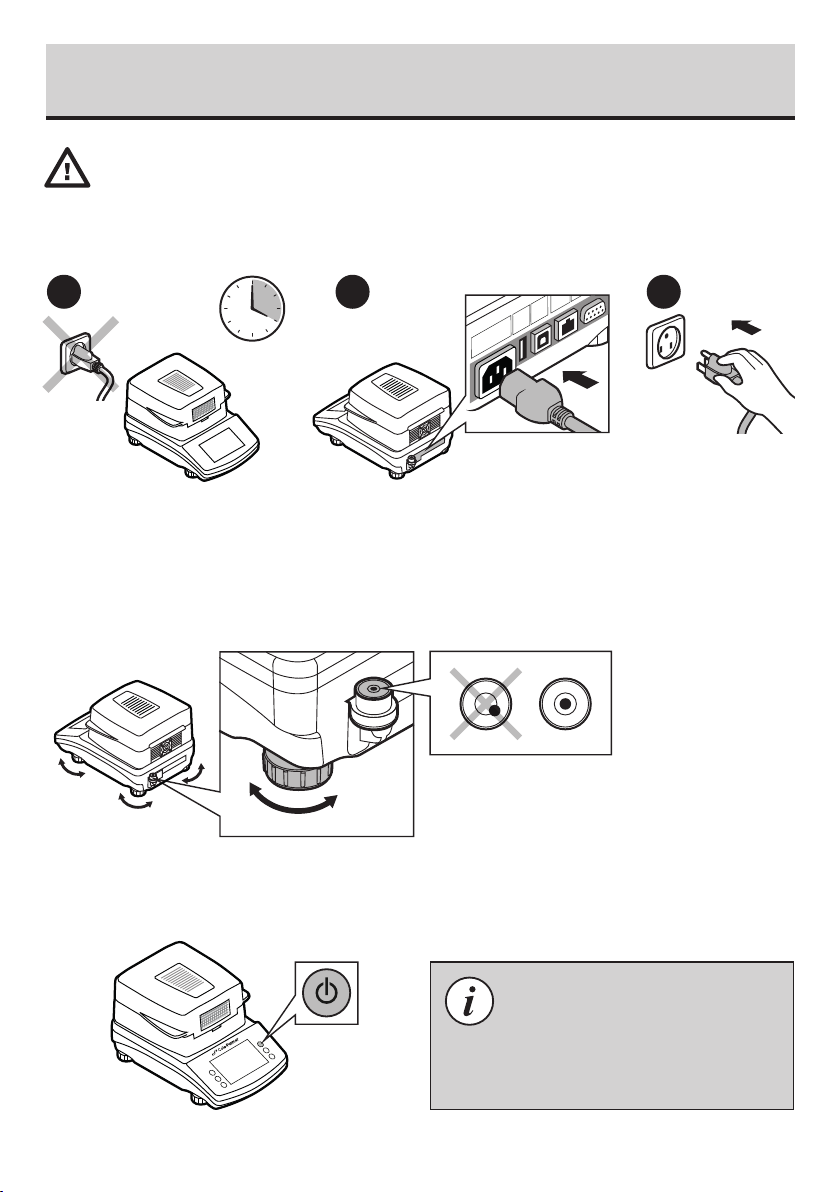

Place the device at the workstation, wait until

it reaches room temperature.

6.1. Balance temperature stabilization time

1 2 2

1-4 h

Prior switching the device on let it reach

room temperature (estimated

stabilization time: 1-4 hours).

6.2. Balance leveling

6.3. Switch the balance on

To switch the device on, press ON / OFF key.

Connect the power cord into the AC socket

located at the back of the device.

To level the balance, turn its feet

and keep turning the feet until the

air bubble takes the central position.

The moisture analyzer

is ready to operate!

It is recommended to carry out adjustment operation

prior running to the WEIGHING mode: read point 8.1.

(adjustment is not required for DRYING).

Connect the device to the

mains.

Page 6

7. PANEL AND SCREEN

7.1. Panel keys

Proximity sensorProximity sensor

Entering balance

setup

Displaying previous

screen

Taring

7.2. Home screen

Press to display list of working

modes: WEIGHING / DRYING

Weighing result window

Editable tool bar with quick

access keys

Switching on / off

Confirming an operation

or printing a report

Zeroing

List of current working

mode functions

Status bar

Enabled for editing info

fields (labels, text boxes,

buttons) providing current

drying parameters

Parameters Users Database Drying mode Open / Close

the chamber

Working mode

parameters

Start Databases

Page 7

8. BASIC OPERATIONS

8.1. Adjustment

It is recommended to carry out adjustment operation prior to running the WEIGHING mode (adjustment is not required for

DRYING). External adjustment is carried out using an external mass standard of the right accuracy and weight value, which

value depends on balance type and capacity.

Prior to adjustment prepare the right mass standard.

You are recommended to use mass standard of class F1 or F2.

View the table and select the mass standard you need.

Caution! Make sure that the disposable weighing pan has been

installed (read point 5.5.). Do not close the drying chamber in the

course of adjustment.

Balance

model

MB-T-50H

MB-T-50

MB-T-210

Mass

standard [g]

50

50

200

21

Products 0

Press "Parameters” button. Respective parameters list is displayed, select

Adjustment option.

43

Press "External Adjustment” parameter.

Wait for completion of the start mass

determination process.

Unload the weighing pan and press

button for confirmation.

65

Load the weighing pan with mass standard and

press button for confirmation.

Page 8

7

8

Wait for the process completion.

8.2. Zeroing

Unload the weighing pan and press

"Zeroing" button.

8.3. Taring

Unload the weighing pan.

21

The balance has been zeroed.

21

When the weighing result has been displayed

press "Tar e" button.

The balance has been tared.

Page 9

8.4. Drying profiles / Drying process finish modes

Press to view list of drying

profiles.

Drying profiles:

Standard:

the most precise moisture content measurement

Fast:

for samples with moisture content between 5% - 15%

Mild:

for substances sensitive to intense heat impact

Step:

for substances with moisture content higher than 15%

Press to view list of drying process

finish modes.

Drying process finish modes:

Automatic:

triggered in accordance with automatic settings

Manual:

triggered manually by the user

Time-defined:

triggered after passage of declared time

User-defined:

triggered in accordance with user settings

Page 10

9. SETTINGS

Some balance settings are accessible for Administrator exclusively.

Prior to balance parameters setup, log in as the Administrator.

9.1. Administrator's login

1

Press "Operators" button.

3

Press

123 button to activate numeric keyboard. Enter

"1111" password and press button to confirm.

2

Users list is displayed, select Admin option.

4

You have logged in the administrator.

Page 11

9.2. User settings

Prior to balance users setup, log in as the Administrator.

21

Press "Databases" button. Select Operator database.

43

Press "Add" button. Select "Name" parameter.

65

Enter user name. User name has been entered.

Following the above procedure, set remaining parameters:

7

Code:

Enter user ID

Password:

Enter user password

Access levels:

Set respective access level (user, advanced, admin)

Page 12

9.3. Proximity sensors setup

Prior to proximity sensors setup, log in as the Administrator.

You can assign the proximity sensors with different functions for each working mode (the sensors will trigger

different operation for each working mode). The diagram presents sensors setup for the weighing mode.

1 2

Press "Parameters" button.

Parameters list is displayed, select

Working Modes parameter.

3 4

Select Weighing parameter.

5

Select Right Sensor parameter. Select function that is to be assigned to the

In order to set left sensor function repeat steps 5 and 6, this time select Left Sensor parameter. Following the

above procedure you can also set sensors for remaining working modes.

Select Proximity Sensors parameter.

6

right proximity sensor.

Page 13

10. SAMPLES AND DRYING METHODS

10.1. Preparing samples

Optimal sample structure and size are crucial features

influencing measurements speed, accuracy and repeatability.

Solids:

- sample crushing necessary,

- sample of low weight required,

- large sample surface.

Samples with low moisture

content:

- sample of heavy weight required

(10 - 15 g).

10.2. Handling hazardous samples

Some sample types require particular caution!

They may pose risk for people and objects. It is the moisture analyzer operator

who is responsible for potential loss being a result of such samples use.

Substances that in the course of

heating may emit vapours causing

corrosion (e.g. acids).

Apply small amount of samples, this

helps to prevent risk of depositioning

of vapour over cool housing

components.

Explosive and flammable substances and substances that in the

course of heating emit flammable

vapours.

Apply small amount of samples and

lower drying temperature, this helps to

prevent flames from rising and

explosion. Use glasses and protective

gloves.

Liquids:

- large sample surface.

Toxic and corrosive substances and

substances that in the course of

heating emit toxic vapours.

Due to risk of eyes, skin and lungs

irritation, and due to risk of death, such

samples must be dried in fume cupboard.

Page 14

11. PERIPHERAL DEVICES CONNECTORS

Power cord

Computer Printer Ambient conditions

Barcode

scanner

AC DB9

USB

USB

module

RS 232DC

Ethernet

Barcode

scanner

Keyboard

USB-A

Printer

USB-B

RJ45

Computer PrinterComputer

Page 15

12. DEVICE CLEANING

12.1. General Recommendations

Prior to cleaning, it is necessary to

disconnect the balance from the mains.

Avoid using cleansers containing chlorine, corrosive chemicals and bleach. Do not use

cleansers containing abrasive substances or scouring preparations.

Use soft cloths made of microfiber,

natural fiber or man-made fiber. Avoid

using abrasive cloths or cloths that might

scratch the surface.

11.2. Glass components

Prior to cleaning the glass panes, it is necessary to disassemble them first.

For detailed instruction on panes disassembly, refer to user manual.

Clean glass components using a solution of water and detergent (liquid soap,

dish-washing detergent, glass cleaner, etc.). In case of heavy contamination,

a mild solution of vinegar or baking soda can be used.

11.3. Plastic components

Prior to cleaning the plastic housing, it is necessary to disassemble

weighing pan components (cover, weighing pan, etc.).

Clean plastic components using a solution of water and detergent

(liquid soap, dish-washing detergent, glass cleaner, etc.).

Apply the cleanser onto the cloth first.

Avoid applying the cleanser directly

onto the device.

11.4. Stainless steel components

Prior to cleaning the stainless steel components, it is necessary

to disassemble them first.

Clean stainless steel components using a solution of water and detergent

(liquid soap, dish-washing detergent, glass cleaner, etc.). In case of heavy

contamination, a mild solution of vinegar or baking soda. can be used.

Page 16

625 East Bunker Court Vernon Hills

IL 60061 USA

Phone: 1-800-323-4340

Fax: 1-847-247-2929

E-Mail: sales@coleparmer.com

Loading...

Loading...