Page 1

IPS Series

Bench Scales

User Manual

xxxxxxxxxx - Revision __, June 2017

Page 2

Page 3

P a g e 3

CONTENT

1.0 SETTING UP AND TURNING ON THE SCALES ................................ 5

2.0 OPERATION ........................................................................................ 5

2.1 ZEROING .......................................................................................... 5

2.2 TARING ............................................................................................. 5

2.3 PARTS COUNTING .......................................................................... 6

2.4 PERCENT WEIGHING ................................................................ ...... 6

2.5 ANIMAL (Dynamic) WEIGHING ......................................................... 8

2.6 ACCUMULATED TOTAL ................................................................... 9

3.0 RS-232 SPECIFICATION ................................................................... 10

4.0 CALIBRATION .................................................................................... 11

5.0 SPECIFICATIONS .............................................................................. 13

6.0 ERROR MESSAGES.......................................................................... 14

7.0 MENU STRUCTURE .......................................................................... 15

8.0 WARRANTY INFORMATION ............................................................. 16

Page 4

P a g e 4

Page 5

P a g e 5

1.0 SETTING UP AND TURNING ON THE SCALES

There is a pillar which must be attached to the base frame first using the 4 bolts supplied. The pillar is

secured to the bracket using 2 sets of screws. Then place the platform in the base. Level the scale by

adjusting the four feet. Attach the indicator module to the pillar by sliding it over the bracket with the flanges

engaged in the groves on the base. Attach the cable from the base to the connector on the rear of the

indicator. Attach the power to the indicator.

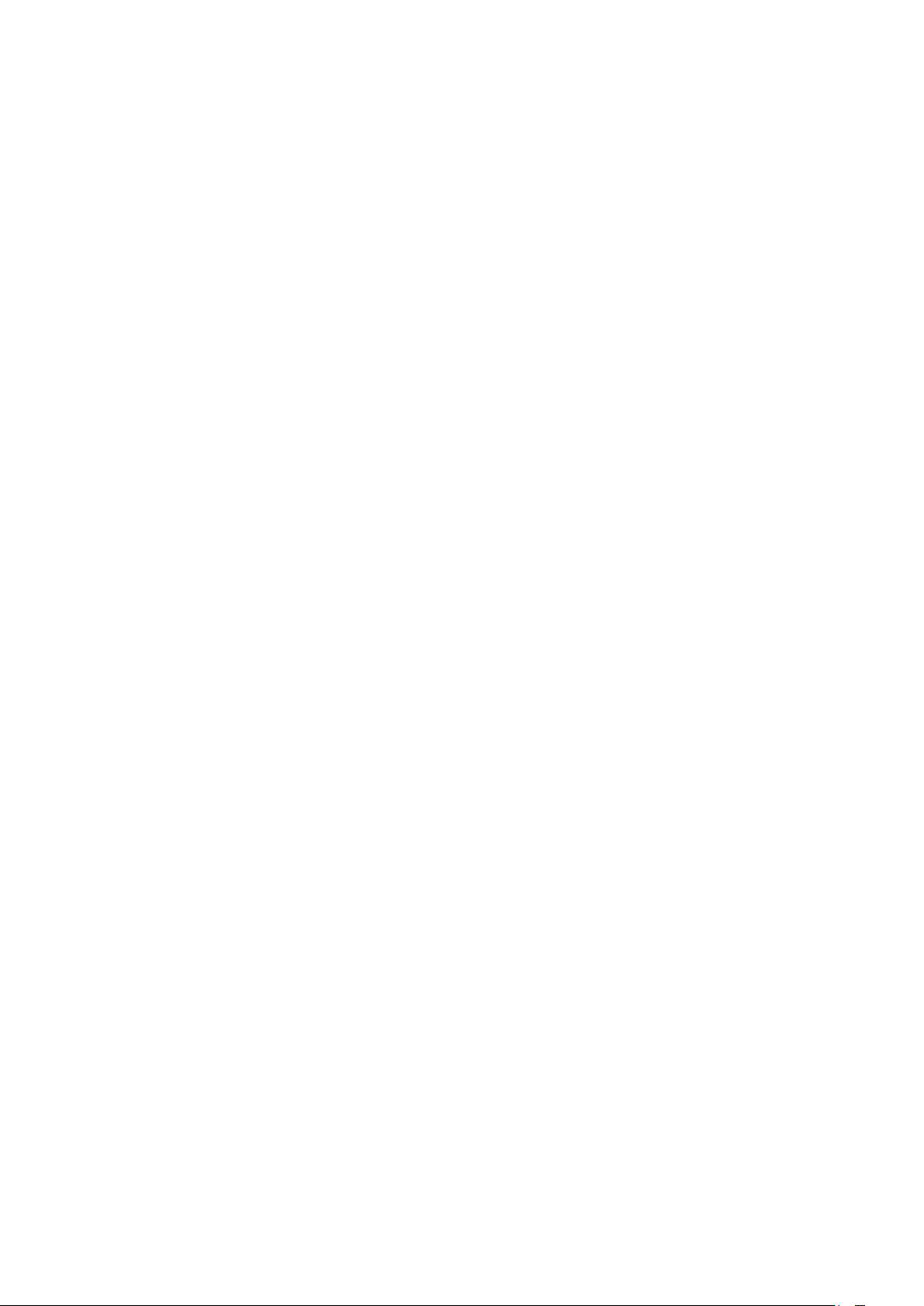

After completion of setting up, press the [On/Off] key on the rear of the indicator. The software revision

number will be displayed followed by a self-test showing all digits before the zero is displayed along with the

unit of weight that was selected last.

NOTE: The IPS can be operated from the rechargeable battery. With a single load cell and backlight

disabled the life is approximately 70 hours before needing to be recharged. The battery should be charged

for 12 hours for full capacity.

2.0 OPERATION

2.1 ZEROING

You can press the [Zero] key at any time to set the zero point from which all other weighing and counting is

measured. The scales have an automatic re-zeroing

function to account for minor drifting or accumulation of

material on a connected platform. However you may

need to press [Zero] to re-zero the indicator if small

amount of weight is still shown when the platform is

empty.

2.2 TARING

To determine a weight of sample which is using a container, you need to tare the empty container. IPS

scales supply two methods of tare: manual tare and preset tare.

Manual Tare

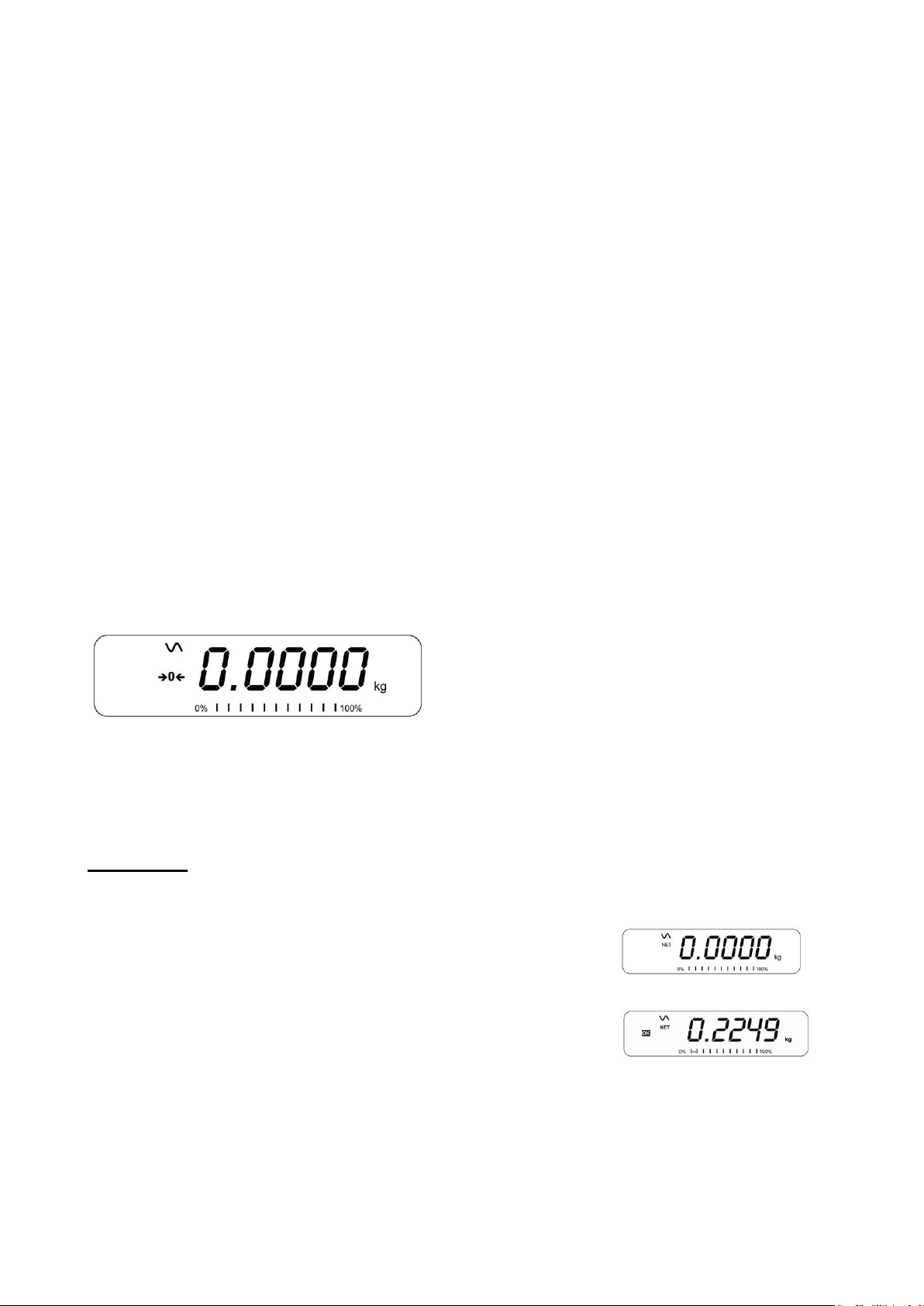

Zero the indicator by pressing [Zero]. The zero indicator will be on. Place a container on the pan.

Press [Tare] when the reading is stable. The weight that was displayed is

stored as the tare value, leaving zero on the display. The stable and Net

indicator will be on.

As a sample is added only the weight of the product will be shown. The

indicator could be tared a second time if another type of product was added

to the first one.

Press [Tare] or [Zero] to remove the tare value and display zero. The Net indicator will disappear.

Page 6

P a g e 6

Preset Tare

When the indicator or scale is at zero with no weight on the platform it is possible to enter a preset tare. First

zeroing the scale, enter a value using the numeric keys. Press [Tare] to tare the indicator. The value that

was entered is stored as the tare value and it is subtracted from the display, leaving a negative number on

the display.

To change the weighing unit press the [Unit] key. The only alternative weighing unit is pounds.

2.3 PARTS COUNTING

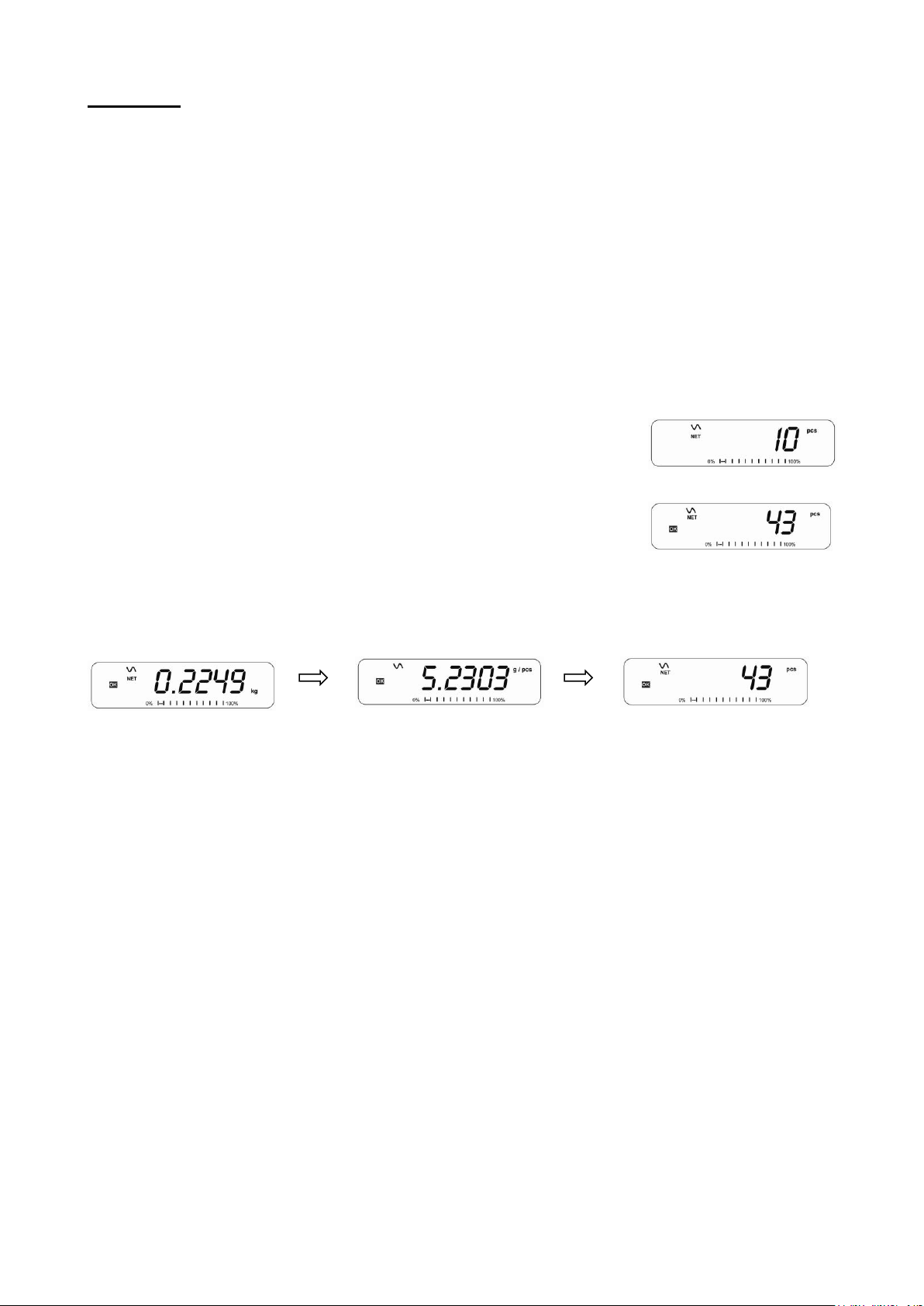

The scale can be used to count parts based on the average weight of a sample weighed. If a container is to

be used, place this container on the platform before entering parts counting and press [Tare]. Press [Cnt] to

enter the Parts Counting mode.

The display will show the last sample size used. For example, “10 Pcs”. To

change the sample size, you can press [CE] to clear the last values and then

enter the value 20 using the numeric keypad.

Place the right number of parts on the platform. Then press [Cnt] to determine

an average piece weight. After the sample has been weighed the scale will

count any other parts added by applying the average piece weight to the weight

of the parts to be counted.

During parts counting the display can be changed to show the net weight, unit weight and number of parts by

each time pressing the [Func] key.

To count a different sample quantity, press the [Count] key. And operate as above. To return to weighing,

press [Unit] when “XX pcs” is displayed.

NOTE: If the parts are too light to measure accurately, the count may become faulty. It is suggested that the

samples to be weighed should each weigh more than the resolution of the indicator.

2.4 PERCENT WEIGHING

The scale will use a mass on the platform as the 100% reference weight or input a reference weight using

the keypad.

Steps:

If using a reference weight (or object) as your 100% reference, add the weight to the platform. Press [Func].

The first option is “FUnC 1”, press the [Func] key 3 more times to display “FUnC 4”

Press the [Tare] key. “F4 PCt” will be displayed. Press [Tare] again to enter percent weighing. The scale will

set the sample mass on the platform as 100% reference weight.

NOTE: If there is no reference weight on the pan and percent weighing function is entered, pressing [Tare]

again will return the indicator to normal weighing.

Remove the sample weight. Then any other weight placed on the platform will be displayed as a percentage

of the original sample.

Page 7

P a g e 7

Users can also input the reference weight using the keypad. Make sure the platform is empty and when “F4

PCT” is displayed, enter the weight to be used for the 100% reference, then press [Tare] to accept the

reference weight. The display will show “0.00 %”.

If the indicator shows “x x . x x %”, which is the last weight used as a reference, press [CE] to clear and use

the numeric keypad to enter a new value. Press [Tare] to accept the new reference weight.

Press [Unit] to return to normal weighing.

NOTE: The weight entered must be greater than 50 scale divisions.

The display may jump by large numbers unexpectedly if small weights are used to set as 100% reference.

The indicator checks if the weight is too small and will show Error 7.

Page 8

P a g e 8

2.5 ANIMAL (DYNAMIC) WEIGHING

Steps:

Press [Func]. The first option is “FUnC 1”, press the [Func] key 3 more times to display “Func 4”.

Press the [Tare] key. “F4 PCt” will be displayed. Press the [Func] key to advance to the second function, “F4

AnL”, Animal weighing. And Press [Tare] to enter.

To use the Animal Weighing function it is necessary to set the amount of filtering. More active animals will

require a higher level of filtering to give a stable result. The display will show “Filt x” where x is a value from 1

to 5. To increment the value shown press the [Func] key then press the [Tare] key to accept it.

The display will flash “Ani “ 2 times then show the current weight, 0.00. The scale is now ready to weigh.

Place containers or blankets onto the platform and press the [Tare] key to zero the display. Place the animal

to be weighed on the platform.

When a stable reading is found, the display will show and lock this value, The display will show the “Hold”

symbol .Remove the animal, the display will hold the weight value.

Press the [Unit] key to unlock the display. The display will flash “Ani” twice, and be ready for the next

animal.

Press [zero] key to return to normal weighing.

Page 9

P a g e 9

2.6 ACCUMULATED TOTAL

The indicator can be set to accumulate when a weight is added to the platform automatically or manually by

pressing [Print]. See menu structure section. The accumulation function is available only during weighing. If

at any time the weighing units are changed, the accumulated data will be lost.

Manual Accumulation

When the scale is set to manual accumulation, the weight displayed will be stored in the memory when the

[Print] key is pressed and the weight is stable.

Steps :

Remove the weight and press [Print] when the display is at zero. The display

will show "ACC 1" and then the weight in memory for 2 seconds before returning

to normal. The weight can be output to a printer or PC using the RS-232

interface.

When the indicator is at zero, place a second weight on the platform. When

stable, press [Print] to accumulate the weight. The display will show "ACC 2"

for 2 seconds and then show the new total.

Continue until all weights have been added. This can continue for up to 99 entries until the capacity of

display is exceeded.

To view the total in memory, press the [Print] key when the indicator is at zero. The display will show the

total number of accumulation "ACC xx" and the total weight before returning to zero.

To print the total, press [Print] to recall and then immediately press [Print] the second time to print the

results. To erase the memory, press [Print] to view the total and then immediately press [CE] to clear the

memory.

Automatic Accumulation

When the indicator has been set to Automatic Accumulation the value will be stored in memory automatically.

Place a weight on the platform. The beeper will sound when the display is stable indicating the value is

accepted. Remove the weight. The display will show "ACC 1" and then the total in the memory before it

returns to zero. Adding a 2nd weight will repeat the process.

While the weight is on the platform, press the [Print] key to view the values- first the accumulation number

"ACC x" and then the total will be shown.

Page 10

P a g e 10

3.0 RS-232 SPECIFICATION

The IPS scale is supplied with a bi-directional RS-232 interface. The indicator when connected to a printer or

computer outputs the weight with the selected weighing unit through the RS-232 interface.

Default Specifications:

Connector:

RS-232 output of weighing data

ASCII code

9600 Baud (user selectable)

8 data bits

No Parity

9 pin d-sub miniature socket

Pin 3 Output

Pin 2 Input

Pin 5 Signal Ground

Page 11

P a g e 11

4.0 CALIBRATION

The scale can be calibrated using kilogram weights or pound weights depending on the weighing unit

selected at the time of calibration.

Steps:

To start the calibration, turn the scale off and switch on again and then press [Tare] during the self-test.

Enter code number 0000 and press [Tare]. This will take you directly to the calibration section or you can get

into the calibration section through the Indicator Settings (“FUnC 3”- see menu structure).

The display will show "UnLoAd"

Remove all weight from the platform and then press the [Tare] key when the display is stable. After the Zero

point is set, the display will show “Ld xx”. Place the suggested calibration mass on the platform. It is best to

use a weight close to the full capacity of the indicator.

If the mass is different from the displayed value, enter the value of the mass in whole numbers. The kg or

the lb symbol will be on to show the active unit. Press the [Tare] key when the stable indicator is on.

When complete, it will display “PASS” and then either display “S8 CAL” (if entered the calibration section

through the Scale Settings) or return to normal weighing (if entered directly). Remove the calibration mass.

If an error message “FAIL H” or “FAIL L” is shown, re-check the calibration and repeat. If the error cannot be

corrected contact your supplier.

Page 12

P a g e 12

Page 13

P a g e 13

5.0 SPECIFICATIONS

IPS Models

Model #

IPS 30

IPS 50

IPS 100

IPS 150

IPS 300

Maximum Capacity

30lb/15kg

50lb/25kg

100lb/50kg

150lb/75kg

300lb/150kg

Readability

0.001lb/0.0005kg

0.002lb/0.001kg

0.005lb/0.002kg

0.01lb/0.005kg

0.02lb/0.01kg

Repeatability (Std Dev)

0.002lb/0.0010kg

0.004lb/0.002kg

0.010lb/0.004kg

0.02lb/0.01kg

0.04lb/0.02kg

Linearity +

0.003lb/0.0015kg

0.006lb/0.003kg

0.015lb/0.006kg

0.03lb/0.015kg

0.06lb/0.04kg

Units of Measure

Kilograms and pounds, grams for all except IPS 300 which is kg and lbs only.

Stabilization Time

2-3 Secs

Operating Temperature

-10°C to +40°C / +14°F to +104°F

Power Supply

12vDC 800mA UL/CSA adapter for USA

Calibration

External

Calibration Mass

User Selectable

Display

Backlit Green display 20mm with capacity tracker

Scale Housing

Welded steel painted base, stainless steel grade 304 Top pan, ABS indicator housing

Pan Size

300mm x 400mm x 50mm / 11.8” x 15.7” x 2”

400mm x 500mm x 50mm / 15.7” x 19.7” x 2”

Overall Dimensions

(w x d x h)

300mmx 520mm x 660mm / 11.8” x 20.5” x 26”

400mm x 620mm x 660mm / 15.7” x 23.7” x 26”

Net Weight

7.6kg / 16.8 lb

Features

Weighing/Counting/ Percentage/Hold function/RS232

Page 14

P a g e 14

6.0 ERROR MESSAGES

During the initial power-on testing or during operation, the indicator may show an error message. The

meaning of the error messages is described below.

If an error message is shown, repeat the step that caused the message. If the error message is still shown

then contact your dealer for support.

ERROR

CODE

DESCRIPTION

POSSIBLE CAUSES

Err 1

Time input Error

Invalid time entry such as “268970” for the time

format “H-m-S”.

Err 2

Date input Error

34th day of a month is an invalid entry.

Err 4

Initial Zero is greater than allowed

(4% of maximum capacity) when

power is turned on or when the

[Zero/Enter] key is pressed.

Weight on the platform when turning the

indicator on.

Excessive weight on the platform when zeroing

the indicator.

Platform is not installed.

Improper calibration of the indicator.

Damaged load cell.

Damaged electronics.

Err 6

A/D count is not correct when turning

the indicator on.

Load cell is damaged.

Electronics is damaged.

Err 7

Percent input error

Percent function is entered with no reference

mass on the platform.

FAIL H or

FAIL L

Calibration error

Improper calibration (should be within +10% of

the factory calibration). The old calibration data

will be retained until the calibration process is

complete.

Page 15

15 | P a g e

7.0 MENU STRUCTURE

PARAMETER LAYOUT for IPS SCALES

Press the [Func] key to

enter Functions mode.

Key functions while in this section

[Tare] enter a parameter or accept the changes

[Func] move to next parameter or option

[Zero] return to previous parameter or return to weighing

FUNC 3

Scale Parameters

S1 Un

Units enable

kg

lb

S2 bL

Backlight

EL oFF

EL on

EL AU (Auto)

S3 AoF

Set Auto off time

(min.)

SLP 0

SLP 1

SLP 5

SLP 10

S4 dt

Set time and date

Set as described in manual

S5 dIS

Display mode

All

StAb (only when stable)

S6 Fi

Set Filter

SLoW

nor (normal)

FASt

S7 SPS

Scale password

Enter using numeric keys

S8 CAL

Perform calibration

FUNC 4

Scale Parameters

F4 Pct

Percent Weighing

Enter 100%

reference weight

F4 Ani

Animal weighing

FLt 1 Filter setting

To

FLt 5

FUNC 2

RS-232 Parameters

C1 on

Enable RS-232

Prt on

Prt oFF

C2 bd

Baud Rate

600

To 19200

C3 Prm

Printing Mode

mA StA (Manual Stable)

mA AnY (Manual Any)

Au StA (Auto Stable)

Au End (Auto End)

Ct StA (continuous Stable)

Ct AnY(Continuous Any)

C4 Aon

Enable

Accumulation

on

oFF

C5 Ln

Language for

printing

English

French

German

Spanish

C6 Uid

User ID

Enter using numeric keys

C7 Sid

Scale ID

Enter using numeric keys

C8 LAb

LAb On

Lab Off

FUNC 1

Function 1 is not used

n/A

Page 16

16 | P a g e

8.0 WARRANTY INFORMATION

The scale is covered by a Limited Warranty (Parts and Labor) for any components that fail due to

defects in materials or workmanship. Warranty starts from the date of delivery.

During the warranty period, should any repairs be necessary, the purchaser must inform its supplier.

The company or its authorized Technician reserves the right to repair or replace the components at any

of its workshops at no additional cost, depending on the severity of the problems. However, any freight

involved in sending the faulty units or parts to the Service Centre should be borne by the purchaser.

The warranty will cease to operate if the equipment is not returned in the original packaging and with

correct documentation for a claim to be processed.

This warranty does not cover equipment where defects or poor performance is due to misuse,

accidental damage, exposure to radioactive or corrosive materials, negligence, faulty installation,

unauthorized modifications or attempted repair, or failure to observe the requirements and

recommendations as given in this User Manual.

This product may include a rechargeable battery that is designed to be removed and replaced by the

user. The supplier will provide a replacement battery if the battery manifests a defect in materials or

workmanship during the initial period of use of the product in which the battery is installed.

As with all batteries, the maximum capacity of any battery included in the product will decrease with

time or use, and battery cycle life will vary depending on product model, configuration, features, use,

and power management settings. A decrease in maximum battery capacity or battery cycle life is not a

defect in materials or workmanship, and is not covered by this Limited Warranty.

Repairs carried out under the warranty do not extend the warranty period. Components removed

during warranty repairs become company property.

The statutory rights of the purchaser are not affected by this warranty.

Page 17

17 | P a g e

Page 18

FCC COMPLIANCE

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. The

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

Shielded interconnect cables must be employed with this equipment to insure compliance with the

pertinent RF emission limits governing this device.

Changes or modifications not expressly approved by the manufacturer could void the user's authority

to operate the equipment.

WEEE COMPLIANCE

Any Electrical or Electronic Equipment (EEE) component or assembly of parts intended to be

incorporated into EEE devices as defined by European Directive 2002/95/EEC must be recycled or

disposed using techniques that do not introduce hazardous substances harmful to our health or the

environment as listed in Directive 2002/95/EC or amending legislation. Battery disposal in Landfill

Sites is more regulated since July 2002 by regulation 9 of the Landfill (England and Wales)

Regulations 2002 and Hazardous Waste Regulations 2005. Battery recycling has become topical and

the Waste Electrical and Electronic Equipment (WEEE) Regulations are set to impose targets for

recycling.

Page 19

Loading...

Loading...