Page 1

C100 Handheld Cond./TDS/Sal. Meter

Instruction Manual

Page 2

Table of Contents

1. Introduction ---------------------------------------------------------------------------------------------------------------------------

1

2. Specifications -------------------------------------------------------------------------------------------------------------------------

3. Instrument Description -------------------------------------------------------------------------------------------------------------

3.1. LCD display-----------------------------------------------------------------------------------------------------------------------

3.2. Keypad functions--------------------------------------------------------------------------------------------------------------

3.3 Meter sockets -----------------------------------------------------------------------------------------------------------------

3.4. Auto power-off --- ------------------------------------------------------------------------------------------------------------------

4. Conductivity measurement - ------------------------------------------------------------------------------------------------------

4.1. Conductivity probe information-------------------------------------------------------------------------------------------

4.2. Conductivity calibration related information---------------------------------------------------------------------------------

4.3. Conductivity Meter calibration--------------------------------------------------------------------------------------------------

4.4. Relationship among TDS, salinity and conductivity-----------------------------------------------------------------

4.5. Customer-defined calibration---------------------------------------------------------------------------------------------------

4.6. Sample measurement------------------------------------------------------------------------------------------------------------

4.7. Conductivity probe maintenance-----------------------------------------------------------------------------------------

5. Parameter setting----------------------------------------------------------------------------------------------------------------------

2

3

3

4

5

5

6

6

6

7

8

9

9

10

11

5.1. Main menu-------------------------------------------------------------------------------------------------------------------------

5.2. Submenu --------------------------------------------------------------------------------------------------------------------------

5.3. Conductivity parameter setting submenu----------------------------------------------------------------------------------

5.4. Basic parameter setting submenu--------------------------------------------------------------------------------------------

6. Meter Kits-------------------------------------------------------------------------------------------------------------------------------

7. Warranty---------------------------------------------------------------------------------------------------------------------------------

Appendix I: Parameter setting & Factory default setting------------------------------------------------------------------------

Appendix II: Code Symbol & Abbreviation Glossary-------------------------------------------------------------------------------

11

11

12

13

14

15

16

17

Page 3

1. Introduction

Thank you for purchasing our C100 Handheld Cond./TDS/Sal. Meter.

This meter is perfect combination of the most advanced electronic technology, sensor technology and

software design, and is the most cost-effective handheld conductivity meter suited for industrial and

mining enterprises, water treatment engineering, environmental protection industry, etc, especially suited

for application in field.

The instrument with built-in microprocessor chips, beautiful appearance, easy to use, has the following

marked characteristics:

z Intelligent functions, such as automatic calibration, automatic temperature compensation, functions

setting, self-diagnosis, automatic power-off and low voltage display etc.

z With advanced digital processing technology, the response speed and accuracy are greatly

improved. Stable reading display mode is also equipped.

z 1-4 point automatic calibration with calibration instruction and automatic checking functions.

z Automatically recognize 4 types of conductivity standard solutions. Customer-defined solution can

also be set-up.

z With conductivity, TDS and salinity three measurement modes, can switch to display the results.

z The meter meets IP67 dust and water proofing rate.

1

Page 4

2. Specifications

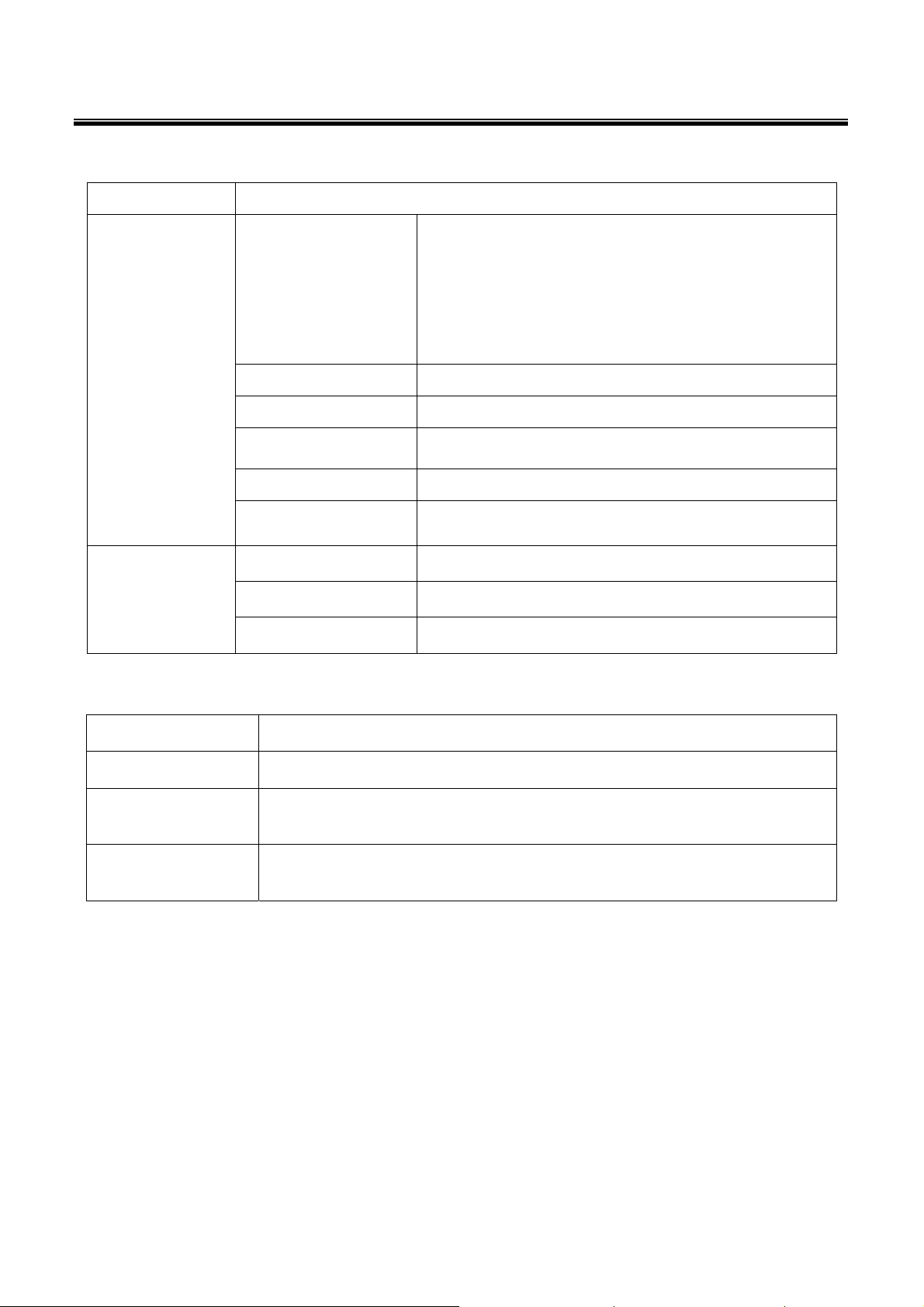

2.1. Technical parameters

Technical parameters

Conductivity: 0~200 mS/cm(divided into four ranges):

(0~199.9)μS/cm ; (200~1999) μS/cm ;

Measuring Range

(2.00~19.99)mS/cm; (20.0~199.9)mS/cm

TDS: (0~100)g/L

Salinity: (0~100)ppt

Conductivity

Resolution 0.1/1μS/cm 0.01/0.1 mS/cm

Accuracy ±1.0% FS ±1digit

Temperature

compensation range

Probe constant 0.1 / 1 / 10 cm-1

Reference temperature 25 °C

Measuring Range 0~100 °C

Temperature

Resolution 0.1°C

Accuracy ±0.5°C±1digit

2.2. Other technical parameters:

Power AA batteries × 3 (1.5V× 3)

IP rating IP67

Dimension &

Weight

(0 ~ 80)°C(manual or automatic)

Meter: (86×196×33 )mm / 335g

Quality and safety

certification

ISO9001:2008 & CE

2

Page 5

3. Instrument description

3.1. LCD display:

1 — Measuring mode icons

○

Diagram-1 LCD screen

2 — Measurements

○

3 — Prompts

○

4 —Measurement Units

○

5 —Conductivity calibration Units

○

6 — Conductivity calibration value and prompts

○

7 —Temperature units

○

8 — Temperature value and prompts

○

9 — Temperature compensation state icons

○

ATC — automatic temperature compensation,

MTC — manual temperature compensation

10 — Calibration indication icon

○

11 — Stable reading indication icon

○

12 — Low battery icon, when this icon appears, please renew the battery

○

3

Page 6

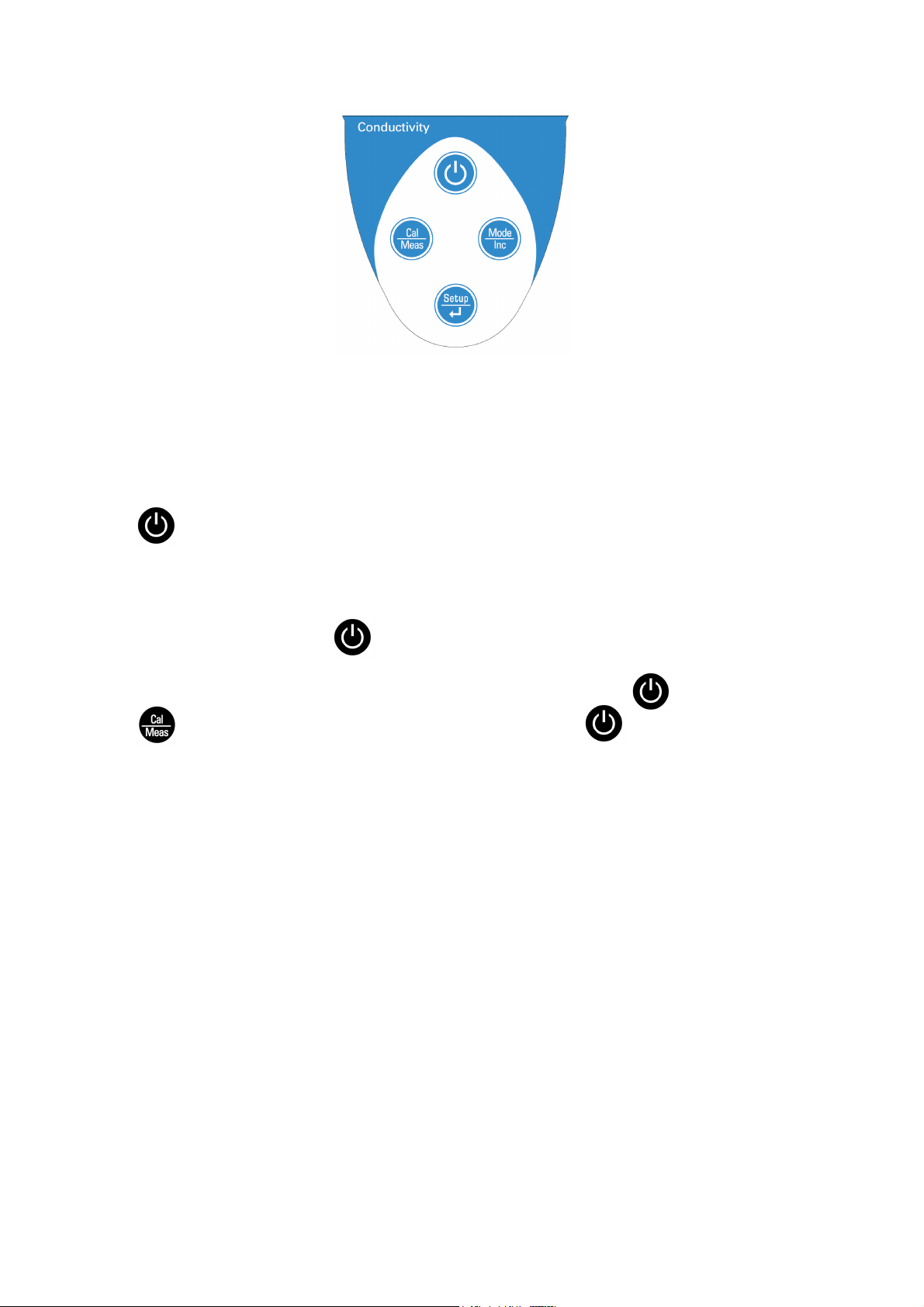

3.2. Keypad functions

3.2.1. Keypad operations

Diagram-2 Keypad panel

Short press: <1.5 seconds , Long press: >1.5 seconds.

3.2.2. Turn on the meter

Press to turn on the meter: LCD full display → display some parameters setting content→ display

the last measuring mode before turning off.

3.2.3. Turn off the meter

In the measurement mode, press and hold for 2 seconds to turn off the meter.

Note: In the calibration mode or the parameter set-up mode, pressing is invalid. Please

Press key to return to the measurement mode, then press to turn off the meter.

4

Page 7

Chart -1 Keypad operations and functions

Keypad Operations Functions

Short press

● In the power-off mode, press this key to turn on the meter

● In the measurement mode, press and hold this key for 2 seconds to

Long press

turn off the meter.

● In the measurement mode, press this key to select measurement

mode: → →

● In the mode of manual temperature compensation (MTC), when

press and hold this key, the temperature value flashes, then press

Short/long press

this key again to change the temperature value (only one

direction), and press to confirm

● In the parameter set-up mode, press this key to change the serial

number of the main menu and the submenu (only one direction)

● In the submenu mode, press this key to change parameters and

set-up (only one direction)

● In the measurement mode, press this key to enter in the calibration

mode

Short press

● In the calibration mode or the parameter set-up mode, press this

key to return to the measurement mode

● In the measurement mode, press this key to enter in the parameter

set-up main menu

Short press

● In the calibration mode, press this key to make calibration

● In the parameter set-up mode, press this key to select programs

3.3. Meter sockets

The meter is with BNC and RCA sockets, which are protected by grey rubber caps. (As showed in

Table-2)

Chart-2- Meter sockets

Photos Descriptions

BNC socket (Left) — for conductivity probe;

RCA socket (Middle) — for temperature probe.

3.4. Auto power-off

The meter will be automatically power-off if nothing is done for 20 minutes. In the parameter setting

menu P6.8, user can set up to turn on or turn off this function.

5

Page 8

4. Conductivity Measurement

4.1. Conductivity probe information

4.1.1. Matching conductivity probe

The meter includes one plastic conductivity probe (Model 2301T-F, K=1.0). With built-in temperature

sensor, the meter can realize automatic temperature compensation. BNC plug of the probe is connected

to the meter’s conductivity socket while RCA plug is connected to the temperature socket. When the

probe is submerged in solution, stir the solution briefly to eliminate the air bubbles and in this way, a

stable measurement will be reached fast.

4.1.2. Conductivity probe constant

The meter can use with conductivity probes with three constants: K=0.1, K=1.0 and K=10.0. Please refer

to chart-3 for the measuring range. Set up constant in menu P2.1 and refer to details in clause 5.3.

Chart – 3 Probe constant and measuring range

Range

Conductivity probe

<20 μS/cm

K=0.1 cm

-1

0.5 μS/cm~100 mS/cm

K=1.0 cm-1 K=10 cm-1

>100mS/cm

constant

Standard solution 84μS/cm 84 μS/cm 1413 μS/cm 12.88 mS/cm 111.9 mS/cm

4.2. Conductivity calibration related information

4.2.1. Conductivity calibration solutions

The meter uses standard series of conductivity solution. The meter can recognize the standard solution

automatically and perform 1 to 4 point calibration. The calibration icons at the bottom left of LCD screen

is corresponding to four built-in standard values. See chart – 4:

Chart – 4 Conductivity standard solution series

Calibration indication icons Calibration solution series Measuring range

84 μS/cm 0-200 μS/cm

1413 μS/cm 200-2,000 μS/cm

12.88 mS/cm 2-20 mS/cm

111.9 mS/cm 20-200 mS/cm

4.2.2. Calibration intervals

(a) The meter is calibrated before leaving the factory and can generally be used right out of the box.

(b) Normally, performing calibration once a month is recommended.

(c) For high accuracy measurement or larger temperature deviation from the reference temperature

(25°C), performing calibration once a week is recommended.

(d) Use conductivity standard solution to check the probe. Perform calibration if the error is big.

6

Page 9

(e) When use a new probe for the first time, or the meter has restored to factory default setting, 3-point or

4-point calibration is recommended. For everyday use, standard solution closer to the sample solution

can be chosen to perform 1- point or 2-point calibration. For example: 1413 μS/cm standard solution is

suitable for measuring range 0-2,000 μS/cm.

4.2.3 1-point and multi-point calibration

If 1-point calibration is preformed after 3-point or 4-point calibration, the previous calibration value in the

same range will be replaced, meanwhile, the meter will show the calibration indication icon of this point,

other two calibration indication icons will be deleted, but the chip will reserve the last calibration data. All

calibration data will be deleted after restoring to factory default, and restore to theory value. When

perform multi-point calibration, the calibration solution should be chosen from low to high concentration

in order to avoid contamination of standard solution in low concentration.

4.2.4. Reference temperature

Factory set reference temperature is 25°C. Other reference temperature can also be set within the range

15°C – 30°C. Set up reference temperature in menu P2.5 and see details in clause 5.3.

4.2.5. Temperature coefficient

Factory set temperature compensation coefficient of the meter is 1.9%. However, the conductivity

temperature coefficient is different from that of varous kinds of solution and concentration. Please refer

to chart – 5 and the data collected during testing and set up the parameter in menu P2.6. See details in

clause 5.3.

Note: When the temperature compensation coefficient is set to 0.00 , meaning no temperature

compensation, the measurment value will be based on the current temperature.

Chart -5 Temperature compensation coefficient of certain solutions

Solution Temperature compensation coefficient

NaCl solution 2.12%/°C

5% NaOH solution 1.72%/°C

Dilute ammonia solution 1.88%/°C

10% hydrochloric acid solution 1.32%/°C

5% sulfuric acid solution 0.96%/°C

4.2.6. Avoid contamination of standard solution

Conductivity standard solution has no buffer. Please avoid being contaminated during usage. Before

submerging the probe in standard solution, please wash the probe and allow it dry. Please do not use

the same cup of conductivity standard solution frequently, especially for standard solution of low

concentration 84μS/cm. The contaminated standard solution will affect accuracy of measurements.

4.3. Conductivity meter calibration (take standard solution 1413μS/cm as an example)

4.3.1. Rinse the probe in pure water, allow it to dry, then wash it with a small amount of standard solution

7

Page 10

and submerge it in standard solution. Stir the solution briefly and allow it to stay in the solution until a

stable reading is reached.

4.3.2. Press key to enter into the calibration mode.

“std” icon will blink at the top right of the screen, while scanning and locking

process of calibration solution will be showed at the bottom right.

Er 2 appears if press key before the value is locked. See Chart – 7.

4.3.3. When the meter locks 1413 μS, stable icon will appear on LCD

screen. Press key to calibrate the meter. End icon appears after calibration

is done. The meter returns to the measurement mode and LCD shows

icon at the bottom left. See Diagram – 3 for the above calibration process.

4.3.4. If exit from calibration mode without confirmation, press key to

return to the measurement mode without calibration.

4.3.5. For multi-point calibration, please repeat clause 4.3.1-4.3.3 until all

the calibration is done. The meter can perform calibration in the same calibration

solution repeatedly until the value displayed is stable and repeatable.

4.4 Relationship among TDS, salinity and conductivity

4.4.1 Press key to switch the measurement mode:

→ →

Diagram- 3

4.4.2 TDS and conductivity is linear related. The conversion

coefficient is 0.40~1.00 which can be adjusted in parameter setting P2.7.

Factory default setting is 0.71 and please refer to clause 5.3 for details. Salinity and conductivity are

interrelated. The calculation formula has been put in the program of the meter. So the meter only needs

to be calibrated in conductivity mode, then switch to TDS and salinity mode.

4.4.3 Customers can adjust TDS conversion coefficient in parameter setting P2.7 according to testing

data and experience. Please refer to chart-6 for some frequently-used conductivity and TDS conversion

coefficients. Just for your reference.

Chart -6 Conversion coefficient between conductivity and TDS

Conductivity of solution TDS conversion coefficient

0~100 μS/cm 0.60

100~1,000 μS/cm 0.71

1~10 mS/cm 0.81

10~100 mS/cm 0.94

8

Page 11

4.5. Customer-defined calibration (take 10.50μS/cm standard solution as an example)

4.5.1. Select CUS in parameter setting P2.2 (please refer to clause 5.3 for customer-defined calibration)

and the meter enters into customer-defined calibration mode. Press , LCD shows blinking CUS at

the top right, indicating that the meter enters into customer-defined calibration.

4.5.2.

Rinse the probe in pure water, allow it to dry, and submerge it in 10.50 μS/cm standard solution.

Stir the solution briefly and allow it to stay in the solution until a stable reading is reached and icon

appears on LCD.

4.5.3. Press key, the measuring value blinks. Press key to adjust the measuring value to 10.50

μS/cm, and press key to calibrate the meter. After the calibration is done, the meter will return to

measurement mode. In conductivity mode with customer-defined calibration, the probe calibration

indication icons will not appear on the screen.

Note: If use conductivity electrode without temperature sensor, meaning manual temperature

compensation (MTC) is adopted, the temperature value blinks when press key, press

key to adjust the temperature value, and when press key, conductivity value blinks.

4.5.4. Only 1-point calibration for customer-defined calibration. The conductivity value of the

customer-defined solution is at a fixed temperature. There is no regulation of temperature coefficient and

reference temperature. The meter has to perform calibration and measurement at the same temperature

to avoid large error. The meter cannot recognize customer-defined calibration solution.

4.6. Sample Measurement

4.6.1. Rinse conductivity probe in pure water, allow it to dry, and submerge it in the sample solution. Stir

the solution briefly and allow it to stay in the sample solution until a stable reading is reached and

icon appears on LCD screen. The reading got is the conductivity value of the solution.

4.6.2. Press key to switch TDS value or salinity value.

4.6.3. During the process of calibration and measurement, the meter has self-diagnosis functions,

indicating the relative information as showed in chart – 7.

9

Page 12

Chart – 7 Self-diagnostic information of conductivity measurement mode

Icons

Self-diagnostic information

Check up

1. Check if the conductivity calibration

Wrong conductivity calibration solution

or exceed recognition range of the

meter

solution is accurate.

2.Check if the connection between meter and

probe is good.

3.Check if the probe is failed.

Press key when measuring value

Press key when icon appears

is not stable during calibration.

During calibration, the measuring value

is not stable for ≥3min.

1.Shake the probe to eliminate bubbles

in probe head.

2.Replace conductivity probe with a new one.

4.6.4 Factory default setting

For factory default setting, please refer to parameter setting P2.8 (Clause 5.3). With this function, all

calibration data will be deleted and the meter will restore to the theory value. Some function settings will

be restored to the original value (refer to appendix -1). When calibration or measurement fails, please

restore the meter to factory default setting and then perform re-calibration or measurement. Please note

that once the meter is restore to factory default setting, all the data deleted will not be retrievable.

4.7. Conductivity probe maintenance

4.7.1. Always keep the conductivity probe clean. Before taking a measurement, rinse the probe in pure

water and then rinse it in the sample solution. When submerge the probe in solution, stir the solution

briefly to eliminate air bubbles and allow it to stay in the solution until a stable reading is reached. For

dry- stored conductivity probe should be soaked in pure water for 5-10 minutes before measuring. Rinse

the probe in pure water after measuring.

4.7.2. The sensitive rod of Model 2301T-F conductivity probe is coated with platinum black to minimize

probe polarization and expand measuring range. Do not scrub platinum black. Only stir the probe in pure

water to avoid damage of the platinum black coating. Clean organic stain on the probe in warm water

with detergent, or alcohol.

4.7.3. If the probe coated with platinum black is found unworkable, immerse it in 10% nitric acid solution

or 10% hydrochloric acid solution for 2 minutes, then rinse the probe in pure water and take

measurement after that. If the probe still does not work, re-coat platinum black, or replace with a new

conductivity probe.

10

Page 13

m

m

0

d

c

e

2

6

m

f

a

p

t

r

4

D

r

a

n

s

k

4

t

o

r

2

u

P

n

→

u

e

PPPPPPP

P

r

o

6

s

m

p

c

r

e

s

T

e

t

a

o

o

p

2

e

g

a

m

r

e

s

f

pa

r

s

a

o

t

t

:

n

g

5. Para

5.1. Main

In the mea

P2.0→P6.

P2.0: Con

P6.0: Basi

5.2. Subm

5.2.1. In P

press

5.2.2. In P

see

Main

eter setti

enu

surement

. Please re

uctivity par

parameter

nu

.0 mode,

key to swi

.0 mode, p

Diagram–

menu of pa

ng

ode, press

er to diagr

meter setti

setting me

ress

ch among

ess

.

ameter set

iagram –

key t

m – 4

ng menu,

u.

key to ente

ubmenu: P

ey to enter

ing

Main men

enter in

in subme

.1→P2.2

in submen

and subm

2.0, then p

u P2.1 of c

P2.5→P2.

P6.1 of ba

Submenu

2.1 Select

2.2 Select

2.5 Select

2.6 Select t

compen

2.7 Select

2.8 Restor

Submenu

6.1 Select

6.8 Autom

nu of para

ess t

nductivity

→P2.7→P

ic paramet

of Cond.

robe const

onductivity

eference te

mperature

ation facto

DS coeffici

to factory

of basic pa

emperature

tic power-o

eter settin

switch to

arameter

.8, see Di

r setting,

rameter se

nt

standard s

p.

nt

et

ameter set

unit

f setup

main menu

etting, the

gram– 4.

tin

lution

ing

11

Page 14

u

t

.

t

P

e

o

a

→

r

e

d

r

e

r

e

r

t

r

o

o

s

o

n

m

r

t

f

m

r

e

C

-

e

n

a

e

m

n

e

m

o

r

Y

s

0

e

r

s

t

s

e

a

e

s

a

4

f

s

e

(

e

r

k

s

1

o

m

o

e

e

o

m

0

o

t

m

o

o

m

o

s

r

e

2

d

2

e

m

0

p

o

o

o

e

e

o

r

.

r

y

t

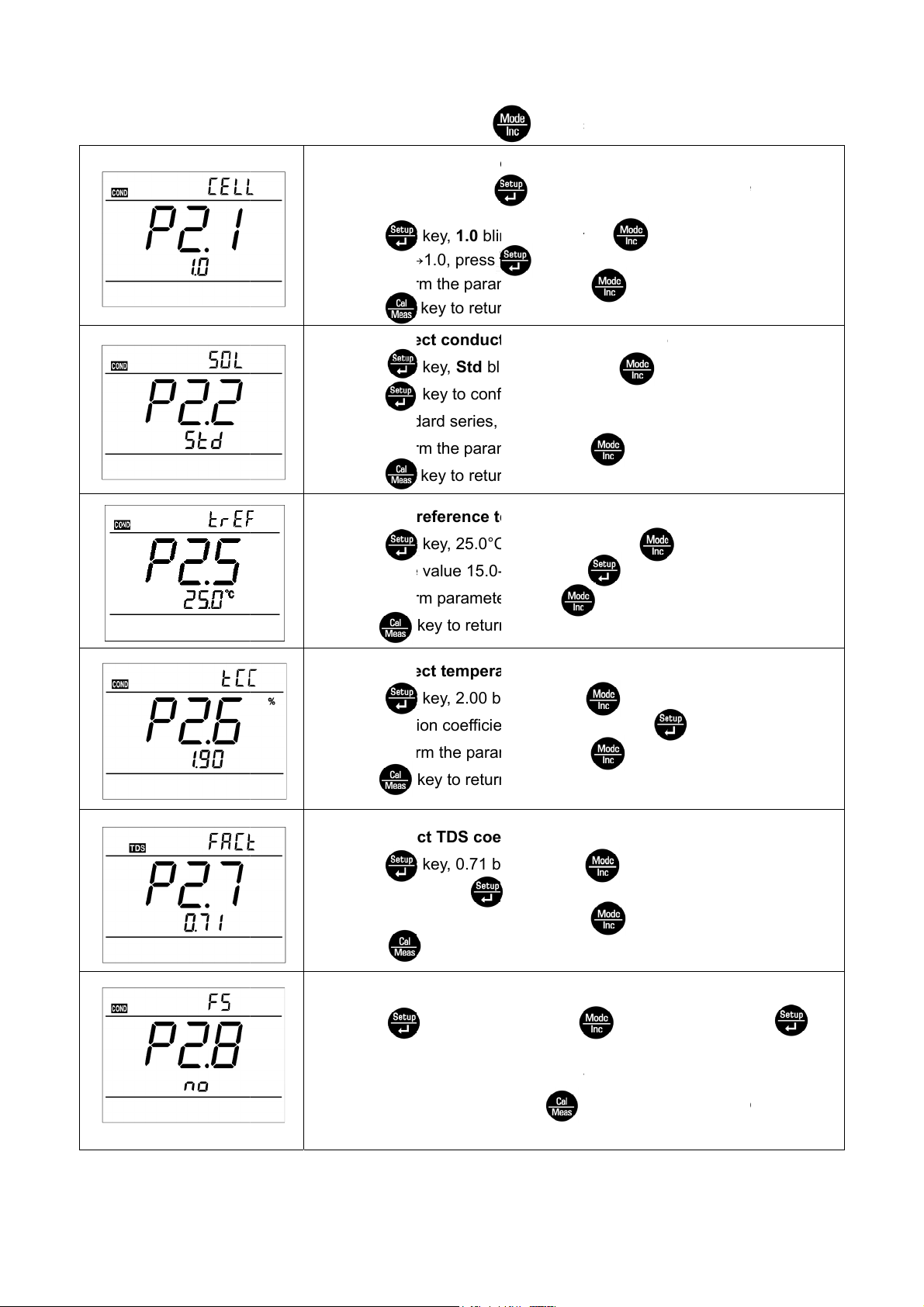

5.3. Cond

ctivity parameter set

1.

2.

3.

ing subme

P2.1 – Sel

In P2.0 m

the left Di

Press

10.0→0.1

After confi

press

nu (press

ct probe c

de, press

gram.

key, 1.0 bli

1.0, press

m the para

key to retu

key to

nstant (1.

key to

ks, then p

key to

eter, pres

n to the me

witch)

-10.0-0.1)

nter in P2.

ess ke

confirm.

key t

asurement

mode, pl

y to select

enter in P

ode.

ase refer t

.2 mode, o

P2.2 – Sel

1.

Press

Press

Std – Stan

2.

After confi

press

P2

5 – Select

1.

Press

emperatur

2.

After confi

press

P2.6 – Sel

1.

Press

compensat

2.

After confi

press

ct conduc

key, Std bl

key to con

ard series,

m the para

key to retu

reference t

key, 25.0°

value 15.0

m paramet

key to retur

ct temper

key, 2.00 b

ion coeffici

m the para

key to retur

ivity stand

inks, then p

irm.

CUS – cus

eter, pres

n to the me

mperatur

blinks, the

30.0, press

r, press

to the me

ture comp

links, press

nt 0.00 – 9.

eter, pres

to the me

ard soluti

ress k

omer-defin

key t

asurement

(15.0°C-3

n press

key t

key to en

surement

nsation c

key to

99, press

key t

surement

n (Standar

y to select

d solution

enter in P

ode.

.0°C)

key to sel

confirm.

er in P2.6

ode.

efficient (

select tem

key to c

enter in m

ode.

-CUS)

CUS→Sad

.5 mode, o

ct

ode, or

.00-9.99%)

erature

nfirm.

de P2.7 or

P2.7 –Sele

1.

Press

coefficien

After confi

2.

press

2.8 – Rest

1.

Press

to confirm

No – Do n

2.

If do not

ct TDS co

key, 0.71 b

, press

m the para

key to retu

re to fact

key, No bli

, the meter

t restore,

elect Yes,

fficient (0.

links, press

key to con

eter, pres

rn to the m

ry setting

ks, press

eturn to th

es – Resto

press

0~1.00)

key to

irm.

key t

asurement

No – Yes)

key, Ye

measurem

e to factory

ey to retu

select TDS

enter in m

mode.

blinks, pr

ent mode.

setting.

n to the m

de P2.8 or

ss ke

asuremen

mode.

12

Page 15

b P

t

o

O

d

g

m

m

m

e

u

r

n

u

n

p

m

n

e

s

m

f

e

a

s

m

O

o

e

5.4. Basic

parameter setting su

1.

2.

3.

1.

2.

menu

6.1. Selec

In P6.0 mo

he left Dia

Press

Press

When para

r press

P

6.8 – Auto

Press

Press

n – turn on

After confir

measurem

t temperat

e, press

ram.

key, °C blin

key to confi

eter is co

key to ret

atic powe

key, On bli

key to confi

automatic

the para

nt mode.

re unit (°C

key to e

ks, then pr

m.

firmed, pre

rn to the

-off setup

ks, press

rm.

ower-off, O

eter, press

—°F).

ter in P6.1

ss key

s key

easuremen

(On-Off)

key to s

f – turn off

key to

mode, plea

to select→℉

to enter in

t mode.

lect Off→

utomatic p

return to th

e refer to

℃

ode P6.8

n.

wer-off.

13

Page 16

6. Meter Kits

No. Include Quantity

6.1 C100 Handheld Cond. Meter 1

6.2 2301T-F plastic conductivity probe 1

6.3 AA Battery 3

6.4 Screw driver 1

6.5 Instruction Manual 1

6.6 Quick manual 1

14

Page 17

7. Warranty

7.1 For three years since the date of purchasing, under regular service condition, we warrant that the

instrument (probe is not included) will be repaired, replaced parts or product free of charge if the meter

doesn’t work well due to quality defects.

7.2 This warranty does not apply to defects resulting from incorrect usage, improper maintenance or

repair.

15

Page 18

Appendix I:

Parameter setting & Factory default setting

Modes Prompts Parameter setting items

P2.1 Select probe constant

Select conductivity

standard solution

Select reference

temperature

Adjust temperature

compensation

P2.0

Cond.

P2.2

P2.5

P2.6

coefficient

P2.7 Adjust TDS coefficient

Restore to factory

default setting

P6.0

P2.8

P6.1 Select temperature unit

Basic

Parameters

P6.8

Automatic Power-off

setup

Code and

Abbr.

Description

1.0-10.0-0.1

Std-CUS

Restore to

factory

default

1.0

Std

15~30 °C 25 °C

0.00~9.99 2.00

0.40~1.00 0.71

No-Yes

No

/ °C-°F -

On-Off -

16

Page 19

Appendix II: Code Symbol & Abbreviation Glossary

Modes Prompts

P2.1

P2.2

P2.5

P2.0

Conductivity

P2.6

P2.7

P2.8

P6.1

P6.0

Basic parameters

P6.8

Code and

abbreviation

/

In English Description

Cell Constant Cell

Calibration solution Calibration solution

Reference temperature Reference temperature

Temperature

compensation coefficient

Adjust TDS coefficient Adjust TDS coefficient

Factory default setting Factory default setting

/

Automatic Power-off Automatic Power-off

Standard Standard

Temperature

compensation coefficient

Others

Customer-defined Customer-defined

OFF OFF

ON ON

NO NO

YES YES

17

Page 20

18

Loading...

Loading...