Page 1

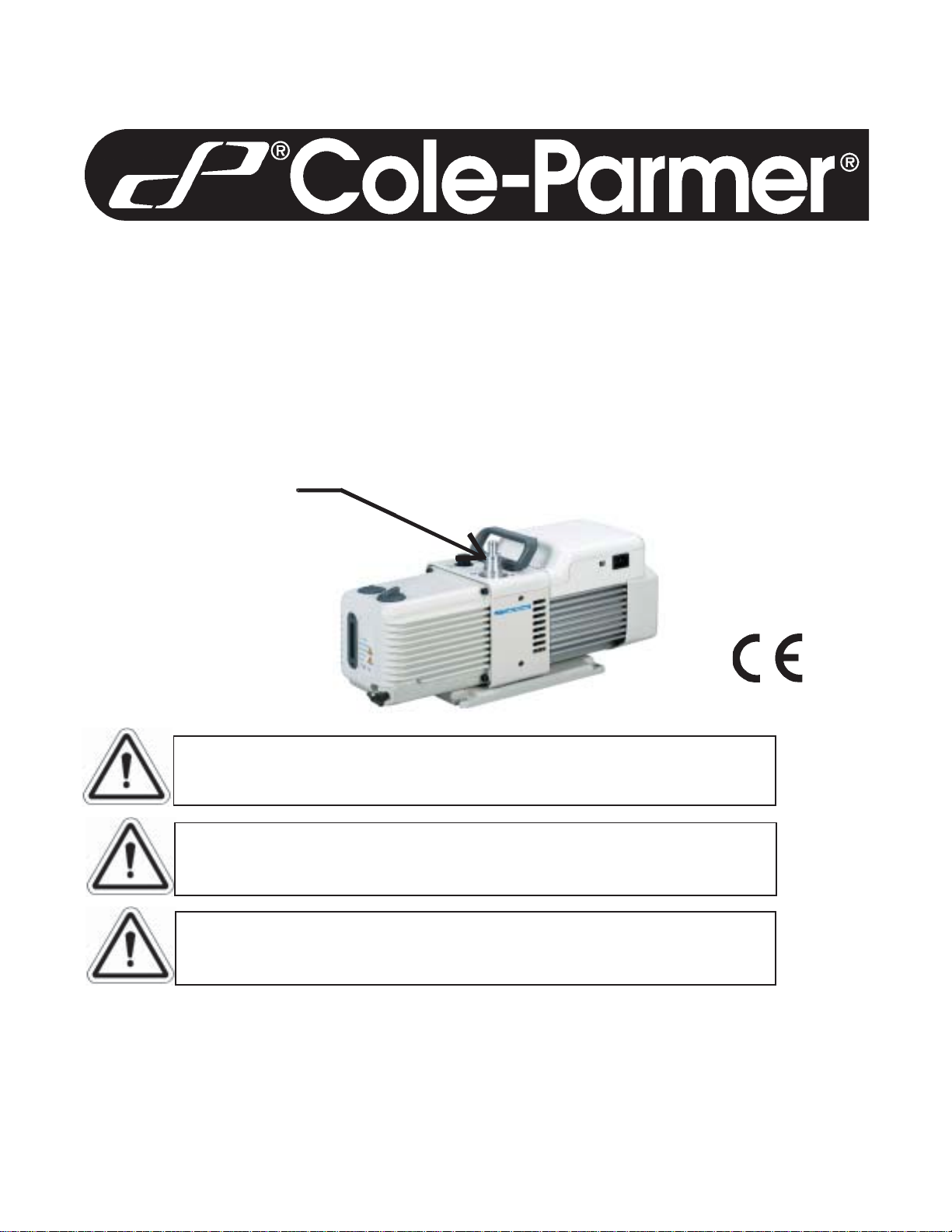

Laboratory Vacuum Pumps

Owner’s Manual

for Models:

79203-00/-05/-10/-20/-30/-40/-45/-50/-55

New and improved

inlet connection.

See Section 2.10

for details.

WARNING

Do not block the exhaust port. Pressure will build up with the

potential of the oil case bursting with possible injury to personnel.

WARNING

Pumps being run continuously above 1 torr should use an

exhaust oil recycler.

WARNING

Pumps not recommended for filtration, aspiration or drying

electrophoresis gels

Cole-Parmer Instrument Company

625 East Bunker Court

Vernon Hills, IL 60061-1844

Phone: 1-800-323-4340

Fax: 847-247-2929

E-Mail: info@coleparmer.com P/N 67-1383R2.3

Web-Page: www.coleparmer.com Printed in USA

Page 2

INSTRUCTION

WARNING AND CAUTION

PLEASE READ BEFORE OPERATION

While reading your manual, please pay close attention to areas labeled W ARNING AND CAUTIONS. The

description of each is found below .

WARNING

W arnings are given where failure to observe instruction

could result in injury or death to people

CAUTION

Cautions are found where failure to observe the instruction should

result in damage to the equipment, associated equipment and process.

These units conform to the SI International system of units of measurement.

The following symbols (with recommendations of IEC1010) of warning will be found on the pump.

Caution - refer to accompanying documents

Caution - risk of electrical shock

Caution - hot surf ace

WARNING

Motor includes a self reseting thermal cut-out and the pump could restart

without actuation under fault condition.

2

Page 3

CONTENTS

Section 1 - Installation

1.1 Unpacking

1.2 Pump Mounting

1.3 Pump Location

1.4 Exhaust Provisions

1.5 Electric Power

1.6 V acuum Connections

1.7 V acuum Gauges

1.8 V acuum Pump Oil

Section 2 - Pump Features & Principles of Operation

2.1 General Description

2.2 Principles of V acuum Pump Operation

2.3 Effects of Continued Pressure Reduction

2.4 Ultimate Pressure

2.5 Pump Mechanism Description

2.6 Intake Anti-suckback Isolation Valve

2.7 Pump Lubrication

2.8 Exhaust Filter

2.9 Gas Ballast V alve

2.10 Unibarb Intake Fitting

Section 3 - Specifications

Pump Specifications Chart

Section 4 - Motor Power Specifications/Features

Motor Specifications Chart

4.1 General Information

4.2 Changing the voltage setting

4.3 Choosing electrical powercord

4.4 Other electrical configurations

4.5 Explosion Proof Pumps

Section 5 - Operation

5.1 Starting Procedure

5.2 High Pressure Operation

5.3 Shutdown Procedures

3

Page 4

Section 6 - Maintenance

6.1 Vacuum Problems

6.2 Oil Change

6.3 Developing a Maintenance Schedule

6.4 Forced Oil Flushing

6.5 Lip Seal/Gasket Change

Section 7 - T roubleshooting

7.1 Leak Detection

7.2 Troubleshooting Guide

Section 8 - Repair Kits

8.1 Shaft Seal Replacement

8.2 Minor Repair Kits

8.3 Major Factory Repair

Section 9 - Accessories

9.1 General

9.2 Pump Oil

9.3 Exhaust Filters

9.4 Traps

9.5 V acuum Gauge

Section 10 - Dimentional Drawings/Speed Curves

10.1 Pumping Speed Curves

10.2 Dimensional Drawings

10.3 Exploded Diagrams and Parts Lists

79203-00 / -05: Part List, Pump Model, Pump Module, Oil Case

79203-10: Part List, Pump Model, Pump Module, Oil Case

79203-20: Part List, Pump Model, Pump Module, Oil Case

79203-30: Part List, Pump Model, Pump Module, Oil Case

79203-40 / -45: Part List, Pump Model, Pump Module, Oil Case

79203-50 / -55: Part List, Pump Model, Pump Module, Oil Case

Section 11 - Warranty

MSDS - 79201-74 - Vacuum Pump Oil

4

Page 5

Section 1: INSTALLATION

1.1 Unpacking

Carefully remove the pump from the shipping carton. Keep all paperwork and inspection tags for future reference.

If shipping damage has occurred, a claim must be filed with the carrier immediately; keep the shipping container for

inspection by the carrier.

1.2 Pump Mounting

Rubber bumpers are supplied with the pump base. They isolate noise and eliminate creeping. For more rigid

mounting requirements the pump base can be bolted directly to a surface by removing the bumpers from the base and

using the mounting holes and slots featured on the base.

1.3 Pump Location

The pump should be located in a clean and well-ventilated area and adequate space should be provided wherever

possible for routine maintenance such as oil changes. For best performance, the pump should be located as closely as

possible to its system. Determining factors for pump location should include length and size of connections, the

number of bends, and the type of exhaust connections.

1.4 Exhaust Provisions

Exhaust connections will be determined by the type of system to be exhausted and the desired cleanliness of the air

surrounding the pump. Under normal pumping conditions the optional exhaust filter will be adequate. Refer to

Section 9, Accessories for available exhaust filters. Where extreme exhaust conditions are encountered, it is best to

pipe the exhaust out of the building. Always use thick walled rubber vacuum hose, wire reinforced PVC tubing or

metal pipe for exhaust lines to avoid the possibility of the line becoming crimped or collapsing resulting in dangerous

exhaust line blockage.

The pumps’ exhaust connection is a 1”-20 threaded port for Models 79203-10, 79203-20 and 79203-30. The port is

located opposite the inlet port on top of the oil reservoir. The models 79203-10 and 79203-20 will accept Model 1417P

Exhaust Filter. Model 79203-30 accepts Model 1417P-7 Exhaust Filter. If a hose nipple is preferred for the exhaust

port, use part number 1393K for models 79203-10, 79203-20 and 79203-30. Call Cole-Parmer customer support

1-800-323-4340, prior to start-up if you have any questions.

WARNING

Never block or impede air flow from the exhaust port. High pressure

can build up within the oil reservoir if the exhaust port is blocked.

Check frequently , especially if exhaust is piped out of the building.

1.5 Electric Power

The voltage setting is perminantly displayed in a small window on the pump motor electrical box. The window is

located next to the power cord connection.

CAUTION

Make certain the power settings on the pump match your power

source before attempting to operate the pump. (Additional

information can be found in section 4: Motor Power).

5

Page 6

1.6 V acuum Connections

"

The pump inlet is equipped with a Unibarb, see table below . The inlet is located next to the pump handle. It contains

a screen to collect any debris from getting into the pump. An extensive line of vacuum pump hoses, traps, etc. is

available from Cole-Parmer to meet the requirements of most vacuum systems. For the best vacuum, use a hose

clamp in conjunction with a vacuum hose to hose nipple connections. Cole-Parmer offers a number of different types

of vacuum tubing and connectors.

See Section 9 - Accessories or call Cole-Parmer customer support 1-800-323-4340.

ledoMpmuP50-/00-3029701-3029702-3029703-3029754-/04-3029755-/05-30297

eziSbrabinU "61/7&"61/3"61/31&"61/7"61/31&"61/7"61/31&"61/7"61/31&"61/9

61/31&"61/9

The choice of connections and fittings can have a very marked effect on the pumping speed at the vacuum chamber .

Any connection placed between the pump and the chamber creates an impedance to the flow of gas. This is

particularly true at low pressures in the millitorr range where the gas flow is substantially molecular in character. The

gas flow is then dependent upon the kinetic activity of the molecules to bring it to the pump intake. This impedance

is described by the term “conductance”.

The conductance of a tube is proportional to the cube of its diameter and inversely proportional to its length. Therefore, connecting lines should be as large in diameter and as short in length as practical. For best results the diameter

of the connecting tube should be at least as large as the diameter of the pump intake. To avoid a large reduction in

pumping speed at the vacuum chamber, the conductance of the line must be considerably greater than the speed of

the pump. Sharp bends in vacuum lines also contribute to conductance. To avoid reductions in pumping speed,

minimize the number of 90º angles in the vacuum system.

1.7 Vacuum Gauges

The type of vacuum gauge to be used in a system is determined largely by the pressure range to be measured. A

thermocouple or pirani gauge is recommended for measuring pressures in the range produced by these pumps. See

W ebsite or call for additional information.

1.8 V acuum Pump Oil

WARNING

The vacuum pump is shipped without oil inside to prevent possible

spillage during shipment. Oil must be added prior to use.

Use only Cole-Parmer V acuum Pump Oil Part No. 79201-74

Filling with Fresh Oil

Be sure the pump is filled with oil to the level indicated on the oil fill window . When additional oil is required, use only

Vacuum Pump Oil Part No. 79201-74; pump performance is not guaranteed with other brands of oil. Do not overfill

the pump, and be sure to replace the oil fill plug. Remove the oil fill plug located on the top of the oil case and add the

oil supplied in a bottle packaged with each pump. To ensure efficient operation and proper maintenance, and to

minimize noise and oil vapors, it is important to use the correct type and quantity of Cole-Parmer Vacuum Pump Oil

Part No. 79201-74 has been especially developed to have the proper viscosity, low vapor pressure, and chemical

stability needed to produce peak pumping efficiency . A sufficient amount of vacuum pump oil, enough for one fill, is

shipped with every pump.

Do not use oils designated Grade 18, 19 or 20.

Remove the fill plug located on the top of the oil case and add pump oil. It is best to check the oil window located on

the front of the oil case for oil level when the pump is running. Do not over fill the pump, and be sure to replace the oil

fill plug.

.

6

Page 7

WARNING

Operating temperature of the oil is hot and can cause burns.

Avoid skin contact with the oil.

The fill plug has a raised middle section and a center slot for easy turning either by hand or with a screwdriver .

After the pump has been running for at least 15 minutes, check the oil level again. The oil level should be maintained

at the “full” mark on the oil level window while the pump is operating. Do not overfill; excess oil tends to be splashed

out the pump exhaust.

Guidelines for the frequency of oil changes and the oil changing procedure

can be found in Section 6-2: Oil Change.

1.9 Pumping Condesable V apors

Liquids can collect in a vacuum pump by being ingested or sucked directly into the pump, or by its vapors condensing

in the pump.

Never allow this pump to ingest liquids directly into the pump. If this should occur, drain the oil, replace with a fresh

supply and prevent a reoccurence.

To prevent condensable vapors from condensing in the vacuum pump, several measures should be taken. Thes

include:

1) Use of the Gas Ballast: It is located at the top of the pump next to the inlet. Turning the gray cap

clockwise opens the valve, letting a small amount of air into the pump.

2) Control of pressure in the system. Not all vacuum system need to, or should be, operated at the

lowest pressure possible for the pump.

WARNING

Cole-Parmer V acuum Pumps should not be operated above 1 T orr

(10mm Hg) for extended periods of time, while unattended.

DO NOT use the pumps for FILTRATION or ASPIRATION.

3) Trap condensable vapors in a cold trap. IF the pressure of the system must be set at or near the

ultimate pressure of the pump (ruling out the use of the gas ballast), or if the vapor load is high,

use of a cold trap is recommended. There are dry ice traps (-75º C), liquid nitrogen traps (-100º C)

and refrigerated traps (-25º C to -80º C). See Section 9, Accessories.

7

Page 8

Section 2: PUMP FEATURES AND PRINCIPLES OF OPERATION

2.1 General Description

The Cole-Parmer Vacuum Pumps are two-stage, rotary-vane, oil sealed vacuum pumps. The three Cole-Parmer

models 79203-10, 79203-20 and 79203-30 offer a range of free air displacements (FAD) from 70 L/min (2.6 CFM)

to 173 L/min (6.1 CFM) at 60 Hz and from 58 L/mm to 141 L/min (8.4 m

79203-10, 79203-20 and 79203-30 Cole-Parmer models is 1 x 10-4 torr.

Cole-Parmer vacuum pumps offer a number of features that improve performance, or protect the pump or vacuum

system under specific operating conditions. Some of these features are a gas ballast, an intake anti-suck-back

isolation valve (or solenoid), and airflow cooling.

The pumps also offer features to enhance the flexibility of the pump and make it easier to use and maintain. These

include an easy pour oil drain, and auxiliary vacuum port to power accessories.

2.2 Principles of V acuum Pump Operation

The main purpose of a vacuum pump is to reduce the pressure in a vessel or a closed system. The degree of pressure

reduction is dependent upon the requirements of the application and the type of vacuum pump employed.

A quantity of gas is removed from the system with each cycle of the pump. Therefore, the pressure of the gas

remaining in the system is reduced with each pump cycle. Since the pump can remove only a small portion of the gas

with each pump cycle, this method of evacuation can never completely remove all gas in the vessel. Also, all components of the system contain minute sources of gas leakage wich are impossible to seal completely against atmospheric

pressure. Out gassing of material within the system provides additional sources of gas.

3hr-1

) at 50 Hz. The ultimate vacuum of

As a result, after prolonged pumping, a state of equlibrium is reached in wich the gas introduced from all of the

leakage sources is balanced by the ability of the pump to remove gas from the system. This state of equlibrium is

referred to as the ultimate pressure or blankoff pressure of the pump and its system.

2.3 Effects of Continued Pressure Reduction

The quantity of gas in the vessel is reduced with each evacuation cycle. The gas remaining in the vessel expands to

fill the vessel and consequently with each cycle the pressure in the vessel is reduced. This is a manifestation of

Boyle’s Law which states that, for a constant temperature, the volume of a body of gas is inversely proportional to its

pressure; i.e., if the volume is enlarged the pressure must be reduced.

As the amount of gas in the vessel is steadily diminished, its pressure is correspondingly reduced. The action of the

pump must therefore compress a successively smaller quantity of gas with each cycle to something greater than

atmospheric pressure in order to expel it from the pump.

At the beginning of an evacuation sequence, the compression ratio is very small. In the first cycle of operation the

pump draws in a volume of gas at atmospheric pressure and expels it at approximately atmospheric pressure. In

contrast, near its ultimate pressure, a pump draws in gas at (for example) 30 millitorr and must compress it to more

than 760,000 millitorr (atmospheric pressure) in order to expel it from the pump. Since the exhaust valve is generally

spring loaded to provide a good seal, the pressure required to open it is somewhat greater than atmospheric pressure.

Therefore, at an ultimate pressure of 1.3 X 10-4 mbar 0.1 millitorr, (1 x 10-4 T orr) the compression ratio performed by

the pump is greater than 1,000,000 to 1.

8

Page 9

2.4 Ultimate Pressure.

As described previously , a quantity of gas is removed from the system with each cycle of the pump. Therefore, the

pressure of the gas remaining in the system is reduced with each pump cycle. Since the pump can remove only a

small portion of the gas with each pump cycle, it is obvious that this method of evacuation can never completely

remove all the gas in the vessel. In addition to this, all the components of the system contain minute sources of gas

leakage which are impossible to seal completely against atmospheric pressure. Outgassing of materials within the

system provide additional sources of gas.

As a result, after prolonged pumping, a state of equilibrium is reached in which the gas introduced from all the leakage

sources is balanced by the ability of the pump to remove gas from the system. This state of equilibrium is referred to

as the ultimate pressure or blankoff pressure of the pump and its system. No matter how much additional pumping

time is provided, no further reduction in system pressure will be accomplished once ultimate pressure is attained.

2.5 Pump Mechanism Description

The Cole-Parmer Vacuum Pumps incorporate two in-line rotary-vane stages with interconnecting ports. In operation,

the intake stage is at a lower pressure and the exhaust stage is at a higher pressure relative to each other. Each stage

contains a rotor assembly consisting of a rotor with two vanes and a stator. The pumps shaft turn the rotors, causing

the vanes in each section to sweep the surface of their stators. The vanes are pressed against the stators by centrifugal force and/or springs.

2.6 Intake Antisuckback Isolation V alve.

When power to the pump is turned off, this valve closes automatically, maintaining vacuum in the system being

evacuated, and vents the inside of the pump to atmospheric pressure. The solenoid is wired to the pump’s on-off

switch. When the pump is turned on, the solenoid plunger opens the valve to allow gas to flow into the pump intake.

2.7 Pump Lubrication.

T o ensure efficient operation and proper maintenance, and to minimize noise and oil vapors, it is important to use the

correct type and quantity of oil. Cole-Parmer Vacuum Pump Oil Part No.79201-74 has been especially developed to

have the proper viscosity , low vapor pressure, and chemical stability needed to produce peak pumping efficiency . The

ultimate vacuum guarantee on Cole-Parmer pumps applies only when this oil is used. Therefore, Cole-Parmer

Vacuum Pump Oil Part No.79201-74 is the only oil recommended for use with these pumps. Each pump is supplied

with a bottle of oil sufficient for filling. Additional oil is available. See Section 9: Accessories.

In Models 79203-10 and 79203-20, oil is fed into the pumping chamber by the differential pressures created by the

rotation of the pump. Oil metered into the pump through a narrow opening is sufficient to lubricate and seal the

moving parts, permitting the pumping of gas a relatively low pressure levels. Model 79203-30 uses a positive placement lubrication system which actively forces lubricating oil onto pumping surfaces.

2.8 Exhaust Filter .

Any oil-sealed vacuum pump tends to discharge oil mist from its exhaust port when the pump operates under highflow conditions, such as when the pump’s intake is at or near atmospheric pressure. T ypically , oil mist in the form of

a white puff of “smoke” can be seen from the exhaust port when no filter is used. Once the vacuum level and the

corresponding air flow through the pump are reduced, very little, if any , oil mist will be emitted.

An optional exhaust filter is recommended for any vacuum pump installation where the pump operates at high intake

pressures for a prolonged period of time. Oil droplets entrained in the pump’s exhaust are removed by the exhaust

filter element. Use of an exhaust filter typically reduces or baffles pump noise as well. Exhaust filters are sometimes referred to as Oil Mist Eliminators. See Section 9 - Accessories.

9

Page 10

2.9 Gas Ballast Valve.

"

The Cole-Parmer Vacuum Pumps have a gas ballast valve that can increase the pump’s water vapor tolerance.

(The gas ballast valve is sometimes referred to as a vented exhaust valve.) In many vacuum pump applications the

gases being pumped from a system are a combination of permanent gases and undesirable vapors such as water

vapor. Under some conditions, the vapors condense in the second stage of the pump and contaminate the oil. The

gas ballast valve reduces oil contamination by decreasing or eliminating vapor condensation.

Vapor condensation is most likely to take place when the gas compression ratio is high, i.e. when the pump compresses a relatively large volume of gas to a small volume. Whether or not condensation takes place is dependent

upon several factors, including the proportion of permanent gases to vapors at the pump intake. If the gases being

pumped consist entirely of vapors, condensation will definitely occur unless the gas ballast valve is opened. The gas

ballast valve adds a small amount of air at atmospheric pressure to the gas being compressed in the second stage.

This reduces the compression required to push the gas out past the exhaust valve (less reduction in volume is

required), and therefore reduces or eliminates condensation.

When the gas ballast valve is open, the pump has to work a little harder, resulting in a slight increase in operating

temperature. The increase in temperature is small, however, and is not harmful to the pump. Also, the pump is

slightly noisier, and the pump’s ultimate pressure is somewhat reduced. Therefore, the gas ballast valve should be

kept closed when it is not needed. Note that the gas ballast is not equally effective on all vapors, so it does not always

eliminate condensation completely.

2.10 UnibarbTM Intake Fitting - Simplifies Small Hose Connections

The Unibarb intake fitting allows the user to be able to use a wide range of ID hose to connect to the system. The

choice of hose size can have a very marked difference on pumping speed. It is the best to have the largest

connection I.D.(internal diameters) as possible. However, we recognize many lab appliances use hose barbs

accepting small I.D. hose.

ledoMpmuP50-/00-3029701-3029702-3029703-3029754-/04-3029755-/05-30297

eziSbrabinU "61/7&"61/3"61/31&"61/7"61/31&"61/7"61/31&"61/7"61/31&"61/9

61/31&"61/9

The conductance of a tube is proportional to the cube of its diameter and inversely proportional to its length.

Therefore, connecting line should be as large in diameter and short in length as practical.

Included is a free hose clamp to hold the hose in place.

10

Page 11

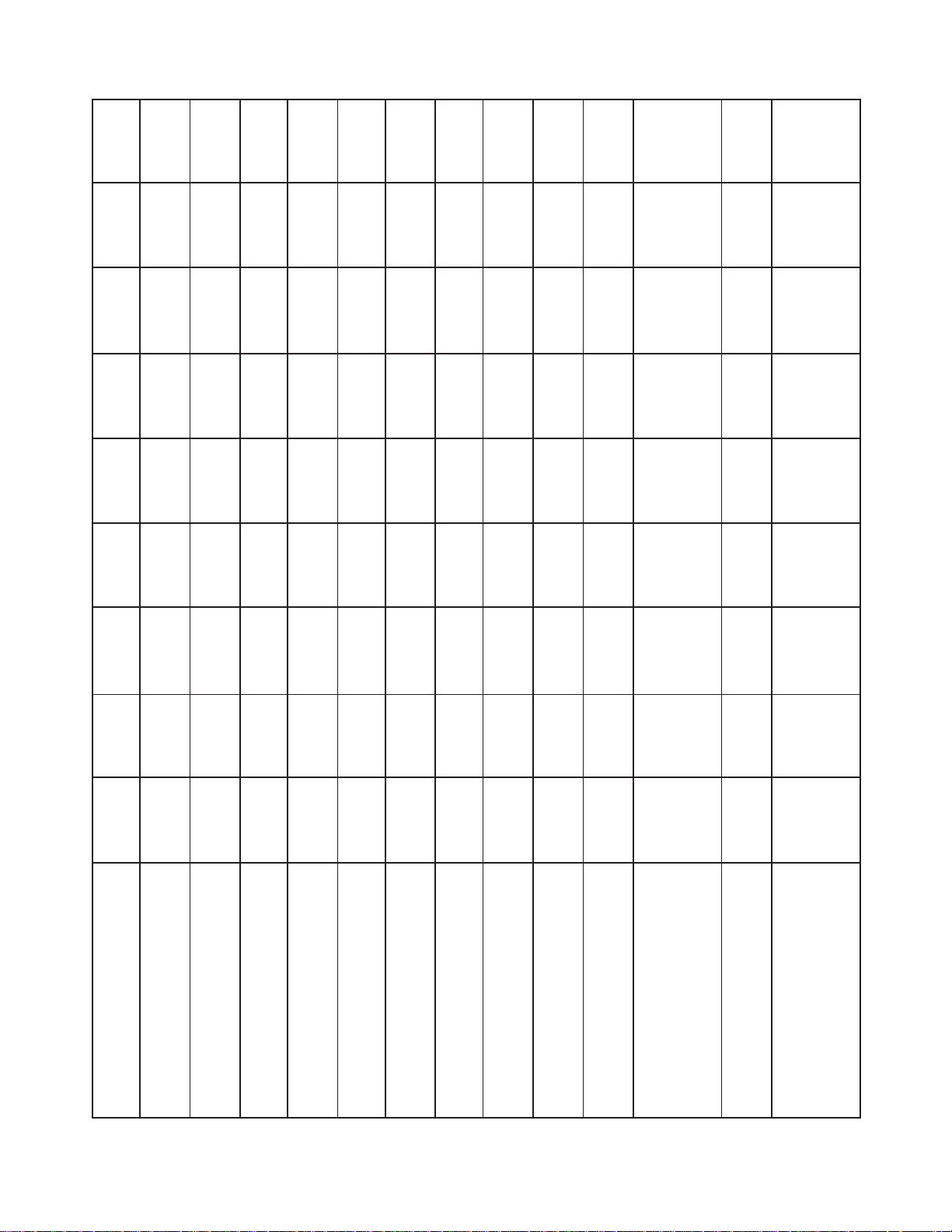

Section 3: PUMP SPECIFICATION

)2.72(7.01

)8.35(2.12

)

4-

4-

01x5(

01x4

)

4-

4-

01x5(

01x4

)

4-

4-

01x4(

01x3

)

4-

4-

01x4(

01x3

)

4-

4-

01x3.1(

01x1

)

4-

4-

01x3.1(

01x1

5241

5271

5241

5271

5241

5271

zH06/V511zH05/V032zH06/V511zH05/V032

5241

5271

zH06/V511

zH05/V032

5241

5271

zH06/V511

zH05/V032

5241

5271

&"61/9

&"61/9

&"61/9

&"61/9

&"61/7

&"61/7

dedaerhT

"61/31

"61/31

"61/31

"61/31

"61/31

"61/31

02-"1

dedaerhT

02-"1

dedaerhT

02-"1

dedaerhT

02-"1

dedaerhT

02-"1

dedaerhT

02-"1

)3.13(

96

)3.13(

96

)6.62(

5.85

)6.62(

5.85

)22(

84

)81(

04

)9.71(1.7

)6.43(

77

)2.72(7.01

)8.35(2.12

)9.71(1.7

)6.43(

77

)2.72(7.01

)1.25(5.02

)9.71(1.7

)8.03(

86

)2.72(7.01

)1.25(5.02

)9.71(1.7

)8.03(

86

)5.61(5.6

)3.42(6.9

)94(3.91

)1.74(5.81

)5.61(5.6

)3.42(6.9

)42(

35

)12(

74

)4.93(5.51

)2.92(5.11

)7.37(92

)4.93(5.51

)2.92(5.11

)7.37(92

)4.93(5.51

)2.92(5.11

)7.37(92

)4.93(5.51

)2.92(5.11

)7.37(92

)8.52(7.01

)53(6.31

)47(9.82

)8.52(7.01

)53(6.31

)47(9.82

zH06/V511

)

4-

4-

01x3.1(

01x1

)

3-

3-

01x6.2(

01x2

)

)15(8.1)34(5.1)07(6.2)801(8.3)371(1.6)812(7.7)181(4.6)023(3.11)362(3.9

3-

3-

01x6.2(

01x2

5241

0382

-

zH05@mprdeepSpmuP/rotoM

5271

-

0543

zH06@mprdeepSpmuP/rotoM

zH05/V032

&"61/7

&"61/3

&"61/3

dedaerhT

"61/31

"61/7

"61/7

02-"1

04

dedaerhT

02-"4/3

5.42

dedaerhT

02-"4/3

5.42

)1.74(5.81

)5.61(5.6

)3.42(6.9

)81(

)9.53(1.41

)3.12(4.8

)1.11(

)1.11(

)31(1.5

)9.53(1.41

)3.12(4.8

)31(1.5

)12(

64

)8.11(

62

)8.11(

62

)8.52(7.01

)53(6.31

)47(9.82

)6.82(2.11

)5.61(5.6

)3.35(12

)6.82(2.11

)5.61(5.6

)3.35(12

snoisnemiDnotraCgnippihS

tnemecalpsiDriAeerF

nierusserPetamitlU

ABdleveLdnuoS252505050545455555

)nim/L(MFC

)rabm(

LEDOM00-3029750-3029701-3029702-3029703-3029704-3029754-3029705-3029755-30297

1-

rroT

rewopesroHrotoM4/14/12/12/12/12/12/14/34/3

sretiLyticapaCliO04.004.058.058.077.002.102.101.101.1

lacirtcelEzH06/V511zH05/V032

noitcennoCbrabinU

noitcennoCtsuahxE

.sblthgieW

snoisnemiDllarevO

)mc(ni:htgneL

)mc(ni:htgieH

)mc(ni:htdiW

).gK(

).gK(

.sblthgieWgnippihS

)mc(ni:htgneL

)mc(ni:htgieH

)mc(ni:htdiW

11

Page 12

Section 4: ELECTRICAL POWER SETTINGS

n

ledoM00-3029750-3029701-3029702-3029703-3029704-3029754-3029705-3029755-30297

rewopesroH4/14/12/12/12/12/12/14/34/3

lacirtcelE

noisrevnoC-

egatloV-

selcyC-

A/N

A/N

VL

zH05@MPR

-

zH06@MPR

VH

zH06

zH05

0382

0543

-

noisrevnoCelpmiS

**neewteb

VH&VL

zH06&zH05

5241

5271

noisrevnoCelpmiS

**neewteb

VH&VL

zH06&zH05

5241

5271

noisrevnoCelpmiS

**neewteb

VH&VL

zH06&zH05

5241

5271

noisrevnoCelpmiS

**neewteb

VH&VL

zH06&zH05

5241

5271

noisrevnoCelpmiS

**neewteb

VH&VL

zH06&zH05

5241

5271

noisrevnoCelpmiS

**neewteb

VH&VL

zH06&zH05

5241

5271

oisrevnoCelpmiS

**neewteb

VH&VL

zH06&zH05

5241

5271

* See Section 4.1 General for details on the “global motor”.

** See Section 4.2 Changing the Voltage setting to see simple conversion between: LV and HV.

4.1 General

Models 79203-10, 79203-20, 79203-30, 79203-40, 79203-45, 79203-50 and 79203-55 include “global motors” to allow

use with most electrical power systems around the world. The pumps may be set for low voltage (LV) allowing use

in power systems within the voltage range, 100 to 120 volts and frequencies of 60 Hz or 50 Hz. They may also be set

for high voltage (HV) allowing use in power systems within the voltage range 200 to 230 volts and frequencies

of 60 Hz or 50 Hz.

CAUTION

Make certain that the voltage setting (L V or HV) is in the correct range

for your power before plugging in.

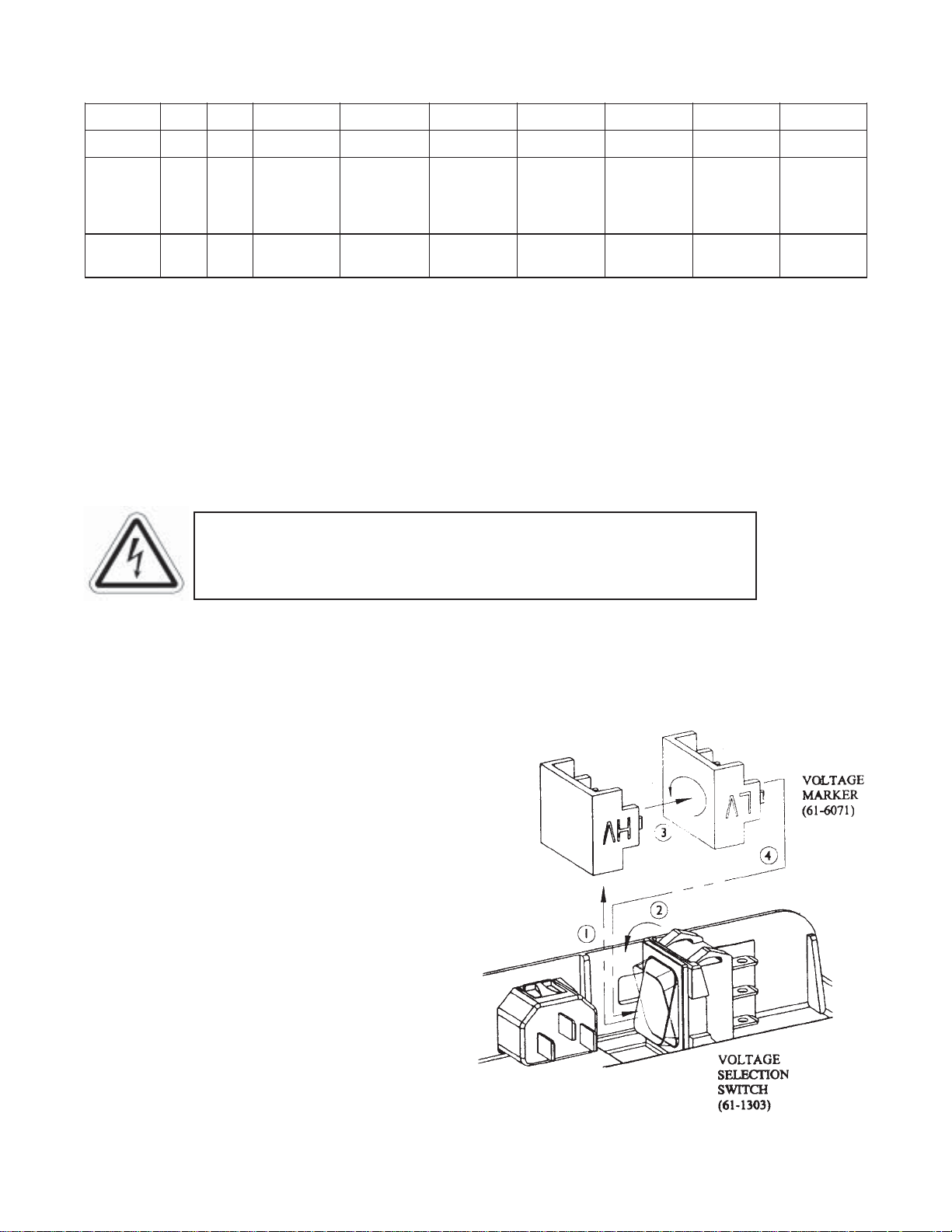

4.2 Changing the V oltage Setting

The voltage setting is permanently displayed in a small window on the pump motor electrical box. The window is

located next to the power cord connection and displays either LV for 100-120V or HV for 200-230V.

To change VOLTAGE setting:

1. Disconnect the electrical power cord.

2. Open the motor electrical box by removing the

four screws and removing the cover.

3. Locate the voltage selection switch next

to the external electrical power cord connector.

4. Remove the voltage marker (61-6071).

The switch is very tightly installed.

T o remove, place index and middle

finger along the top edge and pull backwards.

5. Change the voltage selection switch (61-1303)

to the opposite position.

6. Rotate the voltage marker, 180° and insert

into previous location. The voltage marker

is keyed to the switch setting so that it

can only display the correct setting. The

selected voltage setting can been seen through

the window in the electrical box.

7. Replace the electrical box cover

before reconnection the power cord.

Figure 4.1

12

Page 13

4.3 Choosing Electrical Power Cords

A universal electrical power connector is provided on the Models 79203-10, 79203-20, 79203-30, 79203-40,

79203-45,79203-50 and 79203-55 on the motor electrical box. T o change to a dif ferent wall plug simply choose the

appropriate power cable from the list included below . All include a universal connector on the pump.

CAUTION:

When changing Power cords, always make certain that the motor voltage

setting (L V or HV) is in the right range for the electrical power .

4.4 Other Electrical Configurations

Other electrical configurations of Cole-Parmer pumps may be available. Check with Cole-Parmer for 3-Phase,

explosion-proof and other motor configurations.

-

13

Page 14

Section 5: OPERATION

5.1 Starting Procedur e.

Before using the pump for the first time, it is a good idea to spend a few minutes inspecting the pump and its electrical

and vacuum connections. Review Section 1: Installation as required.

Check the AC power outlet to be sure that it is the same voltage and phase as the pump motor. Connect the power

cord to the power outlet and recheck the oil level.

Close off the pump intake and the gas ballast valve, and run the pump at blankoff for a few minutes. The gurgling

noise should go away after a few minutes of running; it is caused by the high volume of air that flows through the

pump when the pump is first turned on. If the gurgling noise does not stop, check the oil level to see if it is low , and

check the pump intake fitting to be sure that it is tight. Once proper pump operation has been verified, the pump intake

can be opened to the vacuum system.

After running the pump for a few minutes, check the oil level again. If the level is too high or too low, stop the pump

and add or remove oil as needed. Stop the pump and vent it to the atmosphere before adjusting the pump fluid level.

Before starting the pump when connection to the vacuum system, check all vacuum connections.

5.2 High Pressure Operation

The Cole-Parmer Vacuum Pumps are designed to be most efficient when operated at or near their ultimate blankoff

pressure. When operated at elevated pressures for long periods of time, the pump will run hotter . Additional cooling

may be required for both the pump and the motor. At elevated ambient temperatures under these conditions, the

thermal protection switch may cut out. The oil may tend to thin out at these temperatures, losing its ability to lubricate

effectively.

During operation at these pressures, oil mist may be generated at the exhaust port. The mist has the appearance of

a small cloud of smoke. Use of an Exhaust Filter with coalescing element is required. An exhaust filter with an oil

drain back feature is highly recommended. See Section 9: Accessories.

NOTE: If operating this pump for prolonged periods of time at or above 10 Torr,

contact the Cole-Parmer Vacuum Technical Service Department 1-800-323-4340

for further information and precautions.

5.3 Shutdown Procedures.

A few simple precautions are necessary before performing a pump shutdown. If a gauge is connected to the system,

first isolate the gauge, then turn off the power to the pump and open the system to the atmosphere.

NOTE: The intake isolation valve will automatically close when power to the pump

is turned off. This will maintain vacuum in the system (if the pump remains

connected to the rest of the system) and will vent the pump to atmosphere.

If the pump is disconnected from the system for any length of time, cover the pump intake with a rubber stopper or

other suitable cover to protect the pump against contamination. An intake screen is furnished to prevent loose

particles from entering.

If the exhaust port is open, that should also be covered. If the pump oil is contaminated and the pump is going to be

stored for a prolonged period, the oil should be changed before the pump is stored. Even if a pump is stored for a long

period with oil initially in good condition, check the oil when the pump is restarted, and change the oil if necessary .

14

Page 15

Section 6: MAINTENANCE

6.1 V acuum Problems.

Inability to attain sufficient vacuum in a system is usually due to leakage, contamination, or unusual outgassing. A

system must be thoroughly clean and free from leaks to operate efficiently. If the system is found to be clean and

leak-free, but vacuum problems still exist, the pump should be checked. A simple way to test the pump is to measure

its ultimate pressure capability. This can be done by disconnecting the pump from the rest of the system and

connecting a pressure gauge directly to the pump intake. (Be sure to seal the pump intake from the atmosphere, and

be sure the gas ballast valve is closed.) The gauge can be any type that is suitable for the pressure levels expected.

Run the pump until the gauge indicates no further reduction in pressure, and compare the pressure reading to the

pump’s ultimate pressure rating.

If the pump meets its ultimate pressure specifications only when disconnected from the rest of the system, the fault

must be elsewhere in the system. If the pump’s ultimate pressure is unusually high, the pump may be badly contaminated, low on oil, or mechanically defective. However, if the pressure is only slightly higher than the pump’ s guaranteed pressure, an oil change may be all that is needed to bring performance up to specifications. Be sure to use only

Cole-Parmer Vacuum Pump Oil Part No. 79201-74 in Cole-Parmer V acuum Pumps; the ultimate pressure guarantee

does not apply if other types of oil are used.

The most common cause of efficiency loss in a vacuum pump is contamination of the oil, which is usually caused by

foreign particles and/or condensed vapors. The condensate emulsifies with the oil, and when the oil is recirculated,

the condensate evaporates. The resulting vapor then reduces the ultimate vacuum attainable in the system.

Some foreign particles and vapors form sludges with the oil. The presence of sludge in the oil impairs its sealing and

lubricating properties, and eventually could cause pump seizure. Therefore, periodic oil changes are necessary to

maintain efficient operation of the system. The interval at which oil changes are required is different for each set of

operating conditions; experience will help you determine the proper interval for your system and process.

6.2 Oil Change

The best time to change the oil is when the pump is warm and the oil is less viscous. Before attempting an oil change,

the pump must be disconnected from the power outlet.

WARNING

The drain oil is hot and can cause burns.

Operating temperature of the oil is typically 140 degrees

Fahrenheit or higher . A void skin contact with the oil.

Changing the Oil

T o drain old oil, rotate the drain valve counter-clockwise until the handle will no longer turn. A 6-12 in. length of 3/8”

I.D. tubing can be fitted on the oil drain nipple to direct the flow of oil neatly into a bottle or other container. When the

old oil has been removed, close the drain valve by rotating it clockwise ¼ turn until the handle will no longer turn.

Frequency of Oil Changes

The oil change interval is completely dependent upon the running conditions of temperature, operating pressure, hours

of daily operation, and upon the materials pumped. Clean, dry air at pressures below 50 torr are the most forgiving

conditions. T o determine your own oil change interval, visually monitor the pump oil conditions at regular intervals. If

you suspect harsh operating conditions, daily visual checks are recommended. When the oil becomes cloudy , dark or

includes particles of solids, it is time to change the oil.

Oil may be visually checked through the oil level window . However , a much better check is to use the drain to draw

15

Page 16

out 20-50 ml into a small glass beaker and view the oil with a light behind it. Clean oil can be returned to the pump

through the oil fill port.

When filling the pump with oil, be sure to use only Cole-Parmer Vacuum Pump Oil Part No. 79201-74

The ultimate pressure guarantee applies only if this oil is used.

6.3 Developing A Maintenance Schedule

Periodic inspection should be performed to monitor for any color change to the oil. Comparing a sample of new oil

to what can be seen from the pump sight glass is the simplest test for oil condition. In addition, vacuum level

degradation (for example from 5-millitorr to 20-millitorr using a thermocouple gage at blank-off) can be an indication that the oil has deteriorated or that is has become contaminated. Cloudy oil indicates that condensed vapors

have been absorbed during pumping. Trapped condensable vapors can be removed by using the gas ballast (see

section 1.9 and 2.9).Darkening of color, thickening of consistency or a “burnt” smell are all indications of deteriorated oil. Pump should be drained and flushed with new oil before refilling for service. The recommended oil

change interval for pumps operating under normal conditions with clean gases and at below 1-torr should be no

longer than three months. Please note however that each pumping application is different and oil change intervals

need to be adapted to each specific operation. See Section 7 Troubleshooting and Section 9 Accessories for guides

to better oil care.

6.4 Forced Oil Flushing

When you drain oil through the drain valve, you are not removing the oil and contaminants that are inside the pumping

mechanism. You are removing oil only from the oil case. Cole-Parmer recommends that a forced oil flush of pumps

be performed at the regular maintenance oil change. Follow this procedure:

1. Check The Oil Level

If the oil level is well above the full mark, this may indicate either the pump has been overfilled with oil, or has ingested

a liquid or a large amount of vapor (water or organic solvents). Go to Step 2.

If the oil level is even with the full mark and you do NOT suspect corrosive gases or particulates (henceforth called

contaminants) ingested have damaged the mechanism, before going to Step 2, run the pump for 15 minutes to allow

the pump oil to warm up.

2. Drain the Oil

Turn off the motor for the vacuum pump. Drain the oil into a clear plastic container. A short length of hose attached

to the drain nozzle will direct the oil flow neatly without splashing.

Look for contaminants settling to the bottom of container. Depending upon the amount of contaminants, you may

need to repeat the following Steps 3 through 5 several times until the oil drains out clear .

3. Add Pump Oil

Flush the pump by adding approximately 150 ml of vacuum pump oil through the intake (IN) port while the pump is

turned on for 15-20 seconds. While adding the pump oil, block the exhaust (OUT) port with the palm of your hand.

Look for contaminated oil or other materials coming out of the drain. Turn of f the pump.

4. Repeat Step 4

Repeat adding pump oil until only clean oil comes out of the drain hose.

5. Fill the Pump

Add the amount of Vacuum Pump Oil Part No. 79201-74 to the “Full” mark.

6. Run the Pump

Plug the intake (IN) port with a rubber stopper.

Turn the pump on and run it for 10 minutes. Close the gas ballast.

7. Check the Vacuum Reading

16

Page 17

Connect a thermocouple or Pirani vacuum gauge to the pump’ s intake. If the pump is running nearly as well as when

new, the total pressure reading of the gauge will be 10 microns or lower (1 x 10-2 torr, 1.33 x 10-2 mbar).

6.5 Lip Seal/Gasket Change

When the shaft seal in the mounting plate show signs of excess oil leakage, it should be replaced. Before attempting

replacement of the seal, the pump must be disconnected from the vacuum system and from the power outlet.

ledoM01-3029702-3029703-30297

laeSpiL2406-162406-162406-16

teksaG3460-143460-143460-14

MOTOR COUPLING

1. DRAIN OIL by turning the valve handle counter-clockwise in the horizontal position. The pump may be tilted to

remove residual oil from the oil case.

2. Remove the handle of the pump by removing 2 M8 screws.

3. The top cover (located under the handle) and Side Panels can now be removed by removing two size M3 screws

from each.

4. Remove the base by removing four M8 screws. W ipe up any oil in the base. If the Dip Pad is saturated with oil,

replace it.

5. The Electrical Box Cover is removed by unscrewing four Philips-head screws.

6. Disconnect the green quick disconnect located in the electrical box.

7. Motor can be disconnected by removing four motor mounting screws.

8. Remove the coupling from the pump shaft (1 set screw)

9. Remove the three screws attaching lip seal housing.

CAUTION

Don’t lose the woodruff key that sits in the key slot of the coupling;

it can drop out. If the key has any burrs (caused by previous

tightning of the coupling screws), sand it smooth. .

NOTE: If the lip seal gasket (under the lip seal in the lip seal housing) looks intact, there may be no need to

replace it.

IMPORTANT: Note the position of the arrow and “UP” on the housing surface. After you replace the Lip

Seal, be sure the arrow on this coupling again points in the same direction (so that other components will be

properly aligned).

17

Page 18

10. Replace the Lip Seal

a) Place the lip seal housing in a vise (place a rag against the surfaces to protect against scratching). Gently

hammer a screwdriver against the lip seal at opposite sides until it pops out.

b) Before inserting the new lip seal, use your finger to add a thin coating of pump oil around its periphery.

c) Place the new lip seal in the coupling. It is essential that it be positioned perfectly flat on the bottom inner

flange. For best results, use a hand press. Place the coupling upright with the new seal on the hand press.

Then place a block of wood or metal having a very flat surface on top of the Lip Seal. Turn the hand press

lever until the Lip Seal is seated.

d) T o be sure the seal is completely seated, use a round tool having a slightly smaller diameter than the seal

to hammer the seal completely down to the bottom.

e) As for the lip seal gasket, even if you decide it’s not necessary to replace it, clean the coupling surfaces

that the gasket rests on.

11. Replace the Lip Seal Housing

a) It is recommended that you use

3 lockwashers to secure the LIP SEAL

HOUSING. Uniform tightness is important.

Repeatedly finger-tight the 3 screws in

sequence. Then lastly, turn them very tight.

b) Replace the Woodruff Key in its slot.

Use your small finger or a thin tool to hold it

in place as you replace the motor coupling

housing. Be sure the key stays in position.

If it should fall even a little distance, use a

screwdriver to push it back up in the key slot.

Then tighten the set key screw—very tight.

12. Replace Other Components

Reassemble the motor and other components.

Figure 6.5

18

Page 19

Section 7 - TROUBLESHOOTING

7.1 Leak Detection

The importance of eliminating all leaks in a vacuum system is obvious when it is realized that a leak into the system,

at atmospheric pressure, expands in volume by a factor of 750,000 to 10,000,000 or more. The pump must remove

this added volume to maintain the desired vacuum. Fortunately a number of effective techniques for leak detection

have been developed:

Large Leaks

Locate by pressurizing the system and painting the suspected area with a thick soap solution. Escaping air will

produce soap bubbles.

Small Leaks

Locate by spraying a suspected area with acetone or gases rich in hydrogen, then observing a sudden change in

pressure on an thermocouple gauge.

CAUTION:

Use extreme caution, as these materials are highly flammable.

The difference in calibration of these gauges, for air and other gases, will produce a distinct change in the pressure

reading. To use this method of detection, the system must be under vacuum, and the gauge sensing tube must be

located between the pump and the area to be probed.

Fine Leaks

Locate by using a helium-sensitive, mass-spectrometer leak detector. This instrument will locate leaks, which cannot

be detected by any other method. Numerous fine leaks can have the total effect of a large leak.

19

Page 20

7.2 T roubleshooting Guide

For Cole-Parmer Vacuum Pumps.

CONDITION PROBABLE CAUSE RECOMMENDED CORRECTIVE ACTION

Pump will not 1. Power off. Check switches and fuses.

start 2. Coupling damaged or Check coupling.

coupling set-screw loose.

3. Room is too cold. Drain and refill pump with warm oil.

Try with intake open to atmosphere.

4. Pump mechanism is seized. Pump to be repaired.

Pump does not 1. Pump oil is contaminated. Flush and change pump oil.

reach ultimate Use a foreline trap.

pressure 2. Pump is not filled with Add recommended pump oil.

oil, or has low oil level.

3. Pump has wrong oil in it. Flush and refill with recommended oil.

4. Leak in vacuum system. Locate and eliminate leak source.

5. Dirty foreline trap. Clean out cold traps and replacement elements

in coaxial and molecular sieve traps.

6. Gas ballast is open. Close gas ballast.

Excessively 1. Intake or exhaust lines Clear and straighten out lines. Check oil level.

noisy pump. are restricted

2. Coupling damaged. Examine coupling/replace.

3. Slapping noise at ultimate Clean orifice air passage.

pressure is typical for

some pumps.

4. Inside mechanism damaged. Pump to be repaired.

Pump generates 1. Pump overfilled with oil. Drain excess pump oil.

excessive smoke 2. Pump operating Use a larger capacity pump

or oil mist from continuously above its or modify your vacuum system.

exhaust port. maximum operating pressure

Pump oil is 1. Pump oil contaminated by Flush and change oil. Use a foreline trap

dark, has an process gases, or other in future. Consider using an oil

unusual color, foreign material filtration system or inert pump oils.

or is dirty. ingested by pump.

2. Pump oil has degraded. Pump was run too low on oil. The recommended

oil was not used. Pump is running continuously

above its maximum operating pressure.

Pump does not 1. Pump is running too cold. Allow pump to run until it warms up to its

achieve its rated operating temperature.

pumping speed 2. Exhaust or intake line Install larger inner diameter tubing.

is too narrow.

3. Pump oil is contaminated. Flush and change pump oil.

Use a foreline trap in future.

4. Very dirty trap or Clean out cold traps and replacement elements in

intake line. coaxial and molecular sieve traps. Clean or

replace vacuum piping.

Motor is ex- 1. Voltage selection Convert motor to be compatible with electrical sup

cessively noisy is incorrect ply . See Section 4.2 Changing the V oltage Setting.

20

Page 21

Section 8: REPAIR KITS

8.1 Shaft Seal Replacement.

When the shaft seal in the mounting plate shows signs of excessive oil leakage, it should be replaced. Before

attempting replacement of the seal, the pump must be disconnected from the vacuum system and from the power

outlet.

A seal replacement kit is available. This kit contains the outer lip seal assembly and gasket, which can be replaced in

the field.

ledoMpmuPtiKlaeStfahS

50-/00-3029730-K5098

01-3029730-K7198

02-3029730-K7198

03-3029730-K7198

54-/04-3029760-K5198

55-/05-3029730-K5298

8.2 Minor Repair Kits.

A minor repair kit is available that provides a group of parts that can easily be replaced in the field.

ledoMpmuPtiKriapeRroniM

50-/00-3029720-K5098

01-3029720-K7198

02-3029720-K7198

03-3029720-K7198

54-/04-3029720-K5198

55-/05-3029720-K5298

8.3 Major Factory Repair .

With proper care, Cole-Parmer Rotary Vane Pumps will give many years of service. The basic working parts of

vacuum pumps are machined to close tolerances and require assembly on fixtures, with special tools, by mechanics

who are highly skilled at this work. Should major repairs involving the pump mechanism become necessary, we

strongly recommend that the pump be returned to the factory , or to the Cole-Parmer Repair Center, for repair . Obtain

a Returned Goods Number from Cole-Parmer before returning any vacuum pump.

These facilities are well-equipped and staffed with experts to insure prompt reconditioning of all returned pumps.

Broken, worn, scored or corroded parts are replaced with new parts, and the pump is thoroughly evaluated and tested

to determine that it meets the performance requirements.

21

Page 22

9.1 General

4

0

0

This section lists the accessories available for the Cole-Parmer Rotary Vane Vacuum Pumps.

9.2 Pump Oil

SECTION 9: ACCESSORIES

noitpircseDytitnauQ.oNtraP

9.3 Exhaust Filters

retliFtsiMliOMFC5.4"2/1-2x"2/1-400-57797-A

retliFtsiMliOMFC5.4"2/1-2x"2/1-420-57797-A

retliFtsiMliOMFC0.7"2/1-2x"2/1-501-57797-A

retliFtsiMliOMFC0.7"2/1-2x"2/1-521-57797-A

retliFtsiMliOMFC0.42egnalF52WN02-57797-A

9.4 Cold T raps

liOpmuPmuucaVretiL1

noitpircseDyticapaCriAeerFeziStroP.oNtraP

noitpircseD.pmeTwoLnoitcennoCyticapaC.oNtraP

parTdloCecIyrDC°97-61WNtq300-90297-A

parTdloCecIyrDC°97-52WNtq301-90297-A

parTdloCecIyrDC°97-.D.O"2/1tq303-90297-A

parTdloCnegortiNdiuqiLC°891-61WNL57.006-90297-A

7-10297-A

9.5 Coaxial T raps

noitpircseDyticapaCnoitcennoC.oNtraP

parTlaixaoCMFC0.461WN00-80297-A

parTlaixaoCMFC0.2152WN01-80297-A

9.6 Molecular Sieve Traps

noitpircseDyticapaCnoitcennoC.oNtraP

parTeveiSraluceloMMFC861WN

parTeveiSraluceloMMFC852WN

For additional information on Accessories, Parts or Products, please consult:

Cole-Parmer’s website at www.coleparmer.com

parTdloCnegortiNdiuqiLC°891-52WNL57.007-90297-A

3-80297-A

4-80297-A

NOTE:

Cole-Parmer’s Products Catalog

or

22

Page 23

SECTION 10: DIMENSIONAL DRAWINGS/SPEED CURVES

P

7

7

7

7

7

7

7

7

7

10.1 Pumping Speed Curves

10.2 Dimensional Drawings

79203-00 /-05 79203-10 /-20 /-30

79203-40 /-45 79203-50 /-55

ump M odel A B C D E F G H I J K L M N O P Q R S

9203-00 14.13 8.70 5.52 4.07 5.73 6.81 3.16 0.54 5.58 1.56 6.76 8.70 0.95 0.54 7.50 6.68 1.10 0.98 0.85

9203-05 14.13 8.70 5.52 4.07 5.73 6.81 3.16 0.54 5.58 1.56 6.76 8.70 0.95 0.54 7.50 6.68 1.10 0.98 0.85

9203-10 18.90 9.60 6.54 4.76 7.00 9.88 5.05 1.44 7.92 1.90 7.60 9.45 0.87 0.89 8.78 - 1.61 0.94 1.18

9203-20 18.90 9.60 6.54 4.76 7.00 9.88 5.05 1.44 7.92 1.90 7.60 9.45 0.87 0.89 8.78 - 1.61 0.94 1.18

9203-30 18.90 9.60 6.54 4.76 7.00 9.88 5.05 1.44 7.92 1.90 7.60 9.45 0.87 0.89 8.78 - 1.61 0.94 1.18

9203-40 21.00 10.40 6.14 3.86 8.90 10.40 - 0.75 7.85 1.60 8.60 10.30 1.00 1.10 9.40 8.20 1.82 1.25 2.07

9203-45 21.00 10.40 6.14 3.86 8.90 10.40 - 0.75 7.85 1.60 8.60 10.30 1.00 1.10 9.40 8.20 1.82 1.25 2.07

9203-50 20.40 10.40 6.14 3.86 8.90 10.40 - 0.75 7.85 1.60 8.60 10.30 1.00 1.10 9.40 8.20 1.82 1.25 2.07

9203-55 20.40 10.40 6.14 3.86 8.90 10.40 - 0.75 7.85 1.60 8.60 10.30 1.00 1.10 9.40 8.20 1.82 1.25 2.07

23

Page 24

P ARTS LIST 79203-00 /-05 VACUUM PUMP

ITEM QTY P/N A* B* DESCRIPTION

01 2 62-1014 Flat Head Screw 8-32x3/8

02 1 61-2370 Oil Window Cover

03 1 61-2229A Oil Window Glass

04 1 66-0304 1 O-Ring, Fluoroelast. #127

05 1 61-2413 Drain Plug

06 1 61-2158A 1 O-Ring, Fluoroelast. #110

07 1 61-2355 Oil Case

08 1 61-2130A O-Ring, Fluoroelast. #115

09 1 61-2372 Filler Plug

1 0 8 2 -0 0-6 712 Socket Head Screw 10-32x3/4

1 1 22 2-6 2-0 793 Lock Washer #10

12 3 62-0003 Socket Head Screw 10-32x3

13 1 61-2417 End Plate

1 5 4 2- 69- 6108 Lock Washer #8

16 1 61-2415 Baffle Assembly

17 2 61-2128A 2 O-Ring, Fluoroelast. #145

1 8 2 4 -21- 300 6 Dowel Pin 1/8x3/8

19 1 61-2416 Stator

2 0 5 2- 10 -26 05 Round Head Screw 8-32x5/16

2 1 1 2 -68 -56 32 Flat Washer #8

22 1 61-2017A Exhaust Valve Braket Ass’y

23 2 61-2119A 2 Valve Spring

24 2 61-2118A 2 Valve

27 1 61-1123A 1 Valve, Intake

28 1 61-1128A 1 Valve, Backer

29 2 41-2988 2 Lip Seal, Fluoroelast.

30 1 61-2177B Rotor

31 2 61-2179A Exhaust Vane

32 2 61-2178A Intake Vane

34 3 61-2157A 2 O-Ring, Flouroelast. #007

ITEM QTY P/N A* B* DESCRIPTION

35 1 61-2214B Wear Plate

36 1 61-2149B 1 Pump Gasket

3 7 2 2- 62- 0432 Lockwasher #6

38 1 61-2351 Mounting Plate

39 1 61-6324 Gas Ballast Valve Ass’y

40 1 61-9282A 1 O-Ring, Fluoroelast. #011

41 1 61-9479A 1 Drip Pad

42 1 61-2358 Intake Adapter

44 1 61-2159A 1 O-Ring Fuoroelast. #116

4 5 3 2 -0 0-6 708 Socket Head Screw 10-32x1/2

46 1 61-2316 Motor Adapter Plate

4 7 2 4- 21- 5010 Dowel Pin 3/16x5/8

48 2 41-2693 Coupling Body

4 9 4 2 -0 0-6 716 Socket Head Screw 10-32x1

50 1 41-2694 1 Spider Coupling

52 1 61-2377 Handle

5 3 2 2 -61 -11 65 Flat Washer 1/4

5 4 2 2 -0 1-6 112 Socket Head Screw 1/4-20x3/4

55 1 61-2039C Motor Ass’y 1/4 H.P. (115V/60Hz)

55 1 61-9813 Motor 1/4 H.P. (100-120/200-240V)

56 4 61-2123A 4 Bumper

57 1 61-2271C Pump Base

5 8 4 2 -0 0-6 812 Socket Head Screw 10-32x5/8

61 1 61-2139A 1 Disk Ass’y, ISO Valve

62 1 61-2216A Plunger

63 1 61-2155A 1 O-Ring, Fluoroelast. #020

64 1 61-2212A Adapter, ISO Valve

6 5 2 2 -0 0-6 41 0 Socket Head Screw 6-32x5/8

66 1 61-2308 ISO Operator Ass’y, w/O-Ring

24

A*: MAJOR REPAIR KIT CAT # N/A

B*: MINOR REPAIR KIT CAT # 8905K-02

67-1409

Sheet 1 of 2

Rev. 4 6/04

Page 25

P ARTS LIST 79203-10 VACUUM PUMP

ITEM QTY PC. NO. A* B* DESCRIPTION

01 4 62-0325 Screw, Sockethead, M6x20 Blk.

02 1 61-6443 Oil Case Assembly

03 1 61-6354 Pump Module

04 1 61-6385 Gasket

05 1 66-0194 O-Ring, Fluoroelast. #164

06 1 61-2204A Spring, Gas Ballast

07 1 61-6305A Valve, Gas Ballast

08 1 61-9429 Screw w/ O-Ring

09 6 62-0265 Screw, Buttonhead, M4x8 Blk.

10 1 61-5353 Cover, Left

11 4 66-0211 Rubber Feet

12 4 62-0349 Screw, Sockethead, M8x16

13 8 2-63-0356 Lock Washer 5/16

14 1 61-6306 Base

15 1 61-6084 Drip Aid

16 1 61-5352 Cover, Right

17 3 2-63-0193 Lock Washer 1/4

18 1 61-6322 Mounting Plate

19 1 61-2157A O-Ring, Fluoroelast. #007

20 1 61-9282A O-Ring, Fluoroelast. #011

ITEM QTY PC. NO. A* B* DESCRIPTION

21 1 61-6324 Gas Ballast Assembly

22 3 62-0270 Screw, Sockethead, M6x20

23 1 66-0200 O-Ring, Fluoroelast. #216

24 1 61-6325 Intake Fitting Assembly

25 1 61-6360 Cover, Top

26 2 62-0331 Screw, Sockethead, M8x20 Blk.

27 1 61-6038 Coupling, Rubber

28 1 61-6024 Fan

29 1 62-0286 Set Screw, 10-32

30 1 61-6081 Key

31 4 61-9280A Dowel Pin, 1/4"

32 4 62-0346 Screw, Sockethead, M8x35

33 1 62-0344 Line Cord

34 1 61-6461 Motor Assembly 1/2 H.P.

35 1 61-6011 Handle

36 2 41-2363 Washer

37 1 61-6304 Solenoid Valve Assembly

38 1 61-6279 Plunger

39 1 61-9793 Isolator Disc

76 1 61-6076 Exhaust Plug

A*: MAJOR REPAIR KIT CAT # N/A

B*: MINOR REPAIR KIT CAT # 8917K-02

Sheet 1 of 2

Rev. 6 1/06

67-1410

25

Page 26

P ARTS LIST 79203-20 VACUUM PUMP

ITEM QTY PC. NO. A* B* DESCRIPTION

01 4 62-0325 Screw, Socket head, M6x20 Blk.

02 1 61-6443 Oil Case Assembly

03 1 61-6168 Pump Module

04 1 61-6385 Gasket

05 1 66-0194 O-Ring, Fluoroelast. #164

06 1 61-6305A Spring, Gas Ballast

07 1 61-2118A Valve, Gas Ballast

08 1 61-9429 Screw w/ O-Ring

09 6 62-0265 Screw, Button head, M4x8 Blk.

10 1 61-5353 Cover, Left

11 4 66-0211 Rubber Feet

12 4 62-0349 Screw, Socket head, M8x16

13 8 2-63-0356 Lock Washer 5/16

14 1 61-6306 Base

15 1 61-6084 Drip Aid

16 1 61-5352 Cover, Right

17 3 2-63-0193 Lock Washer 1/4

18 1 61-6322 Mounting Plate

19 1 61-2157A O-Ring, Fluoroelast. #007

20 1 61-9282A O-Ring, Fluoroelast. #011

ITEM QTY PC. NO. A* B* DESCRIPTION

21 1 61-6324 Gas Ballast Assembly

22 3 62-0270 Screw, Socket head, M6x20

23 1 66-0200 O-Ring, Fluoroelast. #216

24 1 61-6325 Intake Fitting Assembly

25 1 61-6360 Cover, Top

26 2 62-0331 Screw, Sockethead, M8x20 Blk.

27 1 61-6038 Coupling, Rubber

28 1 61-6024 Fan

29 1 62-0286 Set Screw, 10-32

30 1 61-6081 Key

31 4 61-9280A Dowel Pin, 1/4"

32 4 62-0346 Screw, Socket head, M8x35

33 1 62-0344 Line Cord

34 1 61-6461 Motor Assembly 1/2 H.P.

35 1 61-6011 Handle

36 2 41-2363 Washer

37 1 61-6304 Solenoid Valve

38 1 61-6279 Plunger

39 1 61-9793 Isolator Disc

76 1 61-6076 Exhaust Plug

26

A*: MAJOR REPAIR KIT CAT # N/A

B*: MINOR REPAIR KIT CAT # 8917K-02

67-1411

Sheet 1 of 2

Rev. 5 1/06

Page 27

P ARTS LIST 79203-30 VACUUM PUMP

ITEM QTY PC. NO. A* B* DESCRIPTION

01 4 62-0325 Screw, Sockethead, M6x20 Blk.

02 1 61-6443 Oil Case Assembly

03 1 61-6435 Pump Module

04 1 61-6385 Gasket

05 1 66-0194 O-Ring, Fluoroelast. #164

06 1 61-6305A Spring, Gas Ballast

07 1 61-2118A Valve, Gas Ballast

08 1 61-9429 Screw w/ O-Ring

09 6 62-0265 Screw, Buttonhead, M4x8 Blk.

10 1 61-5353 Cover, Left

11 4 66-0211 Rubber Feet

12 4 62-0349 Screw, Sockethead, M8x16

13 8 2-63-0356 Lock Washer 5/16

14 1 61-6306 Base

15 1 61-6084 Drip Aid

16 1 61-5352 Cover, Right

17 3 2-63-0193 Lock Washer 1/4

18 1 61-6322 Mounting Plate

19 1 61-2157A O-Ring, Fluoroelast. #007

20 1 61-9282A O-Ring, Fluoroelast. #011

ITEM QTY PC. NO. A* B* DESCRIPTION

21 1 61-6324 Gas Ballast Assembly

22 3 62-0270 Screw, Sockethead, M6x20

23 1 66-0200 O-Ring, Fluoroelast. #216

24 1 61-6325 Intake Fitting Assembly

25 1 61-6360 Cover, Top

26 2 62-0331 Screw, Sockethead, M8x20 Blk.

27 1 61-6038 Coupling, Rubber

28 1 61-6024 Fan

29 1 62-0286 Set Screw, 10-32

30 1 61-6081 Key

31 4 61-9280A Dowel Pin, 1/4"

32 4 62-0346 Screw, Sockethead, M8x35

33 1 62-0344 Line Cord

34 1 61-6461 Motor Assembly 1/2 H.P.

35 1 61-6011 Handle

36 2 41-2363 Washer

37 1 61-6304 Solenoid Valve Assembly

38 1 61-6279 Plunger

39 1 61-9793 Isolator Disc

76 1 61-6076 Exhaust Plug

A*: MAJOR REPAIR KIT CAT # N/A

B*: MINOR REPAIR KIT CAT # 8917K-02

Sheet 1 of 2

Rev. 6 1/06

67-1412

27

Page 28

P ARTS LIST 79203-40 /-45 VACUUM PUMP

ITEM QTY P/N A* B* DESCRIPTION

01 2 62-1014 Screw, Flathead, #8-32x3/8

02 1 61-2370 Window Holder

03 1 61-2229A Window Glass

04 1 66-0304 O-Ring, Fluoroelast. #127

05 1 66-0212 O-Ring, Fluoroelast. #119

06 1 61-6020 Oil Fill Plug

07 1 61-5358 Oil Case

08 1 61-2130A O-Ring, Fluoroelast. #115

09 1 61-2372 Drain Plug

10 4 2-01-6116 Screw, Sockethead, 1/4-20x1

11 11 2-01-6114 Screw, Sockethead, 1/4-20x7/8

12 11 2-63-0193 Lock Washer 1/4

13 3 2-62-0793 Lock Washer #10

14 1 61-9793 Isolator Disk

15 1 61-6279 Plunger

16 1 41-0643 Gasket

18 1 61-9539B End Plate

21 1 61-8104A Shaft Seal Housing

22 1 61-9935 ISO Operator Assembly

23 5 2-00-2604 Screw, Fillisterhead, #8-32x1/4

24 1 62-0274 Orifice .014"

25 1 41-3175 Gasket, Nylon

26 5 41-2996 Vane, Spring

30 1 61-9527 O-Ring, Fluoroelast. #137

31 1 61-9598D Exhaust Stage

33 1 61-2118A Valve, Gas Ballast

34 1 61-9561A Exhaust Valve Spring

35 1 61-9580A Exhaust Valve Cover

36 2 61-9478 Stand Off Spacer

38 2 61-9615A Exhaust Vane

40 1 61-9595C Rotor

41 2 61-9616B Intake Vane

42 1 41-0624 Woodruff Key

43 6 61-9280A Dowel Pin, 1/4"

ITEM QTY P/N A* B* DESCRIPTION

44 2 41-3390 Lip Seal, 3/4"

45 1 61-9526 O-Ring, Fluoroelast. #151

46 1 61-9597D Intake Stage

47 3 61-9560A Bypass Valve

48 2 61-9582A Bypass Valve Spring

49 1 61-9516A Intake Valve Cover

50 2 2-69-6108 Lock Washer #8

51 3 2-00-6814 Screw, Sockethead, #10-32x7/8

52 1 61-9640A Valve Cover Assembly

53 1 61-9609B Gasket

54 1 61-6305A Spring, Gas Ballast

56 1 61-5347 Mounting Plate

57 1 61-2157A O-Ring, Fluoroelast. #007

58 1 61-9282A O-Ring, Fluoroelast. #011

59 1 61-6324 Gas Ballast Valve Assembly

60 1 61-5348 Intake Adapter Assembly

62 1 66-0200 O-Ring, Fluoroelast. #216

64 4 62-1071 Lock Washer 1/4 Small

65 2 41-3072 Flange Coupling

66 4 2-01-6516 Screw, Sockethead, 3/8-16x1

67 1 61-5246 Motor Adapter Plate

68 1 61-6011 Handle

69 6 2-01-6316 Screw, Sockethead, 5/16-18x1

70 10 41-2363 Washer

71 4 2-01-6320 Screw, Sockethead, 5/16-18x1-1/4

72 1 41-3073 Coupling Sleeve

73 1 41-2637 Motor Shaft Key (Suppl. w/Motor)

74 1 61-5359 Motor Assembly 3/4 H.P.*

75 1 61-5245 Base

76 1 61-9742 Drip Pad

77 4 61-9607A Rubber Bumper

78 1 41-3005 O-Ring, Fluoroelast. #008

79 2 2-68-5632 Washer #8

80 4 2-63-0593 Lock Washer 3/8

28

A*: MAJOR REPAIR KIT CAT. # N/A

B*: MINOR REPAIR KIT CAT. # 8915K-05

67-1413

Sheet 1 of 2

Rev. 7 1/06

Page 29

P ARTS LIST 79203-50 /-55 VACUUM PUMP

ITEM QTY PC. NO. A* B* DESCRIPTION

1 2 62-1014 Screw, Flathead, #8-32x3/8

2 1 61-2370 Window Cover

3 1 61-2229A Window Glass

4 1 66-0304 O-Ring, Fluoroelast. #127

5 1 66-0212 O-Ring, Fluoroelast. #119

6 1 61-6020 Oil Fill Plug

7 1 61-5358 Oil Case

8 1 61-2130A O-Ring, Fluoroelast. #115

9 1 61-2372 Drain Plug

10 4 2-01-6116 Screw, Sockethead, 1/4-20x1

12 1 61-9539B Cover Plate

13 1 61-9793 Isolator Disc

14 1 61-6279 Plunger

16 1 41-0643 Gasket

20 1 61-9935 Isolator Assembly

21 1 61-8104A Shaft Seal Housing

23 5 2-00-2604 Screw, Fillisterhead, #8-32x1/4

24 1 62-0274 Orifice .014"

25 1 41-3175 Gasket, Nylon

30 1 61-9379 O-Ring, Fluoroelast. #139

31 1 61-5307 Exhaust Stage

33 1 61-2118A Valve, Gas Ballast

34 1 61-9561A Exhaust Valve Spring

35 1 61-9685 Exhaust Valve Cover

36 2 61-9478 Stand Off Spacer

38 2 61-9570A Exhaust Vane

39 5 41-2996 Vane, Spring

40 1 61-5304 Rotor

41 2 61-9571B Intake Vane

42 1 41-0624 Woodruff Key

43 6 61-9280A Dowel Pin, 1/4

44 2 41-3390 Lip Seal, 3/4

45 1 61-9378 O-Ring, Fluoroelast. #152

46 1 61-5305 Intake Stage

47 3 61-9560A Bypass Valve

ITEM QTY PC. NO. A* B* DESCRIPTION

48 2 61-9582A Bypass Valve Spring

49 1 61-9686 Intake Valve Cover

50 2 2-69-6108 Lock Washer #8

51 3 2-00-6814 Screw, Sockethead, #10-32x7/8

52 1 61-9687 Valve Cover Assy

53 1 61-9609B Gasket

54 1 61-6305A Gas Ballast Spring

55 1 61-9742 Drip Pad

56 1 61-5347 Mounting Plate

57 1 61-2157A O-Ring, Fluoroelast. #007

58 1 61-9282A O-Ring, Fluoroelast. #011

59 1 61-6324 Gas Ballast Valve Assy

60 1 61-5348 Intake Adapter Assy.

61 1 66-0200 O-Ring, Fluoroelast. #216

62 11 2-01-6114 Screw, Sockethead, 1/4-20x7/8

63 4 62-1071 Lock Washer 1/4 Small

64 2 41-3072 Flange Coupling

65 4 2-01-6516 Screw, Sockethead, 3/8-16x1

66 1 61-5246 Motor Adapter Plate

67 1 61-6011 Handle

68 6 2-01-6316 Screw, Sockethead, 5/16-18x1

69 6 41-2363 Washer

70 4 2-01-6320 Screw, Sockethead, 5/16-18x1-1/4

71 1 41-3073 Coupling Sleeve

72 1 41-2637 Motor Shaft Key (Suppl. w/Motor)

73 1 61-5359 Motor Assembly 3/4 H.P.*

74 1 61-5245 Base

75 4 2-63-0356 Lock Washer 5/16

76 4 61-9607A Rubber Bumper

77 1 41-3005 O-Ring, Fluoroelast. #008

78 2 2-68-5632 Washer #8

79 4 2-63-0593 Lock Washer 3/8

82 11 2-63-0193 Lock Washer 1/4

83 3 2-62-0793 Lock Washer #10

A*: MAJOR REPAIR KIT CAT # N/A

B*: MINOR REPAIR KIT CAT # 8925K-02

Sheet 1 of 2

67-1414

Rev. 8 1/06

29

Page 30

P ARTS LIST 61-6168 PUMP MODULE

ITEM QTY P/N A* B* DESCRIPTION

40 6 62-0262 Screw, Sockethead, M5x20

4 1 9 2- 62-0 793 Lock Washer #10

42 1 61-6165 Cover Plate

43 1 41-3175 Gasket, Nylon

44 1 62-0274 Orifice .014”

45 1 66-0204 O-Ring, Fluoroelast. #141

4 6 2 4 -21- 300 6 Dowel Pin, 1/8”x3/8”

47 1 61-6167 Exhaust Stage

48 1 61-6058 Exhaust Valve

49 1 61-6057 Bypass Valve

50 1 61-6305 Spring, Exhaust Valve

51 1 61-6164 Holder, Exhaust Valve

5 2 5 2 -69- 6108 Lock Washer #8

53 5 62-0271 Screw, Sockethead, M4x6

54 2 61-6053 Exhaust Vane

Used on:

- 79203-20

ITEM QTY P/N A* B* DESCRIPTION

55 4 41-2996 Vane Spring

56 2 61-6050 Vane, Intake

57 1 41-2732 Key Coupling

58 1 61-6040 Rotor

59 1 66-0203 O-Ring, Fluoroelast. #151

60 1 41-3390 Lip Seal, 3/4”

61 2 61-9280A Dowel Pin, 1/4”

62 1 61-6166 Intake Stage

63 1 41-0643 Gasket

64 1 61-6055 Lip Seal Housing

65 1 61-6042 Lip Seal .669”

66 1 41-2730 Coupling

67 1 61-6123 Cover

68 1 61-2157A O-Ring, Fluoroelast. #007

30

A*: MAJOR REPAIR KIT CAT # N/A

B*: MINOR REPAIR KIT CAT # N/A

67-0957

Sheet 1 of 2

Rev. 6 5/05

Page 31

P ARTS LIST 61-6435 PUMP MODULE

ITEM QTY P/N A* B* DESCRIPTION

40 9 62-0177 Screw, Sockethead, M5x16

4 1 9 2- 62-0 793 Lock Washer #10

42 1 61-6318 Cover Plate

43 1 41-3175 Gasket, Nylon

44 1 62-0274 Orifice .014”

45 1 66-0204 O-Ring, Fluoroelast. #141

4 6 2 4 -21 -3 006 Dowel Pin, 1/8”

47 1 61-6429 Exhaust Stage

48 1 61-9560A Exhaust Valve

49 1 61-6057 Bypass Valve

50 1 61-9561A Exhaust Valve Spring

51 1 61-6432 Exhaust Valve Holder

5 2 2 2- 69- 6108 Lock Washer #8

53 2 62-0271 Screw, Sockethead, M4x6

Used on:

- 79203-30

ITEM QTY P/N A* B* DESCRIPTION

54 2 61-6052 Vane, Exhaust

55 4 41-2996 Vane, Spring

56 2 61-6049 Vane, Intake

57 1 41-2732 Key Coupling

58 1 61-6426 Rotor

59 1 66-0207 O-Ring, Fluoroelast. #149

60 1 41-3390 Lip Seal, 3/4”

61 2 61-9280A Dowel Pin, 1/4”

62 1 61-6427 Intake Stage

63 1 41-0643 Gasket

64 1 61-6055 Lip Seal Housing

65 1 61-6042 Lip Seal .669”

66 1 41-2730 Coupling

67 1 61-5351 Cover

A*: MAJOR REPAIR KIT CAT # N/A

B*: MINOR REPAIR KIT CAT # N/A

Sheet 1 of 2

Rev. 1 5/05

67-1628

31

Page 32

P ARTS LIST 61-6354 PUMP MODULE

ITEM QTY P/N A* B* DESCRIPTION

40 6 62-0177 Screw, Sockethead, M5x16

4 1 9 2- 62-0 793 Lock Washer #10

42 1 61-6318 Cover Plate

43 1 41-3175 Gasket, Nylon

44 1 62-0274 Orifice

45 1 66-0204 O-Ring, Fluoroelast. #141

4 6 2 4 -21- 300 6 Dowel Pin, 1/8”x3/8”

47 1 61-6350 Exhaust Stage

48 1 61-6058 Exhaust Valve

49 1 61-6057 Bypass Valve

50 1 61-6305 Spring, Exhaust Valve

51 1 61-6348 Holder, Exhaust Valve

5 2 2 2 -69- 6108 Lock Washer #8

53 2 62-0271 Screw, Sockethead, M4x6

Used on:

- 79203-10

ITEM QTY P/N A* B* DESCRIPTION

54 2 61-6052 Vane, Exhaust

55 4 41-2996 Vane Spring

56 2 61-6051 Vane, Intake

57 1 41-2732 Key Coupling

58 1 61-6039 Rotor

59 1 66-0207 O-Ring, Fluoroelast. #149

60 1 41-3390 Lip Seal, 3/4”

61 2 61-9280A Dowel Pin, 1/4”

62 1 61-6316 Intake Stage

63 1 41-0643 Gasket

64 1 61-6055 Lip Seal Housing

65 1 61-6042 Lip Seal .669”

66 1 41-2730 Coupling

67 3 62-0262 Screw, Sockethead, M5x20

32

A*: MAJOR REPAIR KIT CAT # N/A

B*: MINOR REPAIR KIT CAT # N/A

67-1407

Sheet 1 of 2

Rev. 3 11/03

Page 33

Used on:

- 79203-10

- 79203-20

- 79203-30

P ARTS LIST 61-6443 OIL CASE ASSEMBL Y

ITEM QTY P/N A* B* DESCRIPTION

69 2 62-1014 Screw, Countersunk, 8-32 x 3/8”

70 1 61-6009 Window Holder

71 1 61-6027 Window Glass

72 1 66-0305 O-Ring, Fluoroelast. #130

73 1 61-2278 Drain Valve

74 1 61-6442 Oil Case

75 1 62-0212 O-Ring, Fluoroelast. #119

77 1 61-6020 Oil Fill Plug

67-1637

Sheet 1 of 2

Rev. 2 6/04

33

Page 34

Section 11: WARRANTY

This Cole-Parmer product is warranted to be free from defects in material and workmanship. This liability of ColeParmer under this warranty is limited to servicing, adjusting, repairing or replacing any unit or component part which

in the judgment of Cole-Parmer has not been misused, abused or altered in any way or damaged by ingestion of

foreign material causing impaired performance or rendering it inoperative. Foreign material includes solids, liquids,

corrosive gases and recondensed water or solvent vapor. No other warranties are expressed or implied. The

method of executing this warranty: servicing, adjusting, repairing or replacing shall be at the discretion of ColeParmer Vacuum pumps that have been operated within a vacuum system, or other system, for any period, however

short, will be repaired under this warranty rather than replaced.

The warranty is effective for one year from the date of original purchase when:

1. The warranty card has been completed and returned.

2. The product is returned to the factory or other designated service centers, freight prepaid.

3. The product in our judgment is defective through no action or fault of the user .

If the product has become defective through misuse, abuse, alteration or ingestion of foreign materials, repairs will be

billed regardless of the age of the product. In this event, an estimate of the repair costs will be submitted and

authorization of these charges will be required before the product is repaired and returned.

34

Page 35

35

Page 36

36

Page 37

37

Page 38

383940

Page 39

Page 40

Cole-Parmer Instrument Company

625 East Bunker Court

Vernon Hills, IL 60061-1844

Phone: 1-800-323-4340

Fax: 847-247-2929

E-Mail: info@coleparmer.com

Web-Page: www.coleparmer.com

Loading...

Loading...