Page 1

Operating manual

ELECTRIC ASPIRATOR

ELECTRIC ASPIRATOR

ELECTRIC ASPIRATORELECTRIC ASPIRATOR

(Model

(Model ::::

(Model(Model

Manual

Manual No:

Manual Manual

No: 00HAA0001135 (

No:No:

75301

75301----00

7530175301

00HAA0001135 (Rev

00HAA0001135 ( 00HAA0001135 (

Rev :::: 1

RevRev

00))))

0000

1))))

1 1

Page 1

Page 2

Page 2

Cole-Parmer Instrument Company

(800)323-4340 Fax:(847)247-2929

Page 3

625 East Bunker Court, Vernon Hills, Illinois 60061

E-mail: info@coleparmer.com

Copyright © 1999

Thank you for purchasing this Cole-Parmer product. This product is

manufactured with state-of-the-art technology and materials.

This operation manual describes the functions of the unit and key

points you should keep in mind when you operate it. Please be sure to

read through this manual for an effective and utmost use of the unit

before operating this Instrument.

Please read this operation manual carefully before you u

Please read this operation manual carefully before you use this unit.

Please read this operation manual carefully before you uPlease read this operation manual carefully before you u

Especially, keep in mind and pay attention regarding safety secure

Especially, keep in mind and pay attention regarding safety secure

Especially, keep in mind and pay attention regarding safety secureEspecially, keep in mind and pay attention regarding safety secure

se this unit.

se this unit.se this unit.

Page 3

Page 4

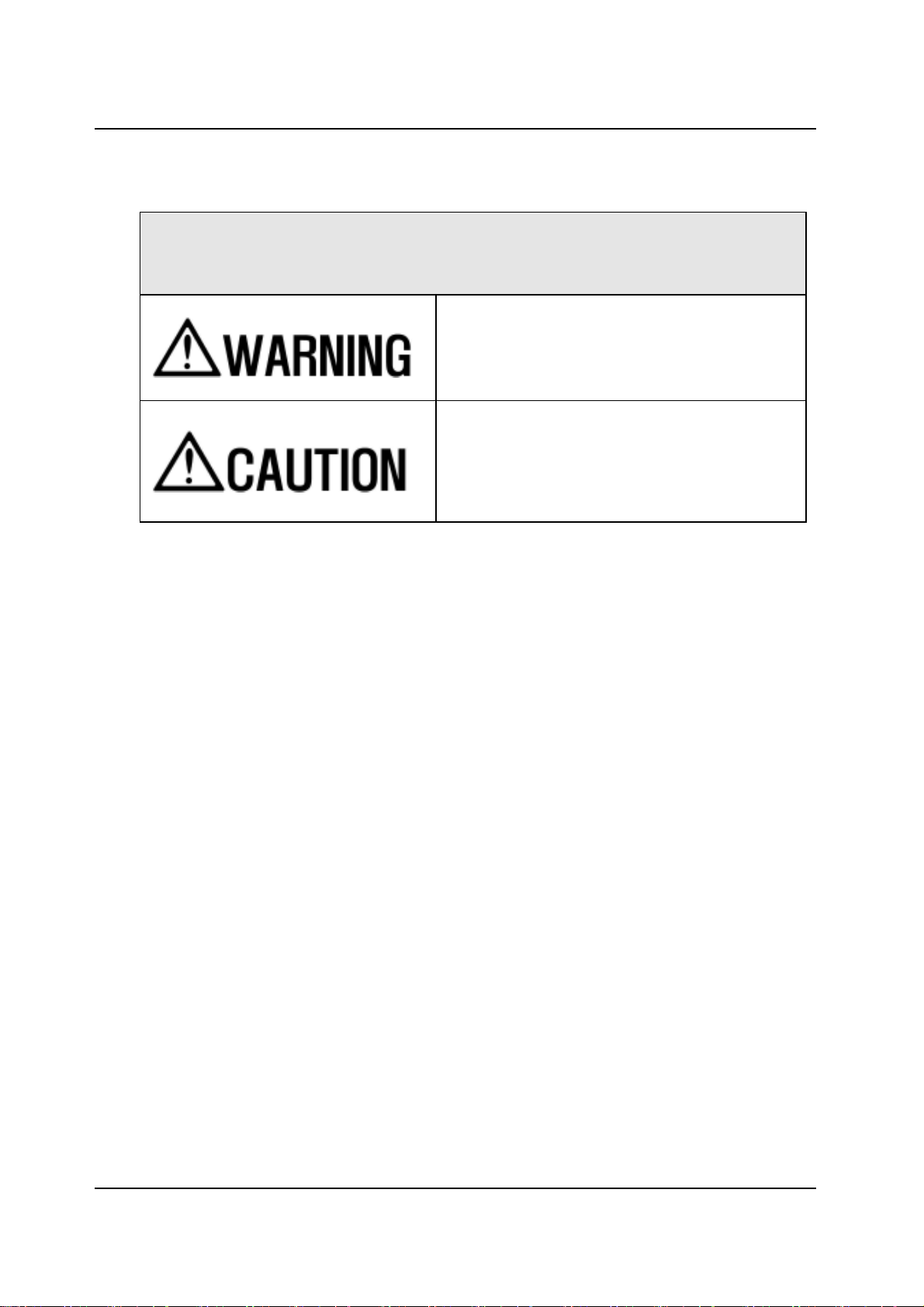

Safety Precaut

Safety Precautiiiions

Safety PrecautSafety Precaut

““““Warning

Warning”””” means that the user may have

WarningWarning

serious damage by wrong handling on this

serious damage by wrong handling on this

serious damage by wrong handling on this serious damage by wrong handling on this

unit.

unit.

unit.unit.

means that the user may have

means that the user may have means that the user may have

ons

onsons

““““Caution

Caution”””” means that the user may have not

CautionCaution

so serious damage a

so serious damage and unit may have

so serious damage aso serious damage a

physical damage by wrong handling on this

physical damage by wrong handling on this

physical damage by wrong handling on thisphysical damage by wrong handling on this

means that the user may have not

means that the user may have not means that the user may have not

nd unit may have

nd unit may have nd unit may have

Contents

1. Application and Features ................................................... 5

2. Installation ..................................................................... 6

Page 4

3. Name of each part .......................................................... 7

4.

Handling and operation ..................................................... 8

5. Precautions for using the organic solvents ........................ 12

6. Maintenance and its cleaning ............................................. 13

7. Causes of malfunction and its repairs .................................. 14

Page 5

8. After Services .................................................................. 15

9. Accessories ..................................................................... 16

10. Technical report ............................................................... 17

11. Warranty ........................................................................ 18

12. Specifications .................................................................. 19

13. Exploded view ................................................................ 20

14. Part list ........................................................................... 21

1. Application and

1. Application and FFFFeature

1. Application and 1. Application and

eaturessss

eatureeature

- The Electric aspirator 75301-00 produces a low vacuum condition using

Bernoulli's principle by pumping water through aspirator head. When using

75301-00 with rotary vacuum evaporator or for Gel dryer or low vacuum oven,

inflow of a little water or solvent into the equipment do not make trouble to the

instrument. And you can use this equipment continuously if you change the

water in the bath.

- The 75301-00 is manufactured as polypropylene that has chemical resistance

against most solvents. For effective usage, a small quantify of water

(100ml/min) has to be continuously supplied by a user through the drain cock at

the bottom part of the bath and drained through the over-flow nozzle. It reveals

liquid circulation of the inner bath and means dilution that helps the instrument

to be used longer.

Page 5

Page 6

- Check-valve is designed for preventing water from flowing backward during the

power failure. But this valve can’t protect the equipment permanently. It is for

short protection that saves the time to fix its original troubles that may be

happened.

To prevent flowing backward of water upon a power failure of the moment, the unit

To prevent flowing backward of water upon a power failure of the moment, the unit

To prevent flowing backward of water upon a power failure of the moment, the unit To prevent flowing backward of water upon a power failure of the moment, the unit

has

has a flowing backward double breaker. It only makes users h

a flowing backward double breaker. It only makes users have some times to deal

hashas

a flowing backward double breaker. It only makes users h a flowing backward double breaker. It only makes users h

with the situation however, it does not mean the complete stop valve.

with the situation however, it does not mean the complete stop valve.

with the situation however, it does not mean the complete stop valve. with the situation however, it does not mean the complete stop valve.

ave some times to deal

ave some times to deal ave some times to deal

2.

2. Installation

Installation

2. 2.

InstallationInstallation

Please read this operating manual carefully before you use this unit.

Please read this operating manual carefully before you use this unit.

Please read this operating manual carefully before you use this unit.Please read this operating manual carefully before you use this unit.

If the unit is

If the unit is installed

If the unit is If the unit is

abnormal operating.

abnormal operating.

abnormal operating. abnormal operating.

1) Please check on the proper voltage for operating. You should check the

electricity in accordance with the ID label plate.

installed on an abnormal installing condition, it m

installedinstalled

on an abnormal installing condition, it might cause damage or

on an abnormal installing condition, it m on an abnormal installing condition, it m

ID label plate. (The backside of unit)

ID label plate.ID label plate.

ight cause damage or

ight cause damage or ight cause damage or

Please check on the proper voltage, phase of capacity for

Please check on the proper voltage, phase of capacity for an

Please check on the proper voltage, phase of capacity for Please check on the proper voltage, phase of capacity for

Main power must be grounded.

Main power must be grounded.

Main power must be grounded. Main power must be grounded.

Page 6

an installing place.

anan

installing place.

installing place.installing place.

Page 7

If it would not be, may cause a serious injury or damage on the unit.

If it would not be, may cause a serious injury or damage on the unit.

If it would not be, may cause a serious injury or damage on the unit. If it would not be, may cause a serious injury or damage on the unit.

2) This instrument is requested not to be used where is inclination and vibration

place.

3) Do not expose to a direct rays.

4) Prevent overflowing of water in the bath, and do not operate with wet hands.

5) Plug out the power cord when you do not use the instrument.

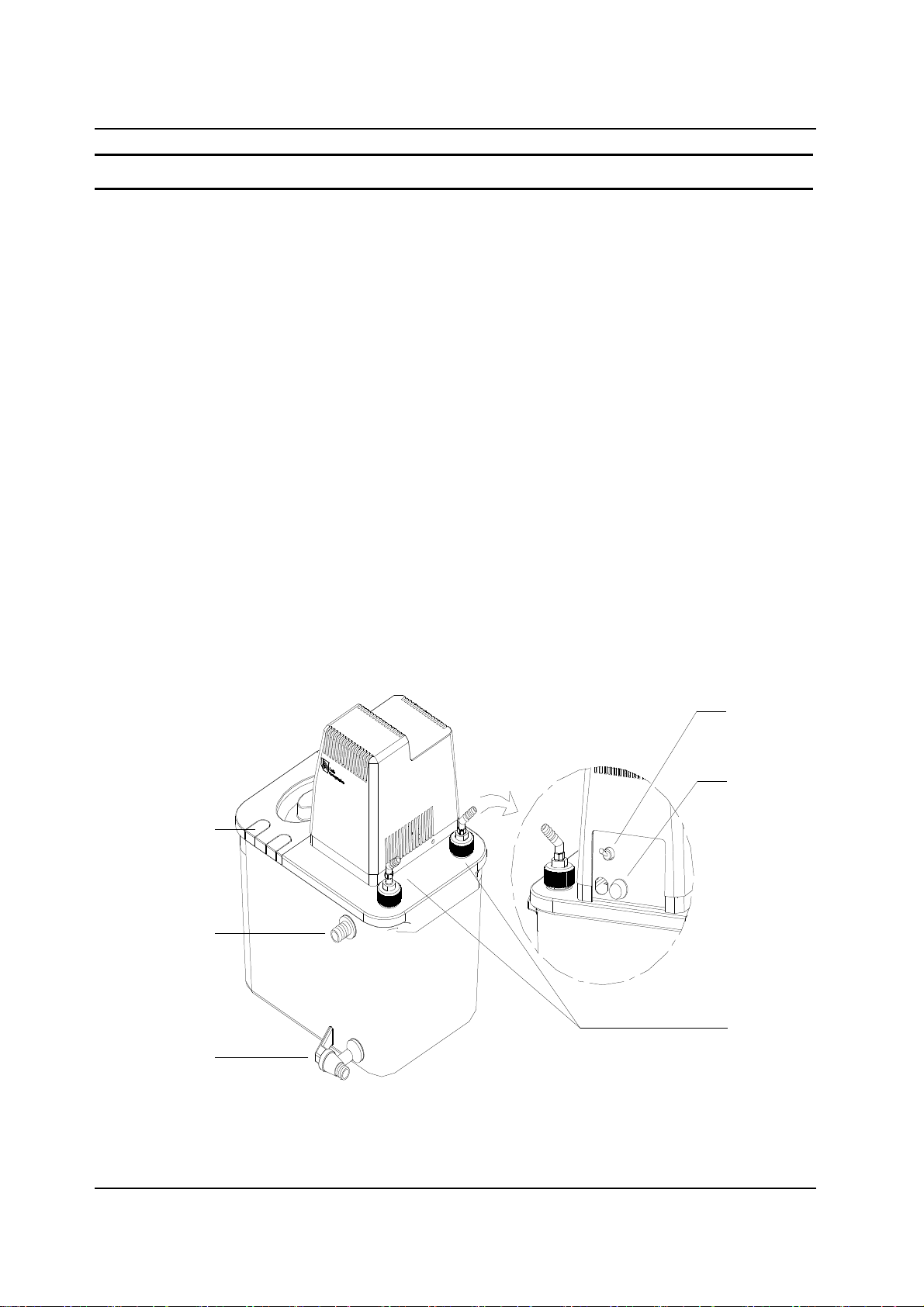

3. Name of each

3. Name of each part

3. Name of each 3. Name of each

part

partpart

Cooling

Coil

Mount

Hole

Overflow

Nozzle

Main Power

Switch

Fuse

Suction

In/Out

Cock

Line

Page 7

Page 8

Aspirator

----

Slots for cooling co

Slots for cooling coil

Slots for cooling coSlots for cooling co

When you need cooling coil, you can put in a cooling coil through these slots.

(Cooling coil is optional accessory.)

il

ilil

Page 8

Page 9

4.

4. Handling and operation

Handling and operation

4. 4.

Handling and operationHandling and operation

Use the machine in dry place, and keep away from flammable gas or dangerous

explosive environment is.

For fear that scale might be occurred in the bath, you had better use Distilled

water.

---- Only use

Only use inner

Only use Only use

inner circulation without infusing cooling water

circulation without infusing cooling water

innerinner

circulation without infusing cooling water circulation without infusing cooling water

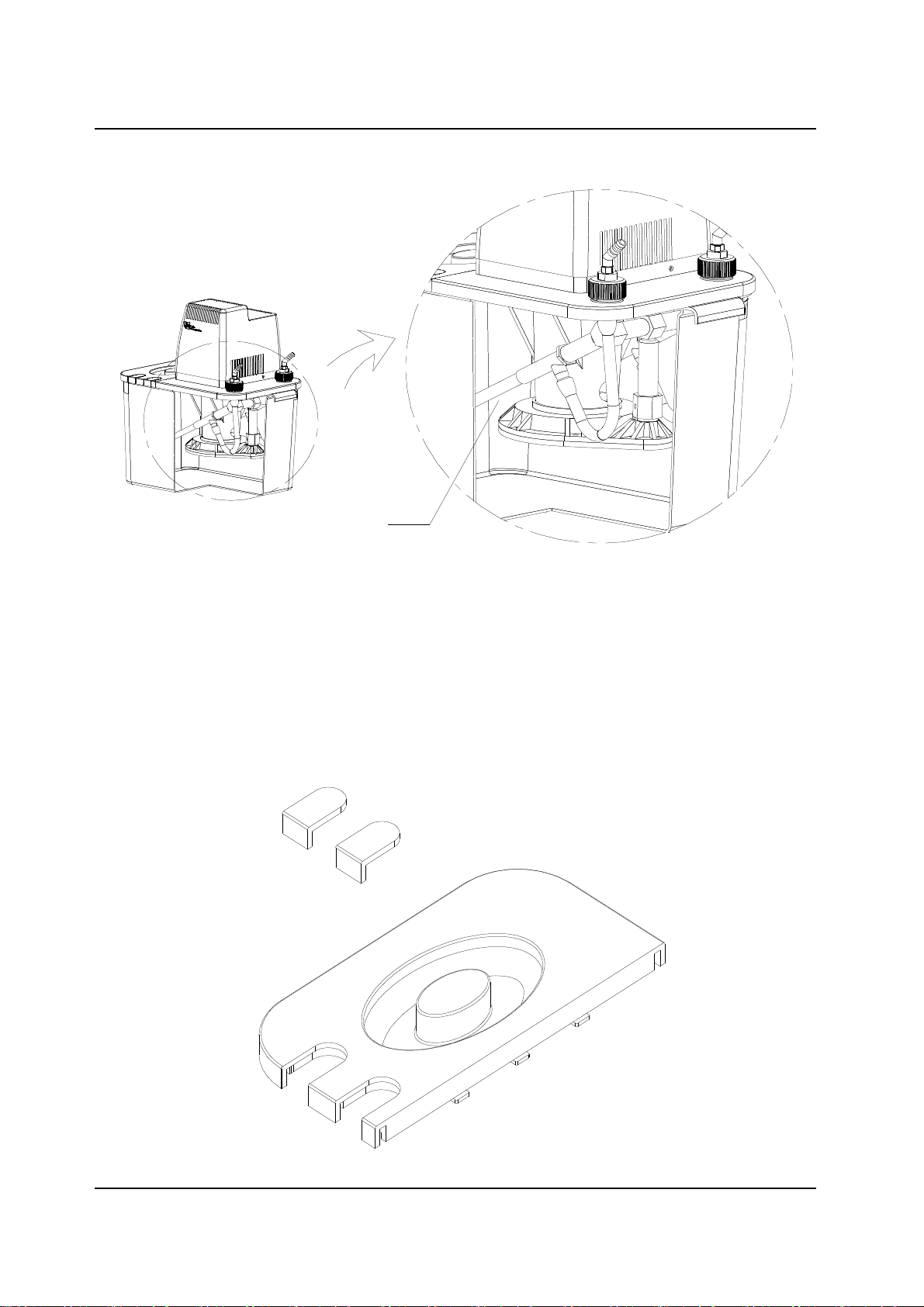

① Fill up the water in the bath up to the over-flow-nozzle.

(About 2 cm below from the nozzle)

② Connect a Y separate type tube to each of the suction ports and also

something which vacuum is needed with silicone Hoses (Ø6).

(Refer to the below image)

Y Type

Seperate Tube

③ After then, turn on the main power switch.

After the power on, the unit is working and is making vacuuming condition.

Page 9

Page 10

In case of using for inner circulation for a long time, if the water temperature

In case of using for inner circulation for a long time, if the water temperature in the

In case of using for inner circulation for a long time, if the water temperature In case of using for inner circulation for a long time, if the water temperature

bath might increase, the vacuuming condition would be limited.

bath might increase, the vacuuming condition would be limited.

bath might increase, the vacuuming condition would be limited.bath might increase, the vacuuming condition would be limited.

In addition to the vacuuming condition might be

In addition to the vacuuming condition might be influenced

In addition to the vacuuming condition might be In addition to the vacuuming condition might be

impurities

impurities that

impuritiesimpurities

that dissolving in the water.

dissolving in the water.

that that

dissolving in the water.dissolving in the water.

influenced by dissolved gas or

influencedinfluenced

by dissolved gas or

by dissolved gas or by dissolved gas or

in the

in the in the

Vapor Pressure of water in millimeters of mercury

60

50

40

30

20

Vapor Pressure[mmHg]

Page 10

10

0

5 10 15 20 25 30 35 40

Water Temperature[℃]

Page 11

The above graph shows that vacuuming fluctuation is depending on water

temperature in the bath.

In case of using for inner circulation for a long time, if the water temperature in

the bath might increase by the motor, the vacuuming condition would be limited.

When you use it for a long time, you had better infuse some cooling water to

decrease the water temperature.

---- Use with inserting cooling water

Use with inserting cooling water

Use with inserting cooling water Use with inserting cooling water

① Fill up the water in the bath up to the over-flow-nozzle.

(Under about 2 cm of the nozzle)

② Connect a Y separate type tube to the suction ports each and also

something which vacuum is needed with silicone Hoses (Ø6).

(Refer to the below image)

Vacuum

Object

Y Type

Seperate Tube

③ Connect a hose with the over flow nozzle to discharge water.

④ Connect a hose to the cock to infuse water (cooling water).

Page 11

Page 12

⑤ Turn on the main power switch.

After the power on, the unit is working and is making vacuuming condition.

Page 12

Page 13

5. Precautions for using the organic solvents

5. Precautions for using the organic solvents

5. Precautions for using the organic solvents5. Precautions for using the organic solvents

① Whenever possible, supply running water regularly in the tank.

☞ Connect the hose for supplying the running water from In/Out cock and

drain from Overflow nozzle.

② If you are using organic solvents, you must supply running water.

After operation, drain the water in the tank. Draining the water will prevent the

unit loss from the organic solvents and vapor.

③ If running water cannot be supplied, change the tank water as often as is

necessary for its frequency of use. In case of using the toxic solvents, you

must change the tank water more frequently.

④ After operation, Rinse the aspirator thoroughly after each use .

Clean and empty the tank in order to avoid any contamination.

Followings are example of organic solvents which need this sort of special care.

Acetic Acid Chloride

Acetone

Alcohols: Benzyl

Alcohols: Methyl

Ammonia

Benzene

Benzene Chloride

Cyclohexane

Chlorobenzene

Chloroform

Cyclohexanone

Dichloroethane

Diethyl Ether

Ethylene Dichloride

Ethanolamine

Ethyl ether

Ethyl Acetate

Hexane

Kerosene

Methyl Acetate

Methylene Chloride

Methyl Butyl Ketone

Methyl Ethyl Ketone

Nitrobenzene

Nitrometane

Pentane

Perchloroethylene

Toluene(Toluol)

Trichloroethylene

Turpentine

Xylene

Page 13

Page 14

6666.

.

Maintenance and

Maintenance and its

. .

Maintenance and Maintenance and

its cleaning

cleaning

its its

cleaningcleaning

1)

1) Cleaning the body

Cleaning the body

1) 1)

Cleaning the bodyCleaning the body

The main plug must be

The main plug must be separate

The main plug must be The main plug must be

It might cause an electric shock.

It might cause an electric shock.

It might cause an electric shock. It might cause an electric shock.

- Remove the power plug from the consent first.

- Clean up the body using a soft cloth or sponge damped with neutral

separated from a terminal before cleaning and

separateseparate

d from a terminal before cleaning and repairing

d from a terminal before cleaning and d from a terminal before cleaning and

repairing it.

repairingrepairing

it.

it. it.

detergent.

- Wipe with dry cloth.

※※※※ Do not use or

Do not use organic solvent.

Do not use or Do not use or

2)

2) Cleaning the bath

Cleaning the bath

2) 2)

Cleaning the bathCleaning the bath

- Clean with sponge or soft cloth with neutral detergent.

- Clean with wet cloth.

※ If you can, please use distilled water to prevent the bath from scaling.

※ If you can, please use distilled water to prevent the bath from scaling.

※ If you can, please use distilled water to prevent the bath from scaling.※ If you can, please use distilled water to prevent the bath from scaling.

※ If you do not use 75301

※ If you do not use 75301----00

※ If you do not use 75301※ If you do not use 75301

3) Silicon hose or Connector

3) Silicon hose or Connector

3) Silicon hose or Connector3) Silicon hose or Connector

- Immerse the silicon hose or connector in the water for 3~5minutes.

- Clean all surfaces with the wet sponge or cloth by neutral detergent.

- Rinse with a wet cloth by clean water.

- Wipe down all surfaces with dry cloth.

ganic solvent.

ganic solvent.ganic solvent.

00 for a long time, drain the water fro

0000

for a long time, drain the water from the bath.

for a long time, drain the water frofor a long time, drain the water fro

m the bath.

m the bath.m the bath.

Page 14

Page 15

Check on the power failure.

7777.

. Causes of malfunction and its repairs

Causes of malfunction and its repairs

. .

Causes of malfunction and its repairsCauses of malfunction and its repairs

Symptoms

Symptoms Problems

SymptomsSymptoms

Problems Solutions

ProblemsProblems

Solutions

SolutionsSolutions

1. When the unit stops

running

2. Has trouble with the

vacuuming

condition.

Check on the fuse

connection.

Check on the main power

switch is on

Check on the terminals of

the motor and capacitor.

Check on the hose nipple

sticks to the check valve.

Check on the temperature

of water in the bath. (over

40℃)

Exchange with new same one.

Turn on the main power switch.

If the motor is corroded, request the

service.

If the capacitor terminal has problems,

request the service.

If it is loose, exchange those.

If it has a high temperature, exchange the

water in the bath or connect with a piped

water line to cool it.

3. Making excessive

noise

4. A liquid (water)

leaks out from the

cock part.

Check on shortage of the

If it is short of water, fill up the water in the

bath up to the over-flow-nozzle. (Under

water.

about 2 cm of the nozzle)

Check on the vacuuming

Fixing up the vacuuming silicon hose tightly.

hose gets left out.

Check on the corrosion of

If it is corroded, request the service.

the motor.

After checking, if it keeps leaking, exchange

Check on the nut is untied.

it.

Page 15

Page 16

The motor

The motor has a thermal protector within.

The motorThe motor

In case of the motor over heating, it would stop automatically. After the over heated

In case of the motor over heating, it would stop automatically. After the over heated

In case of the motor over heating, it would stop automatically. After the over heated In case of the motor over heating, it would stop automatically. After the over heated

motor is getting cool, it will operate ag

motor is getting cool, it will operate again normally.

motor is getting cool, it will operate agmotor is getting cool, it will operate ag

8888.

. After

After Services

. .

AfterAfter

1) When there are malfunctions caused in producing in spite of user's normal

Please give us the information as below;

has a thermal protector within.

has a thermal protector within. has a thermal protector within.

ain normally.

ain normally. ain normally.

Services

ServicesServices

operation, then repairs are going to be provided free of charge for one year

from purchasing.

- Malfunctioning parts and status (if possible, please explain the state of

problems in details.)

- Type of model

- Serial Number

- Purchasing day/month/year

2) Malfunctions are to be fixed with charge in these cases notwithstanding it is

In the warranty period;

- Malfunction due to the user's mistake, improper repairs, or remodeling the

part or whole unit.

- Malfunction due to the user's improper handling or carrying the unit after

purchasing.

- Malfunction due to disasters such as fire, flood, or abnormal power

supply.

- Malfunction due to user's not following the operation manual.

3) Contact to our company or dealer for more information or questions.

Page 16

Page 17

9999. Accessories

. Accessories

. Accessories. Accessories

Accessories are optional.

- Cooling Coil - Vacuum Controller

Page 17

Page 18

10

10. Technical rep

. Technical report

1010

. Technical rep. Technical rep

ort

ortort

1) Bath

The bath is made of P.P (Poly Propylene).

Please be attention to use the unit because P.P is an excellent durable

material against drugs and chemicals, but it may transform the shape with the

follow conditions.

- Need to avoid the follow conditions

It may be burned, but be fired no so easily.

Avoid getting in touch with oxidizer, overheating, spark and flame.

- Need to avoid the follow materials

Chlorine (liquid): reaction of explosion

Hydrogen peroxide: a danger of fire and explosion

Nitric acid: a danger of fire and explosion

Oxidizer (strong): a danger of fire and explosion

Hydrogen manganic acid potassium: firing

Benzene, toluene (aromatic hydrocarbons, halogenations hydrocarbon): On

over 80℃, dissolving by aromatic hydrocarbons like benzene and toluene.

2) Silicone Packing

General rubber is eroded by strong acid and alkali, but it is durable against

normal acid, base, basic inorganic drugs, alcohol, and polar organic

compound like animal / vegetable oil.

- Need to avoid the follow materials

Gasoline, toluene and carbon tetrachloride etc.

(It is swelled by above of the nonpolar solvent but, if the solvent evaporates, it

turns back to the original condition.)

Please read this operatin

Please read this operating manual carefully and obey with the operating condition.

Please read this operatinPlease read this operatin

If you would not obey, it might cause damage or abnormal operating.

If you would not obey, it might cause damage or abnormal operating.

If you would not obey, it might cause damage or abnormal operating. If you would not obey, it might cause damage or abnormal operating.

Page 18

g manual carefully and obey with the operating condition.

g manual carefully and obey with the operating condition.g manual carefully and obey with the operating condition.

Page 19

11

11. Warranty

. Warranty

1111

. Warranty. Warranty

1. Warranty Period

Each Product of Cole-Parmer purchased by customer will be free from defects

in material and workmanship for 2 year limited warranty. Cole-Parmer will

replace faulty parts for a fee based on then current component acquisition

costs after warranty period.

Cole-Parmer will, at its option, repair at no charge, replace or refund the

purchase price of a defective product purchased through a Cole-Parmer

authorized sales outlet and at the applicable price during warranty period.

Cole-Parmer will pay all costs for product repaired or replaced in-warranty in

case of exported items.

2. Limitation

This warranty does not cover fuses, disposable batteries and damage from

accident, neglect, contamination, misuse or abnormal conditions of operation

or handling, including over-voltage failures caused by use outside the

Products’ specified rating, or normal wear and tear of mechanical components.

This warranty covers the original purchaser only and is not transferable.

Warranty is limited to the repair or replacement of the original unit. For

inspection, return the units freight pre-paid to the nearest Dealer of

Cole-Parmer .Upon Cole-Parmer’s evaluation, defective units will be repaired

or replaced at no charge. Cole-Parmer will not accept responsibility for

unauthorized expenditures or losses.

3. General

Send defective product with a description of the problem to the nearest

Cole-Parmer Service Center, postage and insurance prepaid. Cole-Parmer will

pay return transportation for product repaired or replaced in-warranty. Before

making any non-warranty repair, Cole-Parmer will estimate cost and obtain

authorization, then invoice you for repair and return transportation.

This warranty is your only remedy. No other warranties, such as fitness for a

particular purpose, are expressed or implied. Cole-Parmer is not liable for any

special, indirect, incidental or consequential damages or loses, including loss

of data, arising from any cause or theory. Authorized resellers are not authorized

to extend any different warranty on Cole-Parmer ‘s behalf. Since some states

do not allow the exclusion or limitation of an implied warranty or of incidental or

consequential damages, this limitation of liability may not apply to you.

4. Required things for service

• Serial Number • Model •Purchase date from •Claim & Service claim form

Page 19

Page 20

11112222. Specifications

. Specifications

. Specifications. Specifications

Model 75301-00

Capacity

Consisting of

Spec.

Exhaust volume 18ℓ/min×2EA

Vacuum range Depend on saturated vapor pressure

Motor 150W

Aspirator Metal 2ea or plastic 2ea

Bath internal size 298×210×227 mm

Size

Bath volume 9.5ℓ

Bath material Polypropylene

Inhale external Φ9.5, 2ea

Drain Drain cock

Over flow Nozzle Φ17

Pressurization circulating

Exhaust

of water flow Pump

Safety device Thermal protector, Fuse

External size 330×265×390

Weight Approx. 5.7 kg

Page 20

Power supply 115VAC, 50/60Hz

Power consumption 1.5A

Page 21

13

13.

. Exploded View

Exploded View

1313

. .

Exploded ViewExploded View

Page 21

Page 22

14

14.

. Par

1414

. .

Part List

t List

ParPar

t Listt List

Page 22

Page 23

Page 23

Page 24

Page 24

Loading...

Loading...