Page 1

OPERATING MANUAL

VARIABLE-SPEED

PUMP DRIVE

NOTICE D’UTILISATION

ENTRAÎNEMENT DE

POMPE À VITESSE

VARIABLE

BEDIENUNGSANLEITUNG

REGELPUMPENANTRIEB

MANUAL DE OPERACIÓN

MANDO DE BOMBA DE

VELOCIDAD VARIABLE

®

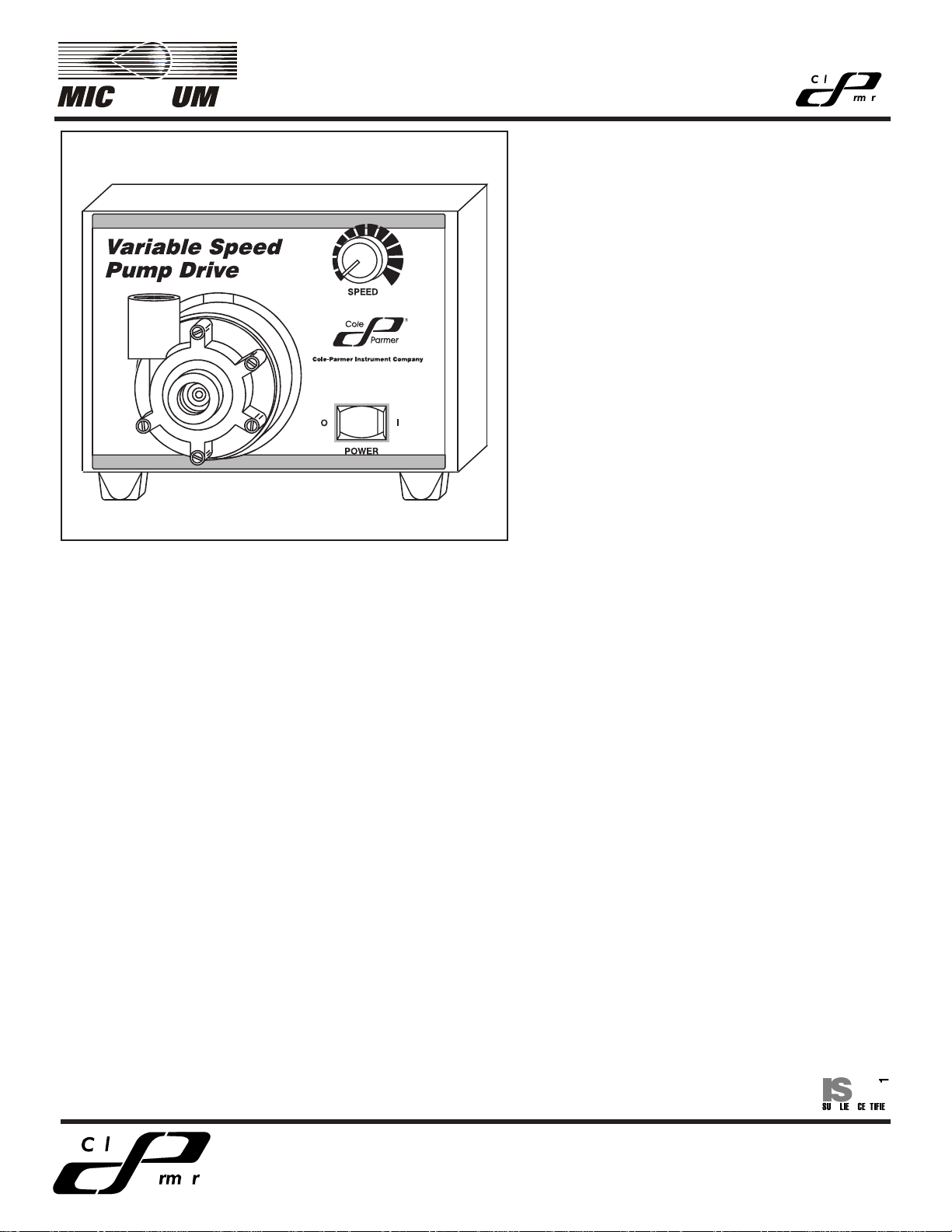

75211-60 Variable Speed Pump Drive with Centrifugal Pump

Entraînement à vitesse variable 75211-60 pour

pompe centrifuge

75211-60 Regelpumpenantrieb mit Kreiselpumpe

Mando de bomba de velocidad variable con bomba

centrífuga 75211-60

75211-60 Azionamento della pompa a velocità variabile

con pompa centrifuga

MANUALE DI ISTRUZIONI

AZIONAMENTO DELLA

POMPA A VELOCITÀ

VARIABILE

Model Nos.

Modèles n°

Modellnummern

Números de modelo

Modelli n°

75211-10

75211-15

75211-60

75211-62

75211-65

75211-67

®

Cole-Parmer Instrument Co.Cole-Parmer Instrument Co.

Cole-Parmer Instrument Co.

Cole-Parmer Instrument Co.Cole-Parmer Instrument Co.

625 East Bunker Court, Vernon Hills, Illinois U.S.A. 60061-1844

800-323-4340 (847) 549-7600 FAX: (847) 247-2929

www.coleparmer.com e-mail: techinfo@coleparmer.com

A-1299-0852

Edition 01

Page 2

EU Declaration of Conformity

Name of Apparatus: Variable Speed Console Analog Gear Pump Drive

Model Numbers: 75211-15, -65, -67

Description of Apparatus: Variable Speed, Gear Pump Motor Drive. Used with

pump head and tubing to pump fluids.

75211-15 (5000 rpm), -67 (9000 r pm);

75211-65 (9000 rpm w/ Pump)

Barnant Company declares that the above models are in conformity to the following

harmonized standards and directives:

Applicable Applicable Manufacturer’s

Directives Specifications Report Number

®

73/23/EEC EN61010-1/A2:1995 TR9643

93/68/EEC

89/336/EEC EN61326-1/A1:1998 TR9644

92/31/EEC

93/68/EEC

The last two digits of the year in which the current configuration of the above models were

assessed per the Low Voltage Directive is: 00.

Manufacturer: Barnant Company Division

Cole-Parmer Instrument Company

28W092 Commercial Avenue

Barrington, IL 60010-2392

USA

Tel: 847-381-7050

Manufacturer’s Signature:

28 July, 2000

James W. Doll Date

Vice President, Engineering

Page 3

TABLE OF CONTENTS

Title Page

SAFETY PRECAUTIONS ............................................................................................................. ........................ ii

INTRODUCTION ................................................................................................................................................... 1

DESCRIPTION ...................................................................................................................................................... 2

INSTALLATION/SETUP ............................................................................................................. ........................... 2

OPERATION ...................................................................................................................... ................................... 3

O/I Control (OFF/ON) ........................................................................................................................................3

Speed Control....................................................................................................................................................3

TROUBLESHOOTING AND MAINTENANCE ................................................................................................ ...... 3

Troubleshooting ..................................................................................................................................................3

Cleaning ....................................................................................................................... ...................................... 3

Replacement Parts ............................................................................................................................................ 3

Motor Brush Check/Replacement......................................................................................................................4

SPECIFICATIONS ................................................................................................................................................ 4

WARRANTY.......................................................................................................................................................... 6

PRODUCT RETURN ............................................................................................................................................. 6

TECHNICAL ASSISTANCE .................................................................................................................................. 6

i

Page 4

SAFETY PRECAUTIONS

DANGER: Disconnect from power source before any cleaning operation is started.

WARNINGS: Gear pumps should not be operated above 5000 rpm.

Unplug Drive prior to checking/replacing MOTOR BRUSHES.

CAUTION: To prevent damage to pump, do not restrict pump inlet or run the pump dry.

WARNING: PRODUCT USE LIMITATION

These products are not designed for, nor intended for use in patient connected applications; including, but not

limited to, medical and dental use, and accordingly have not been submitted for FDA approval.

MICROPUMP - Reg TM Micropump Inc.

Trademarks bearing the ® symbol in this publication are registered in the U.S. and in other countries.

ii

Page 5

INTRODUCTION

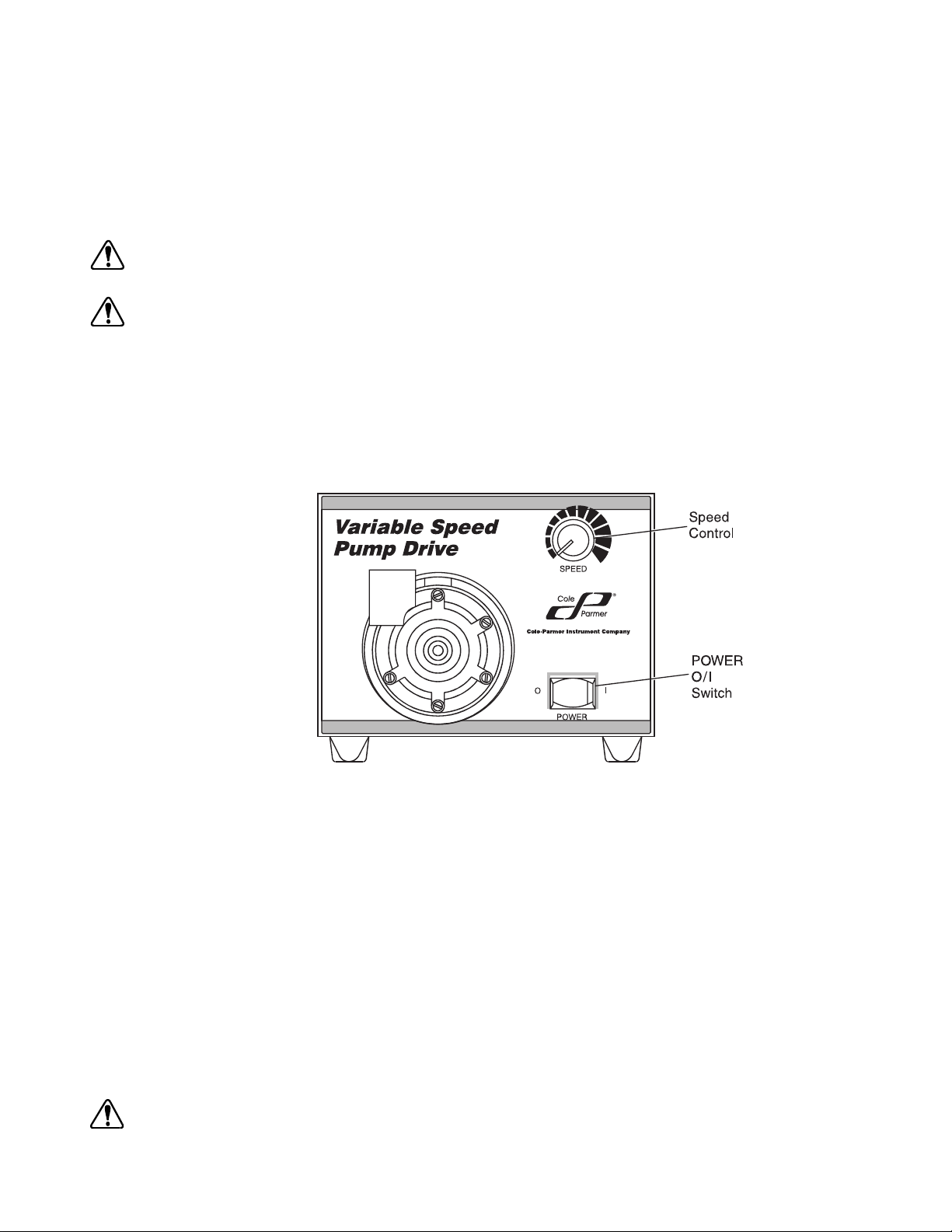

The instructions in this manual are task oriented to allow easy access to the desired information. Figure 1 provides

summarized information on all controls to the Pump Drives. This manual contains complete information on installing

and setting up the Pump Drives, as well as operating and servicing at the user level. The f ollowing chart provides basic

information on models covered in this manual.

Drive Catalog Number Output rpm Flow rate Power Requirement*

75211-10

75211-15 200 to 260V AC

50 to 5000

75211-60

75211-65 200 to 260V AC

90 to 9000

75211-62

75211-67 200 to 260V AC

90 to 9000

*AC voltages can be either 50 or 60 Hz.

The Pump Drives contain the pump drive motor and motor controls in one compact unit. MICROPUMP® Pump Heads

are attached directly to the motor, which is accessible from the front panel. In addition, these drives incorporate the

following features:

• Ball bearing motor for continuous duty

• Have controlled start-up

2.5–5450 mL/min 90 to 130V AC

(purchase pump head separately)

0–7.0 gpm 90 to 130V AC

(with provided pump head)

0–7.0 gpm 90 to 130V AC

(purchase pump head separately)

• Speed control over a 100:1 range

• Pumps are magnetically coupled to motor

• Stackable

• IP22 rating per IEC 529

• Replaceable Motor Brushes

75211-60 and 75211-65 are supplied with a centrifugal pump attached.

1

Page 6

DESCRIPTION

These electronic drives are self-contained compact units that include a drive motor and all operating controls (see

Figure 1). These drives are especially designed for magnetically coupled pumps.

The 75211-10, -15, -62 and -67 drives come without a pump head. They will accept all MICROPUMP Pump Heads with

standard mounting canisters. The Pump Heads can be easily mounted to the motor, which is accessible from the front

panel. High and lo w speed versions are available cov ering a wide range of flo w rates .

Pump Heads and performance information.

WARNING: Gear pumps should not be operated above 5000 rpm.

CAUTION: To prevent damage to pump, do not restrict pump inlet or run the pump dry.

The 75211-60 and -65 drives come with a 7-GPM Centrifugal Pump Head mounted on it. The Pump Head has 3/8 NPT(F)

inlet and 1/4 NPT(F) outlet ports.

The solid-state speed control circuitry offers excellent speed regulation even with line voltage and load variations. A

neon POWER indicator in the switch illuminates whene ver the O/I s witch is in the I (ON) position. Pump drive speed can

be manually controlled over a 100:1 range with the front panel mounted potentiometer. “Soft-start” and smooth g radual

acceleration to speed setting is provided when line power switching.

Contact your dealer for a vailable

Figure 1

INSTALLATION/SETUP

Unpack the Pump Drive and retain all packing material until proper product operation has been verified.

The Pump Drive rests on four vibration isolator f eet f or placement on a bench, desk or tab le . It is supplied with a power

cord.

1. If applicable, attach the MICROPUMP Pump Head.

2. Check that the O/I Switch is in the O (OFF) position.

3. Connect the AC power cord on the rear panel to the AC power source.

4. Set the speed control to minimum.

5. Install the pump below the level of the supply liquid. The liquid must be under atmospheric conditions.

6. This completes the basic setup.

CAUTION: To prevent damage to pump, do not restrict pump inlet or run the pump dry.

2

Page 7

OPERATION

Operation of the Pump Drive has been simplified, requiring only two controls, the O/I Control and the Speed Control

(see Figure 1). The operation of each of these controls is explained below.

O/I Control

The O/I Control is used for turning power OFF or ON. When the control is in the O position, power is OFF and the g reen

POWER light in the switch is not lit.

Speed Control

The Speed Control setting determines the rpm of the pump and, therefore, the flow rate. Depending on the model, the

maximum speed will be either 5000 or 9000. Rotating the Speed Control clockwise increases speed linearly.

TROUBLESHOOTING AND MAINTENANCE

Troubleshooting

SYMPTOM CAUSE REMEDY

The motor does not rotate when

the O/I switch (Figure 1) is

moved to I (ON) position.

POWER indicator does not glow.

No power.

Fuse has blown. Replace with recommended fuse.

1. Check that Pump Drive is plugged into a

power source.

2. Check that cord is inserted properly into

IEC-320 connector.

3. Check fuse.

4. Return for servicing.

CAUTION: Do not substitute.

Erratic variations in speed.

Cleaning

Worn motor brushes.

See Motor Brush Check/Replacement.

DANGER: Disconnect from power source before any cleaning operation is started.

Keep the Pump Drive enclosure clean by wiping down with a mild detergent. Never immerse or use excess fluid.

Replacement Parts

The following parts are user replaceable:

Description Part Number

Brush Caps (set of 2) 07520-03

Motor Brushes (set of 2) 07520-04

Speed Control Knob B-1083-0062

Cordset—Australia (230V units) 50001-60

Cordset—Denmark (230V units) 50001-62

Cordset—India (230V units) 50001-64

Cordset—Israel (230V units) 50001-66

Cordset—USA (115V units) 50001-68

Cordset—European (230V units) 50001-70

Cordset—British (230V units) 50001-72

Cordset—Swiss (230V units) 50001-74

Cordset—Italian (230V units) 50001-76

Cordset—USA (230V units) 50001-78

Fuse—T1.6A, 250V (230V units) 77500-11

Fuse—T3.15A, 250V (115V units) 77500-25

Contact your dealer if you have service needs.

3

Page 8

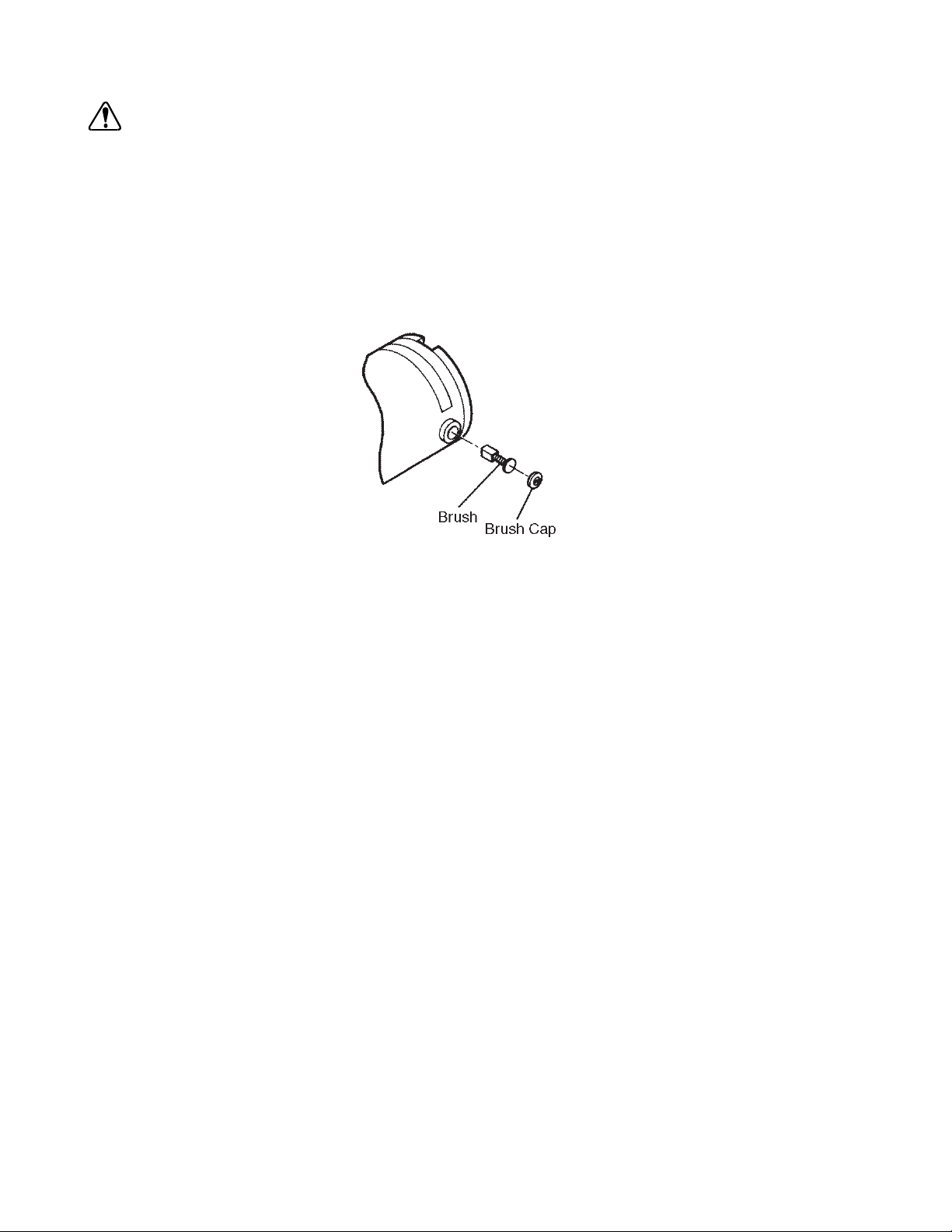

Motor Brush Check/Replacement

WARNING: Unplug Drive prior to checking/replacing MOTOR BRUSHES.

Note: Brushes should be checked ev ery 6 months, or appro ximately 500 operating hours or if err atic operation occurs .

1. Place the POWER Switch (O/I) in the O (OFF) position.

2. Disconnect the AC power input line cord from the AC receptacle.

3. Remove the four screws from each side of the housing and lift off the housing.

4. Carefully unscrew each brush cap on opposite sides of the motor (Figure 2). Withdraw the brush, and examine

it for wear.

Figure 2. Typical Brush Replacement

Note: Replace both brushes if either brush is less than 0.300 in (7.6 mm) long from base to point.

5. Insert brushes and install brush cap on each side of motor.

6. Install housing and secure with the four screws on each side.

7. Connect the AC power input line cord to the AC receptacle.

SPECIFICATIONS

Output:

Speed, Max.:

Model 75211-10, -15 5000 rpm

Model 75211-60, -62, -65, -67 9000 rpm

Speed, Min.:

Model 75211-10, -15 50 rpm

Model 75211-60, -62, -65, -67 90 rpm

Torque output, Maximum: 12 oz-in (85 mN•m)

Flow-range:

Model 75211-10, -15 2.5 to 5450 mL/min (purchase pump head separately)

Model 75211-60, -65 0 to 7.0 gpm (with provided pump head)

Model 75211-62, -67 0 to 7.0 gpm (purchase pump head separately)

4

Page 9

Specifications (Cont.)

Adjustment ranges: Clockwise Motor Rotation

Speed regulation, line: ±1%

Speed regulation, load: ±2%

Speed regulation, warm-up drift: ±10%

Duty Cycle: Continuous

Input:

Supply Voltage Limits: 90 to 130V AC or 200–260V AC

Frequency: 50/60 Hz

Current, max:

115V 2.3A

230V 1.4A

Installation Category: Installation Category II per IEC 664 (local level—appliances,

portable equipment, etc.)

Construction:

Dimensions: 7 in-L × 7 in-W × 5 in-H (17.8 × 17.8 × 12.7 cm)

Weight (Drive only): 8 pounds (3.6 kg)

Enclosure Rating: IP22 per IEC529

Centrifugal Pump

(75211-60, -65 only): Flow rate: 7 gpm

Maximum fluid temperature: 121°C (250°F)

Maximum system pressure: 200 psi

Differential pressure: 10 psi

Wetted parts: 316 SS and PTFE

Environment:

Temperature, Operating: 0°C to 40°C (32°F to 104°F)

Temperature, Storage: −45°C to 60°C (−49°F to 140°F)

Humidity: 10% to 90% non-condensing

Altitude: Less than 2000 m

Pollution Degree: Pollution Degree 2 per IEC 664 (indoor usage—lab, office)

Chemical Resistance: Exposed material is painted steel.

Compliance: 115V: UL508, CSA C22.2, No. 14-M91

230V (For CE Mark):

EN61010-1/A2: 1995 (EU Low Voltage Directive) and

EN61326-1/A1: 1998 (EU EMC Directive)

5

Page 10

WARRANTY

The Manufacturer warrants this product to be free from significant deviations from published specifications. If repair or

adjustment is necessary within the warranty period, the problem will be corrected at no charge if it is not due to misuse

or abuse on your part as determined by the Manufacturer. Repair costs outside the warranty period, or those resulting

from product misuse or abuse, may be invoiced to you.

The warranty period for this product is noted on the Warranty Card.

PRODUCT RETURN

T o limit charges and dela ys, contact the seller or Man ufacturer f or authorization and shipping instructions before returning the product, either within or outside of the warranty period. When returning the product, please state the reason for

the return. For y our protection, pac k the product carefully and insure it against possib le damage or loss. Any damages

resulting from improper packaging are your responsibility.

TECHNICAL ASSISTANCE

If you have any questions about the use of this product, contact the Manufacturer or authorized seller.

Printed in U.S.A.

010400

6

Page 11

TABLE DES MATIÈRES

Intitulé Page

MESURES DE SÉCURITÉ ................................................................................................................................... ii

INTRODUCTION ................................................................................................................... ................................ 1

DESCRIPTION...................................................................................................................................................... 2

INSTALLATION/CONFIGURATION....................................................................................................................... 2

FONCTIONNEMENT ............................................................................................................................................ 3

Commande O/I (ARRÊT/MARCHE) ..................................................................................................................3

Commande de vitesse ....................................................................................................................................... 3

DÉPANNAGE ET ENTRETIEN......................................................................................................... .................... 3

Dépannage ...................................................................................................................... .................................. 3

Nettoyage .......................................................................................................................................................... 3

Pièces de rechange ........................................................................................................................................... 3

Contrôle/remplacement des balais de moteur ................................................................................................... 4

CARACTÉRISTIQUES TECHNIQUES .................................................................................................... ............. 4

GARANTIE....................................................................................................................... ..................................... 6

RETOUR DE MARCHANDISES ........................................................................................................................... 6

ASSISTANCE TECHNIQUE........................................................................................................... ....................... 6

i

Page 12

MESURES DE SÉCURITÉ

DANGER: Débrancher l’appareil avant de procéder à toute opération de nettoyage.

AVERTISSEMENTS : Les pompes à engrenages ne doivent pas fonctionner au-dessus de 5000 tr/mn.

Débrancher l’entraînement avant de contrôler/remplacer les BALAIS DE MOTEUR.

ATTENTION: Pour éviter d’endommager la pompe, ne pas obstruer son orifice d’entrée ni la faire

tourner à sec.

AVERTISSEMENT : LIMITES D’UTILISATION DU PRODUIT

Ces produits ne sont pas conçus pour, ni destiné à, être utilisé dans les applications a vec patients, y compris, entre

autres, les applications médicales et dentaires et n’ont par conséquent pas été soumis à l’agrément de la FDA.

MICROPUMP — Marque déposée de Micropump Inc.

Les marques accompagnées du symbole ® citées dans cette publication sont déposées aux États-Unis et dans d’autres pays.

ii

Page 13

INTRODUCTION

Les instructions données dans cette notice sont orientées vers les différentes tâches pour faciliter l’accès aux informations désirées. La Figure 1 fournit un résumé des informations concernant toutes les commandes des entraînements

de pompes. Cette notice donnent des informations complètes sur l’installation et la configuration des entraînements de

pompes, ainsi que sur l’utilisation et l’entretien par l’utilisateur. Le tableau ci-dessous donne des inf ormations de base

sur les modèles dont traite cette notice.

Numéro catalogue Vitesse de sortie Débit Spécifications

de l’entraînement électriques*

75211-10

75211-15 (avec tête de pompe achetée séparément) 200 à 260 V c.a.

75211-60

75211-65 (avec la tête de pompe fournie) 200 à 260 V c.a.

75211-62

75211-67 (avec tête de pompe achetée séparément) 200 à 260 V c.a.

50 à 5000 tr/mn

90 à 9000 tr/mn

90 à 9000 tr/mn

*La fréquence du secteur peut être de 50 ou 60 Hz.

Les entraînements de pompes regroupent le moteur d’entraînement de pompe et ses commandes en un même appareil

compact. Les têtes de pompes MICROPUMP® sont accouplées directement au moteur, qui est accessible depuis le

panneau avant. En outre, ces entraînements offrent les caractéristiques suivantes :

• Moteur à roulements à billes pour service continu

• Mise en marche contrôlée

2,5–5450 ml/min 90 à 130 V c.a.

0–26,5 l/min 90 à 130 V c.a

0–26,5 l/min 90 à 130 V c.a.

• Réglage de vitesse sur une plage de 100 : 1

• Accouplement magnétique des pompes au moteur

• Possibilité d’empilage

• Classe IP22 aux termes de la norme IEC 529

• Balais de moteur remplaçables

Les modèles 75211-60 and 75211-65 sont fournis avec une pompe centrifuge accouplée.

1

Page 14

DESCRIPTION

Ces entraînements électroniques sont des appareils compacts autonomes qui regroupent un moteur d’entraînement et

toutes les commandes (voir Figure 1). Ces entraînements sont spécialement conçus pour les pompes à accouplement

magnétique.

Les entraînements 75211-10, -15, -62 et -67 sont fournis sans tête de pompe. Ils sont compatibles a vec toutes les têtes

de pompes MICROPUMP à boîtier de montage standard. Les têtes de pompes se montent facilement sur le moteur , qui

est accessible depuis le panneau avant. Des versions haute et basse vitesse offrant une large gamme de débits sont

disponibles.

AVERTISSEMENT : Les pompes à engrenages ne doivent pas fonctionner au-dessus de 5000 tr/mn.

ATTENTION : Pour éviter d’endommager la pompe, ne pas obstruer son orifice d’entrée ni la faire tourner

Les entraînements 75211-60 et -65 sont fournis avec une tête de pompe centrifuge 7-GPM (26,5 l/mn) prémontée.

Cette dernière a un orifice d’entrée de 3/8 po NPT(F) et un orifice de sortie de 1/4 po NPT(F).

Les circuits de réglage de vitesse à semiconducteurs permettent une excellente régulation de la vitesse, même en cas

de variations de la tension du secteur et de la charge. Un témoin d’alimentation au néon incorporé au commutateur

O/I (arrêt/marche) s’allume lorsque ce dernier est en position I (MARCHE). La vitesse de l’entraînement de pompe peut

être commandée manuellement sur une plage de 100 : 1 à l’aide du potentiomètre monté sur le panneau avant. Un

« démarrage en douceur » et une accélération prog ressive sans à-coups sont obten us lorsque le commutateur d’arrêt/

marche est actionné.

S’adresser au revendeur pour les têtes de pompes disponib les et des informations sur leurs performances.

à sec.

Command

de vitesse

Commutateur O/I

(arrêt/marche)

Figure 1

INSTALLATION/CONFIGURATION

Déballer l’entraînement de pompe et conserver le matériau d’emballage jusqu’à ce que le fonctionnement correct du

produit ait été vérifié.

L’entr aînement de pompe repose sur quatre pieds d’isolement antivibratoire pour placement sur un établi, un bureau ou

une table. Il est fourni avec un cordon d’alimentation.

1. Le cas échéant, accoupler la tête de pompe MICROPUMP.

2. Vérifier que le commutateur O/I est en position (ARRÊT).

3. Brancher le cordon d’alimentation qui se trouve sur le panneau arrière au secteur.

4. Régler la vitesse au minimum.

5. Installer la pompe en dessous du niveau de liquide à pomper. Le liquide doit être aux conditions atmosphériques.

6. Cela complète l’installation de base.

ATTENTION : Pour éviter d’endommager la pompe, ne pas obstruer son orifice d’entrée ni la faire tourner

à sec.

2

Page 15

FONCTIONNEMENT

Le fonctionnement de l’entraînement de pompe a été simplifié pour ne demander que deux commandes, le commutateur

O/I et la commande de vitesse (voir Figure 1). Le fonctionnement de chacune de ces commandes est décrit ci-après.

Commutateur O/I

Le commutateur O/I sert à mettre l’appareil hors et sous tension. Lorsqu’il est en position O, le cour ant est coupé et le

témoin vert d’alimentation incorporé au commutateur est éteint.

Commande de vitesse

La position à laquelle est réglée la commande de vitesse détermine la vitesse de la pompe et, par conséquent, le débit.

Suivant le modèle, la vitesse maximum est 5000 ou 9000 tr/mn. La rotation de la commande de vitesse dans le sens

horaire augmente la vitesse linéairement.

DÉPANNA GE ET ENTRETIEN

Dépannage

SYMPTÔME CAUSE MESURE CORRECTRICE

Le moteur ne tourne pas lorsque

le commutateur O/I (Figure 1)

est placé en position I

(MARCHE). Le témoin

d’alimentation ne s’allume pas.

L’appareil est

hors tension.

Le fusible a

sauté.

1. Vérifier que l’entraînement de pompe est

branché dans une prise de courant.

2. Vérifier que le cordon d’alimentation est enfoncé

correctement dans le connecteur IEC-320.

3. Vérifier le fusible.

4. Renvo y er l’appareil pour répar ation.

Le remplace par un fusible du type recommandé.

ATTENTION : ne pas substituer un fusible

d’un autre type.

Vitesse irrégulière.

Nettoyage

Balais de moteur

usés.

V oir Contrôle/remplacement des balais de

moteur.

DANGER :Débrancher l’appareil avant de procéder à toute opération de nettoyage.

Maintenir la propreté du carter de l’entraînement de pompe en le frottant avec un détergent doux. Ne jamais plonger

complètement l’entraînement dans du liquide ni utiliser trop de liquide pour le nettoyer.

Pièces de rechange

Les pièces suivantes peuvent être remplacées par l’utilisateur :

Description Numéro de pièce

Capuchons de balais (jeu de 2) 07520-03

Balais de moteur (jeu de 2) 07520-04

Bouton de réglage de vitesse B-1083-0062

Cordon d’alimentation—Australie (230 V) 50001-60

Cordon d’alimentation—Danemark (230 V) 50001-62

Cordon d’alimentation—Inde (230 V) 50001-64

Cordon d’alimentation—Israël (230 V) 50001-66

Cordon d’alimentation—États-Unis (115 V) 50001-68

Cordon d’alimentation—Europe (230 V) 50001-70

Cordon d’alimentation—Grand-Bretagne (230 V) 50001-72

Cordon d’alimentation—Suisse (230 V) 50001-74

Cordon d’alimentation—Italie (230 V) 50001-76

Cordon d’alimentation—États-Unis (230 V) 50001-78

Fusible—T1.6 A, 250 (230 V) 77500-11

Fusible—T3.15 A, 250 (115 V) 77500-25

S’adresser au revendeur pour tout service après-vente.

3

Page 16

Contrôle/remplacement des balais de moteur

AVERTISSEMENT : Débrancher l’entraînement avant de contrôler/remplacer les BALAIS DE MOTEUR.

Remarque : il convient de contrôler les balais tous les 6 mois, toutes les 500 heures de fonctionnement ou en cas de

fonctionnement irrégulier .

1. Placer le commutateur d’arrêt/marche (O/I) en position O (ARRÊT).

2. Débrancher le cordon d’alimentation de la prise de courant.

3. Retirer les quatre vis de chaque côté du boîtier et soulever ce dernier pour l’enlever.

4. Dévisser avec précaution chaque capuchon de balais sur les côtés opposés du moteur (Figure 2). Retirer le balai et

l’examiner pour voir s’il est usé.

Balai

Figure 2. Remplacement normal des balais

Remarque : remplacer les deux balais si l’un d’eux est long de moins de 7,6 mm de la base à la pointe.

5. Insérer les balais et mettre le capuchon en place de chaque côté du moteur.

6. Remettre le boîtier en place et le fixer au moyen des quatre vis de chaque côté.

7. Rebrancher le cordon d’alimentation dans la prise de courant.

Capuchon

de balai

CARACTÉRISTIQUES TECHNIQUES

Sortie :

Vitesse, max. :

Modèles 75211-10, -15 5000 tr/mn

Modèles 75211-60, -62, -65, -67 9000 tr/mn

Vitesse, min. :

Modèles 75211-10, -15 50 tr/mn

Modèles 75211-60, -62, -65, -67 90 tr/mn

Couple de sortie, maximum : 85 mN•m

Plage de débit :

Modèles 75211-10, -15 2,5 à 5450 ml/min (avec tête de pompe achetée séparément)

Modèles 75211-60, -65 0 à 26,5 l/min (avec la tête de pompe fournie)

Modèles 75211-62, -67 0 à 26,5 l/min (avec tête de pompe achetée séparément)

4

Page 17

Caractéristiques techniques (suite)

Plages de réglage : Rotation du moteur dans le sens horaire

Régulation de vitesse, linge : ±1 %

Régulation de vitesse, charge : ±2 %

Régulation de vitesse,

dérive au réchauffage : ±10 %

Mode de service : Continu

Entrée :

Limites de tension d’alimentation : 90 à 130 V c.a. ou 200 à 260 V c.a.

Fréquence : 50/60 Hz

Intensité, max :

115 V 2,3 A

230 V 1,4 A

Catégorie d’installation : Catégorie d’installation II aux termes de la norme IEC 664 (installation

locale—appareillage, matériel portatif, etc.)

Fabrication :

Dimensions : 17,8 × 17,8 × 12,7 cm

Poids (entraînement seul) : 3,6 kg

Homologation du carter : IP22 (IEC529)

Pompe centrifuge

(75211-60, -65 uniquement) : Débit : 26,5 l/min

Température maximum du liquide : 121°C

Pression maximum du circuit : 13,8 bars

Différence de pression : 0,69 bar

Pièces mouillées : acier inoxydable 316 et polytétrafluoroéthylène

Conditions d’utilisation :

Température, fonctionnement : 0 à 40 °C

Température, entreposage : −45 à 60 °C

Humidité : 10 à 90 % sans condensation

Altitude : Inférieure à 2000 m

Degré de pollution : Degré 2 (IEC 664) (utilisation intérieure—laboratoire, bureau)

Résistance aux attaques chimiques : Les parties exposées sont en acier peint.

Conformités : 115 V : UL508, ACNOR C22.2, n° 14-M91

230 V (pour estampillage CE) :

EN61010-1/A2 : 1995 (Directive européenne sur les basses tensions) et

EN61326-1/A1 : 1998 (Directive européenne sur la compatibilité

électromagnétique)

5

Page 18

GARANTIE

Nous garantissons que ce produit est conforme aux descriptifs. Si une réparation ou un réglage s’avère nécessaire

durant la période de garantie, le problème sera corrigé gratuitement s’il n’est pas dû à une utilisation par le client dont

nous avons déterminé qu’elle est incorrecte ou abusive . Les réparations effectuées en dehors de la période de garantie

ou rendues nécessaires par une utilisation incorrecte ou abusive seront à la charge du client.

La période de garantie pour ce produit est indiquée sur la carte de garantie.

RETOUR DE MARCHANDISES

Pour limiter les frais et délais , le produit ne peut être retourné sans notre autorisation préalable et instructions d’expédition

ou de celles du revendeur. Lors du renvoi du produit, bien vouloir en indiquer la raison. Pour se protéger, nous

recommandons au client d’emballer soigneusement le produit et de le garantir contre les risques de dommages ou de

perte. Nous ne serons pas responsible des dommages résultant d’un emballage incorrect.

ASSIST ANCE TECHNIQUE

Pour toute question concernant l’utilisation de ce produit, prendre contact avec nous ou avec le revendeur agréé.

Imprimé aux États-Unis

010400

6

Page 19

INHALTSVERZEICHNIS

Titel Seite

SICHERHEITSMASSNAHMEN ............................................................................................................................ ii

EINFÜHRUNG ...................................................................................................................................................... 1

BESCHREIBUNG ................................................................................................................................................. 2

INSTALLATION/EINRICHTUNG ........................................................................................................................... 2

BETRIEB............................................................................................................................................................... 3

O/I-Schalter (AUS/EIN) .......................................................................................................................................3

Drehzahlregler.....................................................................................................................................................3

STÖRUNGSBESEITIGUNG UND WARTUNG ................................................................................................ ..... 3

Störungsbeseitigung ............................................................................................................................................ 3

Reinigen .............................................................................................................................................................. 3

Ersatzteile ........................................................................................................................................................... 3

Überprüfen und Auswechseln der Kohlebürsten.................................................................................................. 4

TECHNISCHE DATEN .......................................................................................................................................... 4

GARANTIE....................................................................................................................... ..................................... 6

WARENRÜCKSENDUNGEN................................................................................................................................ 6

TECHNISCHE BERATUNG .................................................................................................................................. 6

i

Page 20

SICHERHEITSMASSNEHMEN

VORSICHT, LEBENSGEFAHR: Vor allen Reinigungsarbeiten die Verbindung zur Stromquelle lösen.

VORSICHT: Zahnradpumpen dürfen mit maximal 5000 U/min betrieben werden.

Vor Überprüfen bzw. Auswechseln der K OHLEBÜRSTEN den Netzstecker des Antriebs

ziehen.

ACHTUNG: Um eine Beschädigung der Pumpe zu vermeiden, den Pumpeneingang nicht bloc kieren

und die Pumpe nicht ohne Flüssigkeit betreiben.

ACHTUNG: ANWENDUNGSEINSCHRÄNKUNGEN

Dieses Gerät ist nicht für den Einsatz am Patienten vorgesehen und auch nicht für diesen Zweck bestimmt (z.B.

medizinischen oder zahnmedizinischen Bereich) und entspricht demgemäß auch keinen FDA (Food & Drug Administration) Normen.

MICROPUMP — Eingetragene Marke von Micropump Inc.

Marken mit dem Symbol ââ in dieser Veröffentlichung sind in den USA und in anderen Ländern eingetragen.

ii

Page 21

EINFÜHRUNG

Die Anleitungen in diesem Handbuch sind nach Aufgaben angeordnet, um das A uffinden der erforderlichen Informationen

zu erleichtern. Die Bedienelemente der Pumpenantriebe sind summarisch in Abbildung 1 dargestellt. Die Installation

und Einrichtung der Pumpenantriebe sowie die benutzerseitige Bedienung und Wartung sind in der vorliegenden

Anleitung eingehend erklärt. Die nachstehende Tabelle enthält die wichtigsten Daten für die in dieser Anleitung

beschriebenen Modelle.

Nummer im Ausgangs-drehzahl Fördermenge Elektrische

Antriebskatalog Anschlusswerte*

75211-10

75211-15 (Pumpenkopf separat erhältlich) 200 bis 260 V~

75211-60

75211-65 (inkl. Pumpenkopf) 200 bis 260 V~

75211-62

75211-67 (Pumpenkopf separat erhältlich) 200 bis 260 V~

50 bis 5000

90 bis 9000

90 bis 9000

* Wechselstromspannungen: 50 oder 60 Hz.

Die Pumpenantriebe enthalten den Pumpenantriebsmotor und die Motorbedienelemente in einer kompakten Einheit.

Die Befestigung der MICROPUMP®- Pumpenköpfe erfolgt direkt am Motor, der von der Frontplatte aus zugänglich ist.

Ferner weisen diese Antriebe die folgenden Merkmale auf:

• Kugellagermotor für Dauerbetrieb

• Geregelter Anlauf

2,5–5450 ml/min 90 bis 130 V~

0–26,5 l/min 90 bis 130 V~

0–26,5 l/min 90 bis 130 V~

• Drehzahlregler für den Bereich 100:1

• Pumpen sind magnetisch mit dem Motor gekoppelt

• Stapelfähig

• Schutzart IP22 nach IEC 529

• Auswechselbare Kohlebürsten

75211-60 und 75211-65 werden mit montierter Kreiselpumpe geliefert.

1

Page 22

BESCHREIBUNG

Bei den hier beschriebenen elektronischen Antrieben handelt es sich um unabhängige kompakte Einheiten, die einen

Antriebsmotor und alle Bedienelemente enthalten (siehe Abbildung 1). Diese Antriebe sind vor allem für magnetisch

gekoppelte Pumpen vorgesehen.

Die Antriebe 75211-10, -15, -62 und -67 werden ohne Pumpenkopf geliefert. Sie sind für alle MICR OPUMP-Pumpenköpfe

mit Standardmontagehülsen geeignet. Die Pumpenköpf e lassen sich einfach am Motor montieren, der von der F rontplatte

aus zugänglich ist. Das Lieferangebot enthält Modelle mit hoher und niedriger Drehzahl und vielen verschiedenen

Fördermengen.

VORSICHT: Zahnradpumpen dürfen mit maximal 5000 U/min betrieben werden.

ACHTUNG: Um eine Beschädigung der Pumpe zu vermeiden, den Pumpeneingang nicht blockieren und

Die Antriebe 75211-60 und -65 werden mit einem montierten 7-GPM Kreiselpumpenkopf geliefert. Der Pumpenkopf hat

einen 3/8 NPT(F) Einlass und 1/4 NPT(F) Auslassöffnungen.

Die Halbleiter-Steuerschaltung bietet selbst bei Netzspannungs- und Belastungsvariationen eine hervorragende

Drehzahlregelung. Eine Neonnetzanzeige im Netzschalter (POWER O/I) leuchtet auf, wenn sich der Netzschalter in

der Stellung I (EIN) befindet. Die Drehzahl des Pumpenantriebs kann über den an der Frontplatte montierten Potentiometer manuell im Bereich 100:1 eingestellt werden. Beim Einschalten erfolgt ein Sanftanlauf und eine allmähliche

Beschleunigung auf die eingestellte Drehzahl.

Über lieferbare Pumpenköpfe und Leistungsdaten informiert Sie Ihr Fachhändler gerne.

die Pumpe nicht ohne Flüssigkeit betreiben.

Drehzahlregler

Netzschalter

(POWER O/I)

Abbildung 1

INSTALLATION/EINRICHTUNG

Pack en Sie den Pumpenantrieb aus und heben Sie die gesamte V erpackung auf , bis Sie das Produkt auf einwandfreien

Betrieb überprüft haben.

Der Pumpenantrieb steht auf vier schwingungsisolierenden Füßen und kann auf einer Werkbank, einem Schreibtisch

oder Tisch aufgestellt werden. Er wird mit einem Netzkabel geliefert.

1. Ggf. den MICROPUMP-Pumpenkopf montieren.

2. Sicherstellen dass der O/I-Schalter auf der Stellung O (AUS) steht.

3. Das Netzkabel an der Rückwand an die Wechselstromquelle anschließen.

4. Den Drehzahlregler auf den niedrigsten Wert einstellen.

5. Die Pumpe unterhalb des Pegels der V ersorgungsflüssigkeit installieren. Die Flüssigkeit muss unter Atmosphärendruck

stehen.

6. Damit ist die grundsätzliche Einrichtung abgeschlossen.

ACHTUNG: Um eine Beschädigung der Pumpe zu vermeiden, den Pumpeneingang nicht blockieren und

die Pumpe nicht ohne Flüssigkeit betreiben.

2

Page 23

BETRIEB

Der Betrieb des Pumpenantriebs wurde vereinfacht. Es sind lediglich zwei Bedienelemente erforderlich: der O/I-Schalter

und der Drehzahlregler (siehe Abbildung 1). Die Bedien ung dieser beiden Elemente wird nachstehend erklärt.

O/I-Schalter

Mit dem O/I-Schalter wird das Gerät ein- bzw. ausgeschaltet. Wenn der Schalter auf O steht, ist das Gerät ausgeschaltet

und die grüne Netzanzeige im Netzschalter (POWER O/I) leuchtet nicht.

Drehzahlregler

Mit dem Drehzahlregler werden die Umdrehungen der Pumpe je Minute und in Abhängigkeit davon die Fördermenge

eingestellt. Je nach Modell beträgt die maximale Drehzahl entweder 5000 oder 9000. Durch Drehen des Drehzahlreglers

im Uhrzeigersinn wird die Drehzahl linear erhöht.

STÖRUNGSBESEITIGUNG UND WARTUNG

Störungsbeseitigung

SYMPTOM URSACHE VORGEHENSWEISE

Der Motor dreht sich nicht, wenn

der O/I-Schalter (Abbildung 1)

auf I (EIN) gestellt wird. Die

Netzanzeige leuchtet nicht.

Kein Strom

Sicherung

durchgebrannt

1. Sicherstellen, dass der Pumpenantrieb an

eine Stromquelle angeschlossen ist.

2. Sicherstellen, dass das Kabel fest in den

IEC-320-Anschluss eingesteckt ist.

3. Sicherung prüfen.

4. Zur Überprüfung zurückgeben.

Gegen empfohlene Sicherung auswechseln.

ACHTUNG: Keinen anderen Ersatz

verwenden.

Sprunghafte

Drehzahländerungen

Reinigen

Verschlissene

Kohlebürsten

Siehe Überprüfung und Auswechseln der

Kohlebürsten.

VORSICHT, LEBENSGEFAHR: Vor allen Reinigungsarbeiten die Verbindung zur Stromquelle lösen.

Das Gehäuse des Pumpenantriebs mit einem milden Reinigungsmittel abwischen. Nie eintauchen oder zu viel Flüssigkeit

verwenden.

Ersatzteile

Die folgenden Teile können vom Benutzer ausgewechselt werden:

Beschreibung Artikelnummer

Abdeckkappen der Kohlebürsten (je 2) 07520-03

Kohlebürsten (je 2) 07520-04

Drehzahlreglerknopf B-1083-0062

Geräteanschlusskabel—Australien (230V-Einheiten) 50001-60

Geräteanschlusskabel—Dänemark (230V-Einheiten) 50001-62

Geräteanschlusskabel—Indien (230V -Einheiten) 50001-64

Geräteanschlusskabel—Israel (230V -Einheiten) 50001-66

Geräteanschlusskabel—USA (115V -Einheiten) 50001-68

Geräteanschlusskabel—Europa (230V -Einheiten) 50001-70

Geräteanschlusskabel—Großbritannien (230V-Einheiten) 50001-72

Geräteanschlusskabel—Schweiz (230V -Einheiten) 50001-74

Geräteanschlusskabel—Italien (230V -Einheiten) 50001-76

Geräteanschlusskabel—USA (230V -Einheiten) 50001-78

Sicherung—T1.6 A, 250 (230V-Einheiten) 77500-11

Sicherung—T3.15 A, 250 (115V-Einheiten) 77500-25

Bei evtl. notwendigen Reparaturen wenden Sie sich bitte an Ihren Fachhändler.

3

Page 24

t

Überprüfen und Auswechseln der Kohlebürsten

VORSICHT: Vor Überprüfen bzw. Auswechseln der KOHLEBÜRSTEN den Netzstecker des Antriebs ziehen.

Hinweis: Die Bürsten müssen alle 6 Monate oder nach jeweils ca. 500 Betriebsstunden geprüft werden, oder wenn

sich Fehler in der Anwendung bemerkbar machen.

1. Den Netzschalter (POWER O/I) auf O (AUS) stellen.

2. Netzstecker aus der Steckdose ziehen.

3. Die vier Schrauben auf jeder Seite des Gehäuses entfernen und das Gehäuse öffnen.

4. Vorsichtig die beiden Abdeckkappen auf den gegenüberliegenden Seiten des Motors abschrauben (Abbildung 2).

Bürsten herausnehmen und auf Abnutzungserscheinungen prüfen.

Kohlebürste

Abdeckkappe

der Kohlebürs

Abbildung 2. Typisches Auswechseln der Kohlebürsten

Hinweis: Beide Bürsten auswechseln, wenn eine Bürste bis auf weniger als 7,6 mm abgenutzt ist.

5. Bürsten einsetzen und Abdeckkappen auf beiden Seiten des Motors wieder befestigen.

6. Gehäuse aufsetzen und mit den vier Schrauben auf beiden Seiten befestigen.

7. Netzstecker wieder an die Steckdose anschließen.

TECHNISCHE DATEN

Ausgangsleistung:

Maximale Drehzahl:

Modell 75211-10, -15 5000 U/min

Modell 75211-60, -62, -65, -67 9000 U/min

Mindestdrehzahl:

Modell 75211-10, -15 50 U/min

Modell 75211-60, -62, -65, -67 90 U/min

Maximales Drehmoment: 85 mN•m

Fördermengenbereich:

Modell 75211-10, -15 2,5 bis 5450 ml/min (Pumpenkopf separat erhältlich)

Modell 75211-60, -65 0 bis 26,5 l/min (inkl. Pumpenkopf)

Modell 75211-62, -67 0 bis 26,5 l/min (Pumpenkopf separat erhältlich)

4

Page 25

Technische Daten (Fortsetzung)

Einstellbereiche: Motordrehung im Uhrz eigersinn

Drehzahlregelung, ohne Last: ±1 %

Drehzahlregelung, mit Last: ±2 %

Drehzahlregelung, Warmlaufabweichung: ±10 %

Arbeitszyklus: Dauerbetrieb

Eingang:

Versorgungsspannungsbereich: 90 bis 130 V∼ oder 200 bis 260 V∼

Frequenz: 50/60 Hz

Maximale Stromstärke:

115V 2,3 A

230V 1,4 A

Installationsklasse: Installationsklasse II nach IEC 664 (Lokale Anwendungen—

Haushaltsgeräte, tragbare Geräte usw.)

Bauweise:

Abmessungen: 17,8 × 17,8 × 12,7 cm

Gewicht (Antrieb): 3,6 kg

Schutzart Gehäuse: IP22 nach IEC 529

Kreiselpumpe

(nur 75211-60, -65): Fördermenge: 26,5 l/min

Max. Flüssigkeitstemperatur: 121°C

Max. Systemdruck: 13,8 bar

Differenzdruck: 0,69 bar

Nassteile: 316 SS und PTFE

Umgebungsbedingungen:

Betriebstemperatur: 0 °C bis 40 °C

Lagertemperatur: –45 °C bis 60 °C

Luftfeuchtigkeit: 10 % bis 90 % nicht kondensierend

Höhe ü. M.: Unter 2000 m

Umweltverschmutzungsgrad: Umweltverschmutzungsgrad 2 nach IEC 664 (Innengebrauch—Labor,

Büroräume)

Chemische Beständigkeit: Exponiertes Material aus lackiertem Stahl

Entspricht den Normen: 115 V: UL508, CSA C22.2, Nr. 14-M91

230 V (für CE-Kennzeichen):

EN61010-1/A2: 1995 (Niederspannungsrichtlinie der EU) und

EN61326-1/A1: 1998 (EMV-Richtlinie der EU)

5

Page 26

GARANTIE

Der Hersteller garantiert, daß dieses Produkt keine nennenswerten Abweichungen von den veröffentlichten

Spezifikationen aufweist. Falls während der Garantiezeit eine Repar atur oder Nachbesserung erforderlich werden sollte,

wird dies kostenlos vorgenommen, vorausgesetzt, es liegt kein vom Hersteller feststellbarer fehlerhafter oder

unsachgemäßer Einsatz seitens des Kunden vor. Reparaturkosten außerhalb der Garantiezeit oder aufgrund von

fehlerhaftem oder unsachgemäßem Gebrauch des Produktes werden Ihnen möglicherweisein Rechnung gestellt.

Die Garantiezeit für dieses Produkt ist auf der Garantiekarte vermerkt.

WARENRÜCKSENDUNGEN

Um Kosten und Verzögerungen so gering wie möglich zu halten, lassen Sie sich in jedem Fall von Ihrem F achhändler

oder dem Hersteller eine Rücksendegenehmigung und die V ersandanw eisungen geben, bevor Sie Ware zurüc kschicken.

Geben Sie bitte den Rücksendegrund mit an. Verpacken Sie die Ware sorgfältig und v ersichern Sie die Sendung gegen

Beschädigung bzw. Verlust. Für Transportschäden aufgrund unsachgemäßer Verpackung haften Sie.

TECHNISCHE BERATUNG

Wenn Sie Fragen zur Anwendung diese Produktes haben, wenden Sie sich bitte an den Hersteller oder autorisierten

Fachhändler.

In den USA gedruckt.

010400

6

Page 27

ÍNDICE GENERAL

Título Página

PRECAUCIONES DE SEGURIDAD ..................................................................................................................... ii

INTRODUCCIÓN .................................................................................................................................................. 1

DESCRIPCIÓN ..................................................................................................................................................... 2

INSTALACIÓN/CONFIGURACIÓN ...................................................................................................... ................. 2

OPERACIÓN......................................................................................................................................................... 3

Control O/I (apagado/encendido) ........................................................................................................................3

Control de velocidad............................................................................................................................................ 3

LOCALIZACIÓN Y REPARACIÓN DE PROBLEMAS Y MANTENIMIENTO......................................................... 3

Localización y reparación de problemas ............................................................................................................. 3

Limpieza.............................................................................................................................................................. 3

Piezas de repuesto..............................................................................................................................................3

Comprobación/Reemplazo de las escobillas del motor ....................................................................................... 4

ESPECIFICACIONES ...........................................................................................................................................4

GARANTÍA............................................................................................................................................................6

DEVOLUCIÓN DEL PRODUCTO ........................................................................................................ ................. 6

ASISTENCIA TÉCNICA ........................................................................................................................................6

i

Page 28

PRECAUCIONES DE SEGURIDAD

PELIGRO: Desconecte de la red de alimentación antes de empezar una operación de limpieza.

ADVERTENCIAS: Las bombas de engranajes no deben hacerse funcionar a más de 5000 rpm.

Desenchufe el mando antes de comprobar/reemplazar las ESCOBILLAS DEL MOTOR.

PRECAUCIÓN: Para impedir daños en la bomba, no obstruya la entrada de la bomba ni la haga funcionar

en seco.

ADVERTENCIA: LIMITACIÓN DEL USO DEL PRODUCTO

Estos productos no están diseñados ni tienen como finalidad ser usados en aplicaciones conectadas al paciente,

incluidas aplicaciones médicas o dentales, pero sin limitarse a las mismas, y en consecuencia no se han enviado

a la FDA para su aprobación.

MICROPUMP—Marca comercial registrada de Micropump Inc.

Las marcas comerciales de esta publicación que tengan el símbolo ® están registradas en EE.UU. y otros países.

ii

Page 29

INTRODUCCIÓN

Las instrucciones de este manual están orientadas por tareas para permitir un acceso sencillo a la información

deseada. La Figura 1 proporciona una información resumida de todos los controles de los mandos de bomba.

Este manual contiene información completa sobre cómo instalar y configurar los mandos de bomba, así como la

operación y servicio a nivel del usuario. La tabla siguiente proporciona información básica sobre los modelos

tratados en este manual.

Número de catálogo Velocidad de Caudal Especificaciones

del mando salida en rpm eléctricas*

75211-10

75211-15 (compre la cabeza de la bomba por separado) 200 a 260 VCA

75211-60

75211-65 (con cabeza de bomba proporcionada) 200 a 260 VCA

75211-62

75211-67 (compre la cabeza de la bomba por separado) 200 a 260 VCA

50 a 5000

90 a 9000

90 a 9000

Los voltajes de CA* pueden ser a 50 o 60 Hz.

Los mandos de las bombas contienen el motor del mando de la bomba y los controles del motor en una unidad

compacta. Las cabezas de bomba MICROPUMP® están conectadas directamente al motor, que es accesible por el

panel delantero. Además, estos mandos disponen de las características siguientes:

• Motor de cojinetes de bolas para servicio continuo

• Tienen un arranque controlado

2,5–5450 ml/min 90 a 130 VCA

0–26,5 l/min 90 a 130 VCA

0–26,5 l/min 90 a 130 VCA

• Control de velocidad en una gama de 100:1

• Las bombas están acopladas magnéticamente al motor

• Apilable

• Clasificación IP22 según IEC 529

• Escobillas de motor reemplazables

75211-60 y 75211-65 se suministran con una bomba centrífuga conectada.

1

Page 30

DESCRIPCIÓN

Estos mandos electrónicos son unidades compactas autónomas que incluyen un motor del mando y todos los controles

de operación (vea Figura 1). Estos mandos están diseñados especialmente para bombas acopladas magnéticamente .

Los mandos 75211-10, -15, -62 y -67 vienen sin una cabeza de bomba. Permiten la instalación de cabezas de bomba

MICROPUMP con receptáculos de montaje normales. Las cabezas de bomba pueden montarse fácilmente en el

motor, que es accesib le por el panel delantero. Las v ersiones de alta y baja velocidad están disponibles para cubrir una

amplia gama de caudales.

y rendimiento.

ADVERTENCIA: Las bombas de engranajes no deben hacerse funcionar a más de 5000 rpm.

PRECAUCIÓN: Para impedir daños en la bomba, no obstruya la entrada de la bomba ni la haga funcionar

Los mandos 75211-60 y -65 vienen con una cabeza de bomba centrífuga de 7 gpm montada en los mismos. La cabeza

de la bomba tiene orificios de entrada de 3/8 NPT (F) y salida 1/4 NPT (F).

Los circuitos de control de velocidad de estado sólido ofrecen una regulación de velocidad excelente incluso con

variaciones de voltaje y carga de la línea. Dispone de un indicador de alimentación de neón en el interruptor que se

enciende cada vez que el interruptor de O/I esté en la posición I (encendido). La velocidad del mando de la bomba

puede controlarse manualmente en una gama de 100:1 con el potenciómetro montado en el panel delantero. Se

proporciona un arranque a baja velocidad y una aceleración gr adual uniforme hasta alcanzar la velocidad fijada cuando

se cambia la corriente de la línea.

Póngase en contacto con su distribuidor para obtener información sobre cabezas de bomba

en seco.

Control de

velocidad

Interruptor O/I

de ALIMENTACIÓN

Figura 1

INSTALACIÓN/CONFIGURACIÓN

Desempaquete el mando de la bomba y conserve todo el material de empaquetado hasta que se haya verificado la

operación apropiada del producto.

El mando de la bomba está apoyado en cuatro patas de aislamiento de las vibraciones para colocarlo en un banco,

despacho o mesa. Viene con un cordón de alimentación.

1. Si se aplica, conecte la cabeza de la bomba MICROPUMP.

2. Compruebe que el interruptor O/I esté en la posición O (apagado).

3. Conecte el cordón de alimentación de CA del panel trasero a la fuente de alimentación de CA.

4. Fije el control de velocidad al mínimo.

5. Instale la bomba por debajo del nivel del líquido de suministro. El líquido debe estar en condiciones atmosféricas.

6. Esto completa la configuración básica.

PRECAUCIÓN: Para impedir daños en la bomba, no obstruya la entrada de la bomba ni la haga funcionar

en seco.

2

Page 31

OPERACIÓN

Se ha simplificado la operación del mando de la bomba, requiriendo sólo dos controles, el control O/I y el control de

velocidad (vea la Figura 1). A continuación se explica la operación de cada uno de estos controles.

Control O/I

El control O/I se usa para desconectar y conectar la corriente. Cuando el control esté en la posición O , la corriente está

desconectada y la luz verde de alimentación en el interruptor no está encendida.

Control de velocidad

El ajuste de control de velocidad determina las rpm de la bomba y, por lo tanto, el caudal. Dependiendo del modelo, la

velocidad máxima será de 5000 o 9000. Al girar el control de velocidad hacia la derecha se aumenta la velocidad linealmente .

LOCALIZACIÓN Y REPARACIÓN DE PROBLEMAS Y MANTENIMIENTO

Localización y reparación de problemas

SÍNTOMA CAUSA SOLUCIÓN

El motor no gira cuando se

mueve el interruptor O/I

(Figura 1) a la posición I

(encendido). El indicador de

alimentación no se enciende.

No hay corriente.

1. Compruebe que el mando de la bomba esté

enchufado a la fuente de alimentación.

2. Compruebe que el cordón esté bien introducido

en el conector IEC-320.

3. Compruebe el fusible.

4. Devuelva par a efectuar reparaciones.

Fusible fundido. Reemplace por el fusible recomendado.

PRECAUCIÓN: No lo sustituya por otro.

V ariaciones irregulares de

velocidad.

Limpieza

Escobillas de motor

desgastadas.

Vea Comprobación/Reemplazo de las

exobillas del motor.

PELIGRO: Desconecte de la red de alimentación antes de empezar una operación de limpieza.

Mantenga limpio el recinto del mando de la bomba limpiándolo con un detergente suave. No lo sumerja nunca ni use

una cantidad excesiva de fluido.

Piezas de repuesto

Las piezas siguientes pueden ser reemplazadas por el usuario:

Descripción Número de pieza

Tapas de escobilla (juego de 2) 07520-03

Escobillas de motor (juego de 2) 07520-04

Perilla de control de velocidad B-1083-0062

Juego de cordón—Australia (Unidades de 230 V) 50001-60

Juego de cordón—Dinamarca (Unidades de 230 V) 50001-62

Juego de cordón—India (Unidades de 230 V) 50001-64

Juego de cordón—Israel (Unidades de 230 V) 50001-66

Juego de cordón—EE.UU. (Unidades de 115 V) 50001-68

Juego de cordón—Europeo (Unidades de 230 V) 50001-70

Juego de cordón—Británico (Unidades de 230 V) 50001-72

Juego de cordón—Suizo (Unidades de 230 V) 50001-74

Juego de cordón—Italiano (Unidades de 230 V) 50001-76

Juego de cordón—EE.UU. (Unidades de 230 V) 50001-78

Fusible—T1.6 A, 250 (Unidades de 230 V) 77500-11

Fusible—T3.15 A, 250 (Unidades de 115 V) 77500-25

Póngase en contacto con su distribuidor si tiene necesidad de que se efectúen reparaciones.

3

Page 32

Comprobación/Reemplazo de las escobillas del motor

ADVERTENCIA : Desenchufe el mando antes de comprobar/reemplazar las ESCOBILLAS DEL MOTOR.

Nota: Las escobillas deben comprobarse cada 6 meses, o aproximadamente cada 500 horas de operación o si se

produce una operación irregular.

1. Ponga el interruptor de ALIMENTACIÓN (O/I) en la posición O (apagado).

2. Desconecte el cordón de la línea de entrada de CA del receptáculo de CA.

3. Quite los cuatro tornillos de cada lado de la caja y levante la caja quitándola.

4. Desatornille cuidadosamente cada tapa de escobilla en lados opuestos del motor (Figura 2). Retire la escobilla, y

examínela para ver si está desgastada.

Escobilla

Tapa de

la escobilla

Figura 2. Reemplazo de escobilla típica

Nota: Reemplace ambas escobillas si cualquiera de las escobillas mide menos de 7,6 mm de largo de la base a la punta.

5. Introduzca ambas escobillas e instale la tapa de la escobilla a cada lado del motor.

6. Instale la caja y sujétela con los cuatro tornillos a cada lado.

7. Conecte el cordón de la línea de entrada de CA al receptáculo de CA.

ESPECIFICACIONES

Salida:

Velocidad máx.:

Modelo 75211-10, -15 5000 rpm

Modelo 75211-60, -62, -65, -67 9000 rpm

Velocidad mín.:

Modelo 75211-10, -15 50 rpm

Modelo 75211-60, -62, -65, -67 90 rpm

Par máximo: 85 mN•m

Gama de caudales:

Modelo 75211-10, -15 2,5 a 5450 ml/min (compre la cabeza de la bomba por separado)

Modelo 75211-60, -65 0 a 26,5 l/min (con cabeza de bomba proporcionada)

Modelo 75211-62, -67 0 a 26,5 l/min (compre la cabeza de la bomba por separado)

4

Page 33

Especificaciones (cont.)

Gamas de ajuste: Giro del motor a la derecha

Regulación de velocidad, línea: ±1%

Regulación de velocidad, carga: ±2%

Regulación de velocidad,

desviación de calentamiento: ±10%

Ciclo de servicio: Continuo

Entrada:

Límites de voltaje del suministro: 90 a 130 VCA o 200–260 VCA

Frecuencia: 50/60 Hz

Corriente máx:

115V 2,3 A

230V 1,4 A

Categoría de la instalación: Categoría de instalación II según IEC 664 (nivel local—aparatos,

equipos portátiles, etc.)

Construcción:

Dimensiones: 17,8 × 17,8 × 12,7 cm

Peso (mando solamente): 3,6 kg

Valores nominales del recinto: IP22 según IEC529

Bomba centrífuga

(75211-60, -65 solamente): Caudal: 26,5 l/min

Temperatura máxima del fluido: 121°C

Presión máxima del sistema: 13,8 bares

Diferencia de presión: 0,69 bares

Piezas mojadas: Acero inoxidable 316 y PTFE

Ambiente:

Temperatura de operación: 0°C a 40°C

Temperatura de almacenamiento: –45°C a 60°C

Humedad: 10% a 90% sin condensación

Altitud: Menos de 2000 m

Nivel de contaminación: Nivel de contaminación 2 según IEC 664 (uso interior—laboratorio,

oficina)

Resistencia a los productos químicos: El material expuesto es acero pintado.

Cumple con las siguientes normas: 115V: UL508, CSA C22.2, No. 14-M91

230V (para la marca CE):

EN61010-1/A2: 1995 (Directiva de bajo voltaje de la UE) y

EN61326-1/A1: 1998 (Directiva EMC de la UE)

5

Page 34

GARANTÍA

El fabricante garantiza que este producto no se desvía significativamente con respecto a la especificaciones pub licadas.

Si es necesario efectuar reparaciones o ajustes en el período de garantía, el problema será corregido de f orma gratuita

si no se debe al uso indebido o abuso por su parte según lo determine el fabricante. Existe la posibilidad de que se le

facturen los costos de reparación fuera del período de garantía, o los resultantes del uso indebido o abuso del producto .

El período de garantía de este producto figura en la tarjeta de garantía.

DEVOLUCIÓN DE PRODUCTOS

Para limitar cargos y retrasos, póngase en contacto con el vendedor o fabricante para obtener la autorización e

instrucciones de envío antes de devolver al producto, ya sea durante o fuera del período de garantía. Al devolver el

producto, indique la razón de la devolución. Para su protección, embale el producto cuidadosamente y asegúrelo

contra los posibles daños o pérdida. Los daños resultantes de un embalaje indebido son responsabilidad suya.

ASISTENCIA TÉCNICA

Si tiene dudas sobre el uso de este producto, póngase en contacto con el fabricante o vendedor autorizado.

Impreso en los EE.UU.

010400

6

Page 35

INDICE

Titolo Pagina

PRECAUZIONI RIGUARDANTI LA SICUREZZA ........................................................................................... ...... ii

INTRODUZIONE................................................................................................................... ................................ 1

DESCRIZIONE .................................................................................................................... .................................. 2

MONTAGGIO E MESSA A PUNTO ...................................................................................................................... 2

FUNZIONAMENTO.................................................................................................................. ............................. 3

Comando O/I (acceso/spento) ............................................................................................................................ 3

Regolatore di velocità..........................................................................................................................................3

INDIVIDUAZIONE E RISOLUZIONE DI PROBLEMI E MANUTENZIONE ........................................................... 3

Individuazione e risoluzione di problemi .............................................................................................................. 3

Pulizia.................................................................................................................................................................. 3

Ricambi ............................................................................................................................................................... 3

Ispezione/sostituzione delle spazzole motore ..................................................................................................... 4

SPECIFICHE TECNICHE ..................................................................................................................................... 4

GARANZIA....................................................................................................................... ..................................... 6

RESTITUZIONE DEI PRODOTTI ...................................................................................................... ................... 6

ASSISTENZA TECNICA .......................................................................................................................................6

i

Page 36

PRECAUZIONI RIGUARDANTI LA SICUREZZA

PERICOLO: prima di effettuare qualsiasi operazione di pulizia, disinnestare l’apparecchio

dall’alimentatore.

ATTENZIONE: le pompe a ingranaggi non devono essere azionate a velocità superiori 5000 giri/min.;

prima di ispezionare/sostituire le SPAZZOLE MOTORE, disinserire la spina

dell’azionamento.

USARE CAUTELA: per evitare di danneggiare la pompa, non ostruirne l’orificio di ammissione e non

azionarla a secco.

ATTENZIONE: RESTRIZIONI SULL’ USO DEL PRODOTTO

Questo prodotto non è progettato per apparecchiature che agiscono direttamente sul paziente e non è inteso, tra

gli altri, per usi medici e odontoiatrici. Di conseguenza non è stato sottoposto all’approvazione della FDA, l’ente

statunitense per gli alimenti e i farmaci.

MICROPUMP — Marchio depositato della Micropump Inc.

I marchi di fabbrica contrassegnati dal simbolo ® in questa pubblicazione sono marchi depositati negli Stati Uniti e in altri paesi.

ii

Page 37

INTRODUZIONE

Le istruzioni contenute nel presente manuale si riferiscono a determinate funzioni e possono essere facilmente consultate.

La Figura 1 riassume schematicamente tutti i comandi degli azionamenti della pompa. Il manuale contiene tutte le

informazioni sul montaggio e la messa a punto degli azionamenti, nonché sul funzionamento e la manutenzione al

livello dell’utente. La tabella che segue contiene le informazioni di base sui modelli trattati nel manuale.

Codice Uscita giri/min. Portata Requisiti di

dell’azionamento alimentazione*

75211-10

75211-15 (acquistare la testa pompante separatamente) Da 200 a 260 V c.a.

75211-60

75211-65 (testa pompante in dotazione) Da 200 a 260 V c.a.

75211-62

75211-67 (acquistare la testa pompante separatamente) Da 200 a 260 V c.a.

Da 50 a 5000

Da 90 a 9000

Da 90 a 9000

* La tensione in c.a. può essere o a 50 o a 60 Hz.

Gli azionamenti della pompa consistono di un’unità compatta che comprende il motore dell’azionamento e i comandi

del motore. Le teste pompanti MICROPUMP® sono montate direttamente sul motore che è accessibile dal pannello

anteriore. Inoltre, gli azionamenti presentano le seguenti caratteristiche:

• Motore con cuscinetti a sfere per il funzionamento continuo

• Avvio controllato

• Regolatore di velocità, gamma superiore a 100:1

2,5–5450 mL/min. Da 90 a 130 V c.a.

0–26,5 litri/min. Da 90 a 130 V c.a.

0–26,5 litri/min. Da 90 a 130 V c.a.

• Pompe con accoppiamento magnetico al motore

• Impilabililà

• Potenza nominale IP22 conforme alla normativa UE CEI 529 della Commissione elettrotecnica internazionale

• Spazzole motore sostituibili

I modelli 75211-60 e 75211-65 sono dotati di pompa centrifuga montata.

1

Page 38

DESCRIZIONE

Questi azionamenti elettronici consistono di un’unità autonoma e compatta e che comprende il motore dell’azionamento

e tutti i comandi necessari al funzionamento (

con accoppiamento magnetico.

Gli azionamenti 75211-10, -15, -62 e -67 sono spediti senza testa pompante. Accettano tutte le teste pompanti

MICROPUMP con dispositivi di montaggio standard. Le teste pompanti possono essere montate f acilmente sul motore

che è accessibile dal pannello anteriore. I modelli ad alta e a bassa velocità sono disponibili per una vasta gamma di

portate.

Per le informazioni sulle teste pompanti disponibili e le prestazioni, rivolgersi al concessionario.

ATTENZIONE: le pompe a ingranaggi non devono essere azionate a velocità superiori a 5000 giri/min.

USARE CAUTELA: per evitare di danneggiare la pompa, non ostruirne l’orificio di ammissione e non

azionarla a secco.

Negli azionamenti 75211-60 e -65 è montata una testa pompante centrifuga da 7-gpm (26,5 litri/min. circa). La testa

pompante è dotata di un orificio di ammissione da 3/8 NPT(F) e un orificio di scarico da 1/4 NPT(F).

La circuiteria a stato solido del regolatore di velocità consente di regolare la velocità efficientemente anche con le

variazioni di linea della tensione e del carico. L’indicatore al neon dell’alimentazione dell’interruttore si illumina quando

l’interruttore O/I è in posizione I (acceso). La velocità dell’azionamento può essere regolata man ualmente secondo una

gamma di 100:1 mediante il potenziometro montato nel quadro anteriore. Nella commutazione della potenza di linea

l’avvio è “dolce” e l’accelerazione è graduale e omogenea fino al raggiungimento della velocità prestabilita.

vedi

Figura 1). Gli azionamenti sono progettati specificamente per pompe

Figura 1

MONTAGGIO E MESSA A PUNTO

Rimuovere l’azionamento della pompa dalla conf ezione e conservare il materiale di imballaggio fino a quando non si è

sicuri che il prodotto funzioni correttamente.

L’azionamento della pompa si appoggia sui 4 piedi dell’isolatore delle vibrazioni. Può essere collocato su un banco , una

scrivania o un tavolo. Un cavo elettrico è in dotazione.

1. Se occorre, montare la testa pompante MICROPUMP.

2. Verificare che l’interruttore O/I sia impostato alla posizine O (spento).

3. Innestare il cavo di alimentazione in c.a. all’alimentatore in c.a. nel pannello posteriore.

4. Impostare il regolatore di velocità al minimo.

5. Montare la pompa al di sotto del livello del liquido che deve essere a condizioni atmosferiche.

6. La messa a punto di base è completata.

USARE CAUTELA: per evitare di danneggiare la pompa, non ostruirne l’orificio di ammissione e non

azionarla a secco.

2

Page 39

FUNZIONAMENTO

Il funzionamento dell’azionamento della pompa è stato semplificato. In fatti, richiede solo due comandi: il comando

O/I e il regolatore di velocità (

Comando O/I

Il comando O/I serve a disinnestare (Off) o innestare (On) l’alimentazione di corrente. Quando il comando si trova in

posizione O, l’alimentazione è disinnestata e la spia verde dell’interruttore è spenta.

Regolatore di velocità

L’impostazione del regolatore di velocità determina i giri/min. della pompa e quindi, la portata. A seconda del modello , la

velocità massima è o 5000 o 9000. Girando il regolatore in senso orario, la velocità aumenta linearmente.

vedi

la Figura 1). La funzione di questi comandi è spiegata qui di seguito.

INDIVIDUAZIONE E RISOLUZIONE DI PROBLEMI E MANUTENZIONE

Individuazione e risoluzione di problemi

SINTOMI CAUSA RIMEDI

Il motore non funziona quando

l’interruttore O/I (Figura 1) viene

spostato su I (accesso). La spia

dell’alimentazione è spenta.

Mancanza di

alimentazione.

Fusibile saltato. Sostituire il fusibile con il fusibile consigliato.

1. Verificare che la spina dell’azionamento sia

inserita nella presa di alimentazione.

2. Verificare che il cavo di alimentazione sia ben

inserito nel connettore conforme a norma UE

CEI-320.

3. Controllare il fusibile.

4. Restituire l’apparecchio per la riparazione.

USARE CAUTELA: non sostituire con

altri fusibili.

Variazioni di velocità erratiche.

Pulizia

Spazzole motore surate.

Vedi

Ispezione/sostituzione delle spazzole

motore.

PERICOLO: prima di effettuare qualsiasi operazione di pulizia, disinnestare l’apparecchio

dall’alimentatore.

Pulire la custodia dell’azionamento della pompa con un panno ed un detersivo leggero. Non immergerla mai e non

usare fluidi in quantità eccessive.

Ricambi

I ricambi sottoelencati possono essere sostituiti dall’utente:

Descrizione Codice

Tappi delle spazzole (confezione da 2) 07520-03

Spazzole motore (confezione da 2) 07520-04

Manopola regolatrice della velocità B-1083-0062

Gruppo cavo elettrico—Australia (unità a 230 V) 50001-60

Gruppo cavo elettrico—Danimarca (unità a 230 V) 50001-62

Gruppo cavo elettrico—India (unità a 230 V) 50001-64

Gruppo cavo elettrico—Israele (unità a 230 V) 50001-66

Gruppo cavo elettrico—U.S.A. (unità a 115 V) 50001-68

Gruppo cavo elettrico—Europa (unità a 230 V) 50001-70

Gruppo cavo elettrico—Gran Bretagna (unità a 230 V) 50001-72

Gruppo cavo elettrico—Svizzera (unità a 230 V) 50001-74

Gruppo cavo elettrico—Italia (unità a 230 V) 50001-76

Gruppo cavo elettrico—U.S.A. (unità a 230 V) 50001-78

Fusibile—T1.6A, 250 V (unità a 230 V) 77500-11

Fusibile—T3.15A, 250 V (unità a 115 V) 77500-25

Per assistenza con la manutenzione, rivolgersi al concessionario.

3

Page 40

Ispezione/sostituzione delle spazzole motore

ADVERTENCIA: prima di ispezionare/sostituire le SPAZZOLE MOTORE, disinserire la spina

dell’azionamento.

Nota: Le spazzole dev ono essere ispezionate ogni 6 mesi od ogni 500 ore d’esercizio circa oppure se il funzionamento

è erratico.

1. Impostare l’interruttore di alimentazione (O/I) alla posizione di spento (O).

2. Disinserire il cavo di ingresso dell’alimentazione in c.a. dal connettore in c.a.

3. Rimuovere le 4 viti situate su ciascun lato dell’alloggiamento e sollevarlo per toglierlo.

4. Svitare con cura il tappo di ognuna delle spazzole sui lati opposti del motore (

ispezionarne lo stato di usura.

Spazzola

Tappo

spazzola

vedi

Figura 2). Togliere le spazzole ed

Figura 2. Sostituzione di una spazzola tipica

Nota: se una delle spazzole misura meno di 7,6 mm dalla base alla punta, sostituire entrambe le spazzole.

5. Inserire le spazzole e rimettere a posto i tappi sui due lati del motore.

6. Rimontare l’involucro e fissarlo su ogni lato con le 4 viti.

7. Innestare il cavo di ingresso dell’alimentazione in c.a. nel connettore in c.a.

SPECIFICHE TECNICHE

Uscita:

Velocità max.:

Modello 75211-10, -15 5000 giri/min

Modello 75211-60, -62, -65, -67 9000 giri/min

Velocità minima.:

Modello 75211-10, -15 50 giri/min

Modelo 75211-60, -62, -65, -67 90 giri/min

Uscita coppia, max: 85 mN•m

Portata:

Modello 75211-10, -15 Da 2,5 a 5450 mL/min.; acquistare la testa pompante separatamente

Modello 75211-60, -65 Da 0 a 26,5 litri/min. circa con testa pompante fornita

Modello 75211-62, -67 Da 0 a 26,5 litri/min. circa; acquistare la testa pompante

separatamente

4

Page 41

Specifiche tecniche (continuazione)

Gamme di regolazione: rotazione del motore in senso orario

Regolazione di velocità, linea: ±1%

Regolazione di velocità, carico: ±2%

Regolazione di velocità,

deriva riscaldamento: ±10%

Ciclo di lavoro utile: continuo

Ingresso:

Limiti di tensione di potenza: da 90 a 130 V c.a. o da 200 a 260 V c.a.

Frequenza: 50/60 Hz

Corrente, max.:

115V 2,3 A

230V 1,4 A

Categoría de la instalación: categoria di impianto II, secondo normativa UE CEI 664 sulla

compatibilità elettromagnetica internazionale (livello locale —

apparecchiature, attrezzature portatili, ecc.)

Costruzione:

Dimensioni: 17,8 × 17,8 × 12,7 cm

Peso (solo azionamento): 3,6 kg

Livello inquinamento custodia: IP22 secondo normativa UE CEI 529

Pompa centrifuga

(75211-60, -65 solamente): portata: da 0 a 26,5 litri/min. circa

max. temperatura fluido: 121 °C

max. pressione sistema 13,8 bar

pressione differenziale: 0,69 bar

elementi bagnati: 316 SS e PTFE

Ambiente:

Temperatura d’esercizio: da 0 °C a 40 °C

Temperatura di stoccaggio: da –45 °C a 60 °C

Umidità: dal 10% al 90% non condensante

Altitudine: inferiore a 2000 m

Grado di inquinamento: gr ado di inquinamento 2 secondo normativa europea CEI 664

(impieghi interni — laboratori, uffici)

Resistenza a prodotti chimici: materiali esposti, in acciaio inox dipinto.

Normativa: 115 V: UL508, CSA C22.2, N. 14-M91

230 V (per norme europee): Direttiva europea sulla bassa tensione:

EN61010-1/A2: 1995 e Direttiva europea sulla compatibilità

elettromagnetica: EN61326-1/A1: 1998

5

Page 42

GARANZIA

Il produttore garantisce che questo prodotto non differisce in maniera significativa dalle specifiche pubblicate. In caso

siano necessarie riparazioni o regolazioni entro il periodo di tempo in cui la garanzia è in vigore, il problema verrà

corretto senza addebito purché, a giudizio del produttore, non sia dovuto ad uso improprio o eccessivo del prodotto. Il

costo delle riparazioni al di fuori del periodo in cui la garanzia è in vigore o i costi risultanti dall’uso improprio o eccessivo

del prodotto potranno essere a carico del cliente.

Il periodo in cui la garanzia di questo prodotto è in vigore è indicato nella cartolina della garanzia.

RESTITUZIONE DEI PRODOTTI

Al fine di limitare i costi e i ritardi, prima di rendere il prodotto, rivolgersi al rivenditore o al produttore per ottenere